Heat exchange tube and heat exchange structure for horizontal tube falling film evaporator

A technology of falling film evaporator and heat exchange structure, applied in the direction of horizontal tube evaporator, evaporation, tubular elements, etc., can solve the problems of occupying a large heat exchange area, splashing, liquid film bias flow, etc., to avoid coking, strengthen transmission Thermal performance, the effect of solving the drift phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

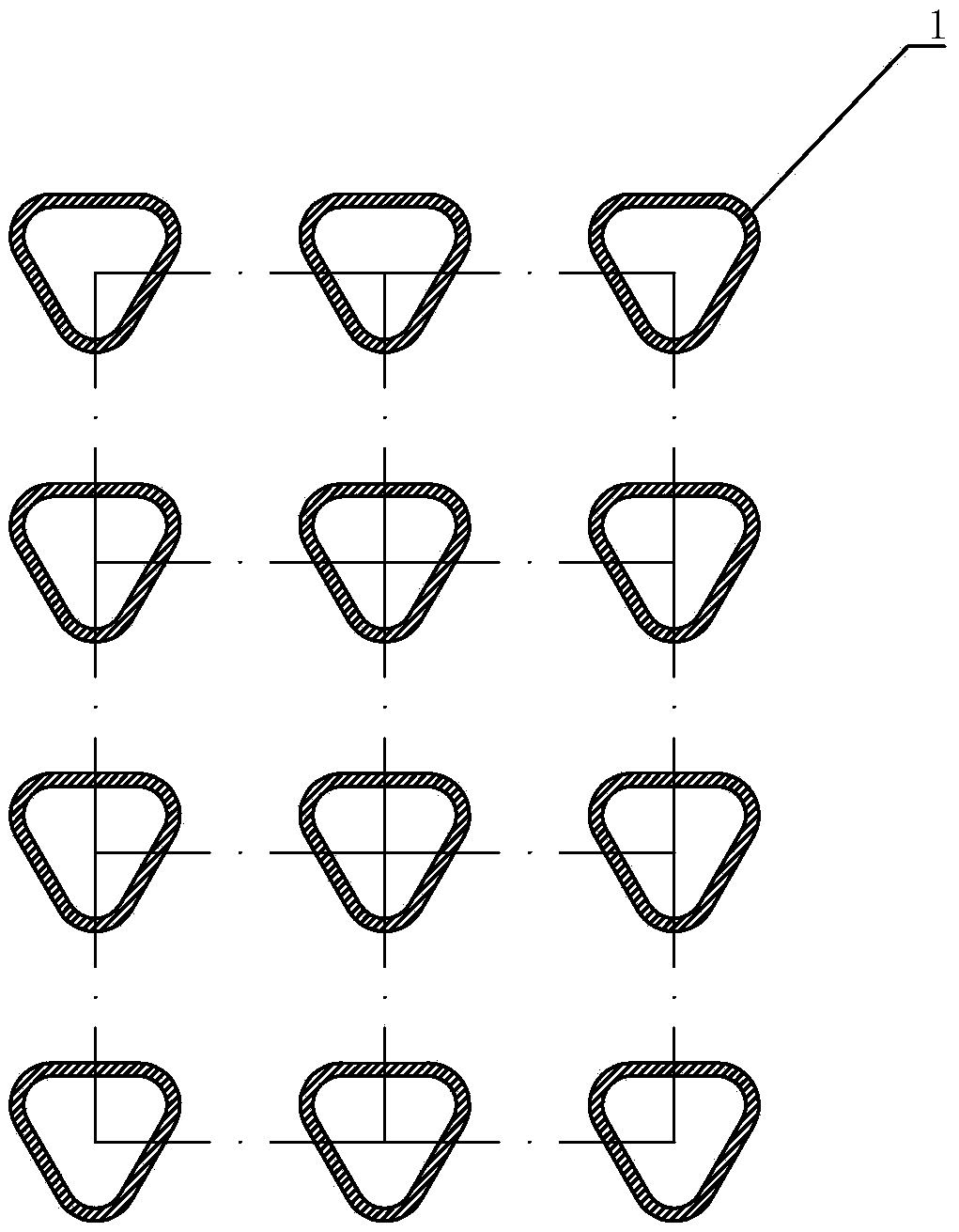

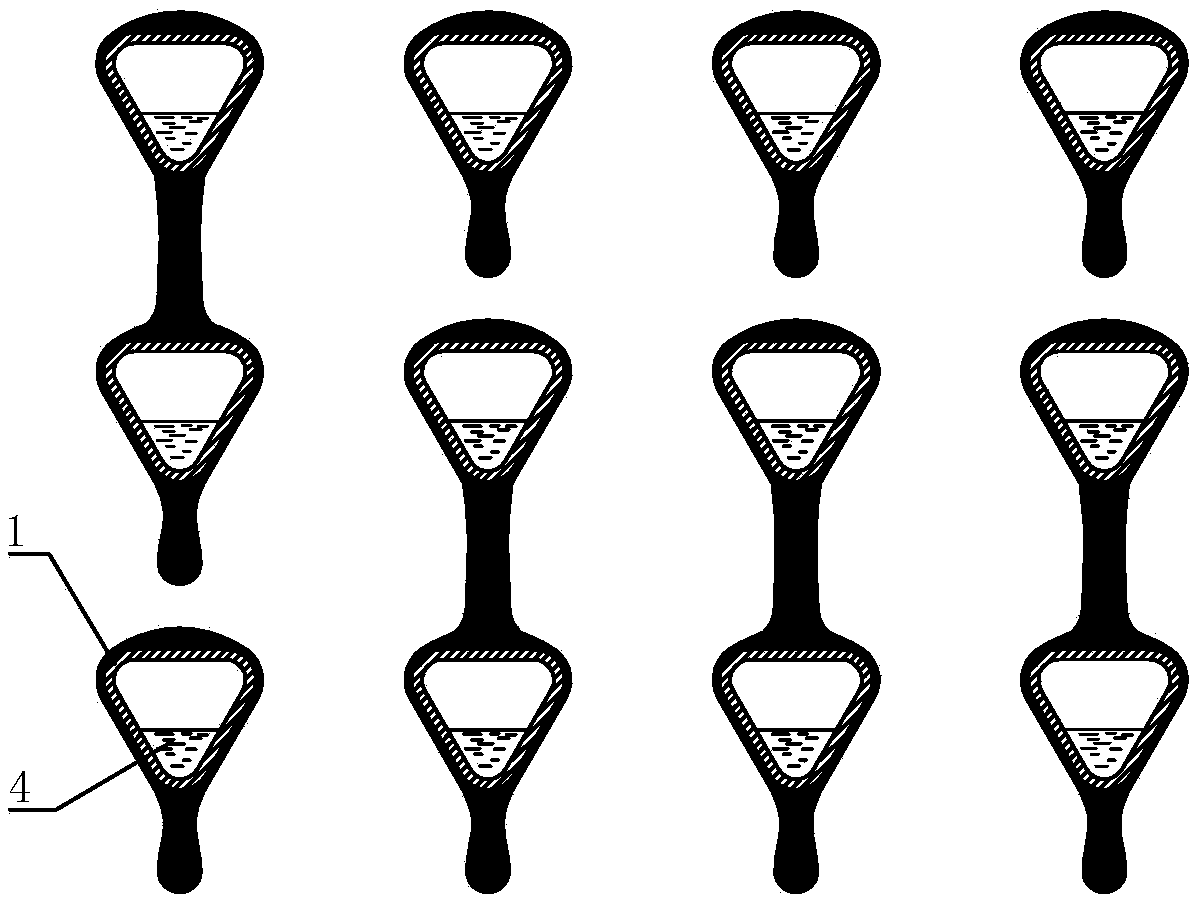

[0014] Such as figure 2 The shown heat exchange tube for a horizontal tube falling film evaporator includes a heat exchange tube body 1, and the heat exchange tube body 1 is a hollow triangular prism structure.

