Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Improve convective heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

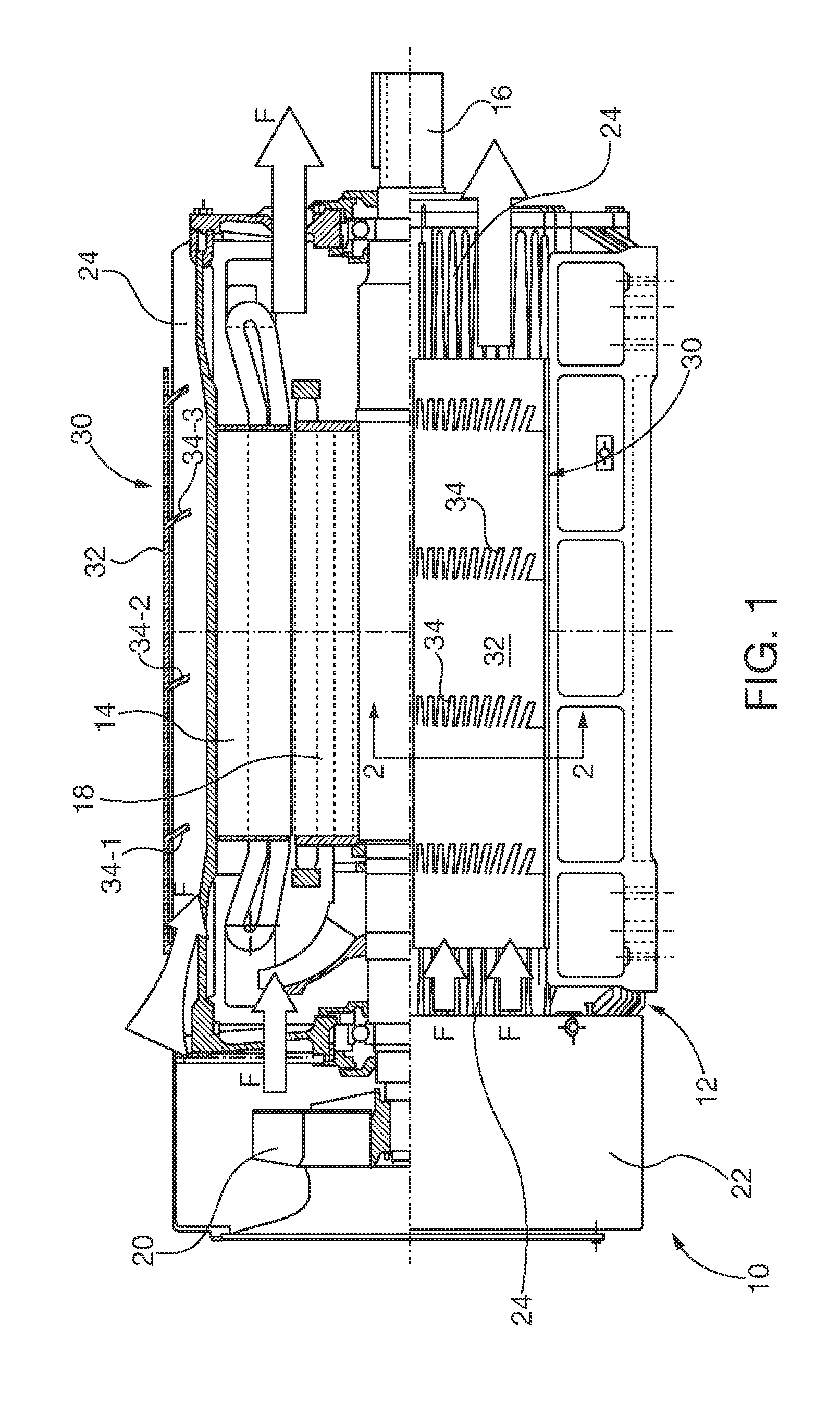

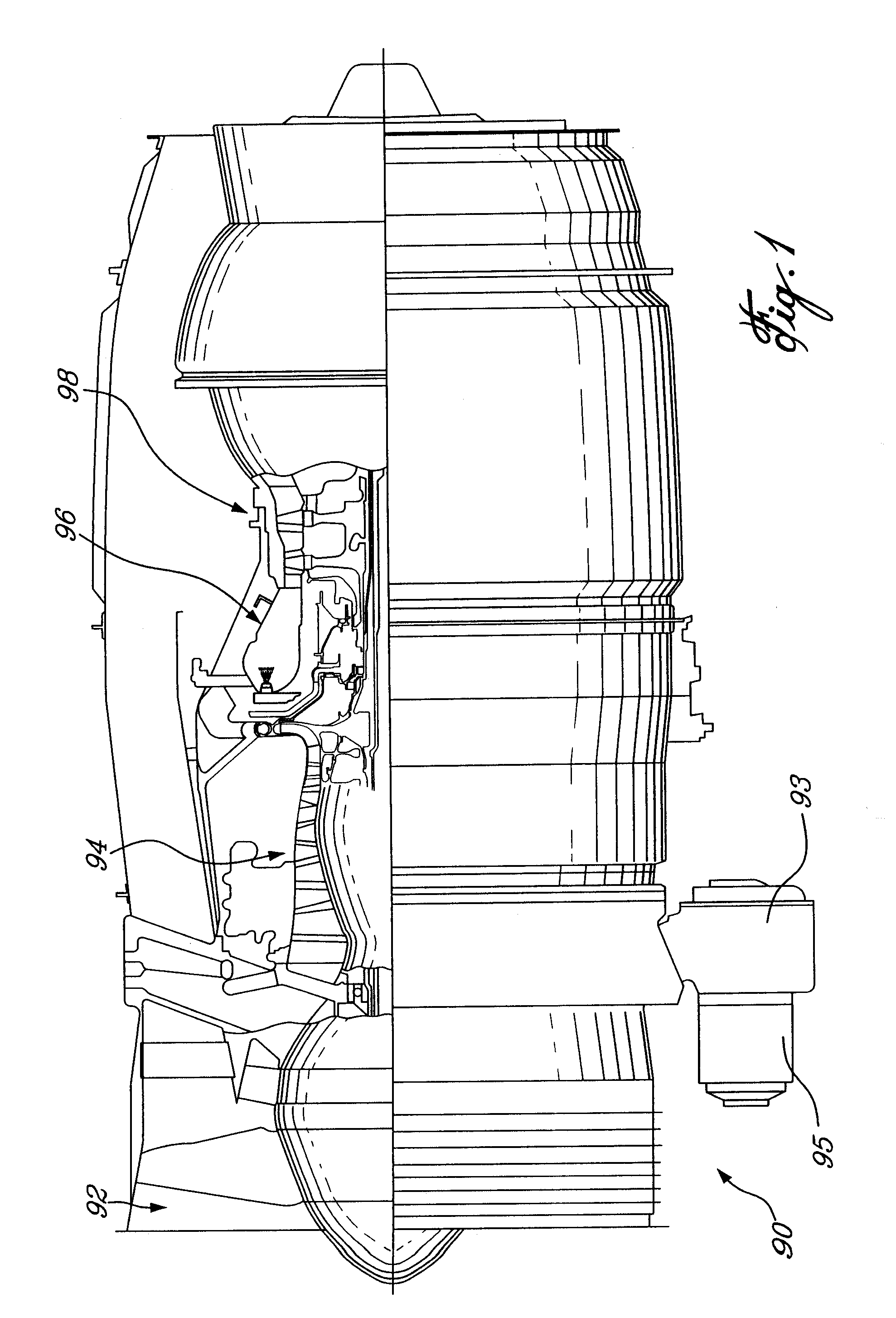

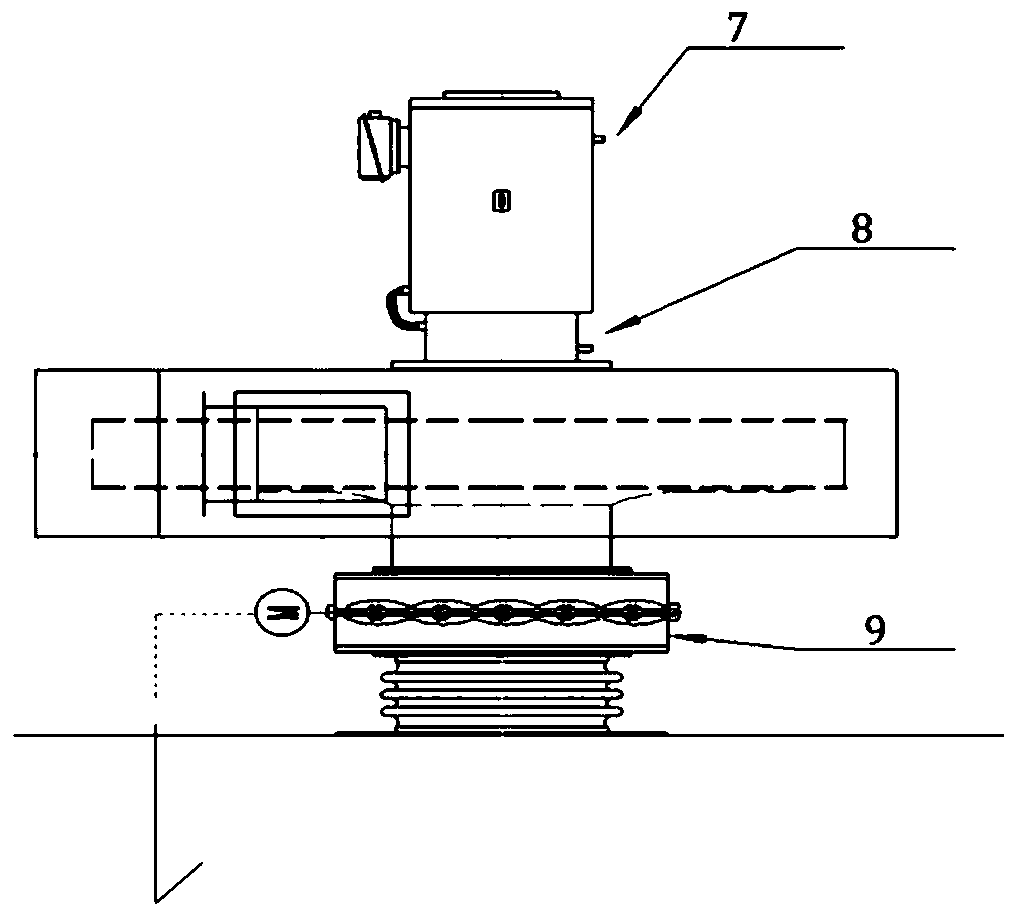

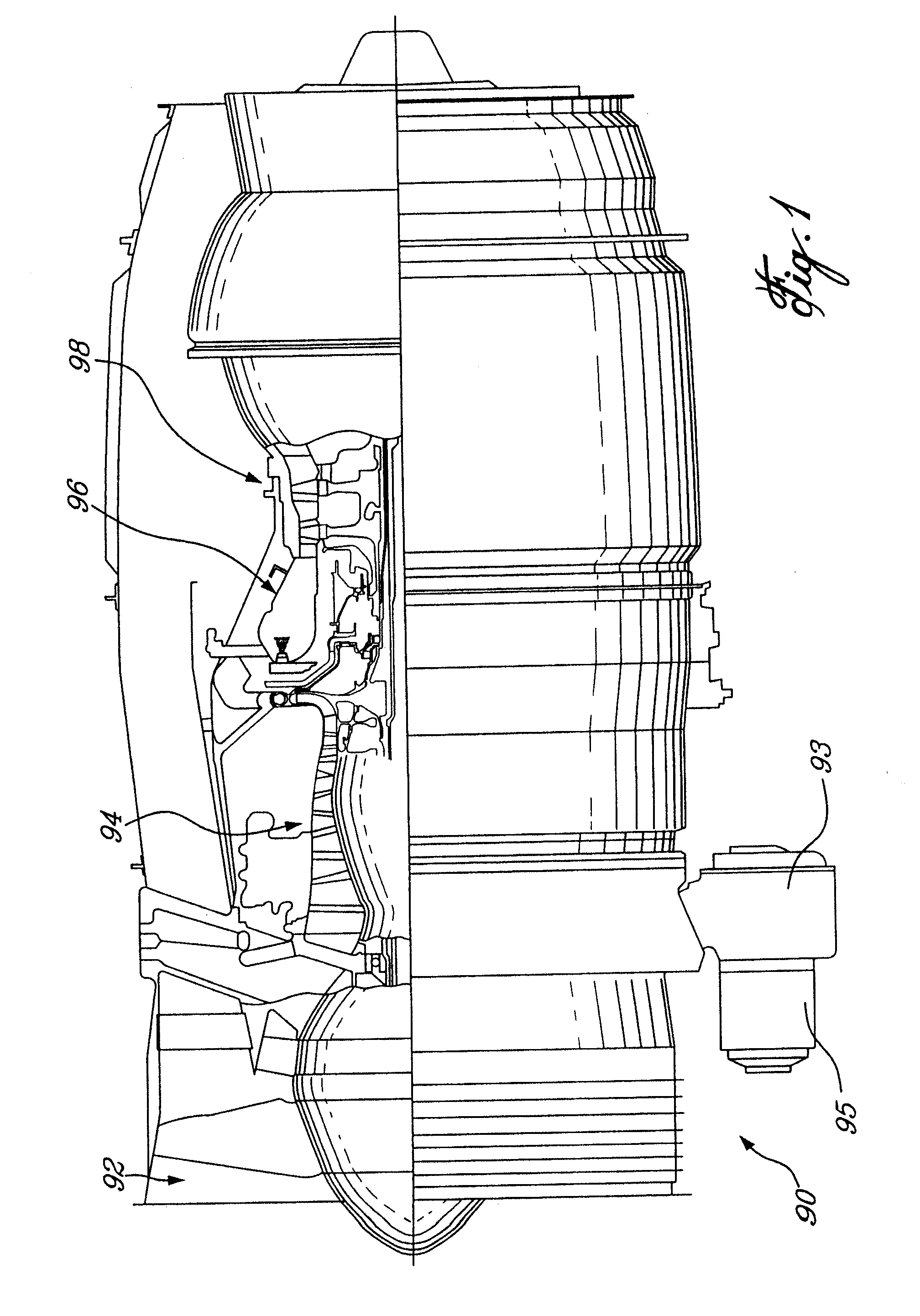

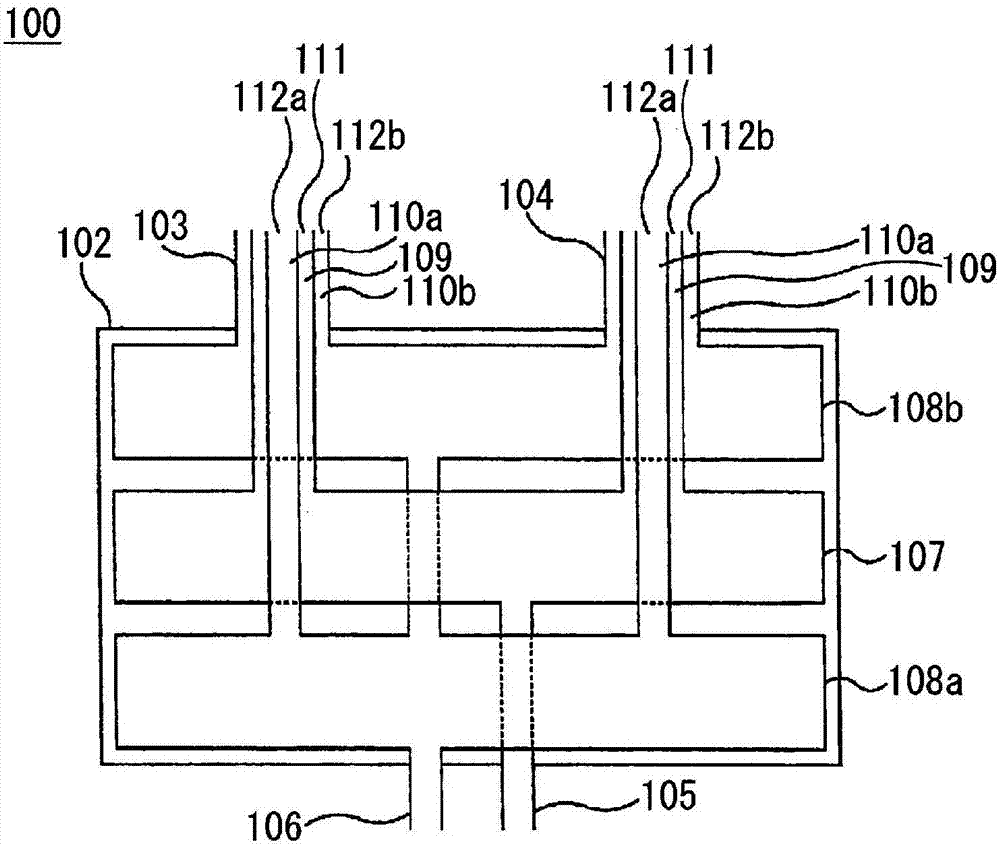

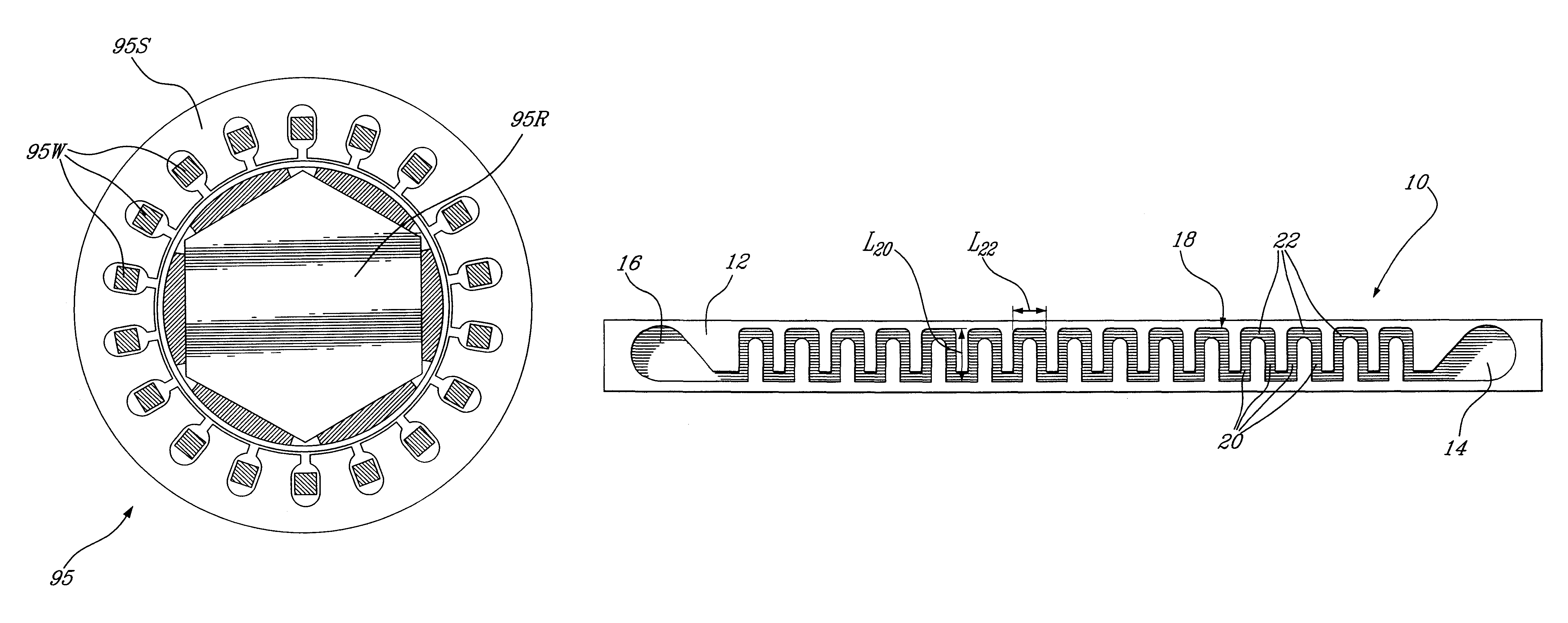

Induction motor auxiliary cooling system

ActiveUS20140021812A1Improve cooling effectLow costCooling/ventillation arrangementContact timeHeat sink

A totally enclosed fan cooled (TEFC) induction motor or other type of induction motor auxiliary cooling system has a buffet thermal shroud that is oriented in opposed spaced relationship over existing motor housing cooling fins. An airflow channel is defined between the motor cooling fins and the shroud, for direction and passage of a cooling airflow. Tabs are oriented in the airflow channel between opposed cooling fins where they are in thermal and fluid communication with the cooling air flow. In some embodiments the tabs are shroud fingers that project inwardly from the shroud. The tabs or shroud fingers create turbulence in the cooling air flow that increases convective heat transfer efficiency and contact time between the cooling air and motor cooling fins. Tabs or shroud fingers also absorb heat from the cooling air flow. Shroud fingers also transfer that absorbed heat conductively to the shroud.

