Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "Achieve the purpose of heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric vehicle and battery heating method and system thereof

InactiveCN106608195AExtended service lifeHeating evenlySecondary cellsVehicular energy storageElectrical batteryBattery electric vehicle

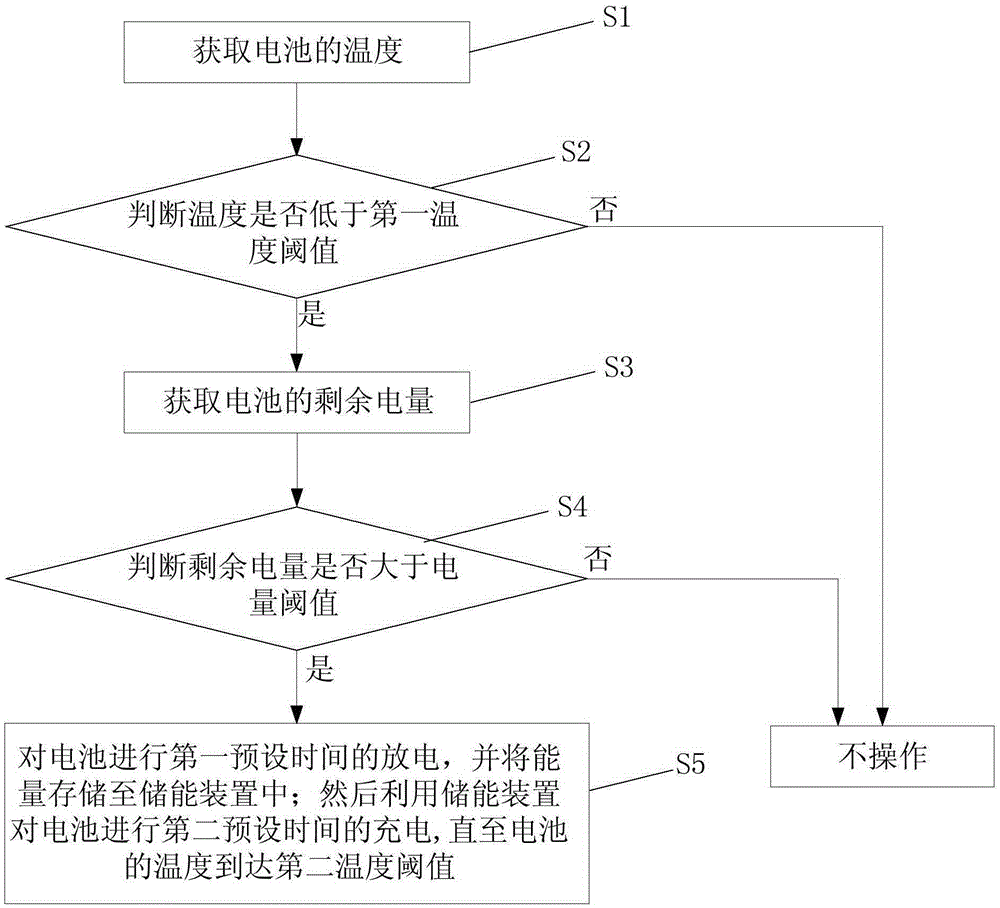

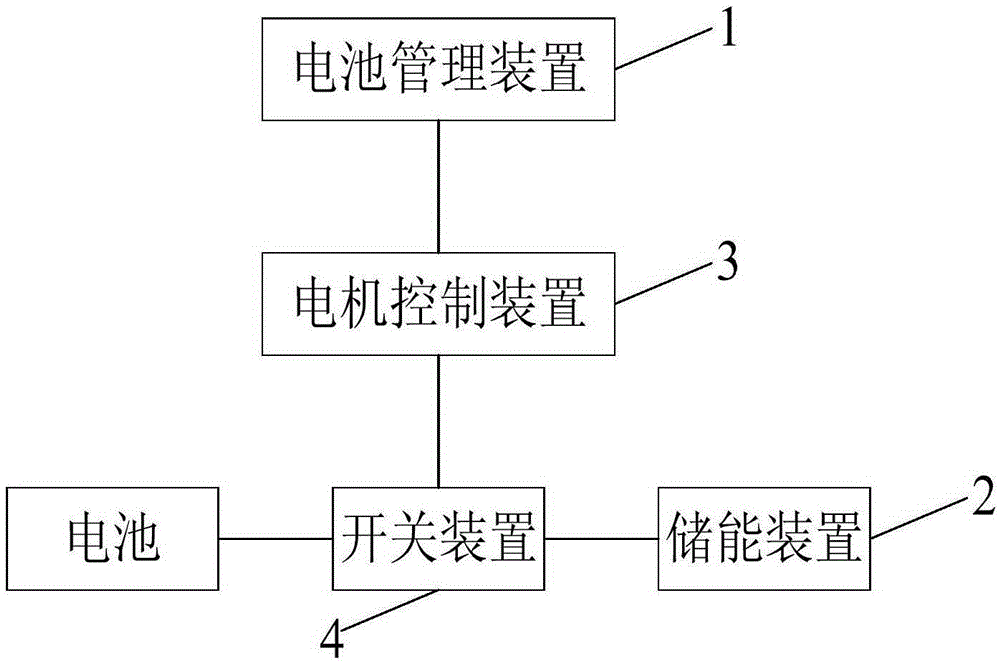

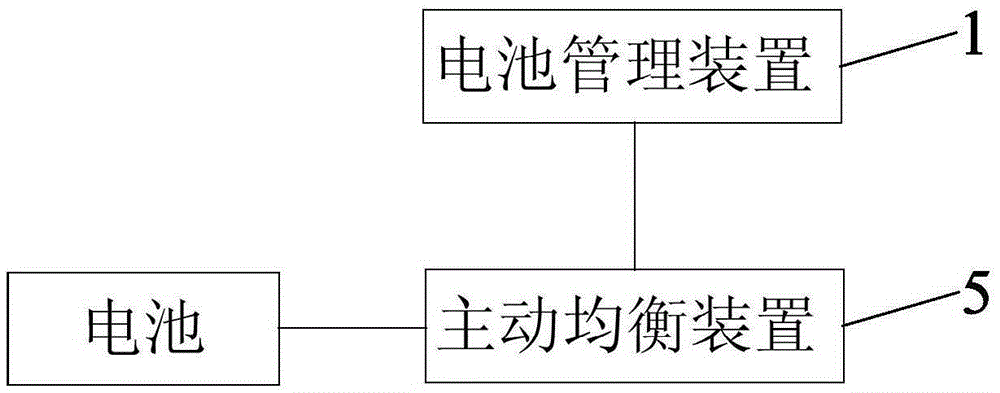

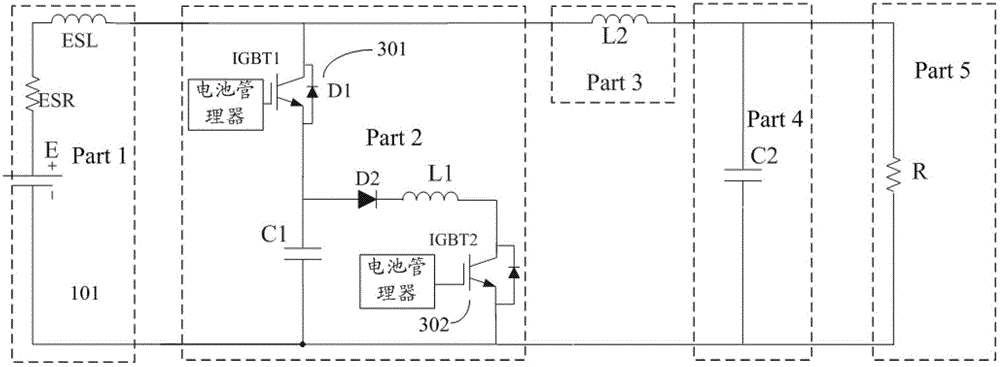

The invention provides a battery heating method and a system of an electric vehicle. The battery heating method comprises the steps of: obtaining the temperature of a battery; judging if the temperature is lower than a first temperature threshold; if so, obtaining a remainder electric quantity of the battery and judging if the remainder electric quantity is higher than an electric quantity threshold; if so, discharging the battery by a first preset time, and storing energy in an energy storage device; then, using the energy storage device for charging the battery by a second preset time; and circulating the step until the temperature of the battery reaches a second temperature threshold. The method and the system uses self-heating characteristic of the battery in the charge / discharge process for heating the battery from inside to outside; compared with a method for heating the battery by external heating equipment in the prior art, the battery heating method is more balanced in heating, and facilitates prolonging of the service life of the battery; and the heat is from the internal of the battery, so that the heating efficiency is higher.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