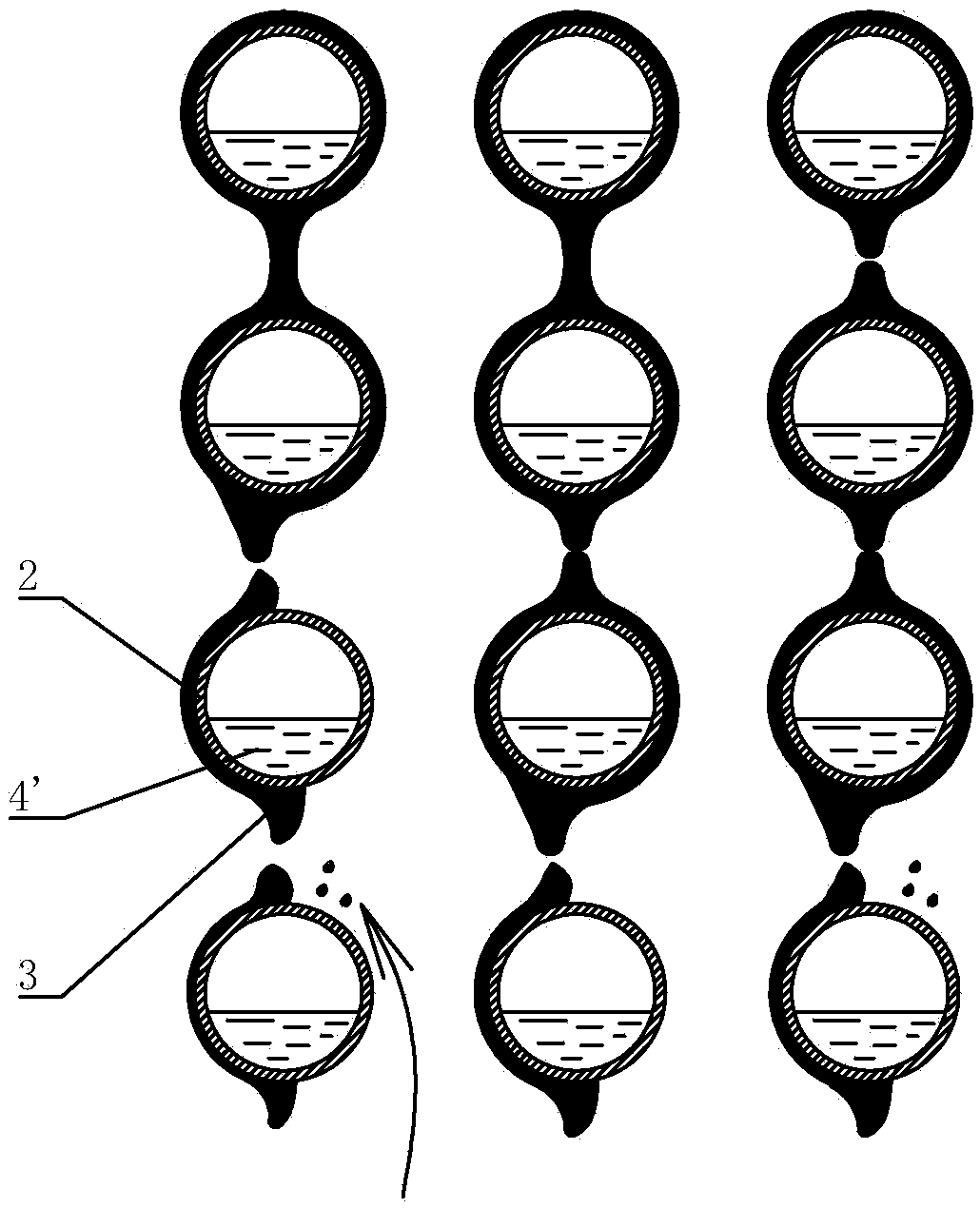

[0015] Such as figure 2 with image 3 In the heat exchange structure for the horizontal tube falling film evaporator shown, several heat exchange tube bodies 1 are arranged parallel to each other and fixed on the tube sheet in a rectangular array, and the upward side of each heat exchange tube body 1 is kept horizontal, forming an inverted triangle shape. . The feed liquid falls on the side of the upper end of the heat exchange tube body 1, first accumulates a thicker liquid film and then spreads to both sides and flows down evenly, thus solving the bias flow phenomenon well, avoiding coking, dry wall, and reduced evaporation and other problems, and when the liquid film of the upper heat exchange tube body 1 falls further, it falls on the liquid film of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com