Owner:SIEMENS IND INC

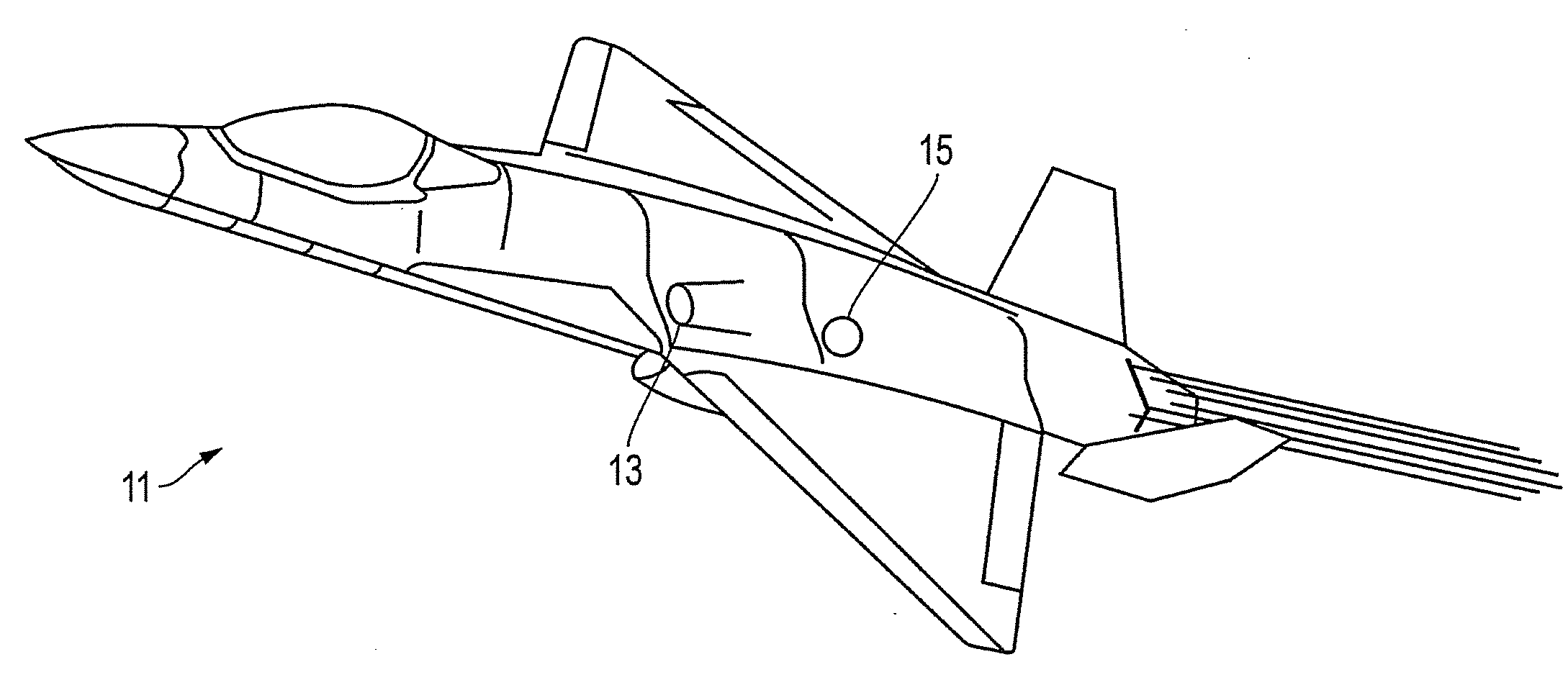

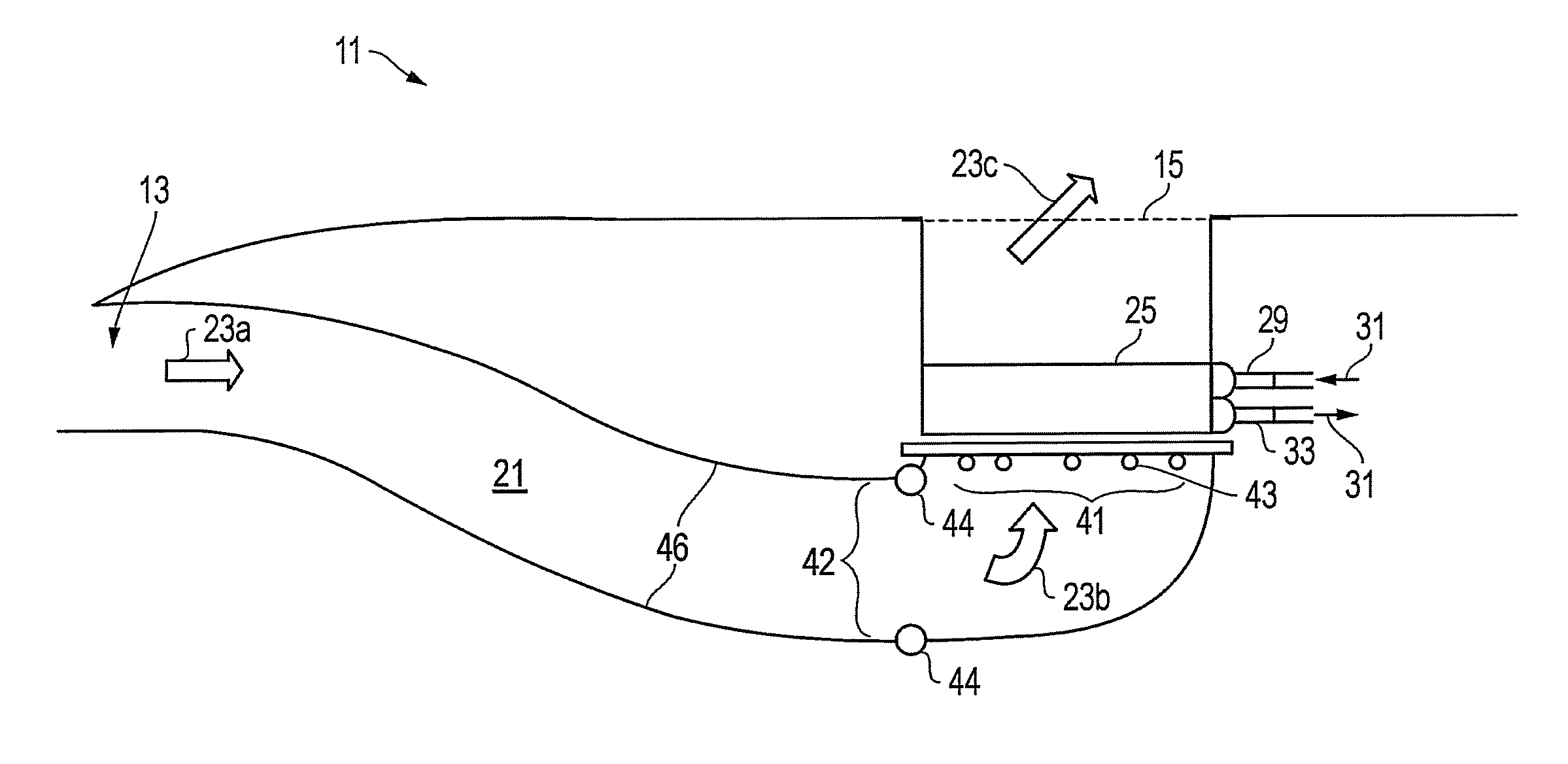

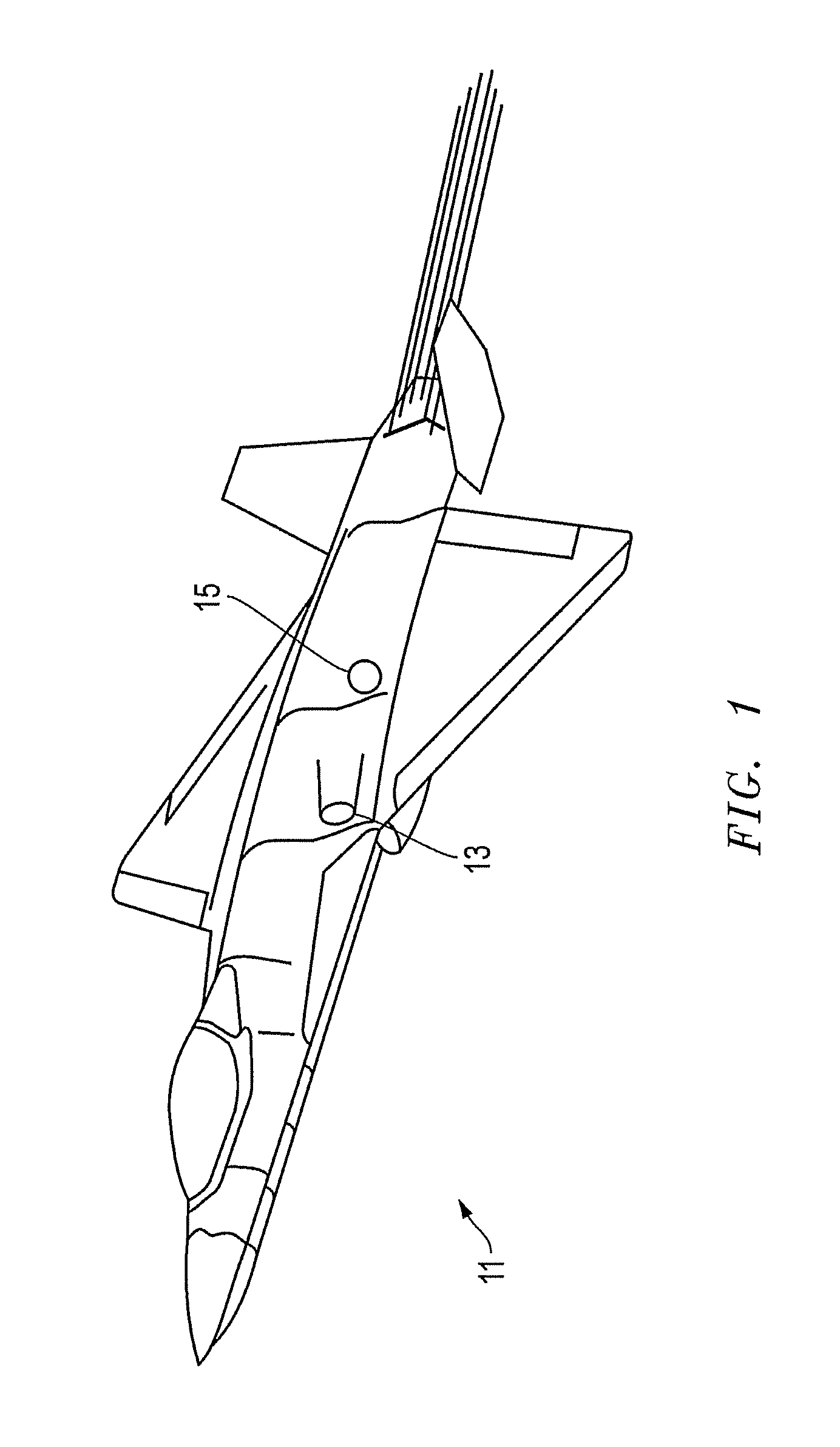

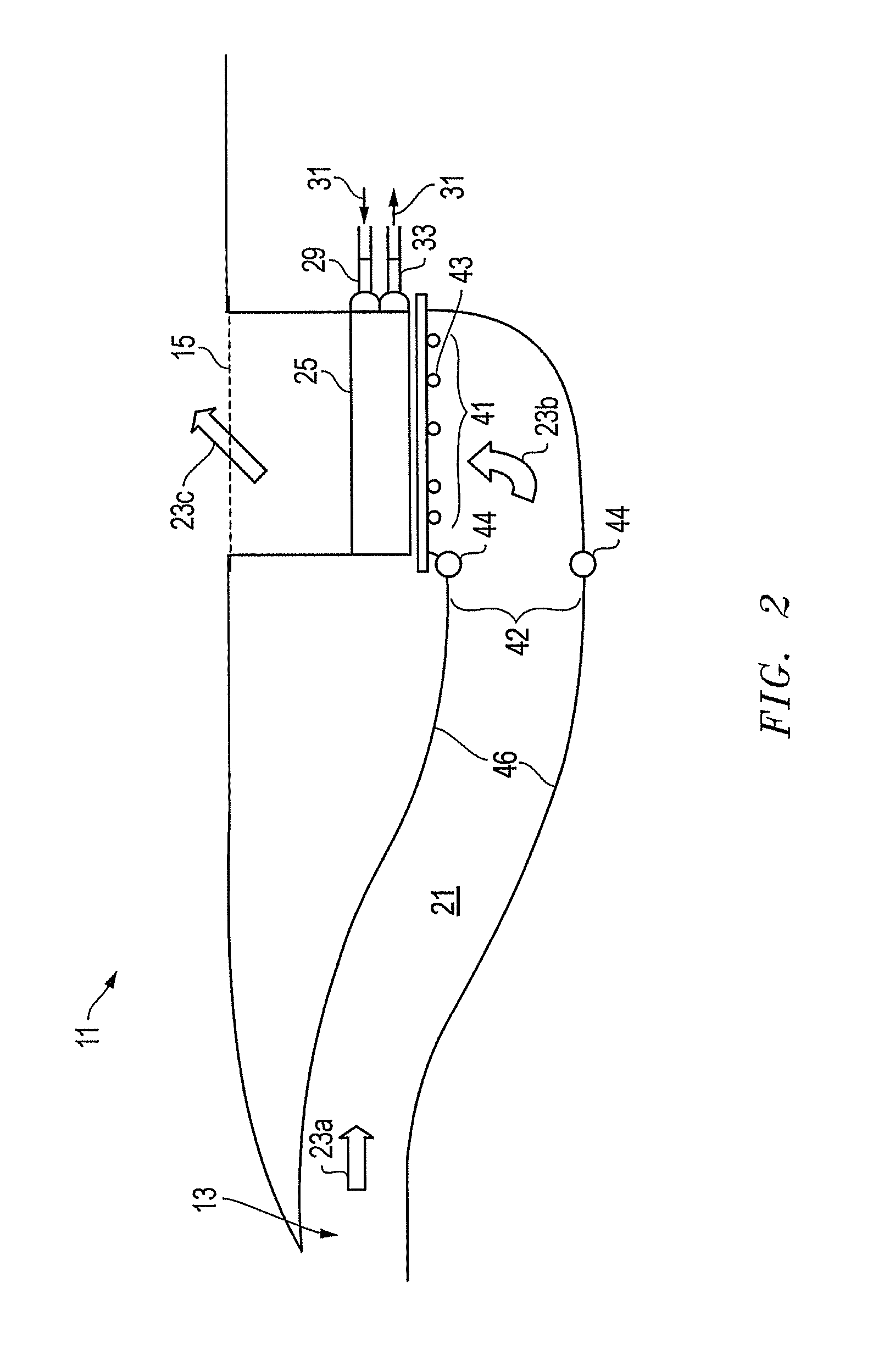

System, method, and apparatus for pulsed-jet-enhanced heat exchanger

ActiveUS20090095446A1Improve convective heat transfer efficiencyImprove thermal management performancePower plant cooling arrangmentsAir-treating devicesWorking fluidEngineering

A pulsed-jet active flowfield control actuation system enhances the rate of heat transfer and heat removal in a heat exchanger for better management of thermal loads. The pulsed jet actuators impart an unsteady component of velocity to the working fluid of the heat exchanger. This design increases the convective heat transfer, and avoids increases in heat exchanger volume and weight for a given performance value.

Owner:LOCKHEED MARTIN CORP

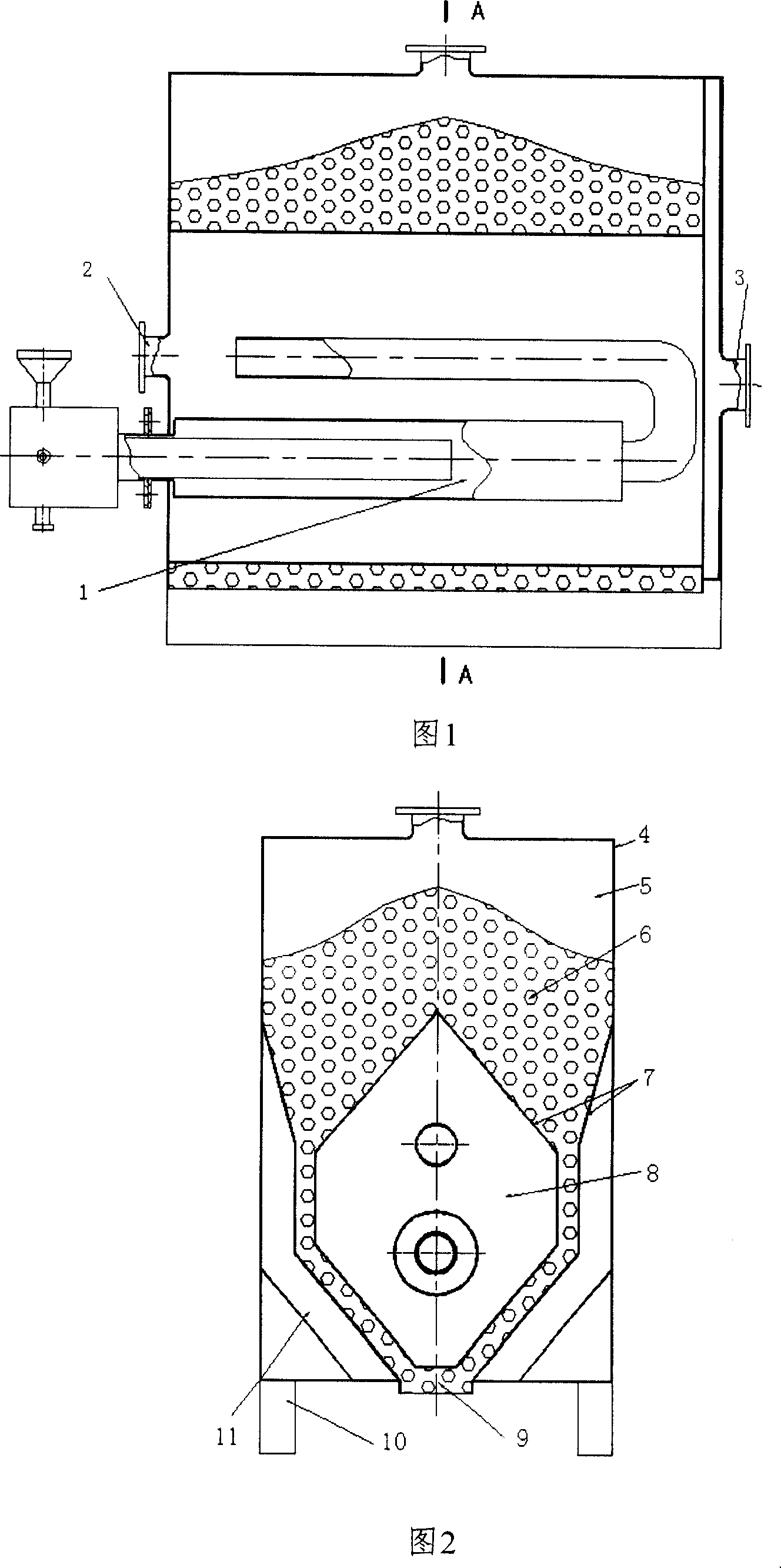

Grain drying device

InactiveCN1971188AKeep dryGuaranteed qualityDrying solid materials with heatHearth type furnacesElectric consumptionEngineering

The invention provides a grain drying equipment, mainly comprising hot-air radiation storehouse and heat resource generator in it. Said heat resource generator comprises pulsating burner and infrared heater. The grain drying equipment in invention applies pulsating burning, infrared radiation and hot-air convection to radiate the grain in indirectly heated infrared with high temperature and shock air flow of high frequency and heat the grain by hot-air convection in combination at the same time. Compared with conventional method, the equipment is provided with low burning consumption ratio and low electric consumption ratio. It improves the speed of drying and precipitation so as to improve the drying efficiency greatly.

Owner:CHINA AGRI UNIV

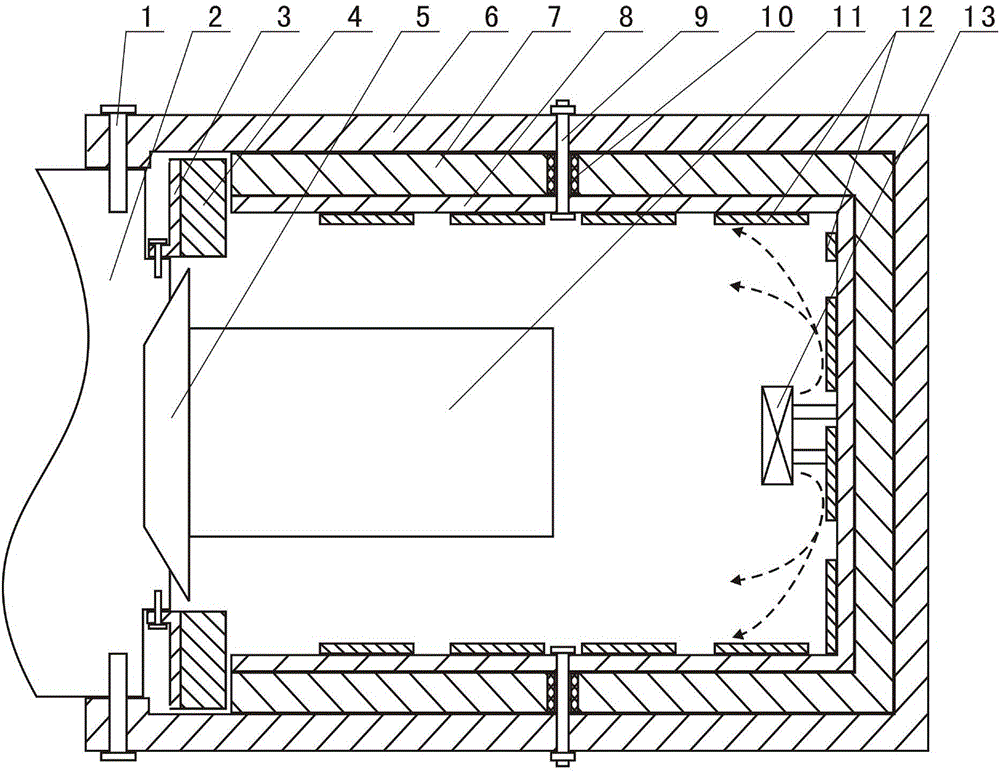

Portable thermal loading device for temperature-acceleration composite environment test

InactiveCN105158006AEasy to installLight in massStructural/machines measurementElectricityInterior space

The invention discloses a portable thermal loading device for a temperature-acceleration composite environment test, comprising a radome having one end open and the other end closed, electric heating membranes and a fan. The radome is in connection with a centrifuge arm through main body bolts; a testpieces is installed on the centrifuge arm through a table top, and is located in the radome; in the radome, a thermal insulation layer is arranged between an outer wall and an inner wall; a plurality of electric heating membranes are uniformly bonded on the inner wall; the fan is installed on the inner wall and is close to the inner bottom center, and the air supply direction just faces the inner bottom center of the inner wall. The portable thermal loading device employs bonded electric heating membranes to realize heating, thereby synchronously controlling the temperature and acceleration, and improving the simulation capability of a temperature-acceleration composite environment test; the radome is of a three-layer structure, thereby reducing the overall mass, and improving insulation effects; the radome is internally provided with the fan, thereby improving the temperature uniformity and the convection heat exchange efficiency of a heating source.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

