Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Achieve wholeness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

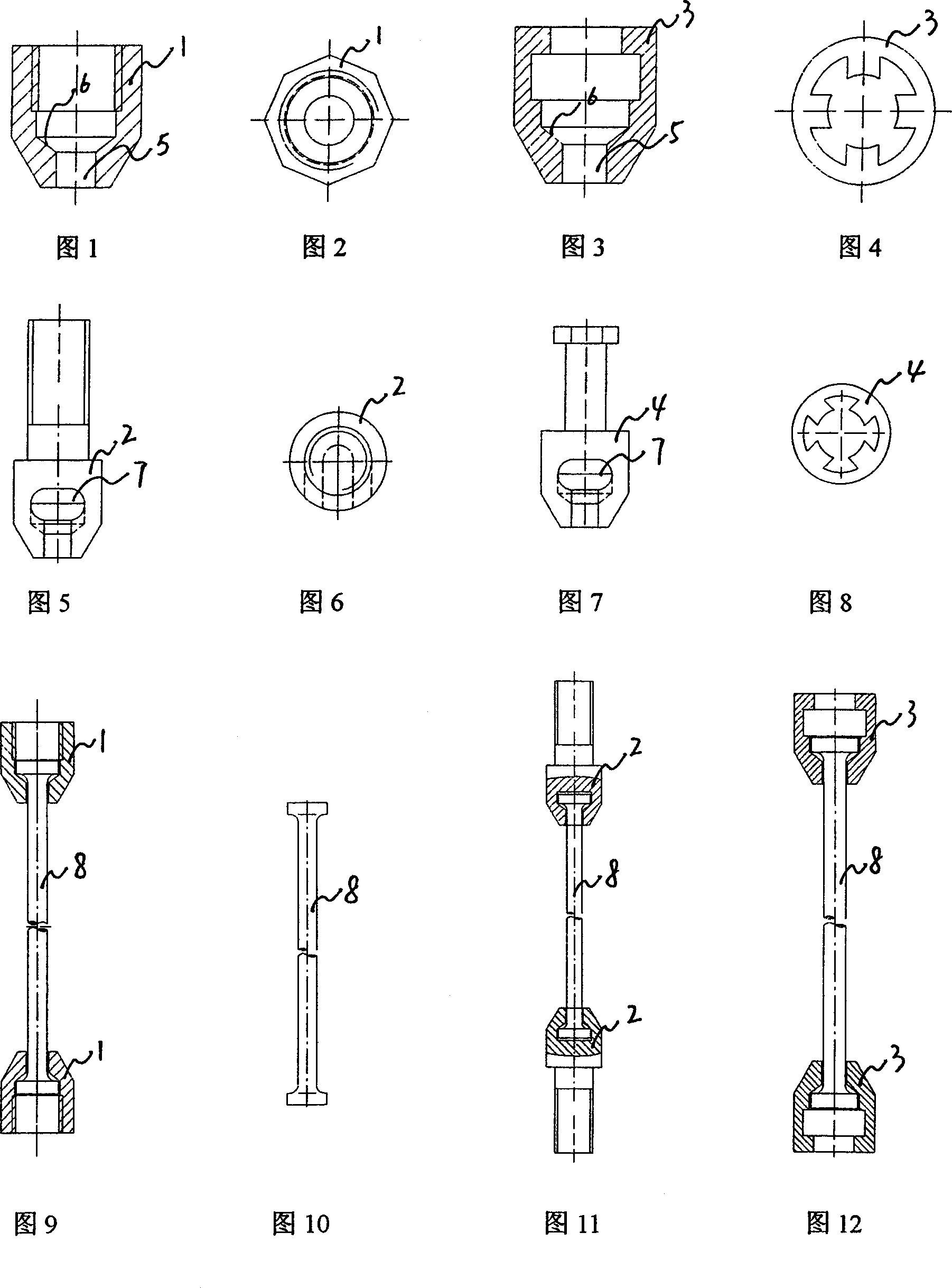

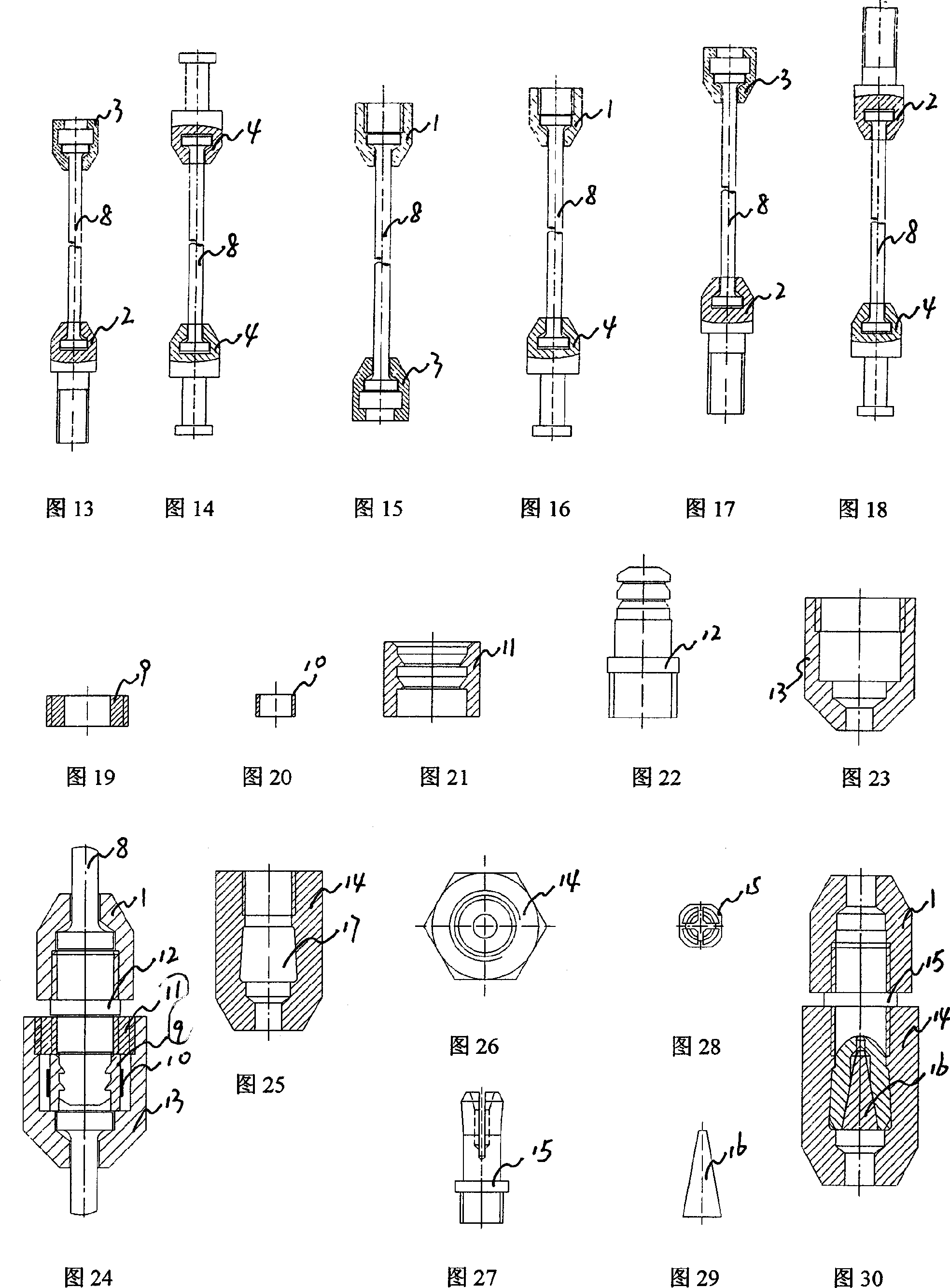

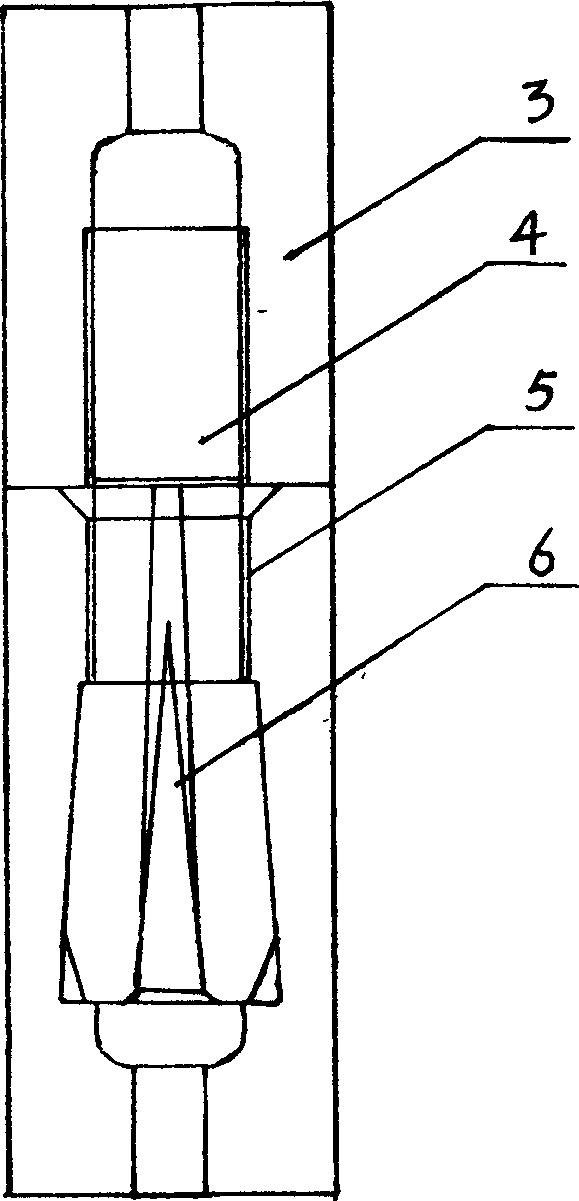

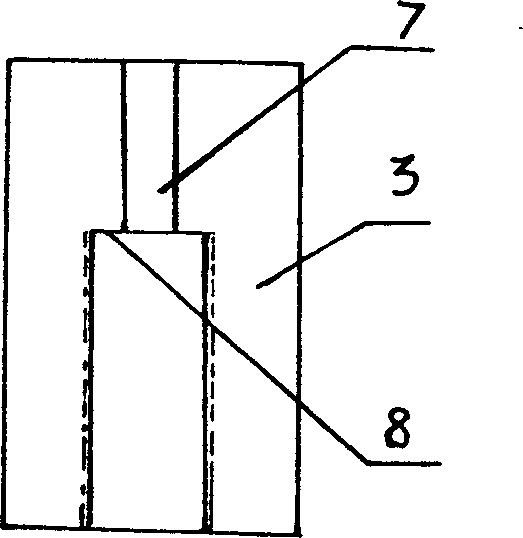

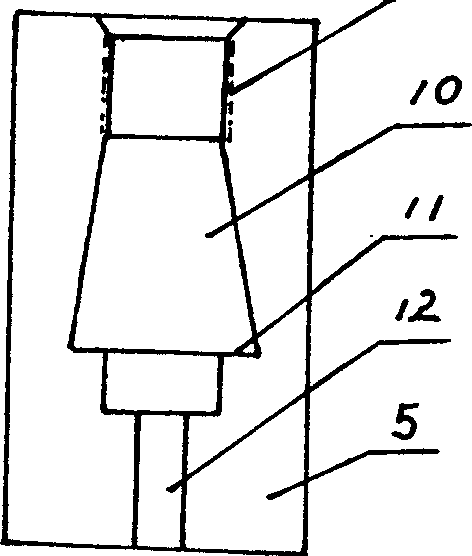

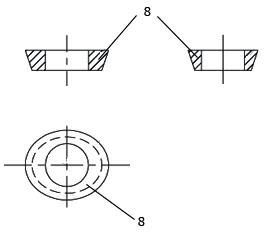

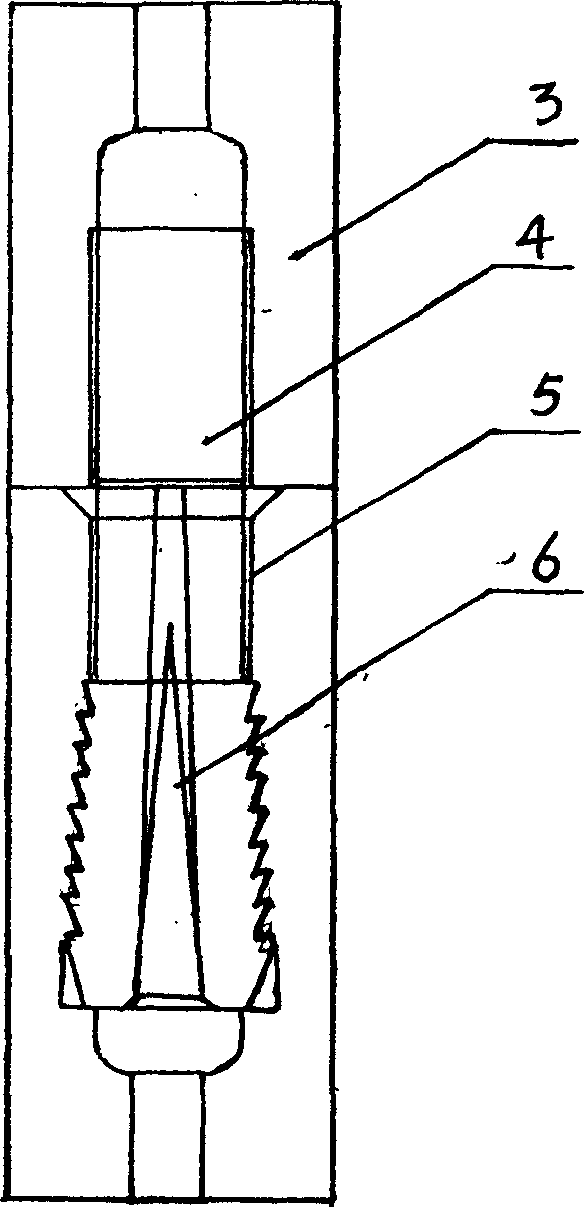

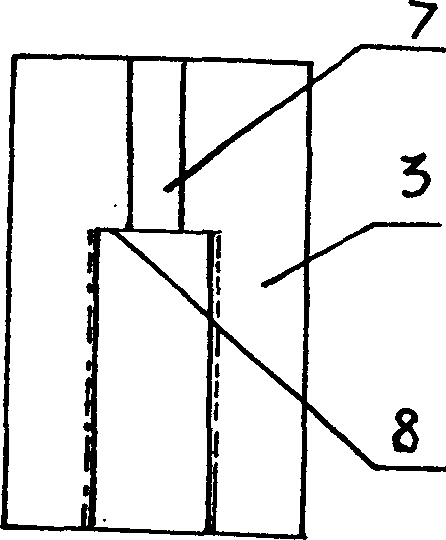

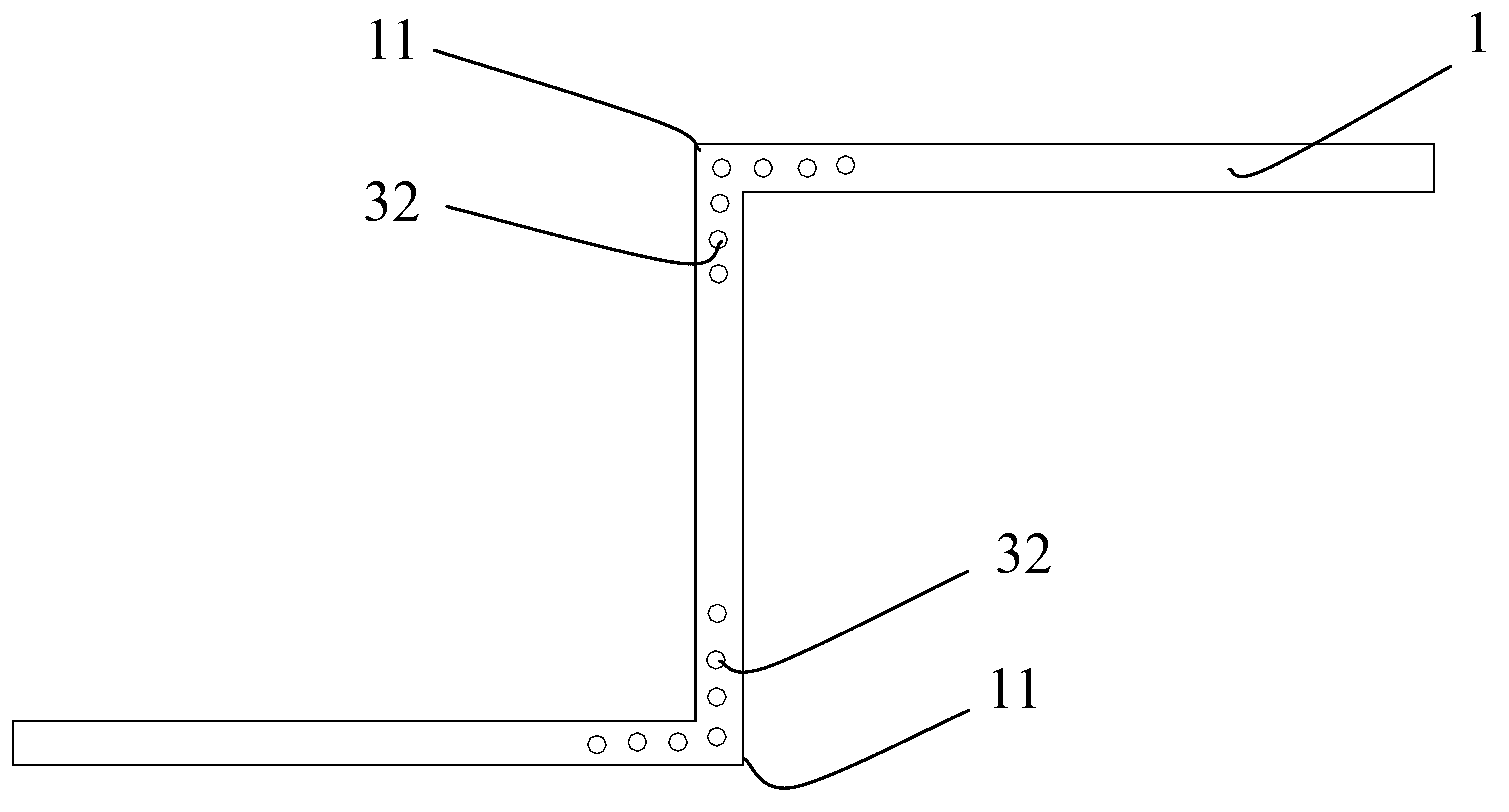

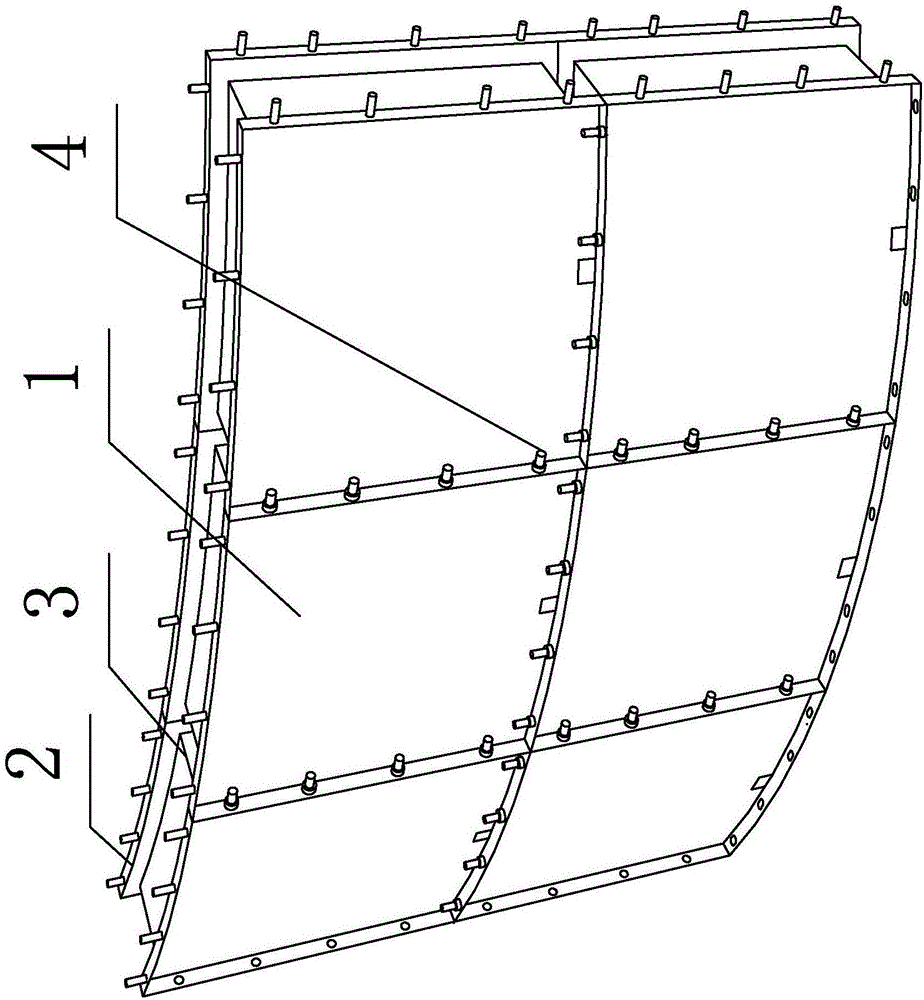

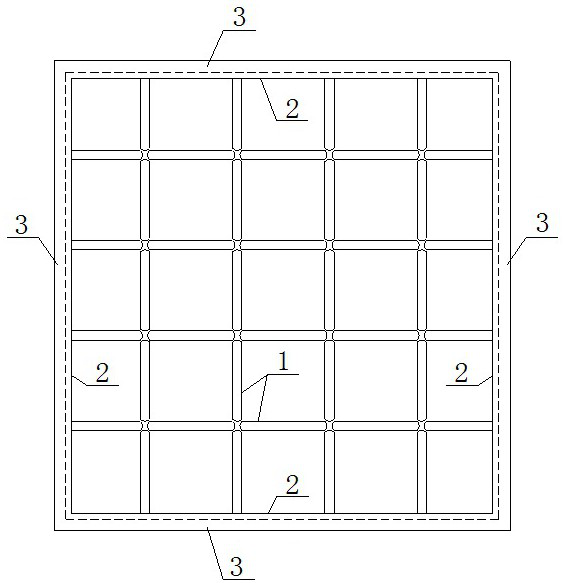

Pile connecting buckle and its prefabricated unit

InactiveCN100348803CReduce manufacturing costAchieve consistencyBuilding constructionsBulkheads/pilesPre stressRebar

The present invention relates to one kind of powerful buckle for prefabricated unit, prefabricated unit with the buckle and it forming process. The powerful buckle has screw thread connecting or bayonet jointing structure with steel bar hole in the center and upset steel bar head clamping stage around the steel bar hole. The prefabricated pre-stressed unit has reinforcing rib skeleton comprising longitudinal ribs and ring ribs and the each end of its longitudinal ribs are bayonet jointed to the upset steel bar head clamping stage. After the powerful buckle has the end fixed onto the fixing board and expanding board and set inside formwork, and concrete is deposited and the expanding board is drawn to set pressure, to form centrifugal pile and obtain prefabricated pre-stressed unit.

