Internal component gas distributor of converter

A technology of gas distributor and synthesis tower, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc. It can solve the problems of difficult temperature difference, gas bias flow, and affecting the uniformity of gas reaction, so as to ensure the uniformity and solve the problem of bias flow Phenomenon, the effect of solving connection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

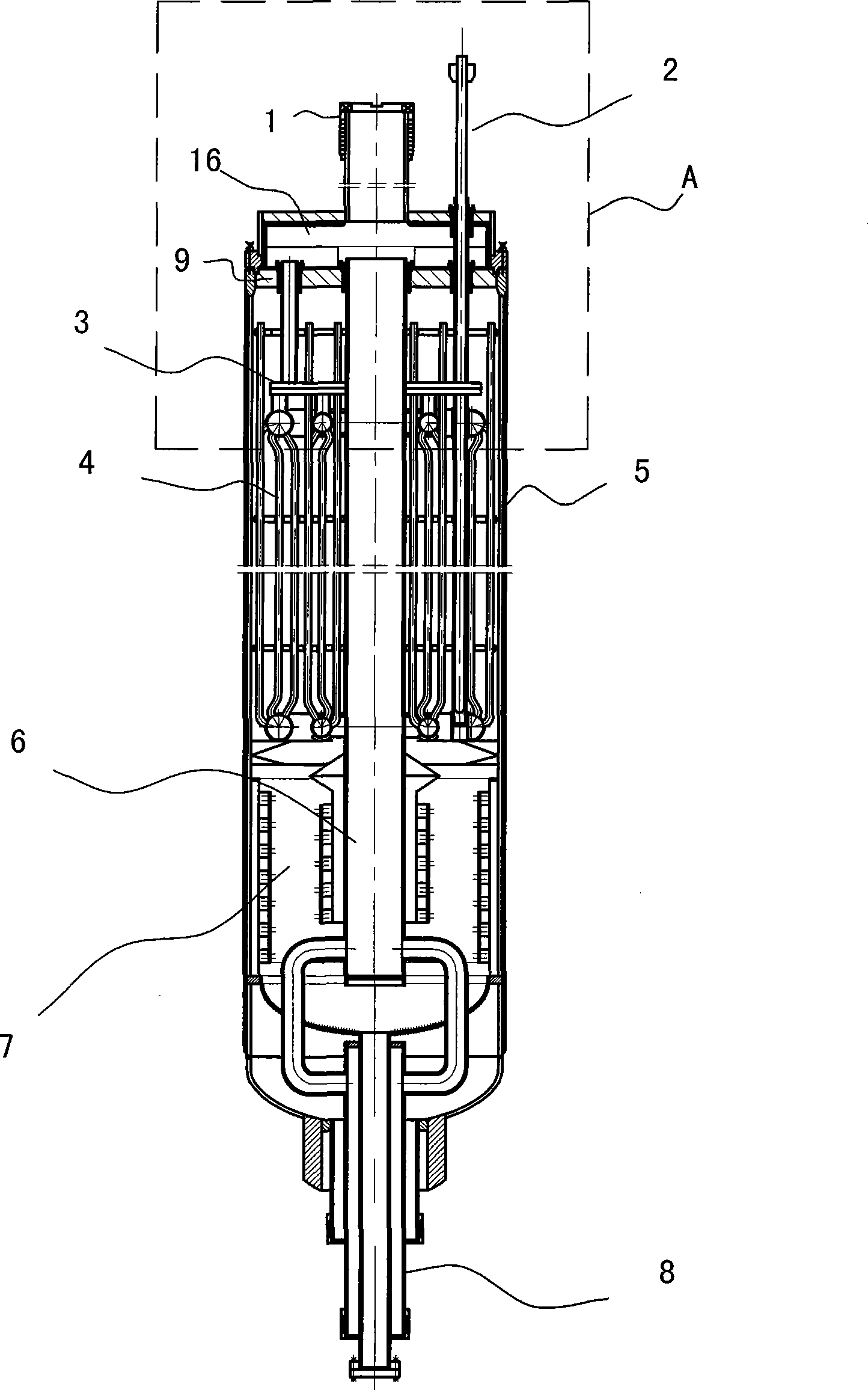

[0018] see figure 1 . This embodiment takes the methanol synthesis tower as an example for illustration. The top of the tower internals structure is provided with a connecting pipe 1, and the temperature measuring pipe 2 is inserted into the inner cavity of the cylinder 5 from the top of the tower. In the inner cavity of cylinder body 5, from top to bottom, a gas collection chamber 16 is formed at the top, below the gas collection chamber 16 is a distributor 3, and an ascending pipe 41 is located near the inner wall of the cylinder body 5; The liner 4 is set at the lower part of the distributor 3 by the support feet, the radial structure is below the support feet, and the bottom structure is the bottom of the cylinder.

