Reforming hydrogen production reactor, hydrogen production conversion furnace and hydrogen production reaction method

A reforming hydrogen production and reactor technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of reducing the operation period of the device, biased flow of raw materials, and low conversion rate of raw materials, so as to improve the conversion efficiency and reduce the Mass transfer resistance, the effect of improving space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

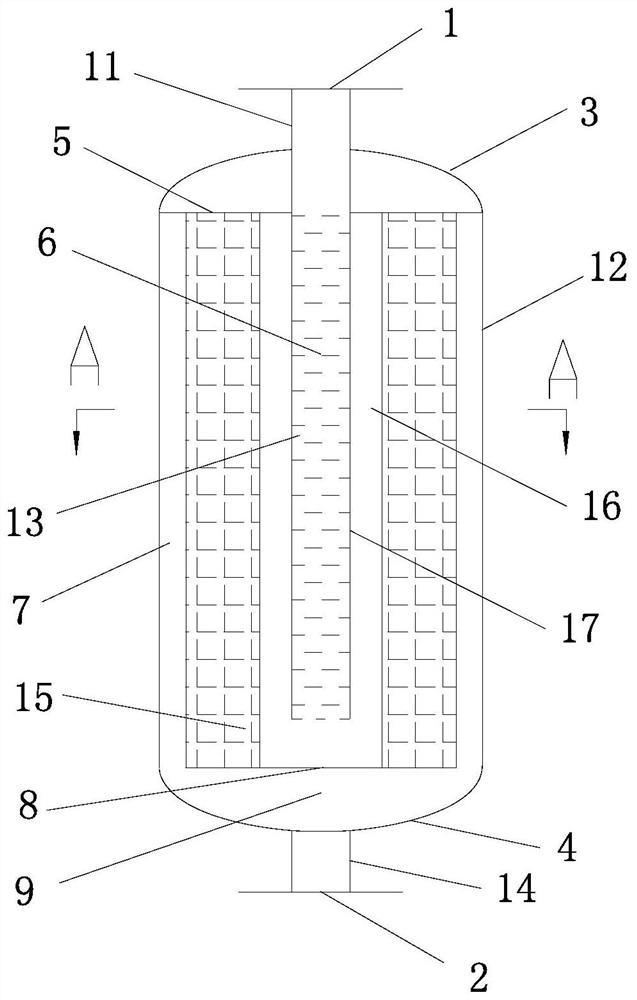

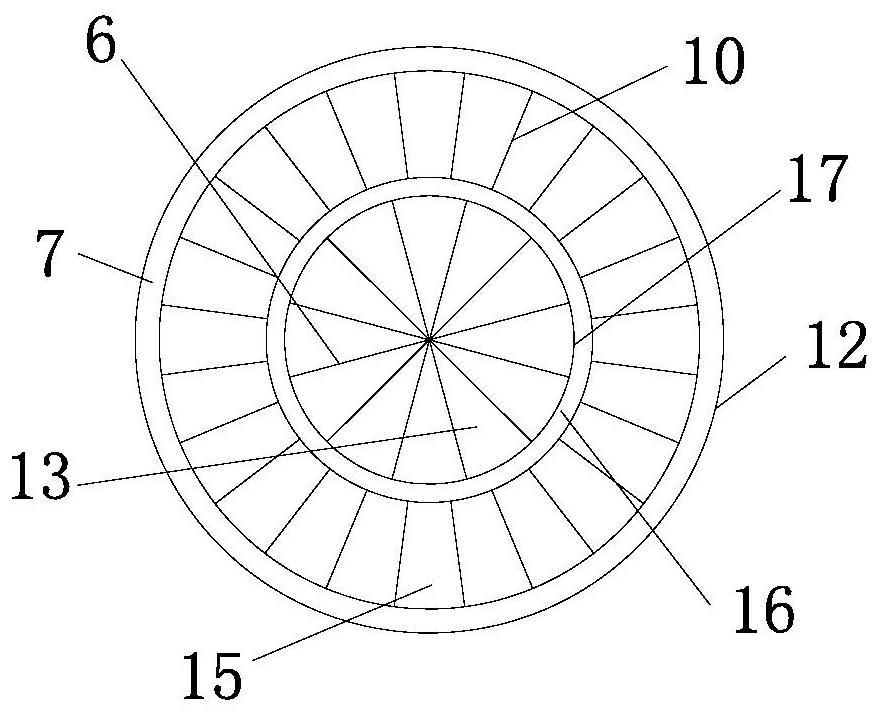

[0085] Such as figure 1 , figure 2 As shown, the reforming hydrogen production reactor used in this embodiment includes a pressure-bearing shell 12 with a first straight pipe 11 at the upper end and a second straight pipe 14 at the lower end. A sleeve 15 and a sleeve 15 are arranged inside the shell. A radial catalytic reaction zone formed by a central cylinder 13; the upper part of the first straight pipe 11 is provided with an air inlet 1, and the lower part of the second straight pipe 14 is provided with an air outlet 2. The micro-catalysis reaction plate 10 and the micro-catalysis reaction plate 6 of the central cylinder extend axially respectively, and the micro-catalysis reaction plate 10 in the sleeve 15 is radially arranged around the central cylinder 13, and the angle between the flat plate and the horizontal direction is 90°, and the central cylinder 13 , the sleeve 15 and the housing 12 are coaxially arranged; the central cylinder micro-catalysis reaction plate 6 ...

Embodiment 2

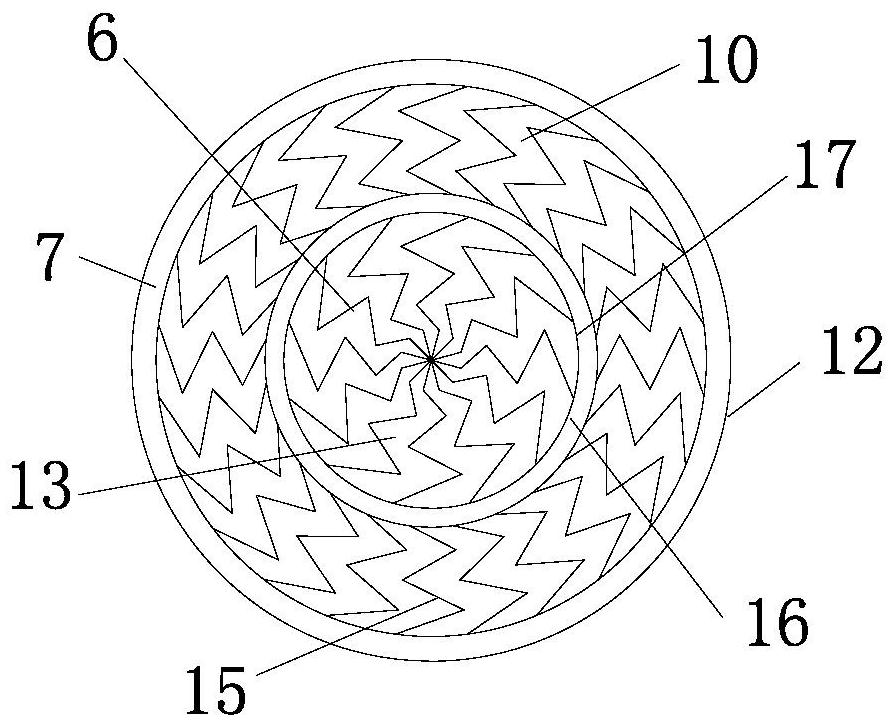