Owner:周兆弟

Upper screw lower connecting pile fastener and precast member

InactiveCN1603523AReduce manufacturing costAchieve consistencyBuilding constructionsBulkheads/pilesNosePre stress

The invention involves a kind of tube column to meet the buckle, as well as uses with the time mouth constitution pre-stressed high strength pre- workpiece and -odd in view of the fact that with the between between connection structure and the connection method, is the pre- workpiece to meet buckles with the pre- workpiece manufacture domain. On under the spiral goes against pile extension buckles by pulls the cap nut, inflates the screw and goes against pulls the cap nut constitution, pulls the cap nut screw together in the spiral which inflates the screw wire shorts, inflates the screw the inflation measure expansion in to go against pulls in the cap nut in the inflation cavity, when pile extension, demands the collection attire two maybe certain to pull the cap nut with the between nose minute to buckle goes against pulls the cap nut mouth which corresponds with the prefabrication, inflates the screw the spiral wire shorts screw together in pulls the cap nut screw thread in, Inflates the screw the inflation to carefully examine like goes against pulls the cap nut the inflation cavity also the inflation sells under the function in its nose to inflate in goes against pulls the cap nut in the inflation cavity, completes docking between the pre- workpiece and pre- workpiece.

Owner:周兆弟

Traditional Chinese medicine composition for treating chronic pharyngitis and preparation method thereof

InactiveCN103055130APromote repairPromote regenerationAnthropod material medical ingredientsRespiratory disorderCaladiumDisease

The invention discloses a traditional Chinese medicine composition for treating chronic pharyngitis and a preparation method thereof, relating to the field of medicines. The invention aims at providing a traditional Chinese medicine composition which can treat both manifestation and root cause of the disease, combine a long-term curative effect with a short-term curative effect and comprehensively treat the chronic pharyngitis, and a preparation method thereof. The key point of the technical scheme disclosed by the invention is as follows: the traditional Chinese medicine composition comprises the following raw materials in parts by weight: 12-20 parts of platycodon root, 9-15 parts of drug sweetflag rhizome, 9-15 parts of blackberrykiky rhizome, 9-15 parts of thinleaf milkwort root-bark, 12-20 parts of medicine terminalia fruit, 8-15 parts of caladium, 8-15 parts of tangerine peel, 8-20 parts of Indian buead, 12-30 parts of honeysuckle flower, 5-15 parts of peppermint, 12-30 parts of Mongolian dandelion herb, 12-30 parts of dwarf lilyturf tuber, 12-30 parts of Chinese angelica, 12-30 parts of radix salviae miltiorrhizae, 10-15 parts of twotooth achyranthes root, 10-20 parts of fructus forsythiae, 5-15 parts of great burdock achene, 3-12 parts of cicada slough, 6-15 parts of figwort root, 5-15 parts of notoginseng, 5-15 parts of cape jasmine fruit, 3-10 parts of liquorice root and the like.

Owner:张洪君

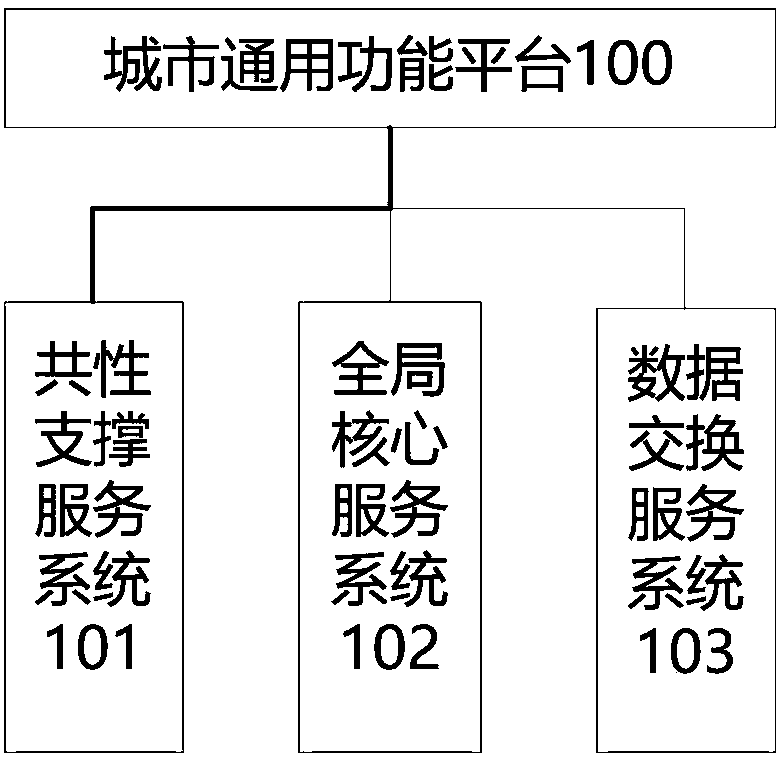

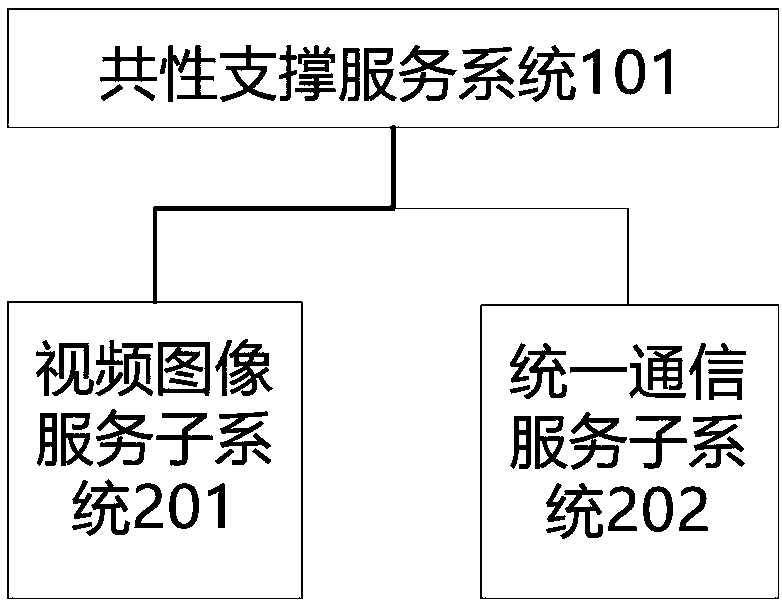

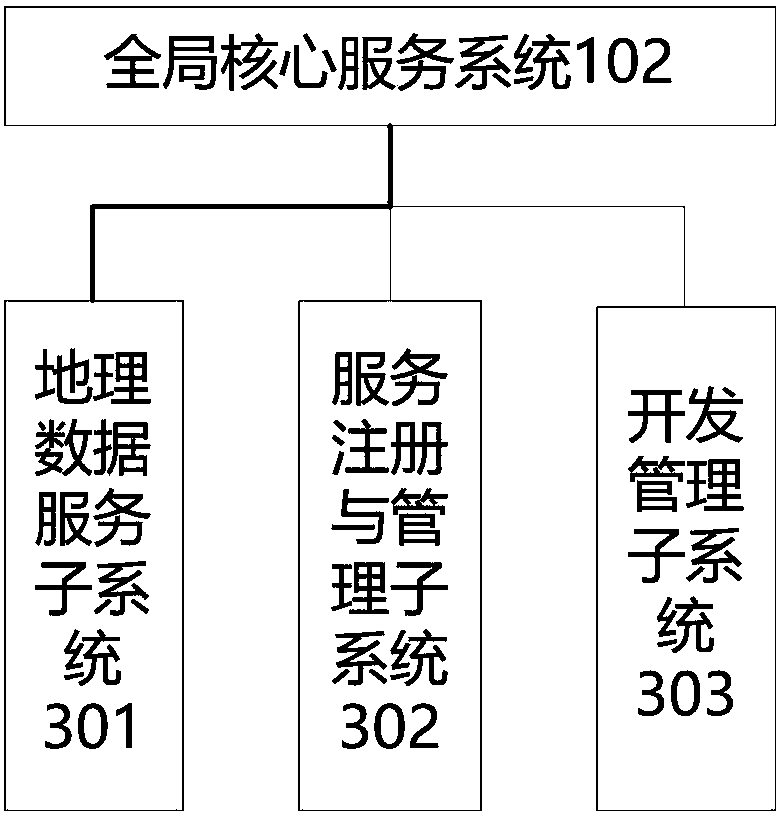

Common functional platform for city

InactiveCN107894990AGlobalizationAchieve wholenessData processing applicationsSpecial data processing applicationsService systemSupport services

The invention provides a common functional platform for a city. The platform comprises a generality supporting service system, an overall core service system and a data sharing exchange service system; the generality supporting service system is used for calling and using data resources, establishing a generality common service which is required by a city running management center, and establishing an application which is related to city operation according to the generality common service; the overall core service system is used for achieving collection and management of geographical information data, city service registration management and service process registration management; the data sharing exchange service system is used for achieving unified management of data exchange and datasharing. The common functional platform for the city has the advantages that municipal resources, society resources, ICT resources, service resources, data resources and object resources are subjectedto unified identification and description, all types of resource data are subjected to information integration, fusion and integration, and services, functions and processes among all services of thecity are integrated.

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

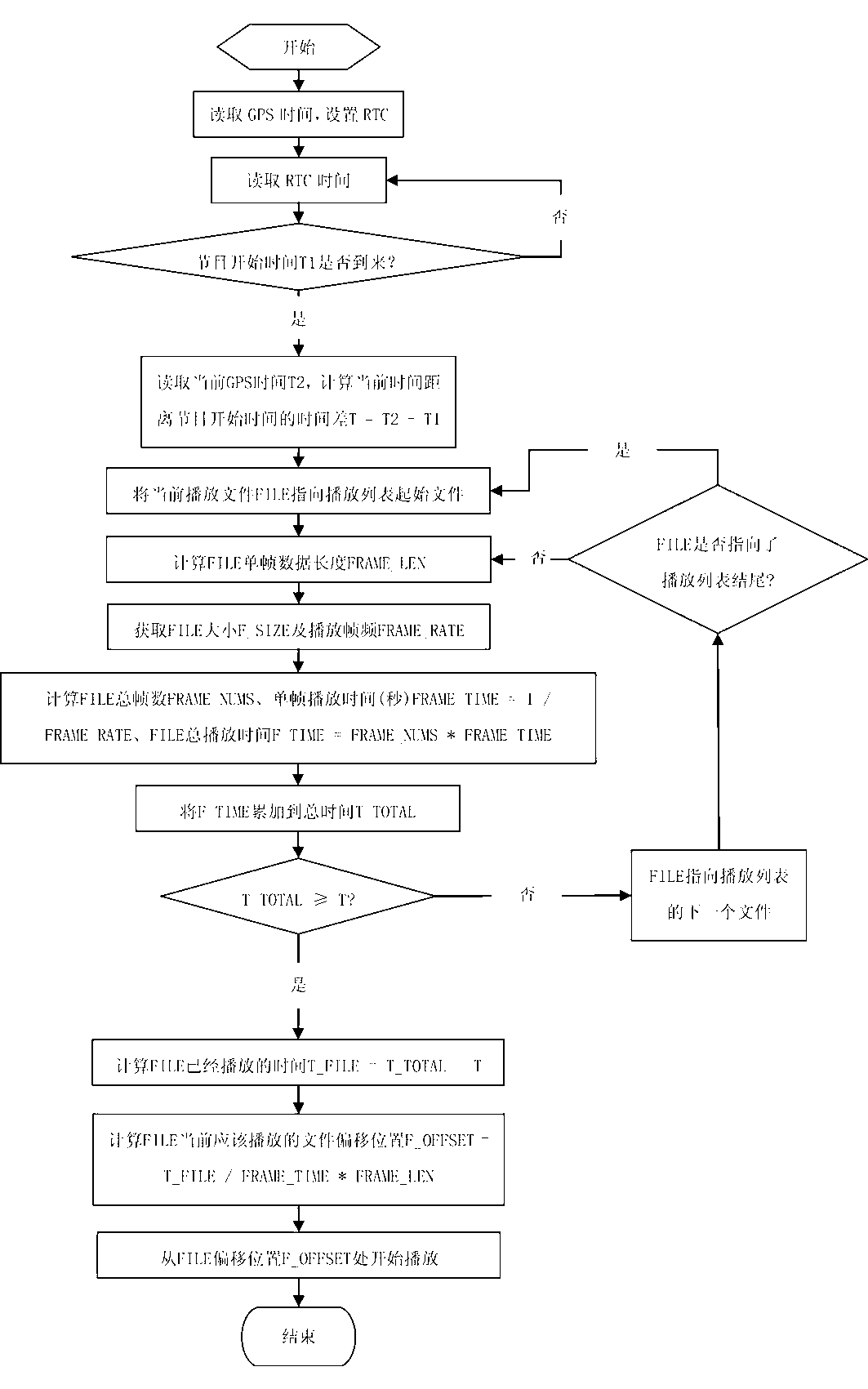

Time synchronization method for plurality of lighting master controllers and realization device of time synchronization method

ActiveCN102915222AAchieve wholenessAchieve consistencyCathode-ray tube indicatorsDigital output to display deviceControl engineeringMaster controller

The invention discloses a time synchronization method for a plurality of lighting master controllers and a realization device of the time synchronization method, relates to a time synchronization method for a plurality of master controllers in a lighting control system, and aims to provide a precise synchronization method of a plurality of lighting master controllers in an off-line playing mode. The time synchronization method comprises the following steps: obtaining program beginning time T1; after the program beginning time T1 is obtained, obtaining current GPS (global positioning system) time T2; calculating time difference T=T2-T1; determining the playing of an nth file in a playing list at the current GPS time T2; and controlling lighting master control equipment to play the file from the offset position of the nth file.

Owner:四川九洲投资控股集团有限公司

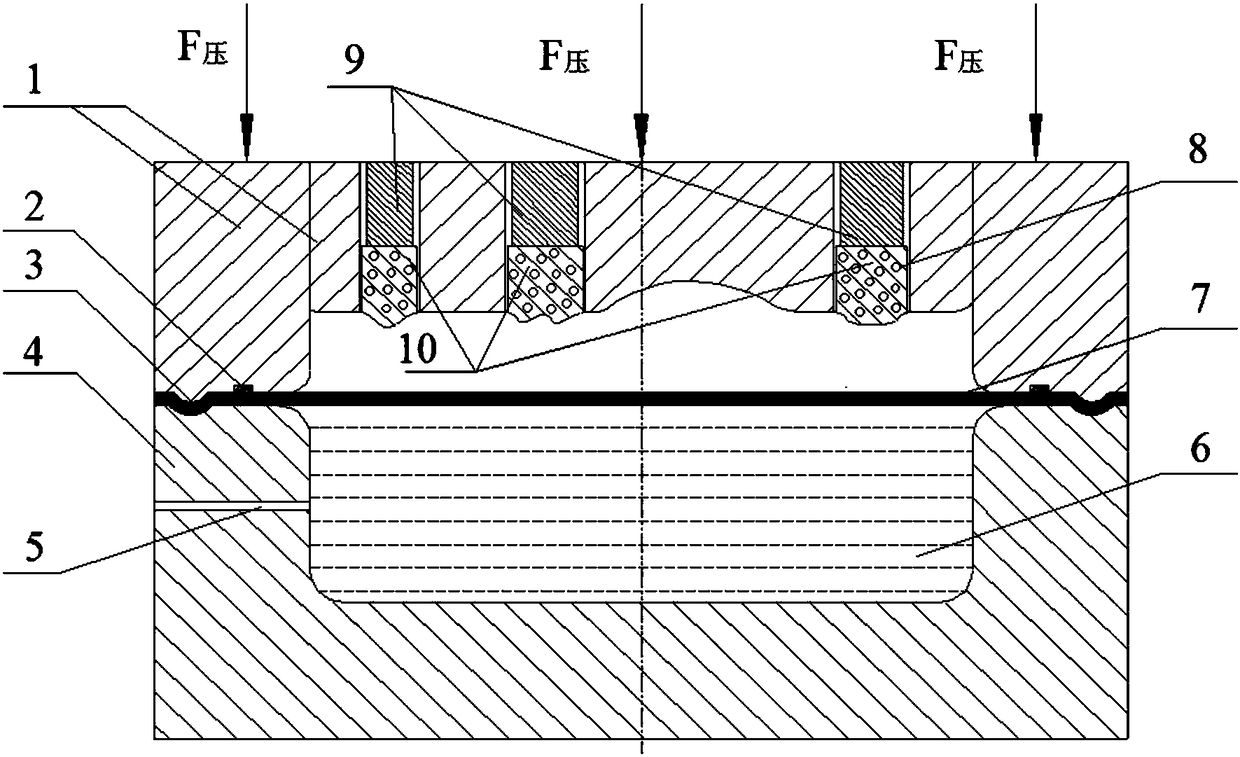

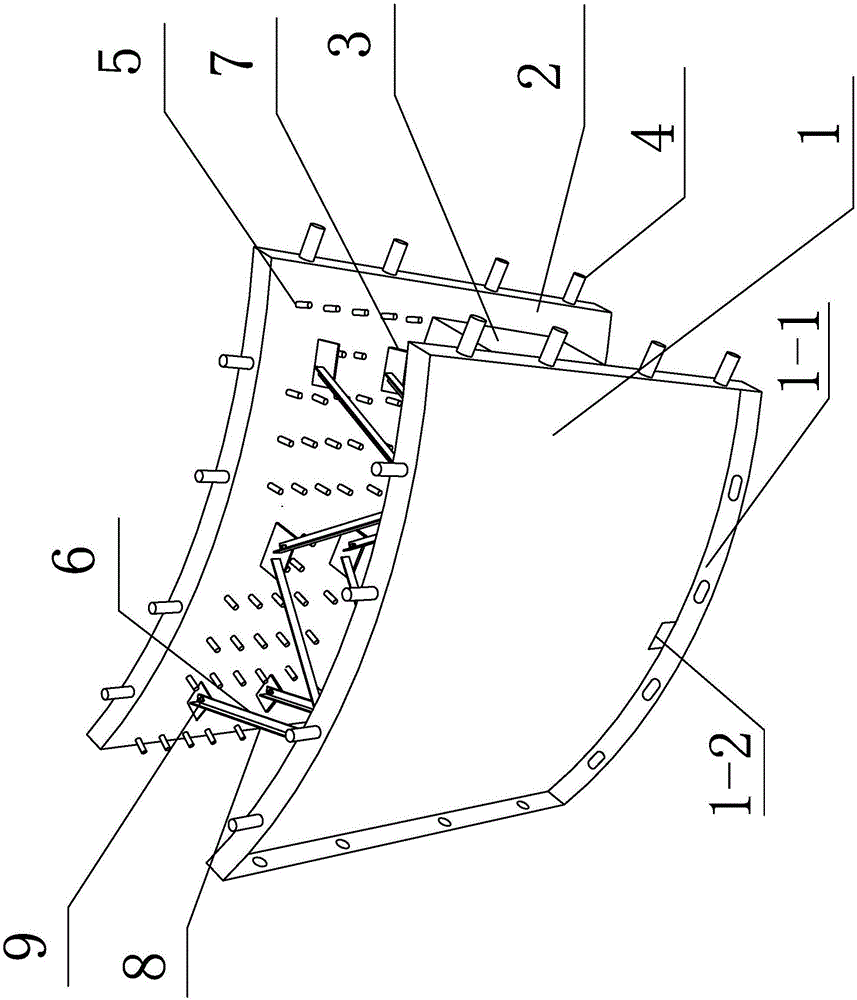

Cold-hot sequential coupling forming technology of large-scale aluminium alloy complex structural members

A cold-hot sequential coupling forming technology of large-scale aluminium alloy complex structural members is a novel forming technology which is derived from the intersection and fusion of liquid-filled forming technology and hot-stamping forming technology. The novel forming technology has the characteristics of liquid filling forming and hot stamping forming at the same time. The cold-hot sequential coupling forming technology comprises the steps that the upper and lower dies are closed, according to adjusting the blank holder force, a panel veneer is impacted between the dies; the panel veneer is attached to die profiles in function of high pressure liquid in a liquid chamber, the forming of most features is completed; and after forming the liquid-filled, according to the characteristic of the thermoplasticity of materials, the hot-stamping technology process is carried out by using heated movable insert blocks, the forming of local features is completed, sequential forming of different part features is completed, and final product parts are obtained. The dies are installed in one time, and two forming processes are realized, and thus the time-consuming of switching the dies is reduced, and the accuracy requirements of global forming and external dimensions of the product parts are guaranteed. At the same time, the movable insert blocks are convenient to install and easy to replace, so the time of repairing dies is reduced and the production efficiency is improved. The sequential forming technology has the unique advantages of in the forming of aerospace, automotive and other fields of complex structural alloy members, and has wide application prospect.

