Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Avoid drift phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

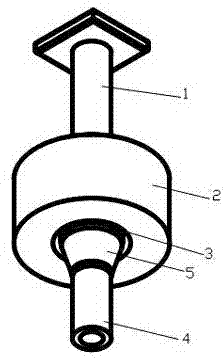

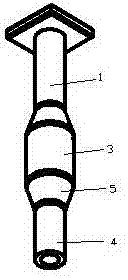

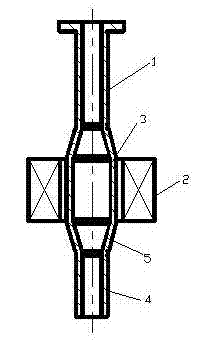

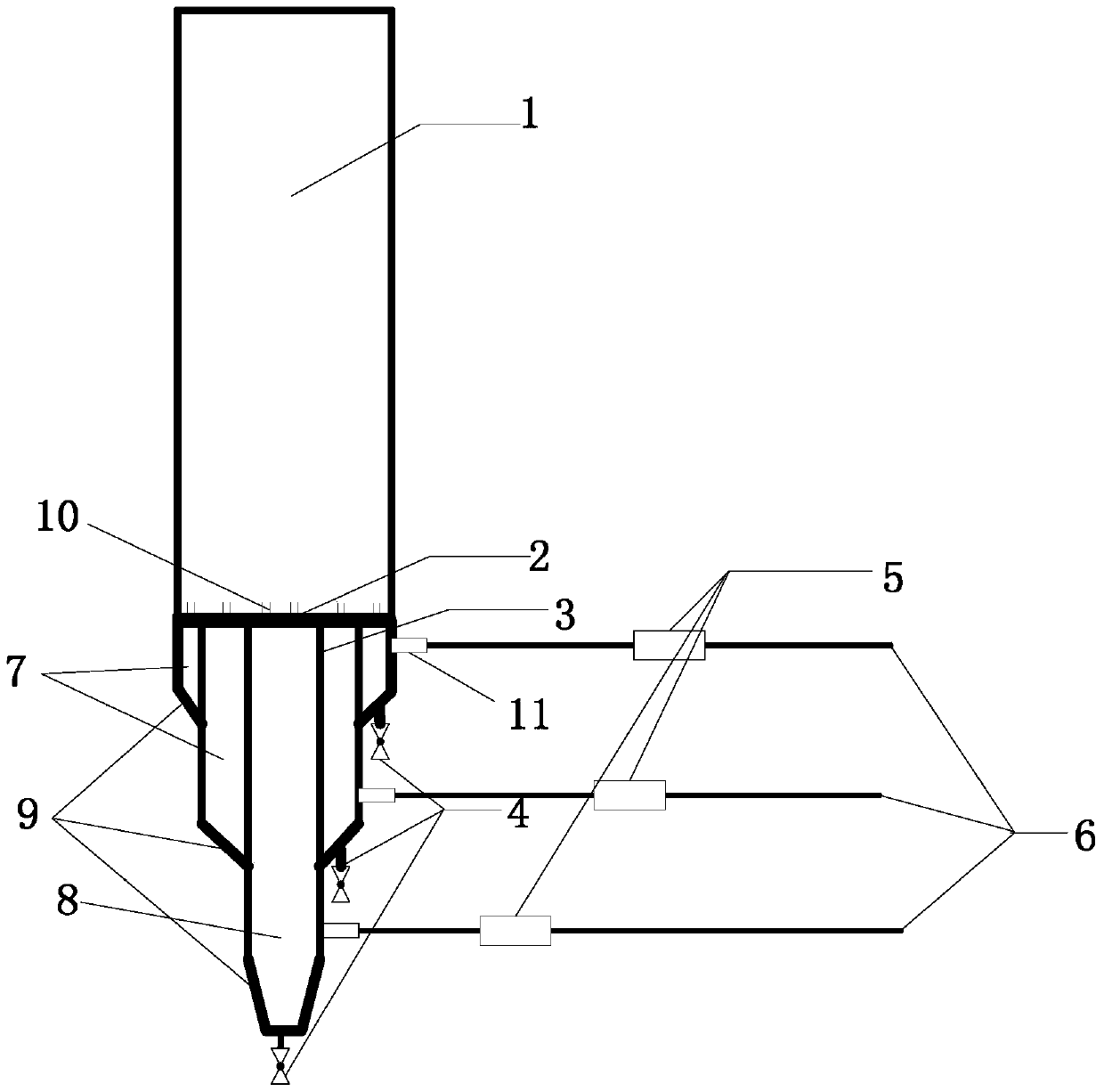

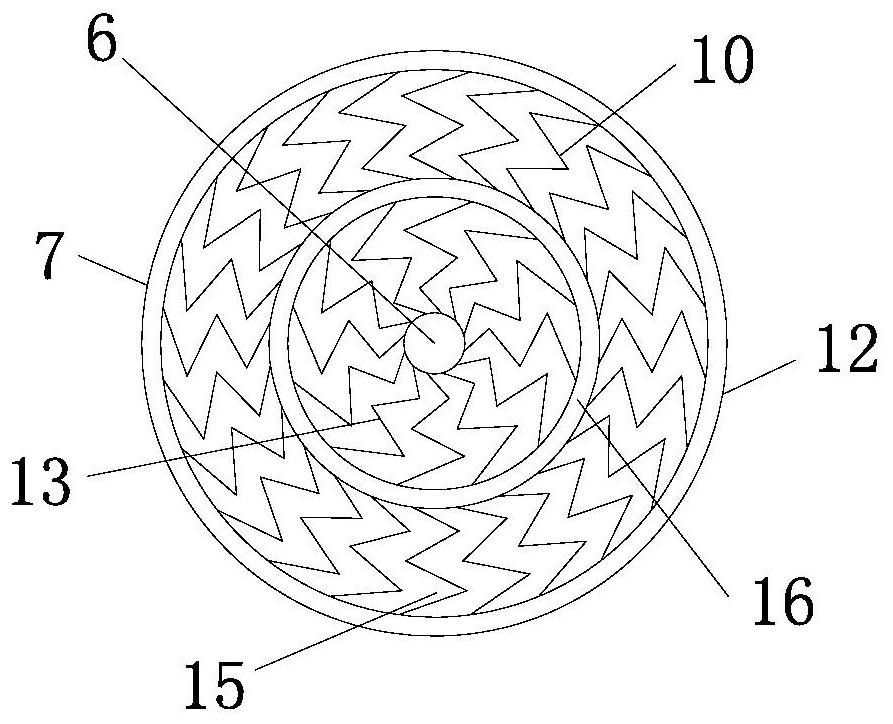

Electromagnetic rotational flow water gap for continuous casting

InactiveCN103203450AImprove utilization efficiencySolve the bias phenomenonMelt-holding vesselsWater pipeEngineering

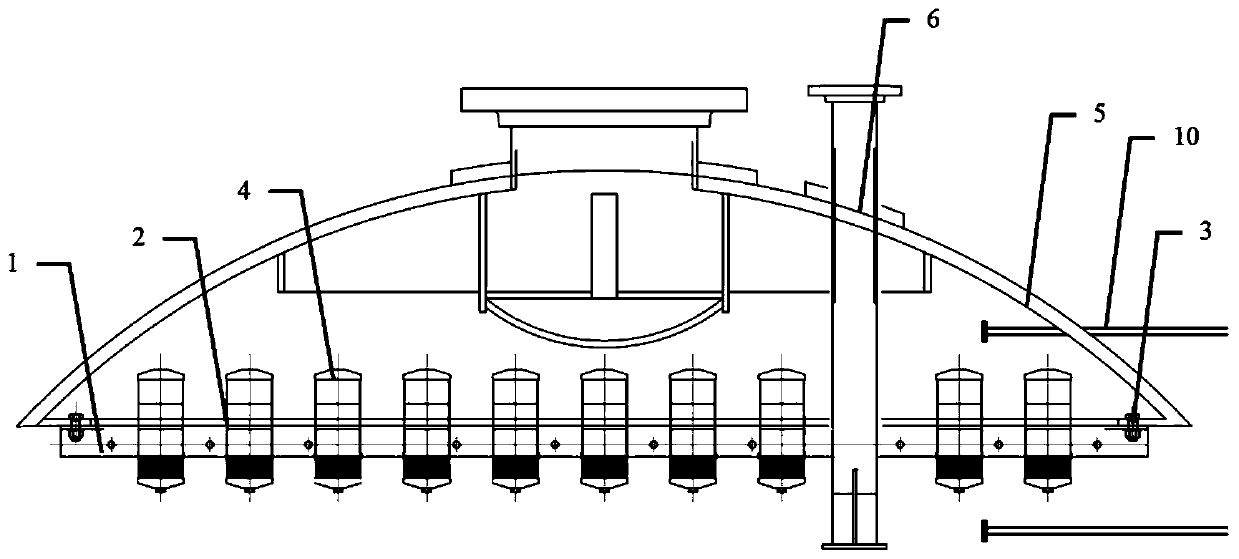

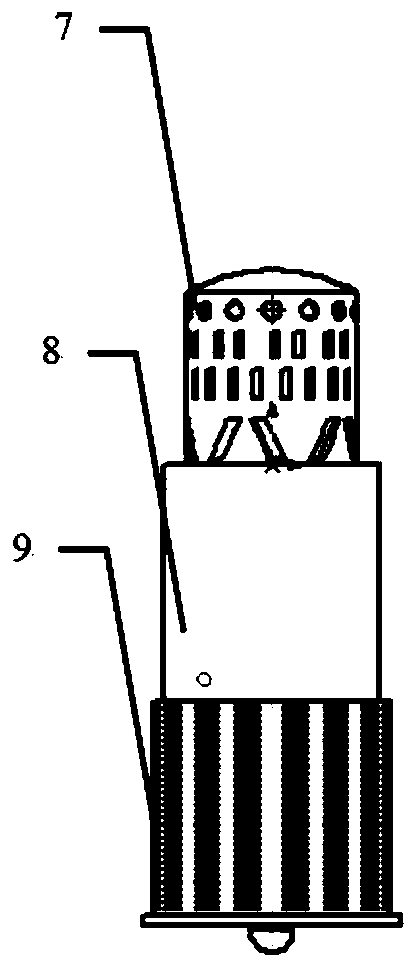

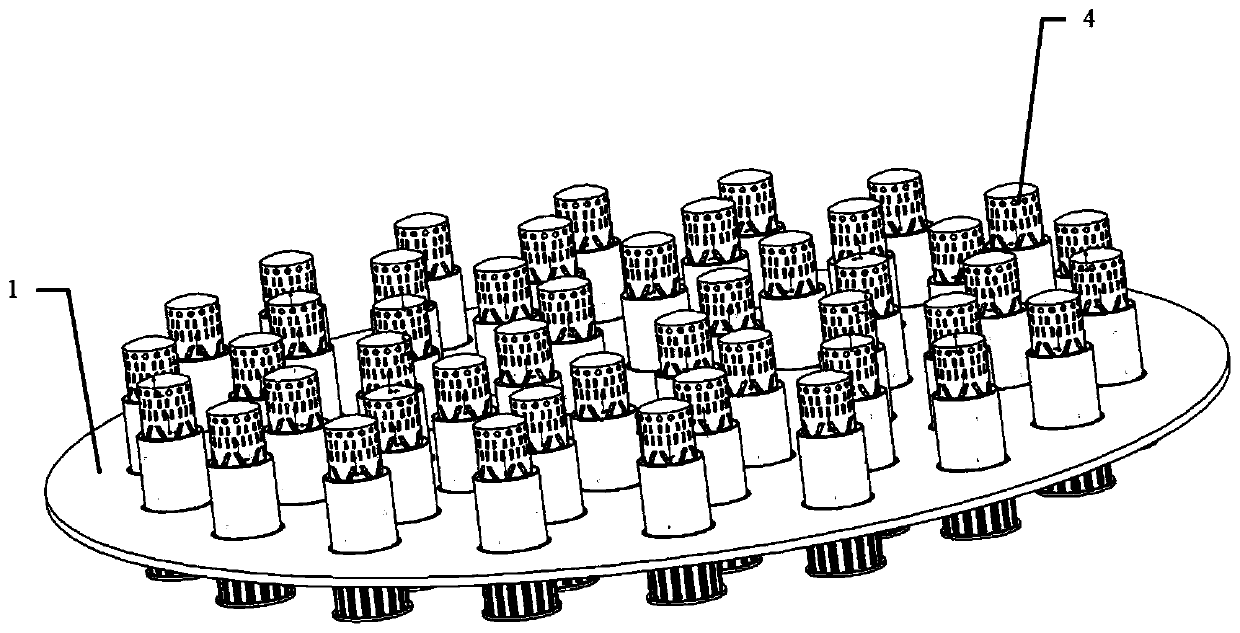

The invention relates to an electromagnetic rotational flow water gap for continuous casting. The electromagnetic rotational flow water gap for continuous casting comprises a water gap pipe and an electromagnetic rotational flow device, wherein the electromagnetic rotational flow device is arranged around the middle area of the water gap pipe; the water gap pipe in a different-diameter structure comprises an upper part of the water gap pipe, the middle area of the water gap pipe and a molten steel outlet part; the sectional area of the middle area of the water gap pipe is 1.1-20 times the sectional area of the molten steel outlet part; the length of the middle area of the water gap pipe is 10-90% of the whole length of the water gap pipe; and the cross section of the middle area of the water gap pipe is a round, an oblong, a rectangle and a polygon with 1-20 sides. By enlarging the sectional area of the middle area of the water gap pipe, the electromagnetic rotational flow water gap for continuous casting adds the functional area of a magnetic field to the molten steel, increases a distance between magnetic poles of an externally arranged electromagnetic rotational flow device and improves efficiency of the magnetic field. The electromagnetic rotational flow water gap for continuous casting enables the molten steel in the water gap pipe to generate a relatively strong rotary force, solves bias flow phenomenon of the molten steel in the water gap pipe efficiently and is good for improving quality of steel billets.

Owner:HEBEI SANFANG ELECTRICAL EQUIP

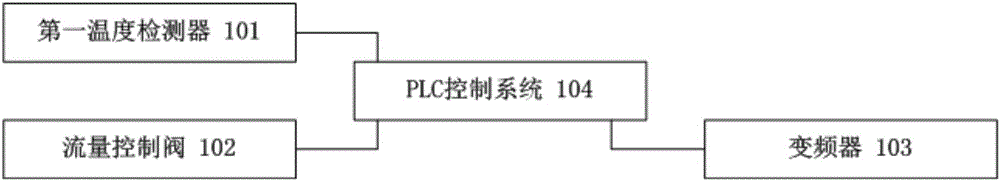

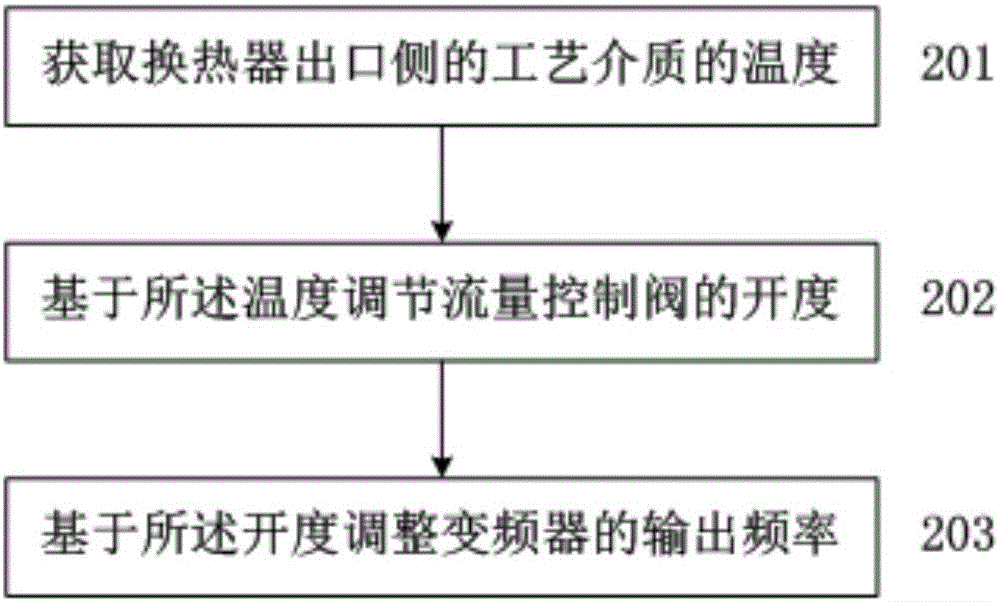

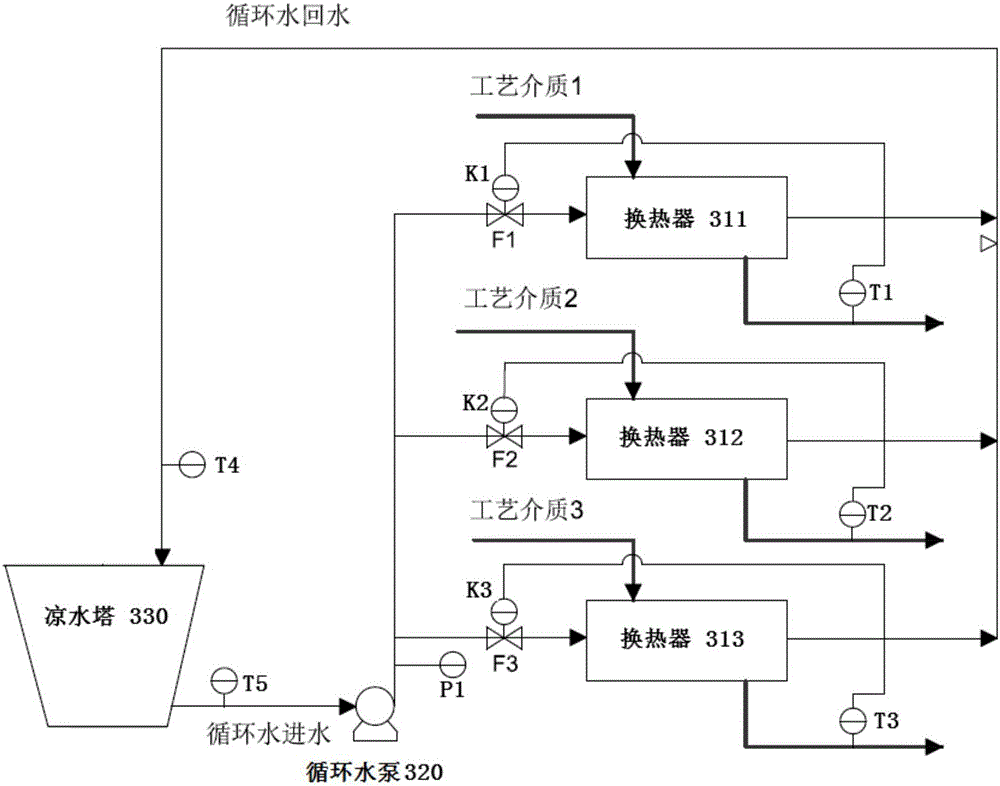

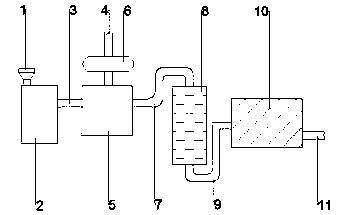

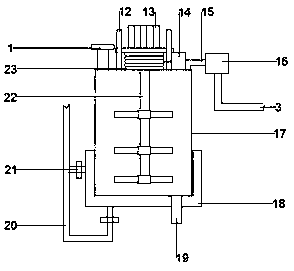

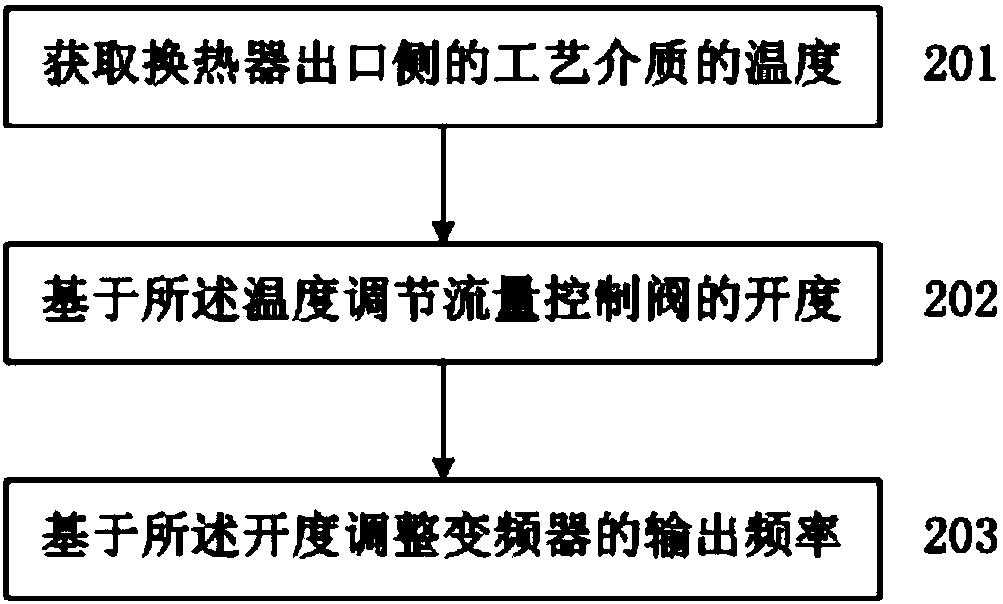

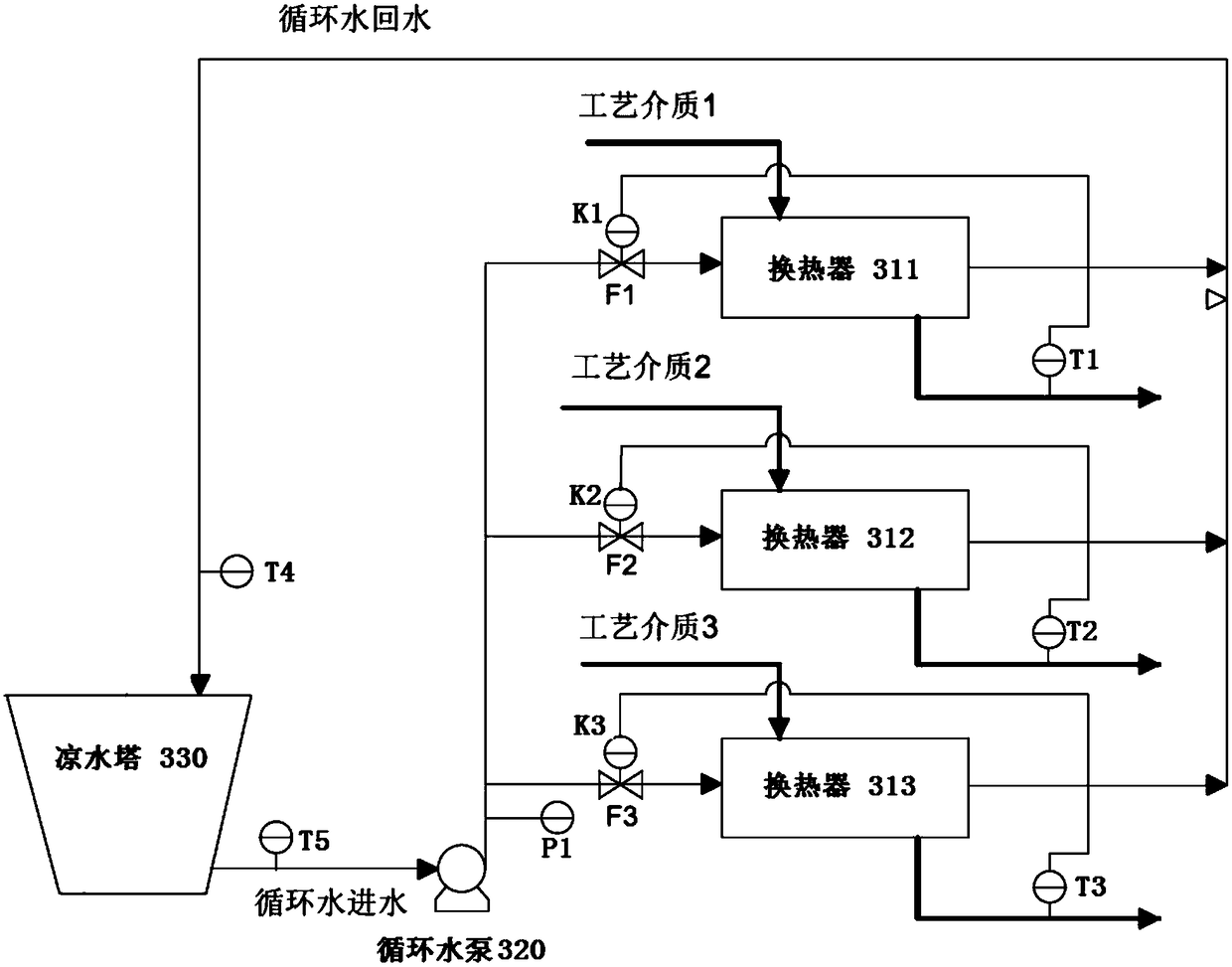

Device and method for variable-frequency optimization and energy conservation of circulating water system

InactiveCN105862983AThe output is adjusted in timeRealize real-time variable frequency controlPump controlHeat exchange apparatusFrequency changerEngineering

The invention relates to the field of control of a circulating water system, and in particular discloses a device and a method for variable-frequency optimization and energy conservation of the circulating water system. The method comprises the following steps: acquiring temperature of a process medium on the outlet side of a heat exchanger of at least one branch; regulating the opening of a flow control valve on a corresponding branch on the basis of the temperature of the process medium; and on the basis of the opening of the flow control valve on the corresponding branch, regulating the output frequency of a frequency converter, wherein the frequency converter is used for controlling the active power of the circulating water pump. With the application of the device and the method disclosed by the invention, the output of the circulating water system can be timely regulated in accordance with the actual operation situation of equipment; the device and the method are outstanding in energy-conserving effect; and by virtue of the device and the method, the occurrence of a bias current phenomenon can be additionally avoided.