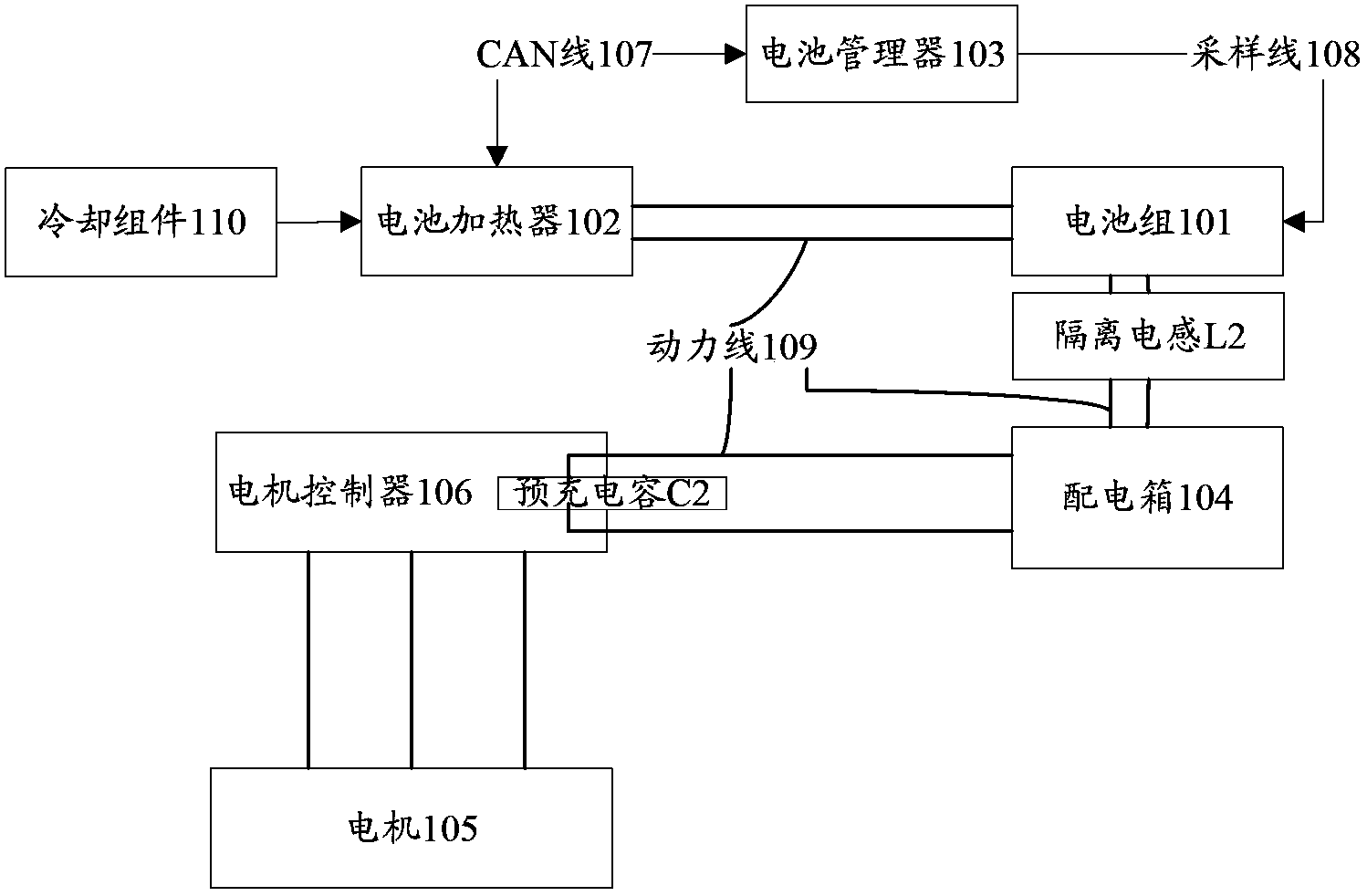

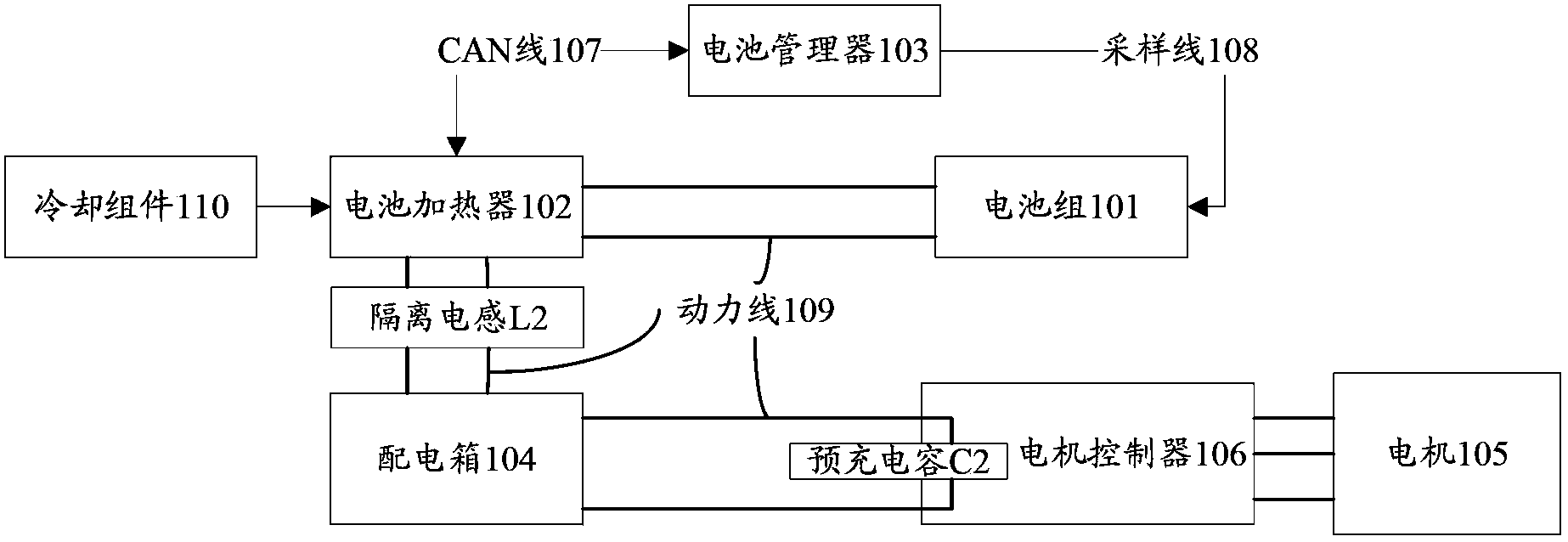

Electric car and electric car power system and battery heating method

ActiveCN103419666AGuaranteed powerExtended service lifeCell temperature controlCell temperature regulationCapacitanceElectrical battery