Owner:BEIHANG UNIV

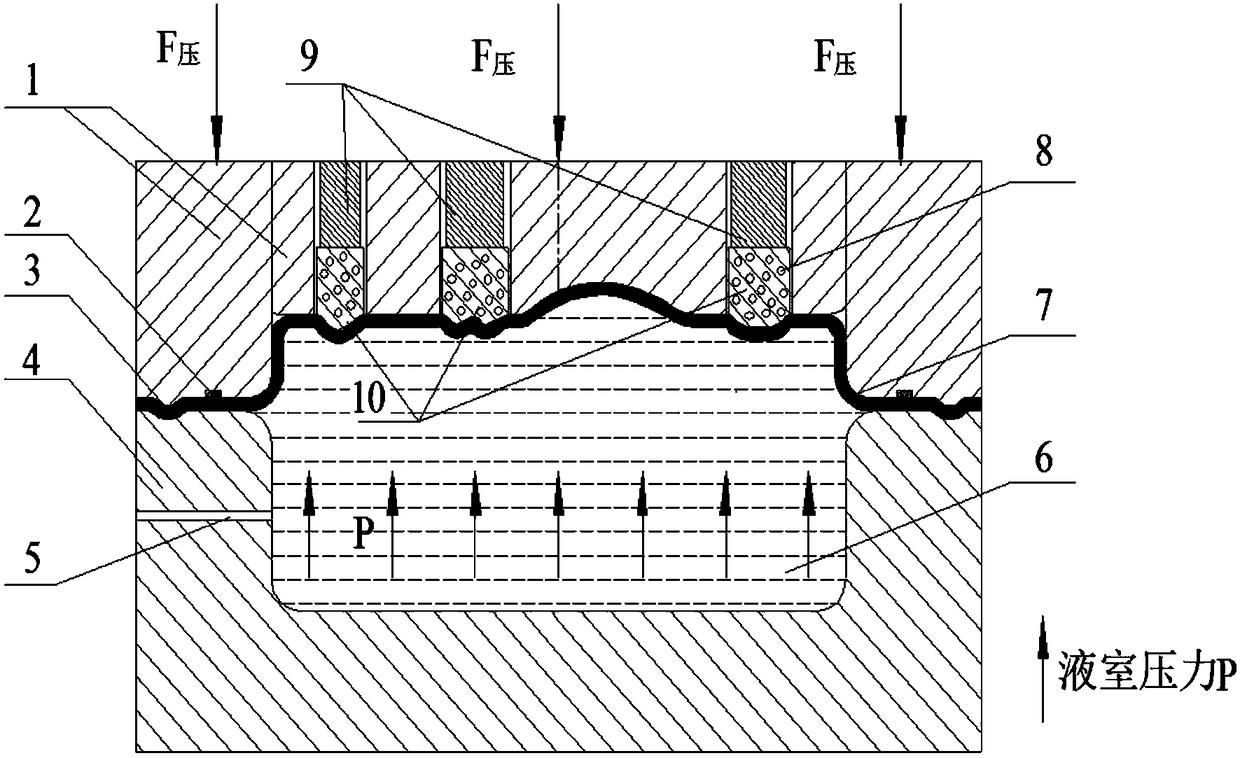

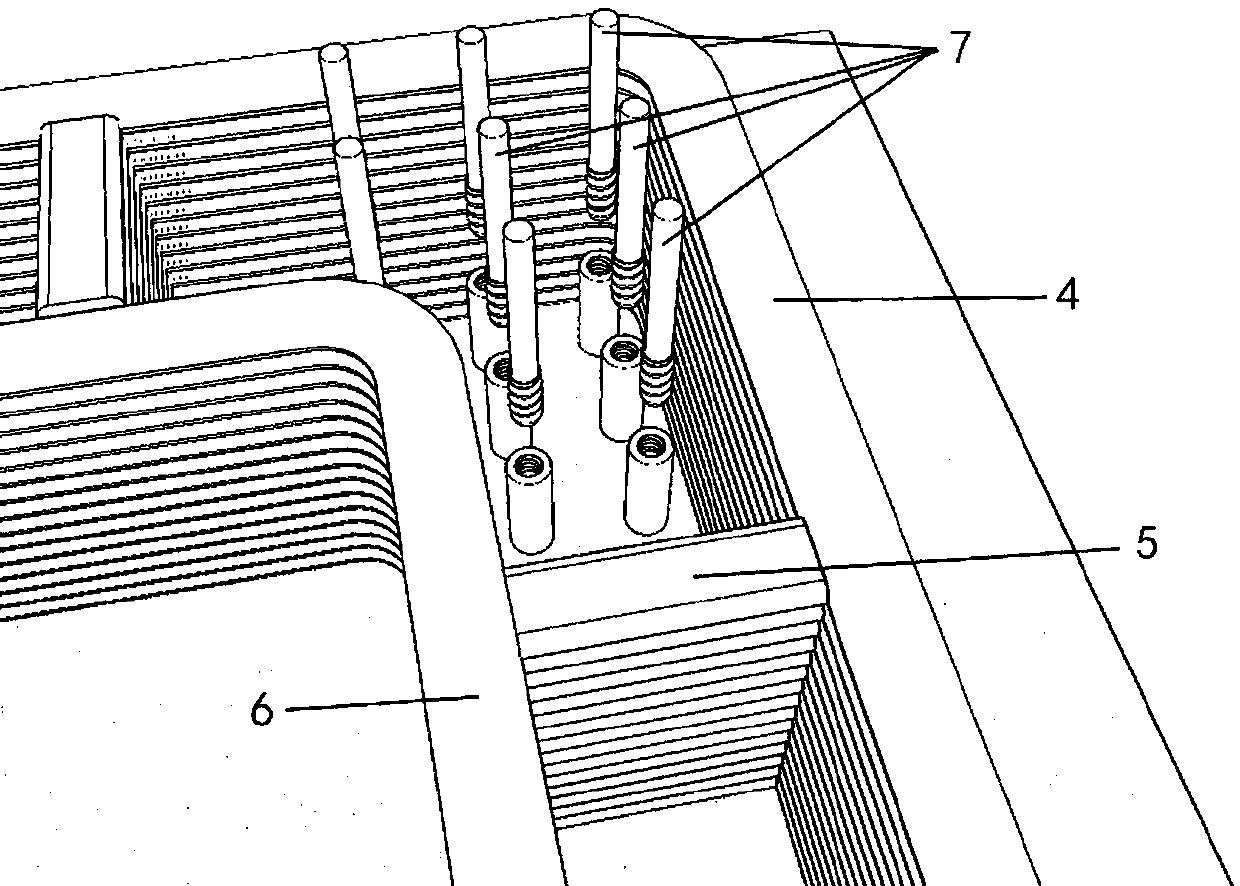

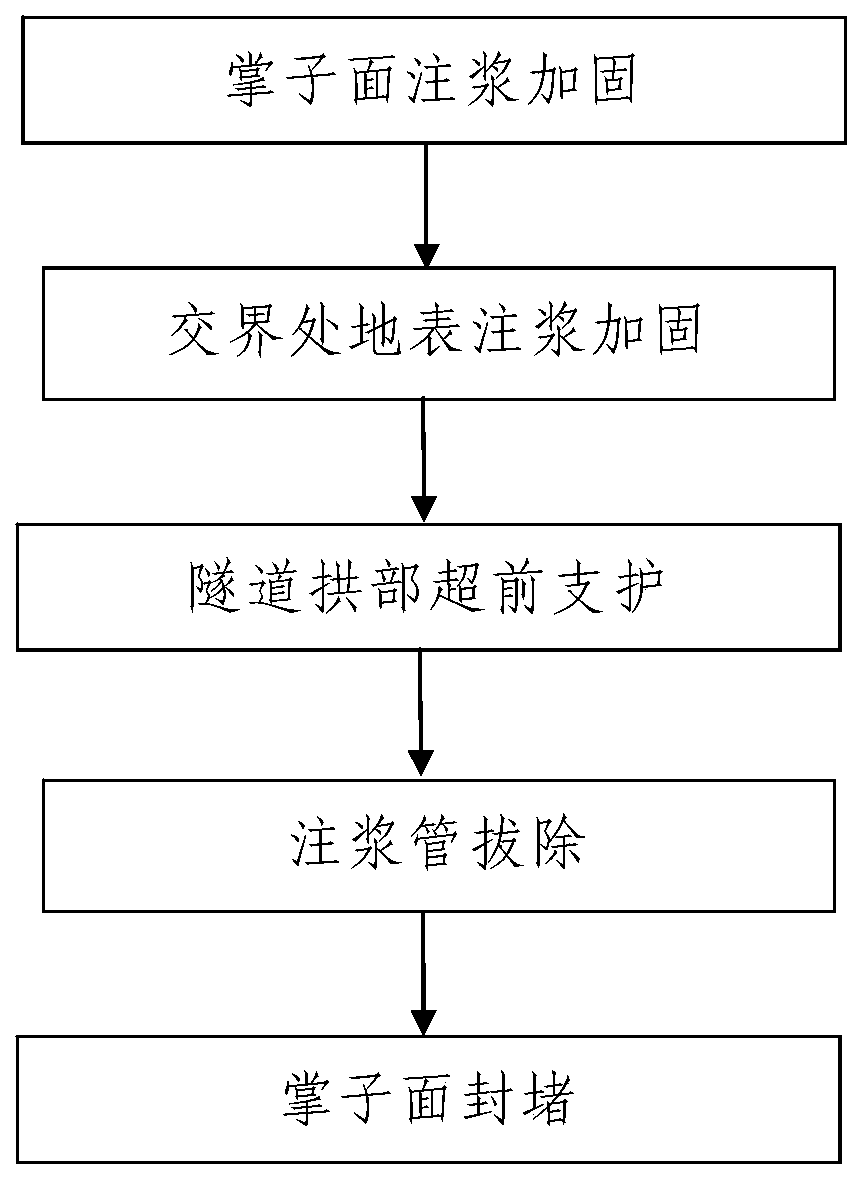

Surrounding rock reinforcement method for junction tunnel section in upper-soft lower-hard stratum constructed adopting shield method and mining method

ActiveCN110878696AThe method steps are simpleReasonable designUnderground chambersTunnel liningStructural engineeringGround settlement

The invention discloses a surrounding rock reinforcement method for a junction tunnel section in an upper-soft lower-hard stratum constructed adopting a shield method and a mining method. The method comprises the steps that 1, tunnel face grouting reinforcement is carried out, specifically, grouting reinforcement is carried out on stratum in front of an excavation face of an upper tunnel body by adopting grouting pipes; 2, junction surface grouting reinforcement is carried out, specifically, grouting reinforcement is carried out on the reinforced stratum by adopting sleeve valve pipes; 3, tunnel arch part advanced support is carried out, specifically, advanced support is carried out on an arch part of the junction tunnel section; 4, grouting pipe removal is carried out; and 5, tunnel faceplugging is carried out, specifically, a tunnel face is plugged through concrete backfilling, and a tunnel face plugging structure is obtained. The method is reasonable in design, simple and convenient to construct and good in use effect, and surrounding rock of the junction tunnel section is effectively reinforced by the method of combining the surface grouting reinforcement with the in-tunnel reinforcement so that the mechanical property of the surrounding rock can be effectively improved; and the tunnel face of the junction tunnel section is reliably plugged before and after reinforcement so that tunnel safety construction can be effectively guaranteed, and ground settlement caused by excavation can be effectively reduced.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