Owner:严义忠

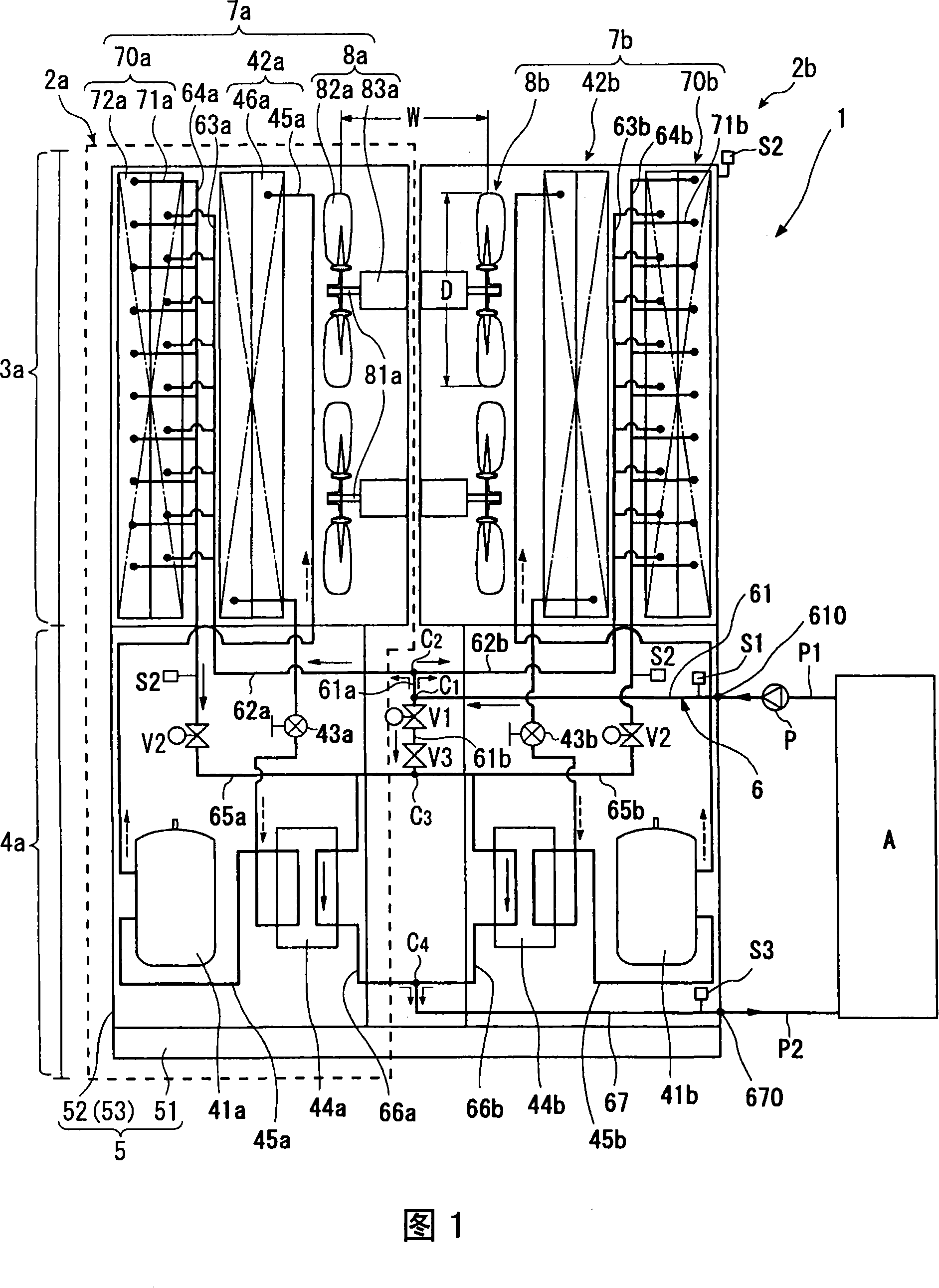

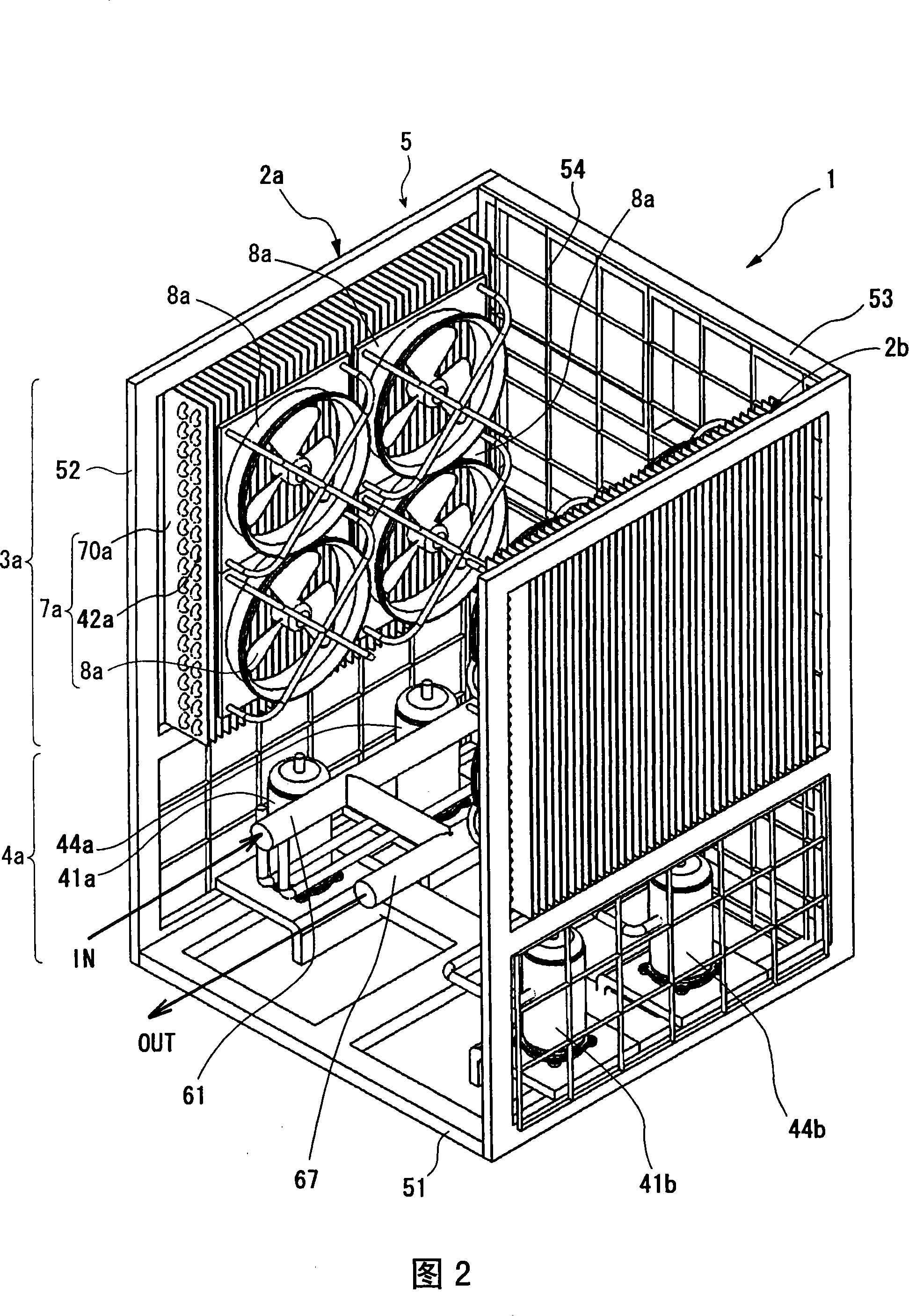

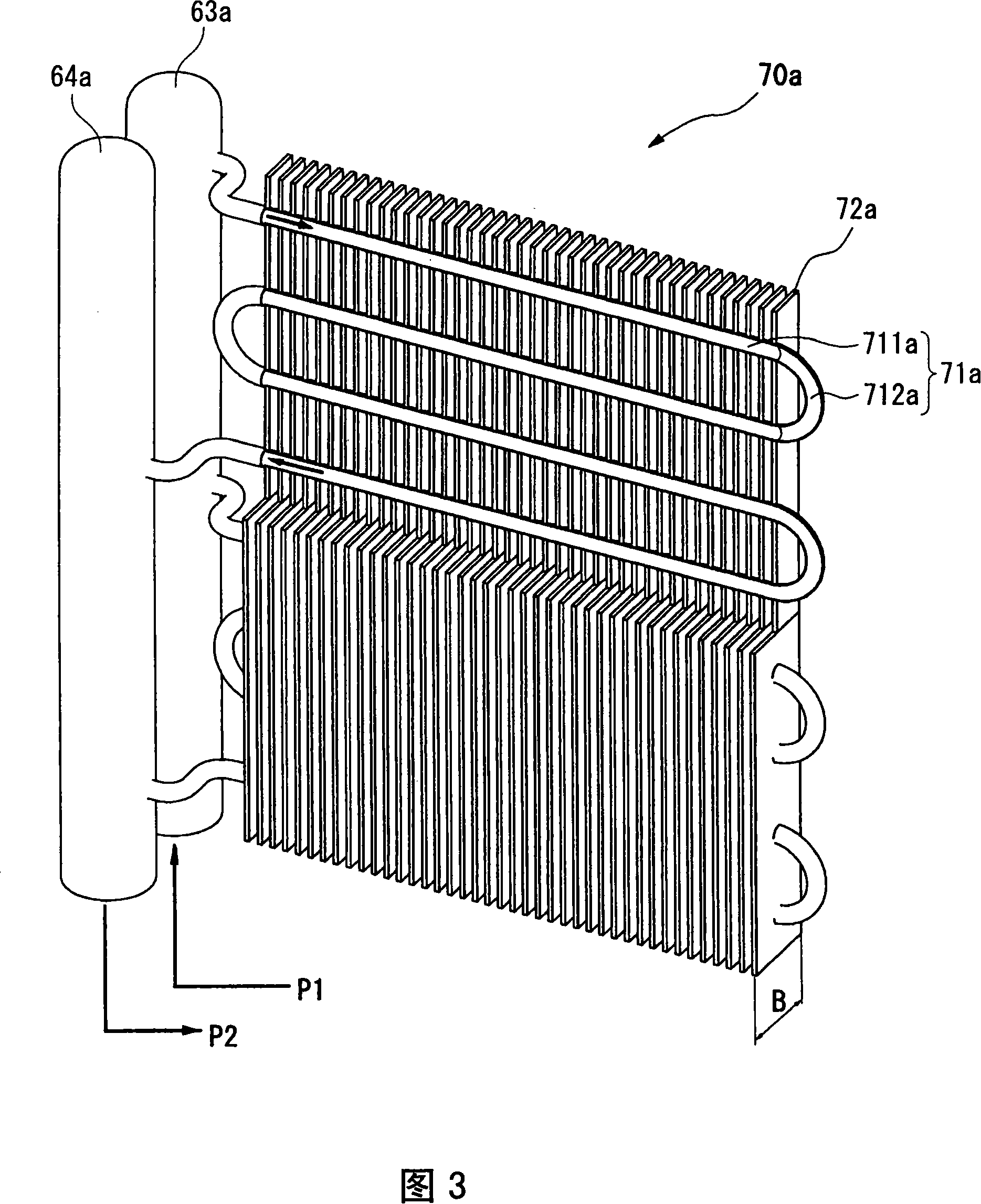

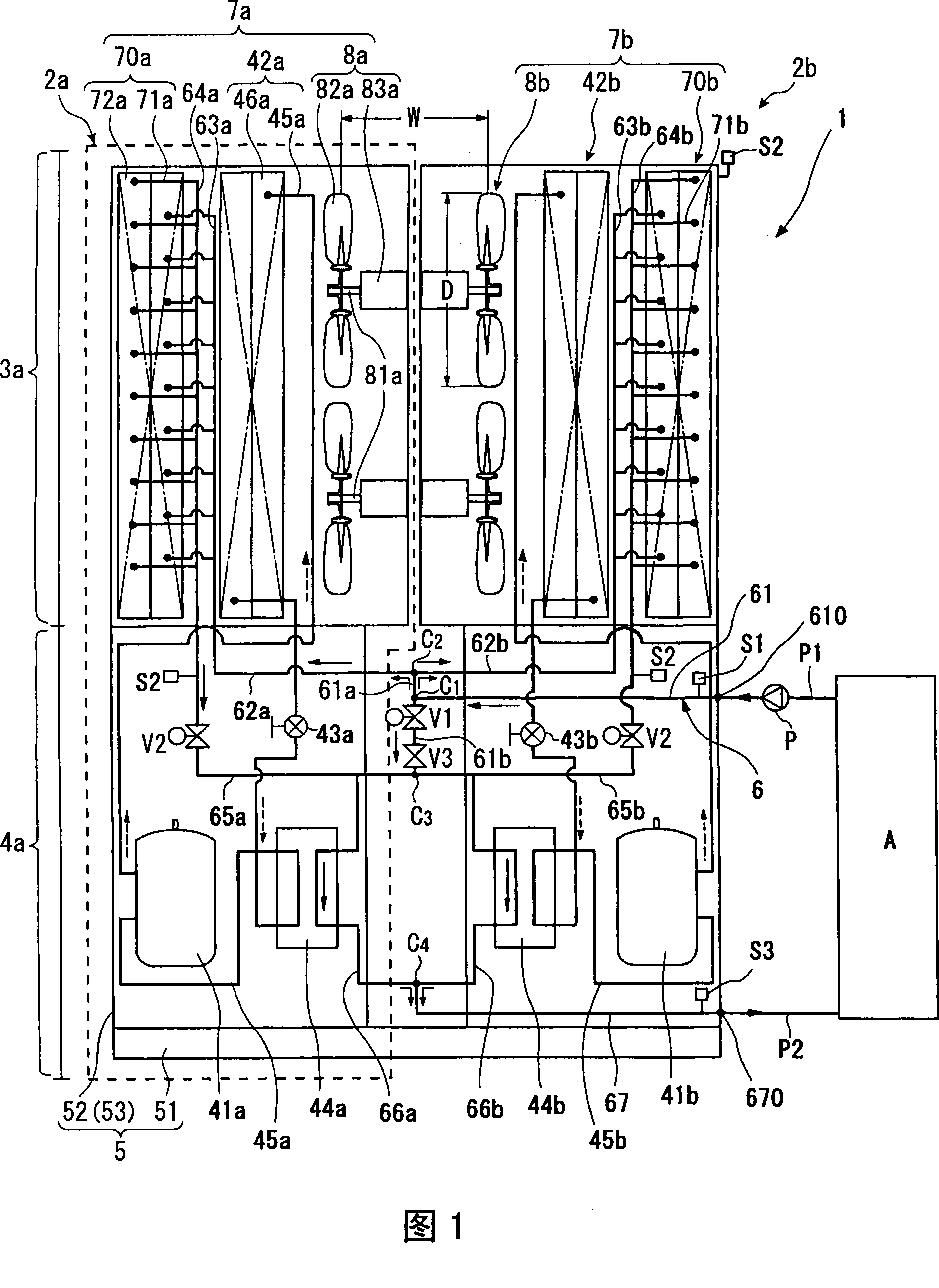

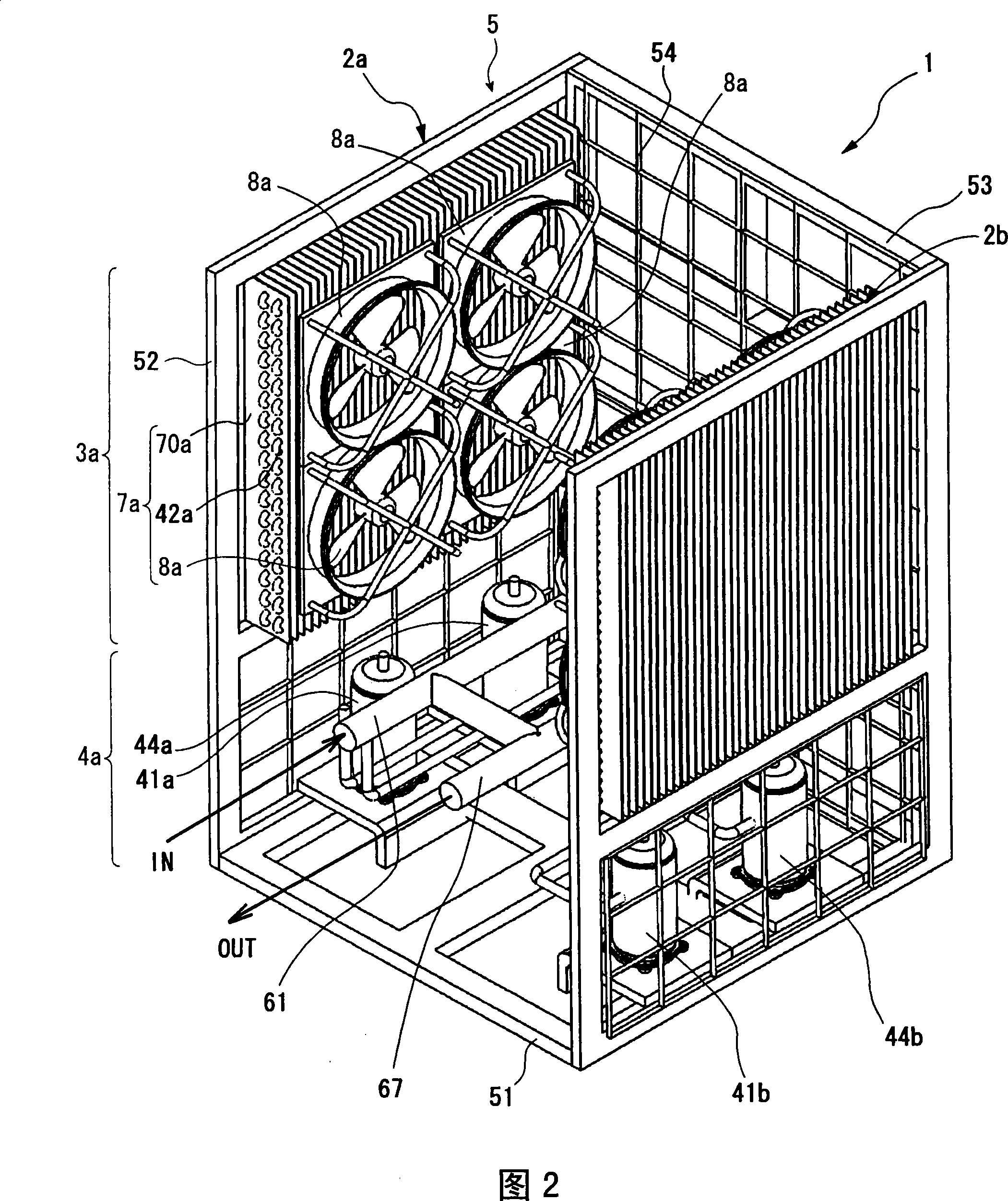

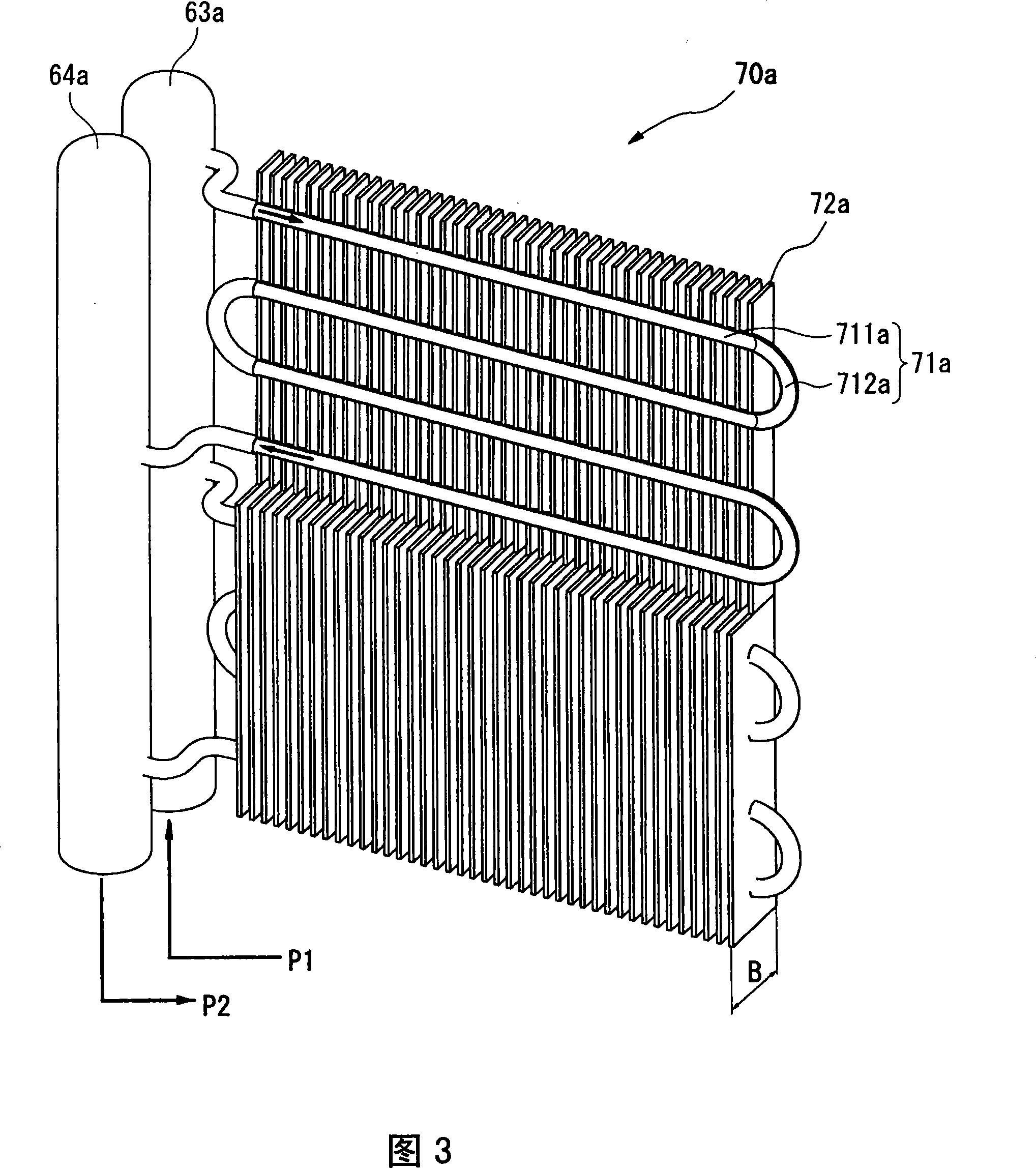

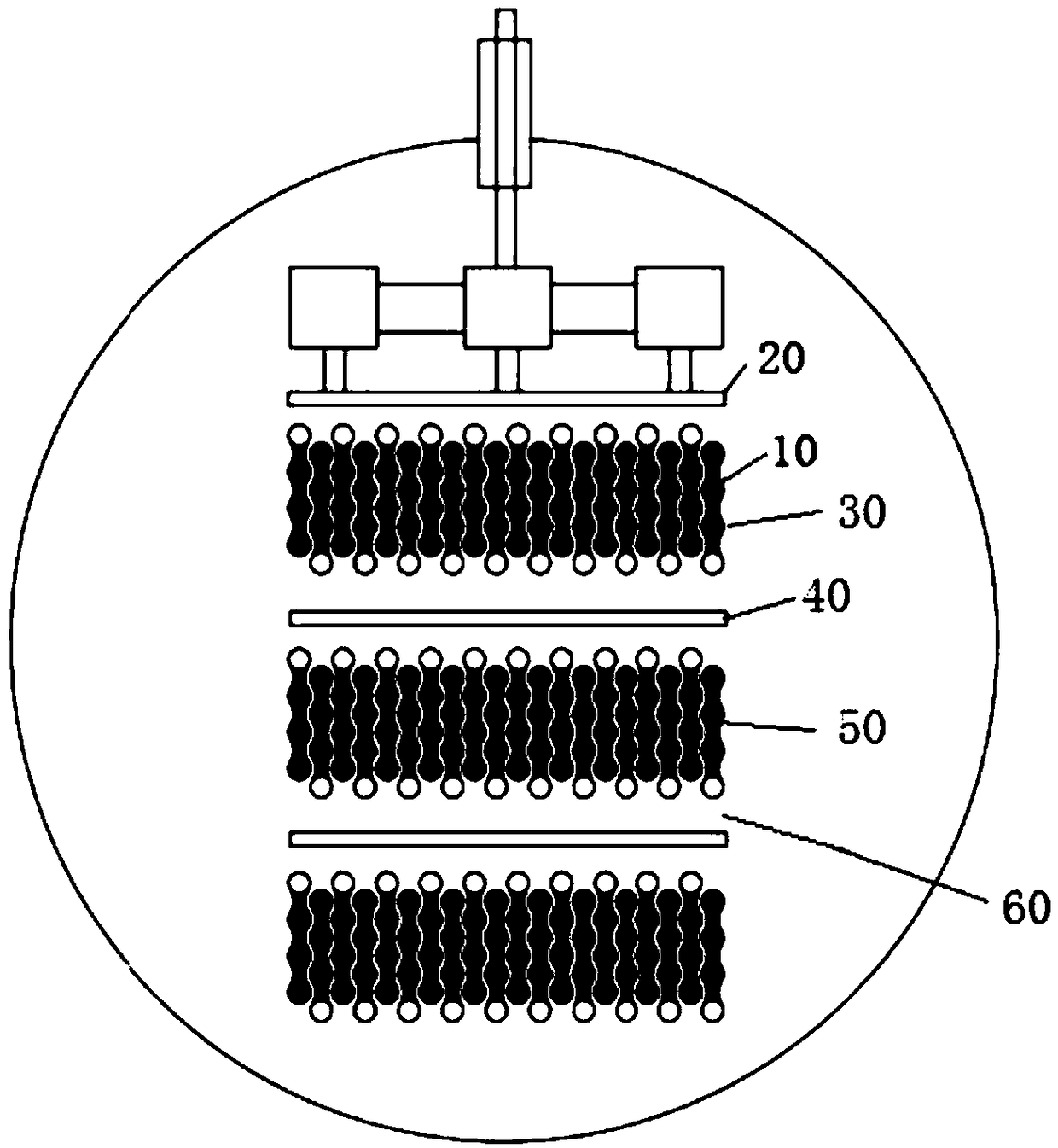

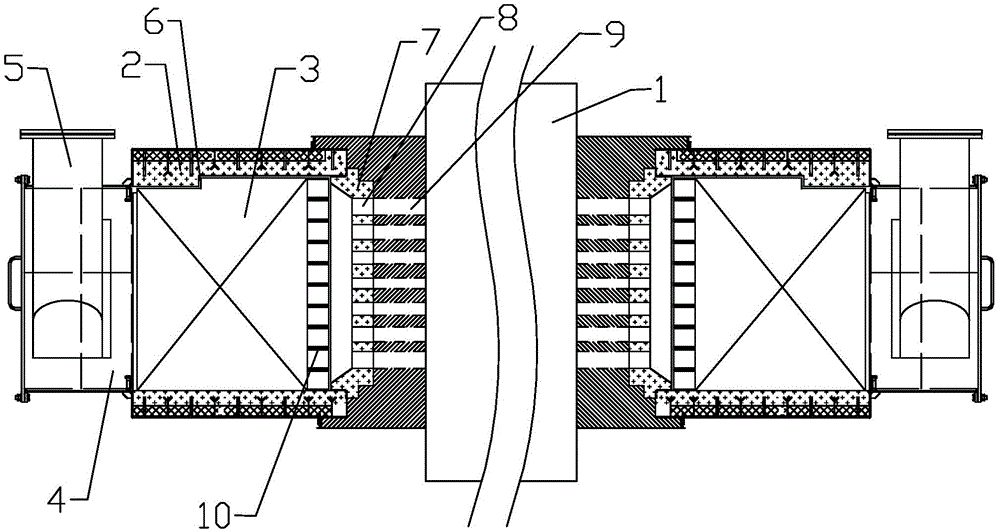

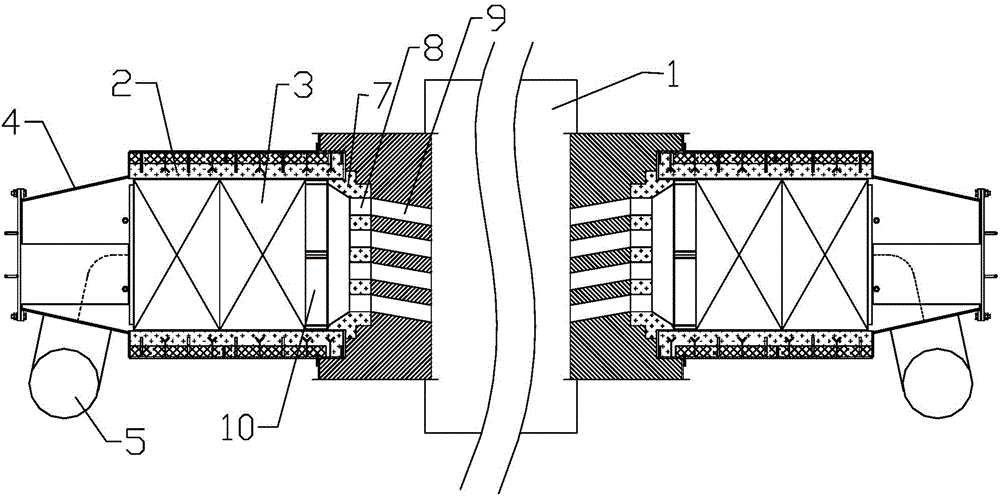

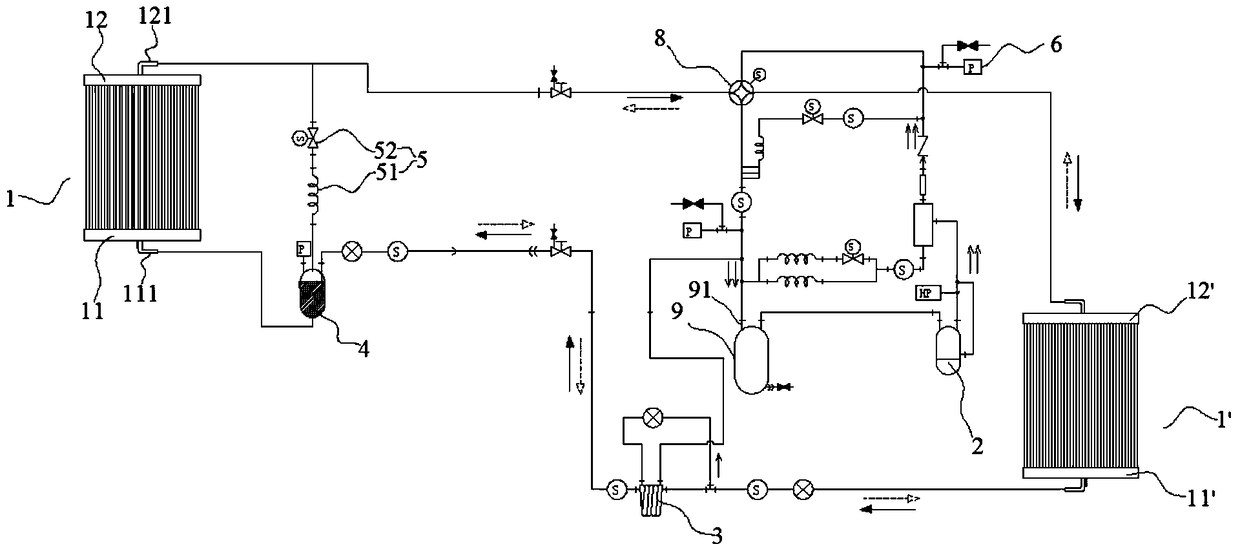

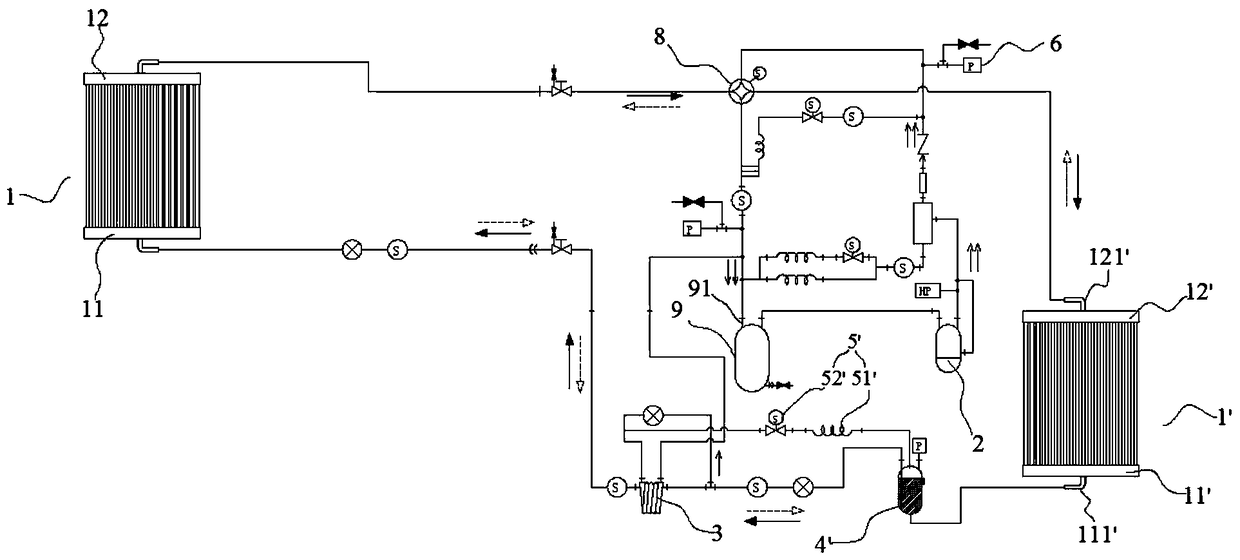

Composite heat dissipation device, cooling unit, cooling device and assembling body

ActiveCN101149203AAvoid drift phenomenonImprove cooling efficiencyCompression machines with non-reversible cycleStationary refrigeration devicesRefrigerantChiller

To provide a cooling device having a plurality of cooling units, wherein, each cooling unit has a cooling tower part, cooling device part and tubing series arranged at single side embedding board, the cooling tower part has: a heat radiation mechanism having a pipeline circulating the cooled fluid; a condenser arranged by abutting against the heat radiation mechanism, having pipeline for circulating refrigerant during executing heat radiation course of refrigeration cycle; a composite heat radiation device arranged by abutting against the condenser, having inspiration fan leading-in the environment gas to the around of the pipeline, the cooling device part has the condenser, and has an expansion valve, an evaporator and a compressor for executing the refrigeration cycle, the tubing serieshas a first tubing series for supplying the cooled fluid to the heat radiation mechanism and a second tubing series for leading the cooled fluid to outflow from the heat radiation mechanism, one partof the second tubing series passes through the evaporator, the inspiration fan of the cooling unit is relatively arranged with regulated alternation.

Owner:HITACHI METALS LTD

Cooling device and assembling body

ActiveCN101149203BImprove cooling efficiencyAvoid drift phenomenonCompression machines with non-reversible cycleStationary refrigeration devicesCooling towerNuclear engineering

To provide a cooling device having a plurality of cooling units, wherein, each cooling unit has a cooling tower part, cooling device part and tubing series arranged at single side embedding board, the cooling tower part has: a heat radiation mechanism having a pipeline circulating the cooled fluid; a condenser arranged by abutting against the heat radiation mechanism, having pipeline for circulating refrigerant during executing heat radiation course of refrigeration cycle; a composite heat radiation device arranged by abutting against the condenser, having inspiration fan leading-in the environment gas to the around of the pipeline, the cooling device part has the condenser, and has an expansion valve, an evaporator and a compressor for executing the refrigeration cycle, the tubing serieshas a first tubing series for supplying the cooled fluid to the heat radiation mechanism and a second tubing series for leading the cooled fluid to outflow from the heat radiation mechanism, one partof the second tubing series passes through the evaporator, the inspiration fan of the cooling unit is relatively arranged with regulated alternation.

Owner:HITACHI METALS LTD

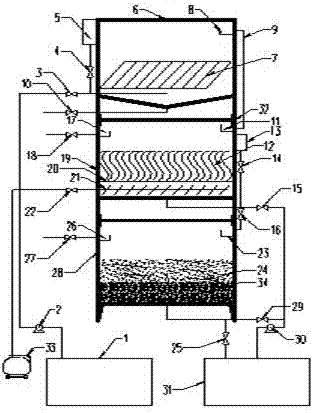

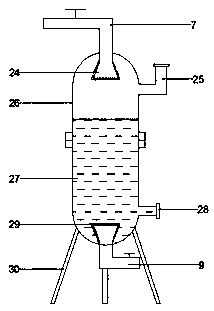

Oil-bearing car-washing wastewater treatment method and equipment

InactiveCN106946377AFast precipitationGood clarificationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFiltrationWater quality

The invention provides a car-washing wastewater treatment method and equipment which are applied to small-sized car-washing stations. The car-washing wastewater treatment method comprises the following steps of: clarifying in a coagulating sedimentation tank with sloping plates by using a coagulant; carrying out turbidity removal and oil absorption by using fiber bundle media; carrying out air-water backwashing after the fiber bundle media become invalid; carrying out oil removal treatment on oil stain accumulated in the fiber bundle media by adding a cleaning agent at a certain water temperature; for residual organic matters of the fiber bundle media, firstly soaking the fiber bundle media by using an agent, and then cleaning; and adsorbing the organic matters and a surface active agent by using diatomite and activated carbon. The equipment adopting the method comprises the coagulating sedimentation tank designed by modular combination, a fiber filtration tank and an adsorption tank; and matched wastewater collection tanks and clear water tanks can be buried in the ground. The equipment is small in volume, low in manufacturing cost and operation cost, simple to operate and convenient to maintain and has a good effluent effect. The quality of water treated by the method and equipment can reach Water Quality Standard for Domestic Miscellaneous Water (CJ / T48-1999). The method and equipment have wide application prospect.

