Composite heat dissipation device, cooling unit, cooling device and assembling body

A heat dissipation device and cooling unit technology, applied in coolers, water shower coolers, household refrigeration devices, etc., can solve the problems of increased number of parts and assembly man-hours, damage to rotating shafts and blades, and high cost of cooling devices. The effect of reducing parts cost, changing the cooling capacity, and reducing the number of manufacturing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0048] (A) Structure of cooling device

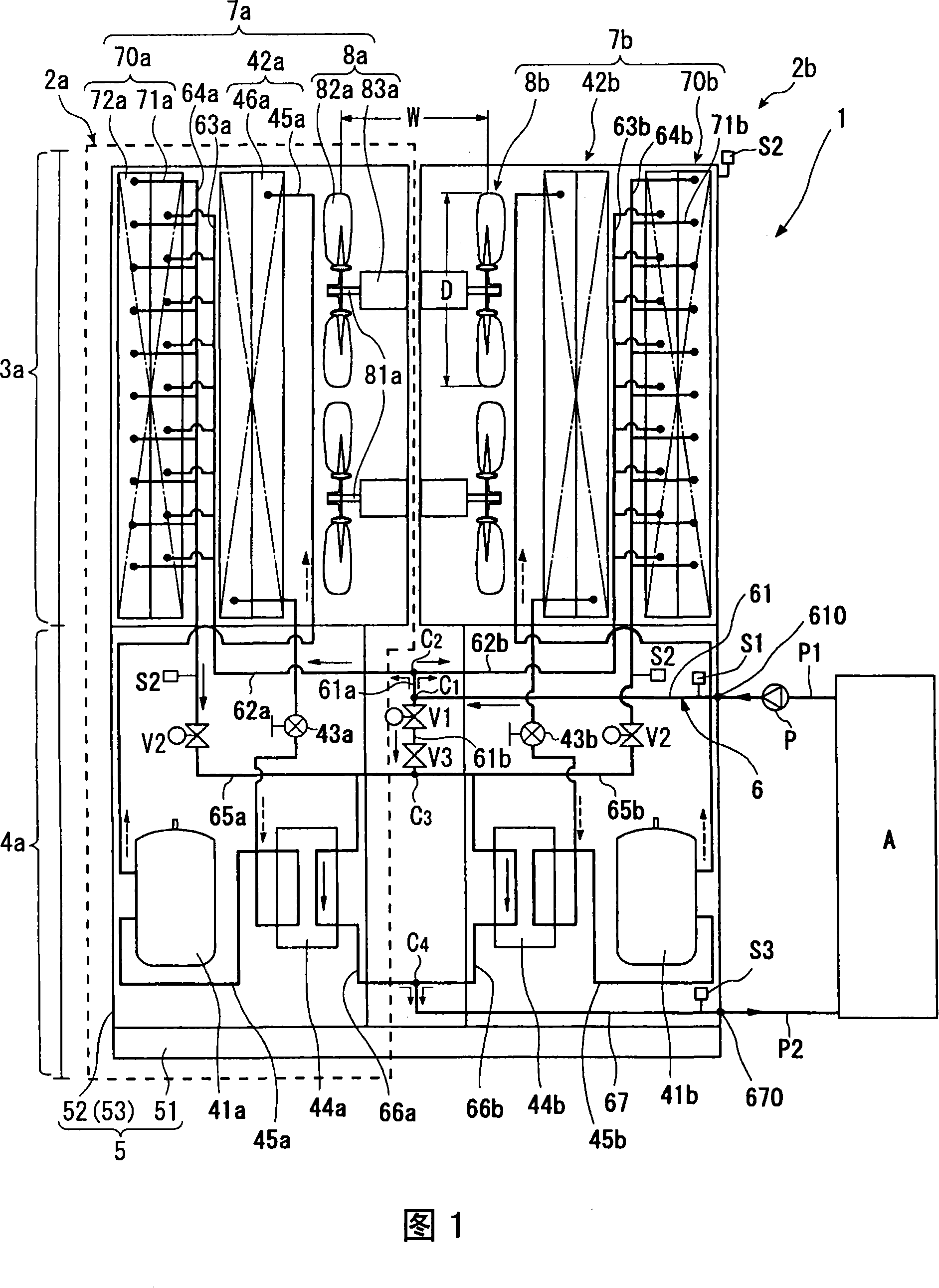

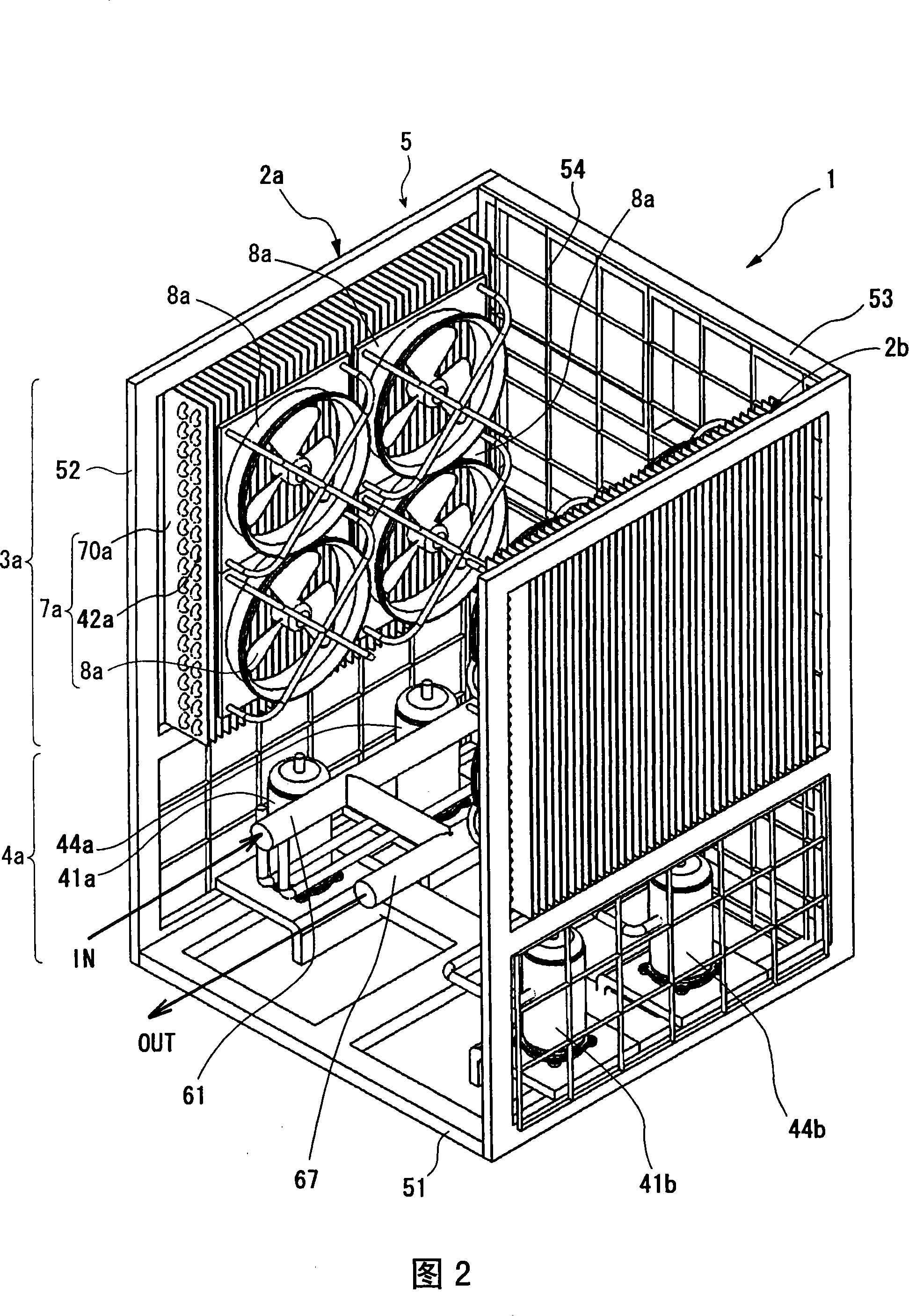

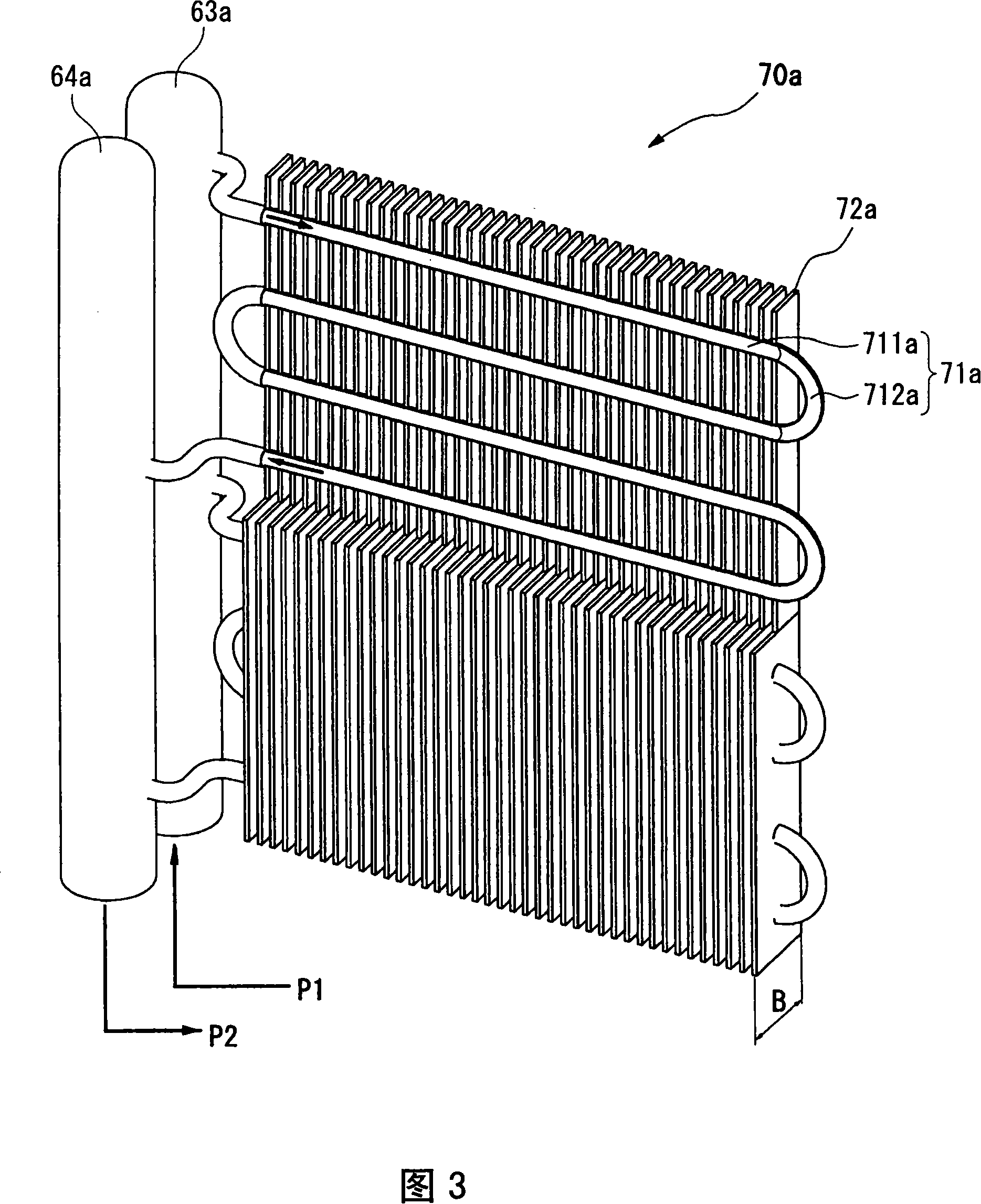

[0049] 1 and 2 are diagrams respectively showing an internal structure and an external appearance of a cooling device according to a first embodiment of the present invention. The cooling device 1 