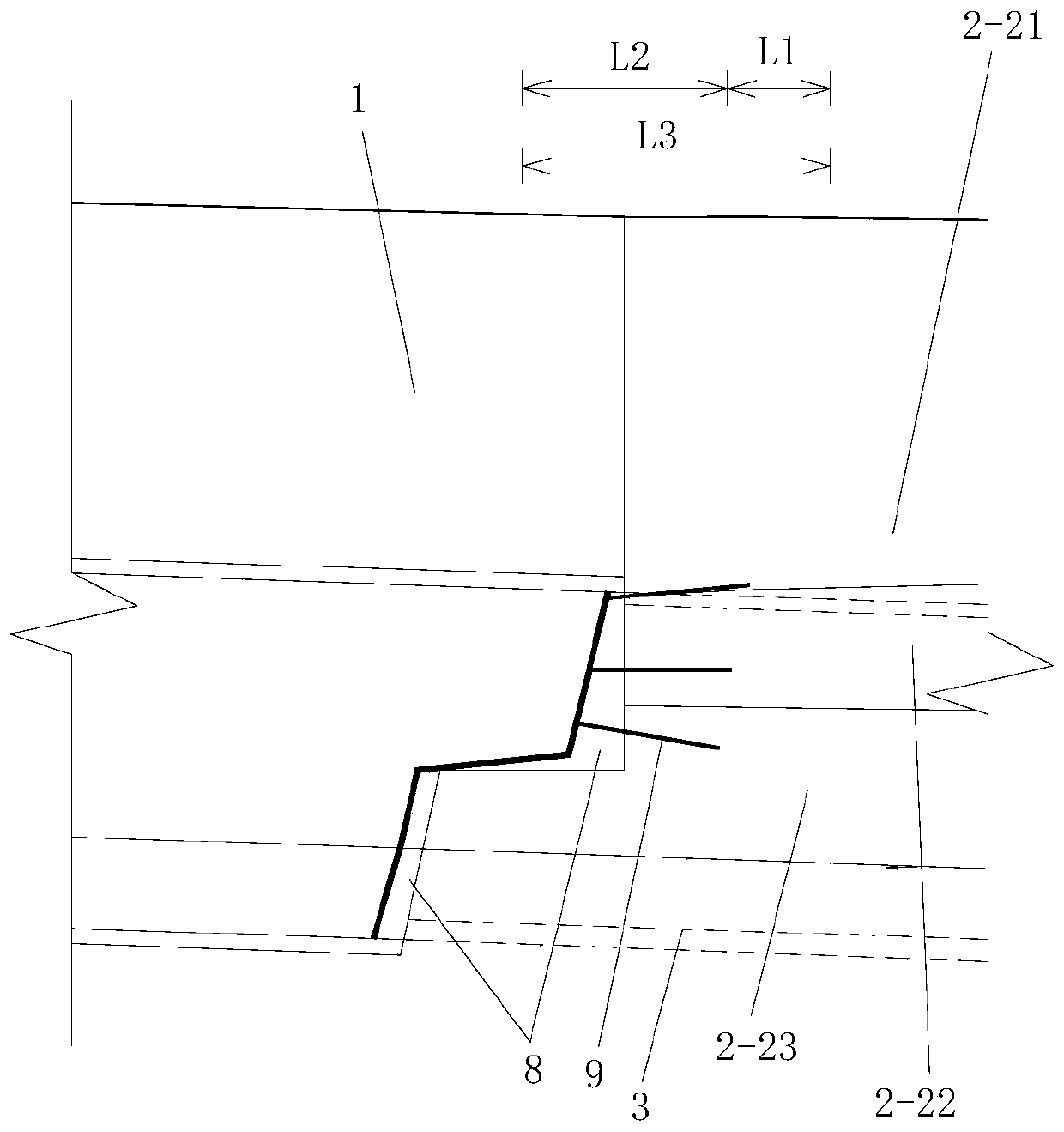

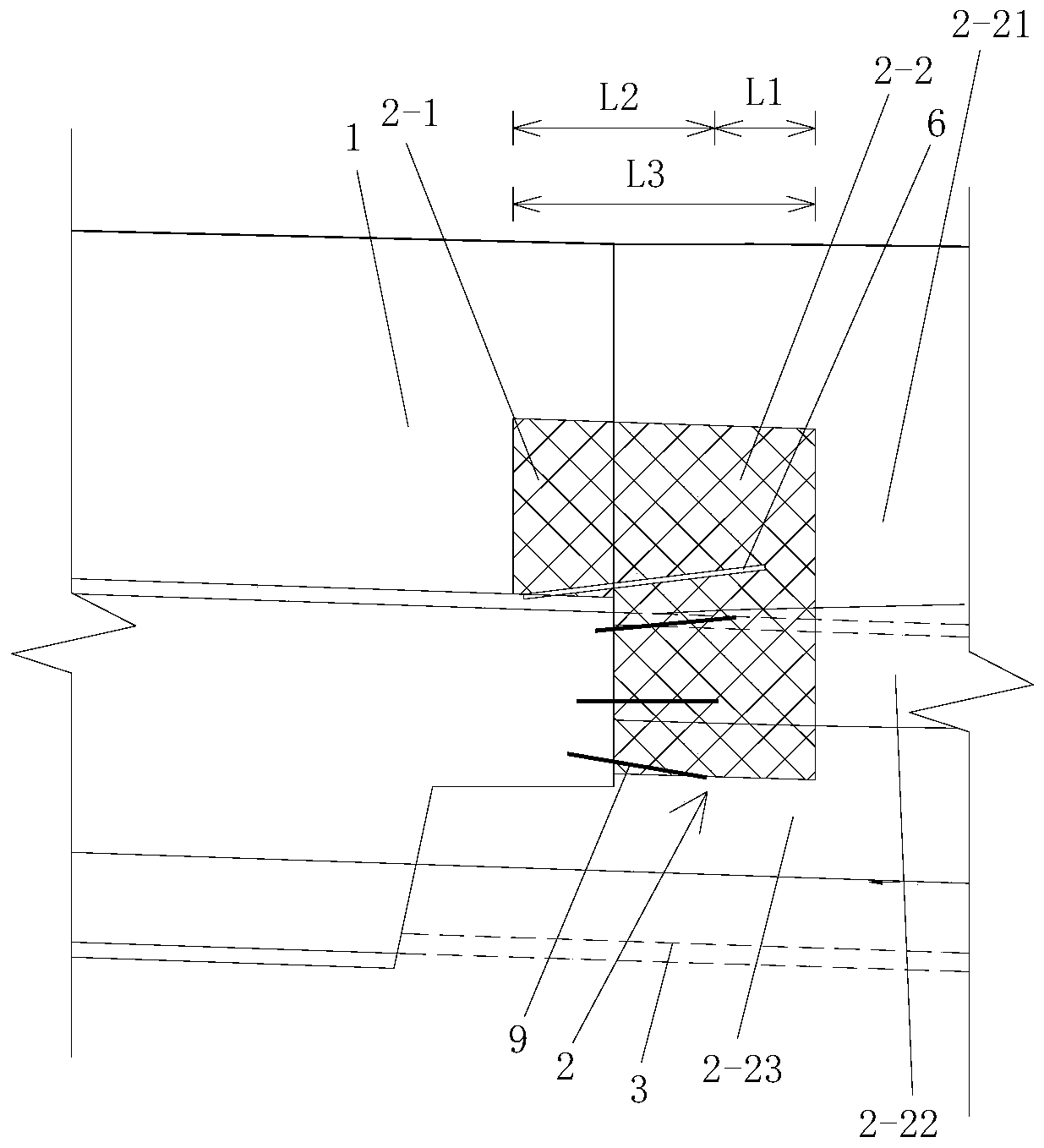

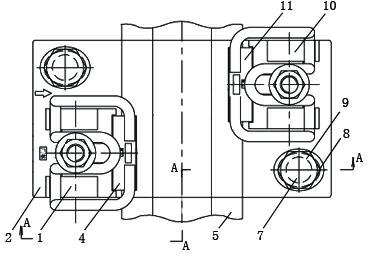

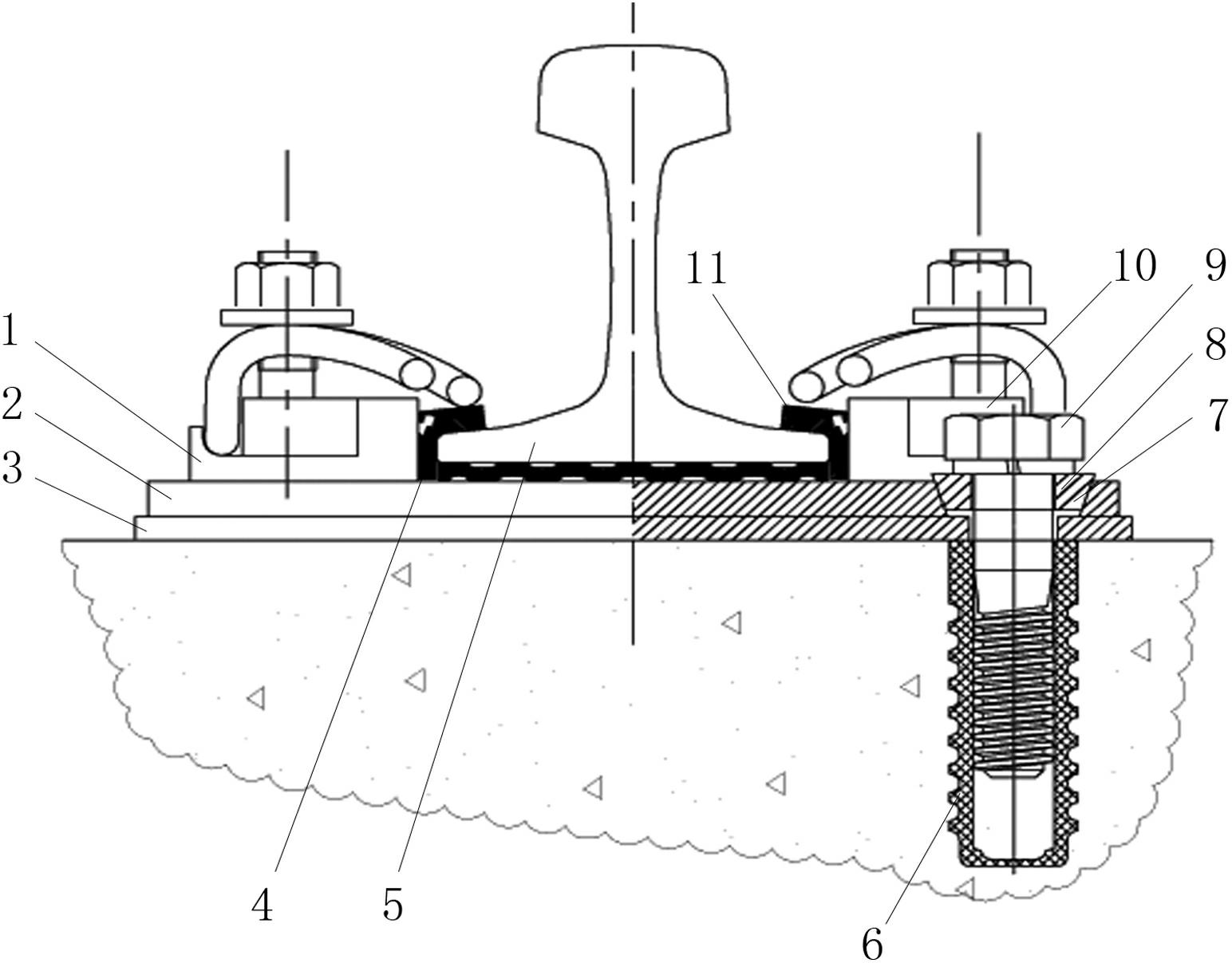

Fastener structure for adjusting track gauge

The invention discloses a fastener structure for adjusting a track gauge. The fastener structure comprises an iron base plate, a left iron seat and a right iron seat which are relatively arranged on two sides of a steel rail and fixed on the iron base plate and a left L-shaped track gauge pad and a right L-shaped track gauge pad which are arranged on the inner sides of the left iron seat and the right iron seat and buckled and pressed on the steel rail, wherein the iron base plate is arranged on a sleeper through a base plate; the two edges of each of the left L-shaped track gauge pad and the right L-shaped track gauge pad have different thicknesses, and a thickness difference is 1 to 3 mm; adjustment components are arranged at adjacent matched positions of the left iron seat and the right iron seat; each of the adjustment components mainly comprises a track gauge positioning block and an anchoring bolt; each track gauge positioning block consists of a central through hole in the middle and an elliptical taper outside; the elliptical tapers are matched with elliptical tapered holes in the iron base plate; and the track gauge positioning blocks are fixedly connected to the sleeper through the anchoring bolts. The fastener structure is simple and rational, has high practicability and a good effect, and is favorable for popularization and application.

Owner:张海洋

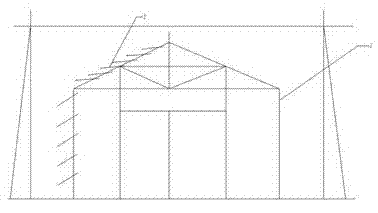

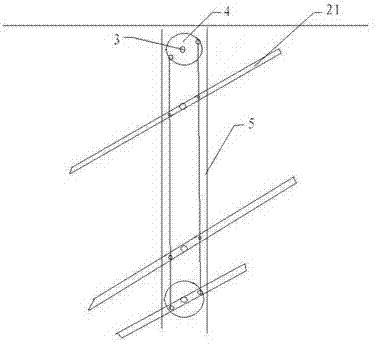

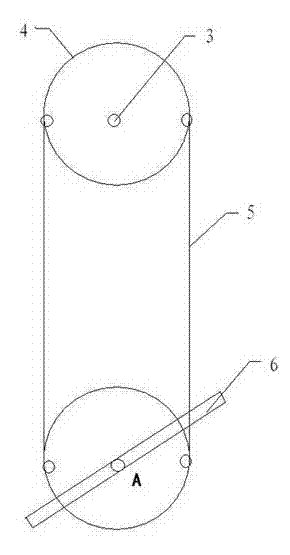

Shutter type sunlight greenhouse and construction method thereof

InactiveCN102771343AAchieve sunshadeAchieve ventilation effectClimate change adaptationGreenhouse cultivationGreenhouseEngineering

The invention relates to a shutter type sunlight greenhouse, comprising a sunlight greenhouse frame, wherein the door panel and the back of the frame are provided with glass. The sunlight greenhouse frame disclosed by the invention is characterized in that two sides and top surface of the frame are respectively provided with a shutter blind, the shutter blind comprises a plurality of acanthuses which are arranged in parallel, the acanthuses are connected into a whole by virtue of annular steel cables which are arranged vertical to the acanthuses, and multiple steel cables are arranged on the acanthuses; and spindles at the upper end and the lower end of the shutter blind are respectively provided with turning wheels in the same quantity, and the steel cables are sheathed onto an upper turning wheel and a lower turning wheel at positions corresponding to the steel cables. According to the invention, the shutter blind is applied to the sunlight greenhouse, sunshading and ventilation of the sunlight greenhouse can be effectively realized, temperature and humidity in the sunlight greenhouse can be scientifically and effectively managed, integrality and accuracy of regulation on the temperature and humidity of the sunlight greenhouse can be realized, labour time can be saved, labour intensity and cost can be reduced, and higher economic value can be achieved.

Owner:JURONG AGRI TECH PROMOTION CENT

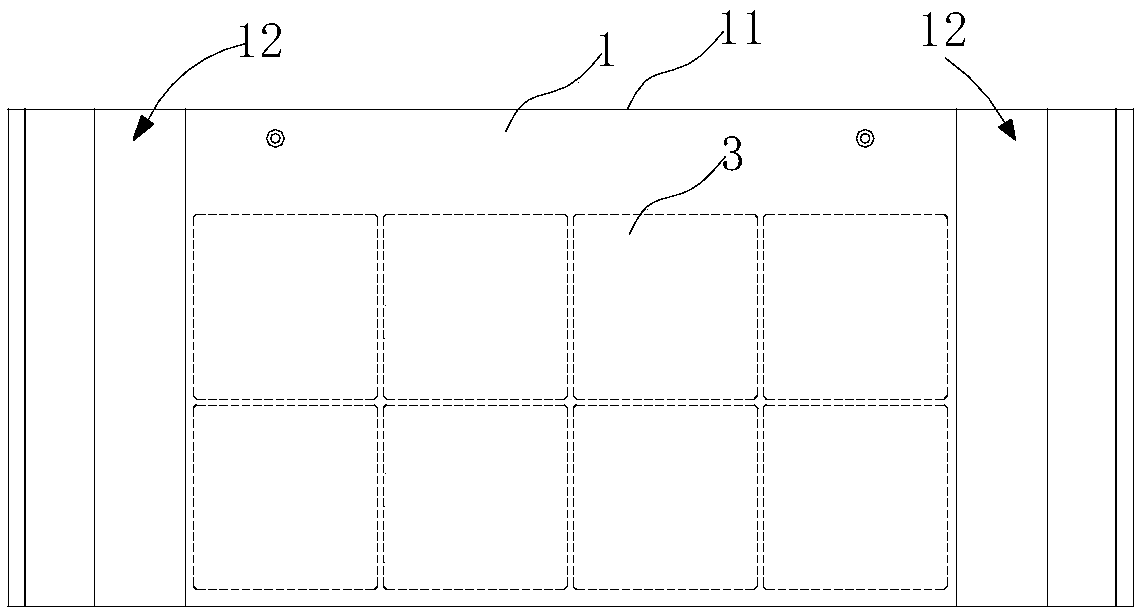

Photovoltaic cell tile, photovoltaic cell installation assembly and roof photovoltaic cell system

PendingCN107612471AAchieve wholenessProtect from direct sunlightPhotovoltaic supportsPhotovoltaic energy generationElectricityGeneration rate

The invention discloses a photovoltaic cell tile, a photovoltaic cell installation assembly and a roof photovoltaic cell system. The photovoltaic cell tile comprises a glass tile body; the glass tilebody comprises a plane installation part used for installing a photovoltaic cell, and reflecting parts which are located on the two sides of the plane installation part and are used for reflecting light rays to the photovoltaic cell at the plane installation part. A wiring box which is electrically connected with the photovoltaic cell is arranged on one side of the back face of the plane installation part. A plurality of photovoltaic cell tiles are sequentially spliced and connected to obtain the photovoltaic cell installation assembly. The reflecting parts on the photovoltaic cell tiles provided by the invention can provide additional light energy, the light energy utilization rate is improved, and the power generation rate of the photovoltaic cell is increased. A new structure installation mode is provided for the combination of the building and photovoltaic power generation in the prior art, the use waste of the product materials can be reduced, and the economic waste caused by secondary construction can be avoided.

Owner:TRINA SOLAR CO LTD

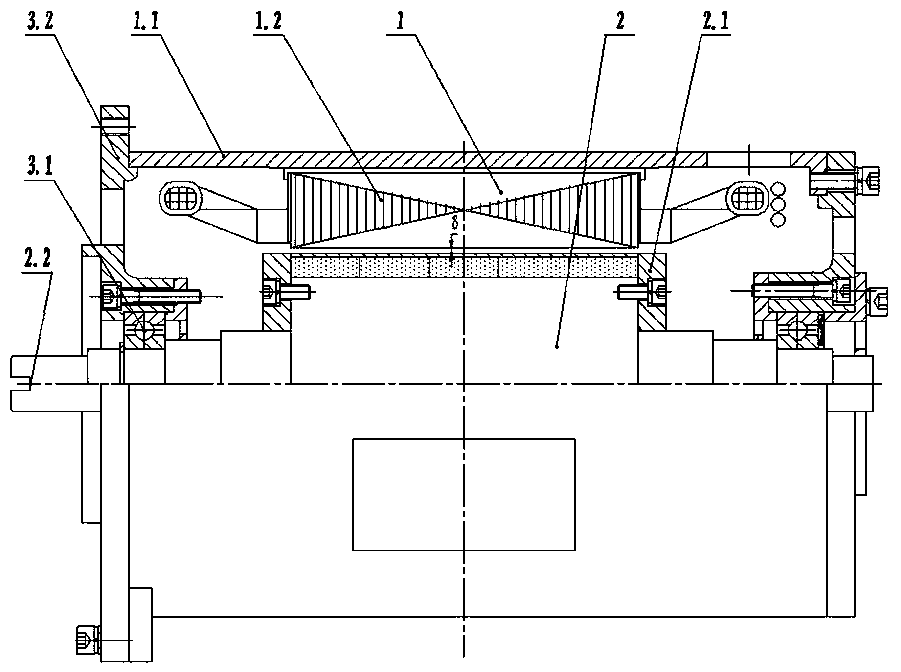

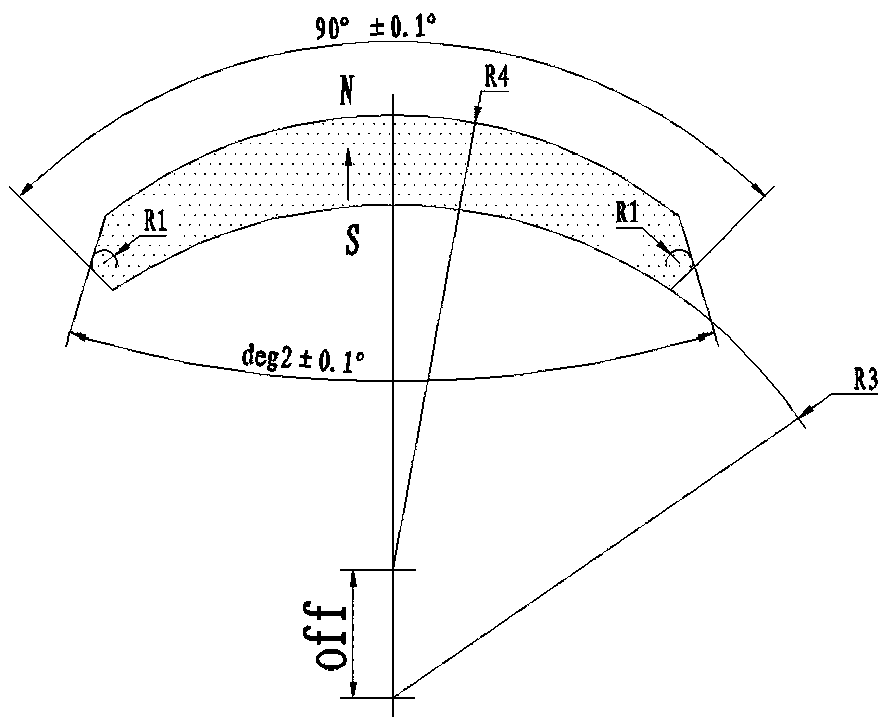

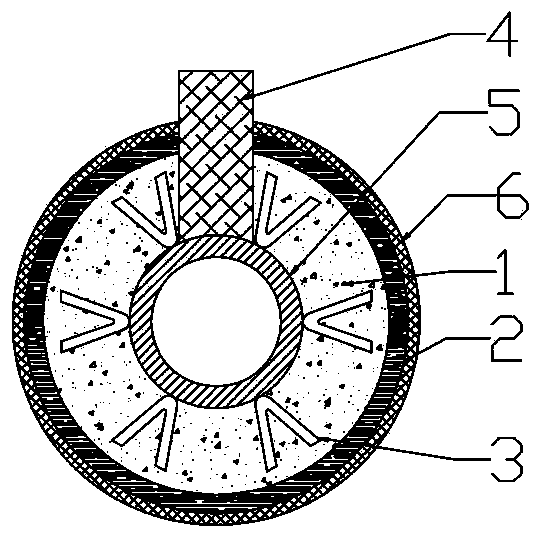

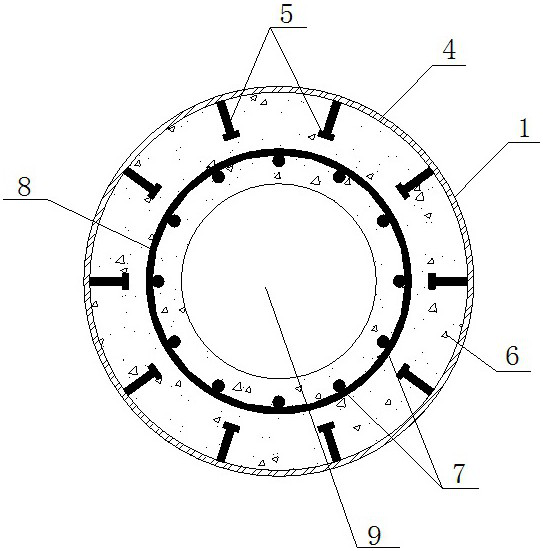

Oil-immersed permanent magnet motor

InactiveCN109713820AEvenly heatedImprove cooling effectMagnetic circuit rotating partsMechanical energy handlingCooling effectPermanent magnet motor

The invention discloses an oil-immersed permanent magnet motor, and the motor comprises a stator and a rotor. The stator comprises an engine base and a stator core with a winding. The rotor comprisesa rotating shaft and a rotor end pressing plate. An even number of open slots are formed in the outer surface of the rotating shaft, and T-shaped magnetic steel pressing blocks with taper is fixedly arranged in the open slots. A first magnetic steel strip and a second magnetic steel strip are fixedly arranged in a magnetic steel mounting cavity at an interval. The first magnetic steel strip is composed of a plurality of first magnetic steels with N poles on the outer circumferences and S poles on the inner circumferences, and the second magnetic steel strip is composed of a plurality of secondmagnetic steels with S poles on the outer circumferences and N poles on the inner circumferences. The outer circumferences of the first magnetic steel strip and the second magnetic steel strip are thermally sleeved by sheaths at intervals. According to the invention, the stator and the rotor are uniformly heated, and the cooling effect is good. Meanwhile, the influence on the eccentric magnetic steel is reduced when the sheath is thermally sleeved, and the reliability and the safety are improved. The motor is completely immersed in hydraulic oil, and an eccentric air gap is adopted to improvethe magnetic density waveform scheme, so that the torque ripple and the vibration noise of the motor are small, and the product competitiveness is improved.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

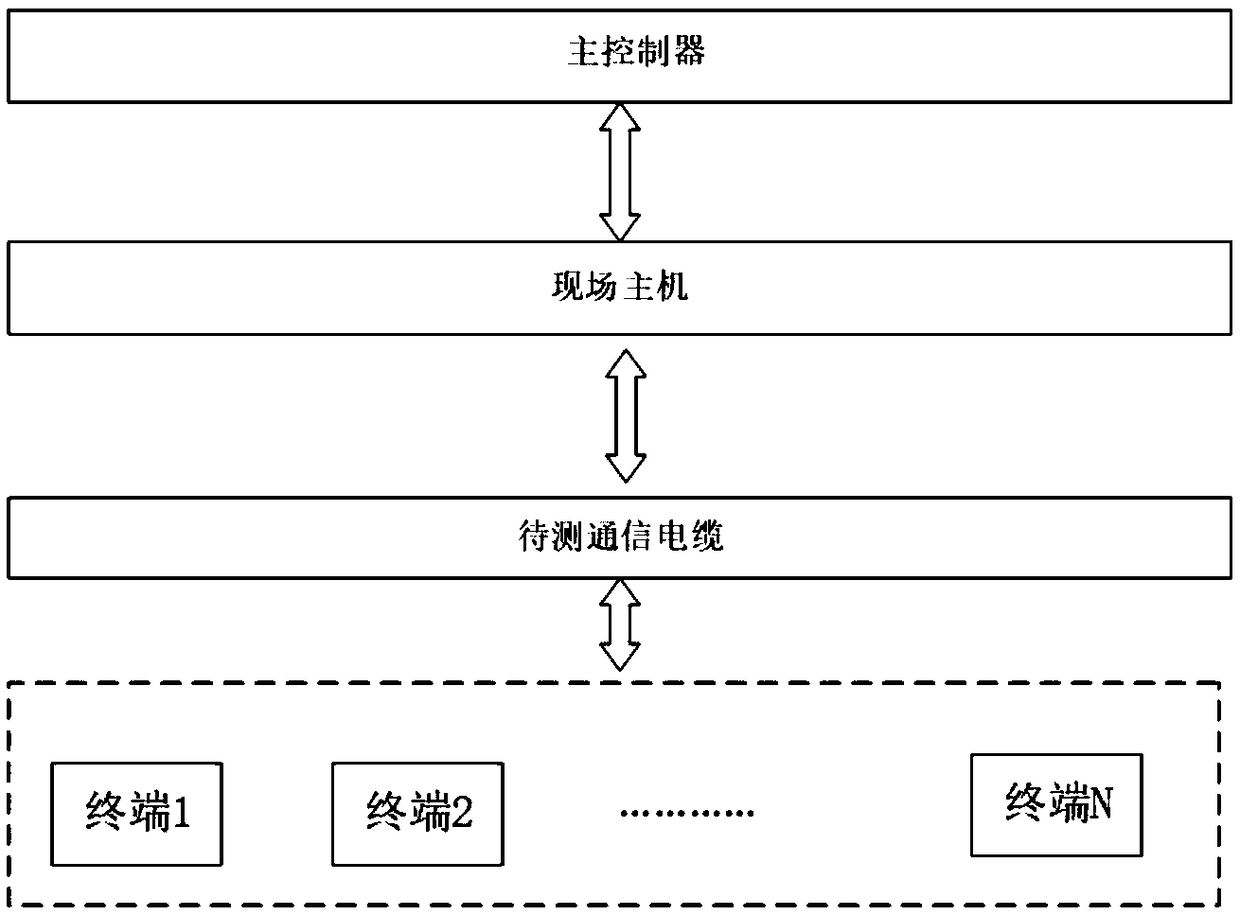

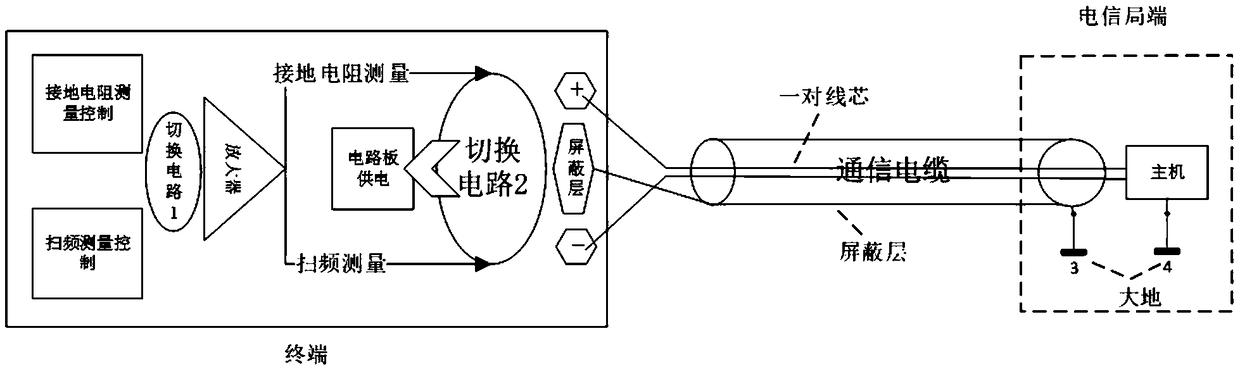

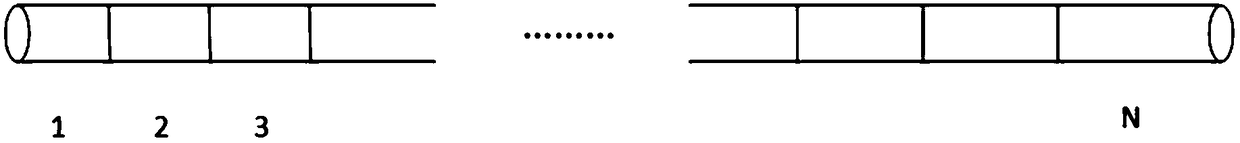

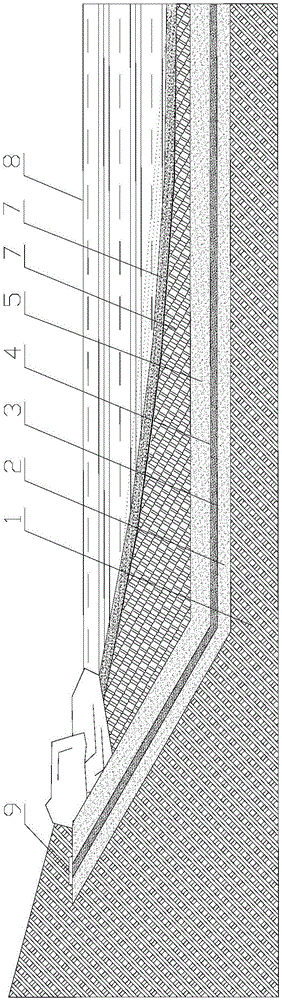

Online monitoring and evaluation method and system for shielding effectiveness of shielding layer of communication cable