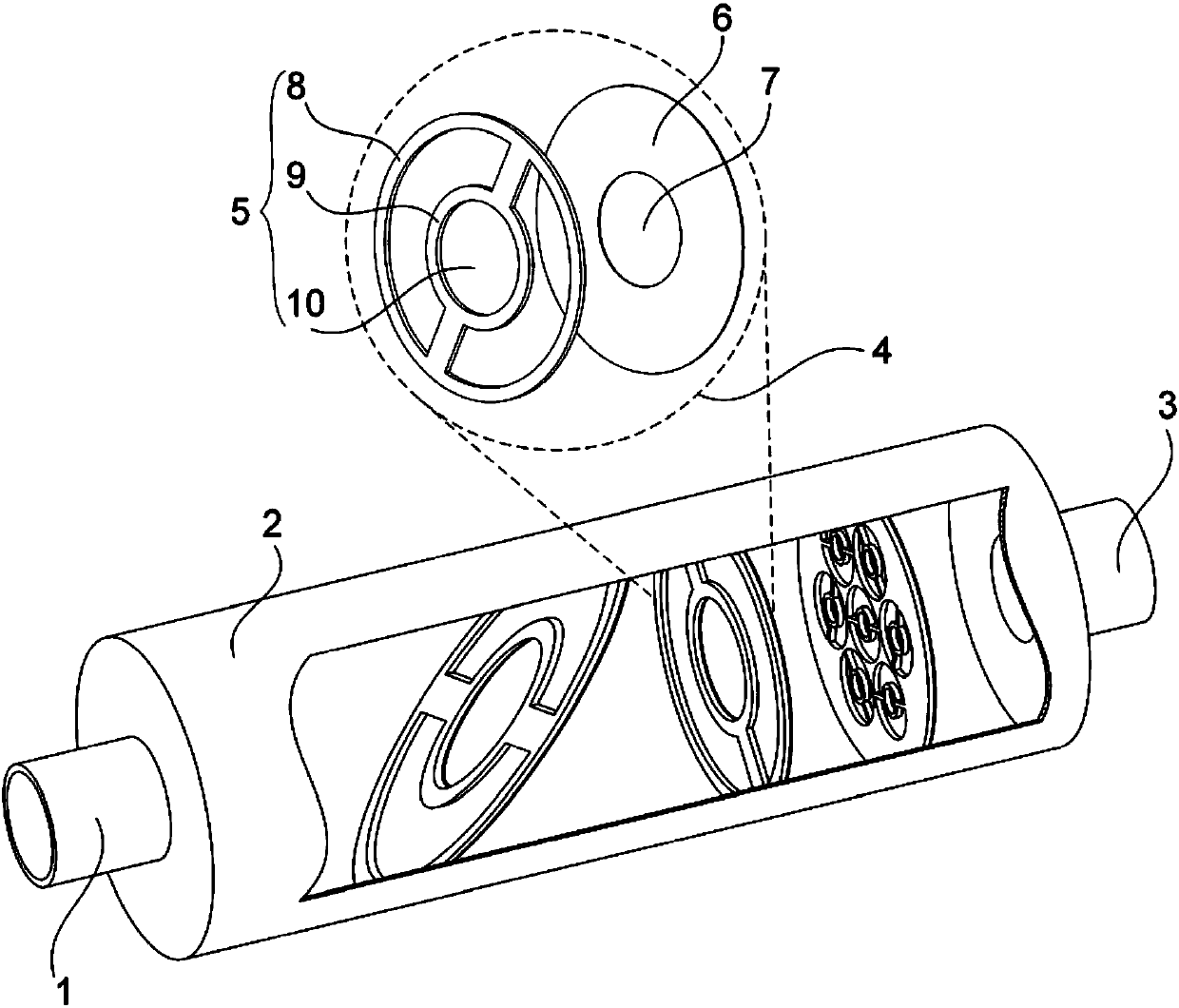

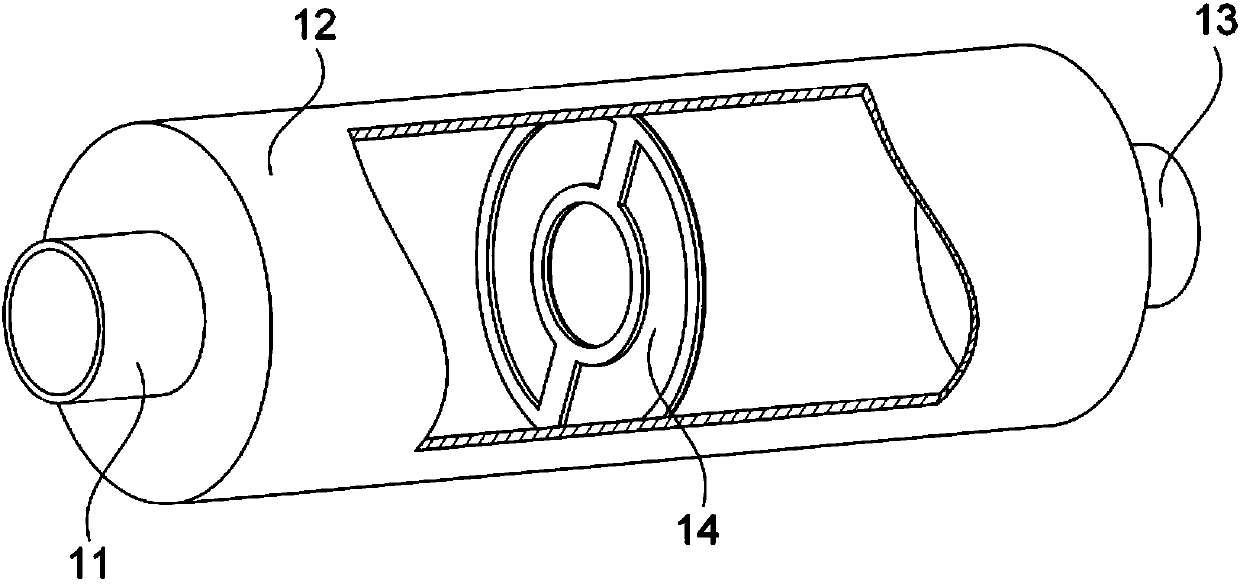

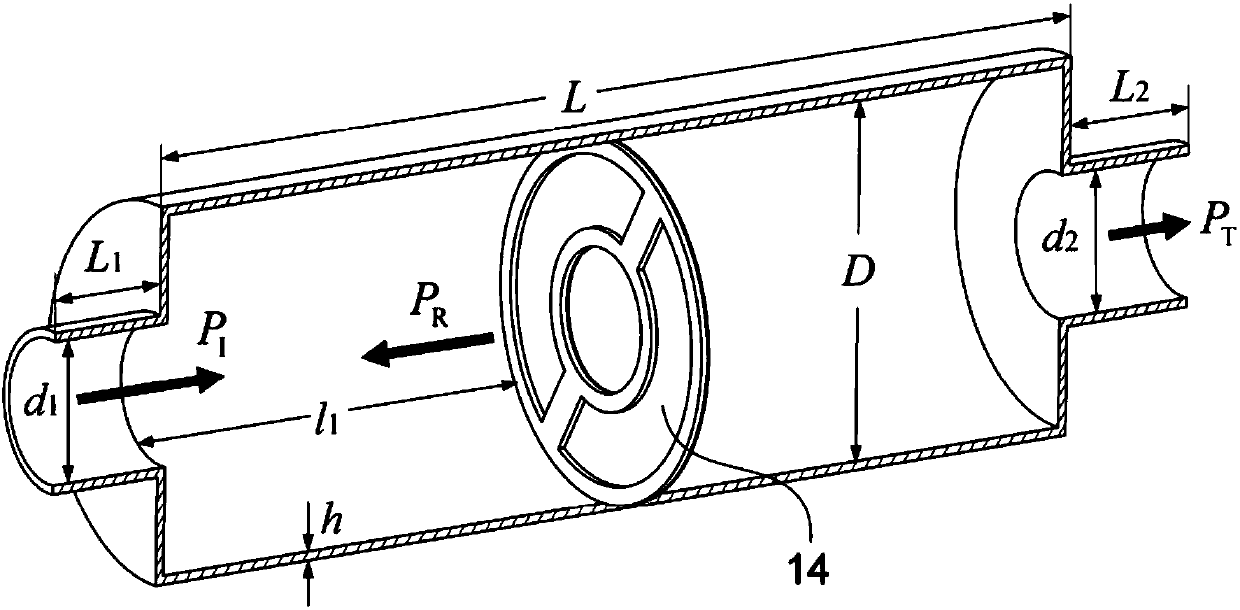

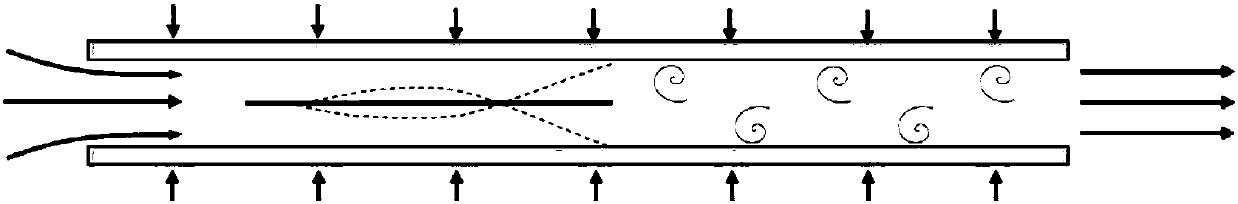

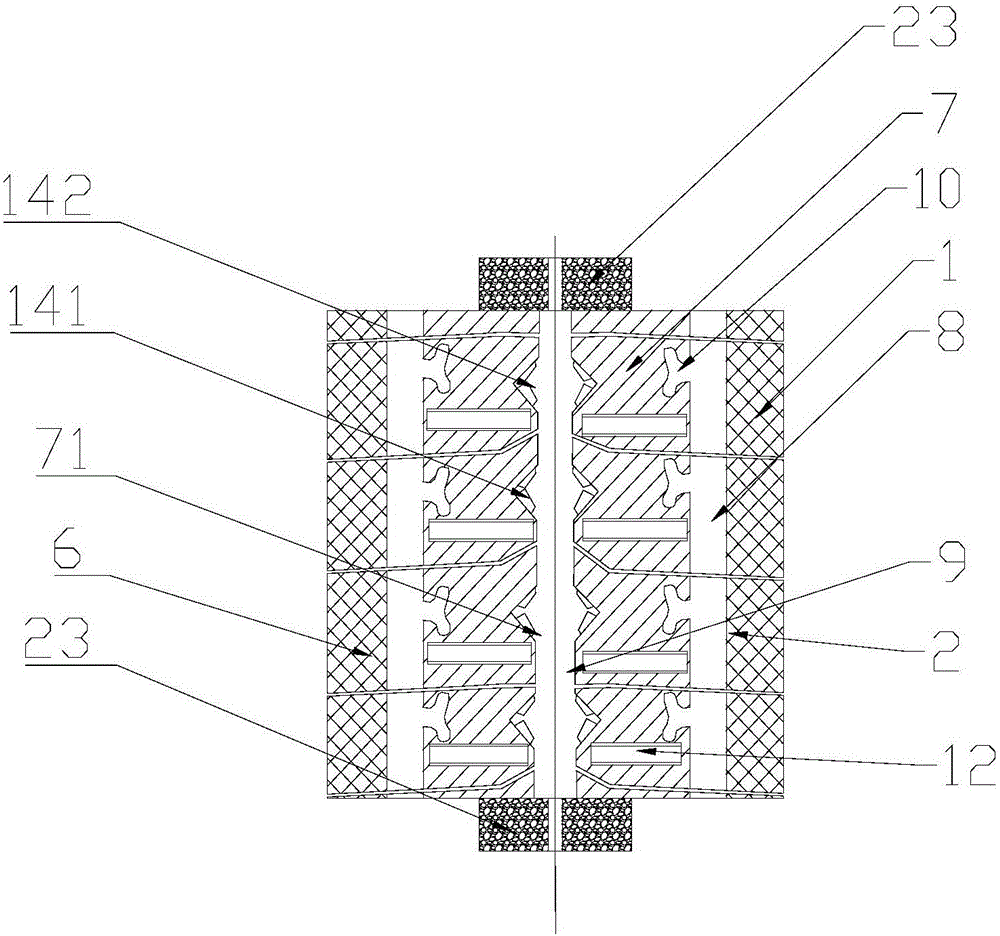

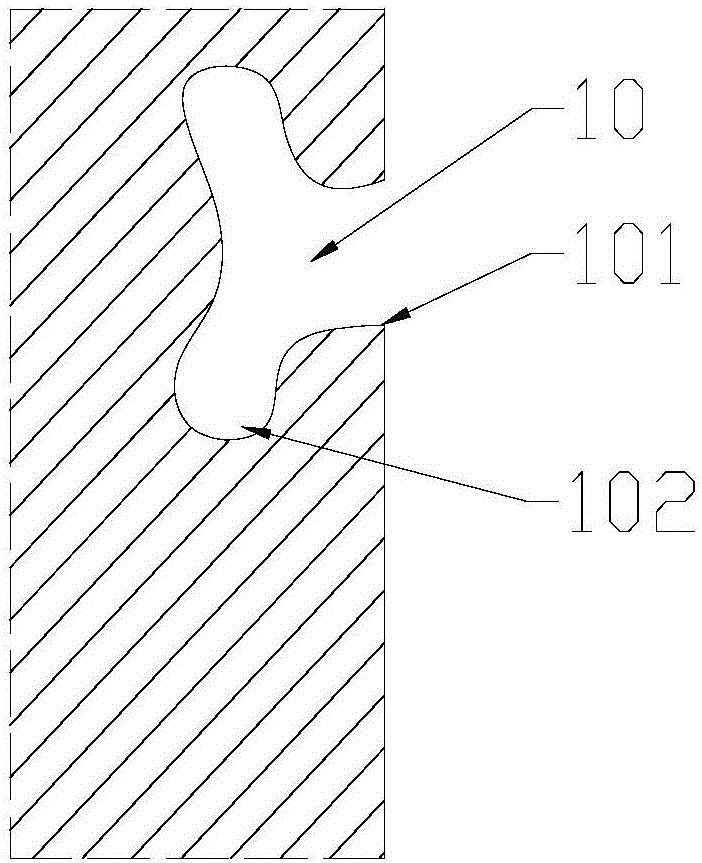

Baffled acoustic metamaterial silencer, and preparation and assembling methods thereof

ActiveCN107633838AExcellent low frequency anechoic bandwidthExcellent noise reductionSound producing devicesEngineeringHeat transfer efficiency

The invention relates to a silencer comprising an inlet pipe, an outlet pipe, a hollow expansion cavity formed between the inlet pipe and the outlet pipe, and a perforated acoustic metamateiral bafflearranged vertically or obliquely at the internal cross section of the hollow expansion cavity. The a perforated acoustic metamateiral baffle includes a frame; a constraint body in rigid connection with the frame is arranged inside the frame; a thin film covers the surface of the frame; and through holes are formed in the constraint body and the thin film. In addition, the invention also relates to an improved silencer; and occurrence of standing wave damping valley of the traditional resistant silencer is avoided and the good low-frequency noise elimination effect is realized. In addition, according to another embodiment, the invention also relates to an improved silencer, so that a problem of the direct contact between the sound absorption material and the fluid is solved. And accordingto another embodiment, the invention also relates to a silencer for improving the heat transfer efficiency of the fluid medium at the two sides of the hole by using vibration of a perforated acousticmetamateiral baffle. Besides, the invention also provides a method for frequency modulation and preparation of a perforated acoustic metamateiral baffle and a method of assembling the silencer. The silencer has characteristics of compact structure, simple process, stable performance, and long service life.

Owner:黄礼范

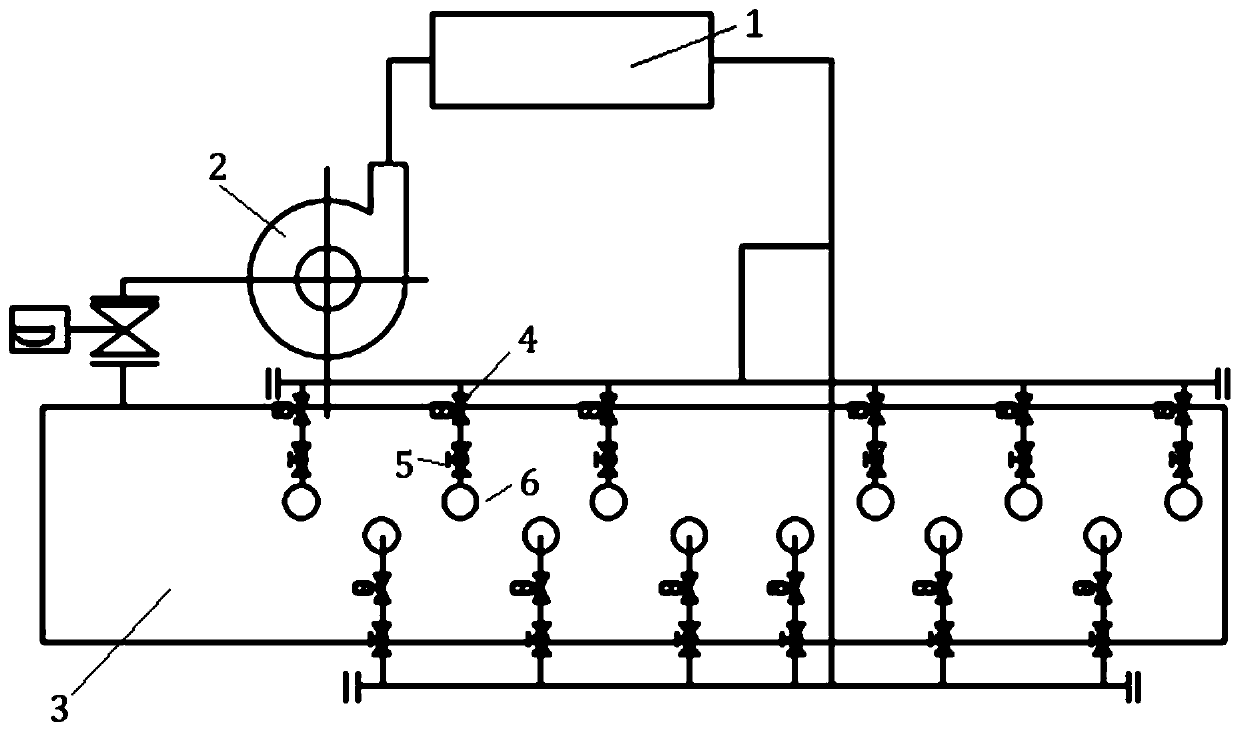

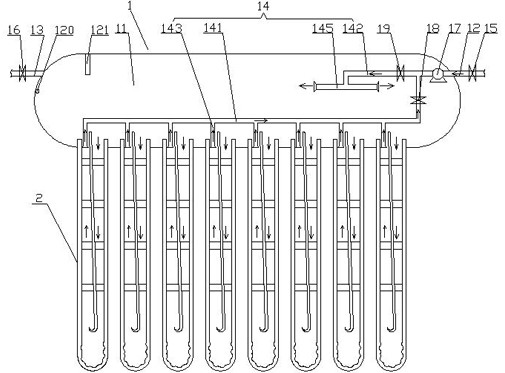

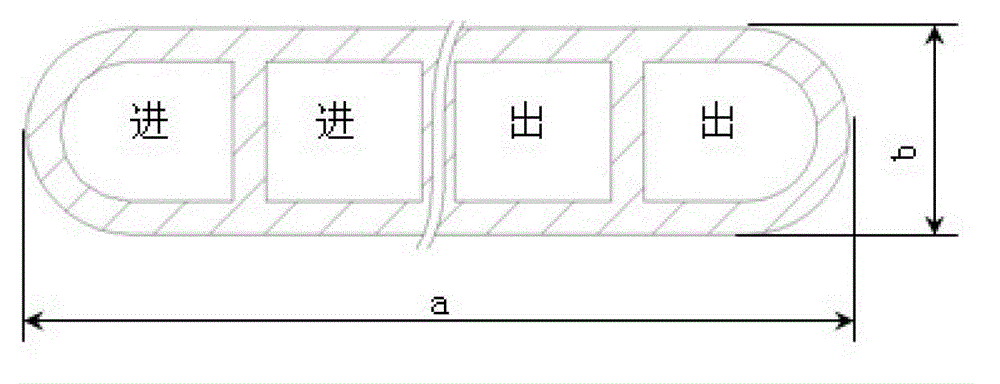

Whole set of ice storage tank equipment

InactiveCN109990417AImprove convective heat transfer efficiencyImprove heat transfer efficiencyLighting and heating apparatusAir conditioning systemsIce storageEngineering

The embodiment of the invention discloses a whole set of ice storage tank equipment. The equipment comprises an ice storage tank equipment body, the ice storage tank equipment body comprises a heat preservation box body and a box cover arranged at the upper end of the heat preservation box body, wherein the heat preservation box body comprises an outer layer, a middle layer and an inner layer, a first coil pipe bracket is arranged in the heat preservation box body, a first coiled coil pipe and a second serpentine coiled pipe are arranged in the first coiled pipe bracket, further comprises an air disturbance device, the air disturbance device comprises an air pump, the air pump is positioned outside the heat preservation box body, the air pump is connected with an air inlet pipeline, the air inlet pipeline penetrates through the box cover and is communicated with a gas conveying main pipe arranged at the bottom of the heat preservation box body, the gas delivery main pipe is communicated with a PVC pipeline arranged at the bottom of the heat preservation box body through a gas delivery branch pipe, further comprises an air outlet pipeline, one end of the air outlet pipeline penetrates through the box cover and is located on the upper portion of the heat preservation box body, and the other end of the air outlet pipeline is communicated with the air pump. The equipment has the advantages of being high in heat exchange efficiency, safe and reliable, and capable of effectively improving the ice making and ice melting rates of ice storage equipment.

Owner:李成军

Water-cooled external mixing type pure oxygen gas burner for rotary iron-melting furnace

InactiveCN105240850AImprove cooling effectAvoid heat damageCombustion technology mitigationGaseous fuel burnerWater flowConvection heat

The invention belongs to the field of casting, and relates to pure oxygen gas burners, in particular to a pure oxygen gas burner for a rotary iron-melting furnace. The front end of the burner is provided with a plurality of gas spray orifices and oxygen spray orifices which are small in equivalent diameter. Meanwhile, line clusters formed by the center lines of the gas spray orifices and line clusters formed by the center lines of the oxygen spray orifices are made to intersect in space in front of the burner. By reducing the flame length, the power density of the pure oxygen gas rotary iron-melting furnace is increased, the melting efficiency of the rotary iron-melting furnace is improved, the melting time of the rotary iron-melting furnace is shortened, fuel is saved, and the production cost is reduced. A water inlet spiral flow channel blade is arranged in a water inlet cavity and a spiral flow channel is formed in a cooling water flow channel of the burner, so that the flow speed of cooling water is greatly increased, the convection heat exchange efficiency between the cooling water and the burner is improved, cooling of the cooling water to the burner is enhanced, and thermal damage to the burner caused by high-temperature flames after the flames of the burner are shortened is prevented.

