Oil-immersed permanent magnet motor

A permanent magnet motor and oil-immersed technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of low efficiency, poor replacement and maintenance, and large volume and weight of asynchronous motors, and achieve magnetic steel protection and rotor protection. Integrity and solid reliability, ensuring compact size and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

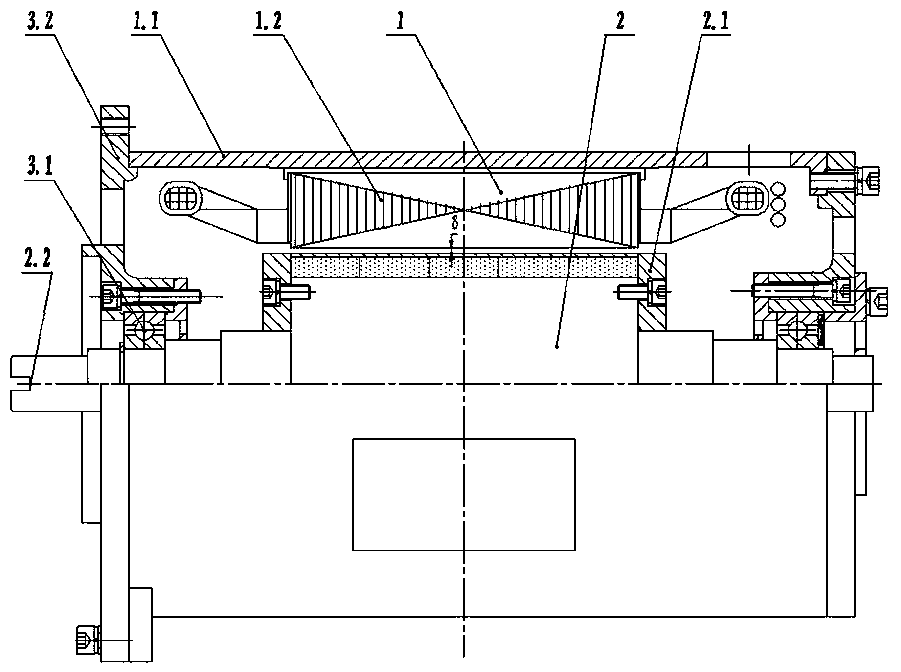

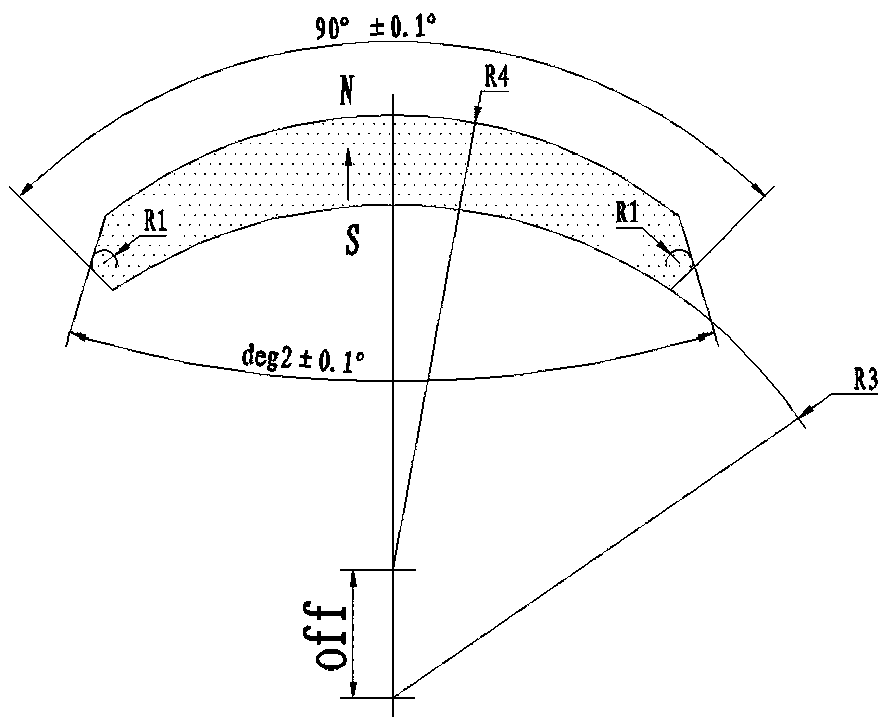

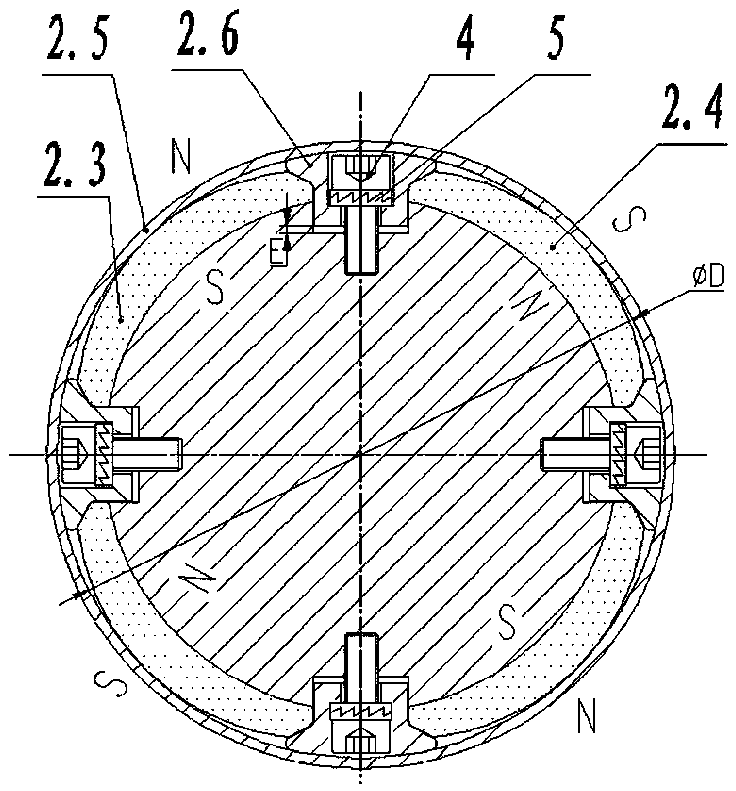

[0031] refer to Figure 1 to Figure 5 As shown, the present invention discloses an oil-immersed permanent magnet motor, including a stator 1 and a rotor 2. The size of the air gap between the stator 1 and the rotor 2 not only affects the performance of the motor, but also affects the high-speed rotation of the motor in hydraulic oil. The viscous loss of the motor has a particularly large influence, and the selection of the size of the air gap needs to be calculated and analyzed through fluid dynamics simulation calculations at different temperatures and different speeds to ensure the efficiency and performance of the motor. In the present invention, the recommended air gap δ is 1.5 to 3.5 times larger than that of common asynchronous motors, and the motor rotor 2 with a larger outer diameter and a higher rotational speed takes a larger value. By optimizing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com