ActiveCN109116126ASolving one of the biggest challenges in shielded securityAchieving system performanceElectromagentic field characteristicsElectrical resistance and conductanceGrounding resistance

The invention discloses an online monitoring and evaluation method and system for the shielding effectiveness of a shielding layer of a communication cable. The method comprises: on the basis of a cable segmented frequency sweeping measuring method, fault identification and positioning of a cable shielding layer are carried out; with a loop impedance measurement method, the state of a grounding resistor of the cable shielding layer is determined; comprehensive analysis and reverse evaluation of the shielding effectiveness of the cable are carried out by using an algorithm. According to the invention, reasonable quantitative evaluation of the shielding effectiveness, which can not be evaluated easily in the prior art, of the shielding layer of the communication cable is realized; and a problem of the safety field of the communication cable shielding is solved. Meanwhile, with measurement of various cable physical parameters, systematic, holistic and complementary evaluation of the cableshielding layer is realized.

Owner:康威通信技术股份有限公司

Waterproof structure for ecological artificial lake

The invention discloses a waterproof structure for an ecological artificial lake, relates to a waterproof technology for underground construction, and specifically relates to a waterproof technology for the bottom of an ecological artificial lake. The waterproof structure for the ecological artificial lake comprises a rammed-earth layer, a silty clay-rolled cushion layer, a silty clay-rolled protection layer and a medium sand water purification layer. The waterproof structure for the ecological artificial lake is characterized in that the constructed layers of the waterproof structure are located at the bottom of the waterproof structure, and sequentially are the rammed-earth layer, the silty clay-rolled cushion layer, a bentonite waterproof layer, a non-woven fabric, the silty clay-rolled protection layer, a silty clay-rolled counter-weight and the medium sand water purification layer from bottom up; the edge of the waterproof structure is more than 200mm higher than the horizontal plane; and a concrete protection belt is laid on the upper part of the edge of the waterproof structure, and the concrete protection belt is located on the upper part of the edge of the bentonite waterproof layer for preventing the bentonite waterproof layer from leakage. The waterproof structure for the ecological artificial lake, which is disclosed by the invention, has the characteristics of being novel in structure, simple and convenient to construct, capable of reducing construction cost, high in waterproofness, capable of achieving a service life of over thousand years, and the like; therefore, a novel waterproof structure for an ecological artificial lake, which integrates economical efficiency with practicability, is achieved.

Owner:何发林

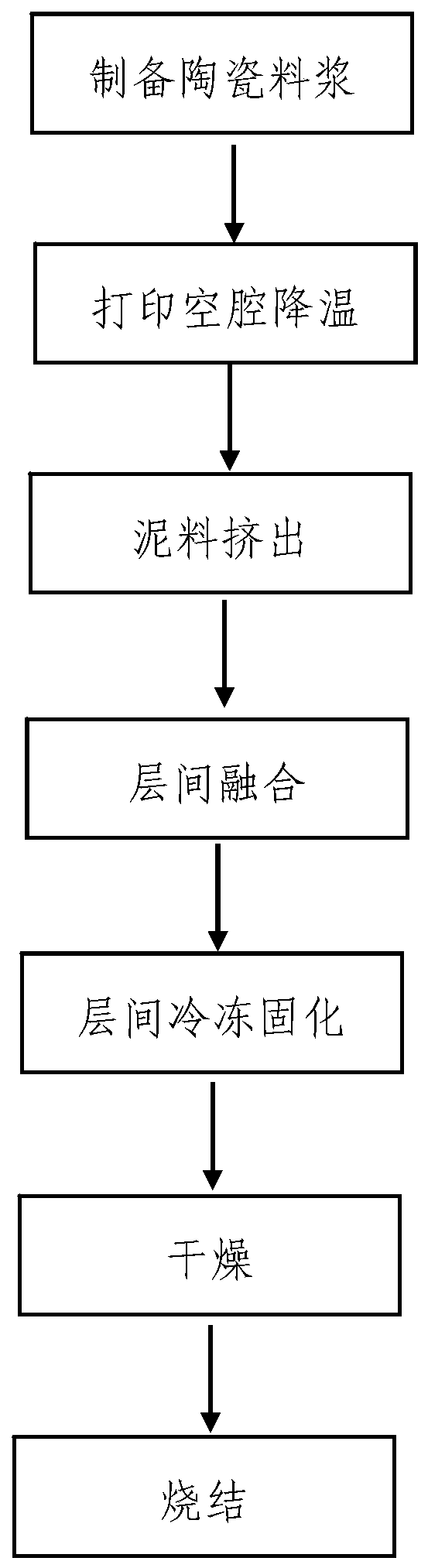

Three-dimensional freezing printing method of ceramic components

ActiveCN110815491AAchieve wholenessHigh bonding strength between layersAdditive manufacturing apparatusCeramic shaping apparatusPolyethylene glycolPolyvinyl alcohol

The invention relates to a three-dimensional freezing printing method of ceramic components. The method comprises the following steps that (1) ceramic powder, silica sol, polyethylene glycol and polyvinyl alcohol are subjected to ball milling to obtain a ceramic slurry; (2) a printing cavity of a 3D printing device is cooled to minus 10 DEG C to minus 60 DEG C, and then the ceramic slurry is usedfor printing; the wet mud material extruded from nozzles is bonded to a printing base plate to form a first layer of mud material; printing is continuously conducted, the wet mud material extruded from the nozzles continuously form a second layer of mud material, a third layer of mud material.., and an Nth layer of mud material on the first layer of mud material; and the formed mud layers are gradually fused, and when printing is carried out to by 4-10 layers, the inner mud material layers and the interlayers are gradually frozen and solidified to obtain a green body; and (3) the green body isfreeze-dried and then heated and sintered to obtain the ceramic component. According to the printing method, the integrity of the printed ceramic can be realized, and the bonding strength between thelayers is improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

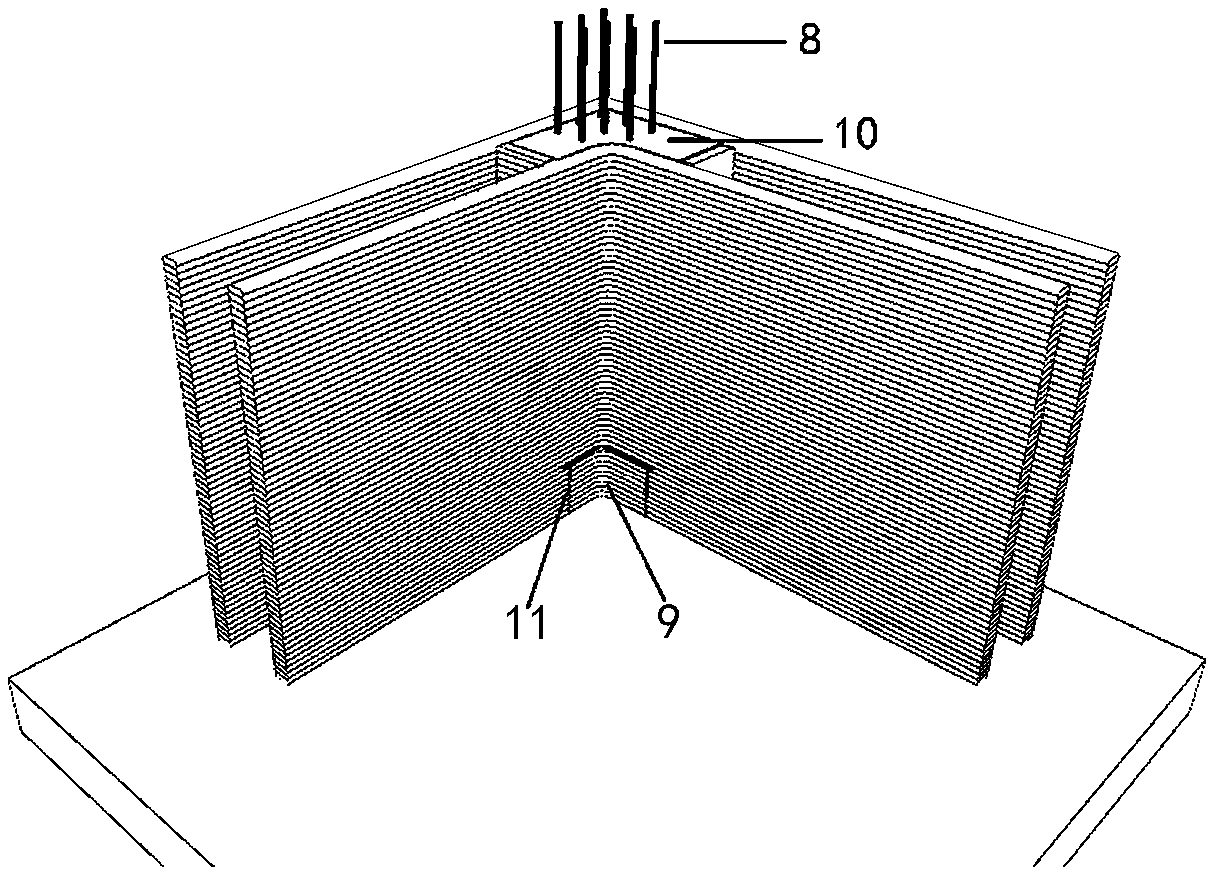

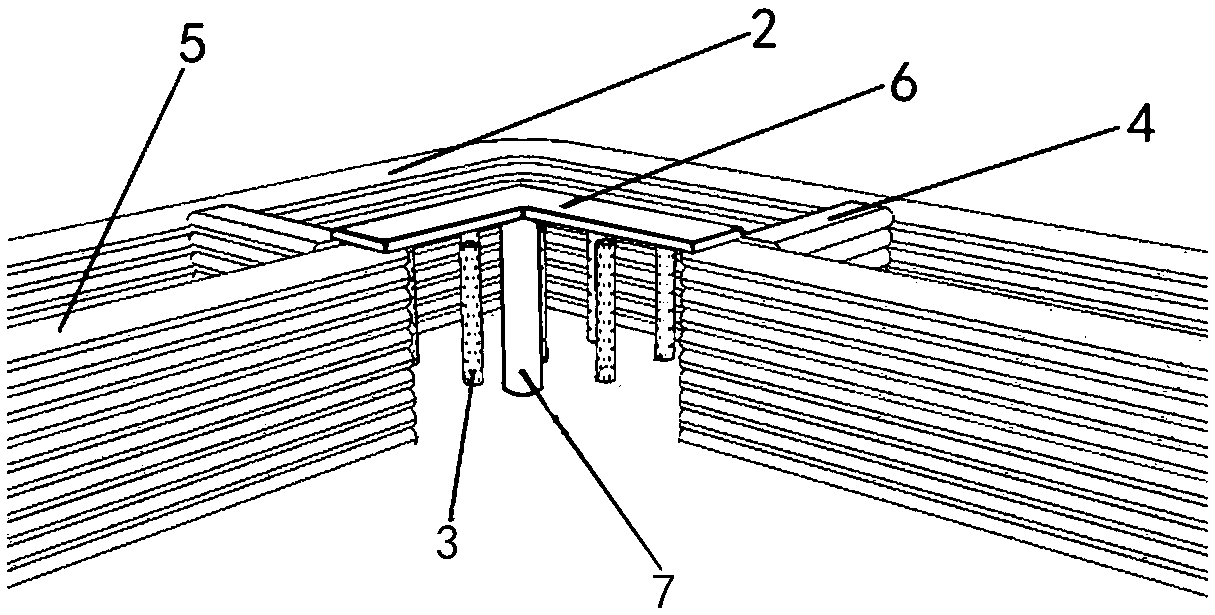

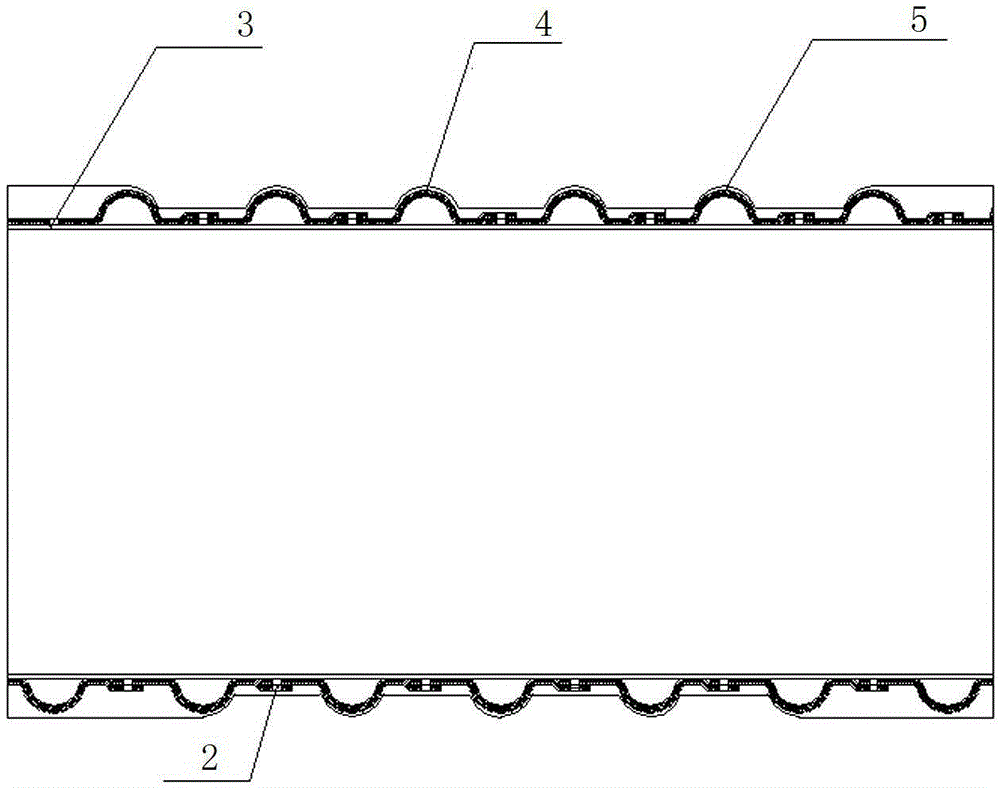

Field 3D printed wall column structure and construction method thereof

PendingCN111379360AImprove structural stabilityQuality assuranceAdditive manufacturing apparatusWalls3d printArchitectural engineering

The invention discloses a field 3D printed wall column structure and a construction method thereof. A concrete structure bottom plate, embedded steel bars, a hole lintel, a structure column reinforcement cage, a 3D printing outer wall, a 3D printing inner wall, 3D printing wall inner ribs and cast-in-place column concrete are included. 3D printing special equipment is adopted for conducting 3D printing wall construction, after a hole is reserved for installing the structure column reinforcement cage, a 3D printing hole prefabricated component is used for blockage, finally, cast-in-place concrete is poured, and an integral structure is formed by a structure column and the 3D printing wall. The field 3D printed wall column structure and the construction method thereof solve the problems thata field 3D printed building is poor in integrity and low in structure safety; and structure stability of the field 3D printed building technology is improved, and the construction quality is guaranteed.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

HDPE flatly sealed all-steel-belt corrugated discharging tube and production technology

The invention discloses an HDPE flatly sealed all-steel-belt corrugated discharging tube and a production technology. A tube wall of the HDPE flatly sealed all-steel-belt corrugated discharging tube comprises a polyethylene inner layer, a spiral steel belt middle layer and a polyethylene outer layer which are tightly attached from inside to outside, wherein the spiral steel belt middle layer is formed by sequentially spirally winding concave and convex steel belts from one end to the other end; a plurality of through holes are formed in edges of adjacent spiral units which are in lap joint correspondingly; the through holes are filled with polyethylene and are connected with the polyethylene inner layer and the polyethylene outer layer to form a whole body; troughs are formed in steel belt lap joint positions of the surface of the tube wall of the discharging tube; crests are formed at steel belt projections; the troughs in ends of the discharging tube are filled with polyethylene so that flat end structures are formed at the ends of the discharging tubes. Plastic-steel separation is realized through the design of the connecting steel belts, continuity of the steel belts and integrity of the tube can be realized, and the compressive property of the tube can be guaranteed. In addition, the ends of the discharging tube are flat, so that flat sealing can be convenient to implement when tubes are in butt joint or are mounted in a wellhead, and construction quality is guaranteed.