Owner:殷黎丽 +1

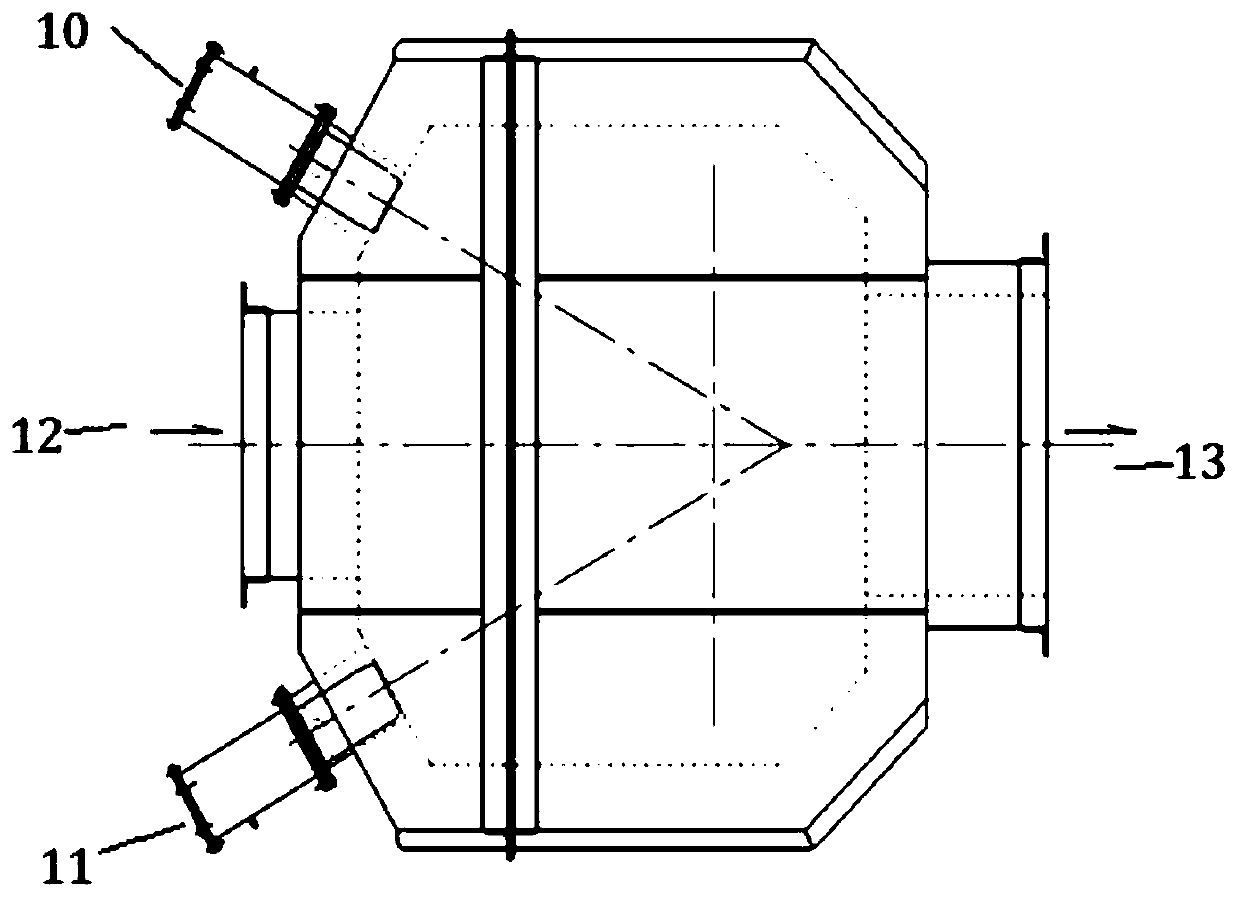

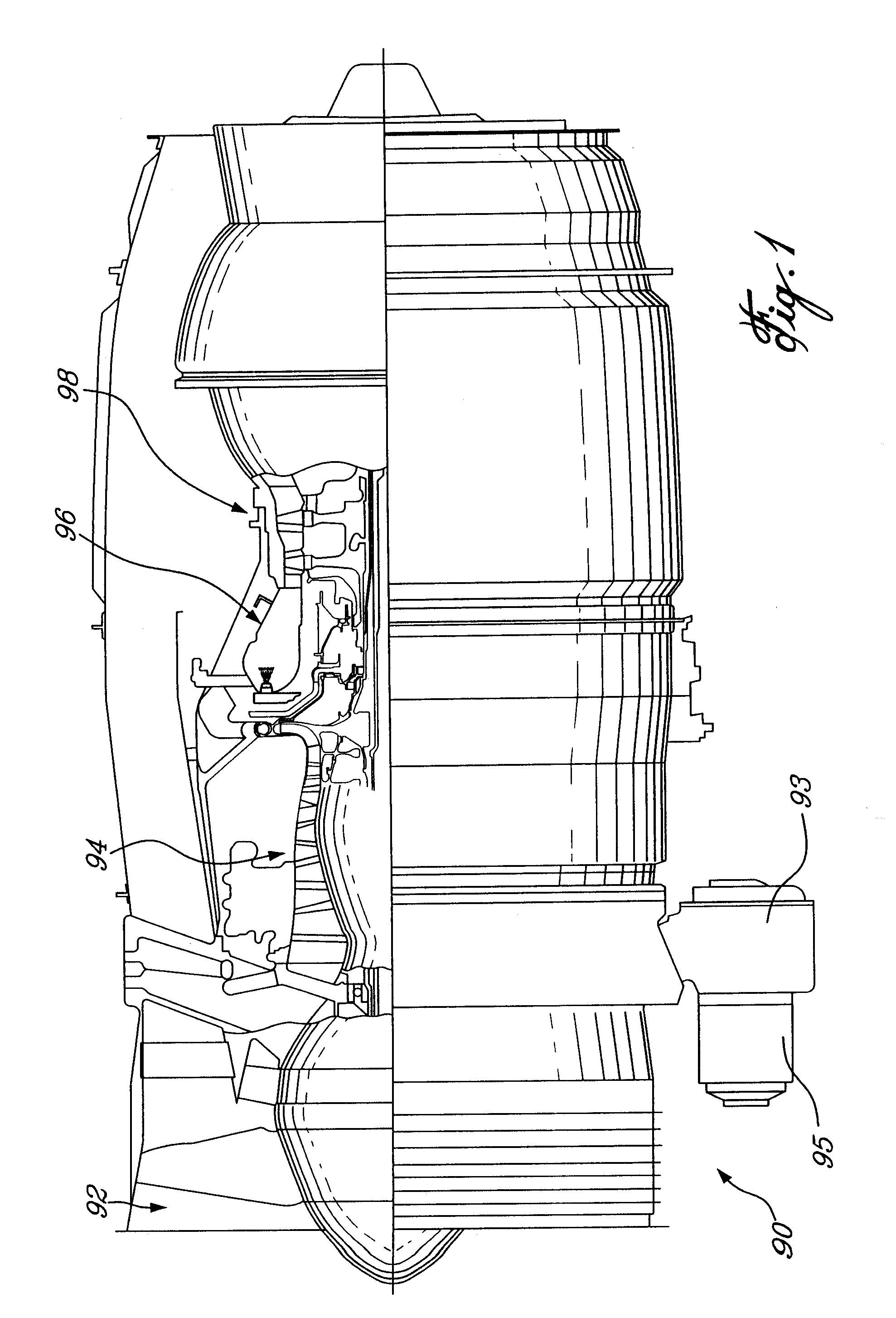

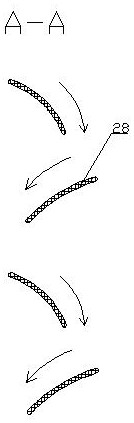

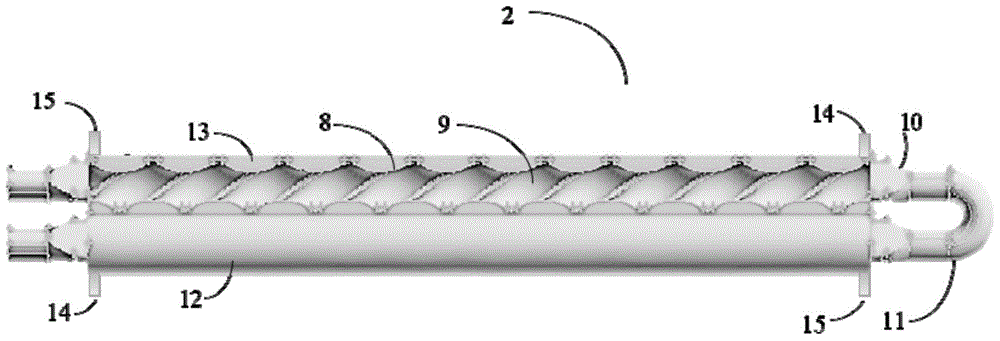

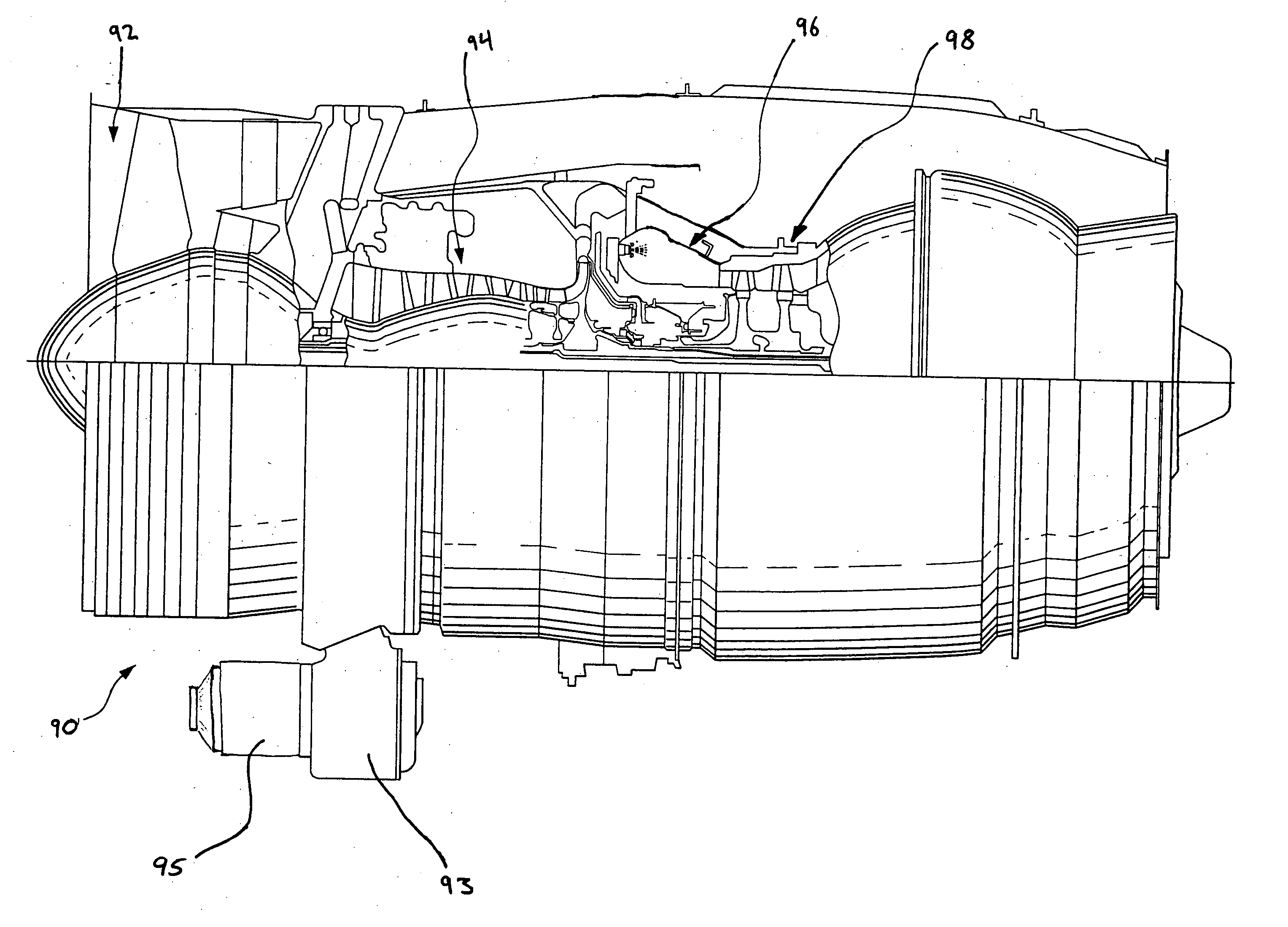

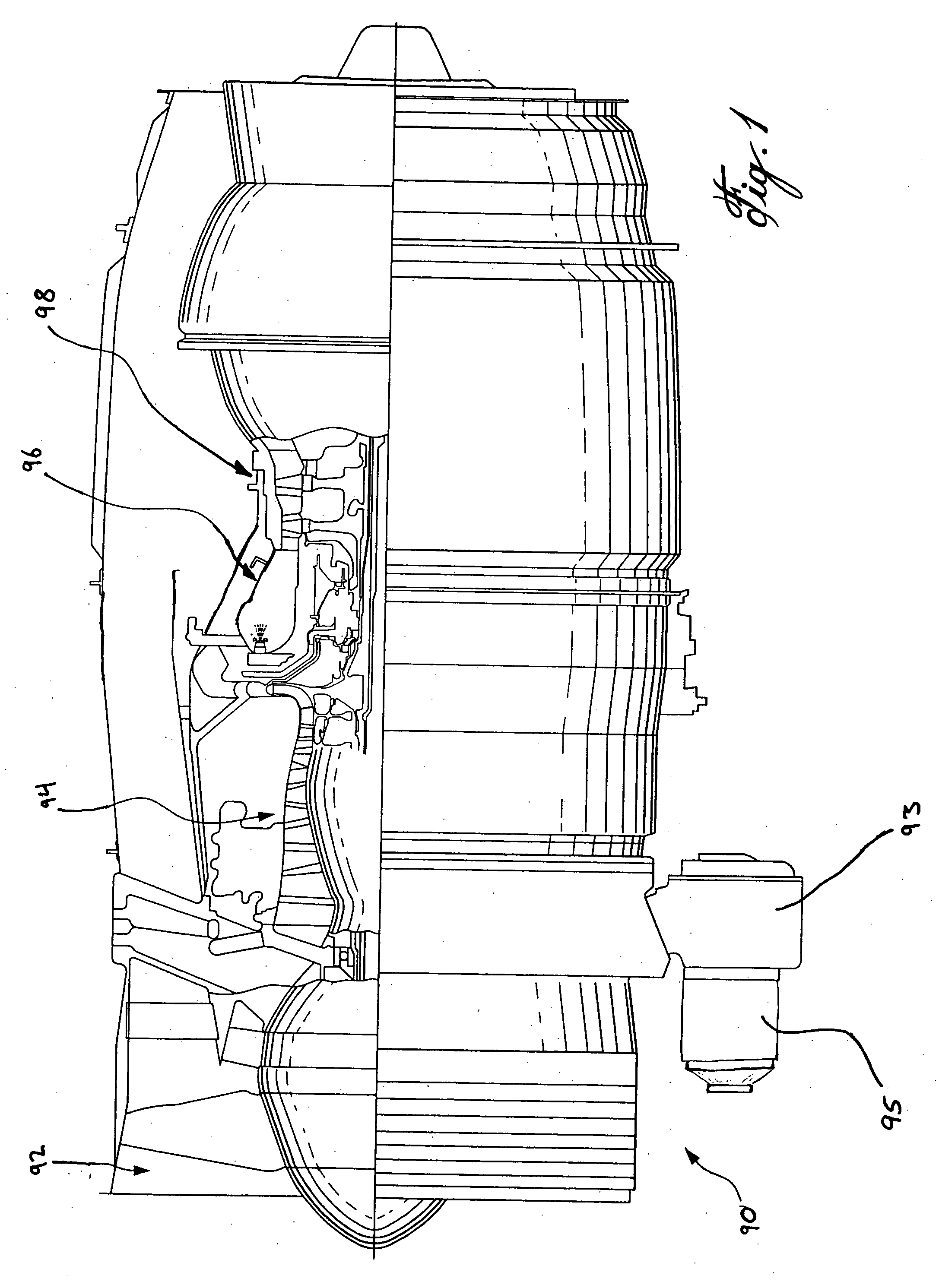

System, method, and apparatus for pulsed-jet-enhanced heat exchanger

ActiveUS8408281B2Improve convective heat transfer efficiencyIncrease pressurePower plant cooling arrangmentsAir-treating devicesWorking fluidEngineering

A pulsed-jet active flowfield control actuation system enhances the rate of heat transfer and heat removal in a heat exchanger for better management of thermal loads. The pulsed jet actuators impart an unsteady component of velocity to the working fluid of the heat exchanger. This design increases the convective heat transfer, and avoids increases in heat exchanger volume and weight for a given performance value.

Owner:LOCKHEED MARTIN CORP

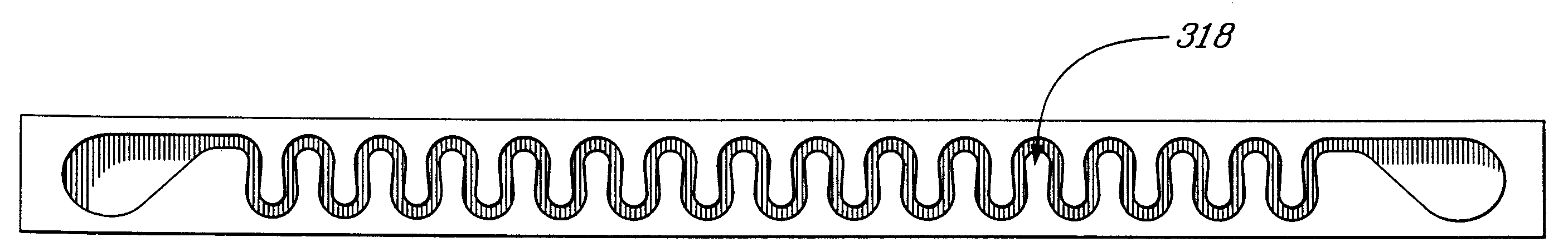

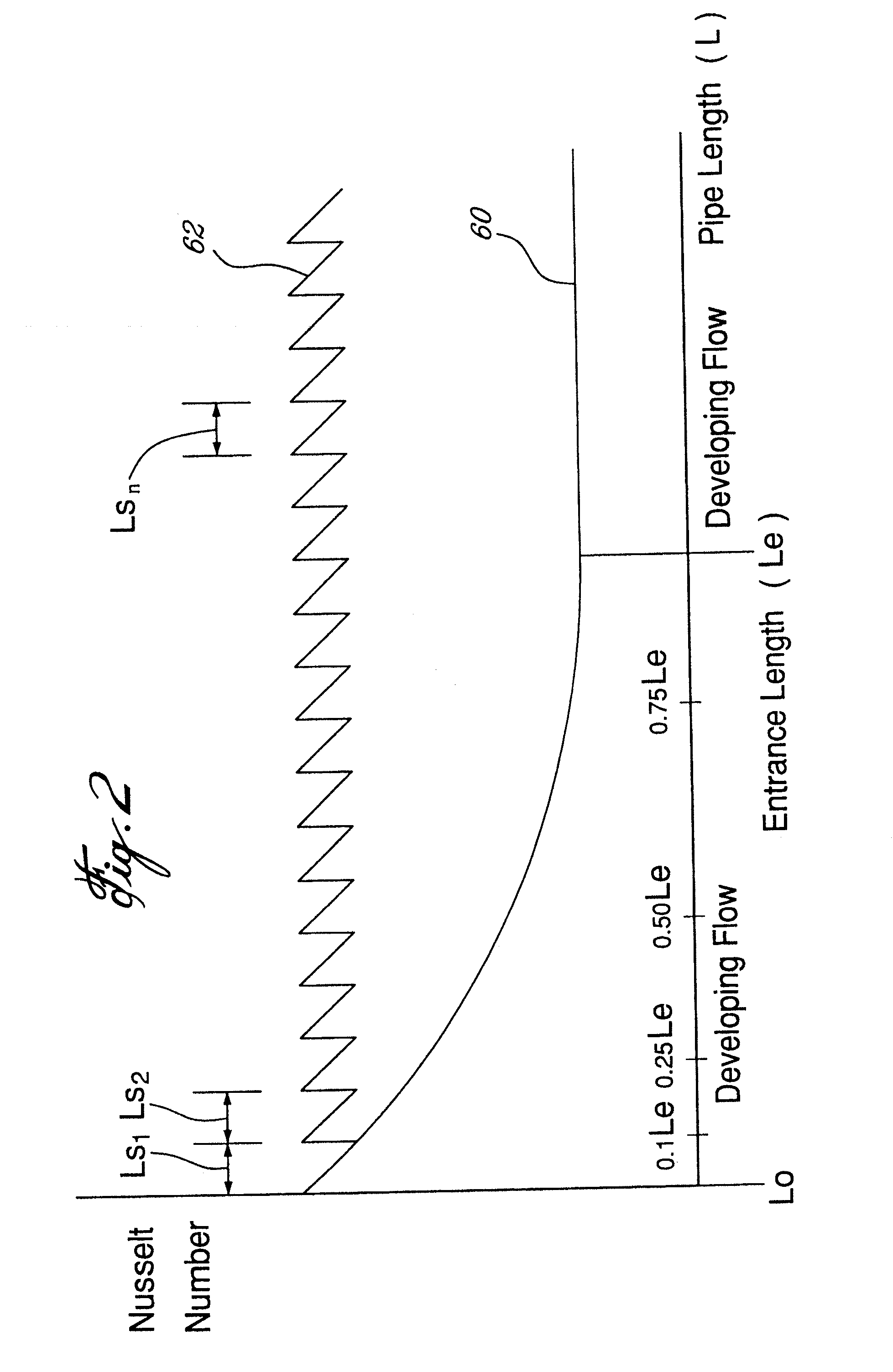

Heat exchange device and method

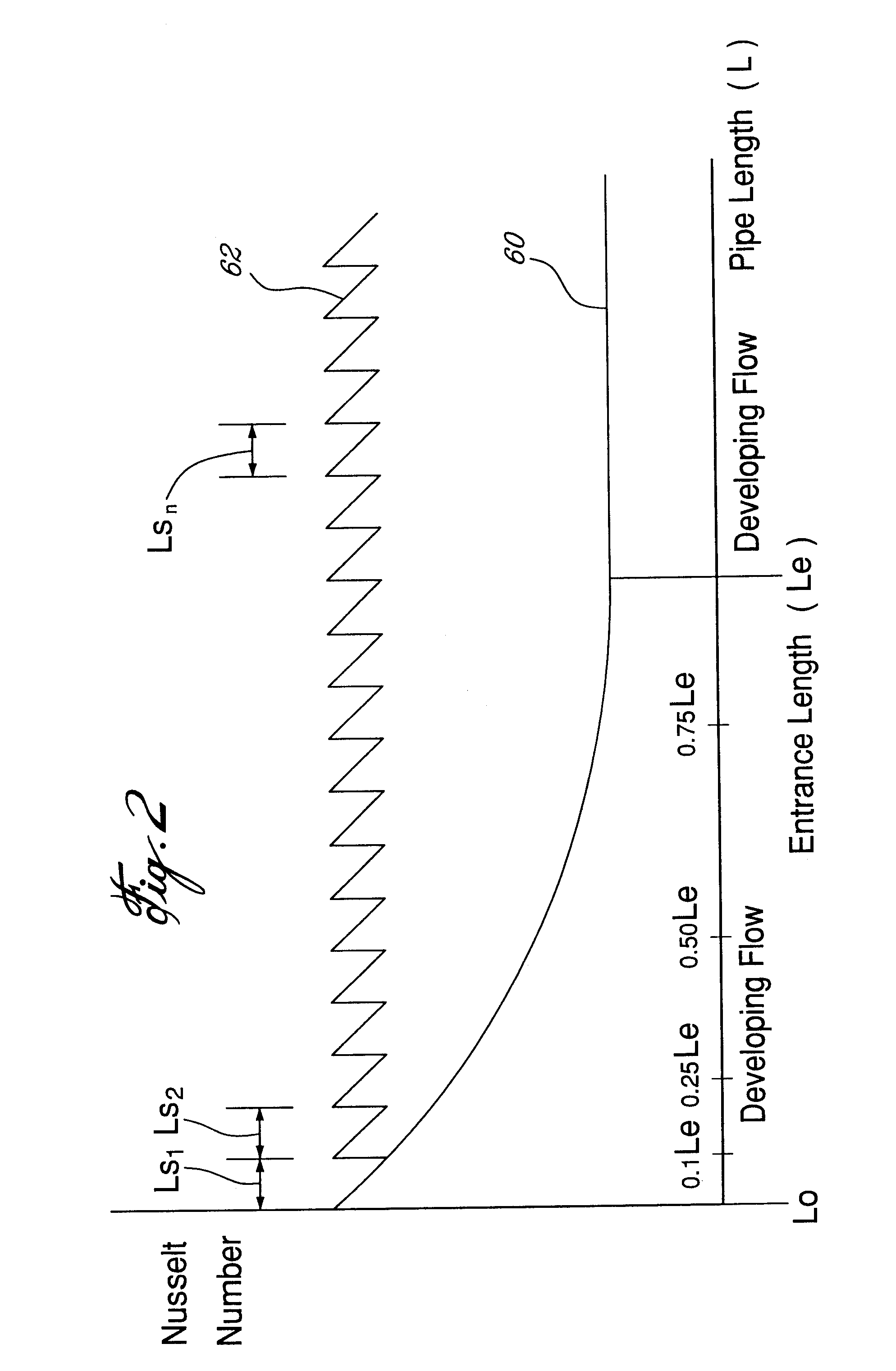

InactiveUS20090255652A1Improve convective heat transfer efficiencyImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat transfer

