Electromagnetic rotational flow water gap for continuous casting

A nozzle and electromagnetic technology, applied in casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of difficult to achieve results, high flow rate, short time for molten steel to flow through the magnetic field area, etc., to improve utilization efficiency , Improve billet quality, solve the effect of drift phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

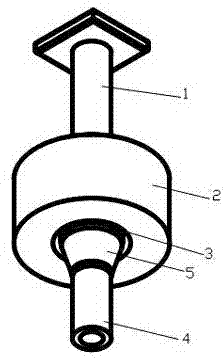

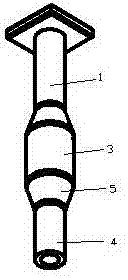

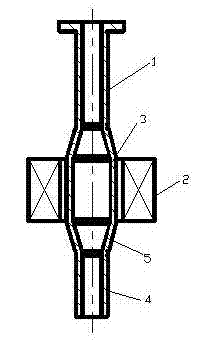

[0015] Electromagnetic swirl nozzle for continuous casting of the present invention, such as figure 1 , image 3 As shown, it includes a nozzle pipe and an electromagnetic swirl device 2, and the electromagnetic swirl device is installed around the middle area 3 of the nozzle pipe. like image 3 As shown, the nozzle pipe is a different diameter structure, including the upper part of the nozzle pipe 1, the middle area of the nozzle pipe 3, the transition section 5 and the molten steel outlet 4, and the middle area of the nozzle pipe is connected to the upper part of the nozzle pipe and the molten steel outlet through the transition section respectively. The cross-sectional area of the middle area of the nozzle pipe is 5 times of the cross-sectional area of the molten steel outlet. The length of the middle area 3 of the nozzle pipe is 40% of the overall le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com