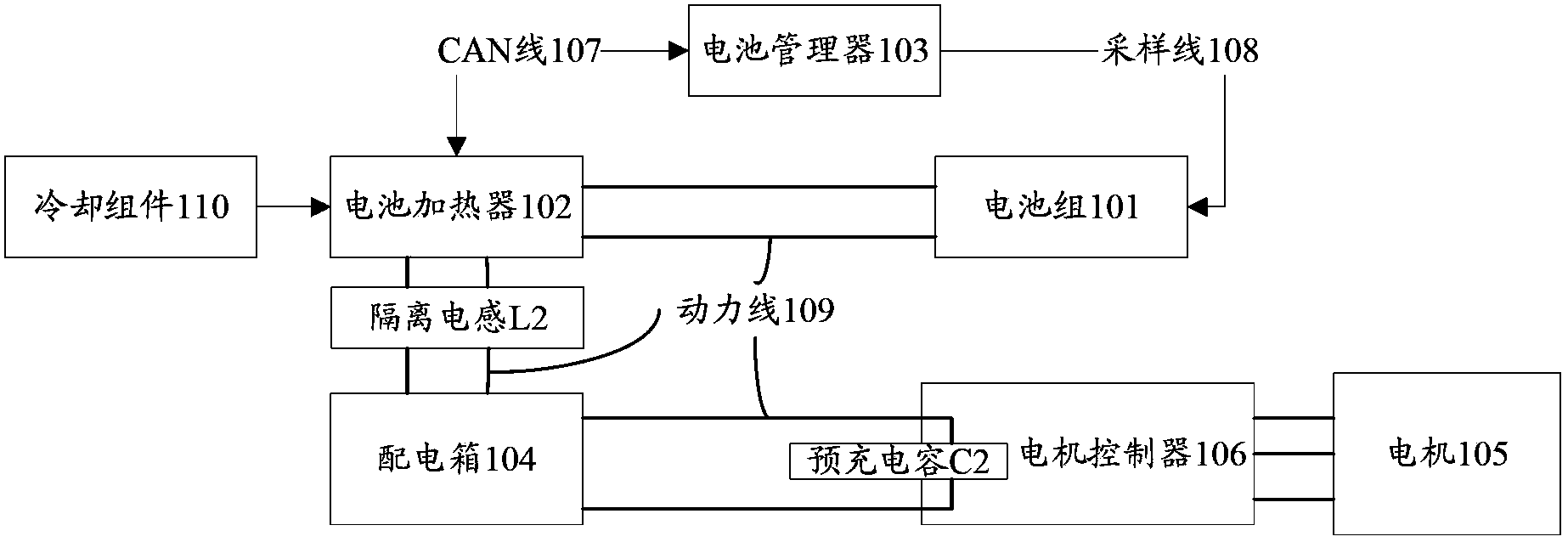

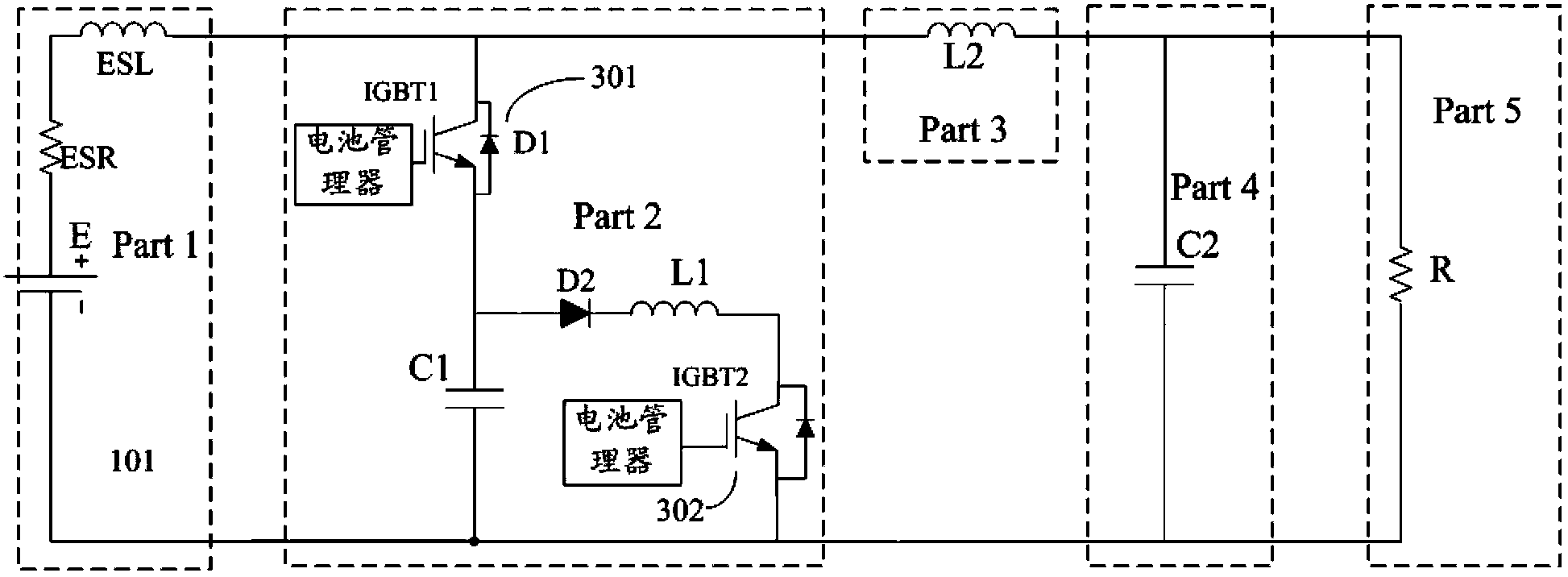

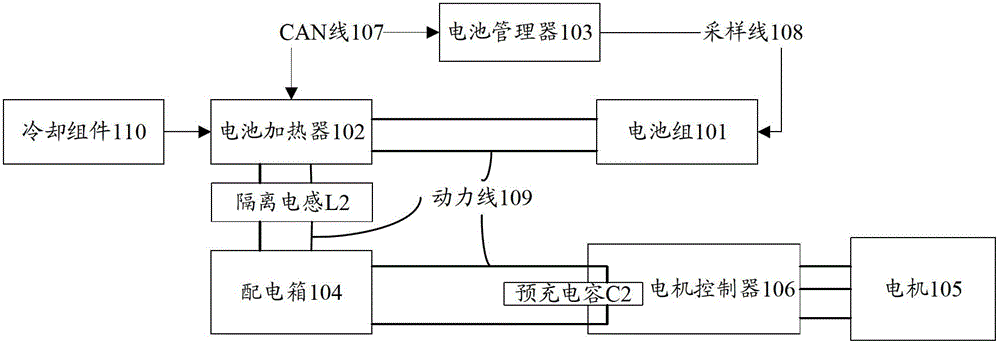

The invention provides an electric car power system which comprises a battery pack, a battery heater, a battery manager, a distribution box, a motor, a motor controller and an isolation inductor. The battery heater is connected with the battery pack. The battery manager is respectively connected with the battery pack and the battery heater and used for alternately controlling the battery heater to heat the battery pack according to accelerator depth change velocity of an electric car when the temperature of the battery pack is lower than a first heating temperature threshold and the residual electric quantity is higher than a shutdown electric quantity threshold. The distribution box is used for distributing voltage output by the battery pack. The motor controller is connected with the motor and the distribution box and provided with a first input end, a second input end and a pre-charging capacitor. The pre-charging capacitor is connected between the first input end and the second input end and matched with the isolation inductor. The power system is capable of realizing heating and greatly lowering use limitation in a low-temperature environment, high in heating efficiency, low in cost, and highly practical. The invention further provides an electric car battery heating method and an electric car.

Owner:BYD CO LTD

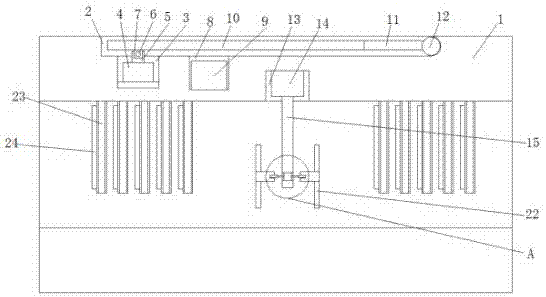

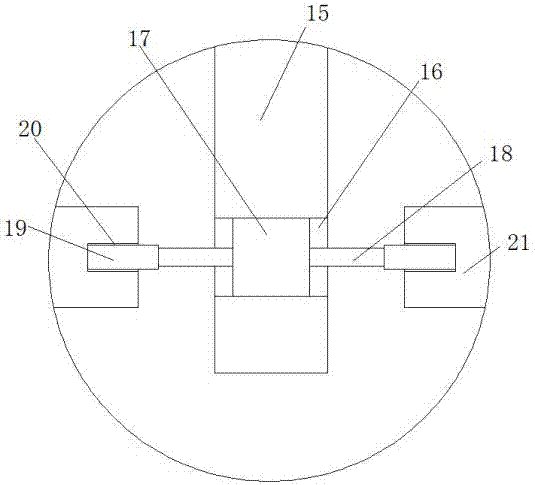

Solar petroleum heating device capable of reducing petroleum viscosity

ActiveCN107387927AAchieve the purpose of heatingPromote absorptionPipe heating/coolingDrive motorPetroleum

The invention discloses a solar petroleum heating device capable of reducing petroleum viscosity. The solar petroleum heating device comprises a petroleum pipeline. A mounting groove is formed in the top of the outer side of the petroleum pipeline. Two first containing grooves are formed in the inner wall of the bottom of the mounting groove and are arranged horizontally. Push rod motors are fixedly mounted in the two first containing grooves. A connecting rod is welded to an output shaft of each push rod motor. A communicating hole is formed in the top of the side, extending into the mounting groove, of each connecting rod, and a rotary shaft is fixedly mounted in each communicating hole. The solar petroleum heating device is economical and practical; a solar panel can be driven by the push rod motors to adjust the angle, and the efficiency that the solar panel absorbs solar energy is greatly increased; a drive motor and a dual-shaft stepping motor are utilized for driving stirring rods, petroleum in the petroleum pipeline can be stirred, the petroleum can have flowability, and then heating pipes and heat radiators are utilized for heating the petroleum; and the solar petroleum heating device is used for reducing the petroleum viscosity and is convenient to use and simple in operation.