Owner:东营市天诚建材有限公司

3D-printed wall column structure of building and construction method of structure

PendingCN111379359AAchieve wholenessAchieve connectionAdditive manufacturing apparatusWallsArchitectural engineeringColumn structure

The invention discloses a 3D-printed wall column structure of a building and a construction method of the structure. The wall column structure comprises a concrete structure bottom plate, embedded bars, a 3D-printed inner wall body, a 3D-printed outer wall body, 3D-printed wall body inner ribs, a structure column reinforcement cage and cast-in-place column concrete. According to the structure andthe method, construction of the 3D-printed wall bodies is performed by the aid of special onsite 3D printing equipment, lapped bars are connected with the embedded bars through bar sleeves after printing construction reaches the certain height, the structure column reinforcement cage is mounted after printing construction is continued to reach the single-layer height, the cast-in-place concrete iscast finally, and thus the structure column and the 3D-printed wall bodies form an integral structure. According to the structure and the method, the problems of poor integrity and low structural safety of the onsite 3D-printed building are solved, the structural stability of the onsite 3D-printed building technology is improved, and the construction quality is guaranteed.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

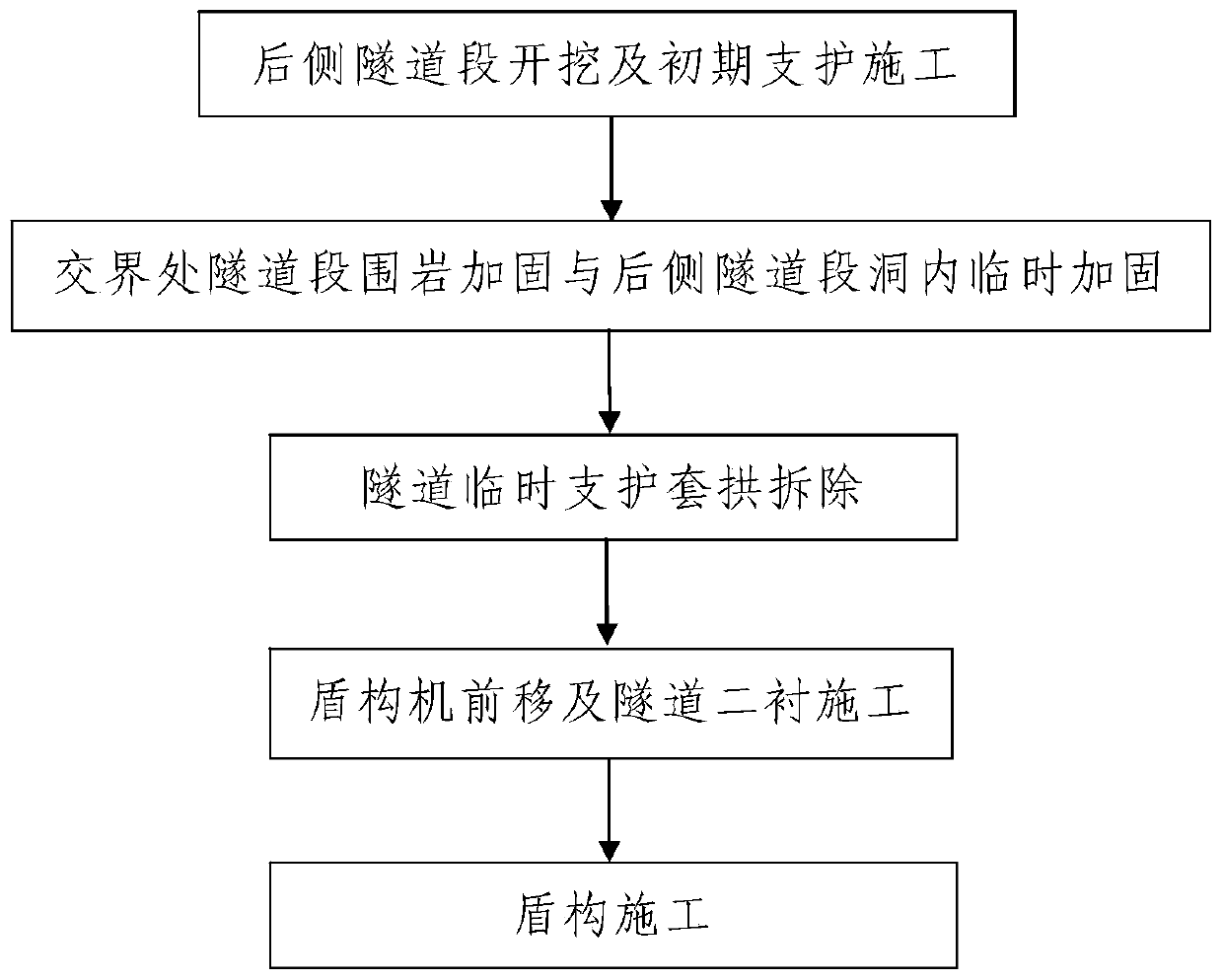

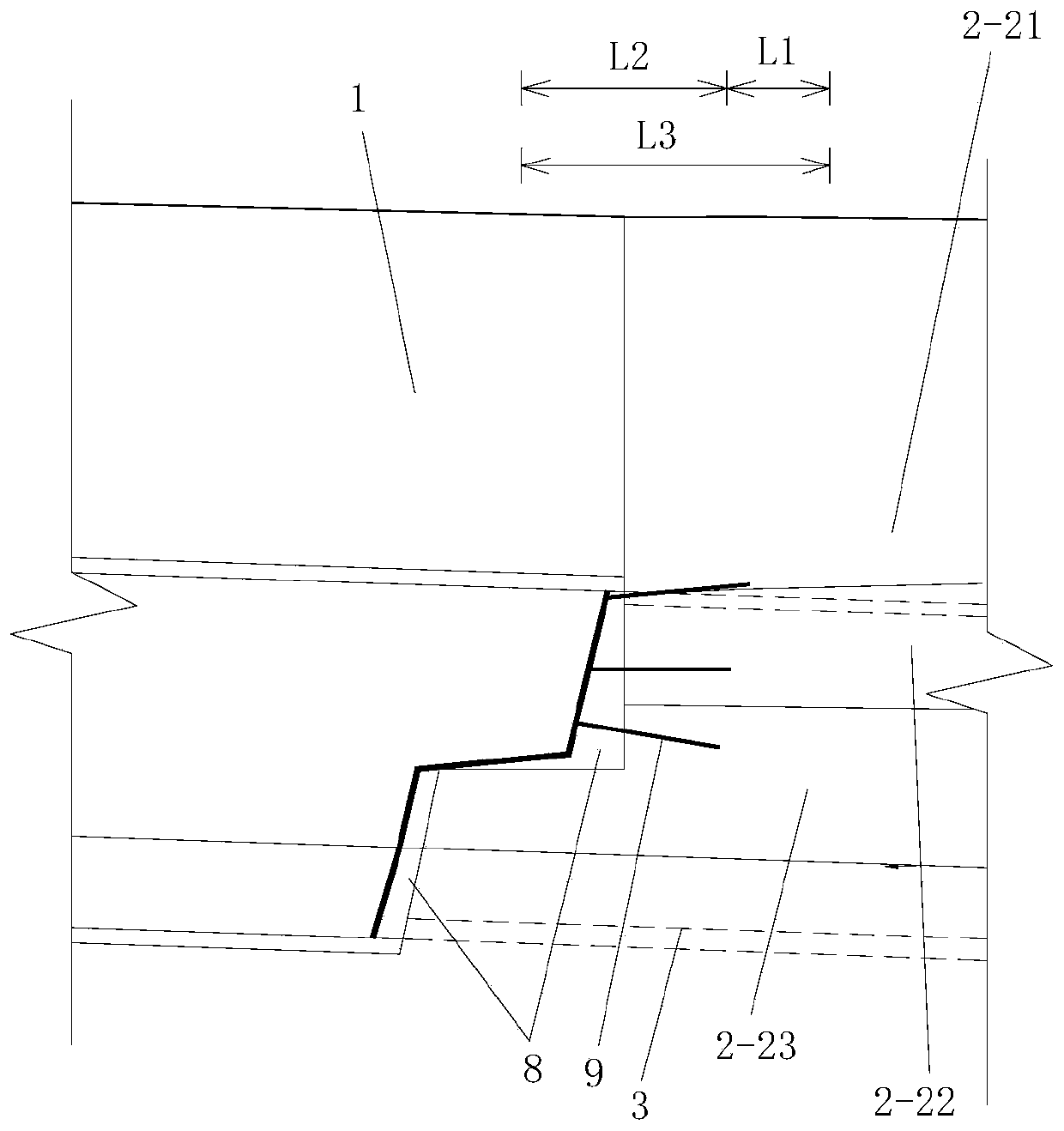

Tunnel construction method for formation with upper soft part and lower hard part

ActiveCN110905527AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringShield tunneling

The invention discloses a tunnel construction method for a formation with an upper soft part and a lower hard part. During construction of any one of to-be-constructed tunnels of the construction tunnel, the method comprises the following steps: 1, performing back side tunnel segment excavation and preliminary bracing construction; 2, performing junction tunnel segment surrounding rock reinforcement and back side tunnel segment in-cavity temporary reinforcement; 3, disassembling a tunnel temporary supporting cover arch; 4, enabling a shield tunneling machine to move forwards and performing tunnel secondary lining construction; and 5, performing shield tunneling construction. The method is reasonable in design, simple and convenient to construct and good in use effect; the stability of theback side tunnel segment is guaranteed by a tunnel temporary supporting cover arch; the junction tunnel segment surrounding rock is effectively reinforced by a mode of combining ground surface grouting reinforcement with in-cavity reinforcement, so that the mechanical property of the surrounding rock can be effectively improved, the safe construction of the tunnel can be effectively guaranteed andsurface subsidence caused by excavation can be effectively reduced; and after the junction tunnel segment surrounding rod reinforcement is completed, the tunnel temporary supporting cover arch is disassembled and the shield tunneling machine moves towards in place to perform construction on the front side tunnel segment, so the construction process is safe and reliable.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

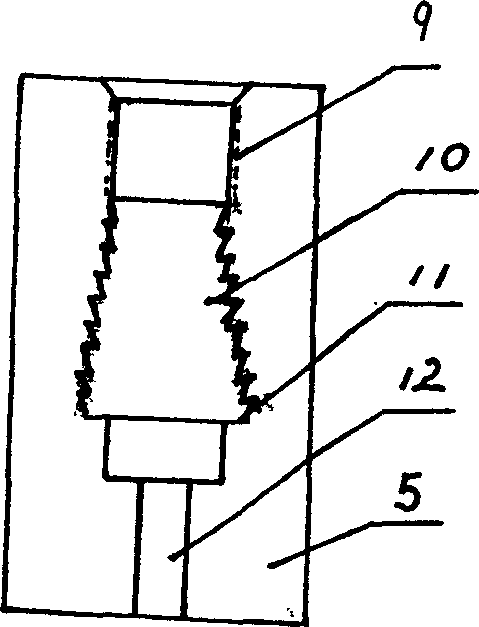

Upper-screw-lower-top expansion meshing body pile-connecting fastener and prefab

InactiveCN1676764AReduce manufacturing costAchieve consistencyBuilding constructionsBulkheads/pilesEngineeringRebar

The invention refers to the methods of making the pipe stake interface, prefabricate part consisted of the interface of the prefabricate part, the connection instruction between the prefabricate parts and prefabricate part. Top screw blow tip inflation mesh connection interface comprises inflation draw screw cap; the inflation mesh the screw; peak draw screw cap and inflation pin. The inflation draw screw cap connects to the screw part of the inflation mesh the screw. When they are face to face connected, the mesh gear of inflation mesh the screw inflate mesh in the inflation mesh cavity of the peak draw screw cap by the role of the inflation pin, the pre-make part which is made of top screw blow tip inflation mesh connection interface has the inflation draw screw cap and the top draw screw cap inserted in the two ends respectively. Many items of the portrait reinforcing steel bar's two ends clip to the steel cap of the inflation draw screw cap and the peak draw screw cap respectively. The inflation mesh screw cap used to the connection between the pre-make parts.

Owner:周兆弟

Furnace beam and vertical column fire-resistant thermal insulation lining structure of walking beam furnace for heating high-temperature oriented silicon steel and manufacturing method of structure

The invention discloses a furnace beam and vertical column fire-resistant thermal insulation lining structure of a walking beam furnace for heating high-temperature oriented silicon steel. The furnace beam and vertical column fire-resistant thermal insulation lining structure comprises a metal pipe forming a foundation of a furnace beam or a vertical column, wherein heat-resistant cushion blocks are arranged on the metal pipe forming the foundation of the furnace beam at intervals along the axis direction, metal anchoring parts are uniformly distributed on the outer wall of the metal pipe along the axial direction and the peripheral direction, a fire-resistant insulating layer is formed to cling to the outer wall of the metal pipe in a pouring manner and is combined with the metal anchoring parts, and the fire-resistant insulating layer is sequentially covered by a slag-bonding prevention layer and an anti-oxidation coating. As the heat preservation and slag-bonding prevention double-layer structure and the design of appropriate thickness are adopted by the furnace beam and vertical column fire-resistant thermal insulation lining structure of the walking beam furnace, the integrality of a thermal insulation lining is improved, and the comprehensive usability of the thermal insulation lining is improved.

Owner:武汉钢铁有限公司

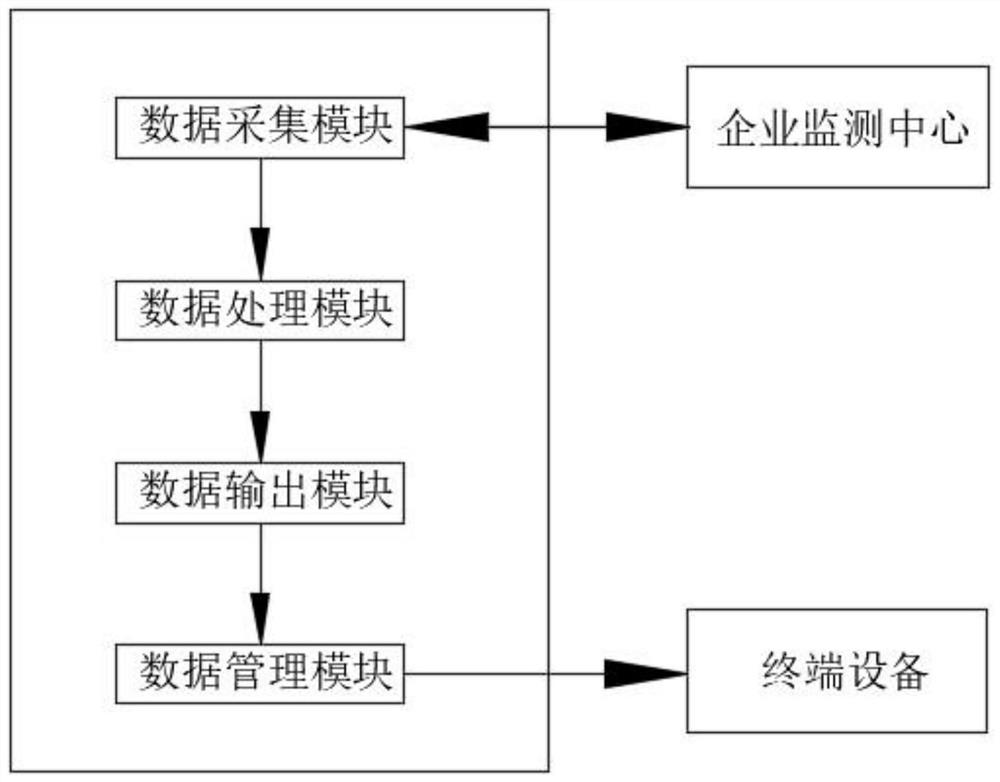

Management system based on industrial Internet of Things platform

PendingCN113298498AAchieve wholenessRealize digital expressionText processingTechnology managementData acquisitionIndustrial Internet

The invention discloses a management system based on an industrial internet of things platform, which comprises an enterprise monitoring center, a data acquisition module, a data processing module, a data output module, a data management module and terminal equipment, and the data acquisition module is used for acquiring employee magnitude information, equipment magnitude information and product quantification information on a production line, and sending the information to the data processing module; the data processing module carries out the following energy level evaluation operation on the received employee magnitude information, equipment magnitude information and product quantification information; according to the system, energy level evaluation operation is carried out on the employee condition and the equipment condition together to obtain magnitude data of the employee aspect and the equipment aspect, then digital integration is carried out on the magnitude data to obtain a comprehensive judgment signal combining the employee and the equipment, and the production condition on a production line is effectively judged through the signal, therefore, integral and digital expression of production equipment, personnel conditions and production capacity on a production line is realized.

Owner:ANHUI VOCATIONAL COLLEGE OF DEFENSE TECH

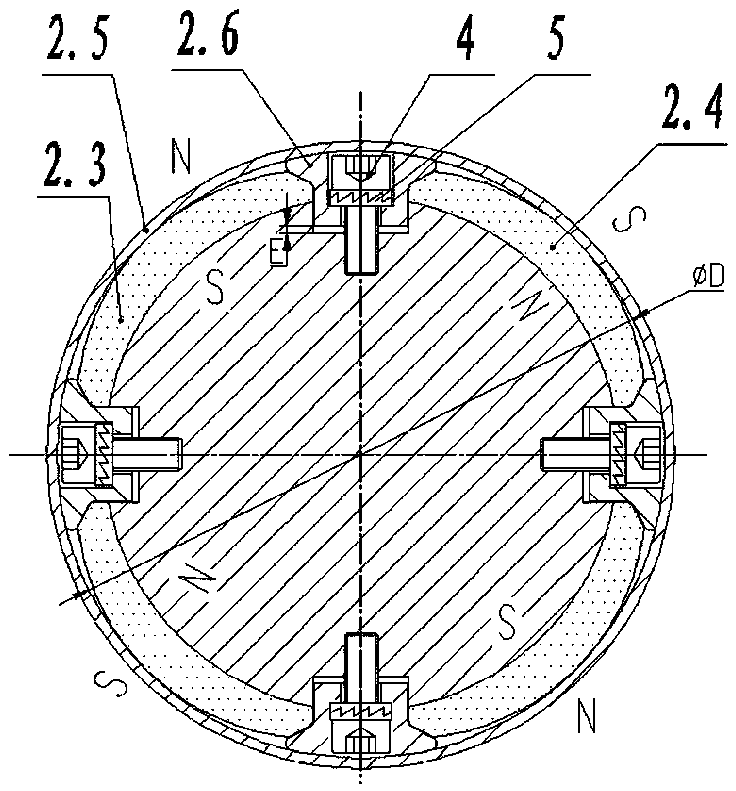

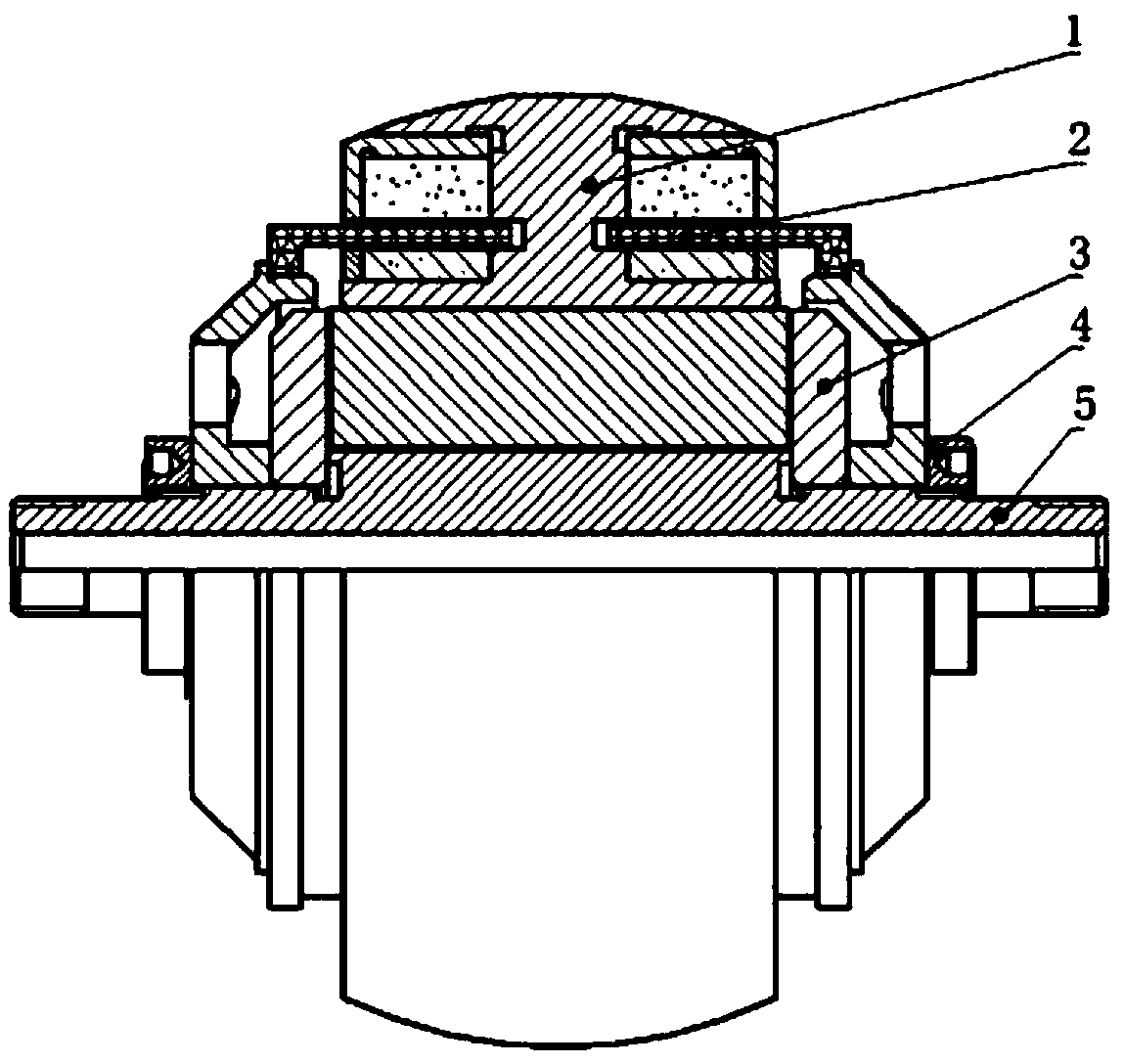

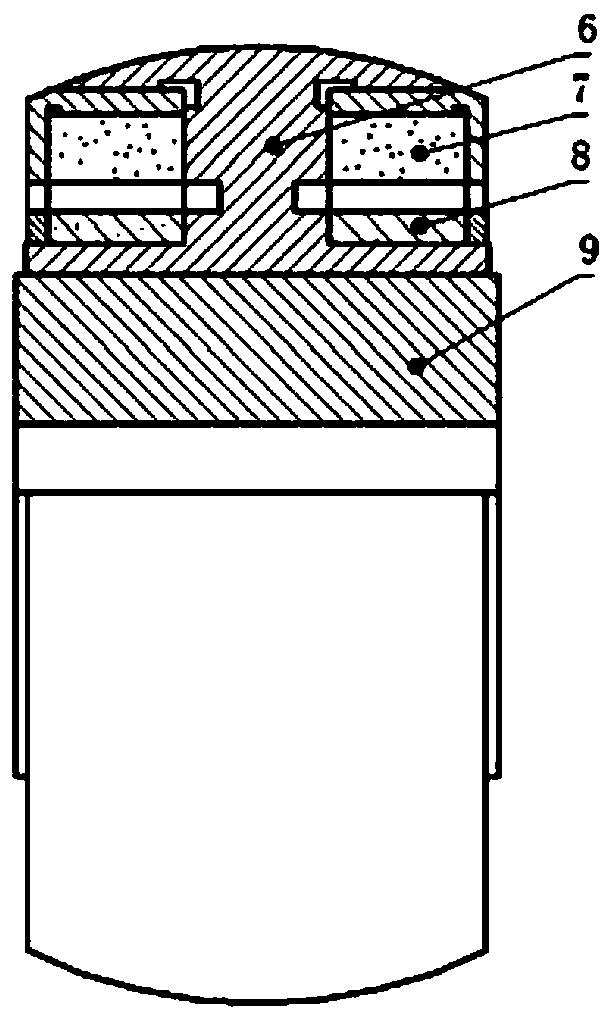

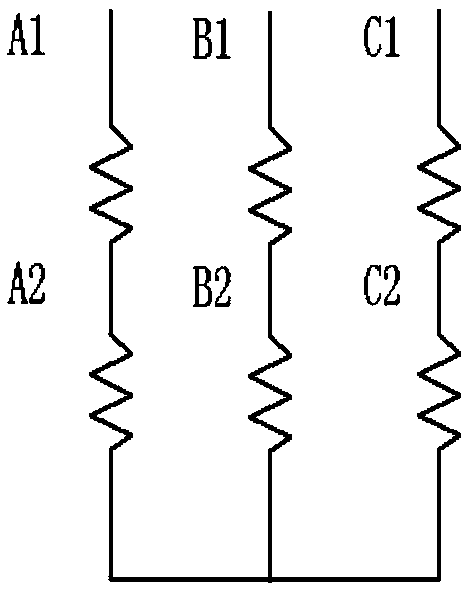

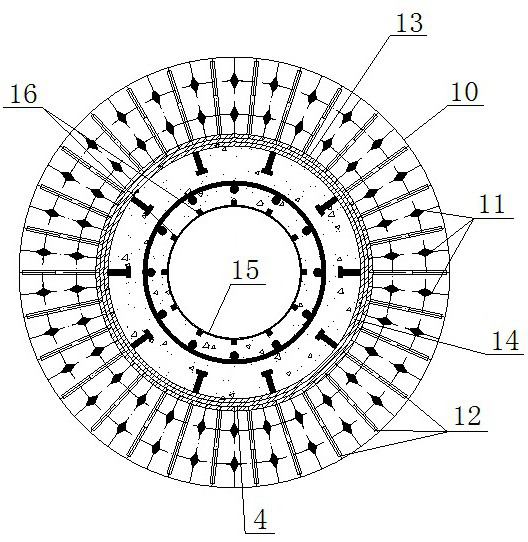

Radially-magnetized double-ring magnetic steel permanent magnet motor

InactiveCN109302026AImprove efficiencyIncrease stiffnessMagnetic circuit rotating partsWindings conductor shape/form/constructionGyroscopePermanent magnet motor

