Reforming hydrogen production reactor and its reformer and method for reforming hydrogen production reaction

A reforming hydrogen production and reactor technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of increasing the energy consumption of the raw gas compressor, increasing the number of catalyst active centers, and the catalyst being prone to carbon deposition and deactivation. , to achieve the effect of long service life, improved conversion efficiency, and not easy carbon deposition and inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

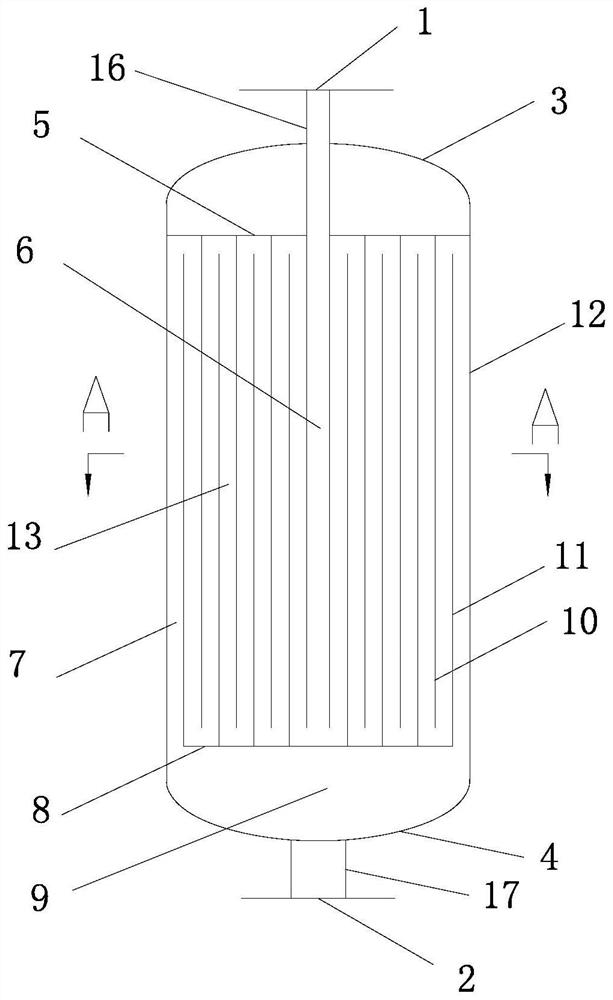

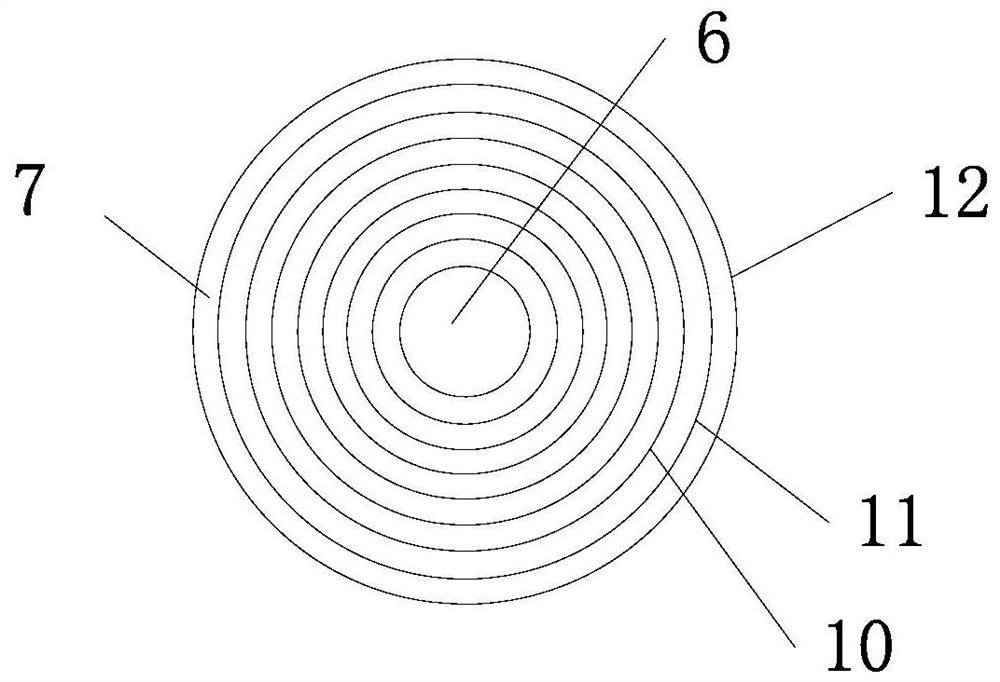

[0079] Such as figure 1 , figure 2 As shown, the reforming hydrogen production reactor adopted in this embodiment includes a pressure-bearing shell 12 with a first straight pipe 16 at the upper end and a second straight pipe 17 at the lower end. In the catalytic reaction unit 13 , the upper part of the first straight pipe 16 is provided with an air inlet 1 , and the lower part of the second straight pipe 17 is provided with an air outlet 2 . The catalytic reaction unit 13 is composed of upper micro-catalytic reaction plates 10 and lower micro-catalytic reaction plates 11 which are sleeved alternately in a cylindrical shape, and the upper micro-catalytic reaction plates 10, the lower micro-catalytic reaction plates 11 and the housing 12 and the center pipe 6 are in the form of Arranged coaxially; the upper micro-catalytic reaction plate 10 is sealed and fixed with the top sealing plate 5, and the lower micro-catalytic reaction plate 11 is sealed and fixed with the bottom seal...

Embodiment 2

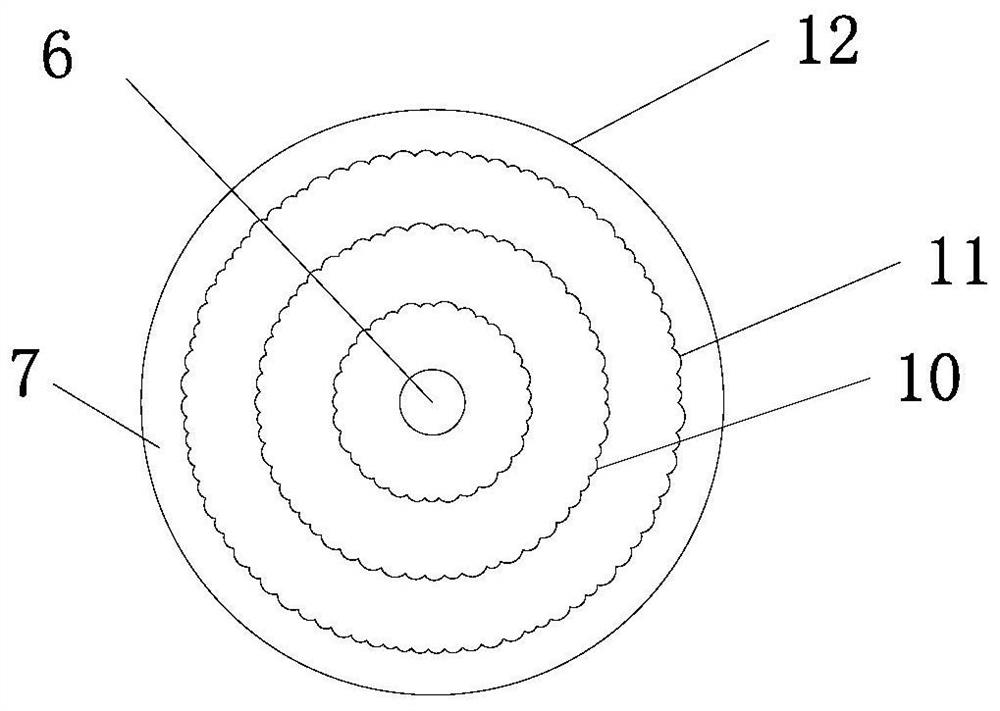