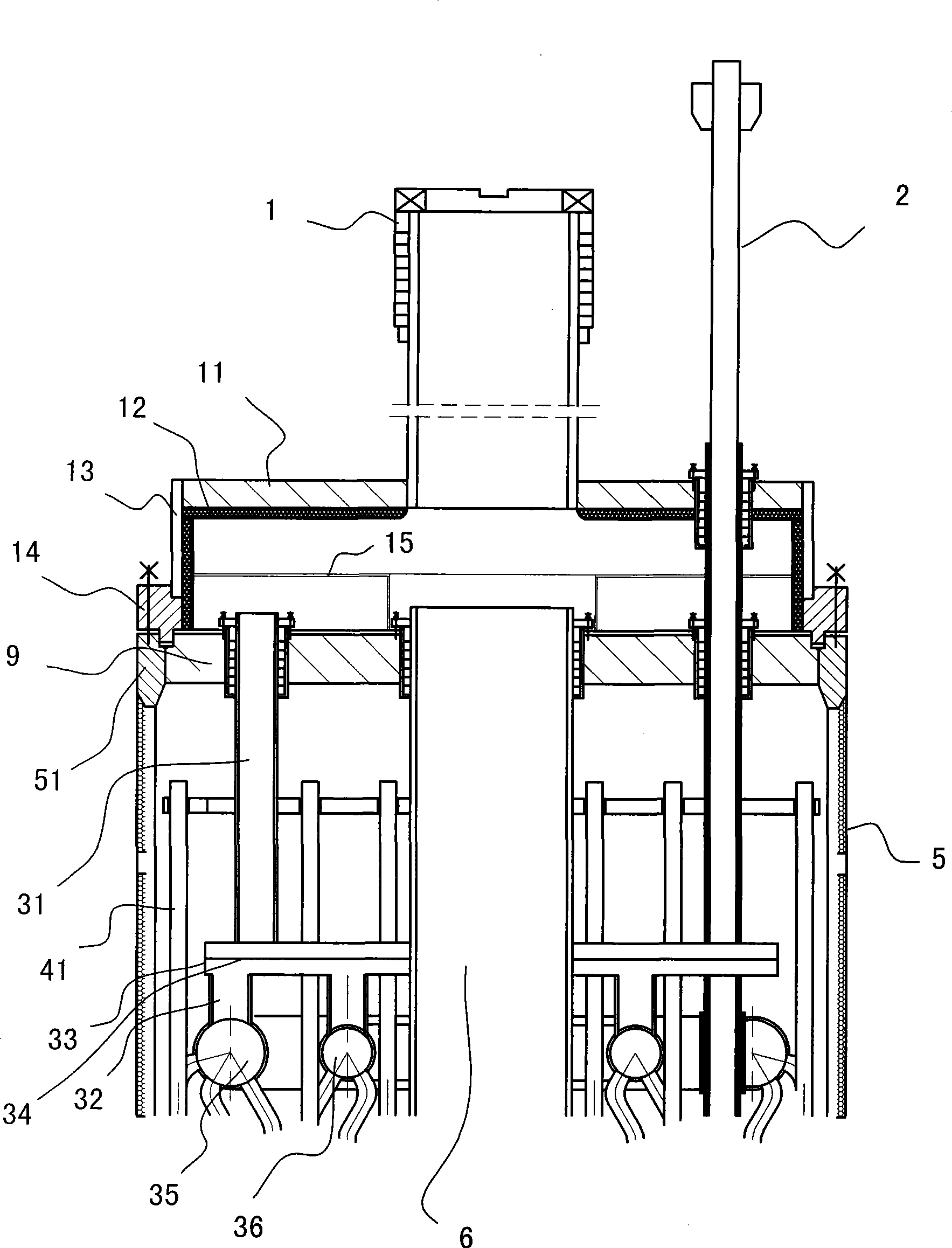

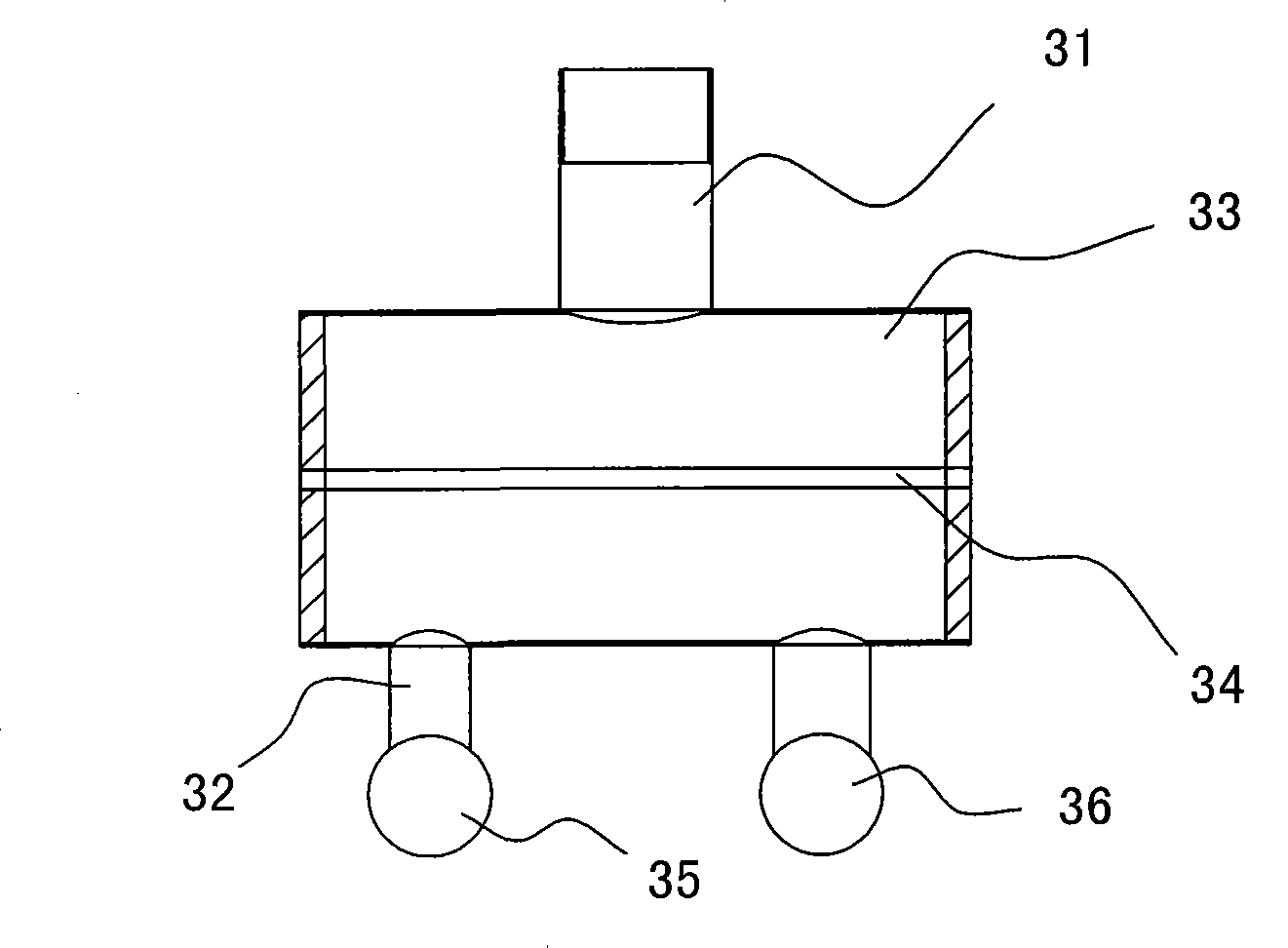

[0019] see figure 2 , and combined with image 3 , Figure 4 . The circular cylinder 5 is connected into a sealed whole through the cylinder flange 51 and the gas collection chamber flange 14, and the large cover plate 9 is arranged on the port of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com