Owner:PRATT & WHITNEY CANADA CORP

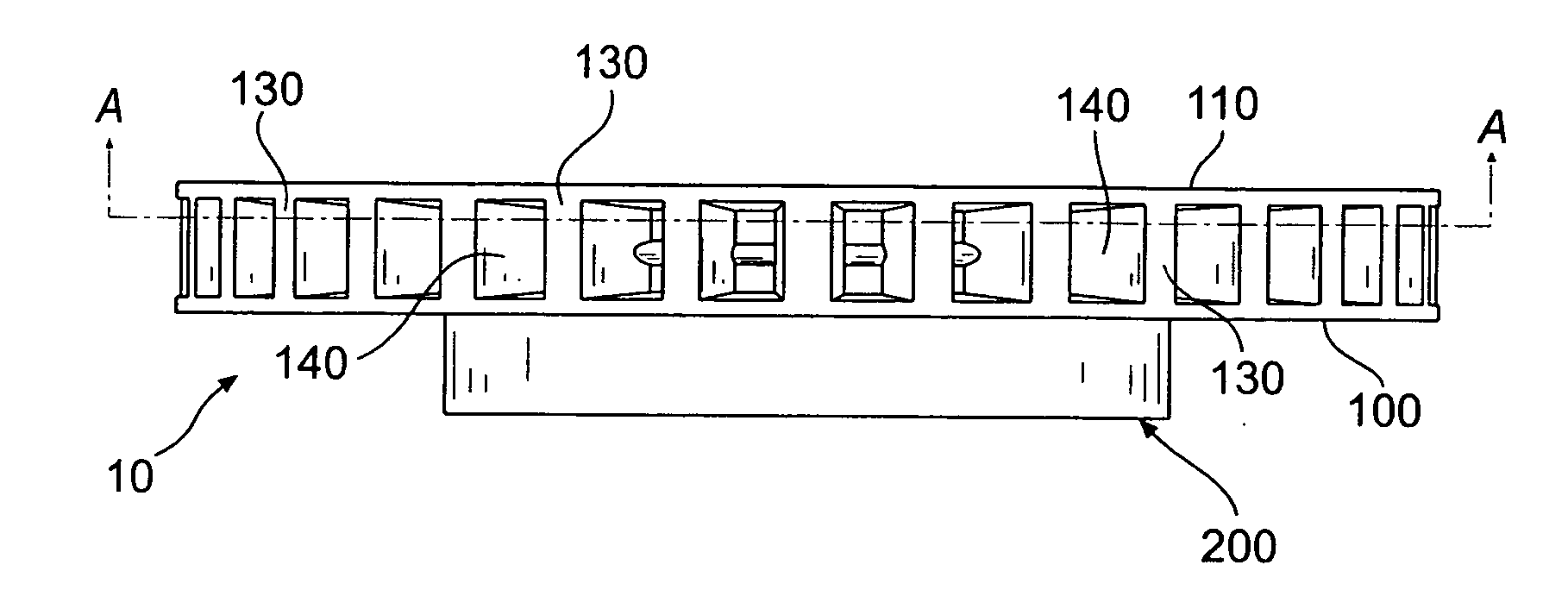

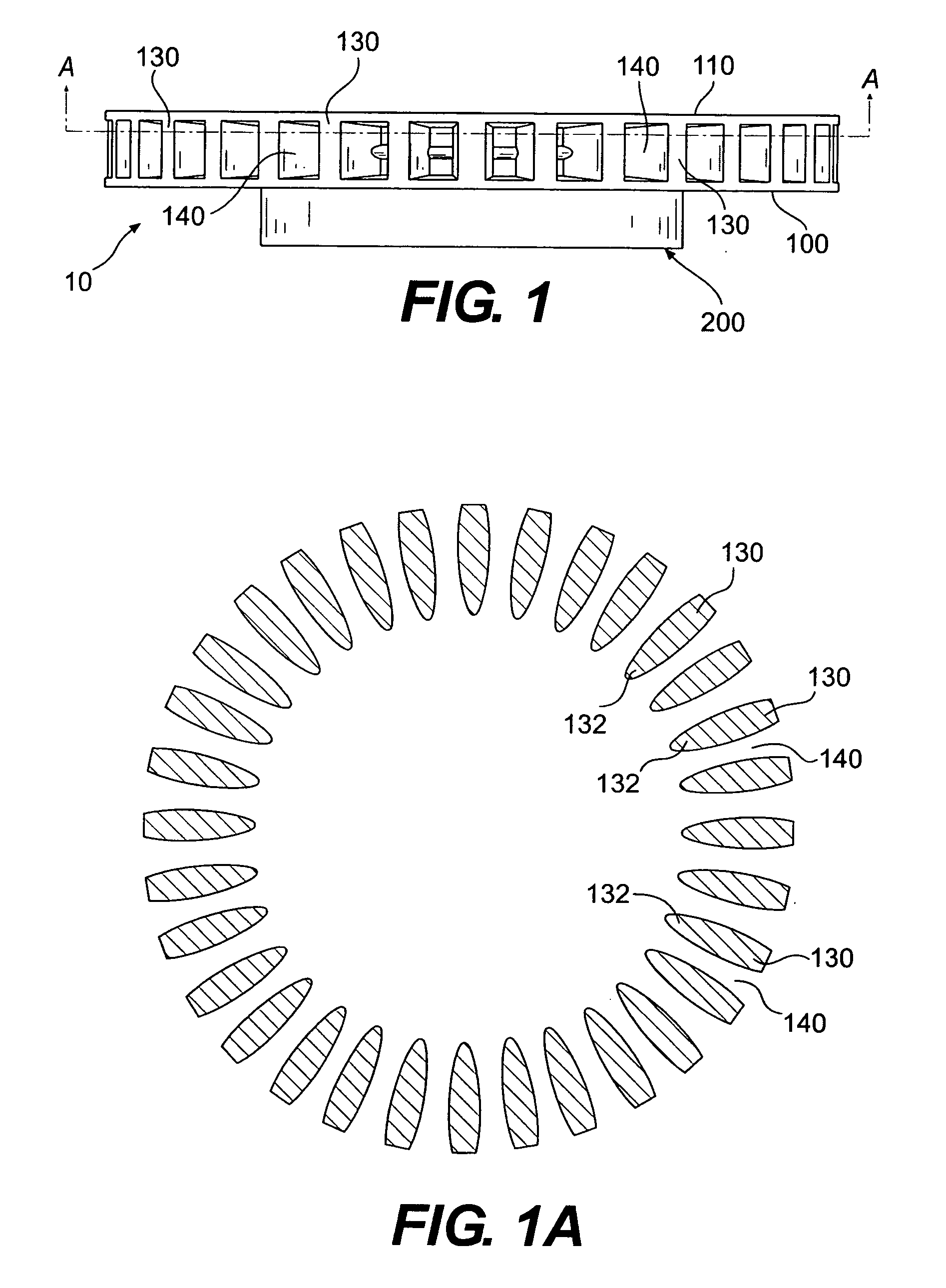

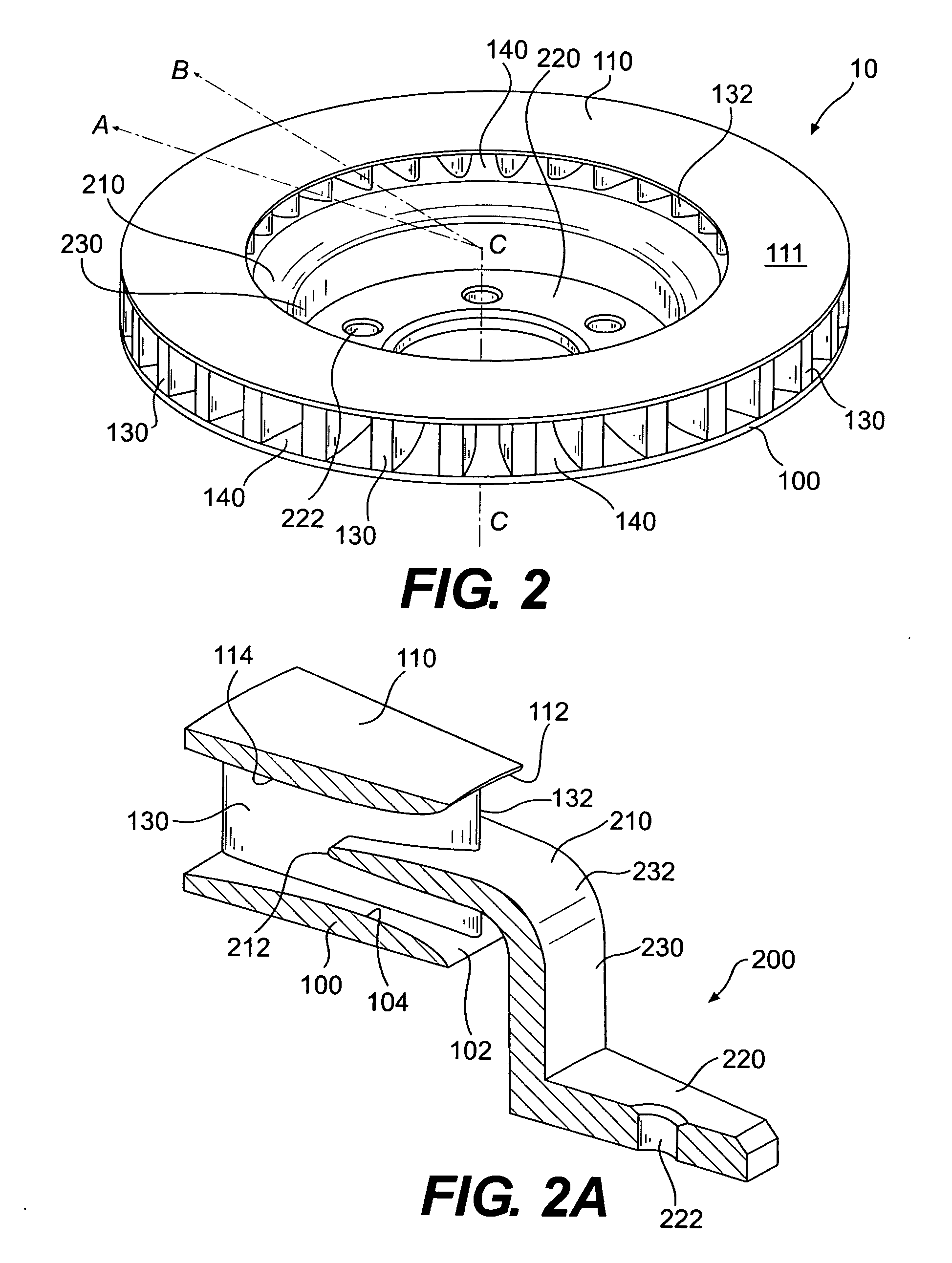

Aerodynamic vented rotor

InactiveUS20070261929A1Minimize thermal distortionUneven heat distributionBraking drumsBraking discsEngineeringAerodynamics

An aerodynamic vented rotor comprises an outboard disc, an inboard disc spaced from the outboard disc, and fins extending between the outboard disc and the inboard disc and defining vents therebetween. The fins have an airfoil-shaped cross section with a leading edge facing radially inwardly on the rotor. The fins constitute an inner core, and a hat section extends from the inner core of the rotor.

Owner:FORD GLOBAL TECH LLC

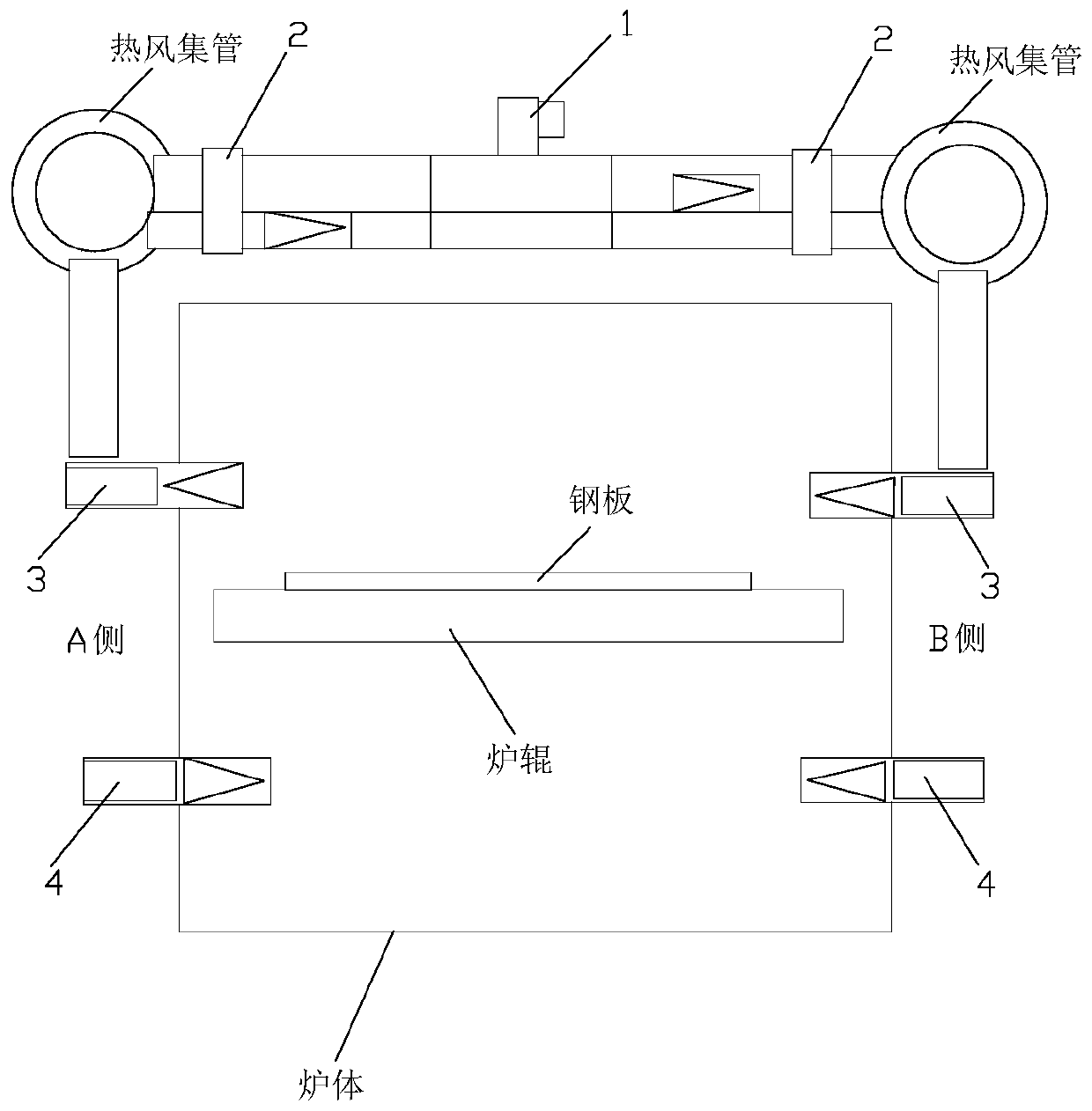

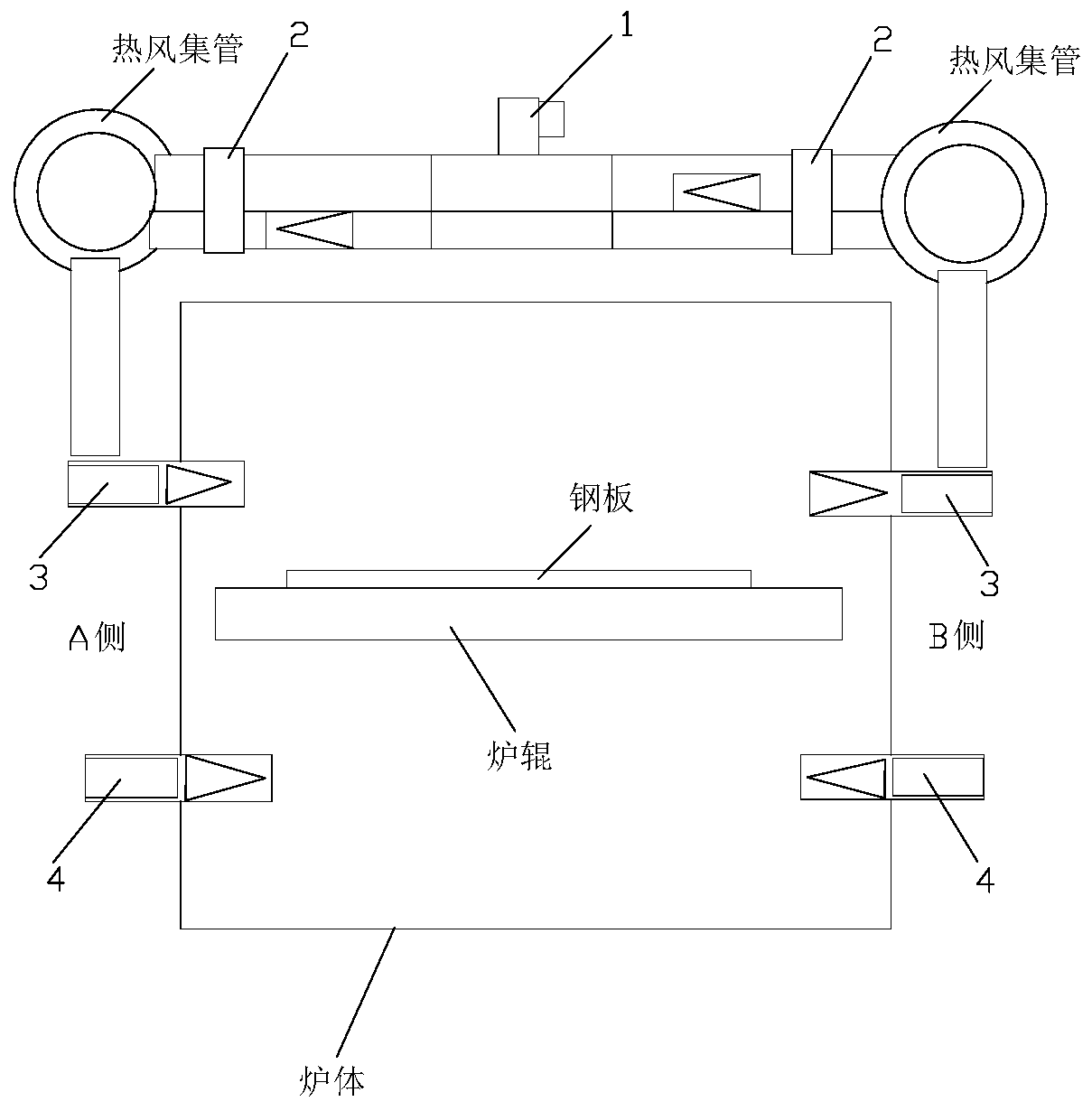

Flue gas circulation type steel plate medium and low-temperature tempering furnace and low-temperature control method

PendingCN109929970AReduce high temperature performance requirementsLess investmentFurnace typesHeat treatment process controlSteel platesHeat transfer efficiency

The invention provides a flue gas circulation type steel plate medium and low-temperature tempering furnace and a low-temperature control method. The tempering furnace integrates burner flame jet heating and circulating flue gas jet heating. The temperature of flue gas supplied to hot air jet nozzles is controllable. The hot air jet nozzles are used for replacing burners to implement flame jet. The jet frequency can be 4-5 times higher than that of the burners. Furnace gas is stirred more violently. Local overheating of steel plates is avoided, and the furnace temperature homogeneity is realized. Meanwhile, the hot air jet nozzles spray the flue gas at the fixed temperature to conduct high-frequency impulse jet impinging on the steel plates, and the convection heat exchange efficiency is improved. Through the flue gas circulation type steel plate medium and low-temperature tempering furnace and the low-temperature control method, high-precision uniform heating of the large-temperature-span heat treatment furnace can be realized, the low-temperature heat transfer efficiency is enhanced, the sides of steel plates are overheated due to the high burner flame temperature during low-temperature heating is avoided, cyclic utilization of flue gas is promoted, emission of the flue gas is reduced, and the effects of energy conservation and emission reduction are achieved.

Owner:NORTHEASTERN UNIV +1

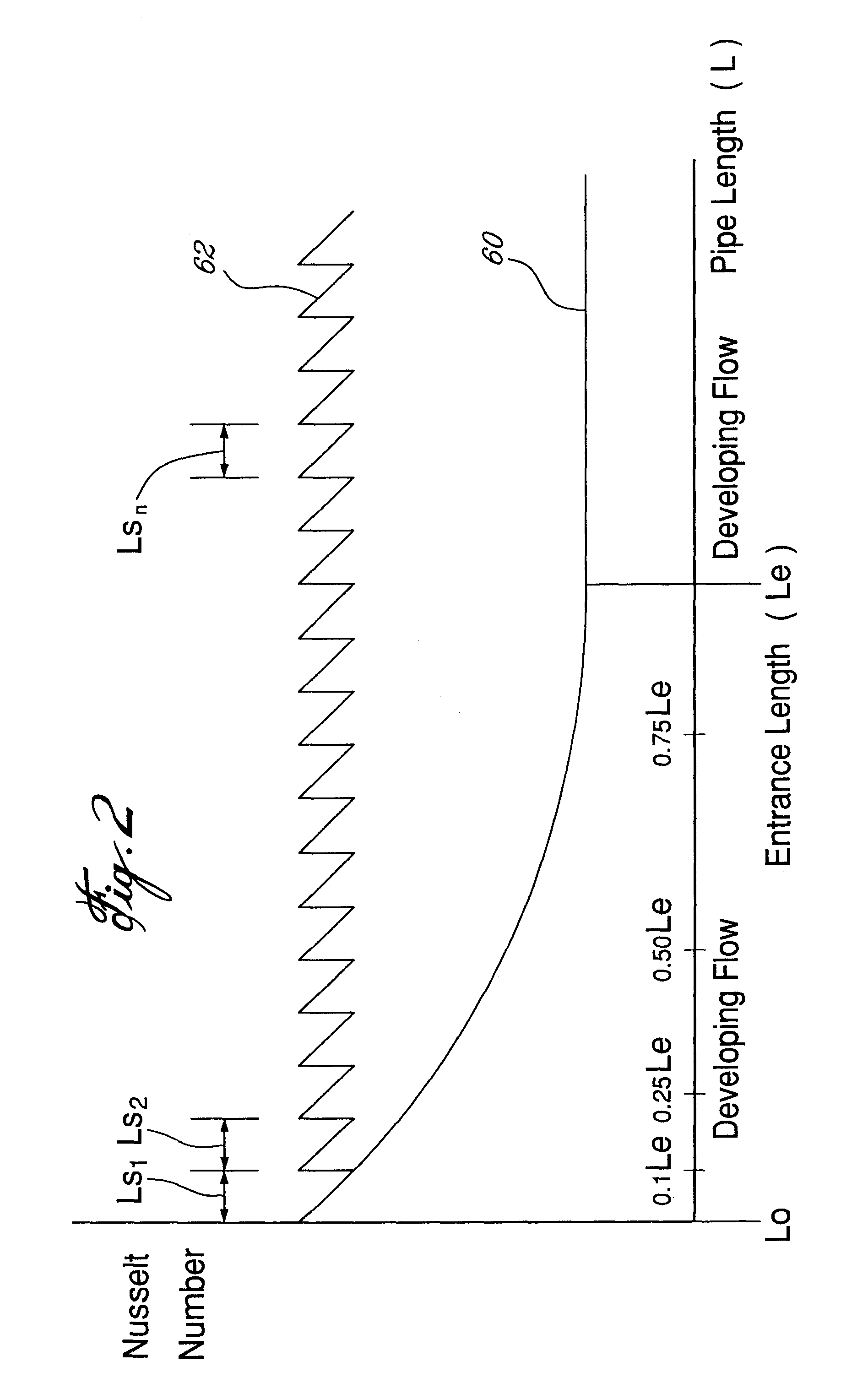

Heat exchange device and method

InactiveUS20140238642A1Improve convective heat transfer efficiencyImprove heat transfer performanceIndirect heat exchangersHeat exchange apparatusEngineeringHeat transfer

A heat exchange device comprising a fluid flow passage having a plurality of successive segments in fluid flow communication with one another, the segments being adapted to maintain a developing flow therein and thereby improve heat transfer.

Owner:PRATT & WHITNEY CANADA CORP

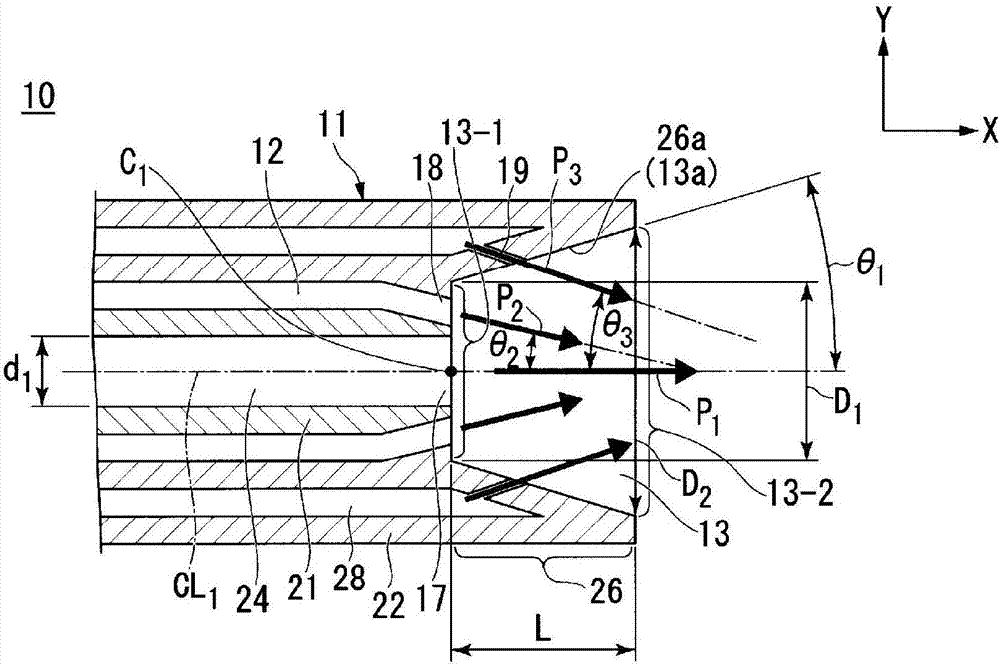

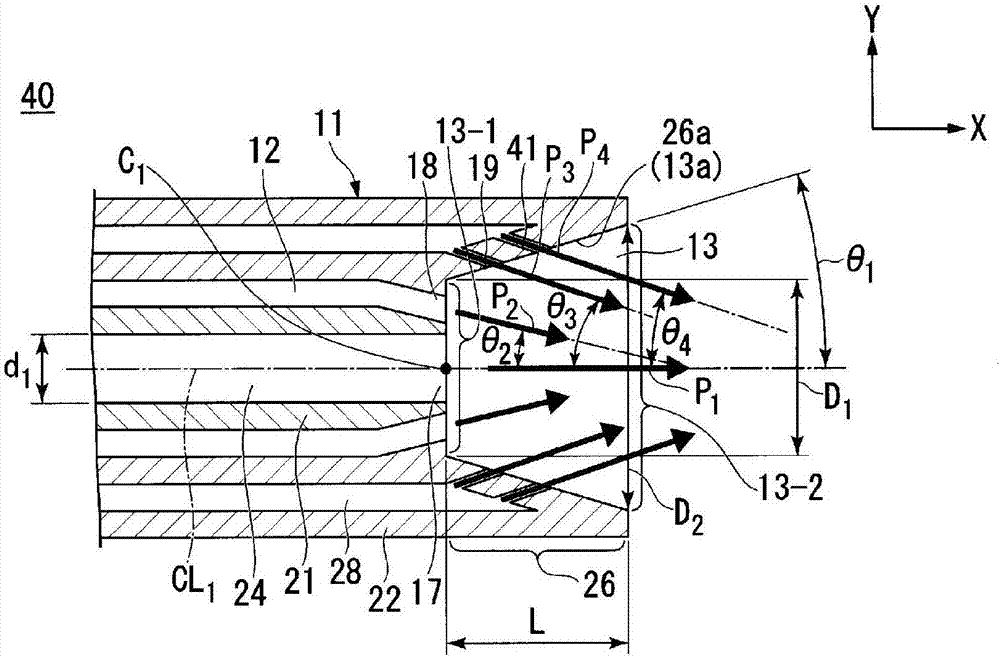

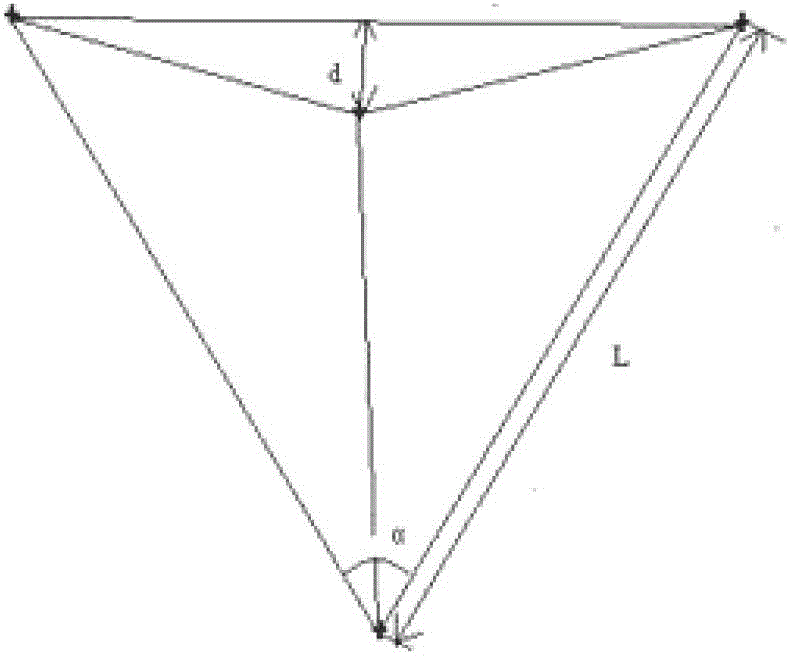

Gas fuel burner and method for heating gas fuel burner

InactiveCN107250669AHigh axial speed and high temperaturePrevent oxidationGaseous fuel burnerCombustorCombustion chamber

The present invention addresses the problem of providing a gas fuel burner and a method for heating the gas fuel burner that allows a high axial flame speed and a high temperature flame without losing combustion efficiency and that can suppress oxidation of the object to be heated and improve convection heat transfer efficiency. This gas fuel burner 10 comprises: a first oxidation agent ejecting port 17 that is disposed in the center C1 of a first circular face 13-1 constituting a combustion chamber 13 having a truncated cone shape that expands from the basal end toward the distal end of a burner body 11 and that ejects a first oxidation agent in the direction that the center axis CL1 of the burner body extends; a gas fuel ejecting port 18 that is disposed on the outside of the first oxidation agent ejecting port 17 and that ejects gas fuel in a direction intersecting the direction that the center axis CL1 extends; and a second oxidation agent ejecting port 19 that is disposed on a side face 13a of the combustion chamber 13 and that ejects a second oxidation agent in a direction intersecting the direction that the center axis CL1 extends.