Owner:兰州天亿石化设备维修技术有限公司

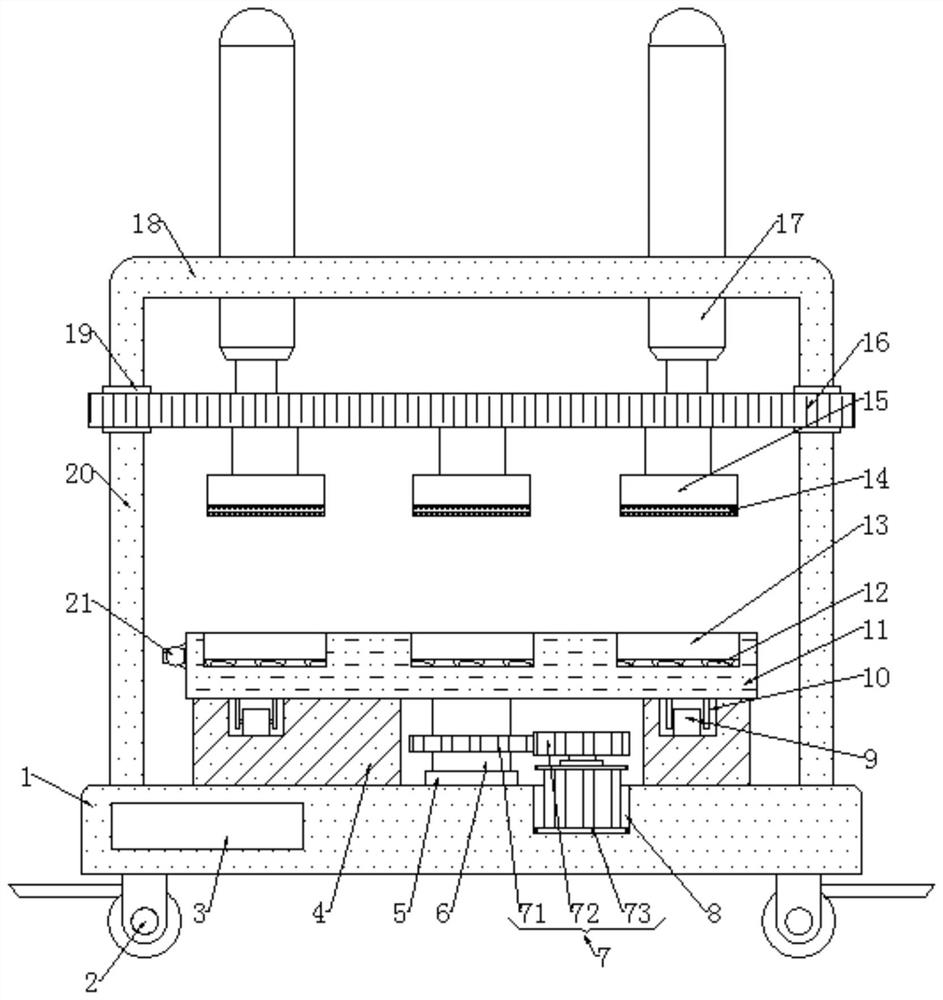

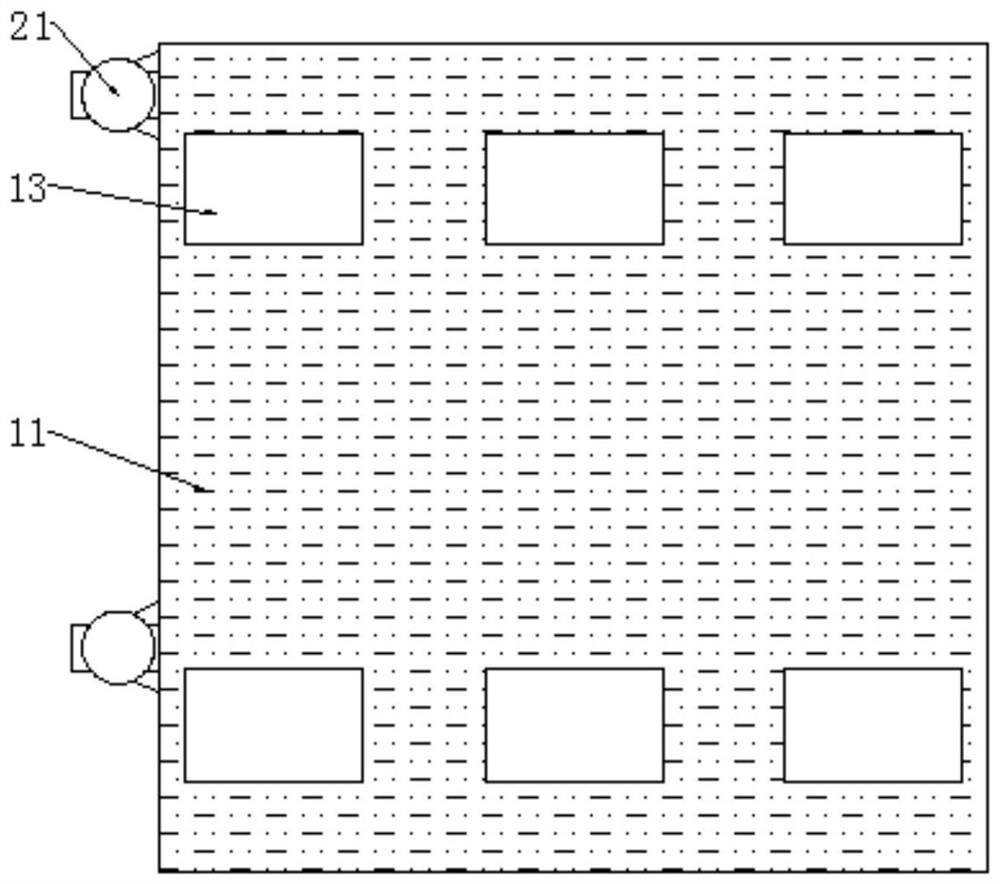

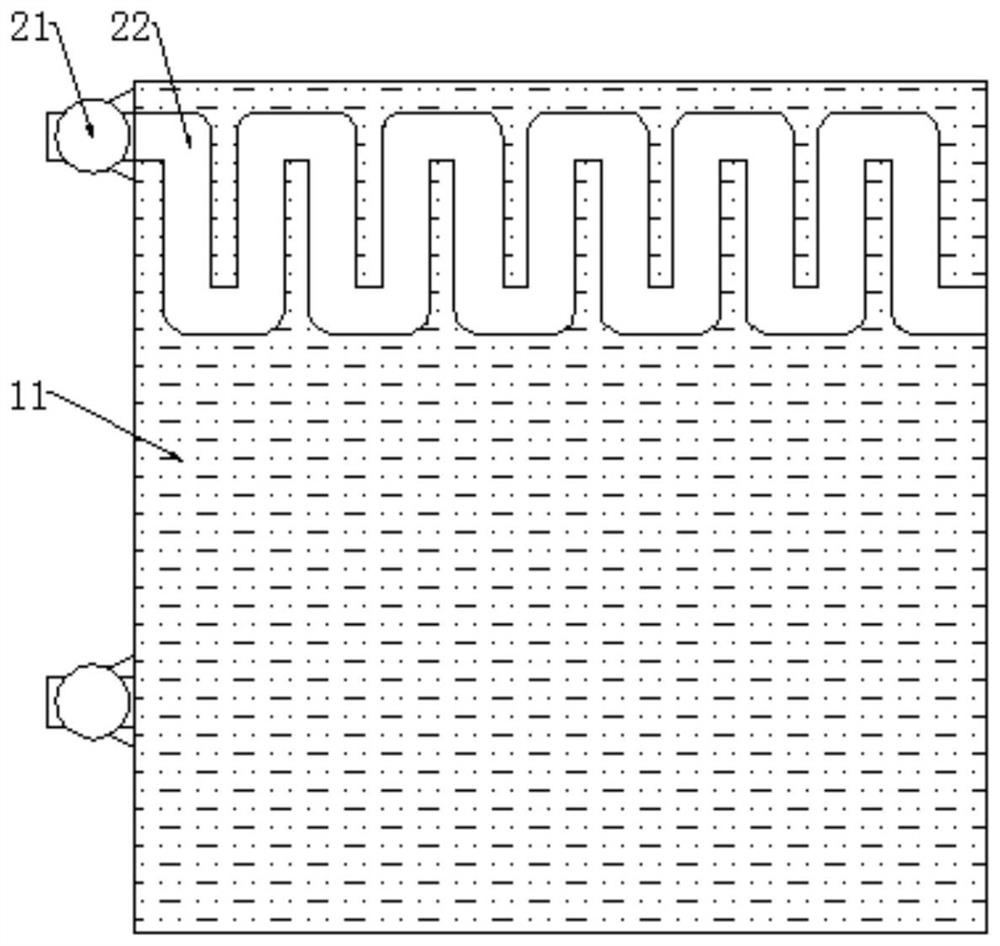

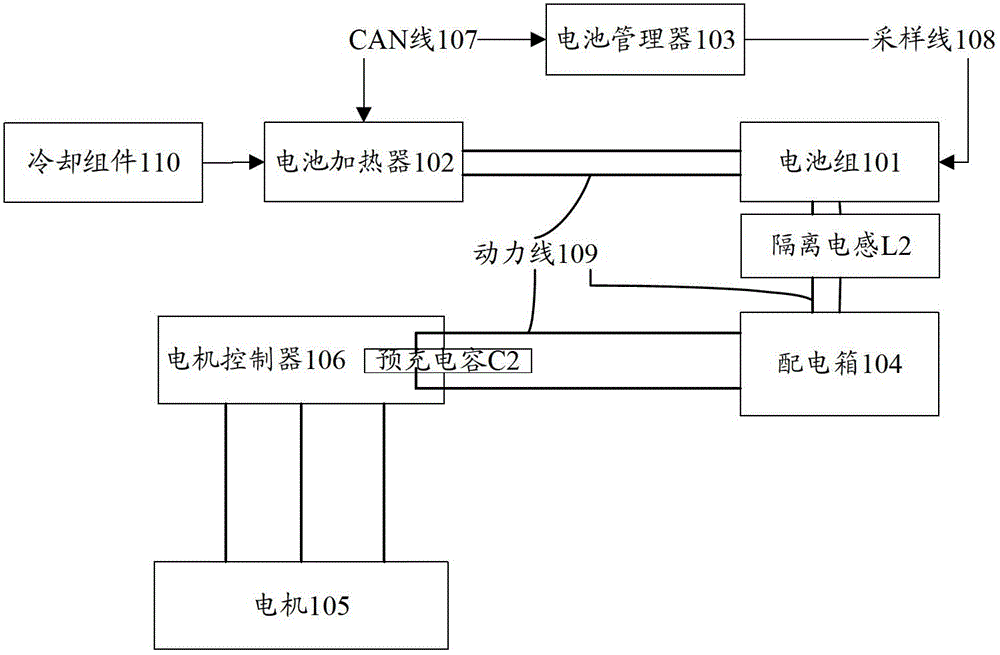

Electric car and electric car power system and battery heating method

ActiveCN103419664AReduce restrictionsAchieve the purpose of heatingSpeed controllerCharging stationsCapacitanceElectrical battery

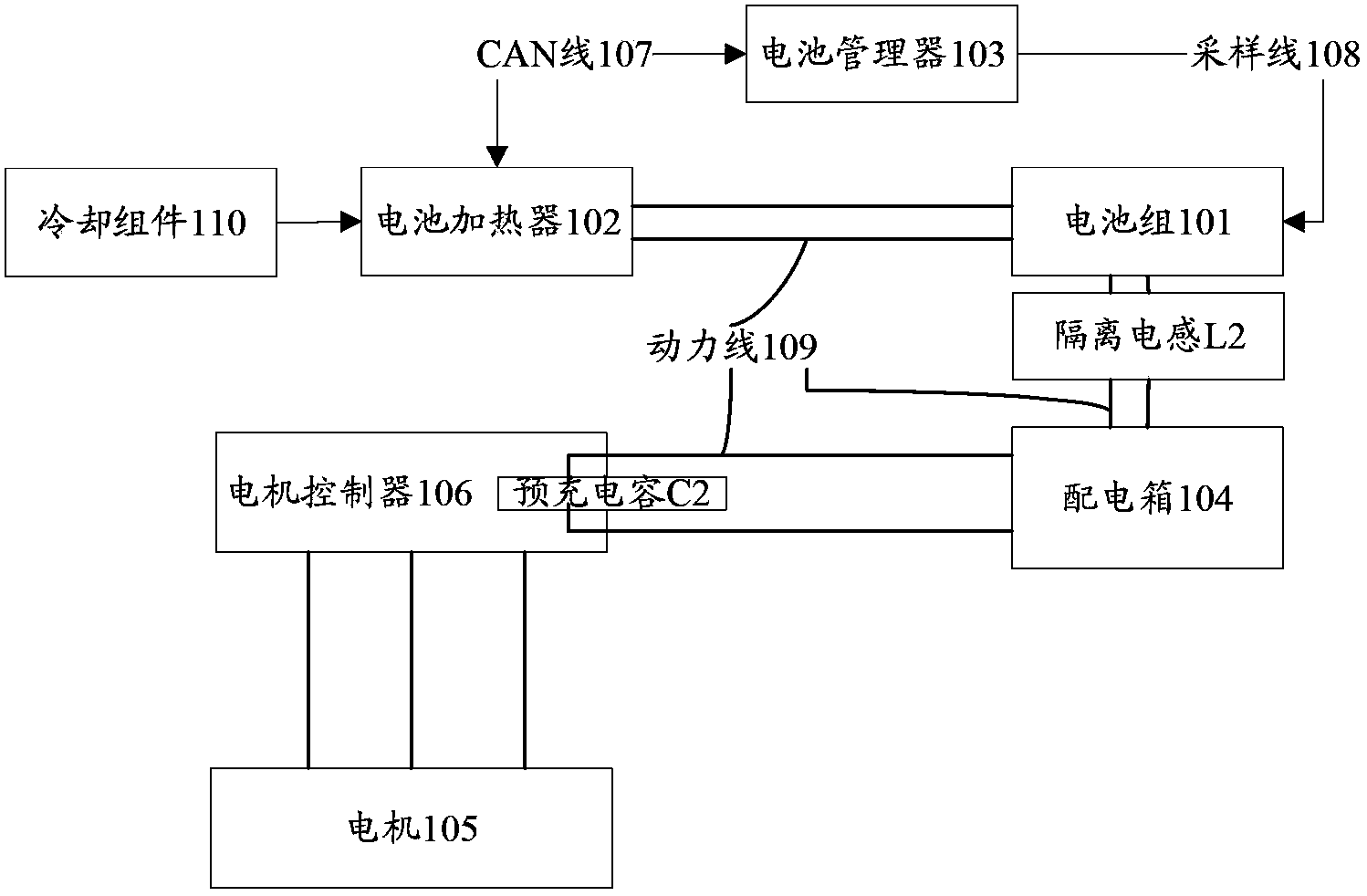

A power system of an electric vehicle, an electric vehicle comprising the same and a method for heating a battery group of the electric vehicle are provided. The power system comprises: a battery group (101); a battery heater (102) connected with the battery group; a battery management device (103), configured to control the battery heater to heat the battery group when a temperature of the battery group is lower than a first heating threshold and a residual electric quantity of the battery group is larger than a running electric quantity threshold, to obtain a current throttle depth change rate of an electric vehicle in real time, and to control the battery heater to stop heating the battery group when the current throttle depth change rate reaches a preset throttle depth change rate threshold; an electric distribution box (104); a motor (105); a motor controller (106); and an isolation inductor (L2).