The invention relates to a radially-magnetized double-ring magnetic steel permanent magnet motor, and the motor comprises a rotor, stators, thrust plates, nuts and a shaft. The rotor consists of a rotor ring, an external magnetic steel ring, an internal magnetic steel ring and a bearing ring. The internal surface of the external magnetic steel ring is a work surface, and the external surface of the internal magnetic steel ring is a work surface. The external and internal magnetic steel rings are installed on the rotor ring, and the rotor ring is installed on an outer ring of the bearing ring to form a rotor. The shaft is installed in a bearing hole of a rotor bearing ring, and the two thrust plates are installed at the left and right sides of the rotor bearing ring. The two stators are installed at two ends of the rotor, and are fixed on the shaft through the nuts. Moreover, the two stators are connected in series. The motor provided by the invention achieves the application of the radially-magnetized double-ring magnetic steel structure in a universal-type hydrodynamic gas-lubricated bearing three-phase permanent magnet motor, improves the efficiency, reduces the generated heat ofa winding, reduces the temperature gradient and mass center drift of a gyroscope, improves the instrument precision, is advanced in technology, and fills a gap of China in the technology.

Owner:TIANJIN NAVIGATION INSTR RES INST

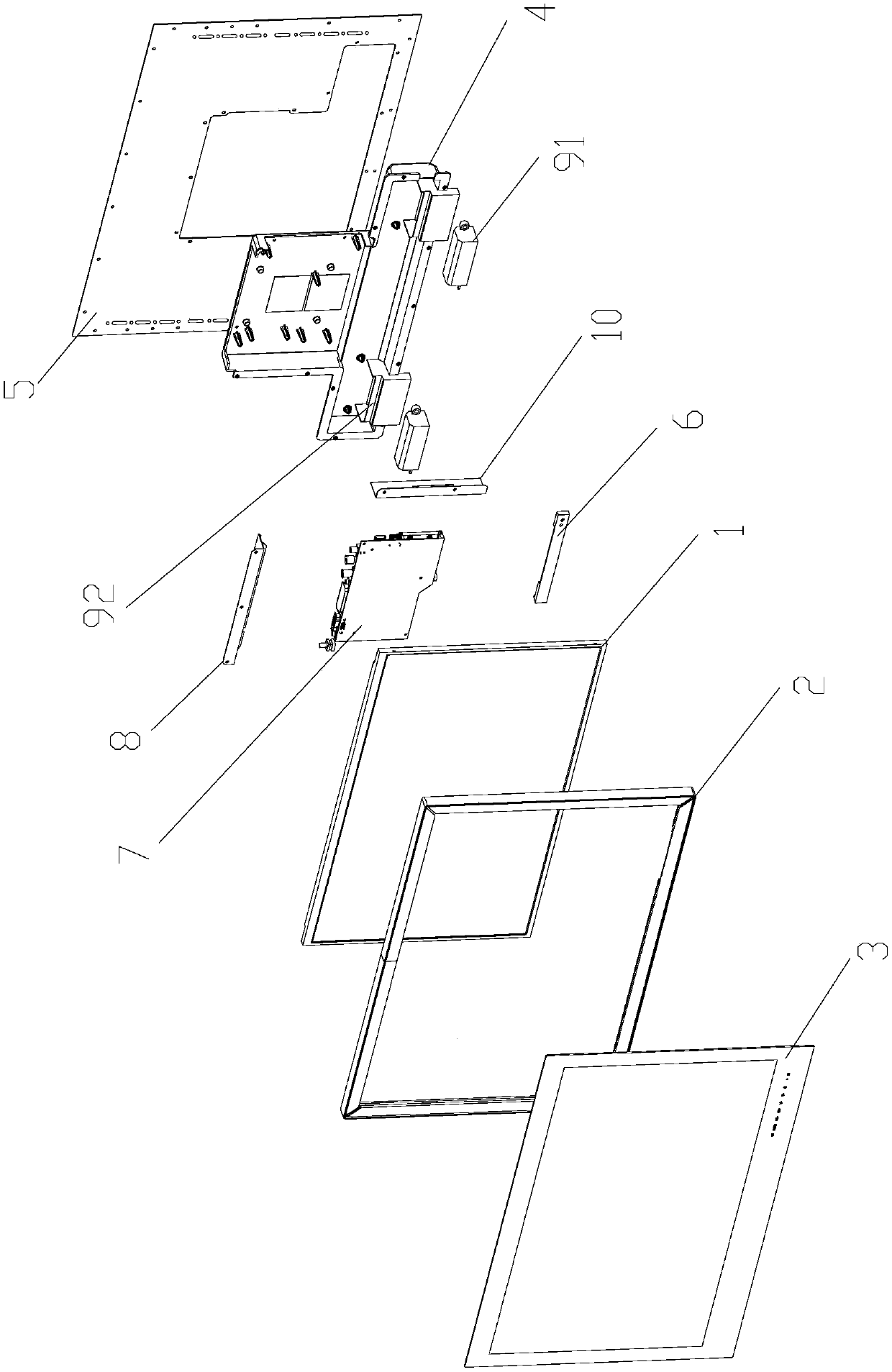

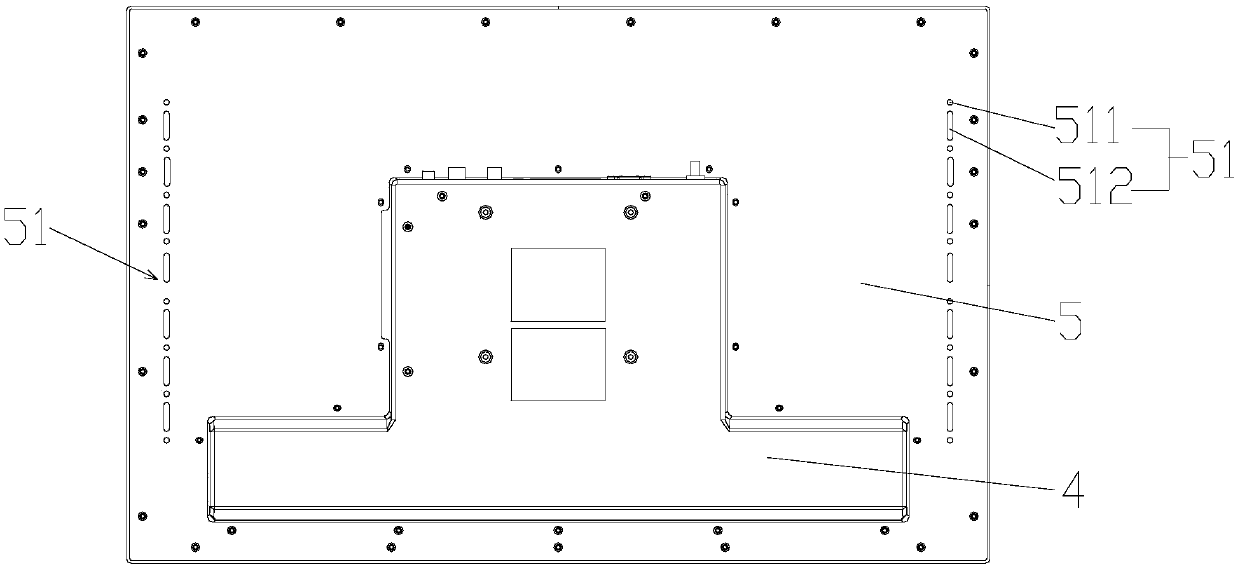

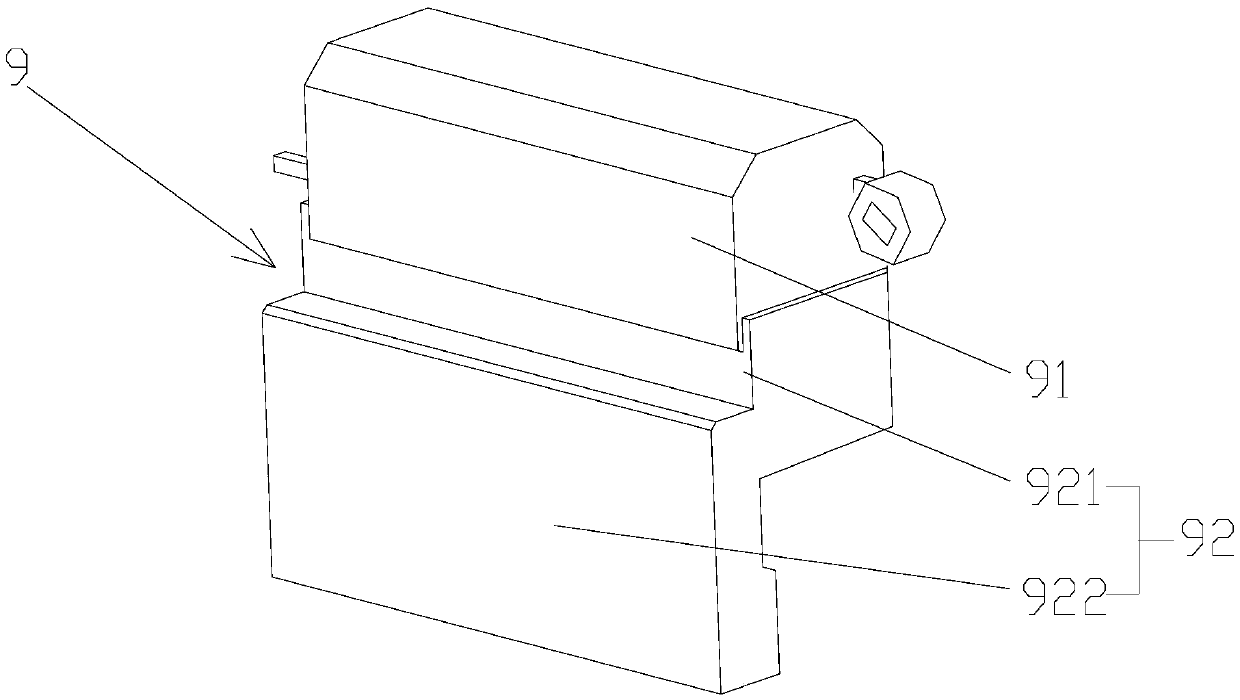

Embedded retractable television

InactiveCN109688356AGuaranteed integrityAchieve wholenessTelevision system detailsColor television detailsLiquid-crystal displayEngineering

The invention discloses an embedded retractable television. An liquid crystal display and a touch keyboard plate are embedded in an outer frame; a glass panel is connected with the outer frame on thefront side of the liquid crystal display; a backplate is connected with the outer frame on the back side of the liquid crystal display; two mounting hole groups are symmetrically and alternately arranged on the backplate along the transverse direction; each mounting hole group is arranged along the vertical direction; a back shell is connected with the backplate between two mounting hole groups, so as to form a chamber between the back shell and the liquid crystal display; a television mainboard and an audio component are connected with the back shell in the chamber; a sound transmission holegroup is opened on the lower side of the outer frame; a sound outlet part of the audio component faces to the sound transmission hole group; a terminal of the television mainboard is arranged upwards;and, a first terminal board is installed on the back shell to corresponds with the terminal of the television mainboard. The television has the following advantages: the embedded type of the television is realized; other external spaces are not occupied; the beauty of the external place is enhanced; particularly, the television is perfectly matched with the existing kitchen electrical equipment;and the mounting hole groups realize the suitability between the television and multiple mounting brackets.

Owner:江苏福莱尔数码科技有限公司

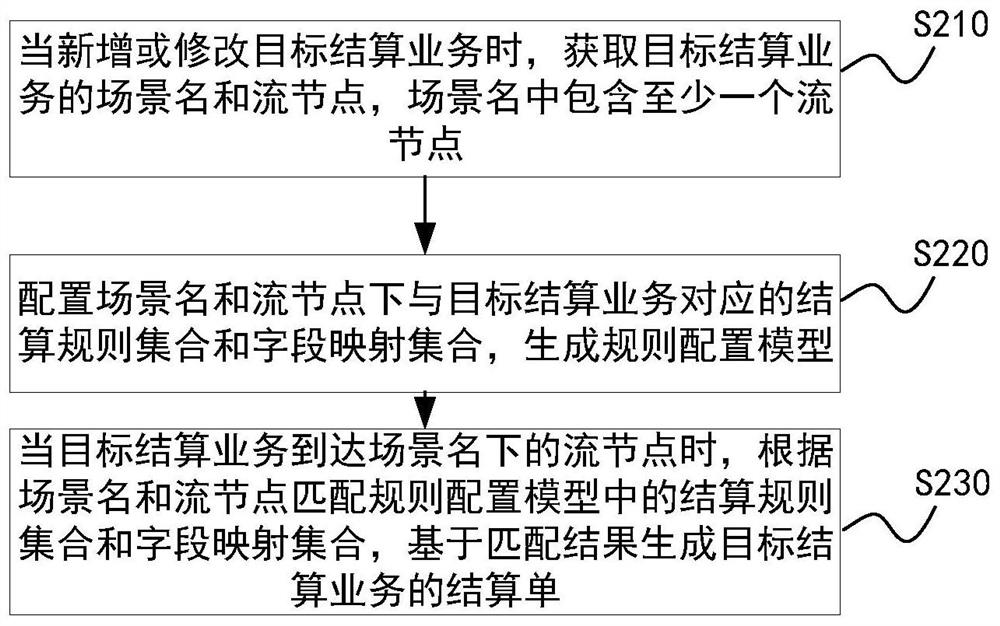

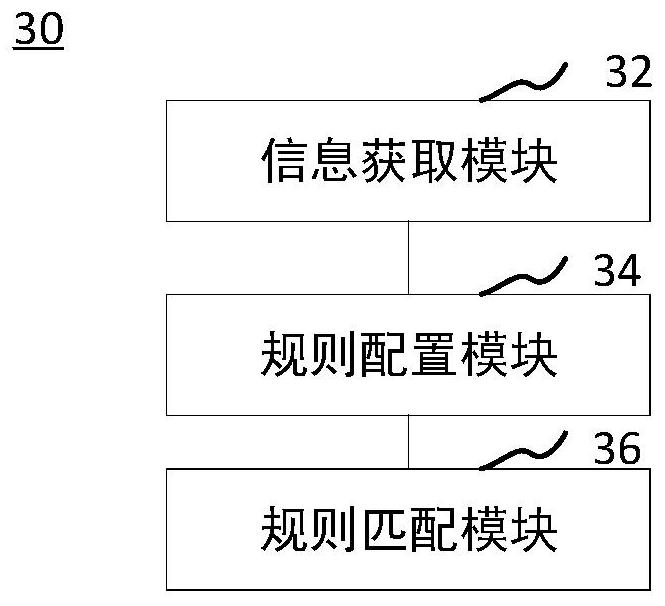

Settlement sheet generation method and device, computer equipment and storage medium

PendingCN112613288AAchieve automationAchieve standardizationText processingBuying/selling/leasing transactionsField mappingData mining

The present invention provides a settlement sheet generation method and device, computer equipment and a storage medium, the settlement rule set and the field mapping set corresponding to the target settlement service are configured under the scene name and the flow node, and the rule configuration model is generated; when the settlement service arrives at the flow node under the scene name, according to the existing rule configuration model matched with the scene name and the flow node, the settlement sheet of the settlement service is generated, the charging module separated from the service rule is integrated into the rule configuration, and the dynamic attribute in the settlement sheet is processed in a configuration field mapping mode, so that the integrity of the rule configuration is realized, and finally, automation and standardization of an online settlement process are achieved.

Owner:杭州搜车网科技有限公司

Face shell for intelligent wearing part

ActiveCN111703013AAchieve wholenessWater resistance is not affectedDomestic articlesTelephone set constructionsPhysicsEngineering

The invention discloses a face shell for an intelligent wearing part. The face shell comprises a face shell body, wherein the face shell body is provided with a display wafer and a face shell sheet ofwhich the outline is the same as that of the face shell body; the face shell body is processed by the following steps: 1, forming a single-color membrane; 2, performing primary injection molding to obtain an injection molding sheet of which the bottom surface is provided with a transparent plastic layer; 3, performing CNC (computer numerical control) cutting to cut the injection molding sheet inthe step 2 into a circular cutting sheet; and 4, performing secondary injection molding to obtain a face shell sheet structure in which the display wafer in the step 3 is embedded, wherein the face shell sheet structure and the display wafer form the face shell body. Compared with the prior art, the face shell is subjected to injection molding twice, and an injection molding part subjected to primary injection molding is used for displaying a transparent area, so that the part, positioned in the transparent area, of the whole face shell achieves a steel wire wear-resistant effect, and the integrity of the face shell is realized; therefore, the waterproofness of the face shell is not influenced, and the injection molding quality is guaranteed.