Owner:NIPPON SANSO CORP

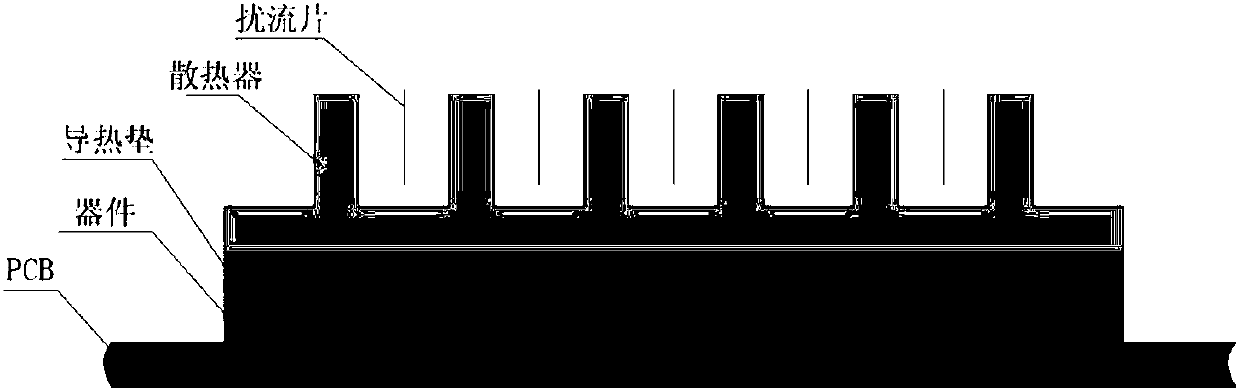

Self-oscillating enhanced heat exchange device and method

InactiveCN108024477AImprove heat transfer efficiencyReduce volumeModifications by conduction heat transferSelf-oscillationEngineering

The invention, which belongs to the technical field of cooling of electronic equipment, relates to a self-oscillating enhanced heat exchange device and method. With oscillation of a spoiler, a staticlayer staying at the surface of a cooling device is eliminated, so that the thermal resistance of the air and the surface of the cooling device is reduced and thus the heat exchange performance of thecooling device is enhanced. The heat exchange device having a simple structure is easy to process and manufacture; no extra power is needed. With air flowing, the spoiler generates self oscillation;when the fluid boundary layer is damaged, the heat convection efficiency is improves substantially, so that the cooling performance of the air cooling device is improved. Moreover, the size and weightof the cooling device are not increased basically.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

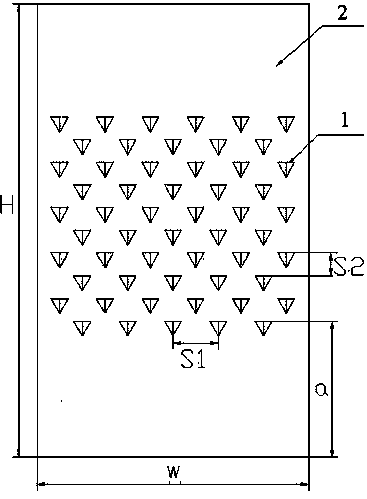

Oil-immersed transformer cooling fin

InactiveCN104019690ASimple processImprove work performanceTransformers/inductances coolingHeat transfer modificationTransformerHeat sink

The invention discloses an oil-immersed transformer cooling fin. A series of three-dimensional protruding turbulence structures are arranged on the air side of the oil-immersed transformer cooling fin through machining modes such as stamping and embossing, the turbulence structures can be in shapes of a pyramid, a semi-conical table body, a semi-bullhead protrusion and the like, a longitudinal vortex generator is formed, the longitudinal vortex generated by the three-dimensional protruding turbulence structures destroy the flowing boundary layer generated when air flows through the cooling fin, and therefore heat convection between the cooling fin and air is enhanced. The oil-immersed transformer cooling fin is simple in structure, low in cost, and capable of improving the heat convection efficiency to a certain degree.

Owner:SHANDONG JIANZHU UNIV

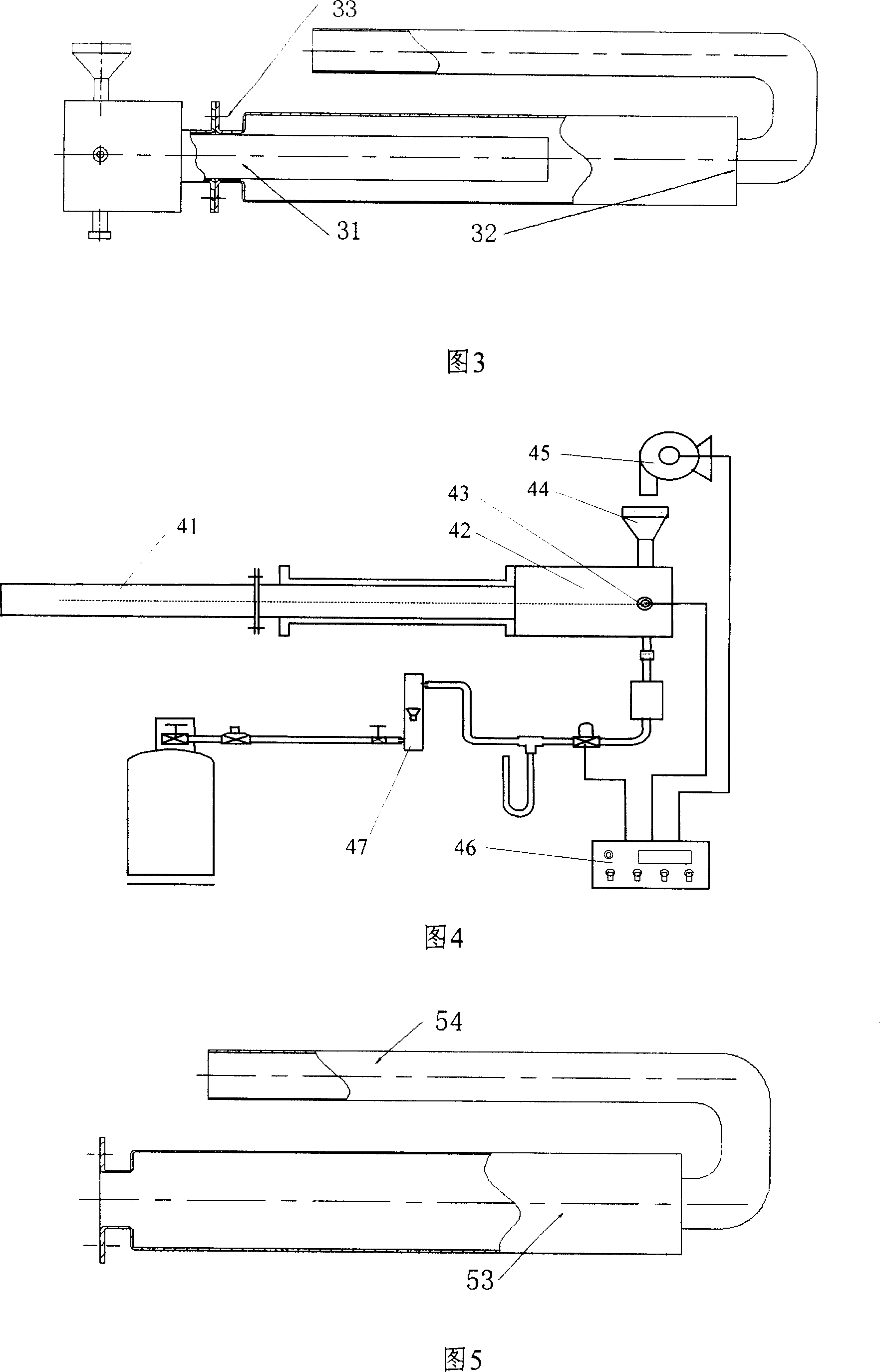

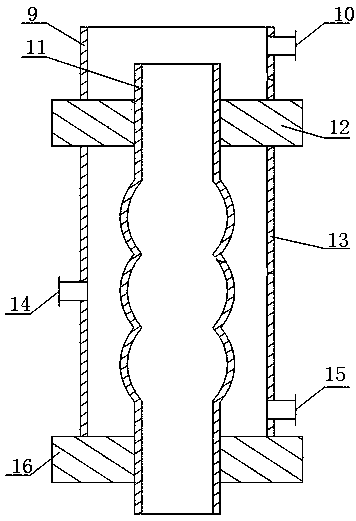

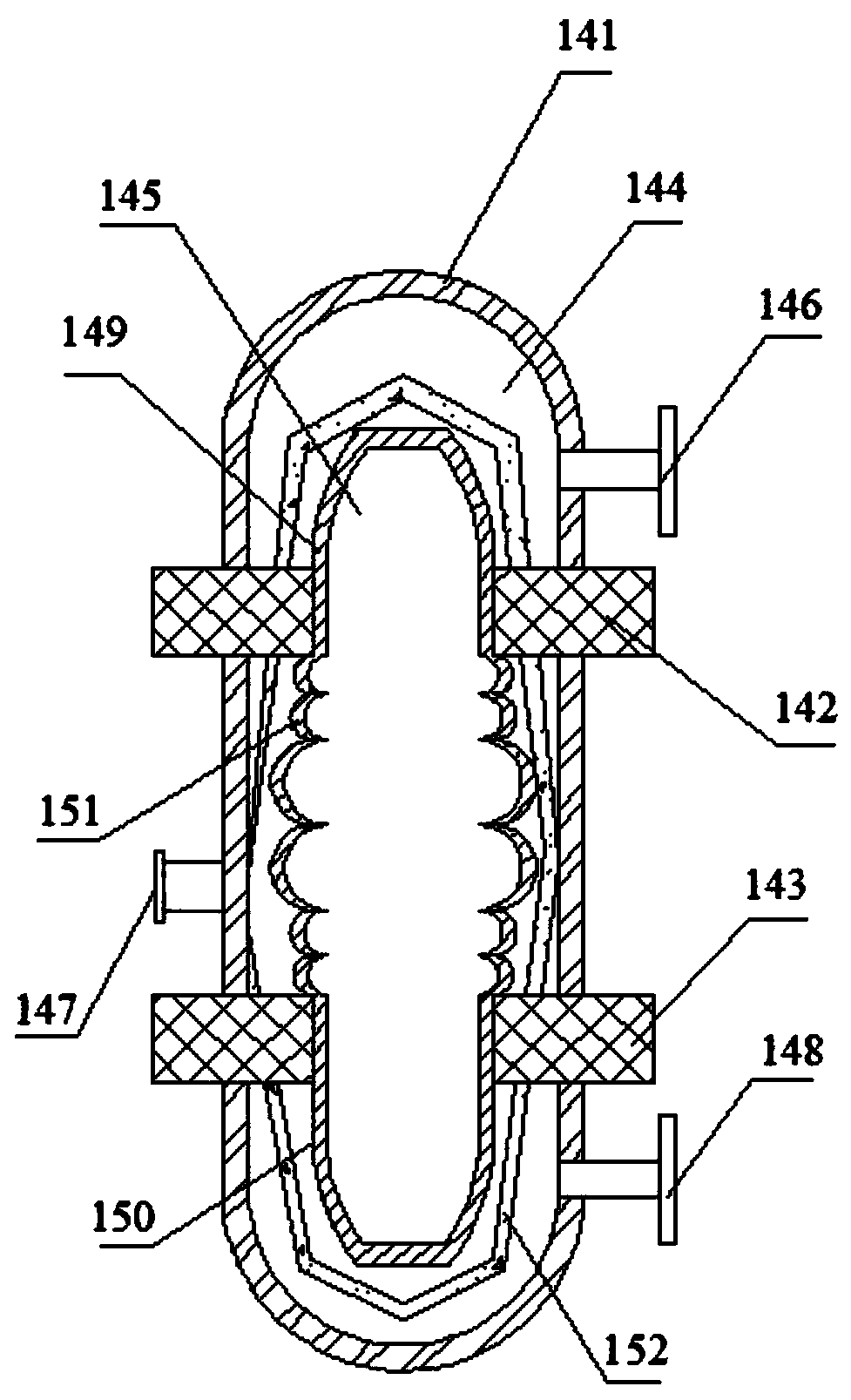

Spiral falling-film evaporator

PendingCN107823903AImprove evaporation and concentration efficiencyImprove convective heat transfer efficiencyEvaporationChemical industryEngineering

The invention provides a spiral falling-film evaporator, and belongs to the field of chemical industry production. The spiral falling-film evaporator comprises an upper barrel, an evaporated stock solution inlet, a spiral falling-film tube, an upper tube plate, a shell, a heating steam inlet, a condensed water outlet and a lower tube plate. The upper end of the upper tube plate is connected with the upper barrel, the evaporated stock solution inlet is formed in the upper end of a side surface of the upper barrel, the lower end of the upper tube plate is connected with the shell, the heating steam inlet is formed in the middle of a side surface of the shell, the condensed water outlet is formed in the bottom of a side surface of the shell, the lower end of the shell is connected with the lower tube plate, the spiral falling-film tube is arranged between the upper tube plate and the lower tube plate, an upper orifice of the spiral falling-film tube extends out of the upper portion of theupper tube plate and is close to the evaporated stock solution inlet, and a lower orifice of the spiral falling-film tube extends out of the lower portion of the lower tube plate. The spiral falling-film evaporator has the advantage that the evaporation concentration efficiency of the spiral falling-film evaporator can be improved.

Owner:江苏迈克化工机械有限公司

Heat exchange device and method

InactiveUS8408282B2Improve convective heat transfer efficiencyImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat transfer

Owner:PRATT & WHITNEY CANADA CORP

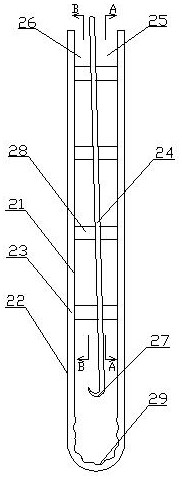

Vacuum tube solar water heater achieving convection heat exchange and control method of vacuum tube solar water heater

InactiveCN111964277AImprove heat transfer efficiencyIncrease temperatureSolar heating energySolar heat collector controllersSolar waterEngineering

The invention relates to a vacuum tube solar water heater achieving convection heat exchange and a control method of the vacuum tube solar water heater. The vacuum tube solar water heater comprises awater box and multiple vacuum tubes communicating with the water box. The water box comprises a box body, a water inlet tube arranged on one side of the box body and a water outlet tube arranged on the other side of the box body, and one end of the water inlet tube is connected with a circulating assembly. Obliquely-arranged flow guide plates are arranged in the vacuum tubes, each vacuum tube is divided by the corresponding flow guide plate into a cold water bin and a hot water bin, the lower end of each flow guide plate smoothly extends towards the corresponding hot water bin to be provided with a flow guide portion, multiple fins are arranged between the side end of each flow guide plate and the inner wall of a metal inner tube and are distributed from top to bottom, openings of the finsin the hot water bins are arranged by facing the open ends of the vacuum tubes, and spiral faces are arranged at the bottoms of the inner walls of the metal inner tubes. The vacuum tube solar water heater has the following advantages that the vacuum tubes of special structures are adopted, rotational flow is formed when water passes through the vacuum tubes to achieve heat transfer, the contact faces with the vacuum tubes are improved, the heat transfer efficiency of the vacuum tubes is improved, and through additional mounting of the circulating assembly, the convection heat exchange efficiency in the water box is improved.

Owner:JIANGSU YUPU SOLAR ENERGY

Double-pipe heat interchanger suitable for sewage with high solid content

InactiveCN106288873ANot easy to foulAvoid easy cloggingCorrosion preventionStationary tubular conduit assembliesSewageEngineering

The invention discloses a double-pipe heat interchanger suitable for sewage with the high solid content. The double-pipe heat interchanger comprises an inner casing pipe used as a sewage channel, and an outer casing pipe providing a heat exchange medium channel. The inner casing pipe is located in the outer casing pipe. The section of the inner casing pipe is triangular, and the inner casing pipe is a triangular twisted pipe formed by spiraling and deforming the pipe wall in the pipe center axial direction. The double-pipe heat interchanger is suitable for sewage with the high solid content, dirt impurities in the sewage are not prone to scaling on the four walls of the sewage channel or blockage, and the heat exchange efficiency and continuous and stable operation of the heat interchanger are ensured; and the pipe pass and shell pass convective heat transfer efficiency of the heat interchanger is quite high, so that the heat interchanger has high heat transfer enhancement performance, and the power consumption of a process pump is small.