Owner:BYD CO LTD

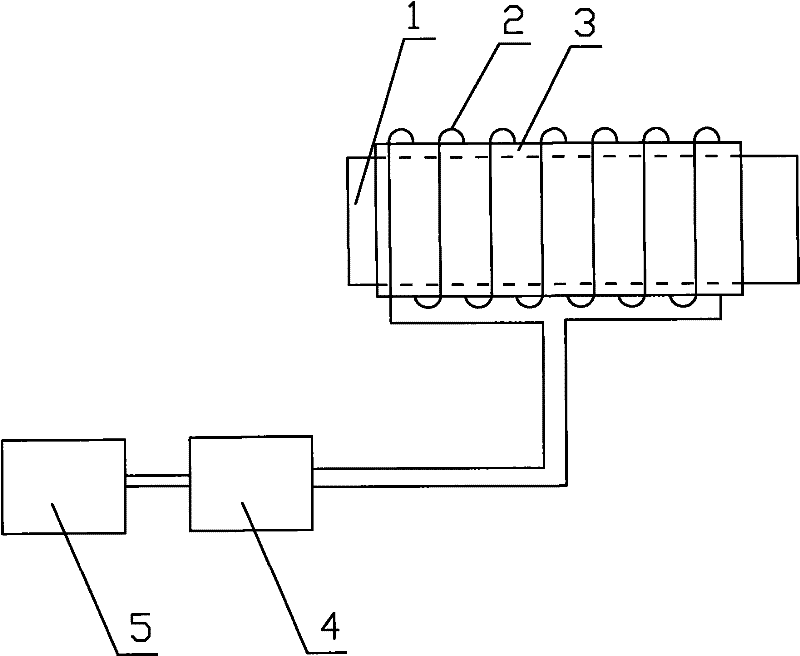

Heat supply device for high-frequency eddy pipeline

InactiveCN102207329AAchieve the purpose of heatingAvoid generatingWater heatersInduction heating apparatusElectricityProcess engineering

The invention relates to a heat supply device for a high-frequency eddy pipeline, and belongs to the technical field of electric heating. The heat supply device comprises a pipeline, wherein a coil is wound on the pipeline; an insulating layer is arranged between the pipeline and the coil; the coil is electrically connected with an inverter circuit; and the inverter circuit is electrically connected with a rectification circuit. In the heat supply device, the heat efficiency is more than 95 percent, the preheating time is shortened by 2 / 3, and compared with a resistance-type heating device, the heat supply device saves electricity by more than 25 percent under the same condition. The heat supply device can prevent scales and microbial membranes, prolong the service life, prevent the pollution of chemical cleaning to environment and save energy.

