Mechanism for adjusting pressure difference of inlet and outlet of EGR pipeline

A technology of inlet and outlet pressure difference and adjustment mechanism, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of smaller inlet and outlet of EGR pipeline, less EGR components, and inability to achieve fuel-saving effect, etc. The effect of reducing pump air loss and cooling loss, improving fuel consumption and reducing effective flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

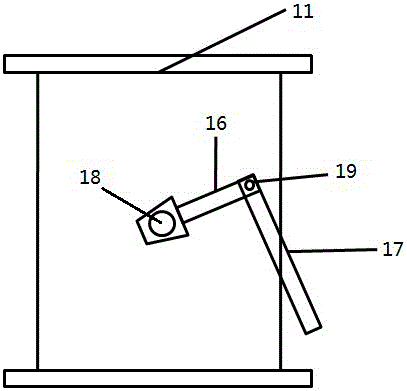

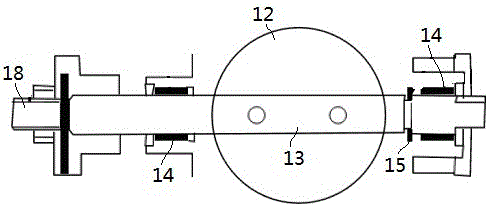

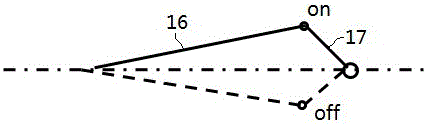

[0027] Figure 1 to Figure 4 Shown is an EGR pipeline inlet and outlet pressure difference adjustment mechanism, including the adjustment mechanism assembly 1 . The adjustment mechanism assembly 1 includes a valve body 11, a baffle plate 12, a rotating shaft 13, a rocker arm 16 and a pull rod 17, such as figure 1 and figure 2 As shown; the baffle plate 12 is arranged in the valve body 11 through the rotating shaft 13, the baffle plate 12 is arranged on the rotating shaft 13, the two ends of the rotating shaft 13 are respectively arranged in the valve body 11 through the bearing 14, and the baffle plate 12 is arranged on the rotating shaft 13 It can rotate 90 degrees with the rotating shaft 13 as the central axis. One end of the rotating shaft 13 stretches out of the valve body 11 and is rigidly connected to one end of the rocking arm 16 , and the other end of the rocki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com