Three-dimensional freezing printing method of ceramic components

A component and ceramic technology, which is applied in the field of 3D cryoprinting of ceramic components, can solve problems such as difficult to overcome ice crystal expansion stress and low interlayer bonding strength, and achieve easy technology expansion and application, improve interlayer bonding strength, and reduce shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

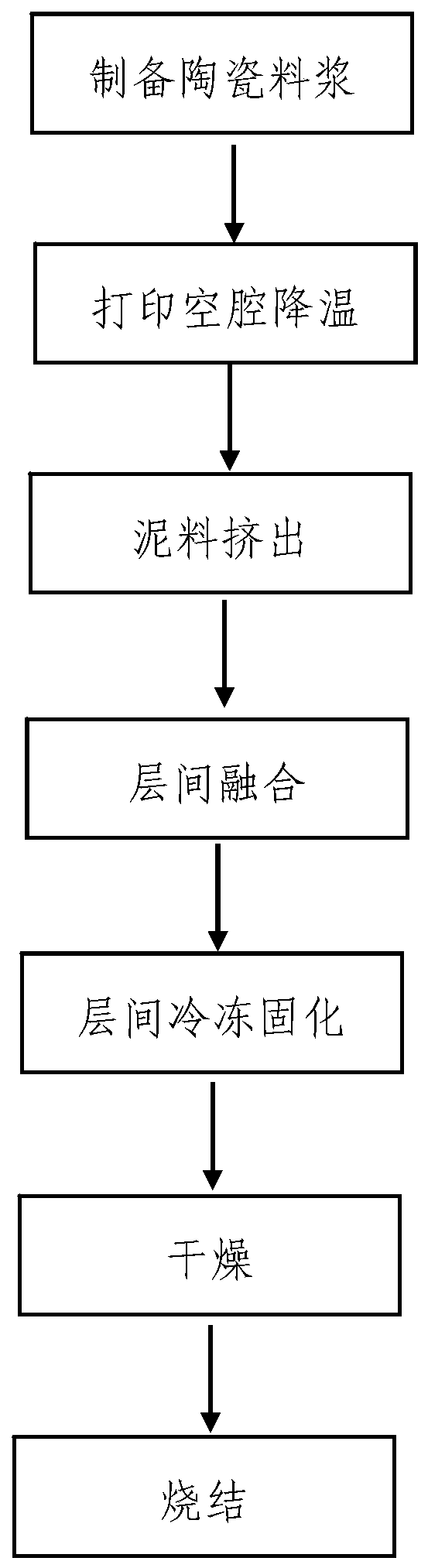

Method used

Image

Examples

Embodiment 1

[0060] Firstly, the particle size is graded as 5% for powders smaller than 200nm, 10% for 200nm-1.0μm powders, 40% for 1-10μm powders, 30% for 10-30μm powders, and 30% for powders larger than 30μm Alumina ceramic powder with a solid content of 15% is dispersed into a silica sol with a solid content of 15%. After adding 0.2% polyethylene glycol and 0.5% polyvinyl alcohol, ball milling for 5 hours, a ceramic slurry with a solid content of 55% is obtained. For 3D cryoprinting. Then, the printing cavity was cooled down to minus 10°C by liquid nitrogen refrigeration. Subsequently, the prepared ceramic mud is extruded out of the nozzle by the motor, and the wet mud is adhered to the printing base plate to start printing. During the printing process, the wet mud forms successively superimposed layers of mud on the printing base, named respectively as the first layer of mud, the second layer of mud, and the third layer of mud,..., the first N layers of mud. The newly extruded mud w...

Embodiment 2

[0063]First, the particle size is graded as 3% for powders smaller than 200nm, 10% for 200nm-1.0μm powders, 40% for 1-10μm powders, 30% for 10-30μm powders, and 30% for powders larger than 30μm Alumina ceramic powder with a solid content of 20% is dispersed in a silica sol with a solid content of 17%. After adding 0.2% polyethylene glycol and 0.5% polyvinyl alcohol, ball milling for 5 hours, a ceramic slurry with a solid content of 60% is obtained. For 3D cryoprinting. Then, the printing cavity was cooled down to minus 10°C by liquid nitrogen refrigeration. Subsequently, the prepared ceramic mud is extruded out of the nozzle by the motor, and the wet mud is adhered to the printing base plate to start printing. During the printing process, the wet mud forms successively superimposed layers of mud on the printing base, named respectively as the first layer of mud, the second layer of mud, and the third layer of mud,..., the first N layers of mud. The newly extruded mud will f...

Embodiment 3

[0066] First, the particle size is graded as 3% for powders smaller than 200nm, 10% for 200nm-1.0μm powders, 40% for 1-10μm powders, 30% for 10-30μm powders, and 30% for powders larger than 30μm The silicon oxide ceramic powder with a solid content of 25% is dispersed into a silica sol with a solid content of 25%, and after adding 0.5% polyethylene glycol and 1% polyvinyl alcohol, ball milled for 8 hours to obtain a ceramic slurry with a solid content of 65%. For 3D cryoprinting. Then, the printing cavity was cooled down to minus 10°C by liquid nitrogen refrigeration. Subsequently, the prepared ceramic mud is extruded out of the nozzle by the motor, and the wet mud is adhered to the printing base plate to start printing. During the printing process, the wet mud forms successively superimposed layers of mud on the printing base, named respectively as the first layer of mud, the second layer of mud, and the third layer of mud,..., the first N layers of mud. The newly extruded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com