Owner:BEIHUA UNIV

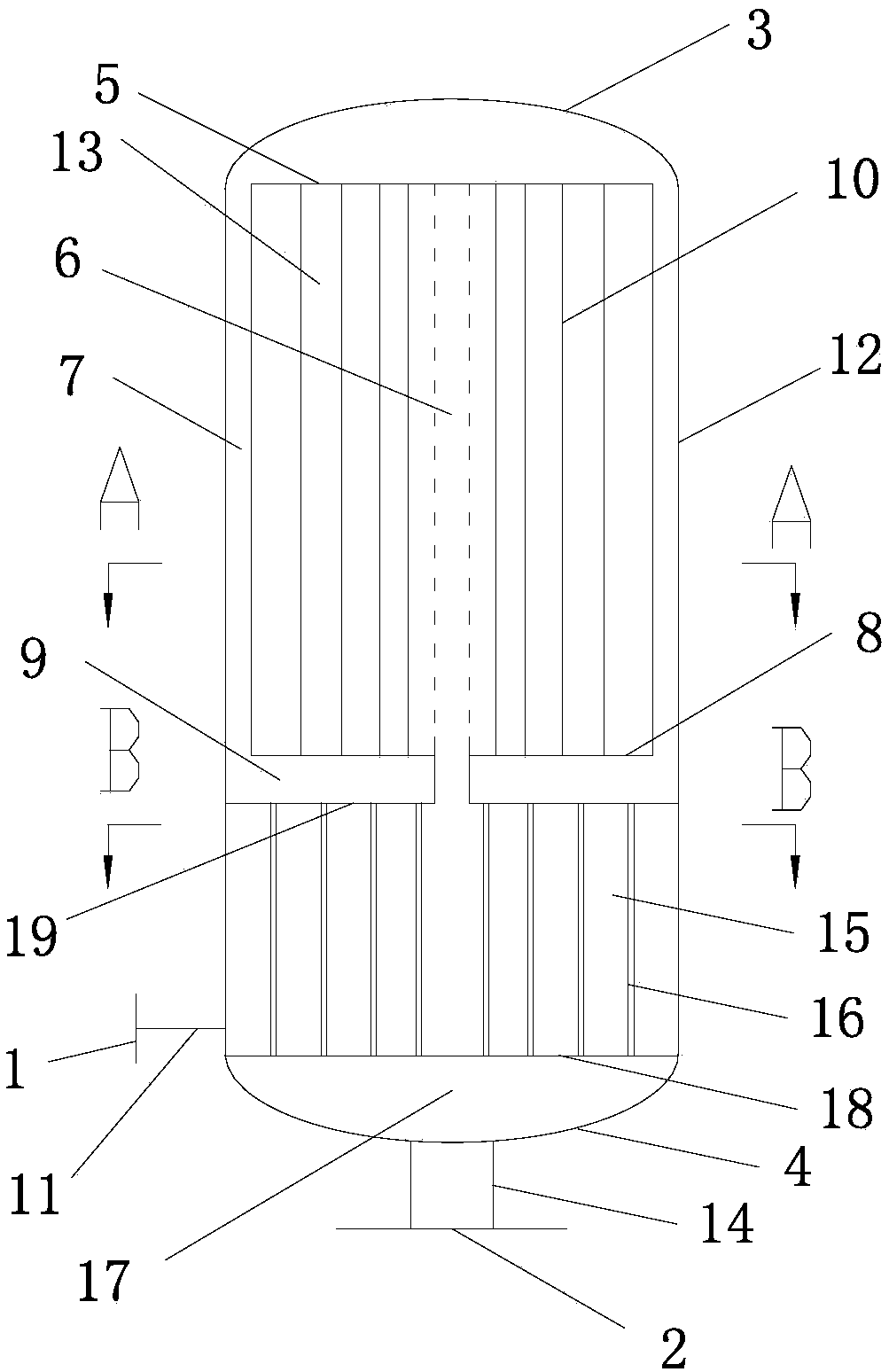

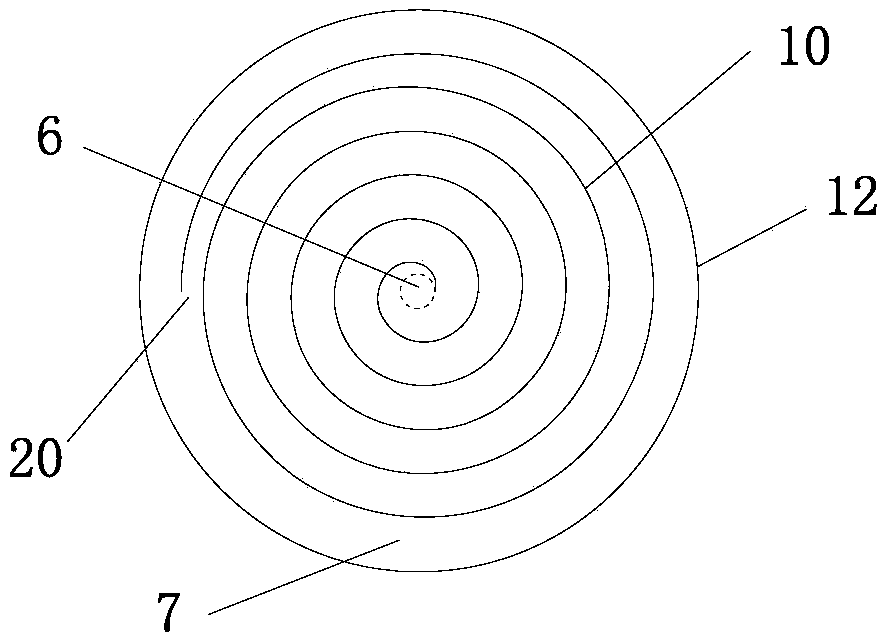

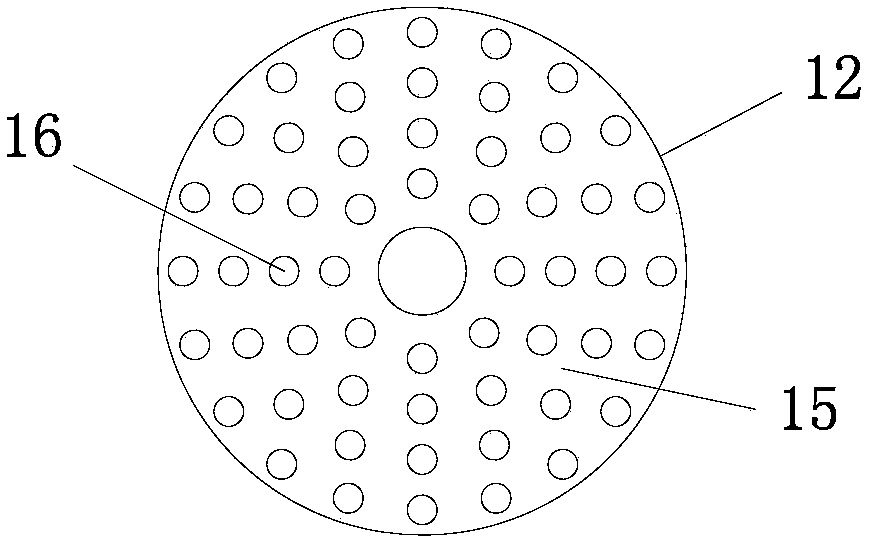

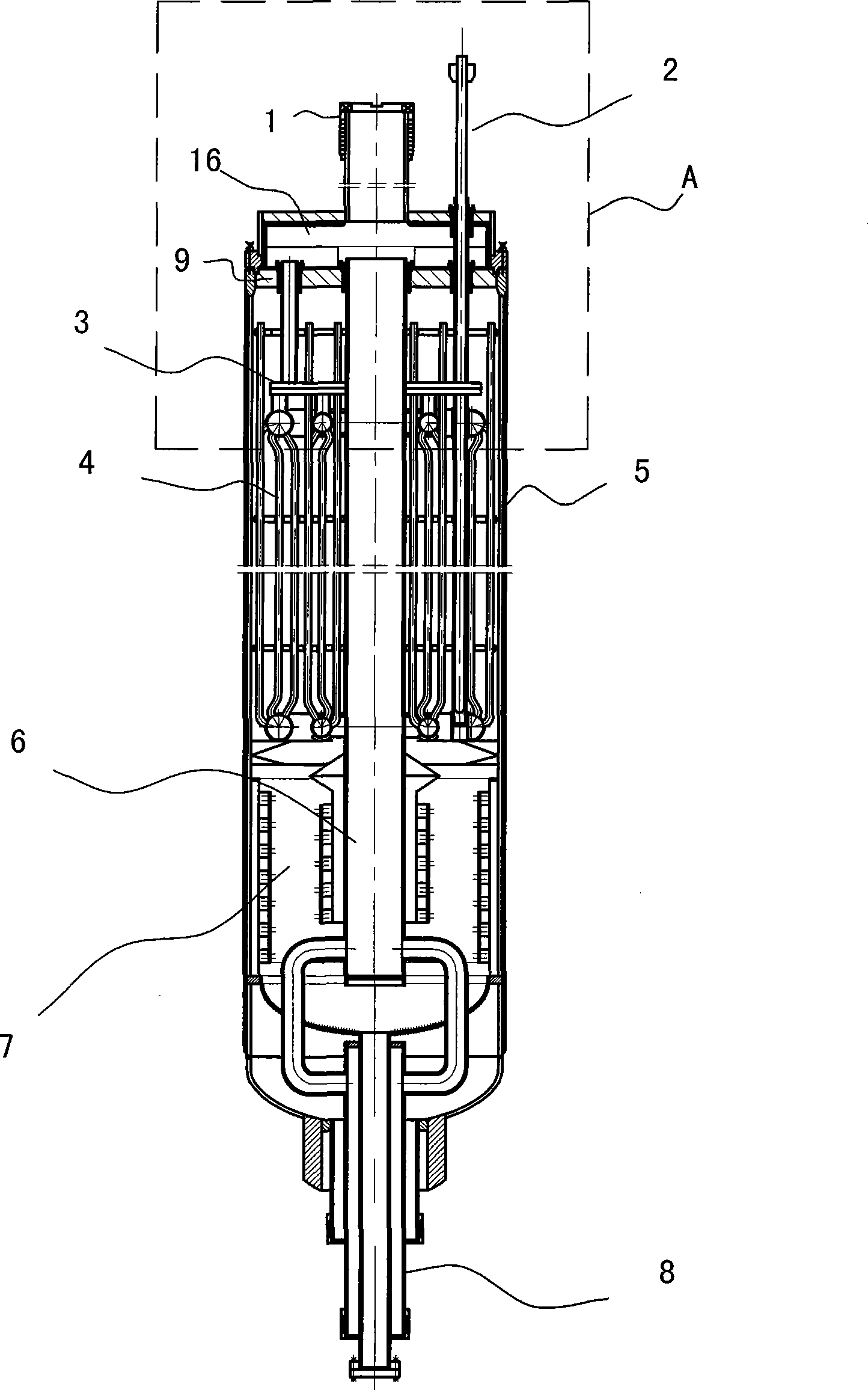

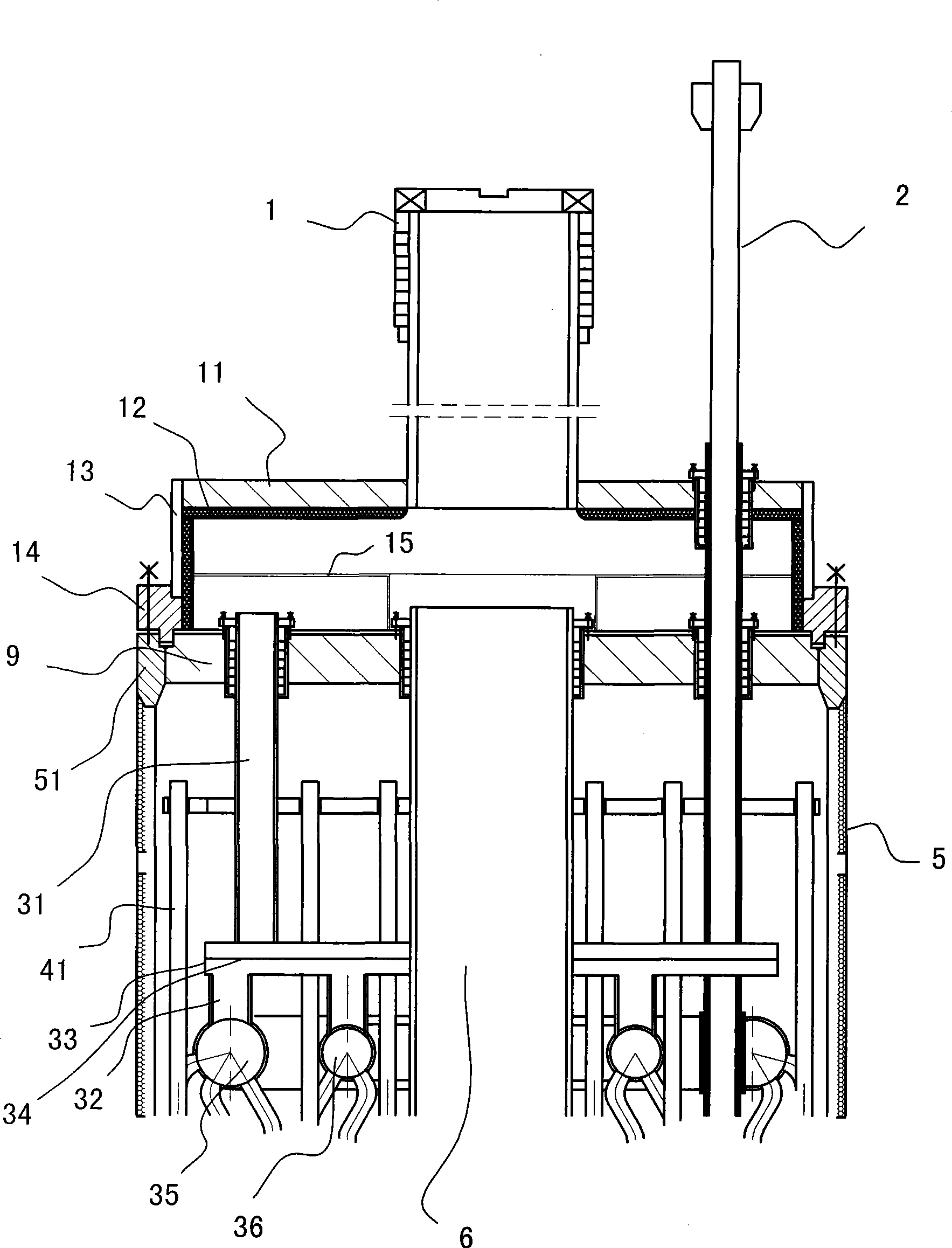

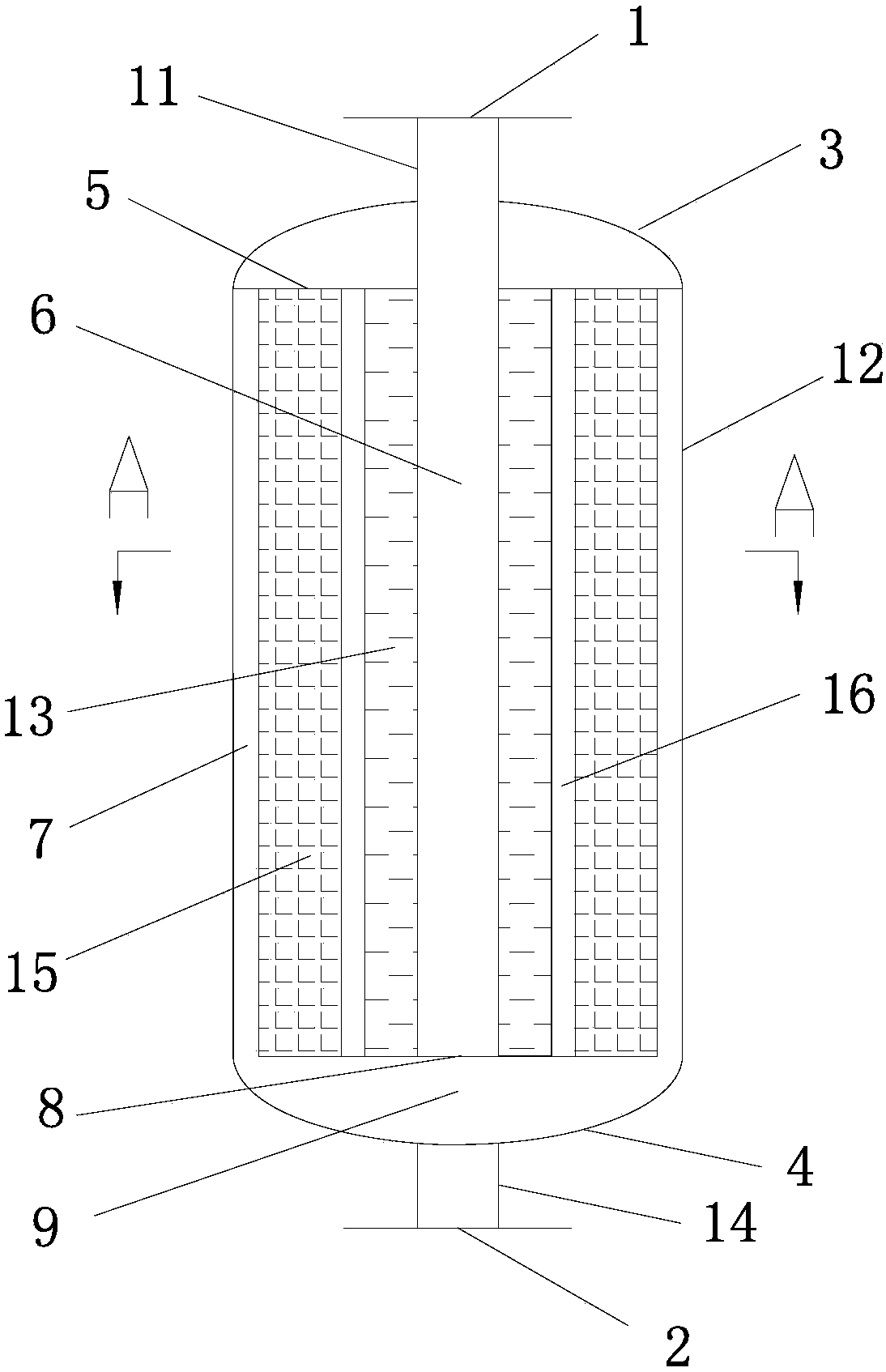

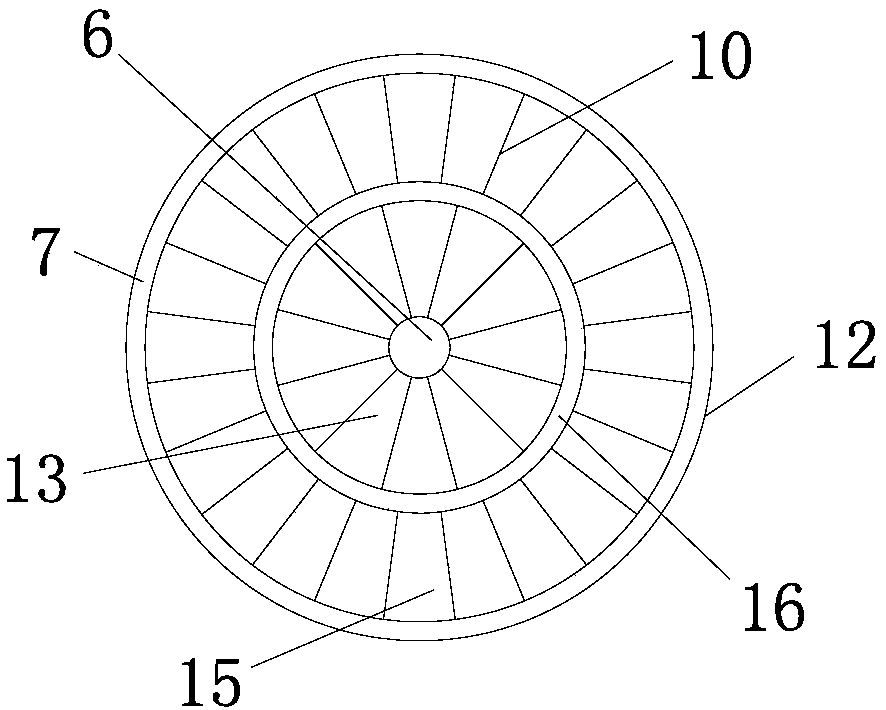

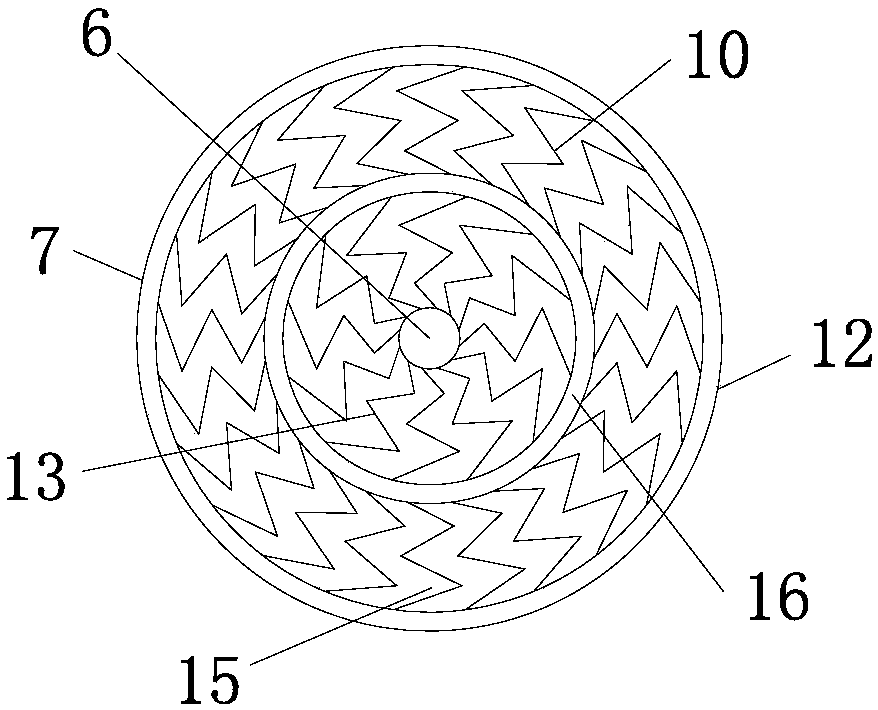

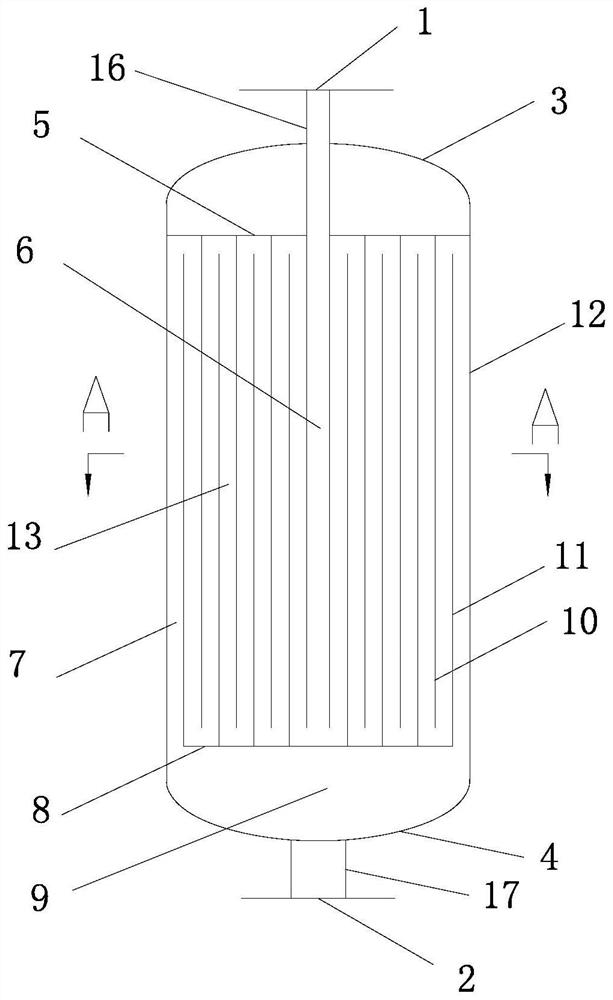

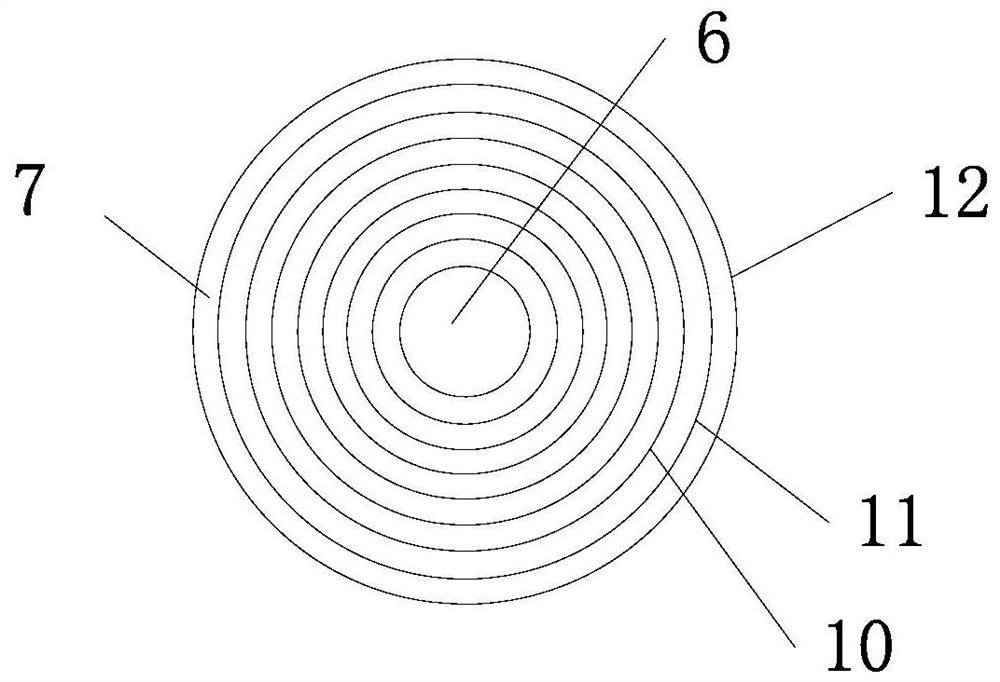

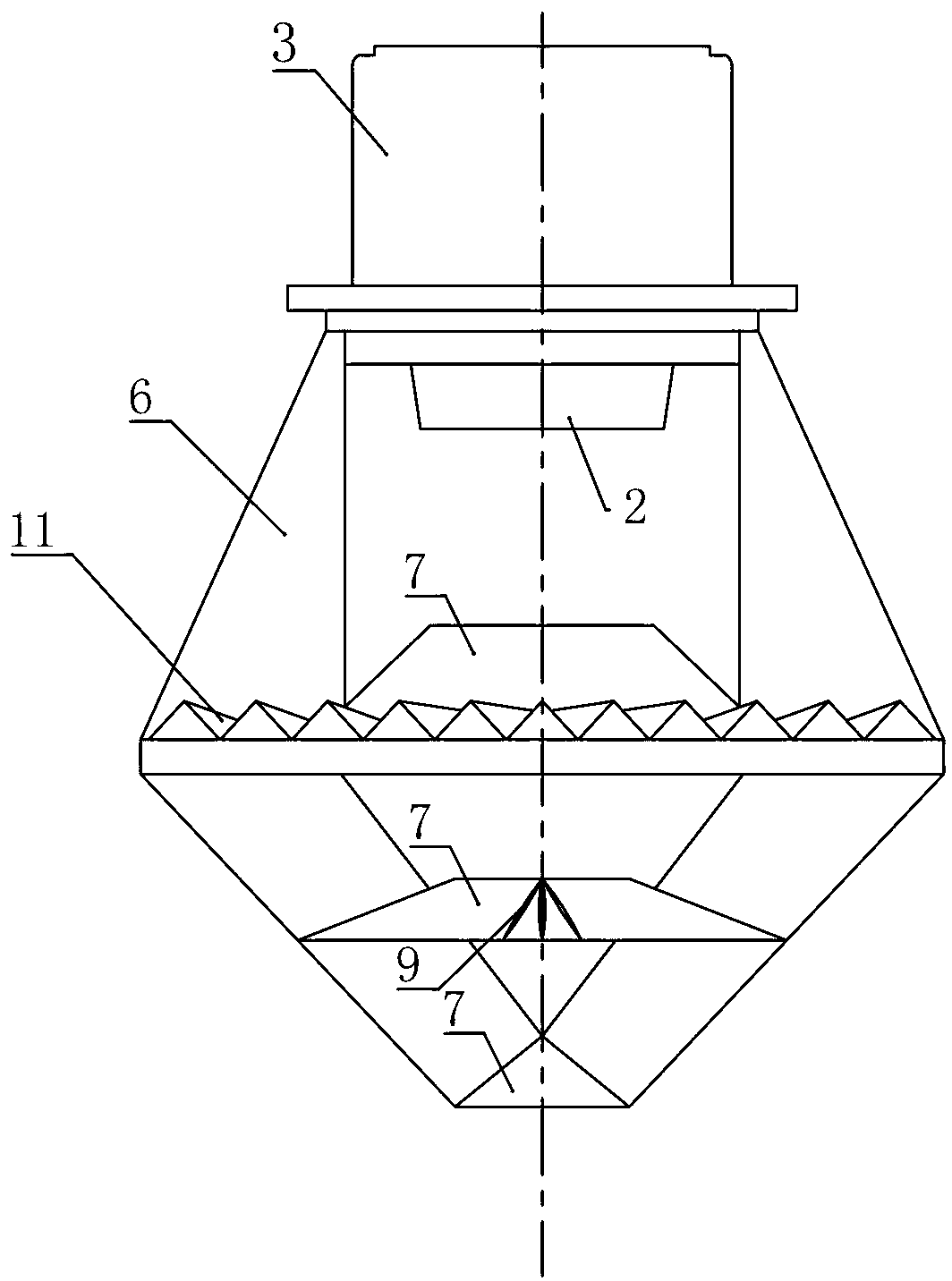

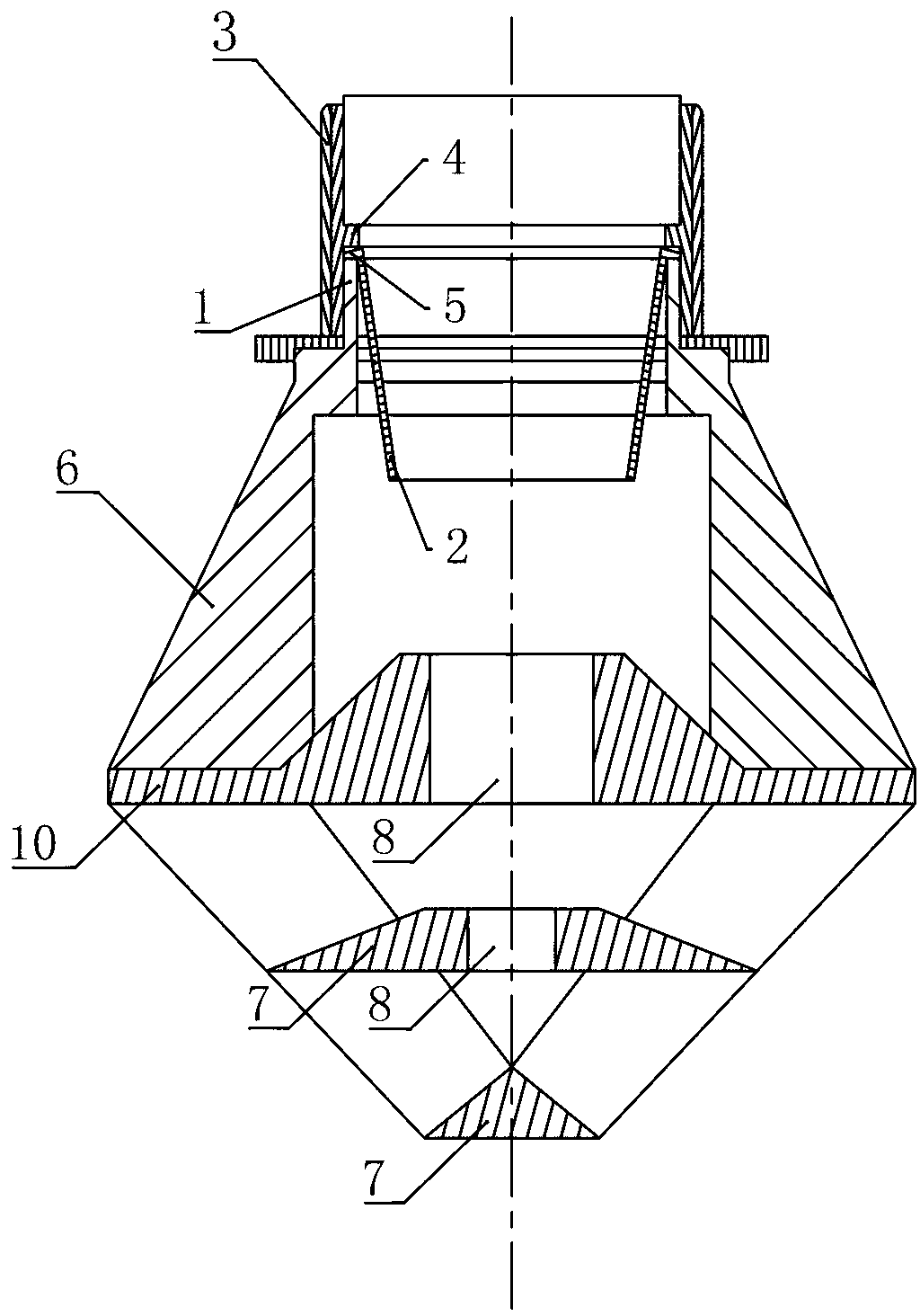

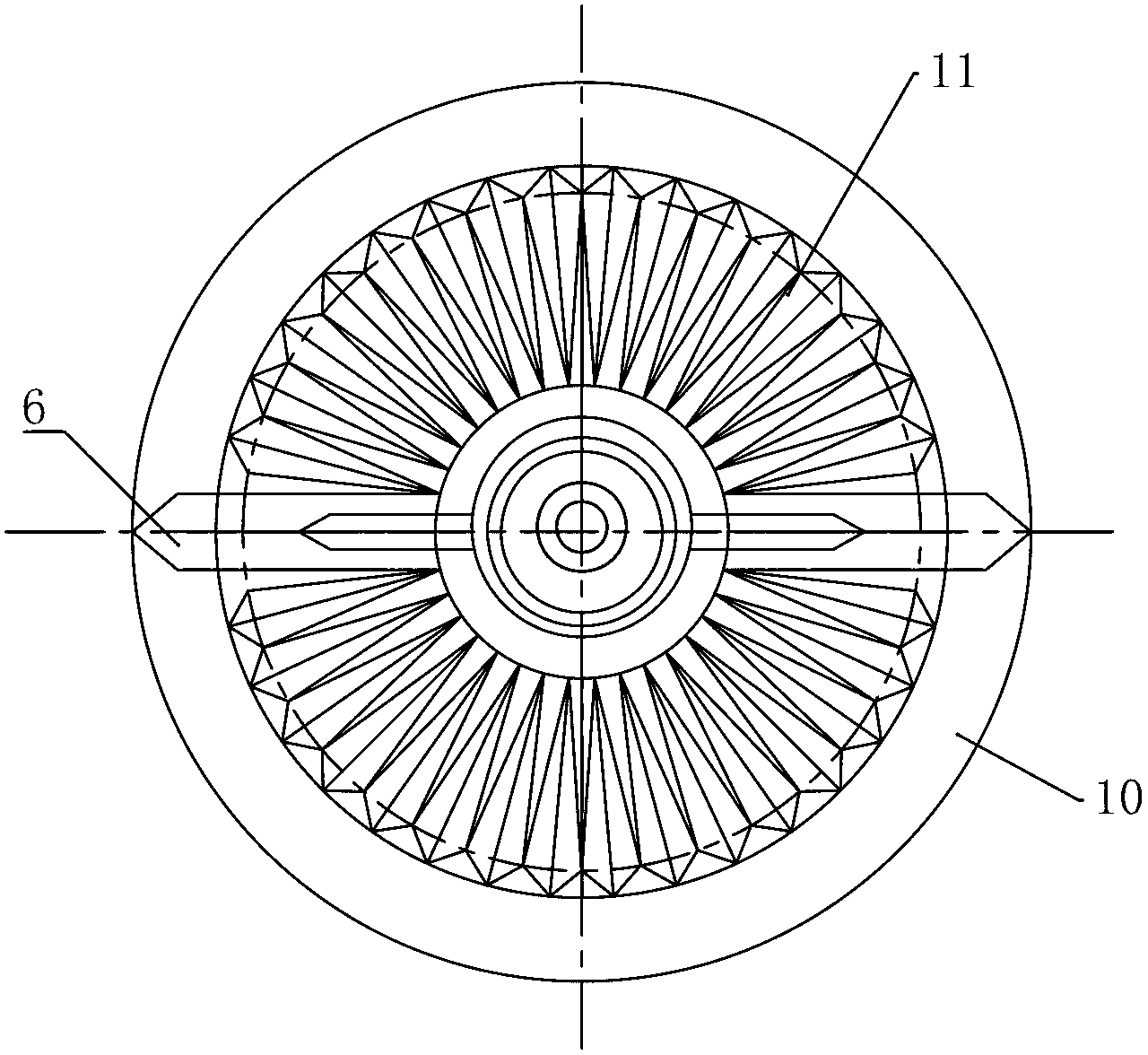

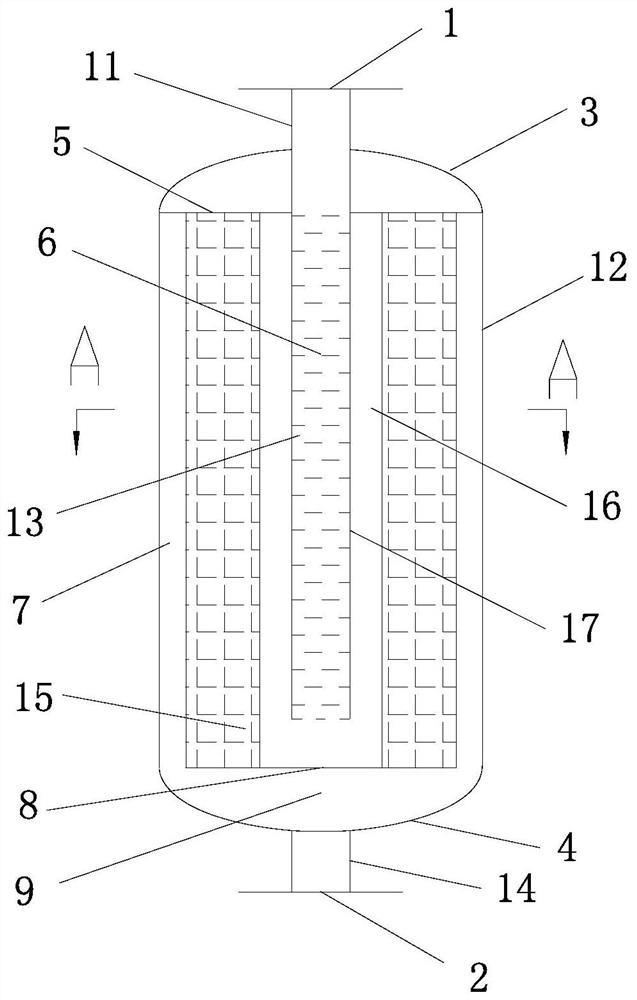

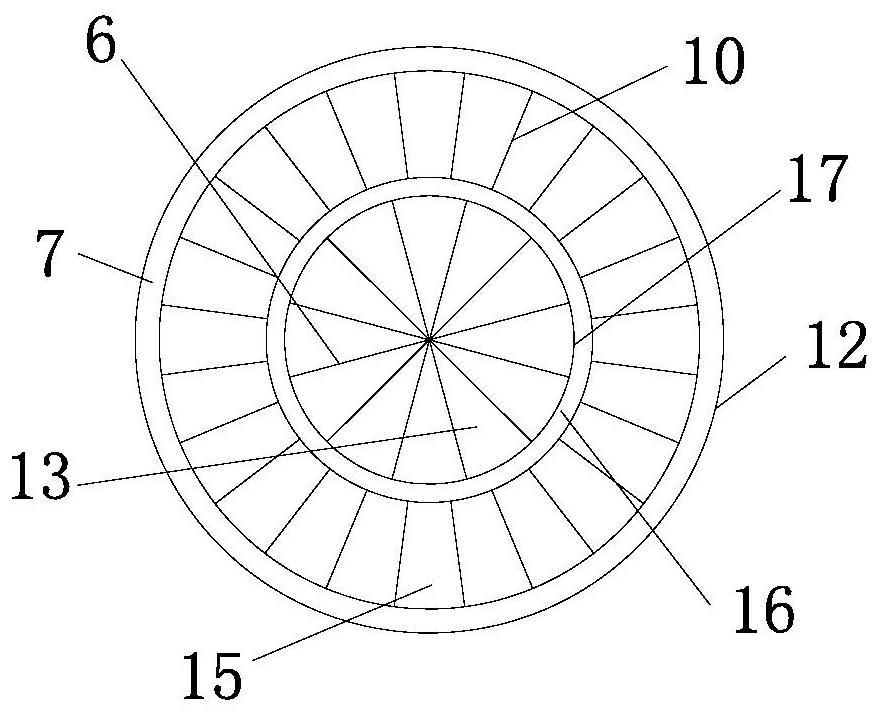

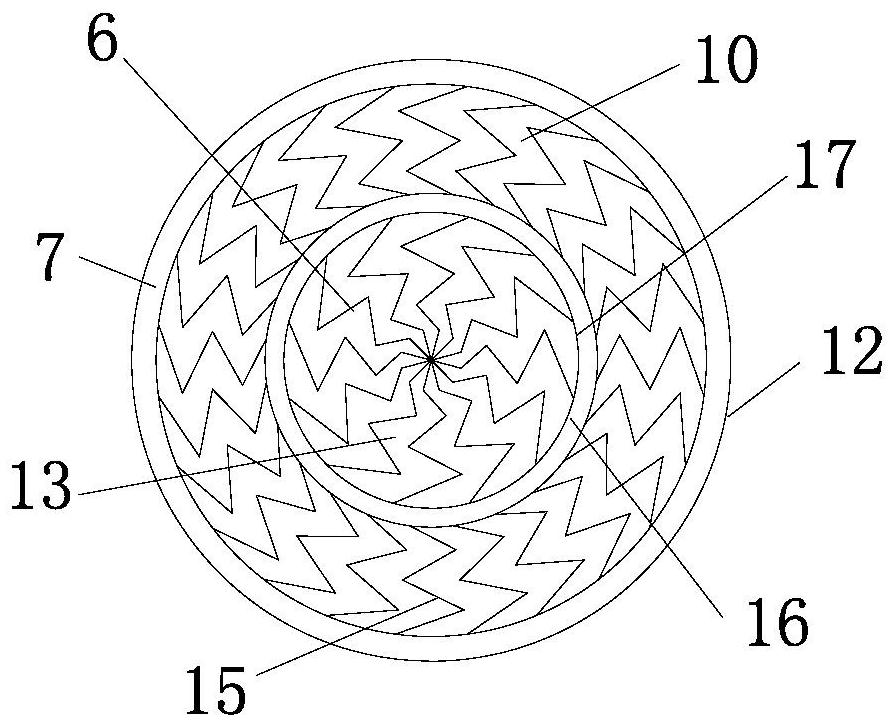

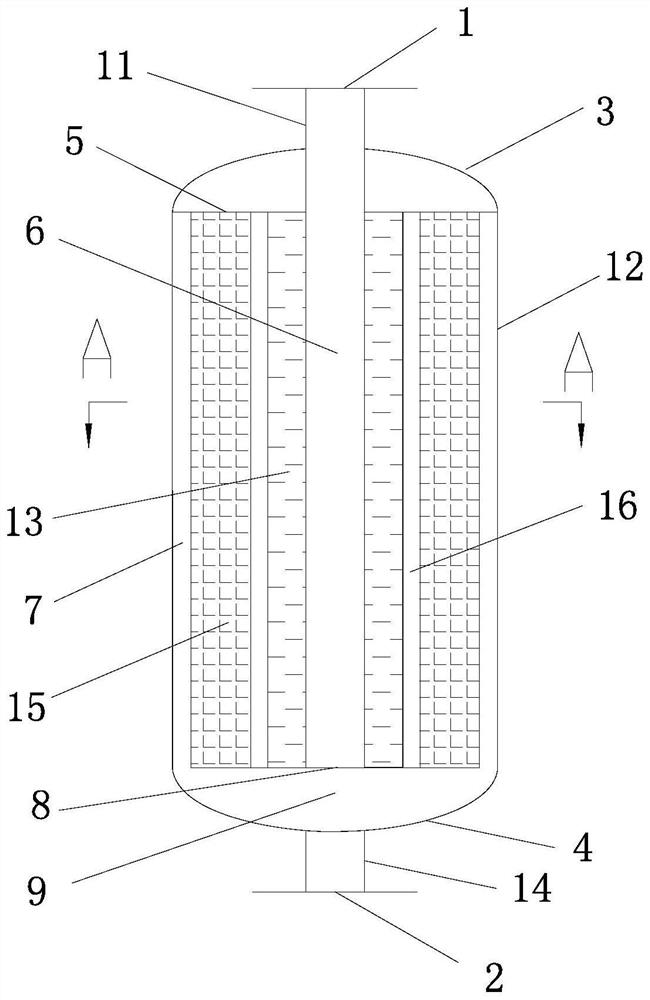

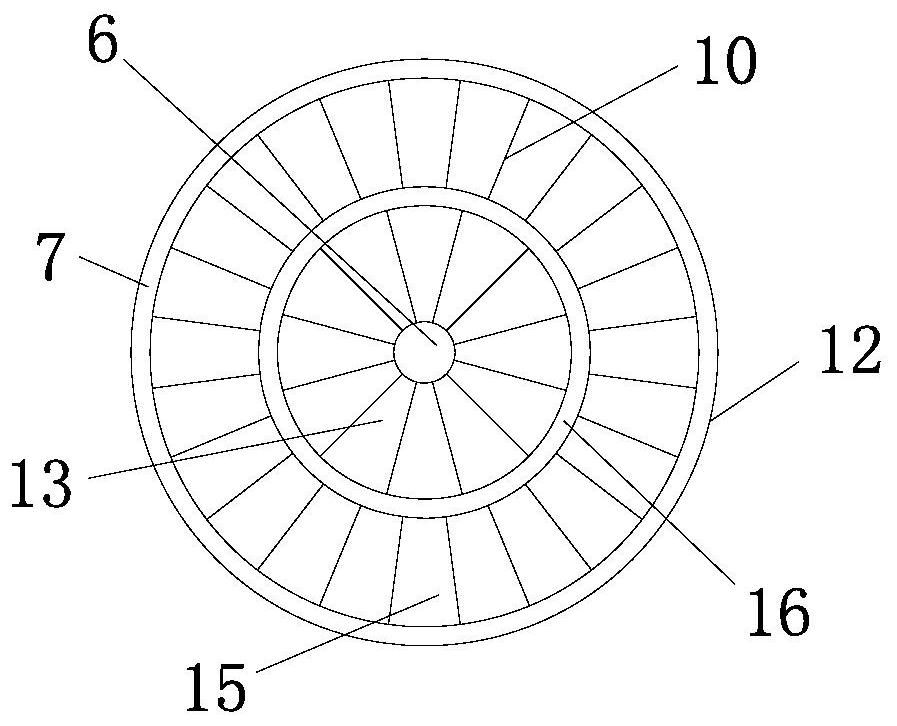

Reforming hydrogen production reactor, conversion furnace, and reforming hydrogen production reaction method

ActiveCN109694041AImprove conversion efficiencyShort stayHydrogenHydrogen/synthetic gas productionMass transfer resistanceReaction rate

The present invention relates to a reforming hydrogen production reactor, a conversion furnace, and a reforming hydrogen production reaction method. According to the present invention, the reforming hydrogen production reactor and the conversion furnace adopt micro-catalytic reaction plates, wherein a catalytic active component is loaded on the reaction plate, such that the consumption of catalytic active metals is reduced, the catalyst is not easily subjected to carbon deposition deactivation, the diffusion distance of the reaction gas to the catalytic active center is shortened, the mass transfer resistance and the pressure drop of the reactor are reduced, and the conversion rate of the hydrogen production reaction is increased; the reaction gas flows outward from the center in the reactor, the flow channel area is gradually increased, and the temperature of the reaction plate is gradually increased, such that the conversion rate of the hydrogen production reaction as volume increaseand endothermic reaction is easily increased; the heat exchange zone is arranged in the reforming reactor, such that the temperature of the raw material gas entering the reaction zone is increased, the temperature of the product at the outlet of the reactor is reduced, the reaction rate is easily improved, and the material requirements on the downstream pipelines and equipment are easily reduced;and the reforming hydrogen production reactor has wide use range, and the furnace tube as the hydrogen production conversion furnace can be used for different types of conversion furnaces.