Owner:NANJING UNIV OF TECH

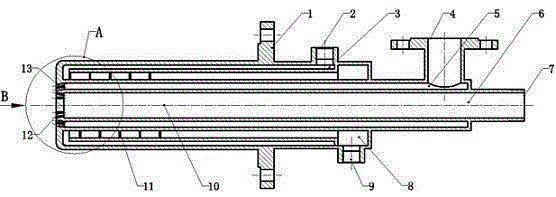

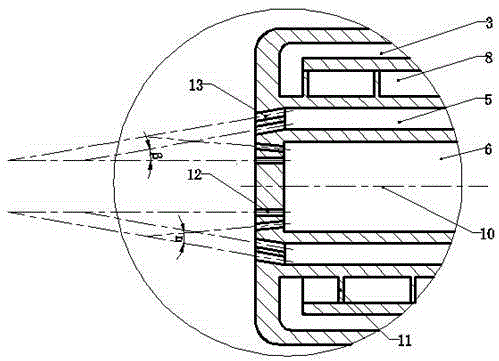

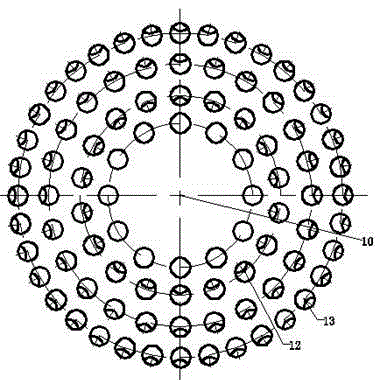

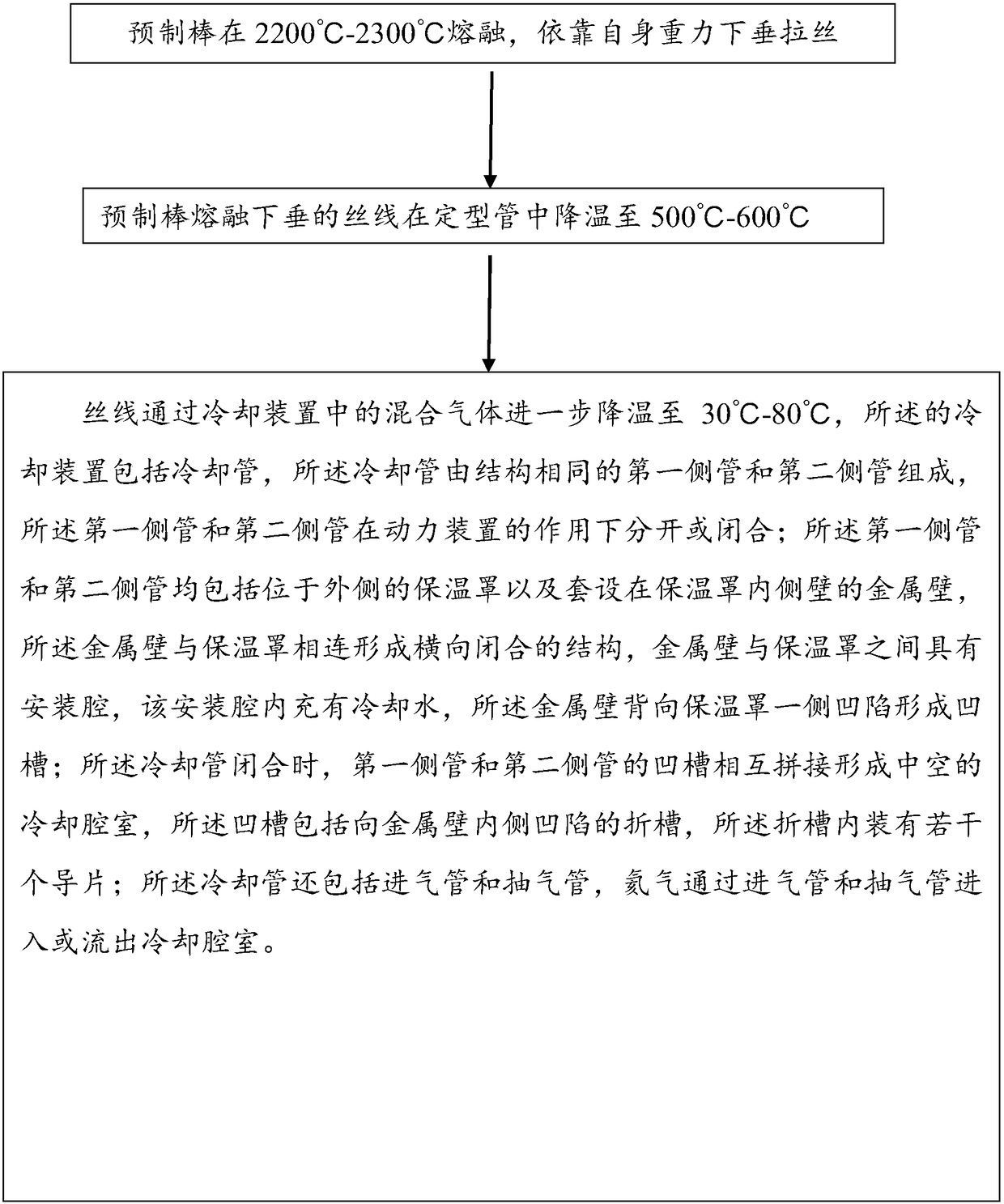

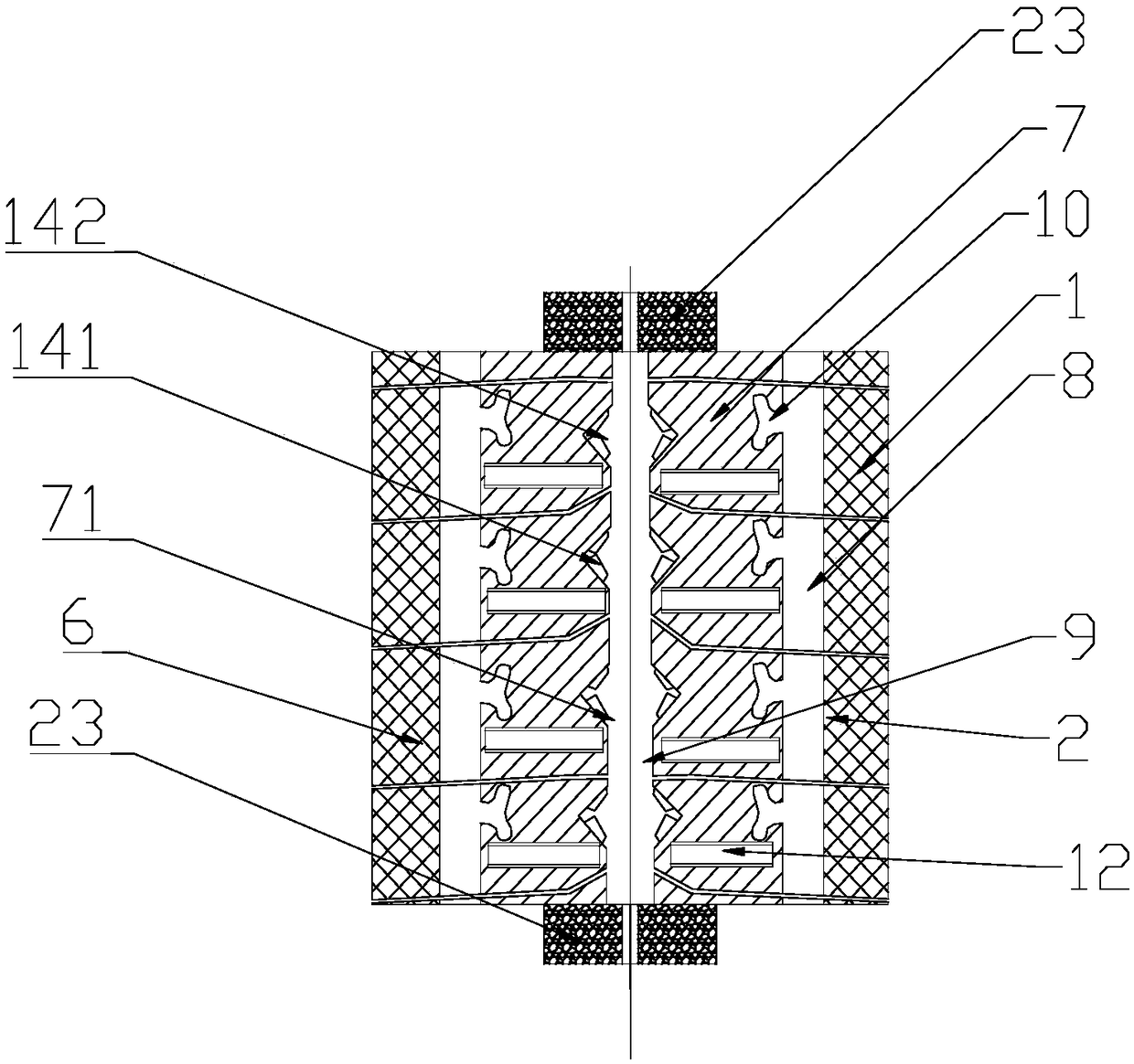

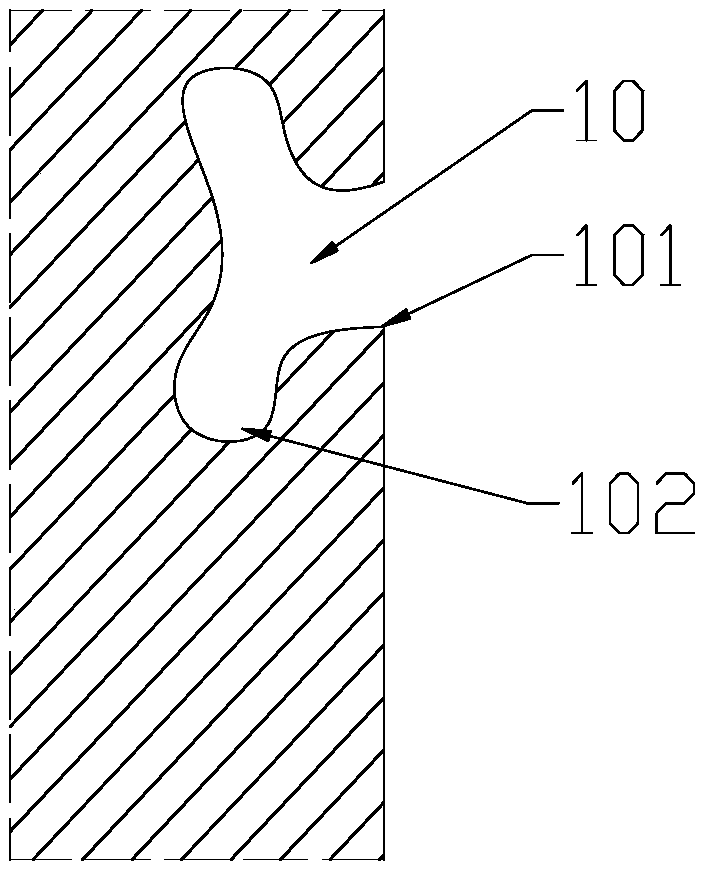

Optical fiber drawing technology

ActiveCN105884187AImprove cooling effectIncrease the Reynolds numberGlass making apparatusCooling effectHelium

The invention discloses an optical fiber drawing technology. The optical fiber drawing technology comprises steps as follows: 1), a melt drawing process: a preform rod is molten at the temperature of 2,200-2,300 DEG C, droops and is drawn by means of own gravity; 2), a shaping cooling process: drooping wires formed after melting of the preform rod are cooled to 500-600 DEG C in a shaping tube; 3), drawn wire cooling process: the wires are further cooled to 30-80 DEG C under the action of helium in a cooling device, and the cooling device in the step 3) comprises a cooling tube, the cooling tube comprises a first side tube and a second side tube with the same structure, a mounting cavity is formed between each metal wall and a corresponding heat insulation cover, and one side, opposite to the heat insulation cover, of the metal wall is recessed to form a groove; the grooves of the pair of side tubes are spliced to form a cooling cavity, each groove comprises a folding slot, and guide vanes are arranged in the folding slot. According to the optical fiber drawing technology, the cooling cavity formed by the grooves, the folding slots, the guide vanes and the like is arranged, turbulence is increased, the thickness of a laminar sublayer formed by downward movement of the optical fiber wires is effectively reduced, and a helium cooling effect is further improved.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

Sewage treatment device for synthesis reaction of phenol and acetone

InactiveCN110228885AHigh recovery rateLow costFatty/oily/floating substances removal devicesWater contaminantsChemistryMulti effect

The invention discloses a sewage treatment device for a synthesis reaction of phenol and acetone. The device is formed through assembly connection of a neutralization kettle, an oil-water separator, asettling tank, a falling-film evaporator, a rectification tower, evaporation crystallization chambers and other equipment through pipelines. Wastewater produced by the rectification tower mainly comprises low-boiling organic matter and a sodium sulfate salt, multi-effect operation is carried out after the wastewater is introduced into the falling-film evaporator so as to achieve sufficient gas-liquid separation, and after the high-boiling sodium sulfate aqueous solution is introduced into a second evaporation crystallization chamber, centrifugal separation and washing are performed on the high-boiling sodium sulfate aqueous solution and sodium sulfate crystal produced in a first evaporation crystallization chamber so as to complete high-purity extraction of sodium sulfate, wherein the recovery rate is high, direct recycling utilization is performed, and the sewage treatment cost is reduced greatly; and the phenol removal rate reaches 99.5% or above after the sewage is treated, the removal rate of acetone, methanol and CODcr reaches 98.5-99.6%, the extraction rate of sodium sulfate reaches 92% or above, and the purity is larger than 95%.

Owner:实友化工(扬州)有限公司

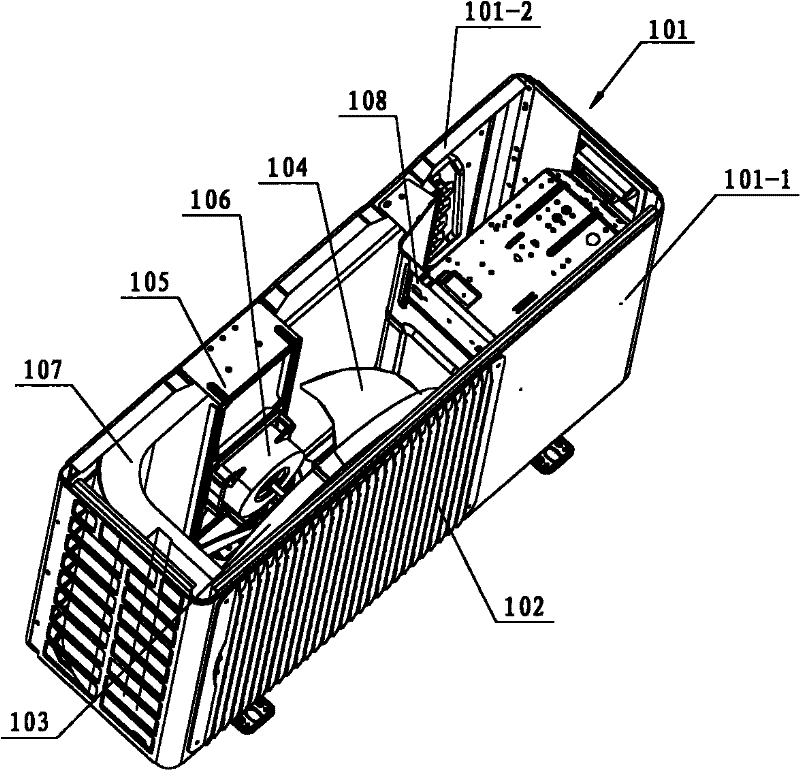

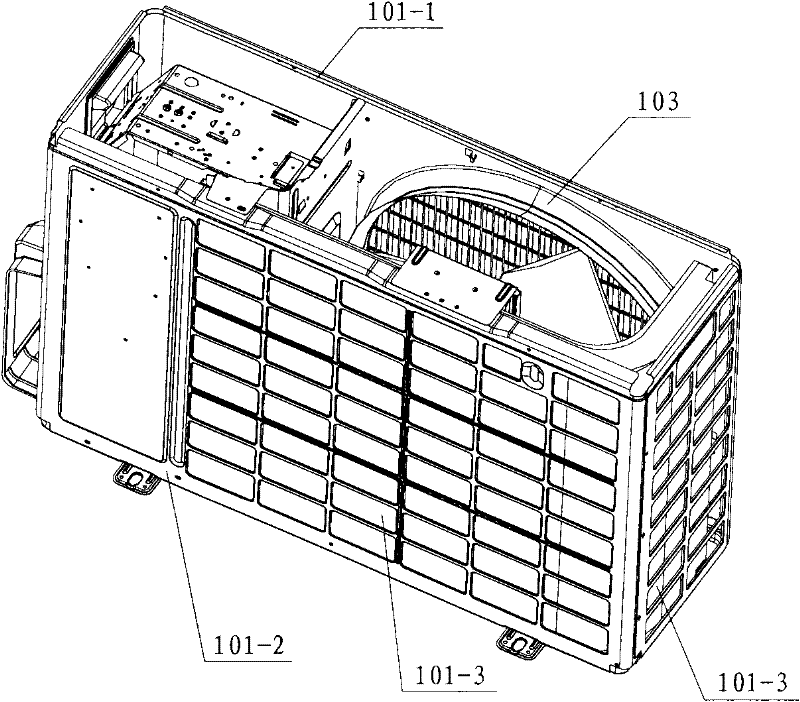

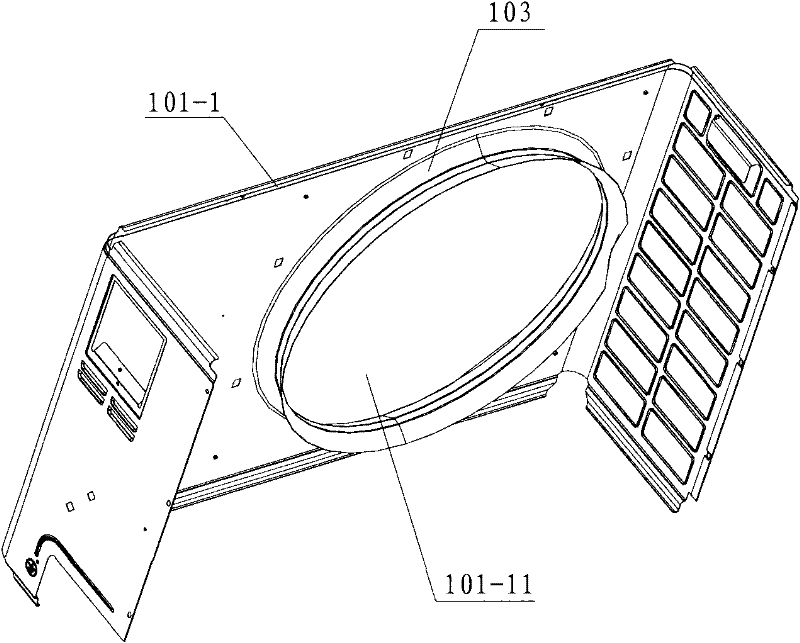

Outdoor unit for air conditioner

ActiveCN102192563AEasy to installImplement bootstrapLighting and heating apparatusAir conditioning systemsMechanical engineeringEngineering

The invention discloses an outdoor unit for an air conditioner. The outdoor unit for the air conditioner comprises a machine shell; a condenser and an axial fan are arranged in the machine shell; a front case opening is formed in a front case of the machine shell corresponding to the axial fan; a rear fan cover is arranged on the condenser, is an opening box and surrounds the condenser from inside to outside; a cover bottom of one side of the rear fan cover close to the axial fan is provided with a rear fan cover opening; a front fan cover is arranged between the rear fan cover opening and a front fan cover opening and is extended from the rear fan cover opening to the front fan cover opening, and an inner cavity is formed; and the axial fan is accommodated in the inner cavity. An air channel for air inlet and outlet is formed by the rear fan cover and the front fan cover to lead air to flow, effectively avoid the turbulence of air and improve the heat exchange efficiency of the outdoor unit, so that the whole performance of the air conditioner is improved.

Owner:QINGDAO HAIER MOLDS

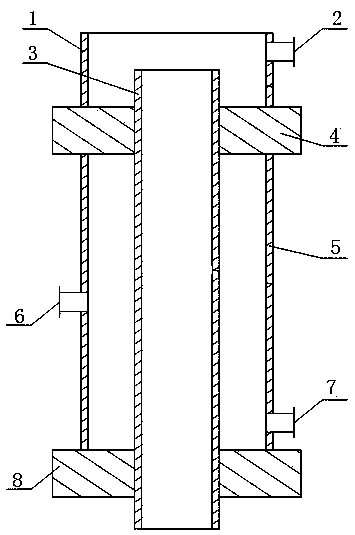

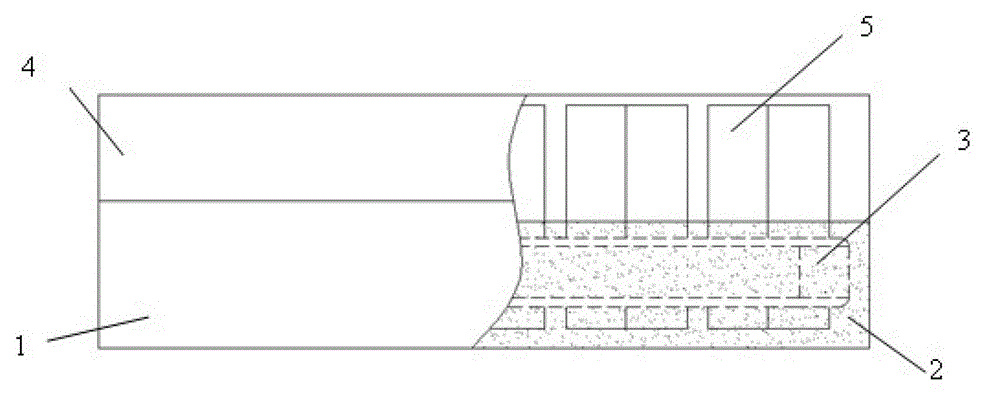

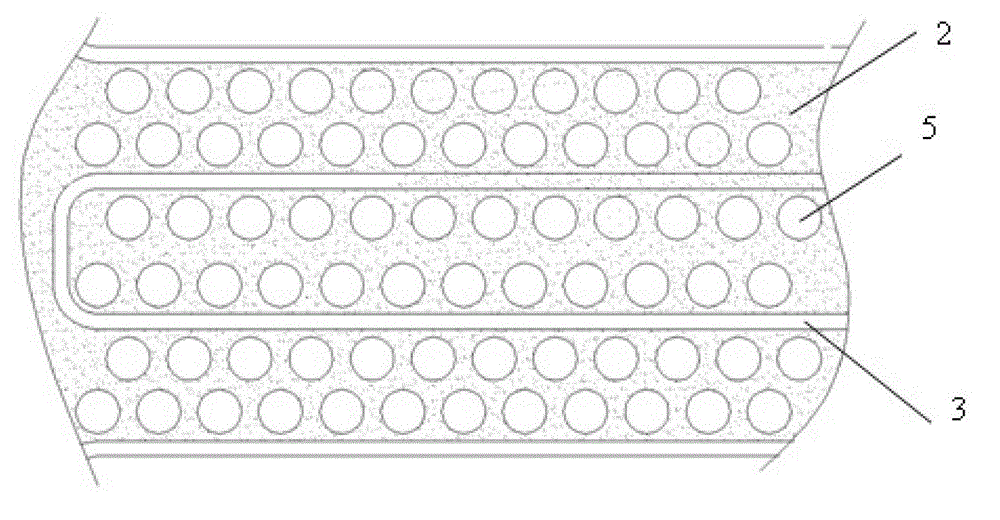

Heat exchange device for lithium ion battery of electric automobile

ActiveCN102983377AAvoid temperature differenceIncrease capacitySecondary cellsCell component detailsEngineeringTemperature difference

The invention discloses a heat exchange device for a lithium ion battery of an electric automobile. The heat exchange device comprises an upper battery bracket (1) and a lower battery bracket (4) fixedly connected with the upper battery bracket (1); a plurality of electric cores (5) are arranged between the upper battery bracket (1) and the lower battery bracket (4); heat exchange pipes (3) are arranged among the electric cores (5); flowing liquid is filled inside the heat exchange pipes (3); and heat conduction glue (2) is filled among the electric cores (5), and between the electric cores (5) and the heat exchange pipes (3). With the adoption of the heat exchange device provided by the invention, a heat exchange effect is improved and the service life of the battery is prolonged; the adjacent pipelines inside the heat exchange pipes are separated by a layer of pipe wall, so that the sufficient heat exchange is realized, and the temperature difference of the both ends of the heat exchange pipes can be avoided; and meanwhile, the sectional area of the pipelines is reduced due to metal partition inside the heat exchange pipes, the flow speed of the liquid is increased and the convection heat exchange efficiency is improved.

Owner:TIANJIN QINGYUAN ELECTRIC VEHICLE

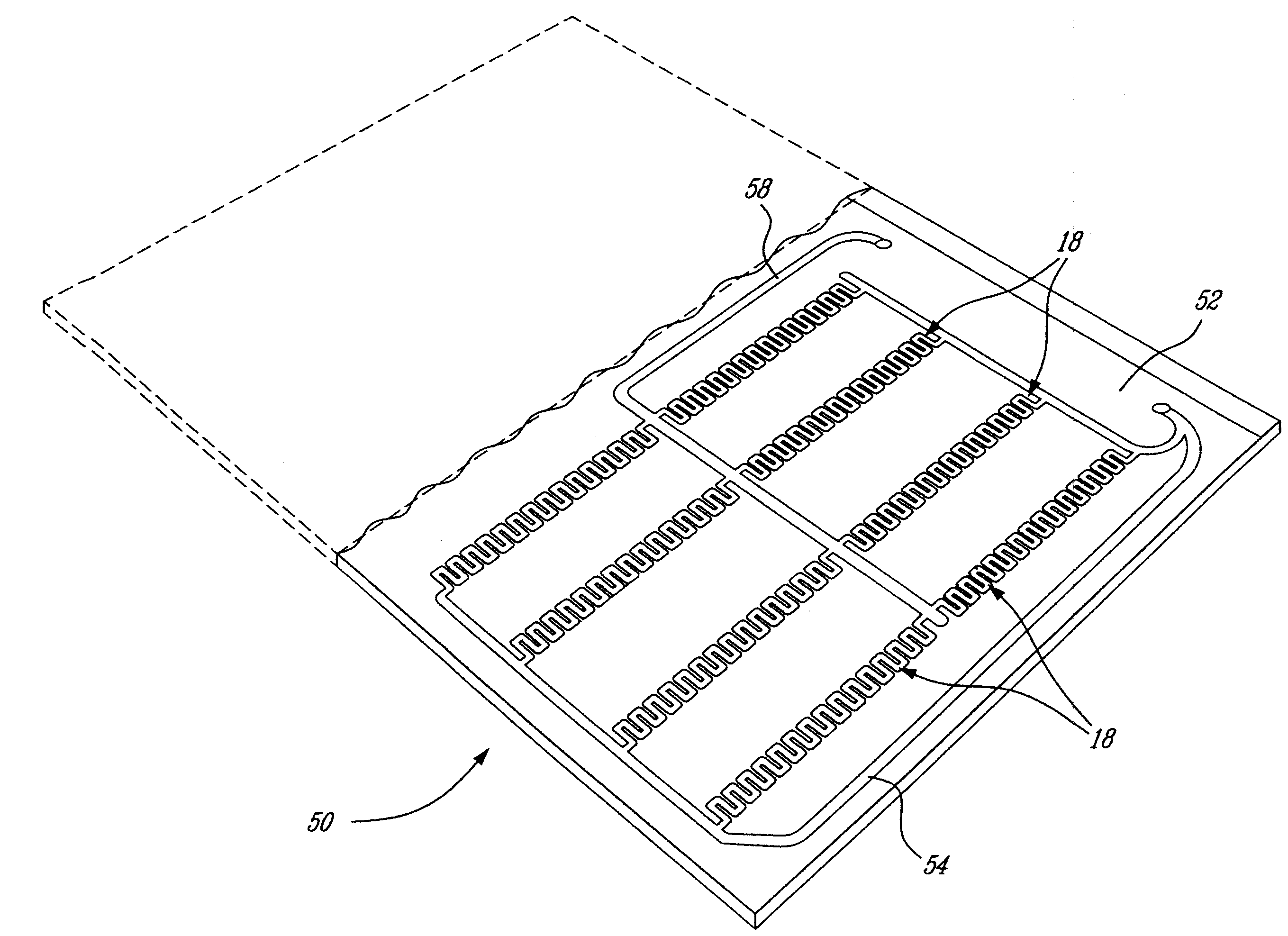

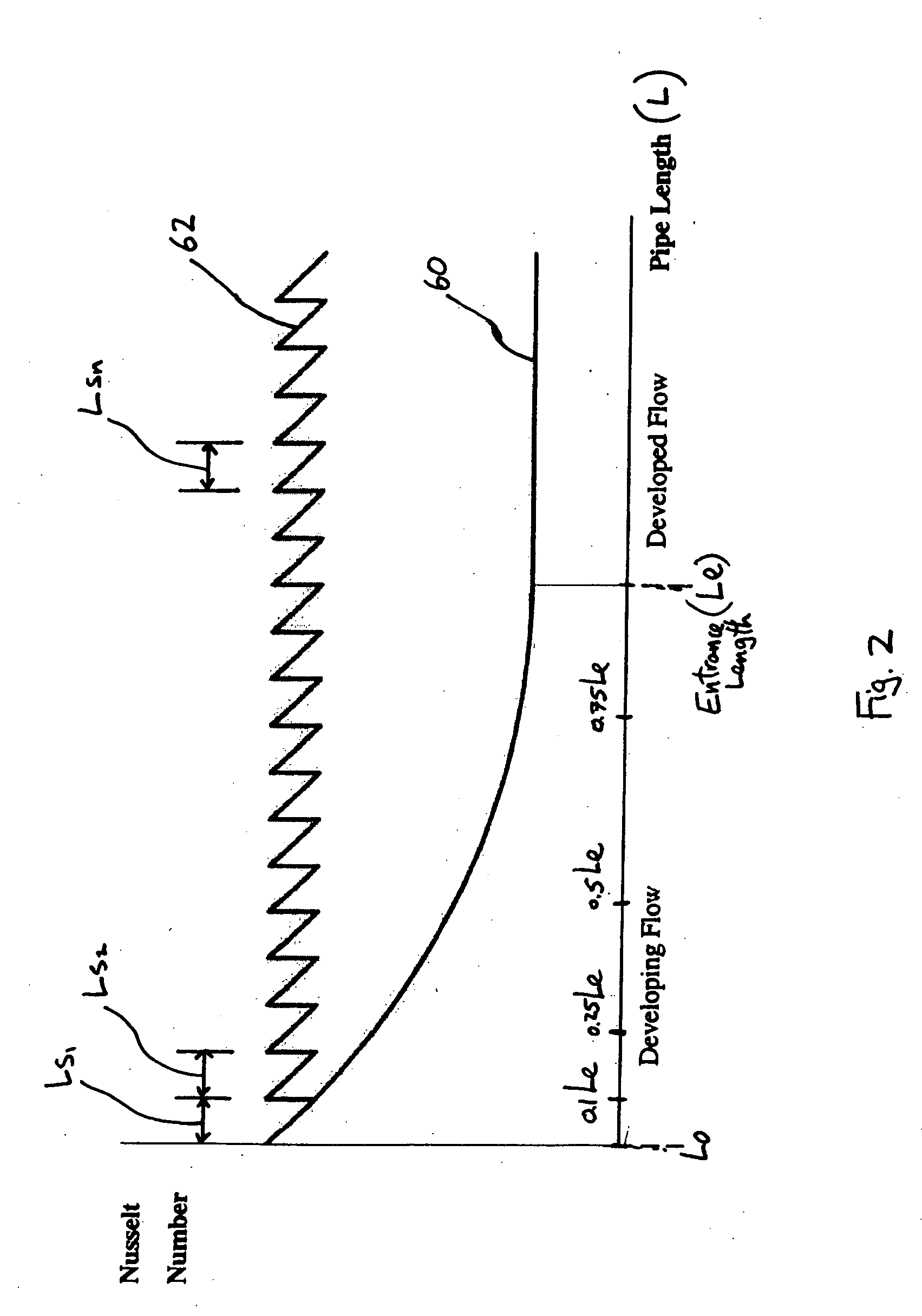

Heat exchange device and method

InactiveUS20050274489A1Improve heat transfer performanceImprove convective heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat transfer

A heat exchange device comprising a fluid flow passage having a plurality of successive segments in fluid flow communication with one another, the segments being adapted to maintain a developing flow therein and thereby improve heat transfer.

