Long-life efficient multiple-stage centrifugal pump

A centrifugal pump, long-life technology, applied to pumps, pump components, non-variable pumps, etc., can solve the problems of increased wear of the middle isolation sleeve, low efficiency, and large leakage of the middle isolation sleeve, so as to reduce leakage and Effects of wear rate, increased volumetric efficiency, and increased flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

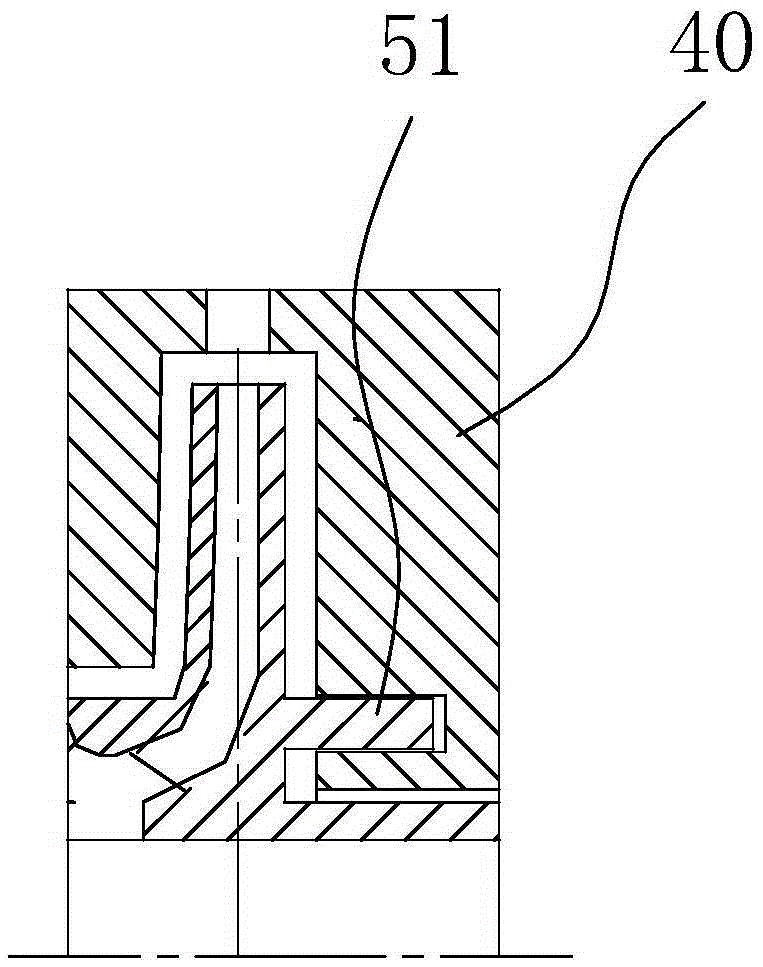

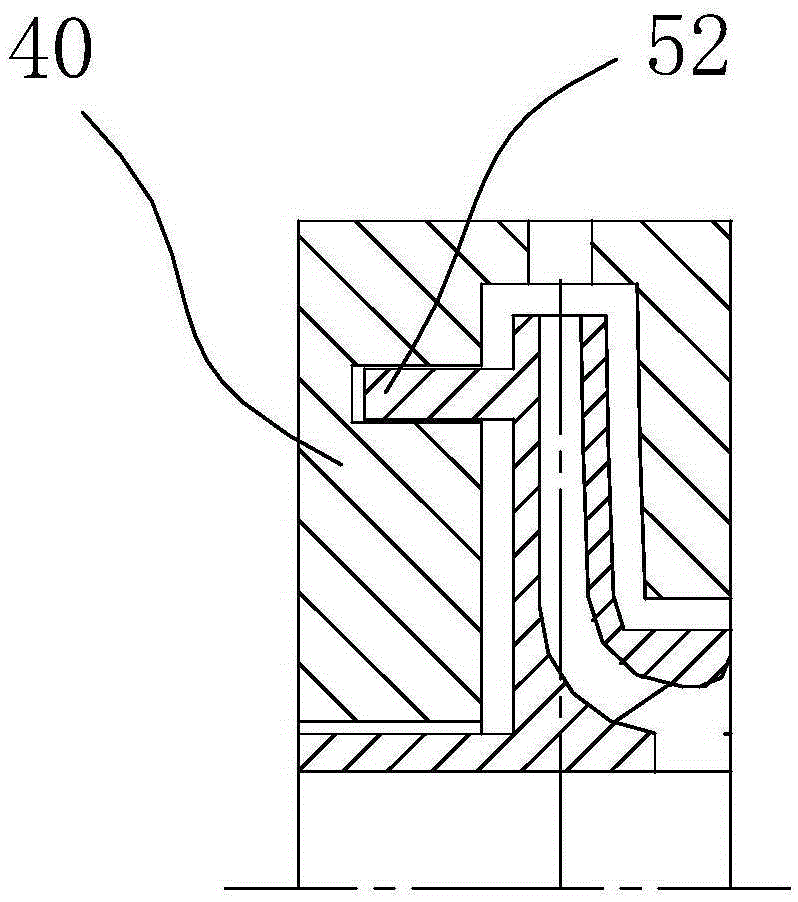

[0030] Below in conjunction with accompanying drawing, structure of the present invention is further described:

[0031] Such as figure 1 Shown: a long-life and high-efficiency multi-stage centrifugal pump, said long-life and high-efficiency multi-stage centrifugal pump includes a first pumping section 20 and a second pumping section fixedly sleeved on the pump shaft 10 along the axial direction of the pump shaft 10 30, and an intermediate spacer 40 located in the middle of the first pumping section 20 and the second pumping section 30 for isolating the first pumping section 20 and the second pumping section 30, the first pumping section 20 The direction of the impeller in the impeller and the second pumping section 30 is oppositely arranged, and the water outlet of the first pumping section 20 is communicated with the water inlet of the second pumping section 30, and the number of impeller stages of the first pumping section 20 is One or two stages more than the second pumpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com