Owner:SINOPEC ENG +1

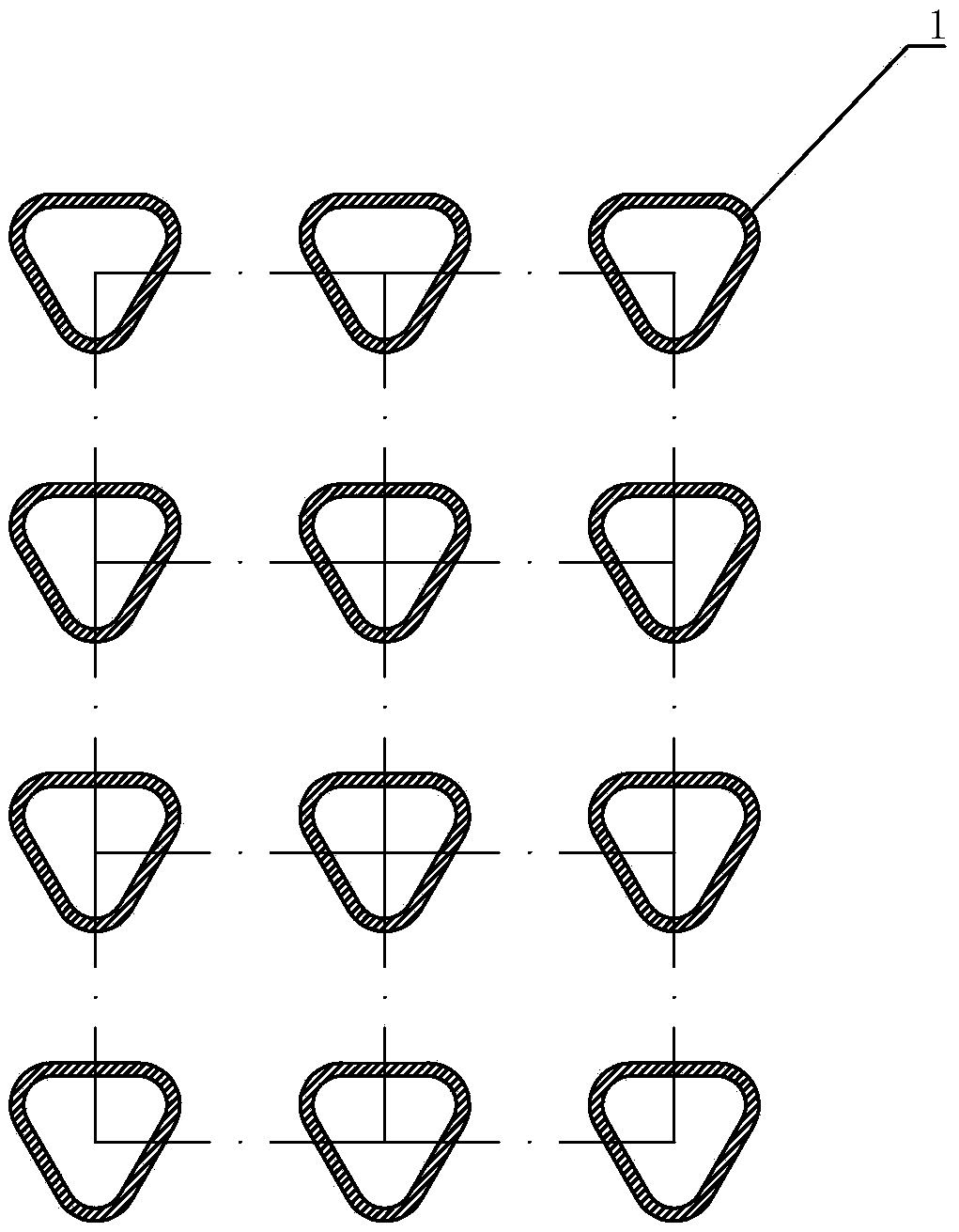

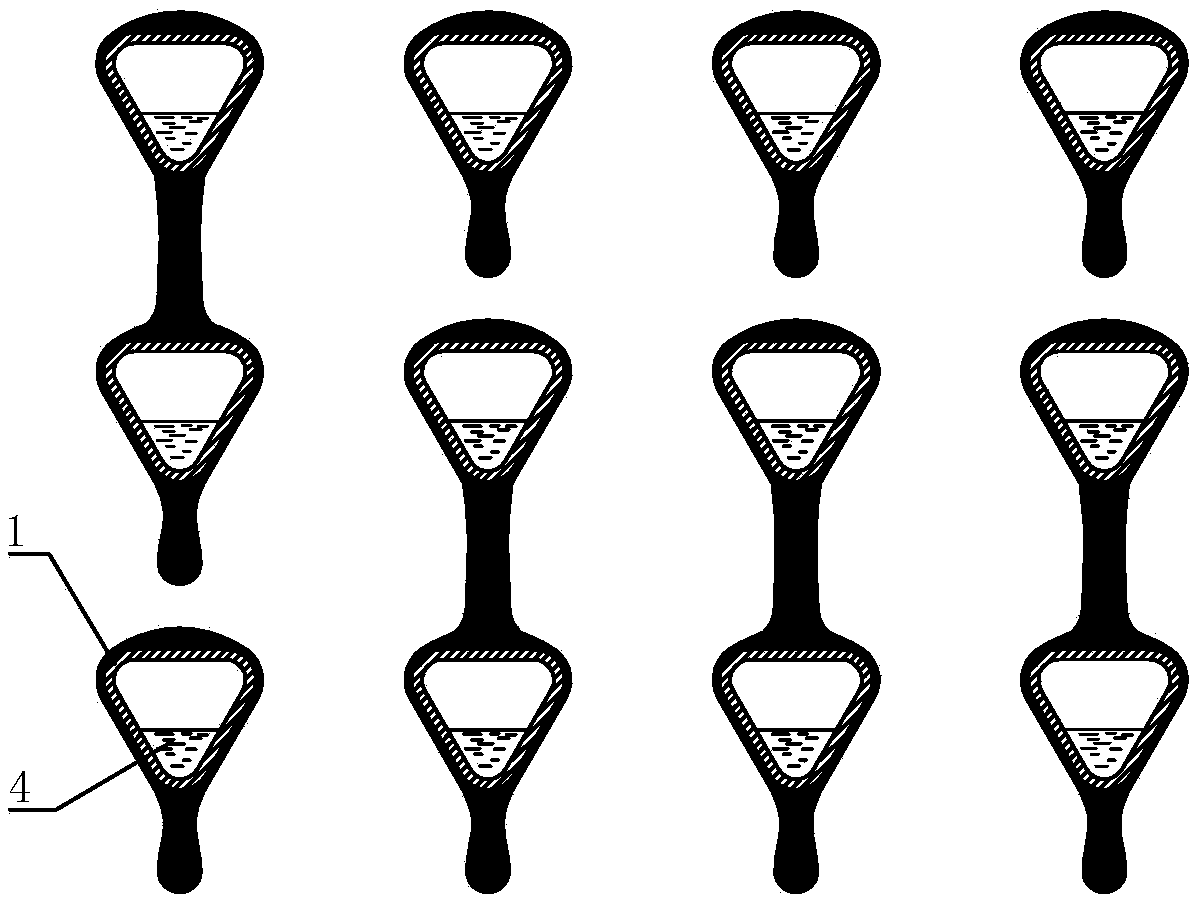

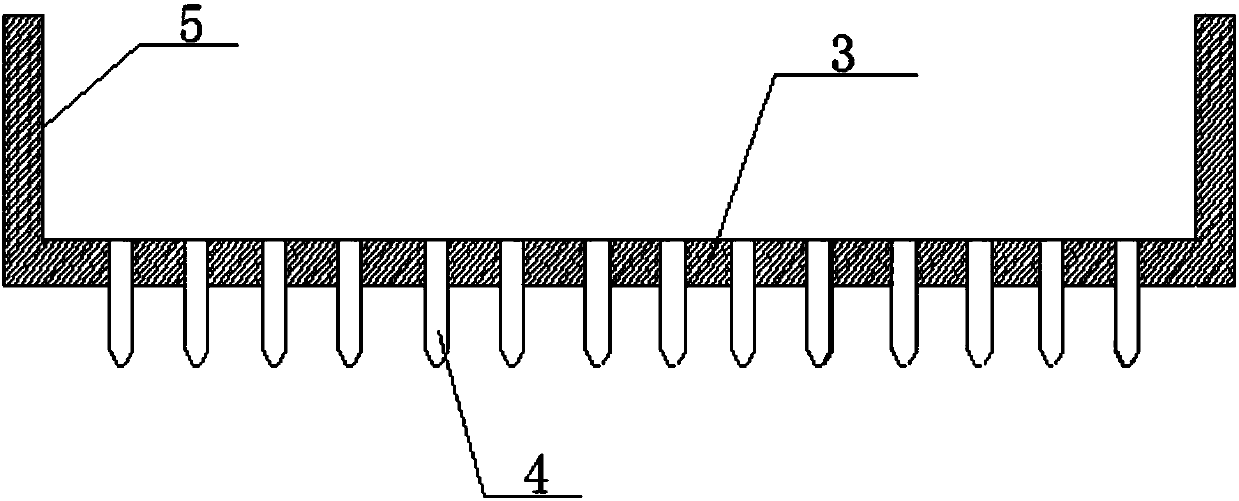

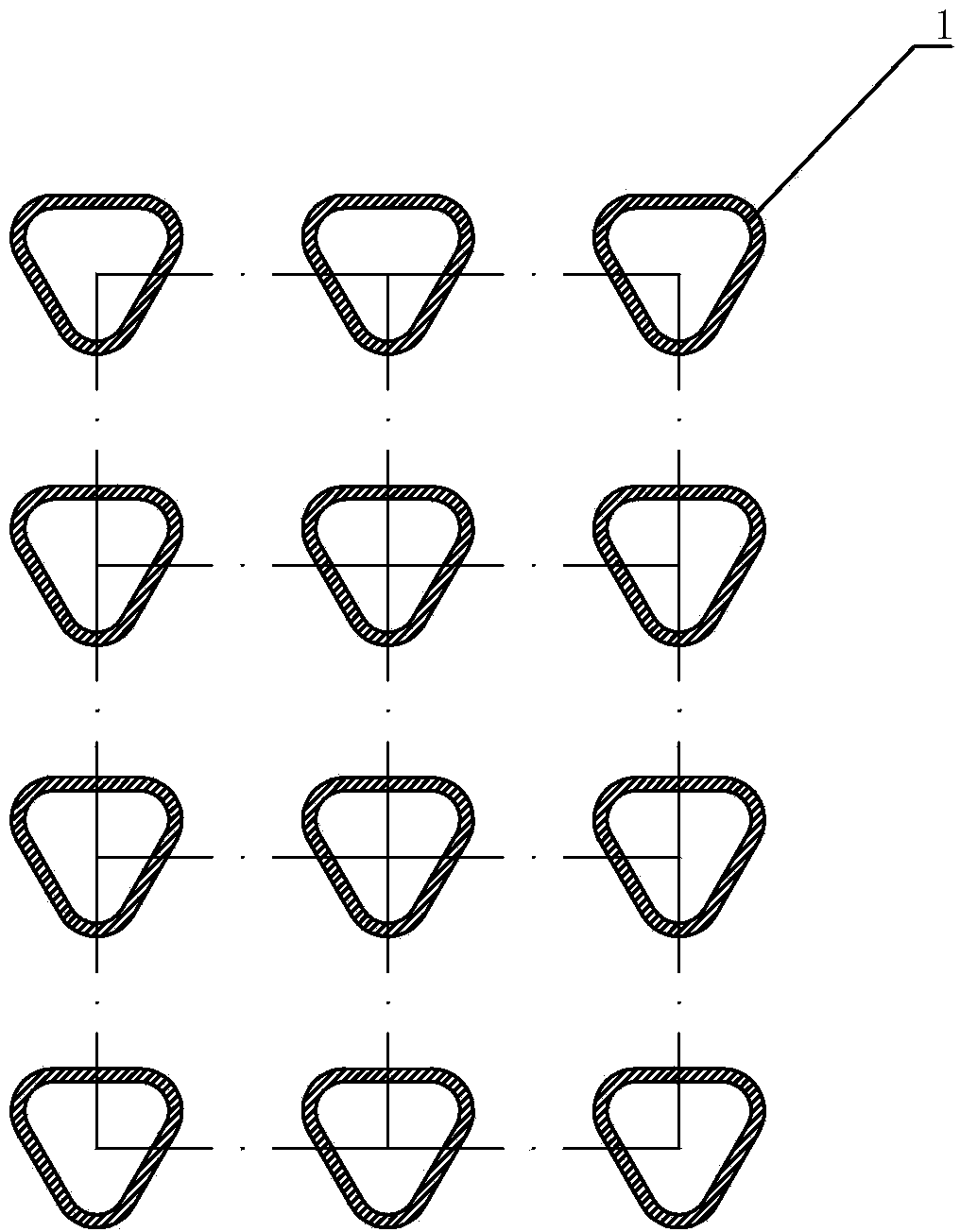

Heat exchange tube and heat exchange structure for horizontal tube falling film evaporator

ActiveCN103900415BReduce splashAvoid drift phenomenonEvaporators with horizontal tubesTubular elementsHeat transmissionEngineering

The invention relates to a heat exchange structure for a horizontal-tube falling-film evaporator. A plurality of parallel heat exchange tube bodies are arranged and fixed on a tube plate in a rectangular array mode. The upturned lateral side of each heat exchange tube body is kept horizontal and is in the shape of an inverted triangle. The invention further relates to a heat exchange tube for the horizontal-tube falling-film evaporator. Feed liquid falls onto the upper end of each heat exchange tube body of a hollow triangular-prism structure, a layer of liquid film is accumulated, and the feed liquid evenly diffuses towards two sides to flow downwards, so that current bias is solved well, and the problems such as coking, wall drying and evaporation quantity reduction are avoided; when falling off again, the feed liquid falls onto the liquid film of the heat exchange tube body below rather than the wall of the tube, so that liquid splashing is reduced, good flaky currents are formed, and heat transmission performance is enhanced. The heat exchange tube and the heat exchange structure are applied to the horizontal-tube falling-film evaporator.

Owner:GUANGZHOU SCHIN TECH IND CO LTD

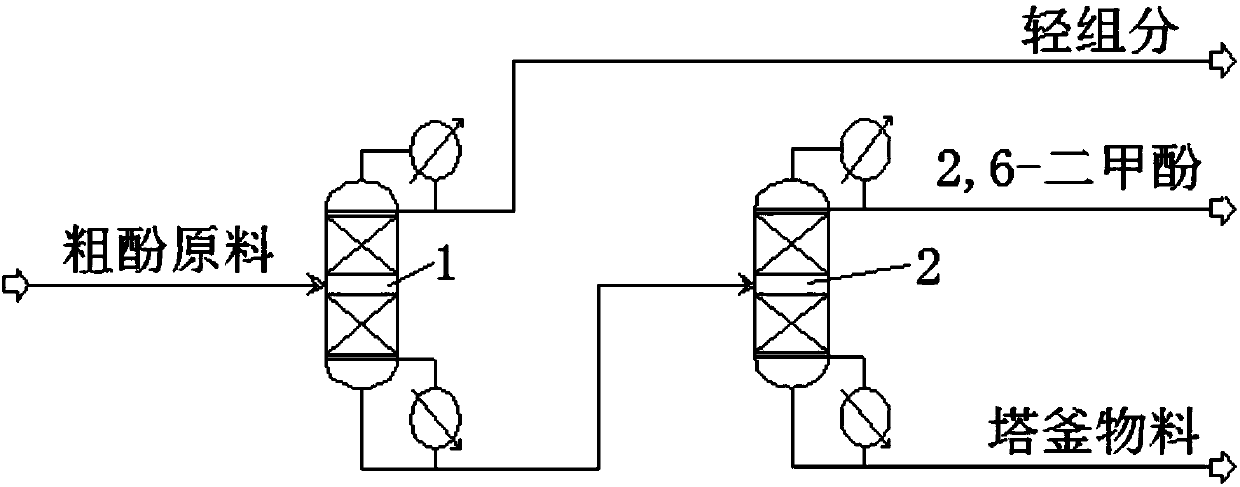

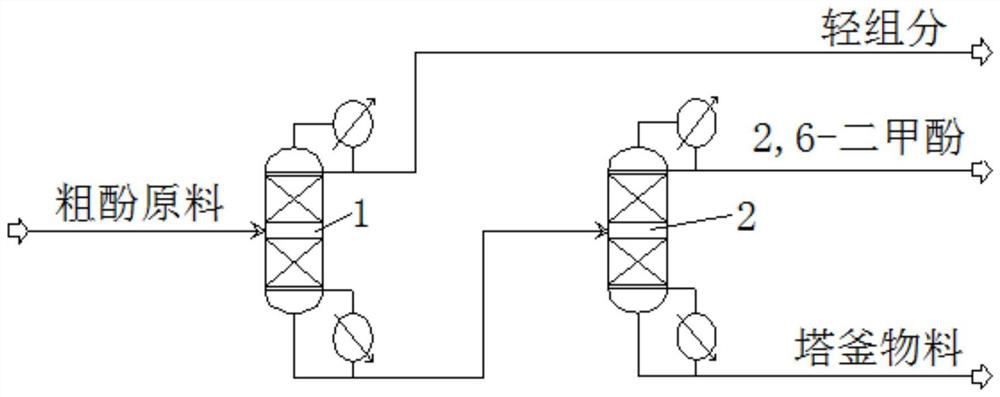

Method for extracting 2,6-dimethylphenol from crude phenol and device applied to method

ActiveCN107556165AReduce gas loadReduce tower diameterOrganic chemistryOrganic compound preparationChemistryHigh concentration

The invention discloses a method for extracting 2,6-dimethylphenol from crude phenol and a device applied to the method. A two-stage distillation technology is adopted for the method, primary distillation treatment is performed on crude phenol firstly to remove light components lighter than 2,6-dimethylphenol, the light components are prevented from affecting the effect of follow-up secondary distillation treatment, and product yield and quality of 2,6-dimethylphenol are improved; then secondary distillation treatment under specific operation conditions is performed, especially, the operationpressure of the secondary distillation treatment is controlled to be not higher than 5 KPa, so that on one hand, the relative volatility of 2,6-dimethylphenol and other components in a primary distillation product is improved and high-concentration 2,6-dimethylphenol can be obtained by extraction, on the other hand, 2,6-dimethylphenol cannot have an isomerism change in the distillation processes,and the 2,6-dimethylphenol separation effect is guaranteed. Tests prove that the yield of 2,6-dimethylphenol is as high as 99.98%, and the purity is as high as 99.9%.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