Owner:陈勇青

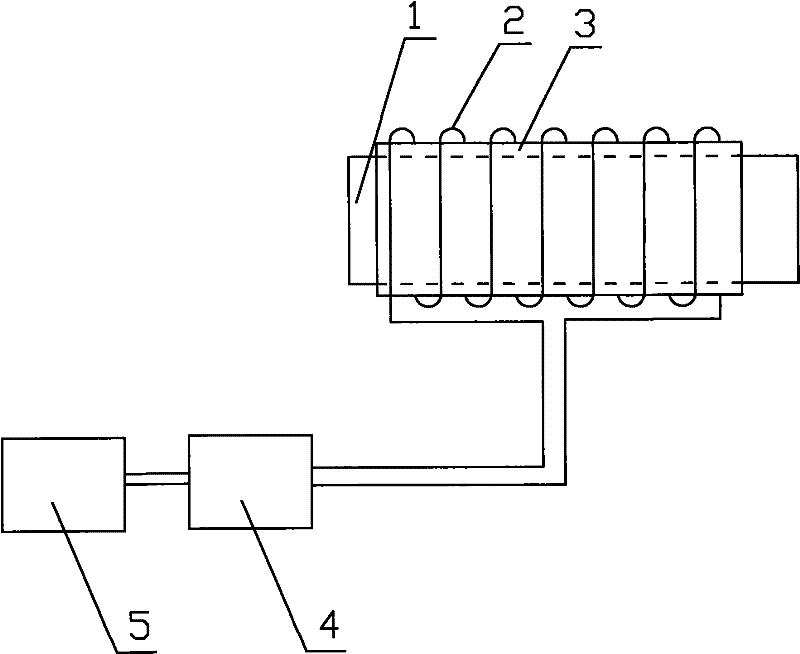

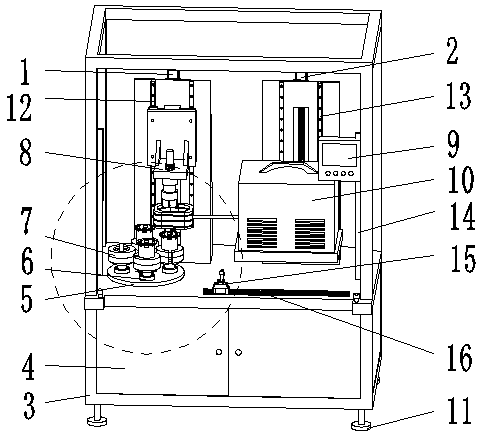

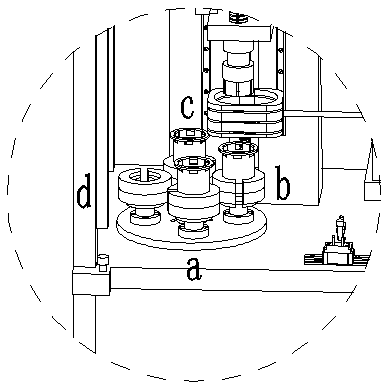

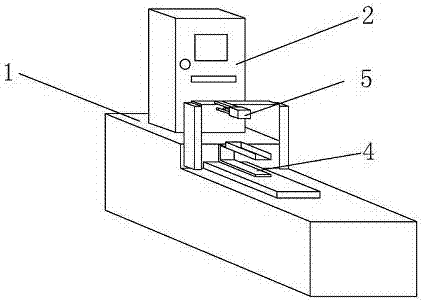

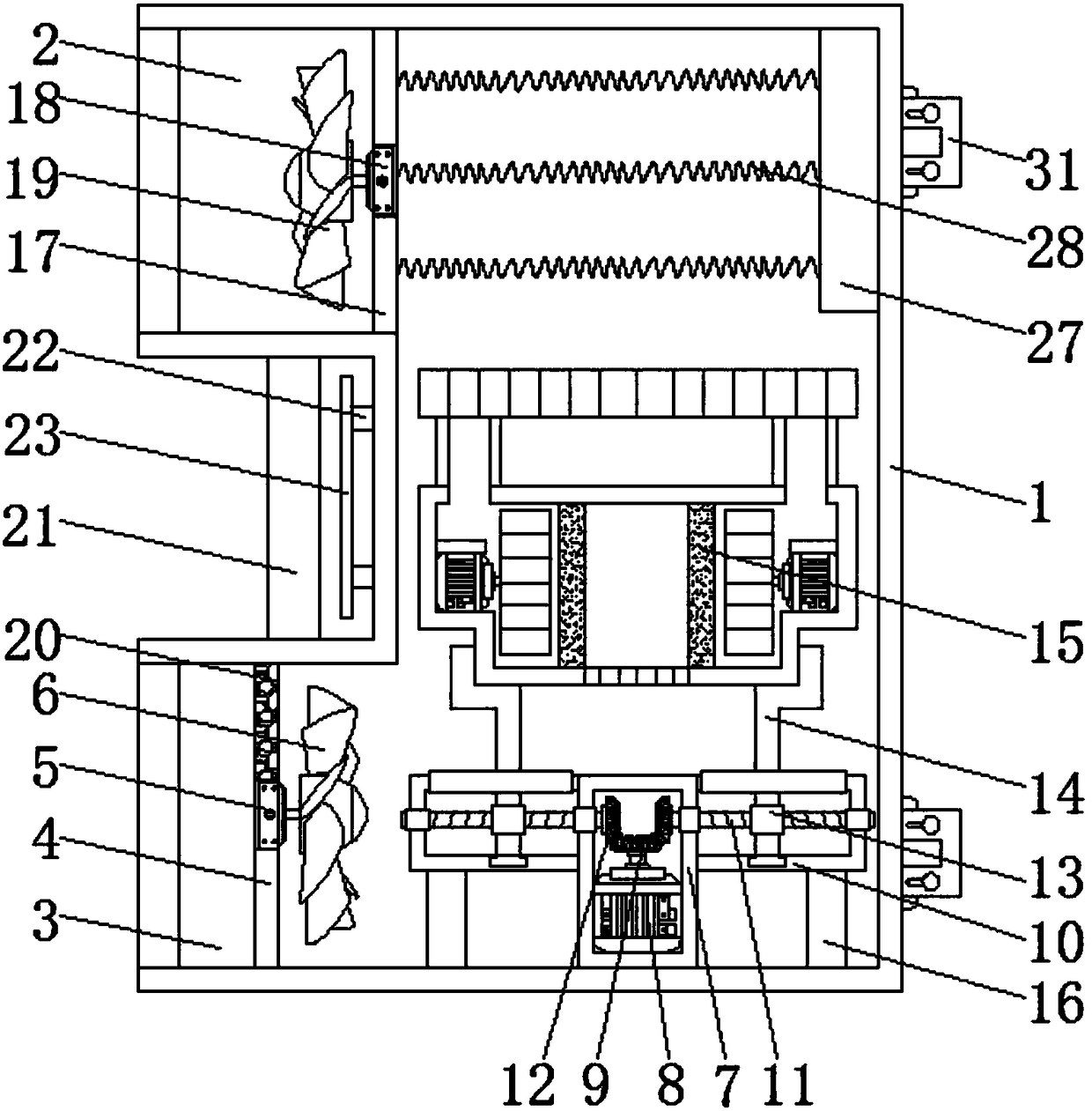

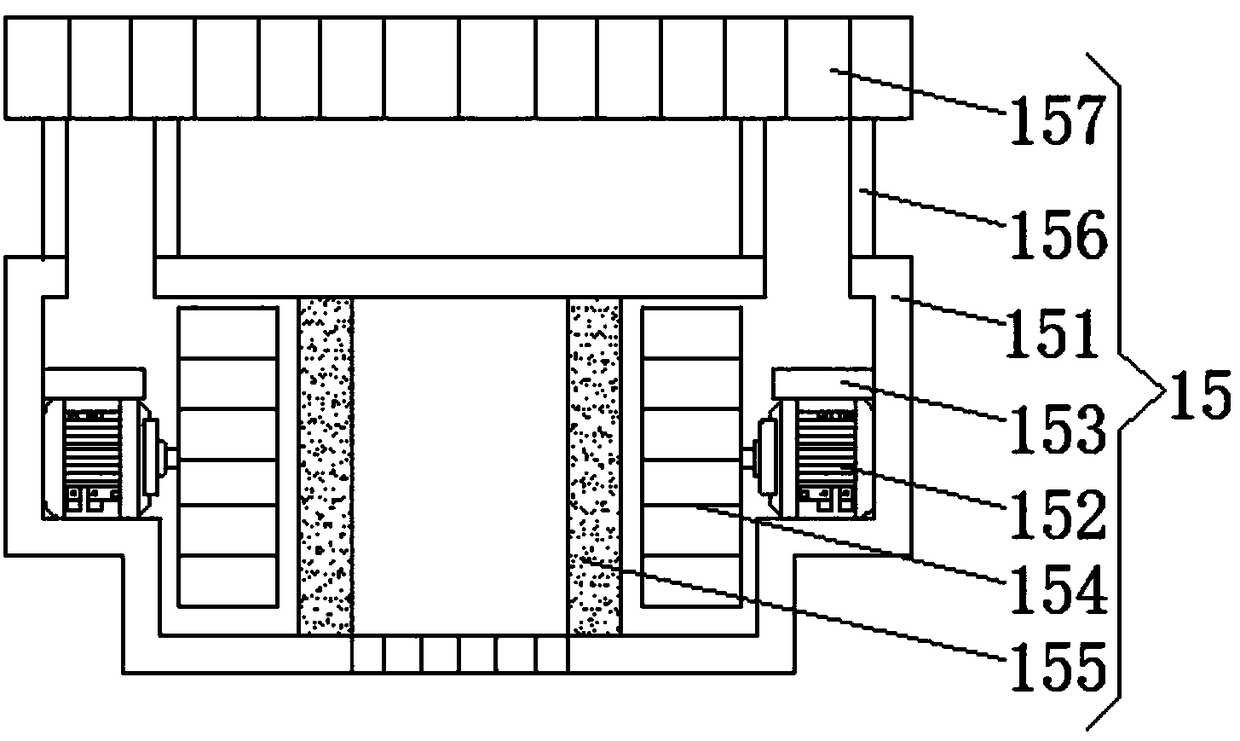

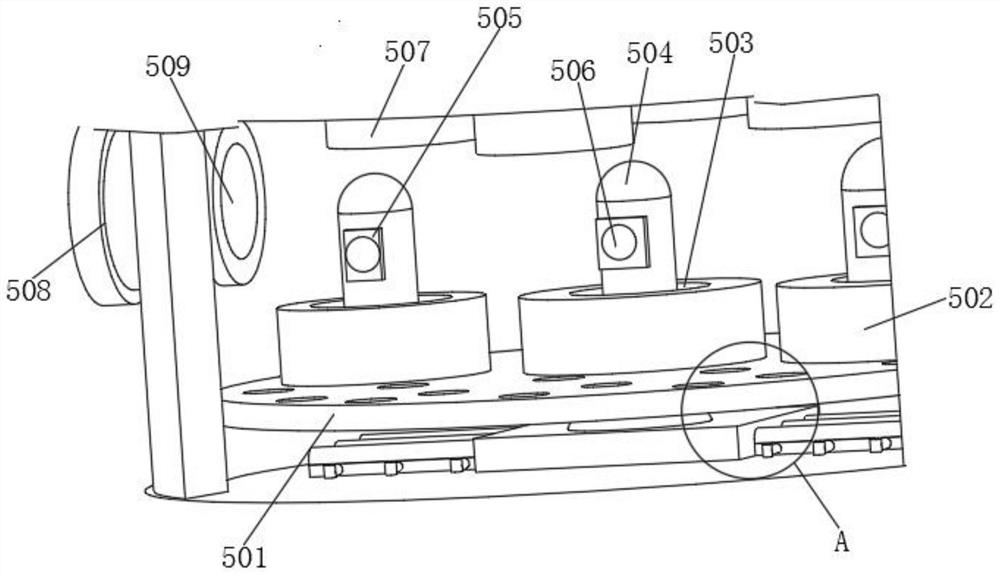

Automatic heat sleeving assembly machine

InactiveCN105537902AImprove automationAvoid uncontrollabilityMetal working apparatusProgrammable logic controllerEngineering

The invention relates to an automatic heat sleeving assembly machine and belongs to the field of machining equipment. The automatic heat sleeving assembly machine comprises an electrical system, a mechanical system and a programmable logic controller (PLC) control system. The electrical system comprises a tool servo system, a heating servo system and a moving part control system and is controlled by the PLC control system. The mechanical system comprises a machine frame, a built-in control cabinet, a tool dividing device, a touch device and a high-frequency induction heating device, wherein the built-in control cabinet, the tool dividing device, the touch device and the high-frequency induction heating device are installed on the machine frame. The automatic heat sleeving tooling process is completed through the cooperation of the electrical system, the mechanical system and the PLC control system. According to the automatic heat sleeving assembly machine, high-frequency induction heating is adopted, so that resource waste and potential safety hazards caused by indirect heating are avoided; in addition, the automation degree of the whole tooling process is greatly improved, the qualified rate of products and the production efficiency are also improved, and labor consumption is reduced.

Owner:HANGZHOU HUANJIE AUTOMATION EQUIP

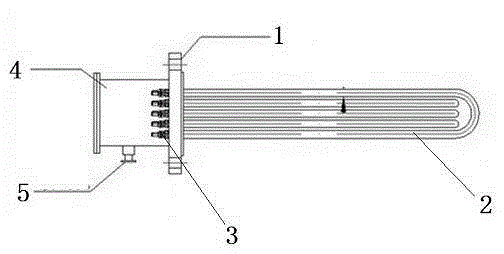

Flange heating tube device

InactiveCN104320867ASimple structureImprove thermal efficiencyHeating element shapesEngineeringTemperature resistance

The invention discloses a flange heating tube device. The flange heating tube device comprises a connecting flange and a plurality of heating tubes, wherein the heating tubes are U-shaped; one end of each heating tube is fixed to the connecting flange; and one end of the connecting flange is provided with a plurality of locking screws for locking the heating tubes; the external portion of the other end of the connecting flange is sleeved with a protective cover; and the protective cover is provided with a wiring hole into which an external power source line can be inserted. With the above structure adopted, the flange heating tube device of the invention has the advantages of being advanced, high thermal efficiency and uniform heat emission. According to the flange heating tube device, when current passes through a high-temperature resistance wire, generated heat is diffused to the surface of a metal tube through crystallized magnesium oxide powder, and then is transferred to a heated component or the air, and as a result, heating can be realized; the size and the shape of the flange can be changed; and the plurality of heating tubes are welded to the flange in a centralized manner, so that heating can be performed.