Owner:FUJIAN SHISHI TONGDA ELECTRICAL APPLIANCE

Precast pavement structure and Z-shaped rubber insert applied to structure

ActiveCN103061228AAvoid wrinklesAchieve wholenessSingle unit pavingsPaving detailsStress concentrationRotational deformation

The invention provides a precast pavement structure and a Z-shaped rubber insert applied to the structure. The pavement structure is formed by a plurality of T-shaped precast block pavement spliced and clamped together, and the Z-shaped rubber insert is arranged between the splicing faces of the adjacent T-shaped precast blocks in a clamping way. The rubber insert comprises an insert framework and rubber at the outer layer of the insert framework, the insert framework is provided with transverse reinforcing steel wires along two vertical bending directions starting from the corner center, and the framework is provided with a plurality of longitudinal reinforcing steel wires in the longitudinal direction. Under the action of the insert, the tiny rotational deformation of the T-shaped precast blocks under the action of wheels can be achieved so as to reduce the rotational displacement, so that the smoothness in the traveling of construction vehicles is improved, meanwhile, the stress-focusing effect at the internal corners of the precast blocks in the traveling process is weakened, and the integrity and the continuousness of the interlock effect of the pavement structure are achieved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

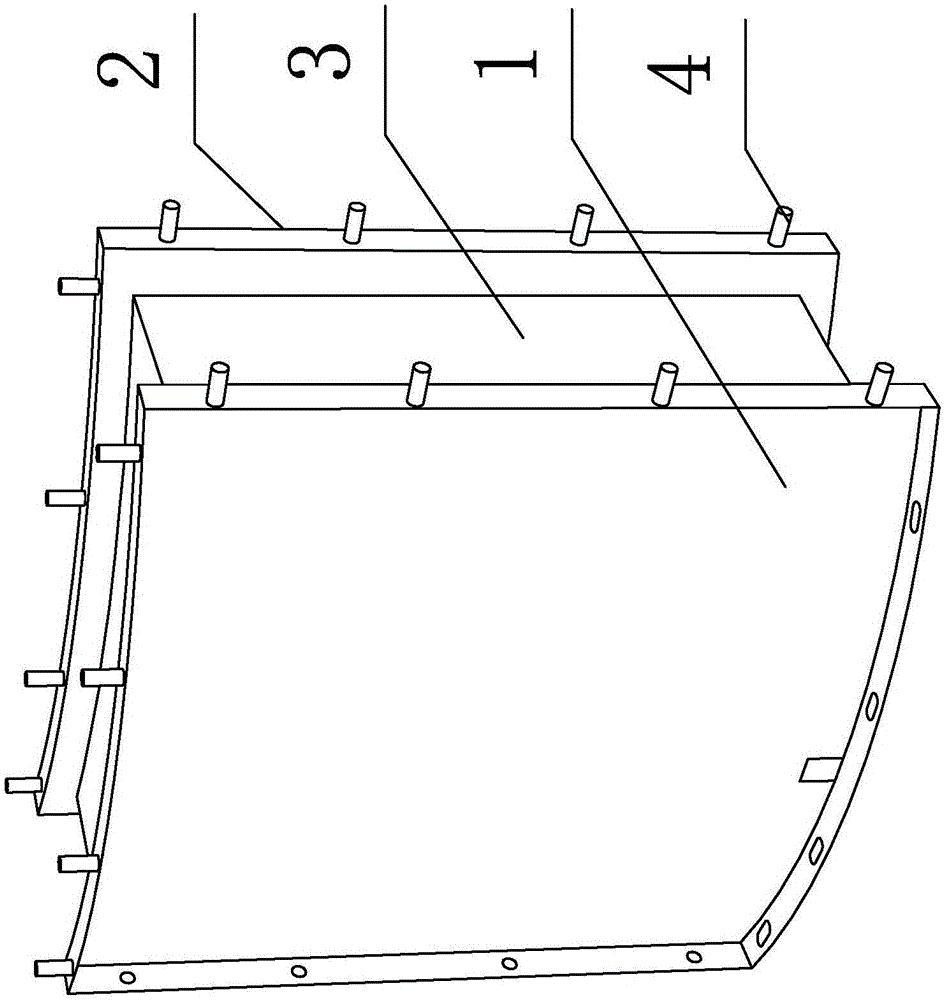

Assembly type tank steel plate-concrete combined member and construction method thereof

The invention relates to an assembly type tank steel plate-concrete combined member and a construction method thereof. The assembly type tank steel plate-concrete combined member and the construction method thereof aim at solving the problems of influence to whole stress property due to positioning deviation caused by large tank structure, high difficulty in construction, long cycle, and high manufacturing cost; narrow internal space of structure modularizing unit, dense reinforcement pipelines, strict requirement on side pressure of steel pipes, high difficulty in deformation control and the like in the energy source engineering; because of difficulty in casting of cast-in-situ concrete, the whole stress property also suffers from adverse effect. The assembly type tank steel plate-concrete combined member comprises an outer steel plate, an inner steel plate, concrete blocks, tie bar assemblies, fixed bolts and bolt screws. The construction method comprises the following steps of 1, preparation of material; 2, manufacturing and processing of the edges of the outer steel plate and inner steel plate; 3, welding and fixing of bolt screws and lug plates on the outer steel plate and inner steel plate; 4, fixed connection of the outer steel plate and inner steel plate; 5, injecting of concrete. The assembly type tank steel plate-concrete combined member is applied to building construction.

Owner:HARBIN INST OF TECH

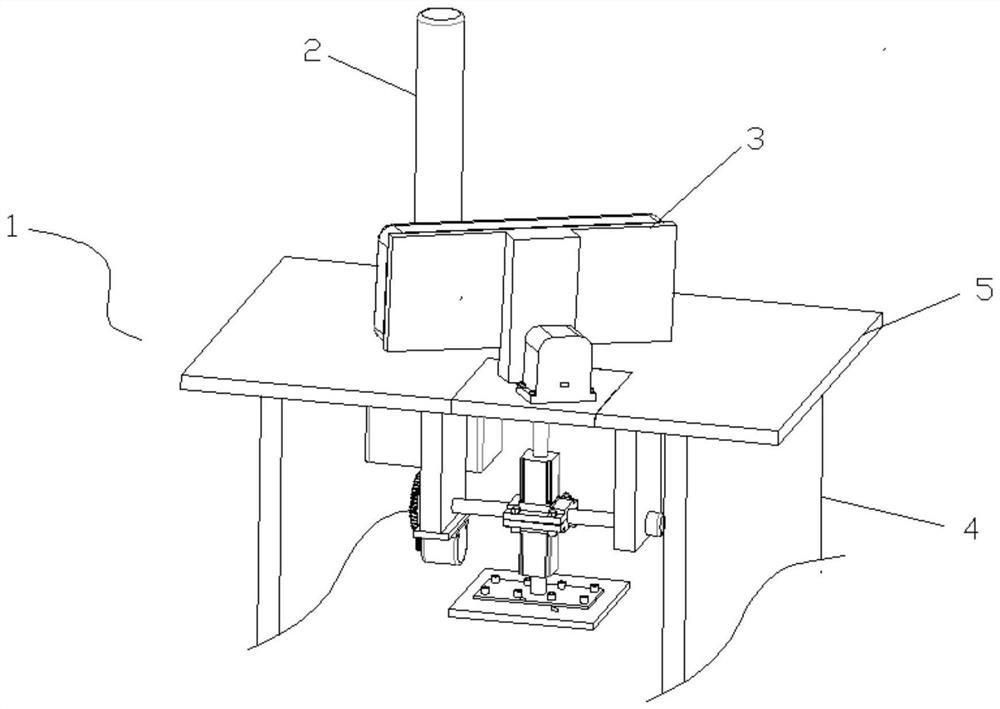

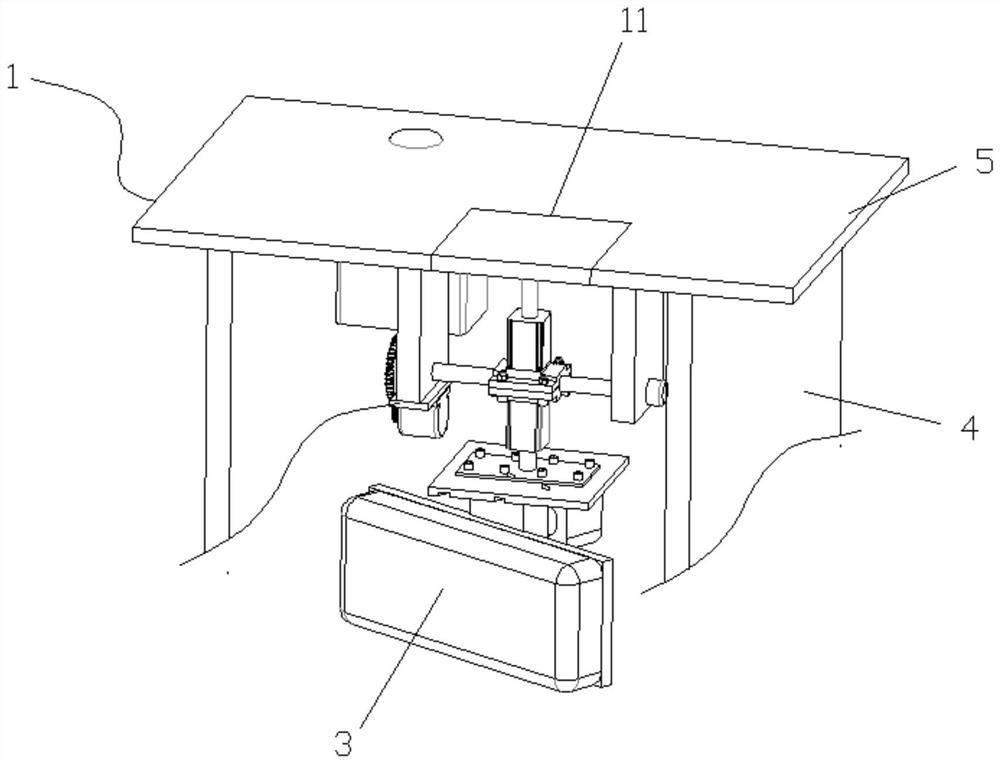

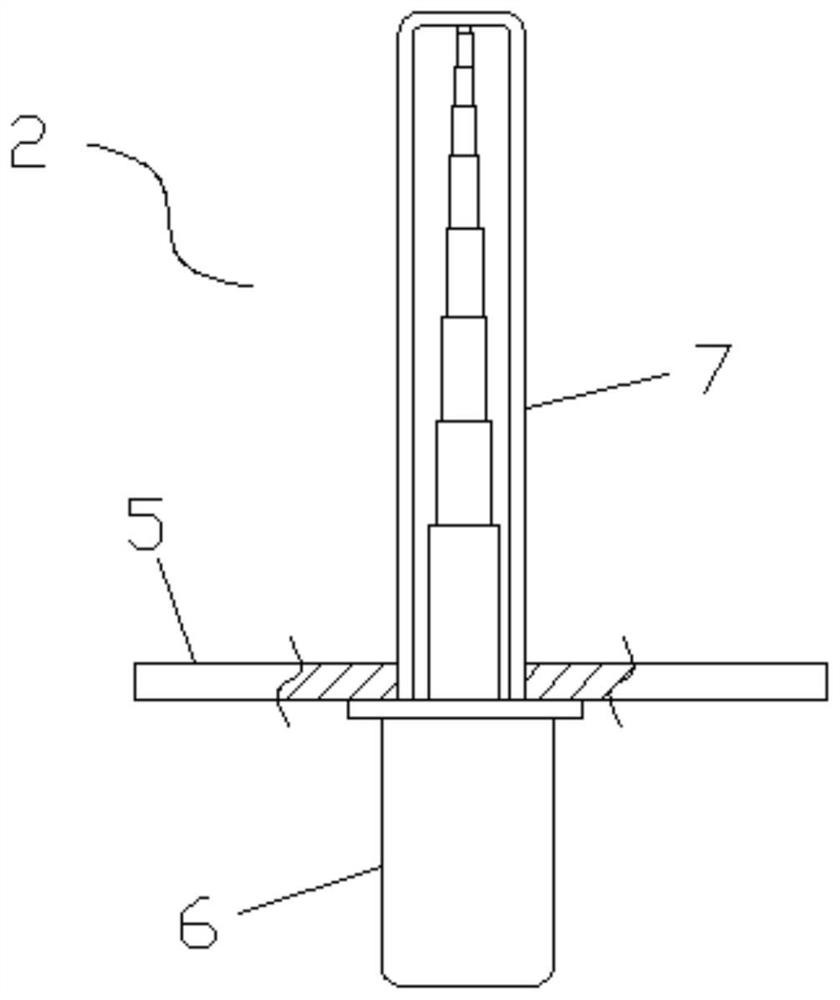

Lumbar puncture operating table and limiting method thereof

The invention relates to the technical field of medical instruments, and particularly discloses a lumbar puncture operating table and a limiting method thereof. The lumbar puncture operating table comprises a supporting frame, a knee limiting device and a back pressing device.The supporting frame comprises a support and a supporting plate horizontally arranged on the support, and the knee limiting device comprises an electric push rod and an isolation body; the fixed end of the electric push rod is fixed to the lower portion of the supporting plate, a via hole is formed in the supporting plate, the telescopic end of the electric push rod penetrates through the via hole and extends upwards, the telescopic end of the electric push rod is sleeved with the isolation body, and a splicing groove is formed in one side edge of the supporting plate in a penetrating mode. The back pressing device comprises a fixing frame, a rotating shaft, a first telescopic mechanism, a second telescopic mechanism, a first splicing plate, a second splicing plate, a rotating mechanism and a pressing mechanism, a patient can be reliably limited, so that the body posture can be kept for a long time, the operation quality is guaranteed, the operation risk is reduced, meanwhile, thelumbar puncture operating table can be used for resting, the patient does not need to be transferred, and the safety is improved.

Owner:重庆檀科科技有限公司

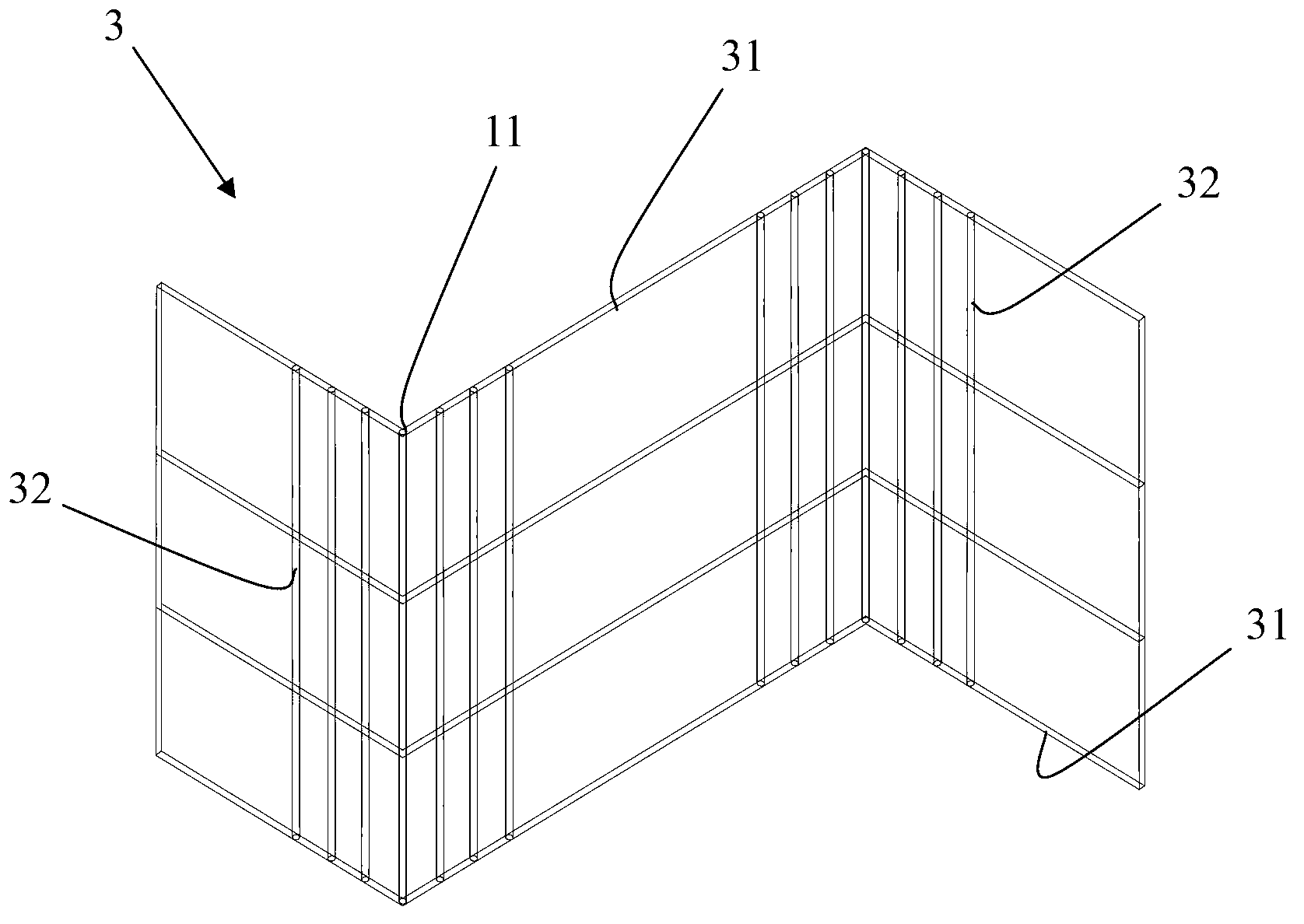

Hollow concrete-filled steel pipe support, prefabricated part, construction method, and supporting system

The invention belongs to the technical field of foundation pit engineering, and particularly relates to a hollow concrete-filled steel pipe supporting prefabricated part and a construction method thereof. The hollow concrete-filled steel pipe supporting prefabricated part comprises a steel pipe and a connector steel plate, the steel pipe is filled with concrete, and a hollow part penetrating in the axial direction is arranged in the concrete; a steel reinforcement framework is arranged in the concrete; annular joint steel plates are welded to the two ends of the steel pipe; and the inner sidesof the joint steel plates are connected with the steel reinforcement framework, and the outer sides of the joint steel plates are located outside the steel pipe. The invention further provides a hollow concrete-filled steel pipe support and a supporting system. The hollow concrete-filled steel pipe support is formed by connecting and assembling a plurality of the hollow concrete-filled steel pipesupport prefabricated parts through bolts. The supporting system comprises an enclosure structure, a top beam, a waist beam, and the hollow concrete-filled steel pipe support. The hollow steel pipe concrete supports are supported between the two opposite sides of the top beam and between the two opposite sides of the waist beam. The bearing capacity, the deformation resistance, the integrity, andthe middle joint strength of the hollow steel pipe concrete support can be improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

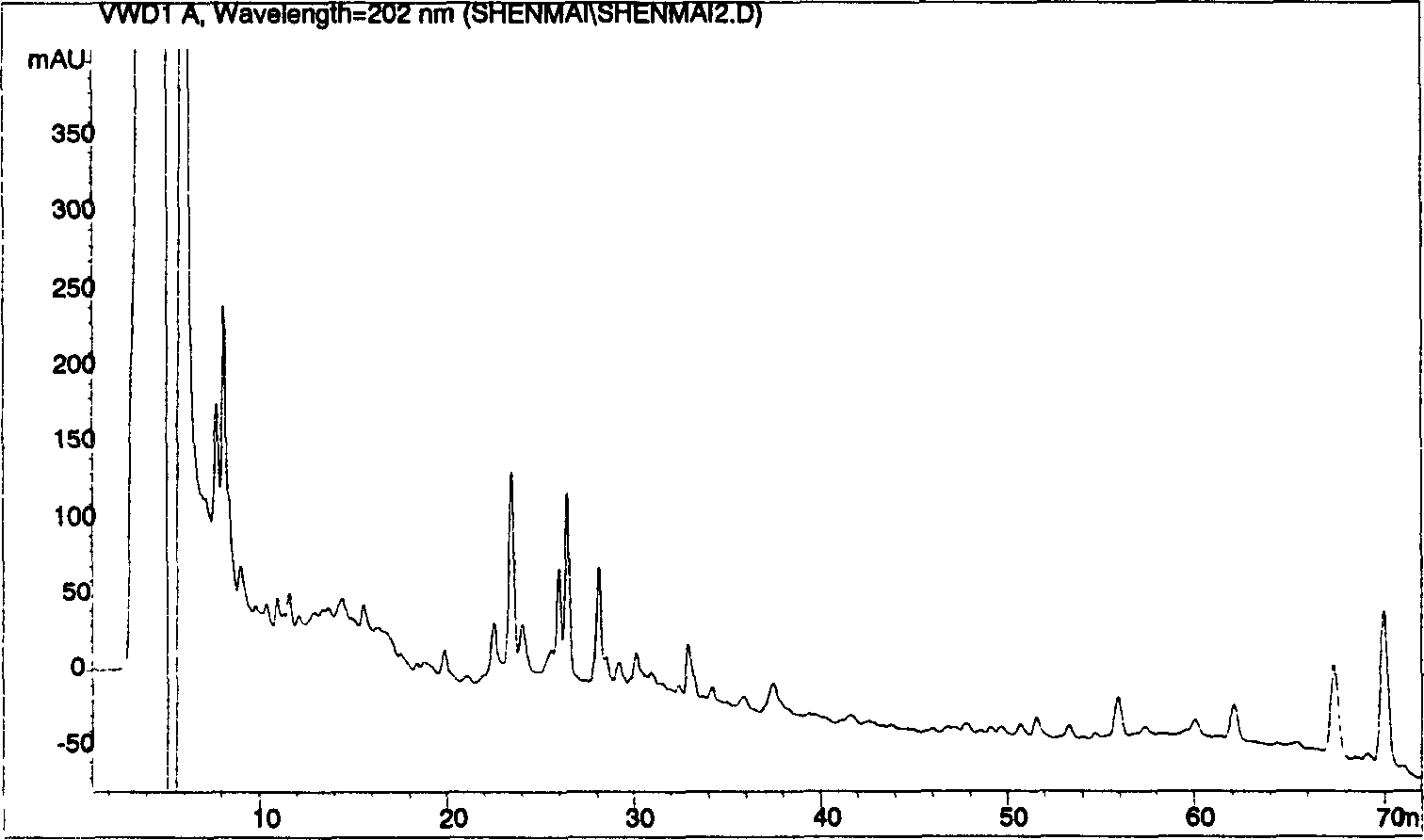

Chinese medicine quality control and evaluation method

InactiveCN1209628CStrong process controllabilityStrong specificityComponent separationMaterial analysis by optical meansAdditive ingredientTraditional medicine

A quality control and evaluation method of traditional Chinese medicine is a method for controlling and evaluating the quality of traditional Chinese medicine by combining the fingerprint analysis method of traditional Chinese medicine with the content determination method of index components. Compared with the traditional method of judging the quality of traditional Chinese medicine based on the content of index components, the method for quality control of traditional Chinese medicine provided by the present invention has the advantage of reflecting the overall quality of the complex system of traditional Chinese medicine more exclusively, comprehensively and scientifically. Utilizing the new method for quality control of traditional Chinese medicines of the invention can formulate new quality standards for traditional Chinese medicine preparations including process characteristics, so as to achieve the purpose of protecting the varieties of traditional Chinese medicines produced by manufacturers. It can also conduct a comprehensive evaluation of the quality stability of traditional Chinese medicine.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com