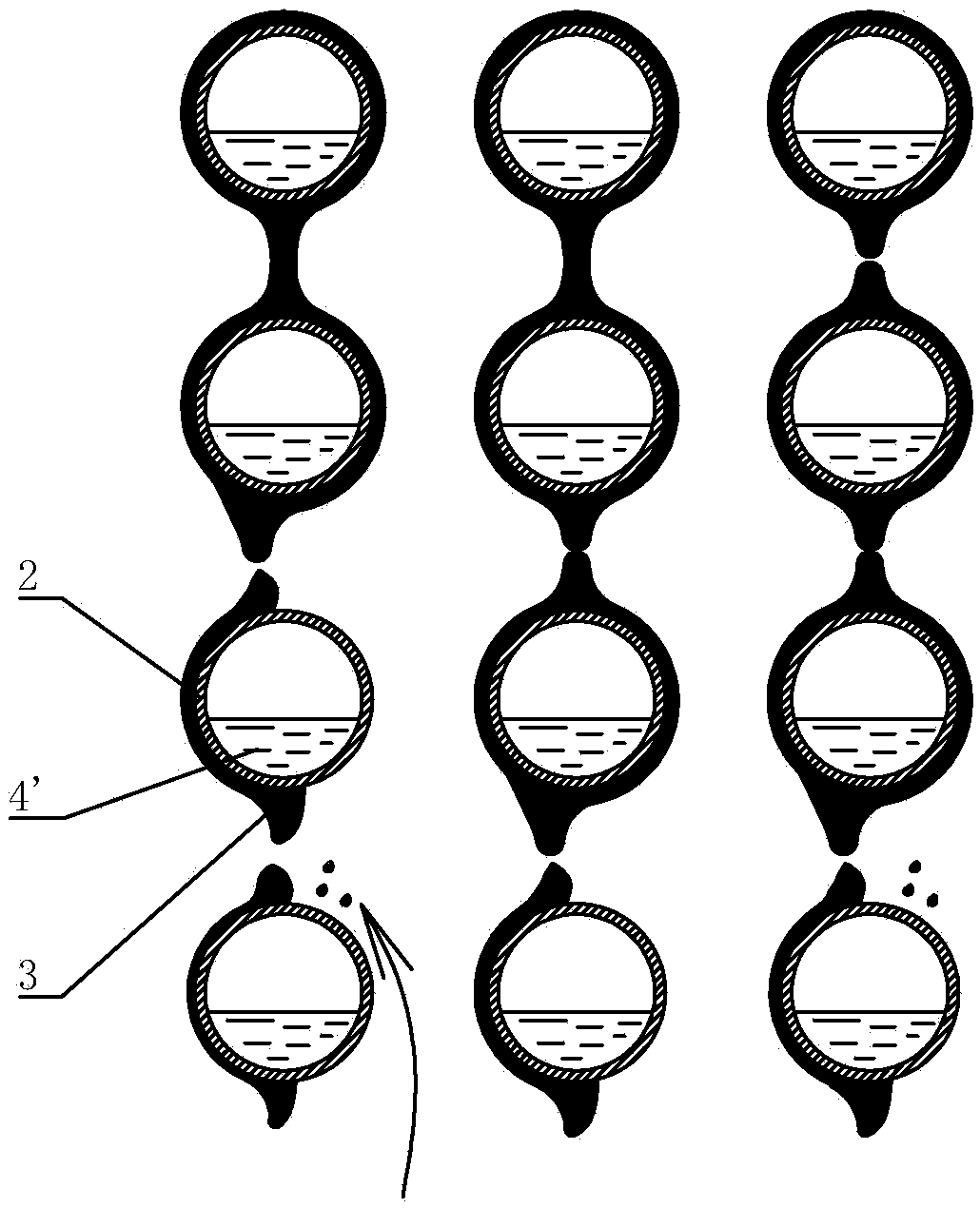

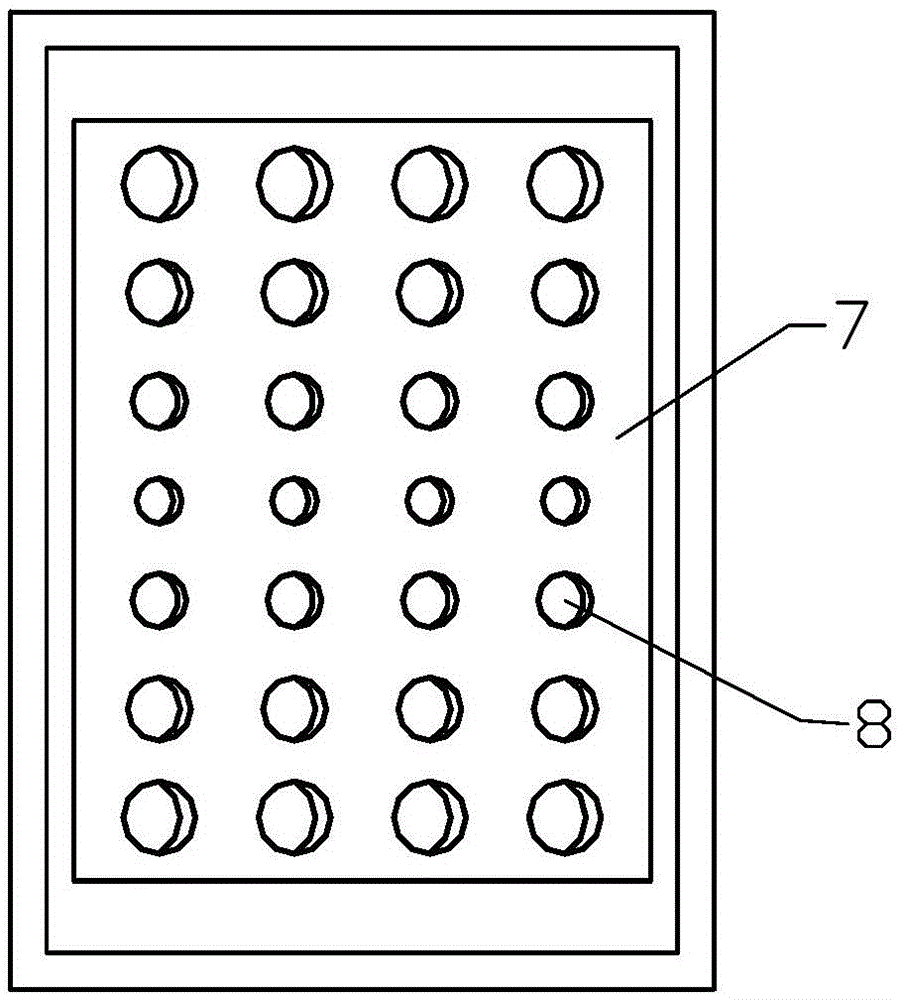

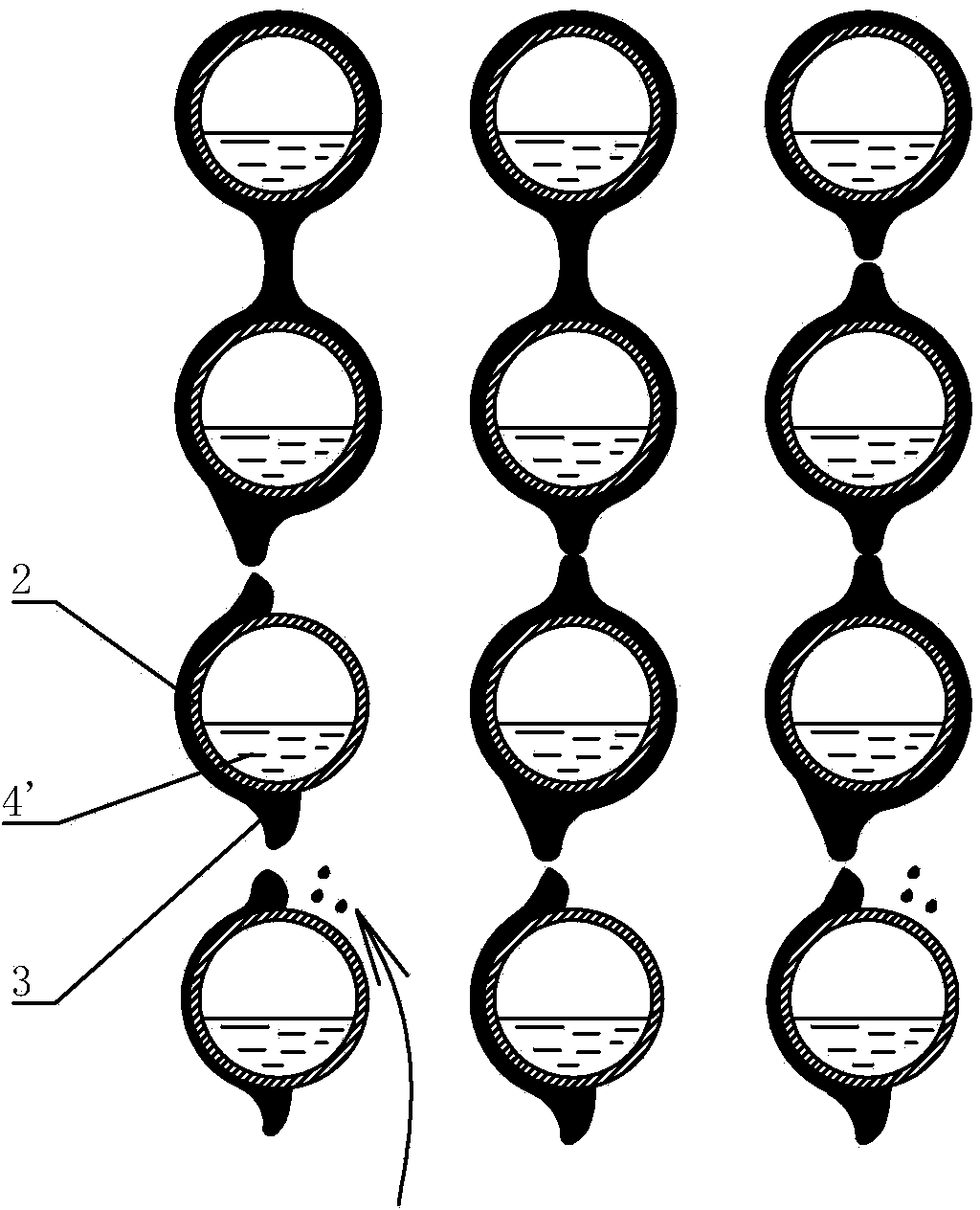

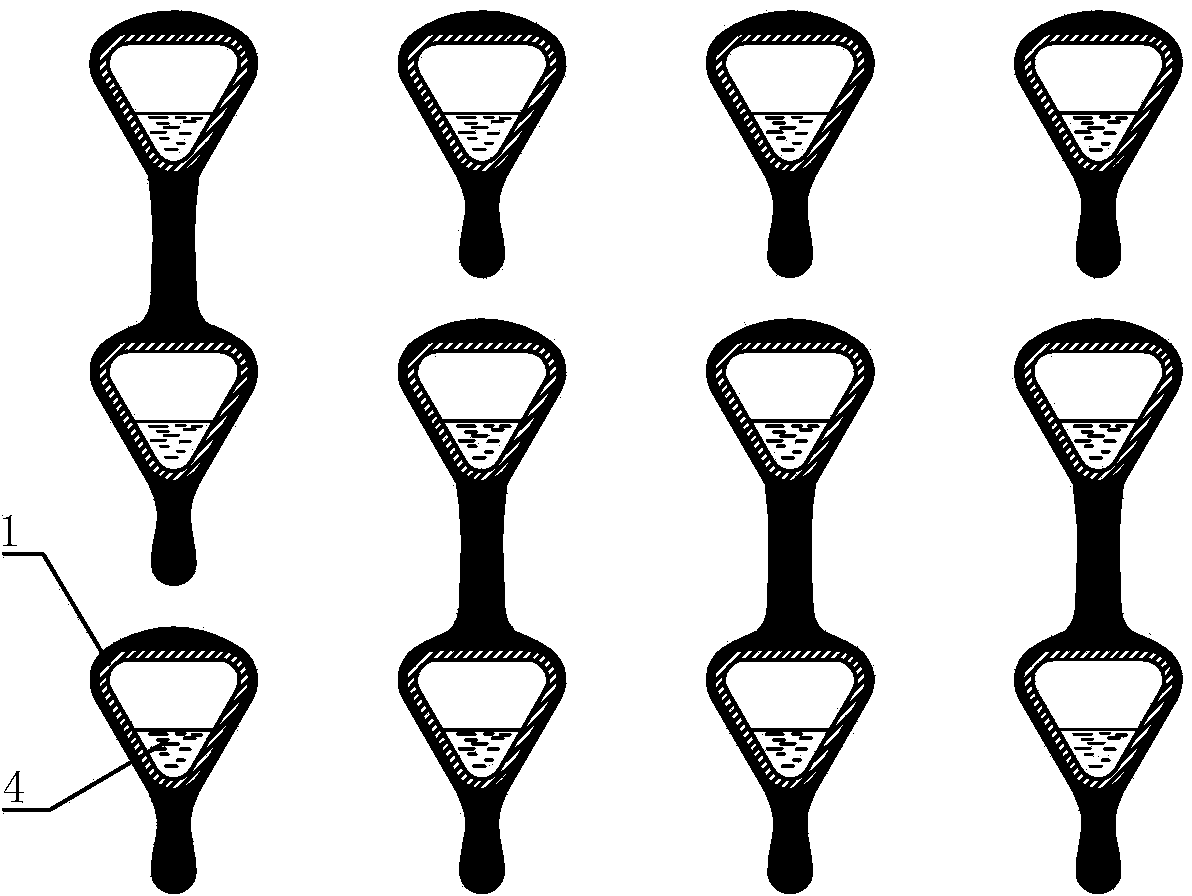

Heat exchanger for horizontal-tube falling film evaporator

PendingCN108759180ASolve the accumulationImprove heat transfer efficiencyEvaporators/condensersEngineeringDistributor

The invention discloses a heat exchanger for a horizontal-tube falling film evaporator. The heat exchanger comprises a liquid distributor and a heat exchange tube group, wherein the heat exchange tubegroup comprises a tube plate and a plurality of parallelly arranged curved heat exchange tubes side by side; each curved heat exchange tube comprises a water inlet tube, a water outlet tube, a baffleplate and a partition plate; the curved heat exchange tubes are of hollow structures; the partition plate covers two curved sides of each curved heat exchange tube hermetically, the baffle plate is arranged in the hollow structure, and a plurality of limber holes are uniformly formed in the baffle plate; the longitudinal sections of the curved heat exchange tubes are symmetrical curved surfaces symmetrical about the longitudinal axis, and each symmetrical curved surface comprises n circles and (n-1) necks, wherein n is greater than or equal to 2; convex arcs of the circles and concave arcs ofthe necks are in tangential transitional connection; the central angle between concave points of the two concave arcs of the necks and the center of circle of each circle is alpha; and the circles and the necks of adjacent two curved heat exchange tubes in the heat exchange tube group are arranged in a staggered mode. The heat exchanger disclosed by the invention can guarantee the flowing stability of a refrigerant, and solves the problem of accumulation and current deflection of liquid films at the bottom of a round tube effectively.

Owner:NANJING NORMAL UNIVERSITY

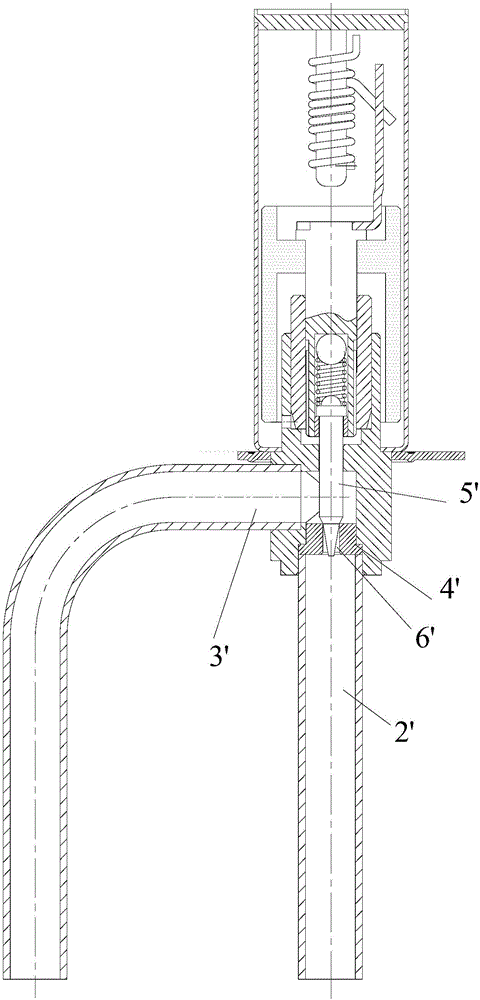

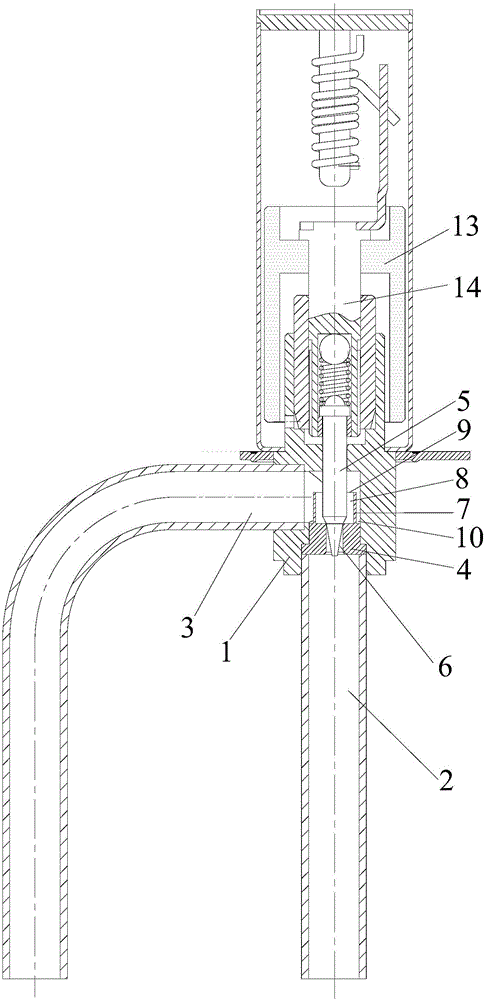

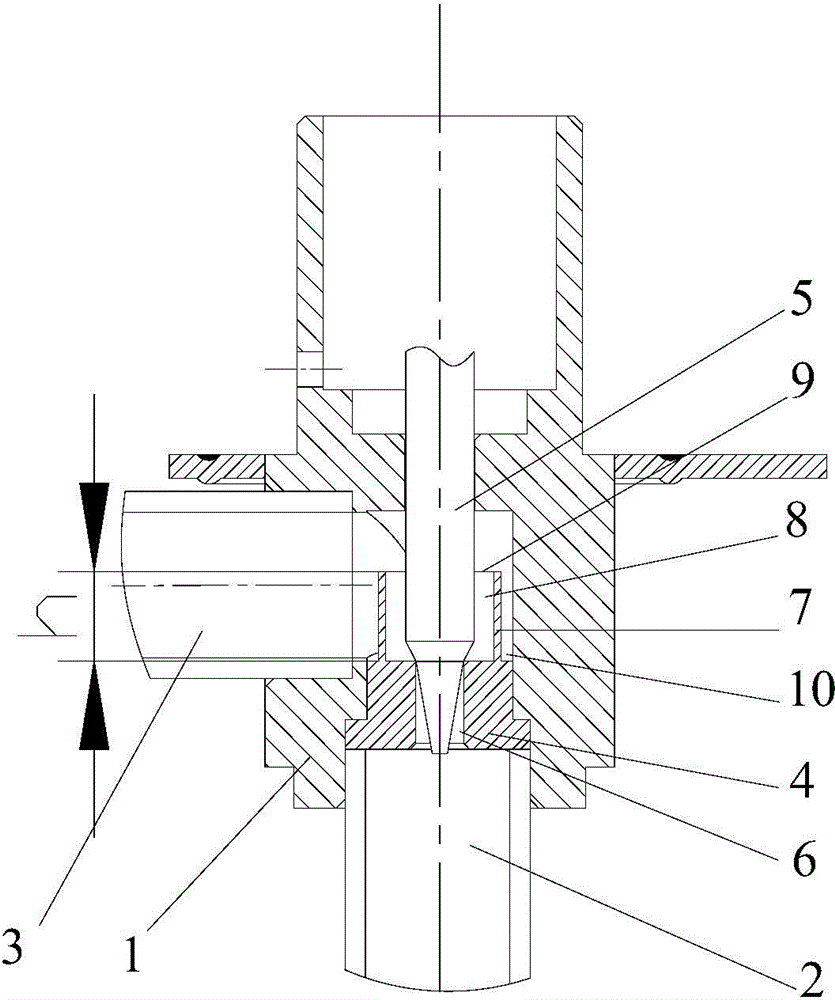

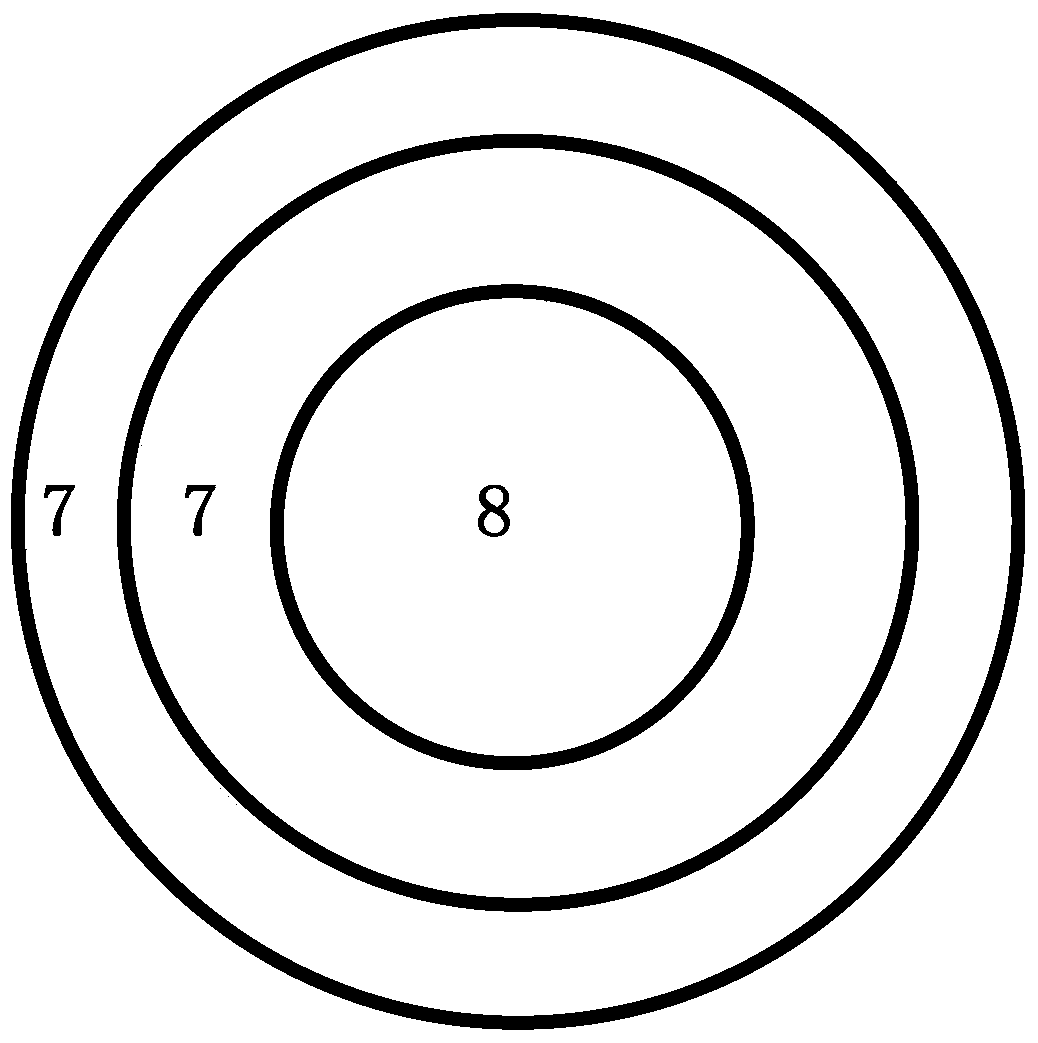

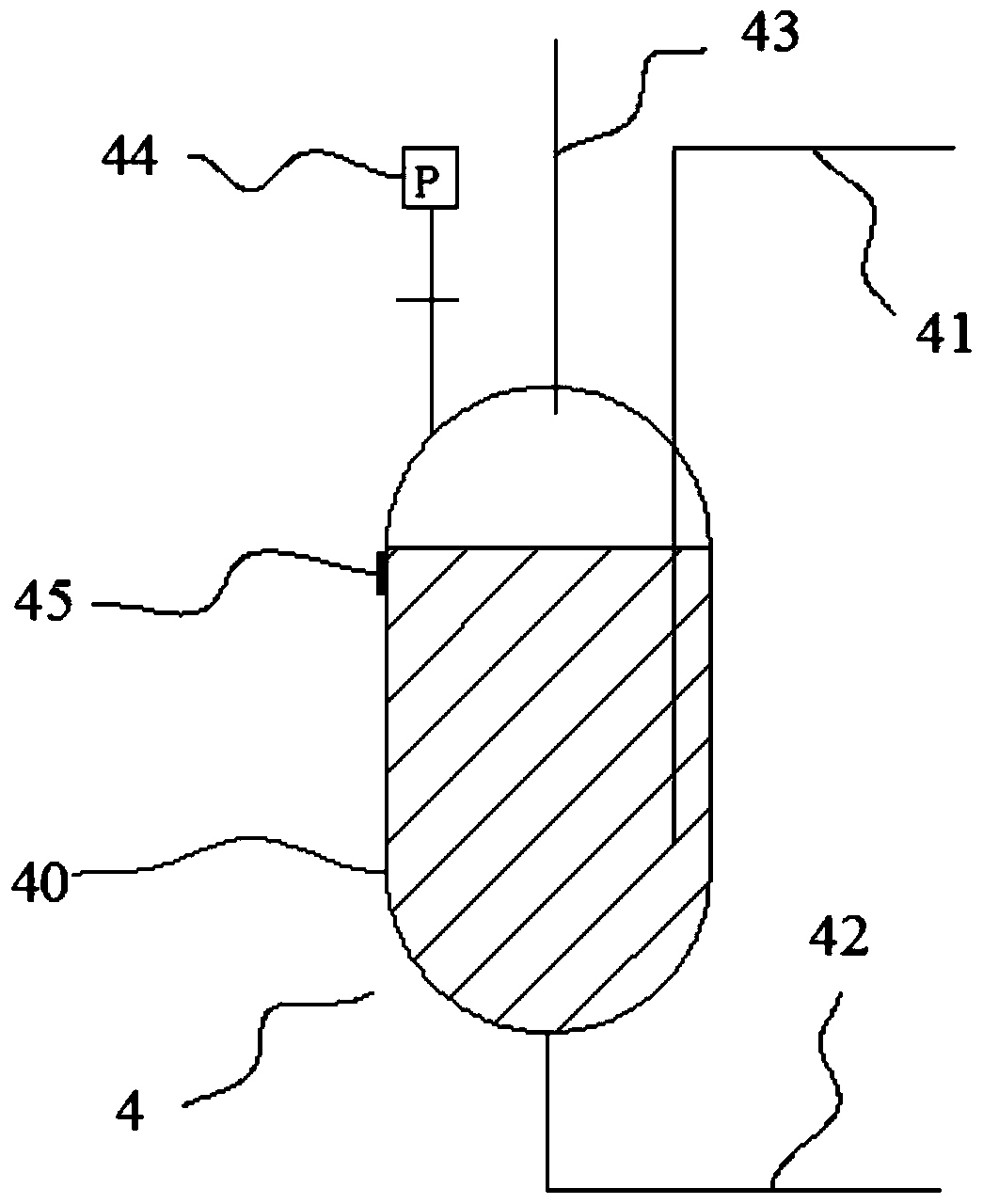

Electronic expansion valve

InactiveCN105485349AAvoid drift phenomenonAvoid loud noiseLift valveValve housingsEngineeringElectronic expansion valve

The invention provides an electronic expansion valve. The electronic expansion valve comprises a valve body (1), a vertical connecting pipe (2), a transverse connecting pipe (3), a valve seat (4) and a valve needle (5). The valve seat (4), the vertical connecting pipe (2) and the transverse connecting pipe (3) are all arranged on the valve body (1). A main valve port (6) is formed in the valve seat (4). The valve needle (5) can move in the axial direction relative to the main valve port (6) of the valve seat (4) so as to open or close the main valve port (6). The electronic expansion valve is characterized in that an annular sleeve (7) is arranged on the valve seat (4) in the axial direction, the valve needle (5) is sleeved with the annular sleeve (7), and an annular channel (8) is formed between the annular sleeve (7) and the valve needle (5); the height of the annular channel (8) is larger than or equal to a quarter of the stroke of the valve needle (5). According to the electronic expansion valve, the problem that the phenomenon of deviated flow occurs when refrigerating fluid flows reversely, and consequentially high noise is generated can be solved.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

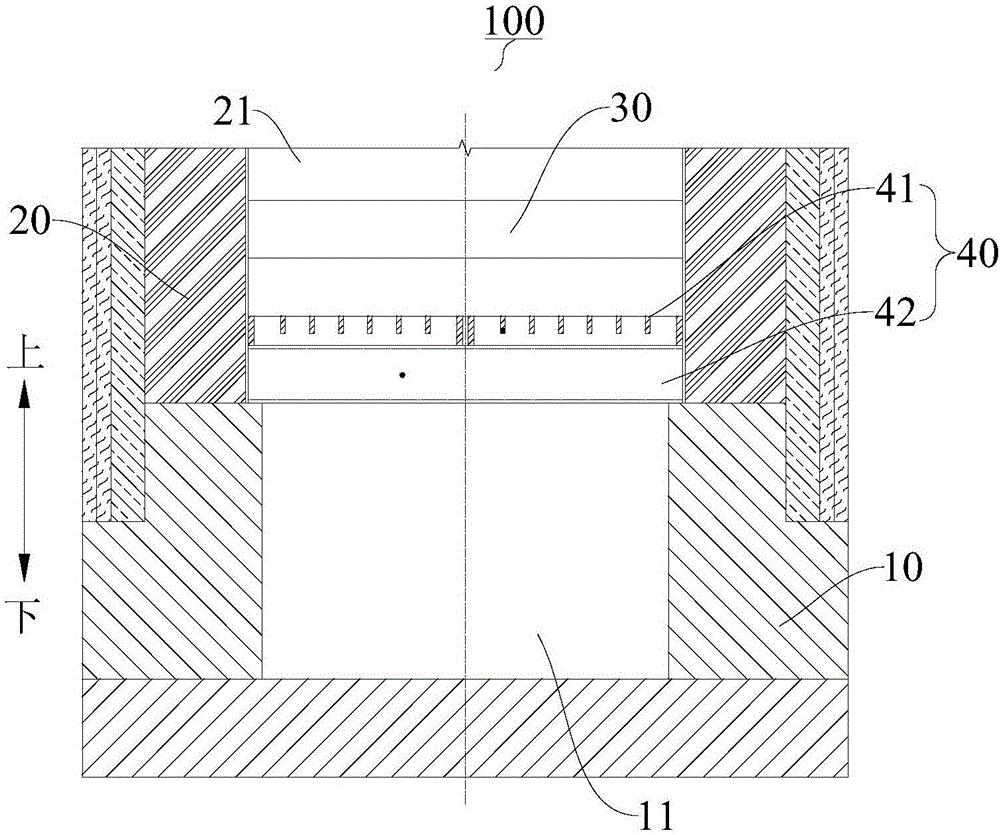

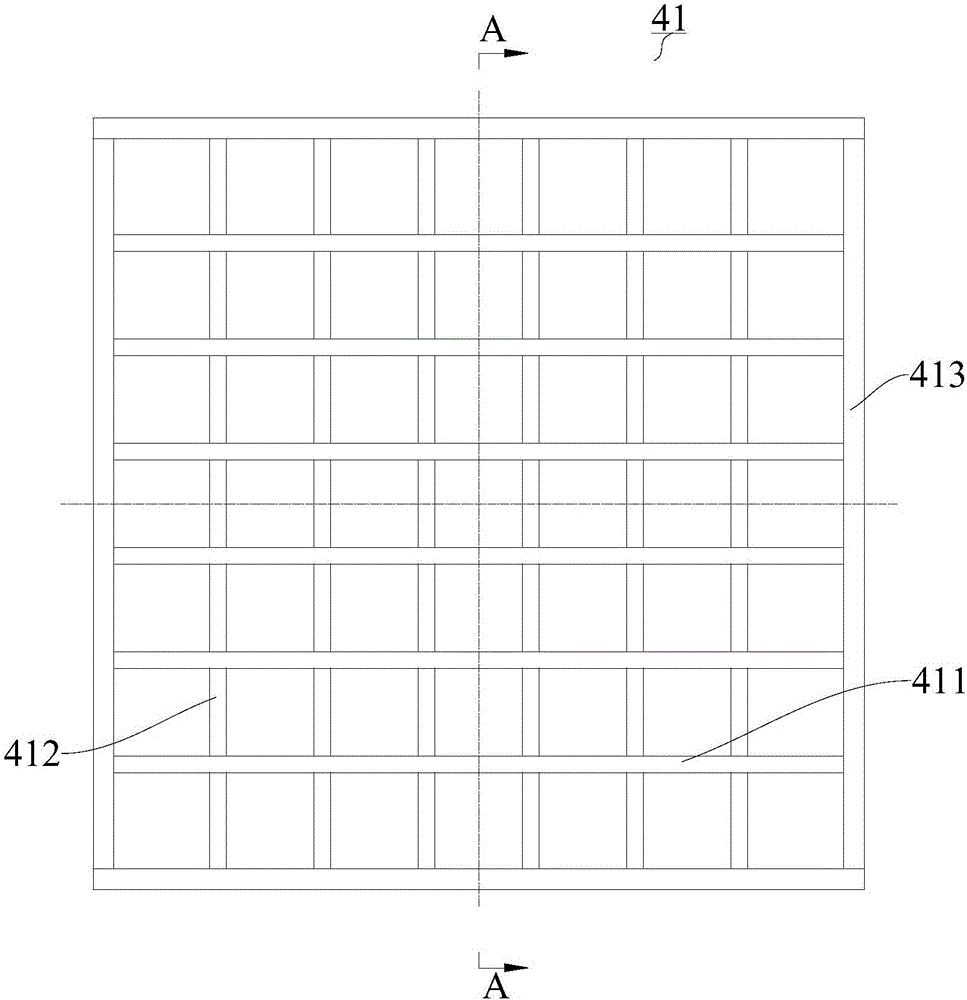

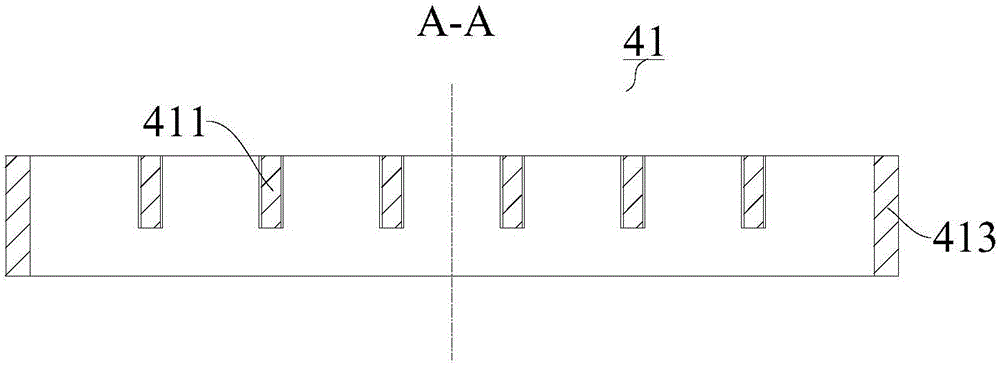

Heat storage chamber

PendingCN106802089AImprove performanceSimple structureIndirect carbon-dioxide mitigationGaseous fuel burnerBrickSoftware engineering

The invention discloses a heat storage chamber. The heat storage chamber comprises a lower enclosing wall, an upper enclosing wall, a heat storage body and an airflow distributor, wherein a flue with an opening top is defined by the inner peripheral wall of the lower enclosing wall; the upper enclosing wall is arranged on the top of the lower enclosing wall, and a mounting cavity communicating with the flue is defined by the inner peripheral wall of the upper enclosing wall; the heat storage body is mounted inside the mounting cavity; and the airflow distributor is arranged inside the mounting cavity, located at the bottom of the heat storage boxy and provided with a plurality of overflowing through holes, and each overflowing through hole makes the flue and the heat storage body communicate. According to the heat storage chamber in the embodiment, a fire bar arch brick structure in correlation techniques is replaced with the airflow distributor provided with the multiple overflowing through holes, so that cost is reduced; and through the airflow distributor, uniform airflow can be obtained, a bias current phenomenon is prevented, local thermal stress is eliminated, and the performance of the heat storage chamber is improved.