Owner:PRATT & WHITNEY CANADA CORP

Optical fiber wiredrawing technology

ActiveCN108383371AImprove cooling effectIncrease the Reynolds numberGlass making apparatusCooling effectCooling chamber

The invention discloses an optical fiber wiredrawing technology. The optical fiber wiredrawing technology comprises the following steps: 1) a melting and wiredrawing procedures: melting a preformed rod at 2200 DEG C to 2300 DEG C, drooping by self gravity and carrying out wiredrawing; 2) a shaping and cooling procedure: cooling melted and drooped wires of the preformed rod in a shaping pipe to 500to 600 DEG C; 3) a wiredrawing cooling procedure: further cooling the wires through helium gas in a cooling device to 30 DEG C to 80 DEG C, wherein the cooling device in step 3) comprises a cooling pipe, the cooling pipe is composed of a first side pipe and a second side pipe, which have the same structure, a mounting cavity is formed between a metal wall and a heat-insulation cover, the metal wall is concave in a direction opposite to the heat-insulation cover, the grooves of one pair of the side pipes are spliced to form a cooling chamber, each groove comprises a foldable groove and each foldable groove is internally provided with a guide blade. According to the optical fiber wiredrawing technology disclosed by the invention, the cooling chamber formed by structures including the grooves, the foldable grooves, the guide blades and the like is arranged, so that the turbulent flow is increased and the thickness of a laminar flow bottom layer formed by downward movement belts of optical fiber wires is effectively reduced, and furthermore, the helium gas cooling effect is improved.

Owner:FUTONG GROUP CO LTD

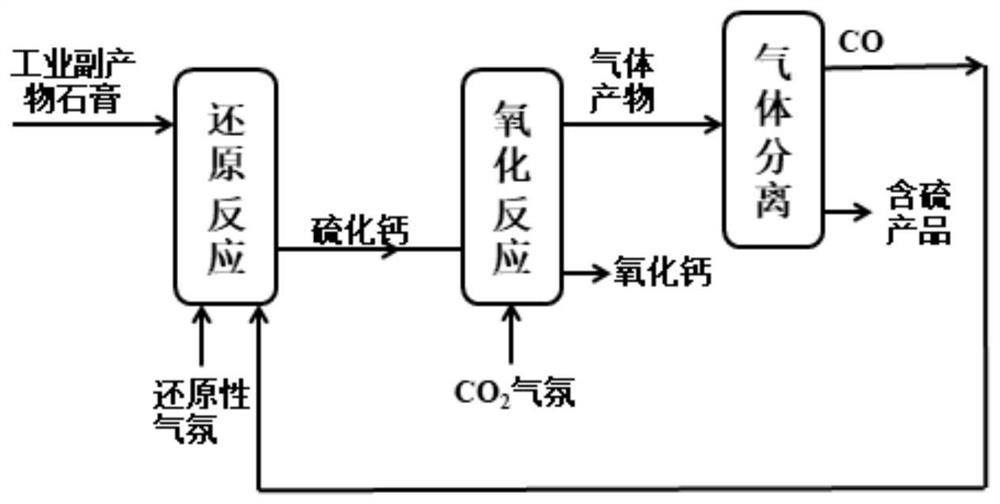

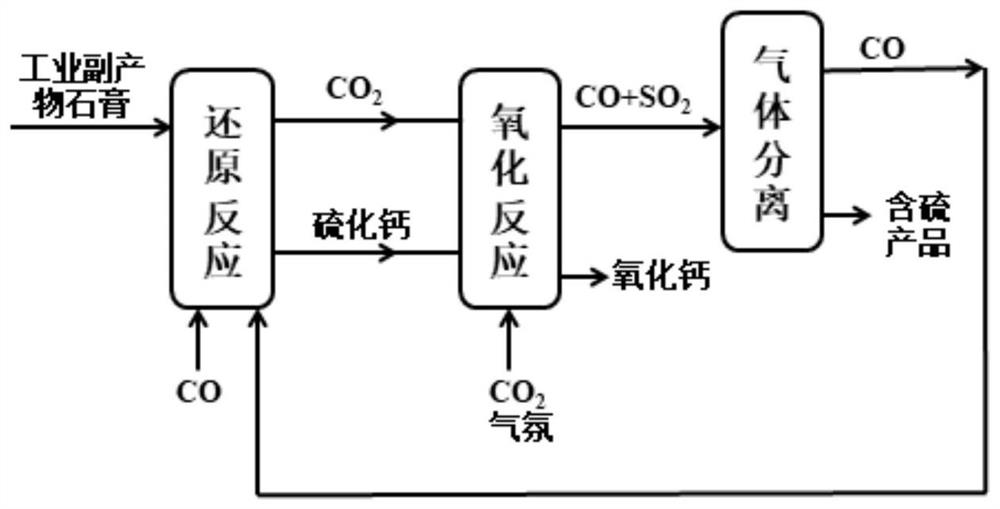

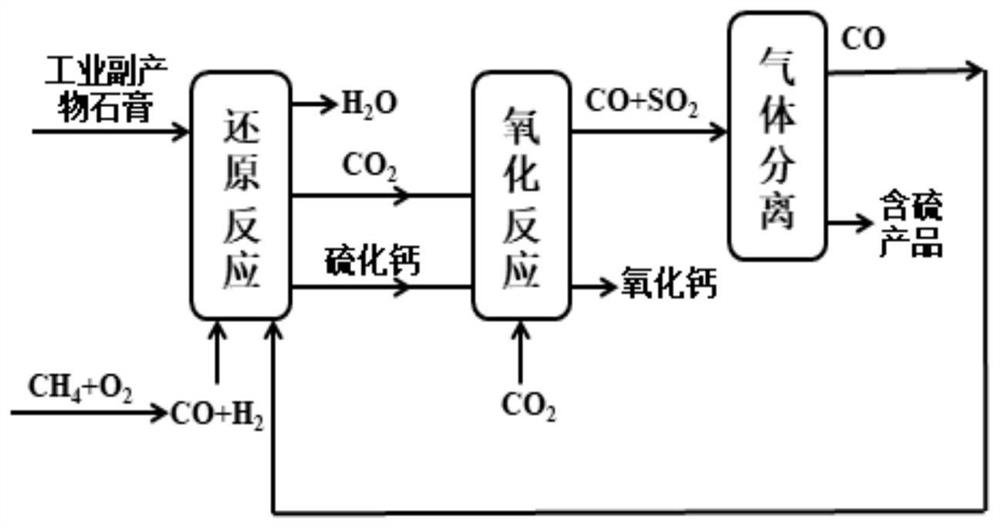

Method for preparing calcium oxide by using industrial byproduct gypsum

ActiveCN113603126AAvoid the problem of low selectivityHigh puritySulfur compoundsCarbon monoxideReduction treatmentCalcium sulfide

The invention provides a method for preparing calcium oxide by using industrial byproduct gypsum, which comprises the following steps: carrying out reduction treatment on the industrial byproduct gypsum, and carrying out oxidation treatment on the obtained calcium sulfide in a CO2 atmosphere. According to the method, two treatment processes of reduction and oxidation are adopted, the initial reaction temperature can be effectively reduced, the decomposition rate and the conversion rate of raw materials can be increased, heat released in oxidation treatment can provide heat for self reaction and can also provide heat for reduction reaction, system energy consumption and operation cost are reduced, and the economical efficiency of the process is improved. No secondary pollutant is discharged in the calcium oxide preparation process, gas generated in the process can be recycled, the gypsum decomposition rate reaches 99%, the calcium oxide conversion rate reaches 97%, and efficient resource utilization of the industrial byproduct gypsum waste residues is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Grain drying device

InactiveCN100513957CKeep dryReduce energy consumptionDrying solid materials with heatHearth type furnacesEngineeringAir convection

The invention provides a device for grain drying, which mainly includes a hot air radiation bin and a heat source generator located therein, wherein the heat source generator includes a pulse burner and an infrared radiator. The grain drying device of the invention combines pulsating combustion, infrared radiation and hot air convection to simultaneously heat the grains by side-heating infrared radiation and high-frequency hot air convection with high temperature and high frequency oscillating airflow. Compared with the traditional method, the device has low fuel consumption rate and low power consumption rate, and the drying precipitation rate is increased, which greatly improves the drying efficiency.

Owner:CHINA AGRI UNIV

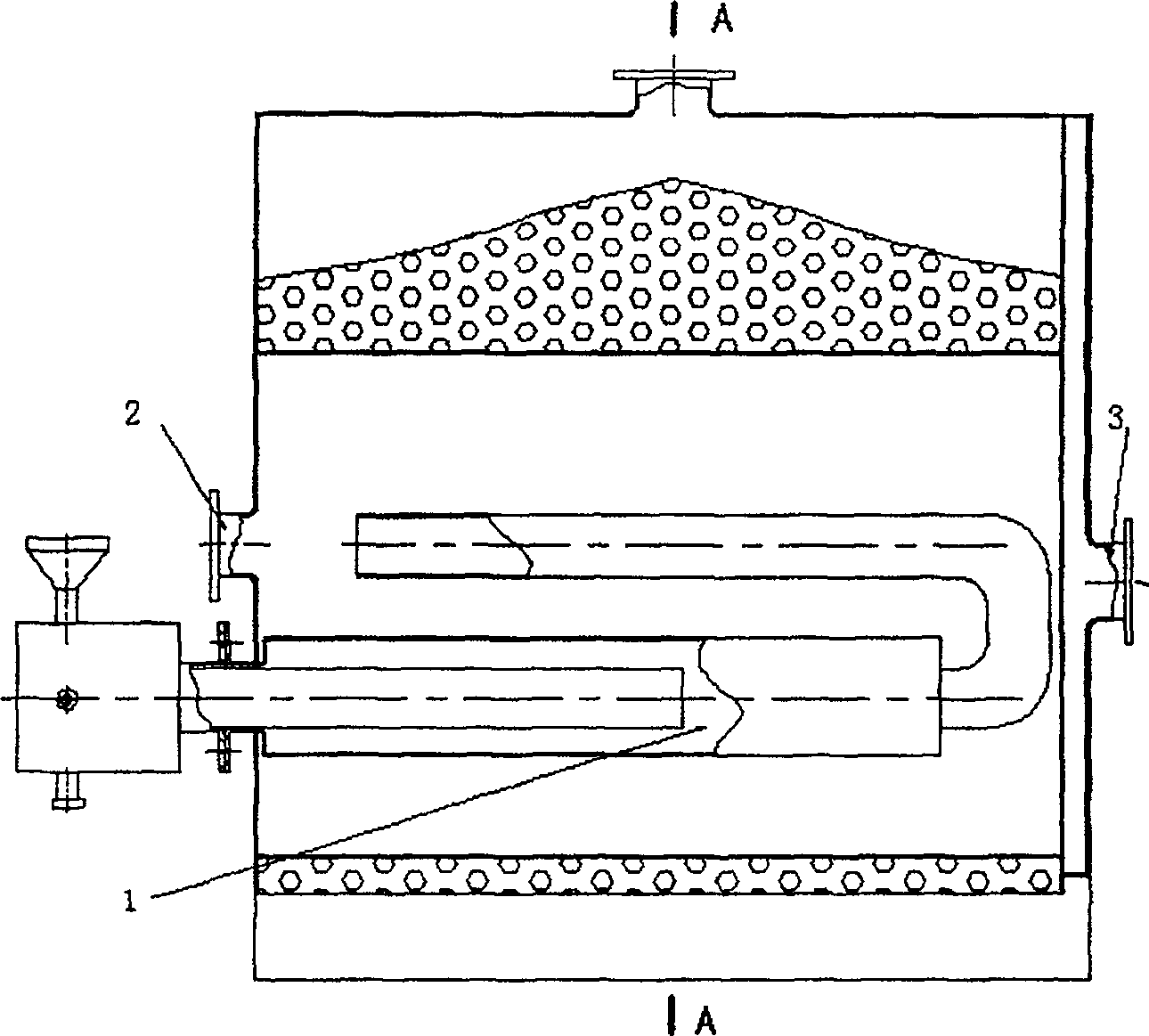

Heat dissipating device for oil-immersed transformer

InactiveCN103363836AEnhanced convective heat transferImprove cooling effectTransformers/inductances coolingHeat transfer modificationTransformerEngineering

The invention discloses a heat dissipation device for an oil-immersed transformer. The heat dissipation device comprises an oil-immersed transformer radiating fin on which a plurality of stereoscopic protruding spoiler structures are punched; the plurality of stereoscopic protruding spoiler structures are staggered at a certain interval, and are 80 mm in transversal space and 40 mm in longitudinal space; preferably, the oil-immersed transformer radiating fin is 800 mm in length and 480 mm in width; the first row of stereoscopic protruding spoiler structures are 240 mm away from the bottom of the oil-immersed transformer radiating fin. According to the invention, longitudinal vortex generated by the stereoscopic protruding spoiler structures destroys a flowing boundary layer formed when air flow passes through the radiating fin, so that convective heat exchange between the radiating fin and air is enhanced. The numerical calculation result shows that when a longitudinal vortex generator is available, the watt-dissipating capacity is improved by about 7% in comparison with the watt-dissipating capacity under the condition of no longitudinal vortex generators.

Owner:WEIFANG LULI MACHINERY

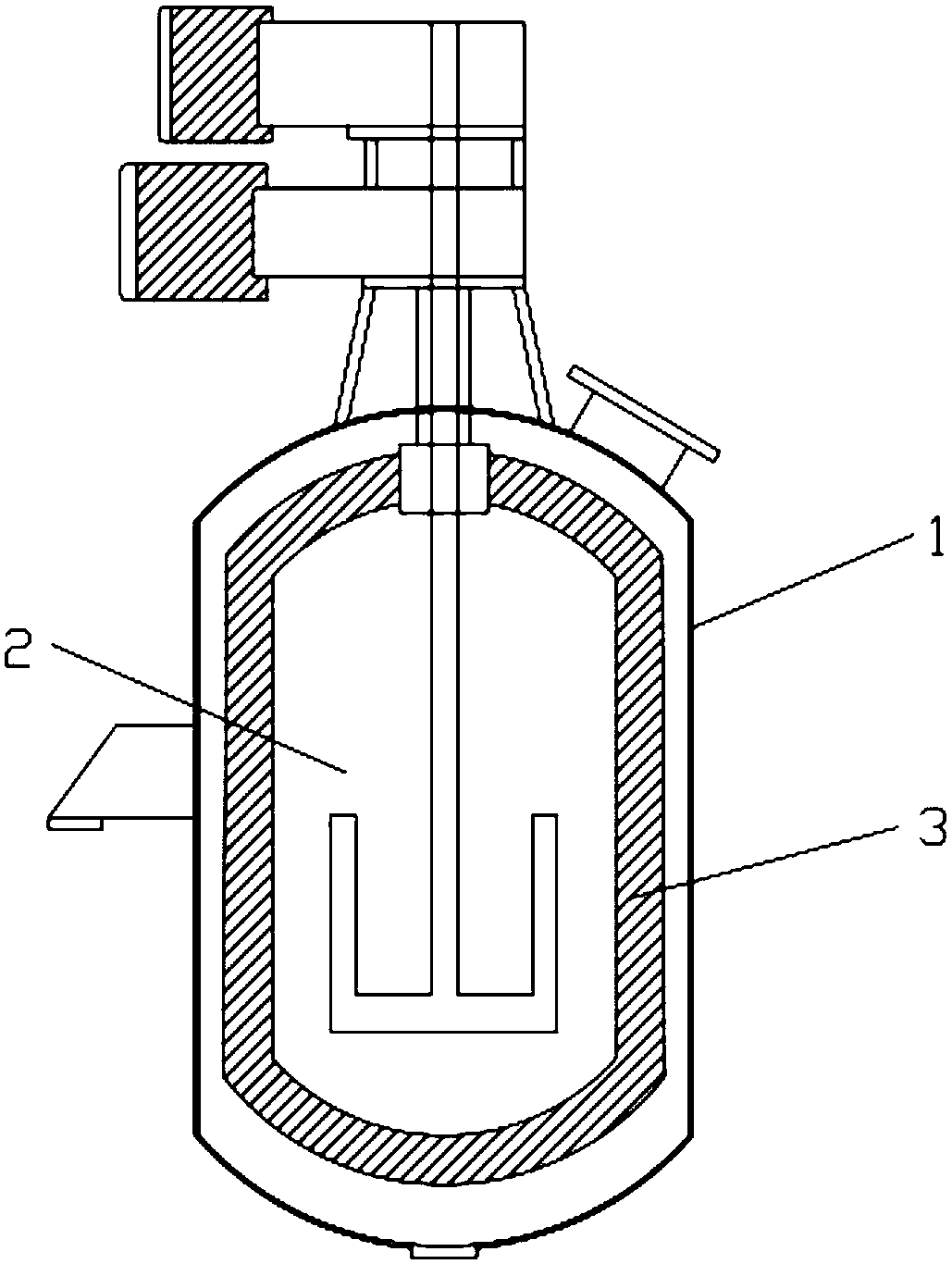

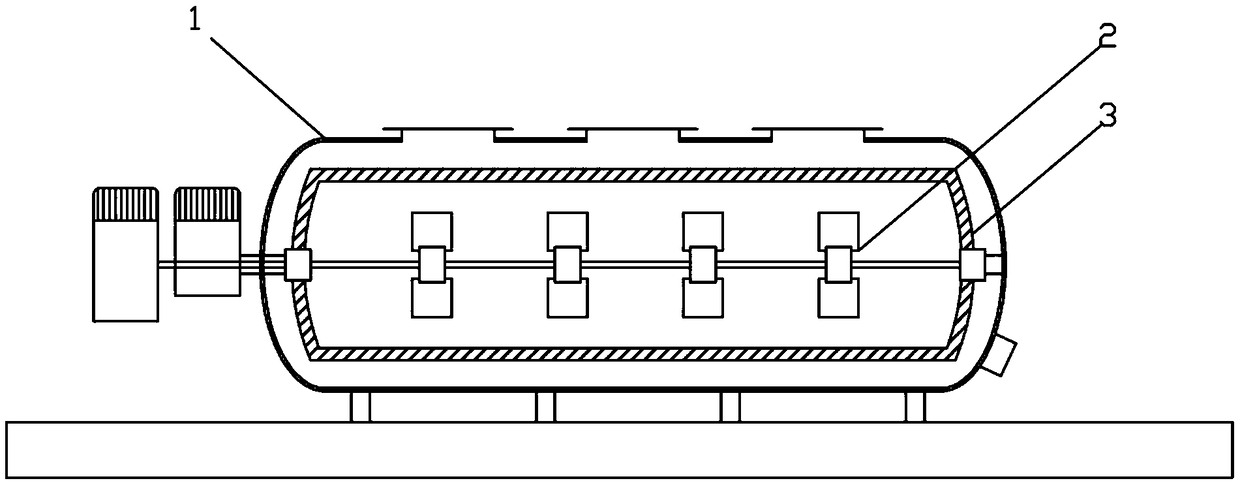

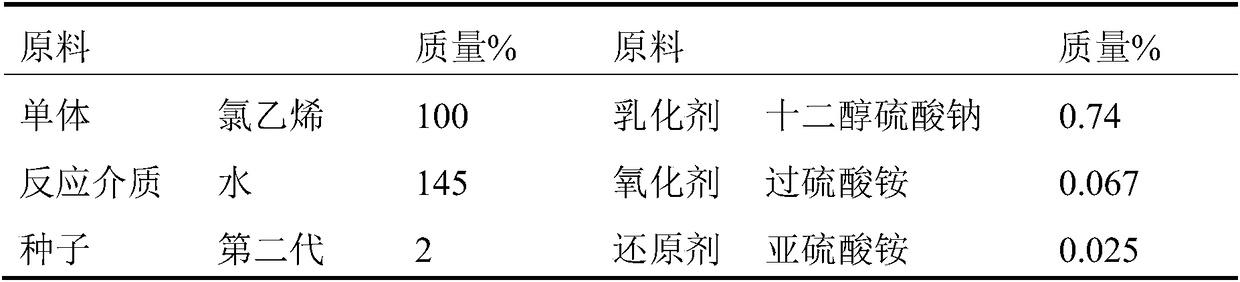

Stirring structure for reinforcing olefin polymerization and method for reinforcing olefin polymerization

InactiveCN109261101AReduce equipment investment costsImprove convective heat transfer efficiencyChemical/physical/physico-chemical stationary reactorsOlefin polymerizationMass transfer

The invention relates to a stirring structure for reinforcing olefin polymerization and a method for reinforcing olefin polymerization. The stirring structure comprises a reaction kettle body and an inner-outer double-layer stirrer arranged in the reaction kettle body, wherein the inner-outer double-layer stirrer consists of an inner-layer paddle and an outer-layer paddle arranged outside the inner-layer paddle; the inner-layer paddle and the outer-layer paddle are coaxially mounted in the reaction kettle body; the inner-layer paddle and the outer-layer paddle rotate at different speeds and indifferent directions as required. According to the stirring structure provided by the invention, through different combinations of the paddle types of the inner- and outer-layer paddles and by adjusting the speeds and directions of the inner- and outer-layer paddles in the polymerization process, the processes of slurry polymerization, solution polymerization, emulsion polymerization, suspensionpolymerization and gas-phase polymerization are reinforced, the mass transfer and heat transfer are promoted, the product quality is improved while the conversion rate is increased; moreover, the structure of the reaction kettle is not transformed, thus the investment cost on the equipment is saved.

Owner:SHANGHAI RES INST OF CHEM IND

Mixed heating roller hearth type medium plate open-fire tempering furnace and application

InactiveCN111593176AEnhanced convective heat transferIncrease unit capacityFurnace typesHeat treatment furnacesFlue gasProcess engineering

The invention discloses a mixed heating roller hearth type medium plate open-fire tempering furnace and application and relates to the technical field of heat treatment equipment. The mixed heating roller hearth type medium plate open-fire tempering furnace comprises an upper heating section and a lower heating section; the heating temperature range of the lower heating section is the same as thatof the upper heating section, the lower heating section adopts a fuel gas open-fire burner, the upper heating section adopts a plurality of flue gas circulating heating systems distributed in the length direction of the tempering furnace, and circulating flue gas of the flue gas circulating heating systems comes from the flue gas of the fuel gas open-fire burner. A mixed heating mode of the upperflue gas circulating heating system and the lower fuel gas open-fire burner for heating is adopted, reversing is conducted through the flue gas circulating heating system, convective heat transfer inthe tempering furnace is enhanced, and the unit capacity of the tempering furnace is improved.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com