Combustion device with heat exchange function

A technology of combustion equipment and combustion chamber, which is applied in the direction of lighting and heating equipment, burners, combustion methods, etc., which can solve the problems of short circuit of heat storage body, reduced heat exchange efficiency, and easy occurrence of bias flow, etc., so as to suppress the formation of nitrogen oxides , Improve heat exchange efficiency and slow down the effect of local high temperature zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

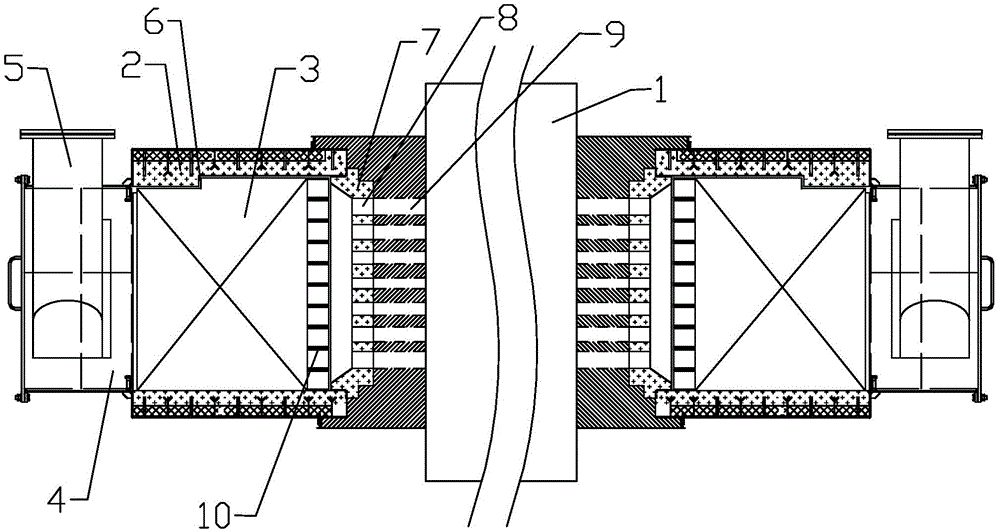

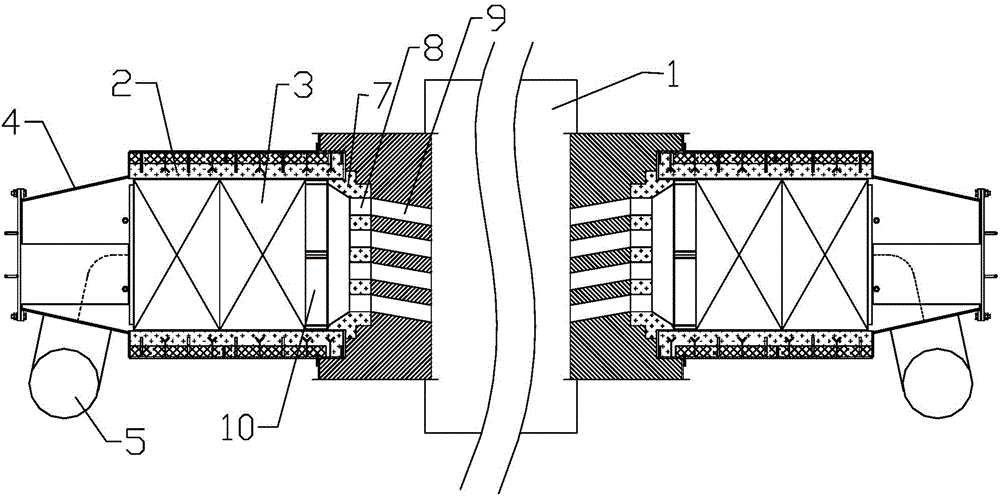

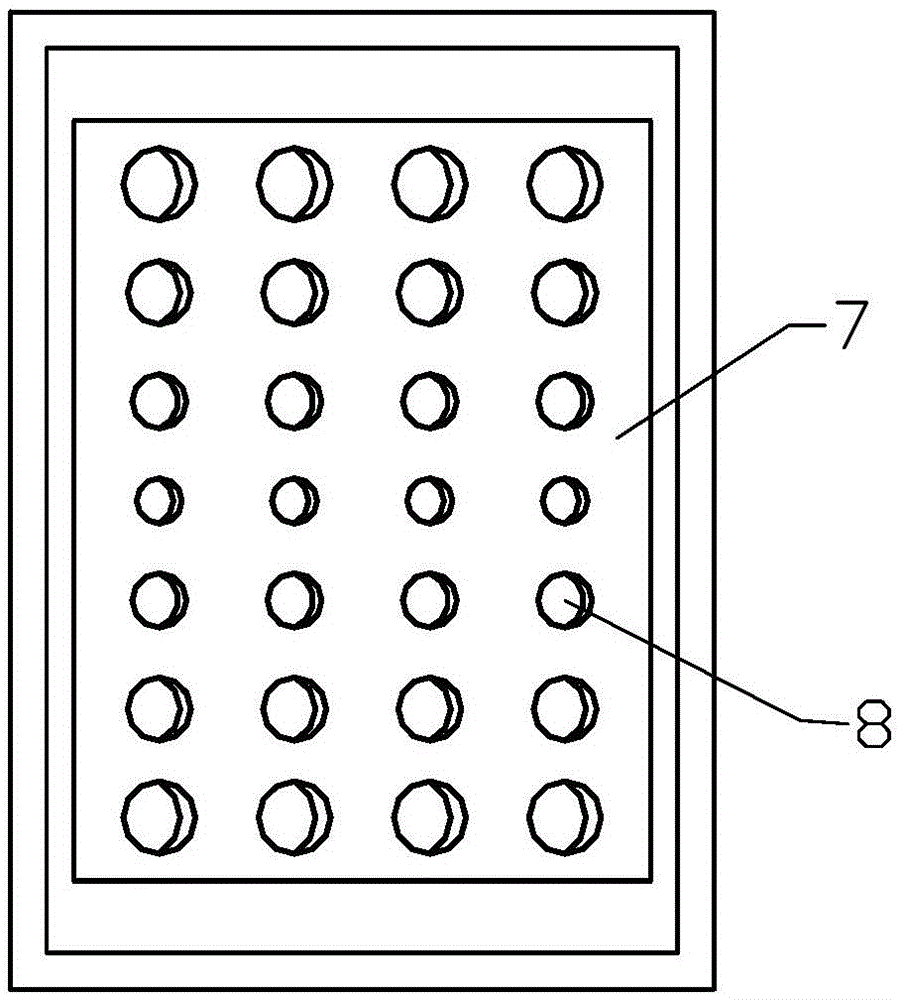

[0020] Such as Figure 1-2 As shown, the heat exchange combustion equipment described in the embodiment of the present invention at least includes a combustion chamber 1 and a heat storage device communicated with the combustion chamber. Such as Figure 1-2 As shown in , it can be divided into the first heat storage device on the left and the second heat storage device on the right. Wherein, the structures of the first heat storage device and the second heat storage device are the same. First of all, it needs to be introduced that the heat storage device includes a heat storage box 2 with a heat storage body 3 inside, one end surface of the heat storage box communicates with the interior of the combustion chamber through an array hole structure, and the heat storage box The other end face communicates with a drainage cavity 4; a flow diverter is provided in the drainage cavity; the drainage cavity 4 communicates with a gas connection pipe 5; the upper edge surface of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com