Owner:SHENWU TECH GRP CO LTD

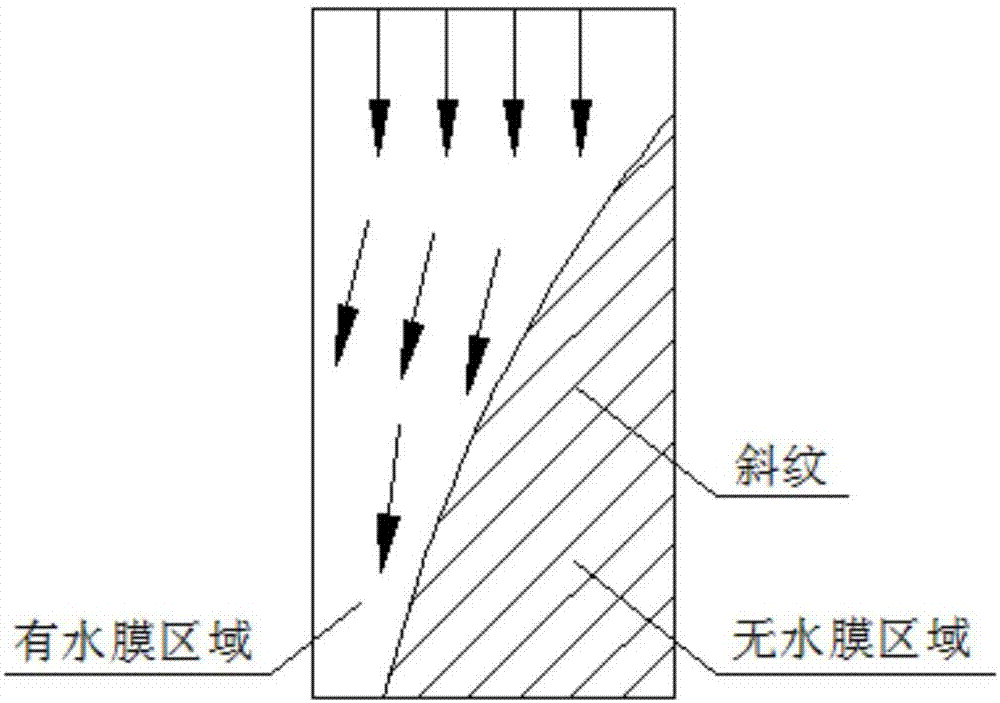

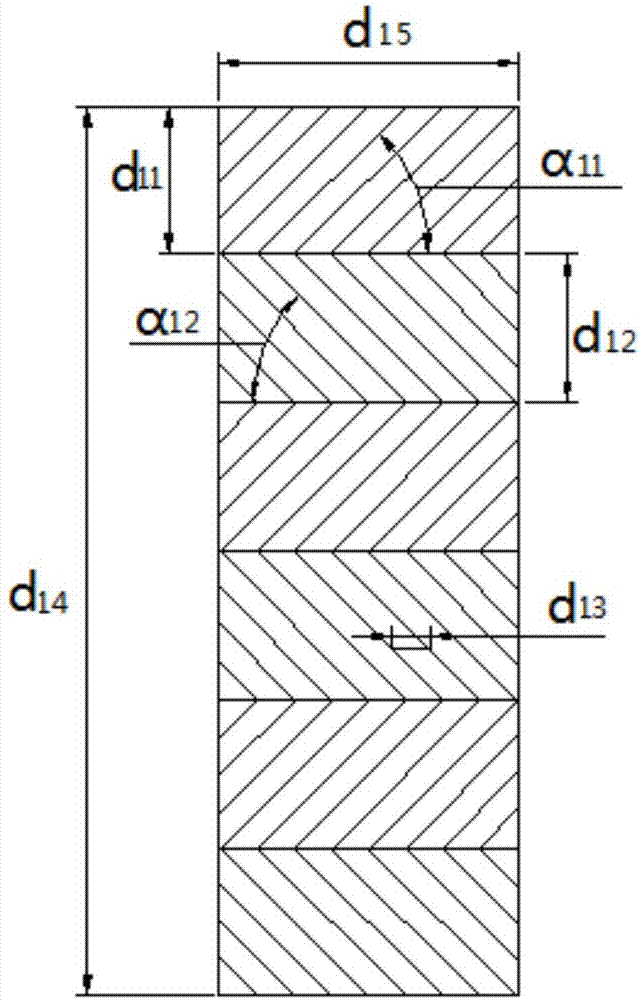

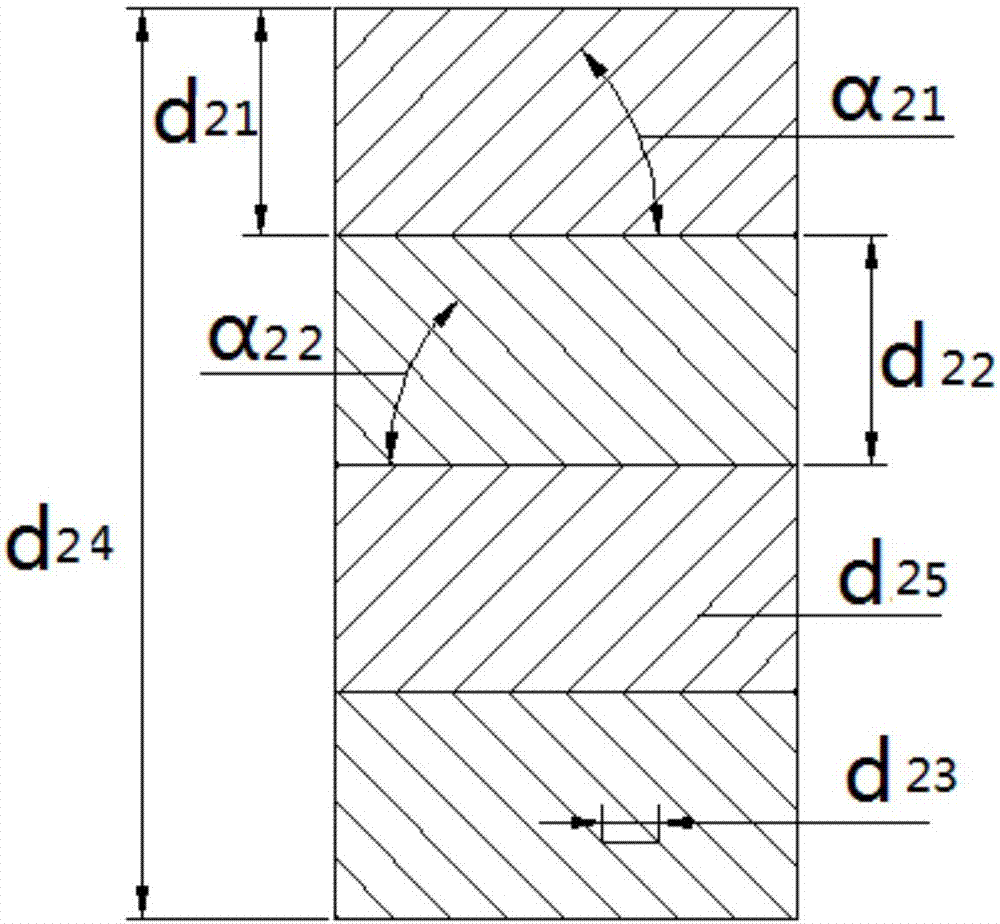

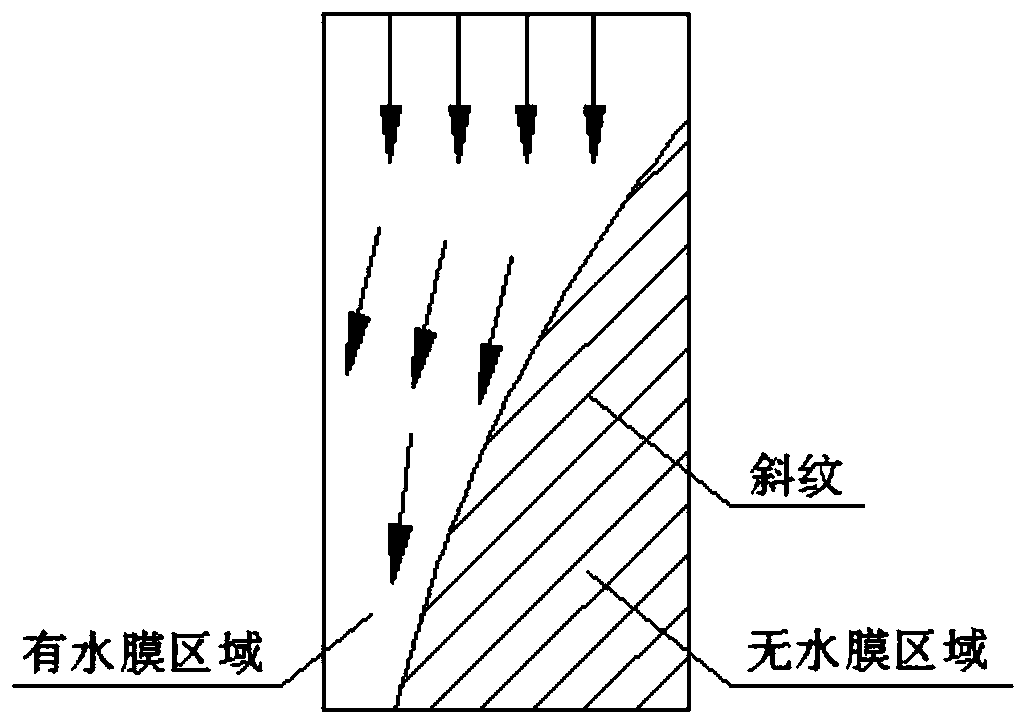

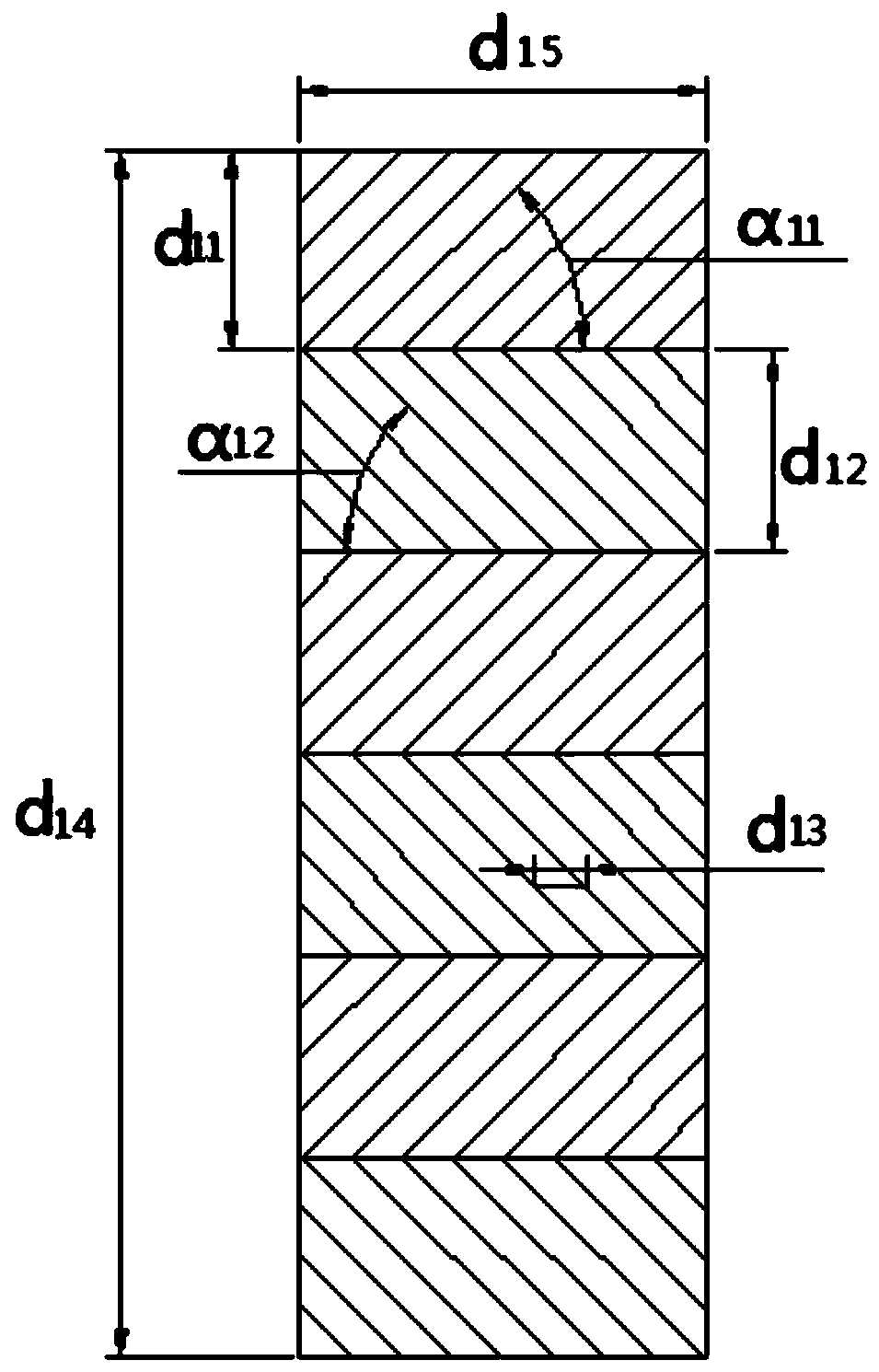

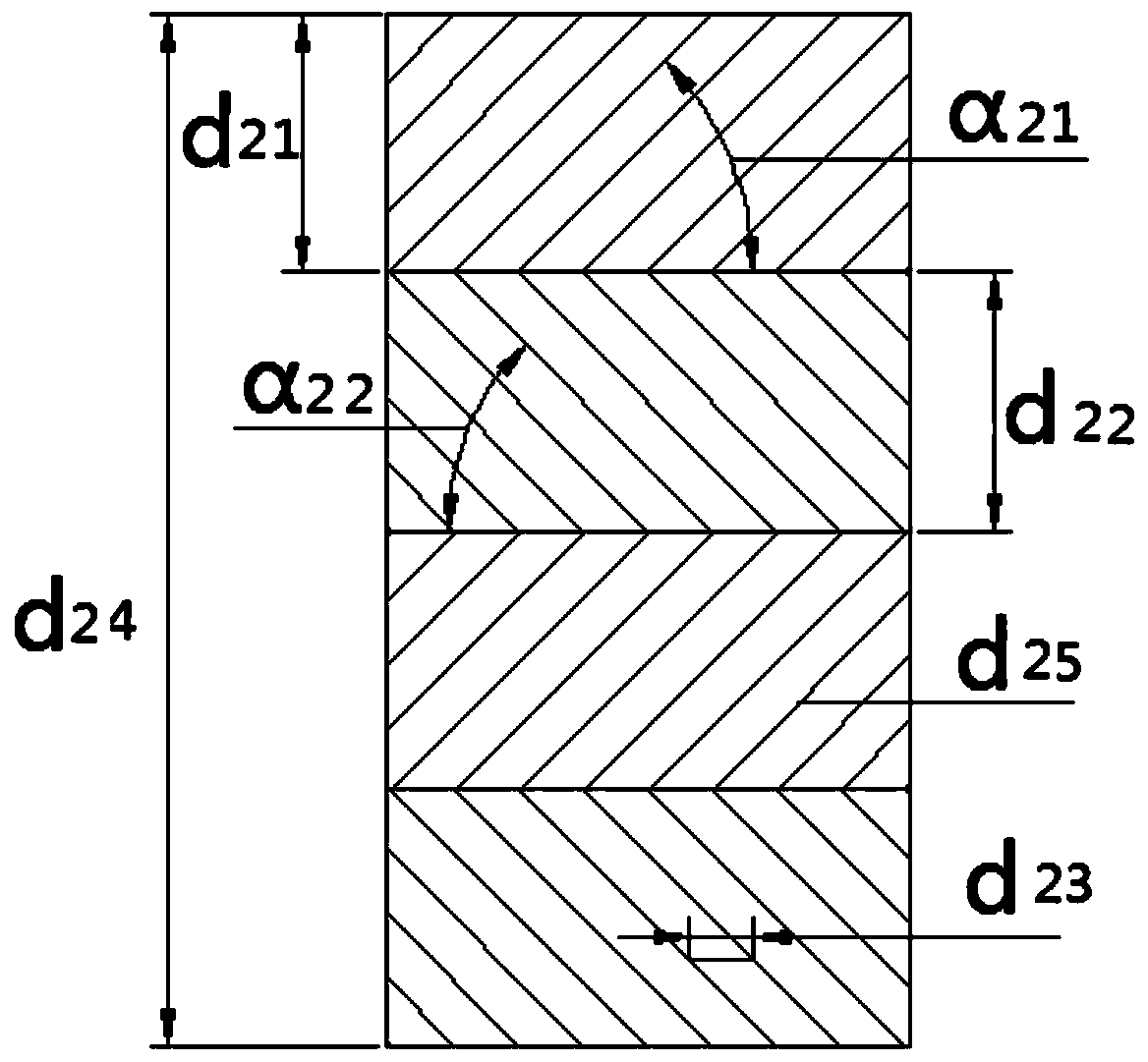

Pole plate with water film uniformly distributed and wet electrostatic precipitator

ActiveCN107537691APlay a diversion roleAvoid drift phenomenonExternal electric electrostatic seperatorElectrode constructionsElectricityAcute angle

The invention discloses a pole plate with water film uniformly distributed and a wet electrostatic precipitator. The pole plate is composed of at least two pole plate areas. Sloping grains are arranged on the surfaces of the pole plate areas correspondingly and are parallel. The horizontal distances between the slopping grains are equal. The adjacent sloping grains on the surfaces of the two poleplate areas are opposite in direction. Angles formed by the sloping grains are acute angles formed between the sloping grains and the latitude line direction. According to the pole plate with the water film uniformly distributed and the wet electrostatic precipitator, surface characteristics of the pole plate of the wet electrostatic precipitator are improved, consumption of washing water is reduced, the water film is uniformly distributed under small water amount distribution conditions, and accordingly the efficient dedusting efficiency is guaranteed.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Baijiu production dilution equipment

InactiveCN109504593AIncrease productivityQuality improvementAlcoholic beverage preparationBiochemical engineeringFiltration

A Baijiu production dilution device comprises a production device. A feed hopper is installed above the production device in a penetration mode, a first conduit is installed on one side of the production device in a penetration mode, and one end of the first conduit is movably connected to the production device, the other end of the first conduit is movably provided with a dilution tank, a raw water pipe is installed above the dilution tank in a penetration mode, and an outer surface of the raw water pipe is movably provided with a softening box, and a second conduit is installed on one side of the dilution tank in a penetration mode. The beneficial effect of the invention is that: the extraction by the production device improves the production efficiency of the Baijiu, and reduces the waste of the raw materials during the working process of the Baijiu production dilution device; and the filtration through the filtering device removes the precipitation caused by the dilution of the water, and improves the quality and taste of the Baijiu; the filtration by the fine filtration device removes the toxic substances produced during the working process of the Baijiu production dilution device.

Owner:金洁琼

Internal component gas distributor of converter

InactiveCN101480593AFirmly connectedGuaranteed uniformityChemical/physical processesStraight tubeProcess engineering

The invention relates to a gas distributor of synthesis tower internals, which comprises a plurality of gas introducing tubes and gas guide tubes which are vertically arranged and a plurality of layers of coil tubes arranged radially. The gas distributor is characterized in that a perforated plate is horizontally arranged above gas inlets of all gas introducing tubes respectively, and a gas outlet of each gas introducing tube is communicated with one straight tube arranged radially. Compared with the prior art, the invention ensures that gas in a gas collecting chamber realizes primary uniform stream distribution through the perforated plate and realizes secondary uniform stream distribution under the action of the perforated plate in the straight tube, thereby laying a foundation for ensuring the uniformity of reaction gas and the uniform distribution in a basket. In addition, as the straight tube is arranged radially, the coil tubes arranged radially can be connected with the gas introducing tubes through the gas guide tubes in an approaching mode, and the difficult connection between ring tubes and the plurality of the coil tubes of the prior large-diameter tower internals is solved.

Owner:衢州新前程塔器技术有限公司

Reforming hydrogen production reactor, reforming hydrogen production conversion furnace, and reforming hydrogen production reaction method

ActiveCN109694037AReduce mass transfer resistanceImprove conversion efficiencyHydrogenHydrogen/synthetic gas productionChemistryUnit volume

The present invention relates to a reforming hydrogen production reactor, a reforming hydrogen production conversion furnace, and a reforming hydrogen production reaction method. According to the present invention, the reforming hydrogen production reactor and the reforming hydrogen production conversion furnace adopt a micro-catalytic reaction plate, wherein a catalytic active component is loadedon the reaction plate, such that the consumption of catalytic active metals is reduced, the catalyst is not easily subjected to carbon deposition deactivation, the diffusion distance of the reactiongas to the catalytic active center is shortened, the mass transfer resistance and the pressure drop of the reactor are reduced, and the conversion rate of the hydrogen production reaction is increased; the reaction gas flows outward from the center in the reactor, the flow channel area is gradually increased, and the temperature of the reaction plate is gradually increased, such that the conversion rate of the hydrogen production reaction as volume increase and endothermic reaction is easily increased; the reactor has wide use range, and the furnace tube as the hydrogen production conversion furnace can be used for different types of conversion furnaces; and the hydrogen production method using the reforming hydrogen production conversion furnace has the reduced furnace tube pressure drop,the space-time yield of the product per unit volume of the catalyst in the furnace tube is high, the conversion rate of the raw material gas processing capacity is high, and the requirements of the hydrogen production reaction can be met.

Owner:SINOPEC ENG +1

Combustion device with heat exchange function

InactiveCN104154542AReduce the effective flow areaLower actual thermal efficiencyIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberBrick

The invention discloses a combustion device with the heat exchange function. The combustion device with the heat exchange function at least comprises a combustion chamber and a heat storage device which is communicated with the combustion chamber, wherein a heat storage device comprises a heat storage box, a heat storage body is arranged inside the heat storage box, one end face of the heat storage box is communicated with the interior of the combustion chamber through an array hole structure, the other end face of the heat storage box is communicated with a drainage cavity, a drainage device is arranged in the drainage cavity, the drainage cavity is communicated with an air pipe, the surface of the upper edge of the inner wall of the heat storage box is of a step structure in the direction of airflow, and the upper surface of the heat storage body is matched with the surface of the upper edge of the inner wall of the heat storage box, and a gap is reserved between the upper surface of the heat storage body and the surface of the upper edge of the inner wall of the heat storage box. According to the combustion device with the heat exchange function, air or gas is divided into multiple fluid regions through a drainage plate structure and is led into the heat storage body, and the phenomenon that airflow deviates due to the fact that on-way resistances to the airflow in the heat storage body are different is avoided; due to the fact that the step structure is arranged on the surface of the upper edge of the inner wall of the heat storage box, the phenomenon that overburning occurs due to excessively-high local temperature, caused by short circuits of smoke, of the heat storage body is avoided during reversing combustion; due to the fact that guiding bricks with array holes are adopted, air and gas are mixed more evenly, and combustion can be more complete.