includes a pair of cooling units 2a, 2b for cooling a fluid to be cooled (for example, warm water) sent from an external device (not shown) to near room temperature and then sending it back to the external device. In FIG. 1 , one cooling unit 2 a is surrounded by a dotted line, and the solid arrows indicate the flow direction of the fluid to be cooled, and the dotted arrows indicate the flow direction of the refrigerant. The number of cooling units is not limited to two, and may be one or three, which may be selected according to the cooling capacity.

[0050] The cooling device 1 includes a frame body 5 formed of a bottom panel 51 , a side panel 52 , and a rear side panel 53 , and cooling units 2 a and 2 b housed in the frame body 5 . Each ...

no. 3 approach

[0075] Fig. 6 shows the appearance of a cooling device assembly according to a third embodiment of the present invention. The structure of the cooling device assembly 100 is that two sets of cooling devices 1 (shown in FIG. 2 ) are adjacent to each other along the flow direction of the fluid to be cooled, and the respective cooling units 2 a to 2 d are arranged in parallel with the inflow pipe 61 and the outflow pipe 67 . Since the components constituting the cooling device assembly 100 are the same as those shown in FIGS. 1 to 4 , they are denoted by the same reference numerals, and description thereof will be omitted. In the cooling device assembly 100, the number of connected cooling units is appropriately selected according to the required cooling capacity. According to such a structure, a cooling device having a desired cooling capacity can be easily obtained simply by assembling a plurality of cooling devices 1 having the same structure on site.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com