[0091] Such as figure 1 , image 3 , Figure 12 As shown, the reforming hydrogen production reactor and the reformer of the present embodiment are compared with the reactor size, the height of the catalytic reaction unit, the distance between the opening at the bottom of the central tube and the sealing plate 8 at the bottom of the catalytic reaction unit of the embodiment 1, and the upper micro-catalytic reaction The distance between the bottom of the plate 10 and the bottom sealing plate 8, the distance between the bottom of the lower micro-catalytic reaction plate 11 and the top sealing plate 5, the distance between two adjacent catalytic reaction plates, the distance between the outermost micro-catalytic reaction plate and the inner wall of the housing, The substrate material of the micro-reaction plate is the same as the NiO loading parameter of the active component per unit area. The difference from Example 1 is that the micro-catalytic reaction plate in this example i...

Embodiment 3

[0097] Such as figure 1 , Figure 4 , Figure 10As shown, the reforming hydrogen production reactor and reforming furnace of the present embodiment are compared with the reactor size, the height of the catalytic reaction unit, the distance from the opening at the bottom of the central tube to the bottom sealing plate 8 of the catalytic reaction unit, and the upper micro-catalytic reaction of the embodiment 2. The distance between the bottom of the plate 10 and the sealing plate 8 at the bottom of the catalytic reaction unit, the distance between the bottom of the lower micro-catalytic reaction plate 11 and the top sealing plate 5, the distance between two adjacent catalytic reaction plates, the ring between the outermost micro-catalytic reaction plate and the inner wall of the housing The gap distance, the substrate material of the micro-reaction plate and the loading amount of active component NiO per unit area are the same. The difference from Example 2 is that the micro-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com