Owner:中冶华天南京工业炉有限公司

Heat exchange tube and heat exchange structure for horizontal-tube falling-film evaporator

ActiveCN103900415AReduce splashAvoid drift phenomenonEvaporators with horizontal tubesTubular elementsHeat transmissionEngineering

The invention relates to a heat exchange structure for a horizontal-tube falling-film evaporator. A plurality of parallel heat exchange tube bodies are arranged and fixed on a tube plate in a rectangular array mode. The upturned lateral side of each heat exchange tube body is kept horizontal and is in the shape of an inverted triangle. The invention further relates to a heat exchange tube for the horizontal-tube falling-film evaporator. Feed liquid falls onto the upper end of each heat exchange tube body of a hollow triangular-prism structure, a layer of liquid film is accumulated, and the feed liquid evenly diffuses towards two sides to flow downwards, so that current bias is solved well, and the problems such as coking, wall drying and evaporation quantity reduction are avoided; when falling off again, the feed liquid falls onto the liquid film of the heat exchange tube body below rather than the wall of the tube, so that liquid splashing is reduced, good flaky currents are formed, and heat transmission performance is enhanced. The heat exchange tube and the heat exchange structure are applied to the horizontal-tube falling-film evaporator.

Owner:GUANGZHOU SCHIN TECH IND CO LTD

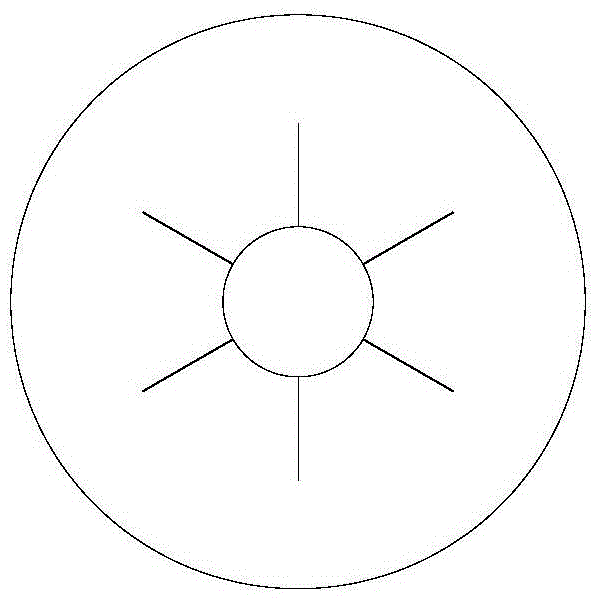

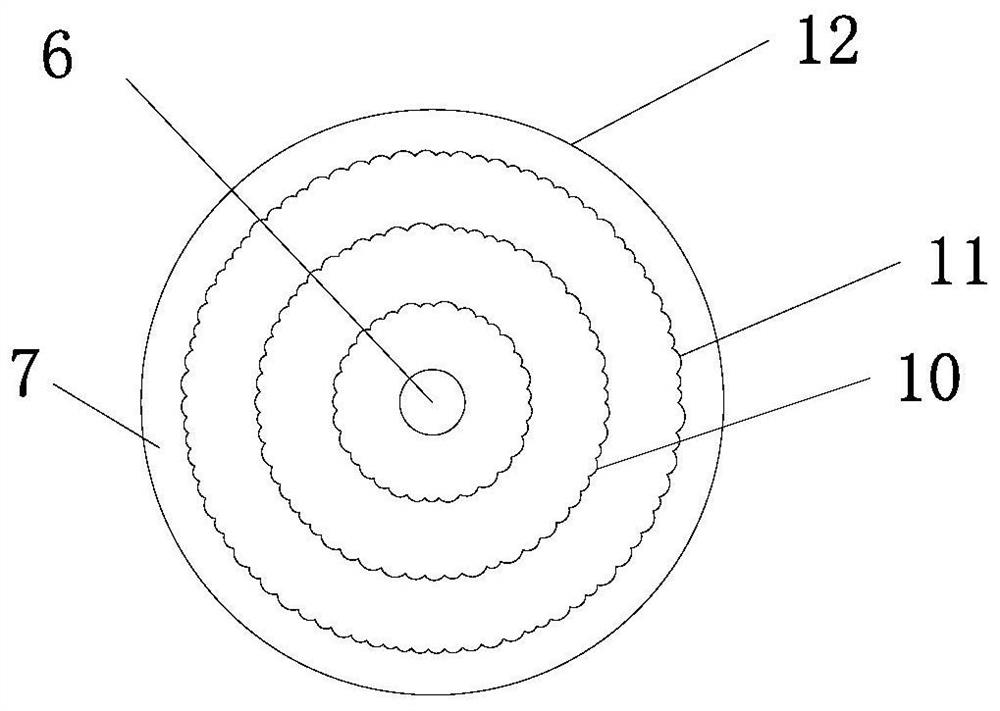

A uniform gas distribution device for tower-type gas-liquid contact equipment and its application

InactiveCN105170069BImprove the uniformity of air distributionUniform air distributionSolvent extractionChemical/physical/physico-chemical processesBody axisEngineering

The invention provides a uniform gas distribution device for tower-type gas-liquid contact equipment and its application. The device includes a cylindrical tower body and more than two coaxial hollow cylinders arranged at the bottom of the tower body. The central axis of the cylindrical tower is the axis, and the inner diameter and length of each hollow cylinder are not equal, and there is a gap between two adjacent hollow cylinders; the bottom of each hollow cylinder is provided with an inverted tapered closing plate, A liquid discharge pipe is arranged on the closed plate; an air distribution plate is arranged at the bottom of the cylindrical tower, and there are holes on the air distribution plate, and the base of the air distribution plate is sealed and connected with the upper end of the hollow cylinder; An air inlet is provided below the wall. The device can realize the uniform distribution of air bubbles in the cross section of the tower body, the diameter of the air bubbles is uniform, and the device has a simple structure and is easy to process, and is especially suitable for large-scale air distribution equipment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A polar plate and a wet electrostatic precipitator for realizing uniform distribution of water film

ActiveCN107537691BPlay a diversion roleAvoid drift phenomenonExternal electric electrostatic seperatorElectrode constructionsAcute angleRinse water

The invention discloses a pole plate with water film uniformly distributed and a wet electrostatic precipitator. The pole plate is composed of at least two pole plate areas. Sloping grains are arranged on the surfaces of the pole plate areas correspondingly and are parallel. The horizontal distances between the slopping grains are equal. The adjacent sloping grains on the surfaces of the two poleplate areas are opposite in direction. Angles formed by the sloping grains are acute angles formed between the sloping grains and the latitude line direction. According to the pole plate with the water film uniformly distributed and the wet electrostatic precipitator, surface characteristics of the pole plate of the wet electrostatic precipitator are improved, consumption of washing water is reduced, the water film is uniformly distributed under small water amount distribution conditions, and accordingly the efficient dedusting efficiency is guaranteed.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

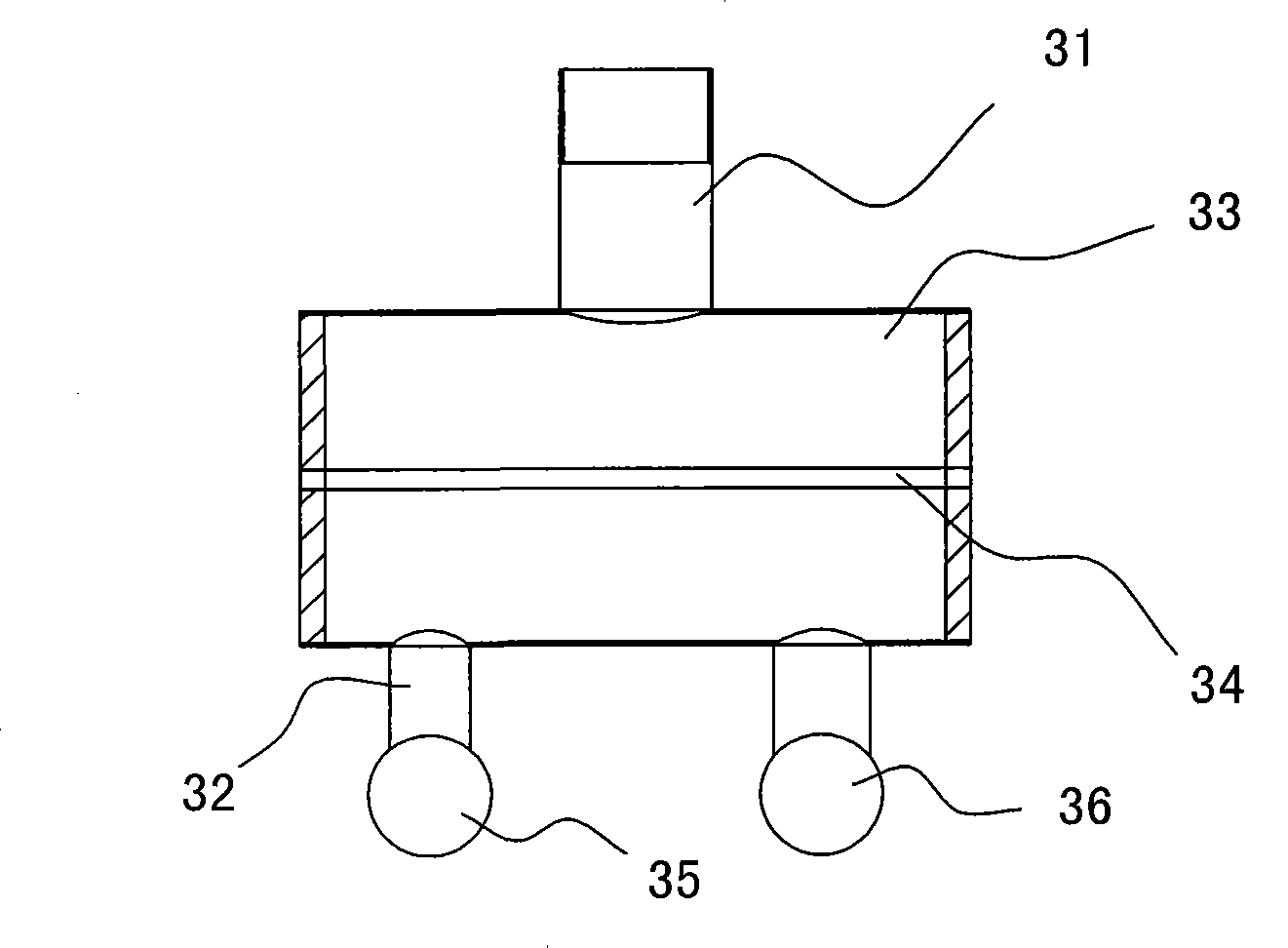

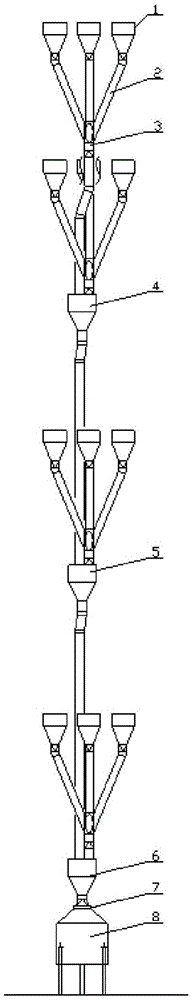

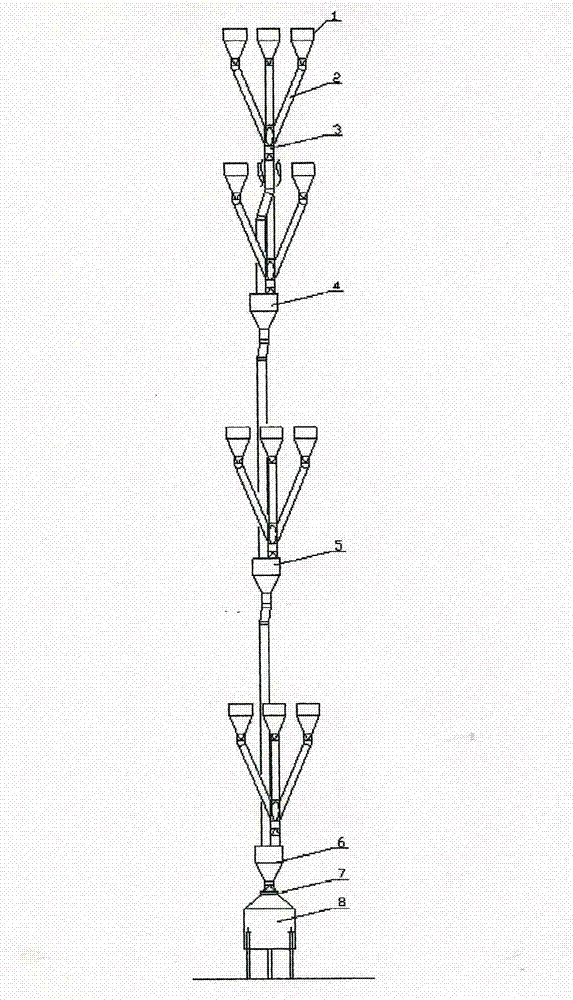

A blanking distribution device

ActiveCN102730431BAvoid drift phenomenonReduce wearLoading/unloadingEngineeringMechanical engineering

The invention relates to a blanking and distributing device. The blanking and distributing device comprises a funnel set, a blanking pipe, a collecting pipe, a distributing cabin, a bottom valve and a bottom storage bin, wherein the upper part of the blanking pipe is connected with funnels; the lower part of the blanking pipe is connected with the upper part of the collecting pipe; the lower part of the collecting pipe is placed into the distributing cabin; the lower part of the distributing cabin is connected with the bottom valve; and the bottom storage bin is located at the lower part of the bottom valve. The blanking and distributing device can sequentially and quantitatively discharge materials, can be quickly opened or closed, and avoids the bias phenomenon of the upper part of the materials. The blanking and distributing device has less wear on the materials in the opening or closing process and can be tightly closed at the same time.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

Reforming hydrogen production reactor and its reformer and method for reforming hydrogen production reaction

ActiveCN109692629BImprove conversion efficiencyShort stayHydrogenChemical/physical processesMass transfer resistancePtru catalyst

The present disclosure relates to a reforming hydrogen production reactor and its reformer, and a method for reforming hydrogen production. The amount of catalytically active metal is reduced, the catalyst is not easy to be deactivated by carbon deposition, the distance from the reaction gas to the catalytic active center is shortened, the mass transfer resistance and the pressure drop of the reactor are reduced, and the conversion rate of the hydrogen production reaction is improved; It flows from the center to the outside, the flow channel area gradually increases, and the temperature of the reaction plate gradually increases, which is beneficial to the improvement of the conversion rate of the hydrogen production reaction as a volume increase and an endothermic reaction; the reforming hydrogen production reactor has a wide range of applications. As the furnace tube of the hydrogen reformer, it can be applied to different types of reformers. The hydrogen production method using the reforming hydrogen production reformer reduces the furnace tube pressure, the product space-time yield per unit volume of the catalyst in the furnace tube is high, and the raw gas processing capacity can be converted, and the hydrogen production reaction requirements can be met.

Owner:SINOPEC ENG +1

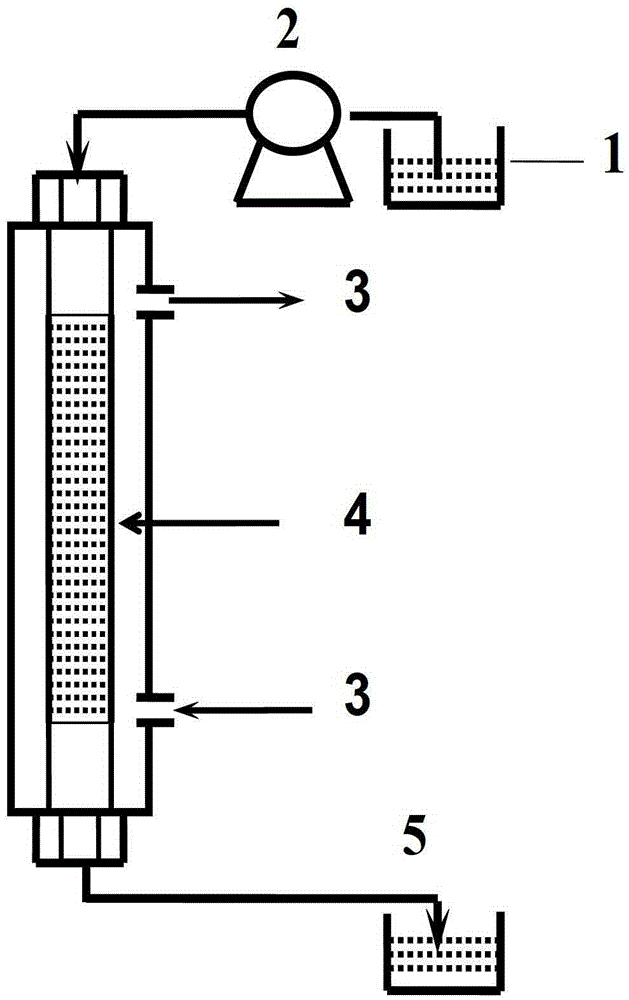

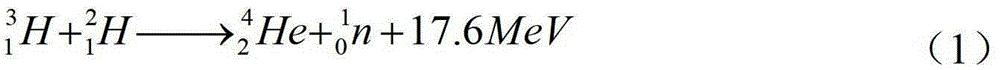

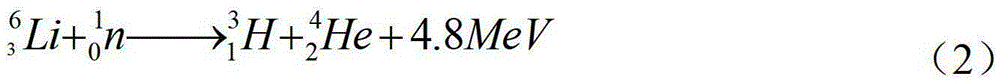

A non-woven matrix composite membrane for lithium isotope separation and its preparation method and method for membrane chromatography to separate lithium isotopes

InactiveCN103386299BAchieve serializationSerialization is easy to implementOther chemical processesSolid sorbent liquid separationChromatographic separationComposite film

The invention provides a non-woven base composite membrane for lithium isotope separation and a preparation method thereof, as well as a lithium isotope separation method by using a membrane chromatography. The non-woven base composite membrane takes a non-woven fabric as a porous support body or a micropore membrane, a coating is prepared on the non-woven fabric by taking a crown ether graft polymer or a Kryptofix graft polymer with a lithium isotope separation effect as a film forming matter, or a coating can be prepared on the non-woven fabric by blending crown ether or Kryptofix and derivates of the crown ether or the Kryptofix into a film-formation polymer solution, and the coating and a base membrane are combined to form a composite separated membrane; the composite separated membrane is taken as a membrane chromatography medium stationary phase, so as to separate lithium isotopes by using the membrane chromatography. The non-woven base composite membrane or the lithium isotope separation method by using the membrane chromatography can effectively improve the contact and coupling efficiency of crown ether molecules and Lithium Ions in the separation process for solid-liquid extraction lithium isotopes, and realize the greenization, serialization and high efficient of the process of lithium isotope separation.

Owner:TIANJIN POLYTECHNIC UNIV

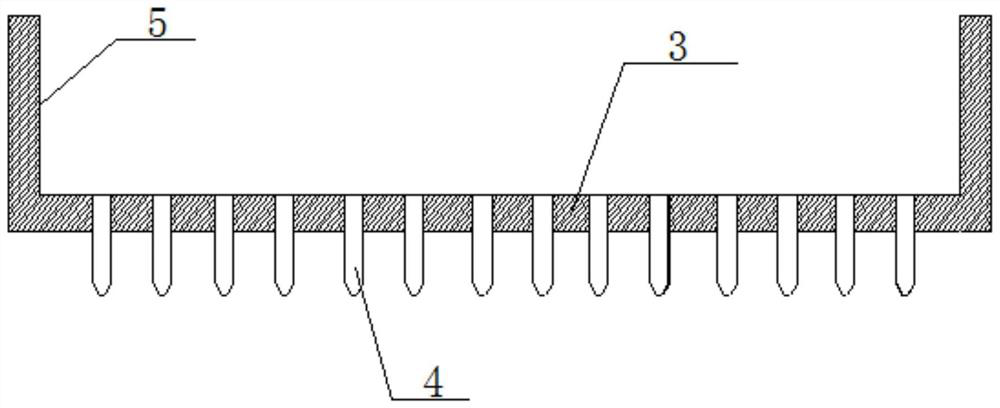

Falling nozzle for bromine blowout tower

The invention discloses a falling nozzle for a bromine blowout tower. The falling nozzle comprises a nozzle body. A nozzle nut connected with a bittern pipeline is arranged on the nozzle body. A nozzle frame is connected below the nozzle nut. A flow distribution device is arranged on the nozzle frame and below an inlet of the nozzle body, and comprises a plurality of tapered flow distribution plates which are parallelly arranged in an up-and-down mode. The diameters of the bottoms of the flow distribution plates gradually decrease from top to bottom, except for the diameter of a flow distribution plate at the lowest position. A through hole is formed in the middle of each flow distribution plate, and the diameters of the through holes gradually decrease from top to bottom. Uniformity of water distribution is improved, formation of water columns and bias currents in the tower is avoided, and blowout effect is improved.

Owner:山东昌邑灶户盐化有限公司

Reforming hydrogen production reactor, hydrogen production conversion furnace and hydrogen production reaction method

ActiveCN109694040BImprove conversion efficiencyShort stayHydrogenHydrogen/synthetic gas productionMass transfer resistancePtru catalyst

Owner:SINOPEC ENG +1

Reforming hydrogen production reactor, reforming hydrogen production reformer and reforming hydrogen production reaction method

ActiveCN109694037BImprove conversion efficiencyShort stayHydrogenHydrogen/synthetic gas productionMass transfer resistancePtru catalyst

The disclosure relates to a reforming hydrogen production reactor, a reforming hydrogen production conversion furnace and a reforming hydrogen production reaction method. The reforming hydrogen production reactor and the reforming hydrogen production conversion furnace adopt micro-catalytic reaction plates, and the reaction plates are loaded with catalytic active components, which reduces the amount of catalytically active metals and the catalyst is not easy to deactivate due to carbon deposition, shortening the diffusion of reaction gases to The distance between the catalytic active centers reduces the mass transfer resistance and the pressure drop of the reactor, and improves the conversion rate of the hydrogen production reaction; the reaction gas flows from the center to the outside in the reactor, the area of the flow channel increases gradually, and the temperature of the reaction plate gradually increases , which is conducive to the improvement of the conversion rate of the hydrogen production reaction as a volume increase and endothermic reaction; the reactor has a wide range of applications, and can be applied to different types of reformers as a furnace tube of a hydrogen production reformer. The hydrogen production method using the reforming hydrogen production conversion furnace has a lower pressure of the furnace tube, a high time-space yield of the catalyst per unit volume in the furnace tube, and a high conversion rate of the raw material gas treatment capacity, which can meet the requirements of the hydrogen production reaction.

Owner:SINOPEC ENG +1

Air conditioner indoor unit, outdoor unit and air conditioner

ActiveCN105318606BEven by forceAvoid drift phenomenonMechanical apparatusEvaporators/condensersRefrigerant distributionEngineering

The invention provides an air conditioner indoor unit, an outdoor unit and an air conditioner, relates to the technical field of air conditioners, and is invented for improving the uniformity of refrigerant distribution of a microchannel heat exchanger. The indoor unit of the air conditioner includes an indoor micro-channel heat exchanger, the indoor micro-channel heat exchanger includes a first header and a second header, and also includes a first gas-liquid separation device, the first gas-liquid separation device The liquid separation device includes a hollow first shell, the interior of the first shell is used for gas-liquid separation, and the first shell is provided with a liquid inlet pipe and an outlet pipe respectively connected with the inside of the first shell. A liquid pipe and an air outlet pipe, the liquid inlet pipe of the first gas-liquid separation device communicates with the supercooling device of the outdoor unit of the air conditioner, and the liquid outlet pipe of the first gas-liquid separation device is connected with the first header In communication, the outlet pipe of the first gas-liquid separation device communicates with the second header. The indoor unit of the air conditioner provided by the invention is used for the air conditioner.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Device and method for frequency conversion optimization and energy saving of circulating water system

InactiveCN105862983BThe output is adjusted in timeRealize real-time variable frequency controlPump controlHeat exchange apparatusFrequency changerControl valves

Owner:严义忠

Blanking and distributing device

The invention relates to a blanking and distributing device. The blanking and distributing device comprises a funnel set, a blanking pipe, a collecting pipe, a distributing cabin, a bottom valve and a bottom storage bin, wherein the upper part of the blanking pipe is connected with funnels; the lower part of the blanking pipe is connected with the upper part of the collecting pipe; the lower part of the collecting pipe is placed into the distributing cabin; the lower part of the distributing cabin is connected with the bottom valve; and the bottom storage bin is located at the lower part of the bottom valve. The blanking and distributing device can sequentially and quantitatively discharge materials, can be quickly opened or closed, and avoids the bias phenomenon of the upper part of the materials. The blanking and distributing device has less wear on the materials in the opening or closing process and can be tightly closed at the same time.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

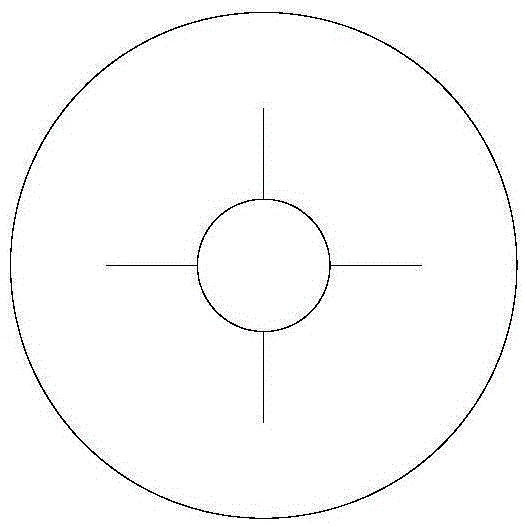

Constant-flow water distribution device of mixed ion exchanger

PendingCN111285436AAvoid drift phenomenonSimple structureWater distributersWater/sewage treatment by ion-exchangeIon exchangeWater flow

The invention discloses a constant-flow water distribution device of a mixed ion exchanger. The constant-flow water distribution device comprises a high-speed mixed bed, an alloy water distribution plate connecting frame and a plurality of constant-flow water caps, wherein the bottom of the high-speed mixed bed is fixed on the alloy water distribution plate connecting frame; a plurality of preformed holes are formed in the alloy water distribution plate connecting frame; one preformed hole corresponds to one constant-flow water cap; each constant-flow water cap comprises a flow equalizing water inlet chamber, a constant-flow valve liner chamber and a water distribution cap which are sequentially communicated from top to bottom; the top of the flow equalizing water inlet chamber is closed;the bottom of the water distribution cap is closed; a plurality of water inlet flow channels are formed in the side wall of the flow equalizing water inlet chamber, a plurality of opening gaps are formed in the side face of the water distribution caps, the size of the opening gaps is larger than the diameter of mixed ion resin in the high-speed mixed bed, and the constant-flow valve liner chamberis fixed in the preformed holes. The device can effectively solve the problem of resin bias flow in the mixed bed body.

Owner:XIAN THERMAL POWER RES INST CO LTD

A method and device for extracting 2,6-xylenol from crude phenol

ActiveCN107556165BHigh yieldQuality improvementOrganic chemistryOrganic compound preparationHigh concentrationProcess engineering

The invention discloses a method for extracting 2,6-dimethylphenol from crude phenol and a device applied to the method. A two-stage distillation technology is adopted for the method, primary distillation treatment is performed on crude phenol firstly to remove light components lighter than 2,6-dimethylphenol, the light components are prevented from affecting the effect of follow-up secondary distillation treatment, and product yield and quality of 2,6-dimethylphenol are improved; then secondary distillation treatment under specific operation conditions is performed, especially, the operationpressure of the secondary distillation treatment is controlled to be not higher than 5 KPa, so that on one hand, the relative volatility of 2,6-dimethylphenol and other components in a primary distillation product is improved and high-concentration 2,6-dimethylphenol can be obtained by extraction, on the other hand, 2,6-dimethylphenol cannot have an isomerism change in the distillation processes,and the 2,6-dimethylphenol separation effect is guaranteed. Tests prove that the yield of 2,6-dimethylphenol is as high as 99.98%, and the purity is as high as 99.9%.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com