[0096] Such as figure 1 , image 3 , Figure 9 As shown, the reforming hydrogen production reactor and the reforming furnace of the present embodiment are the same as the reactor size of the embodiment 1, the distance between two adjacent catalytic reaction plates, the distance between the annular gaps, the substrate material of the micro-reaction plate and the active component per unit area NiO The payload parameters are the same. The difference from Example 1 is that in this embodiment, the micro-catalytic reaction plate 10 and the central tube micro-catalytic reaction plate 6 are tooth-shaped micro-reaction plates, and the wave direction is along the radial direction of the reactor. For the tooth-shaped plate, the distance between the crest and the trough is 3mm, and the distance between two adjacent crests or adjacent troughs on the same micro-catalytic reaction plate 10 or central cylinder micro-catalytic reaction plate 6 is 5.5mm. The reforming hydrogen production rea...

Embodiment 3

[0101] Such as figure 1 , Figure 4 , Figure 11 As shown, the reforming hydrogen production reactor and the reforming furnace of the present embodiment are the same as the reactor size of the embodiment 1, the distance between two adjacent catalytic reaction plates, the distance between the annular gaps, the substrate material of the micro-reaction plate and the active component per unit area NiO The payload parameters are the same. The difference from Example 1 is that the micro-catalytic reaction plate in this example is a corrugated micro-reaction plate, and the wave direction is along the radial direction of the reactor. For the corrugated plate, the distance between the crest and the trough is 3mm, and the distance between two adjacent crests or adjacent troughs of the same microplate is 5.5mm.

[0102] Similarly, the reforming hydrogen production reactor and reformer of this embodiment are applied to the hydrogen production reaction by steam reforming of natural gas....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com