Pile connecting buckle and its prefabricated unit

A technology of prefabricated parts and fasteners, which is applied in the field of prefabricated parts strong tension fasteners and prefabricated parts manufacturing, which can solve the problems such as the inability to guarantee the relative strength and reliability of the connection, the inability to ensure the reliable docking of the upper pile and the lower pile, corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

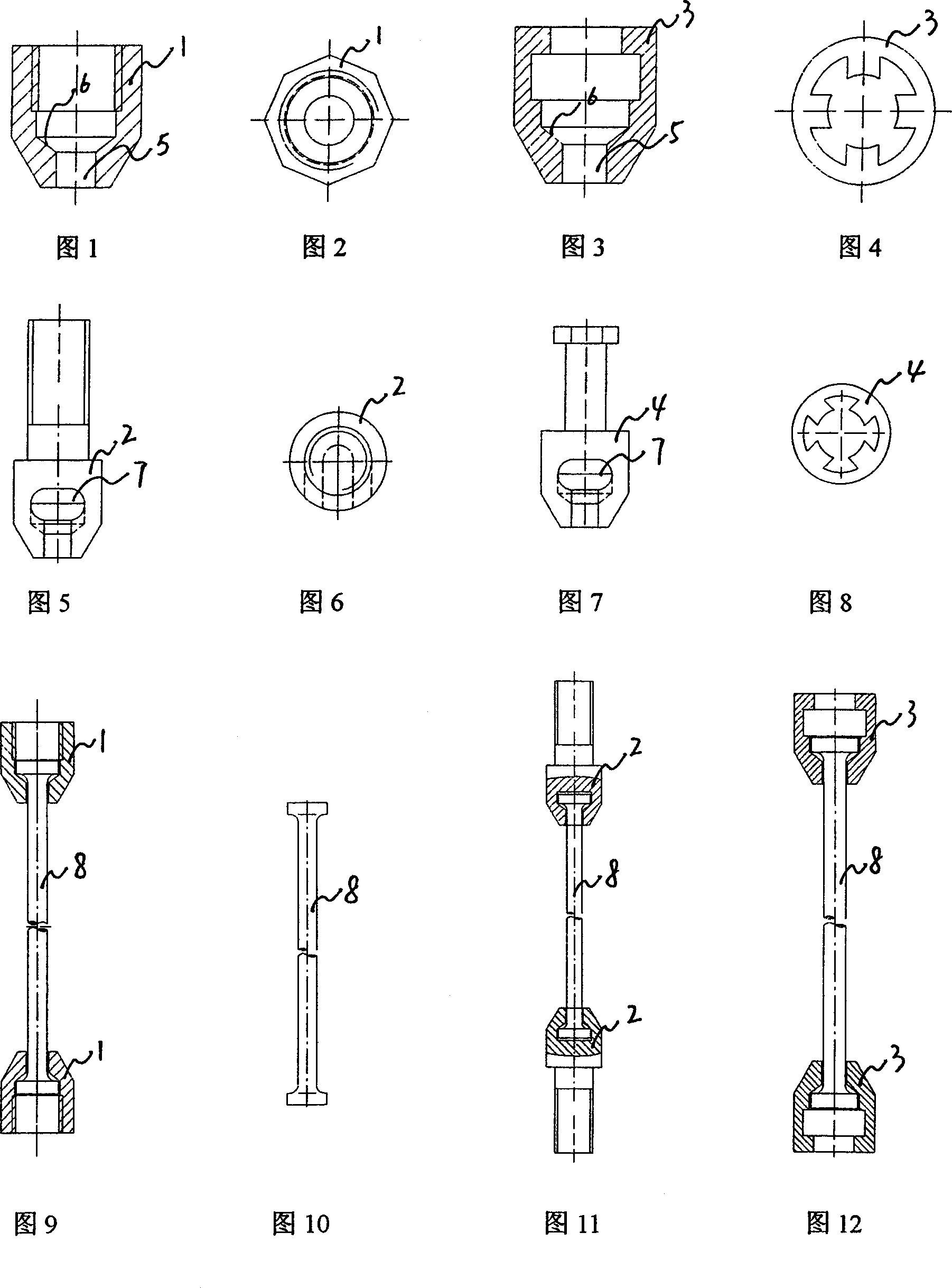

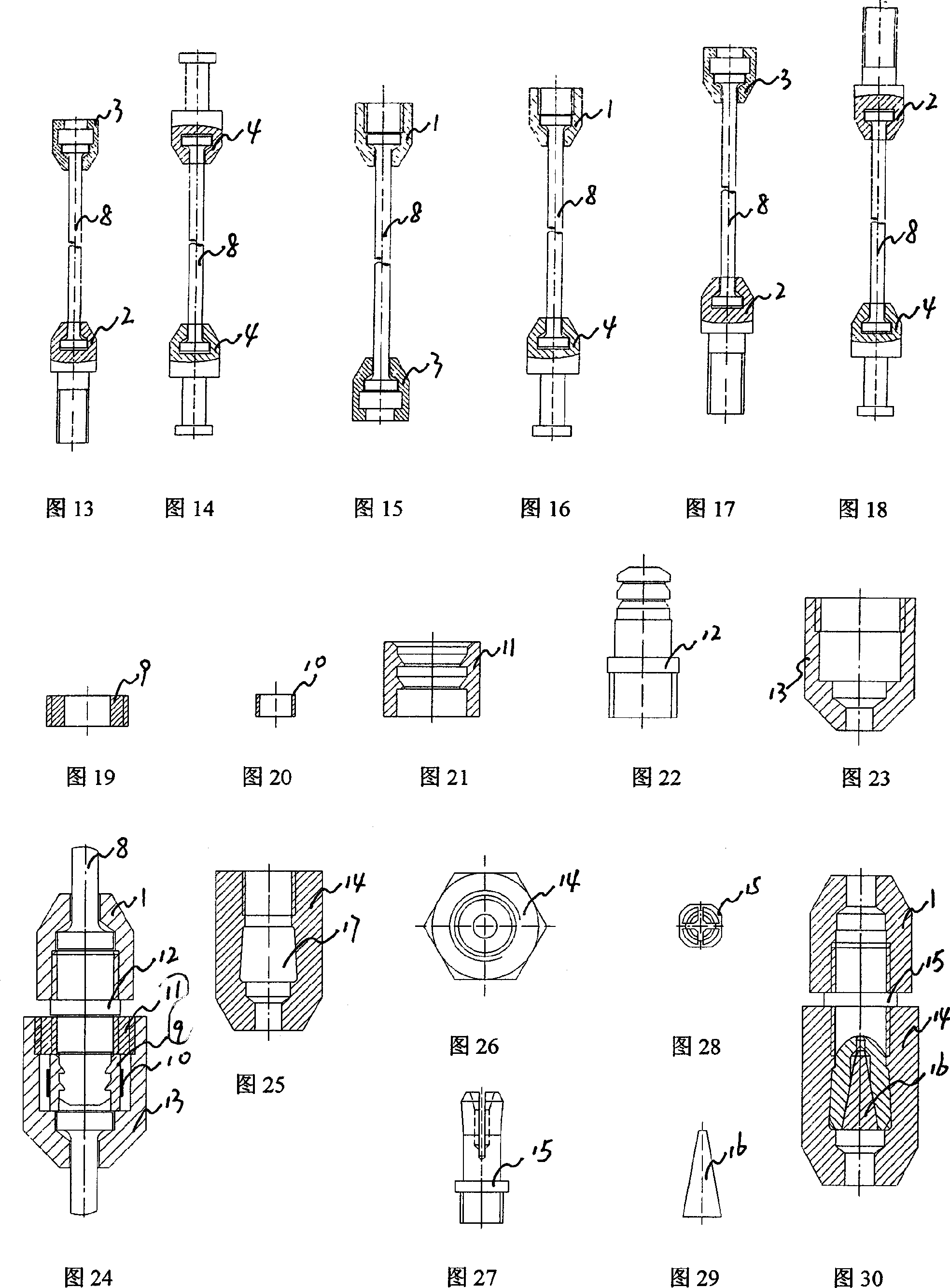

[0166] Embodiment 1: with reference to accompanying drawing 1~8. The prestressed pipe pile reinforced fasteners are made of cast steel, cast iron, forgings, steel, nylon and other materials and are formed into internal thread structures 1 and 2, see attached drawing 1; or in external threaded structure 2, see attached drawings 5 and 6 ; or an internal clamping structure 3, see accompanying drawings 3 and 4; or an external clamping structure 4, see accompanying drawings 7 and 8; internal thread structure 1, external thread structure 2, internal clamping structure 3, external clamping The bottom center of the fastener cavity of the structure 4 is provided with a reinforcing bar hole 5, and the periphery of one end of the reinforcing bar hole is a reinforcing bar header card platform 6, and the header 7 of the reinforcing bar is clamped on the card platform. The shape of the strong-pull fastener with the internal card structure or the strong-pull fastener with the external card...

Embodiment 2

[0167] Embodiment 2: with reference to accompanying drawing 9 and 10. On the basis of Example 1, the prestressed pipe pile reinforced reinforcement fastener is composed of two fasteners 1 with internal thread structure and steel bars (steel rods) 8 .

Embodiment 3

[0168] Embodiment 3: with reference to accompanying drawing 11. On the basis of Embodiment 1, the prestressed pipe pile steel bar strong tension fastener is composed of two fasteners 2 with external thread structure and steel bars (steel rods) 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com