Heat exchanger for horizontal-tube falling film evaporator

A falling-film evaporator and heat exchanger technology, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve the problems of liquid film accumulation, liquid film drift, etc., to solve coking and ensure stability , the effect of enhancing heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

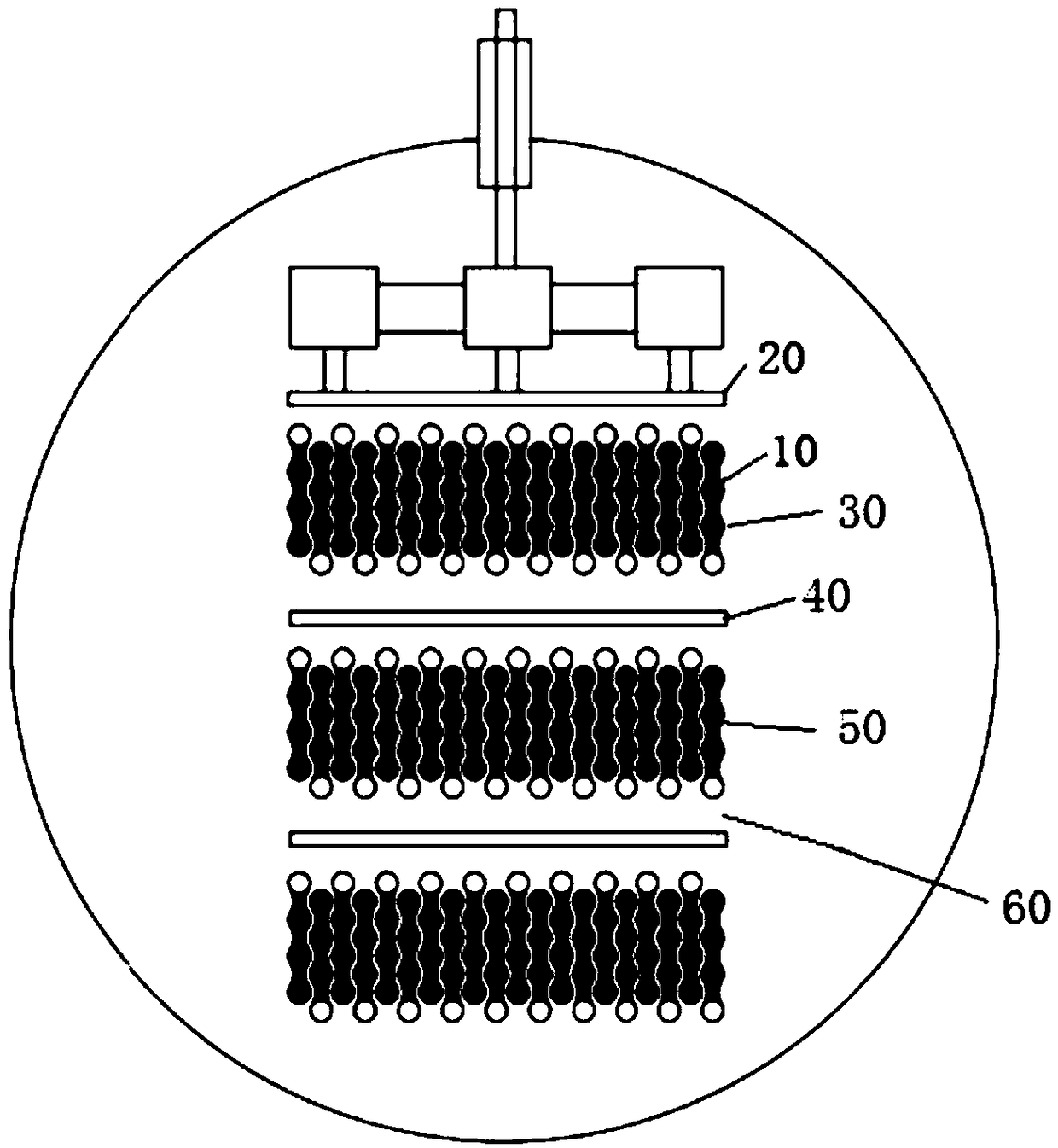

[0041] Such as figure 2 As shown, a heat exchanger for a horizontal tube falling film evaporator includes a liquid distributor 20, a heat exchange tube group 30 located below the liquid distributor, two secondary liquid distributors 40 and two secondary heat exchange tube groups 50. A secondary heat exchange tube group is arranged under each secondary liquid distributor.

[0042] The installation positions of the liquid distributor 20, the heat exchange tube group 30, the two secondary liquid distributors 40 and the two secondary heat exchange tube groups 50 are prior art, specifically refer to the application number 201710545425 filed by the applicant in 2017 , 4 Chinese patent applications.

[0043] Such as figure 2 and image 3 As shown, the heat exchange tube group and each secondary heat exchange tube group 50 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com