Owner:张谷一

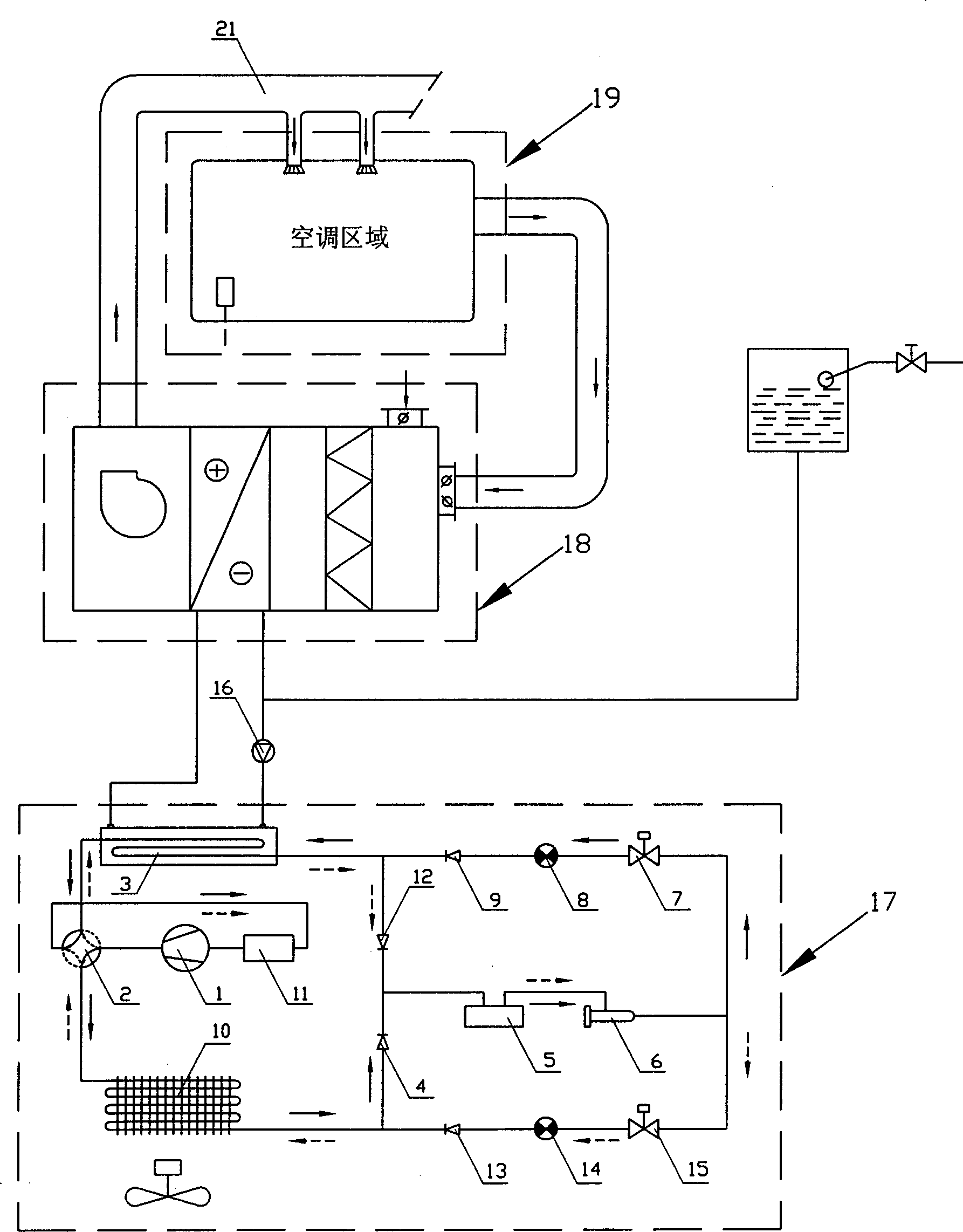

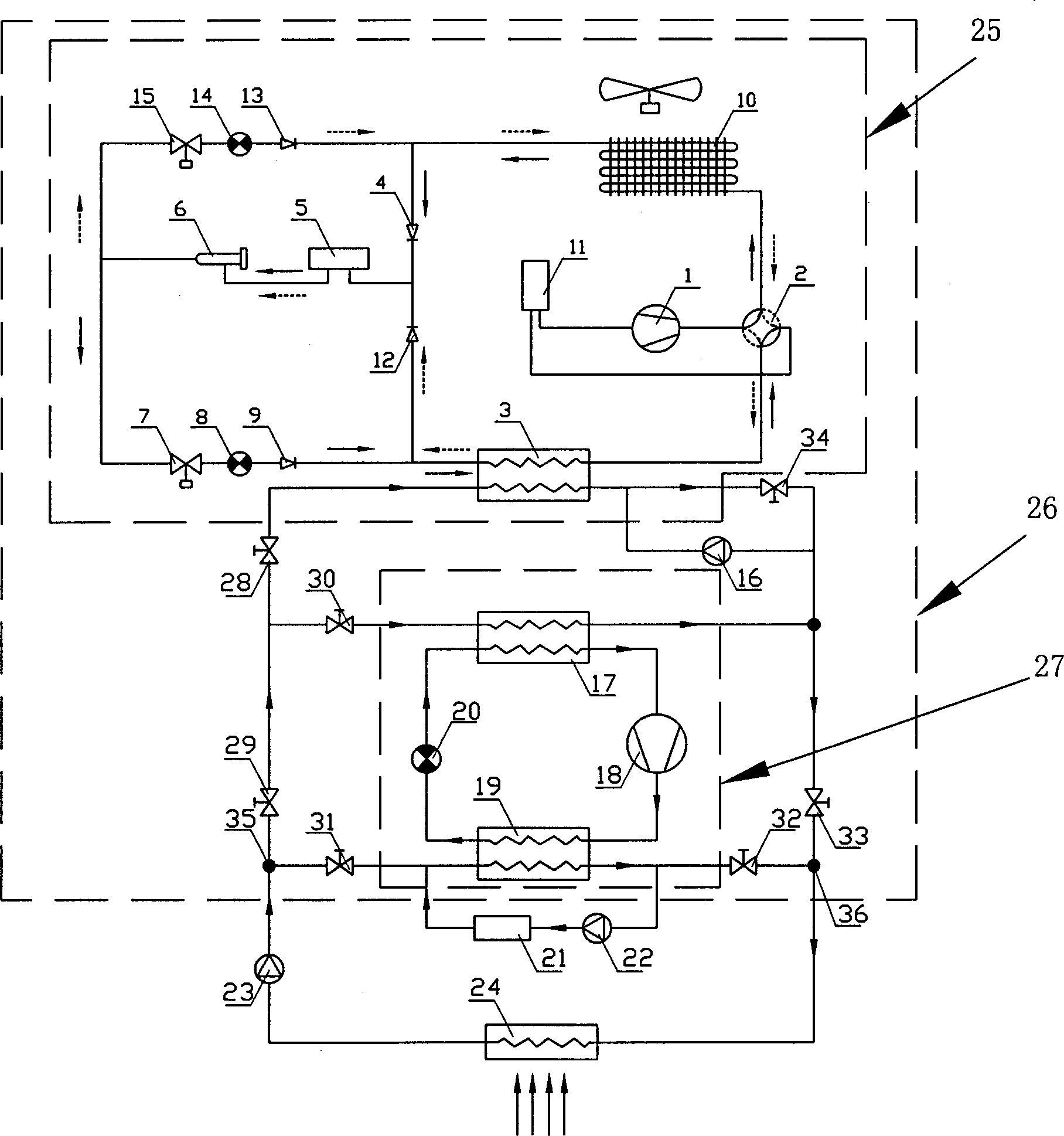

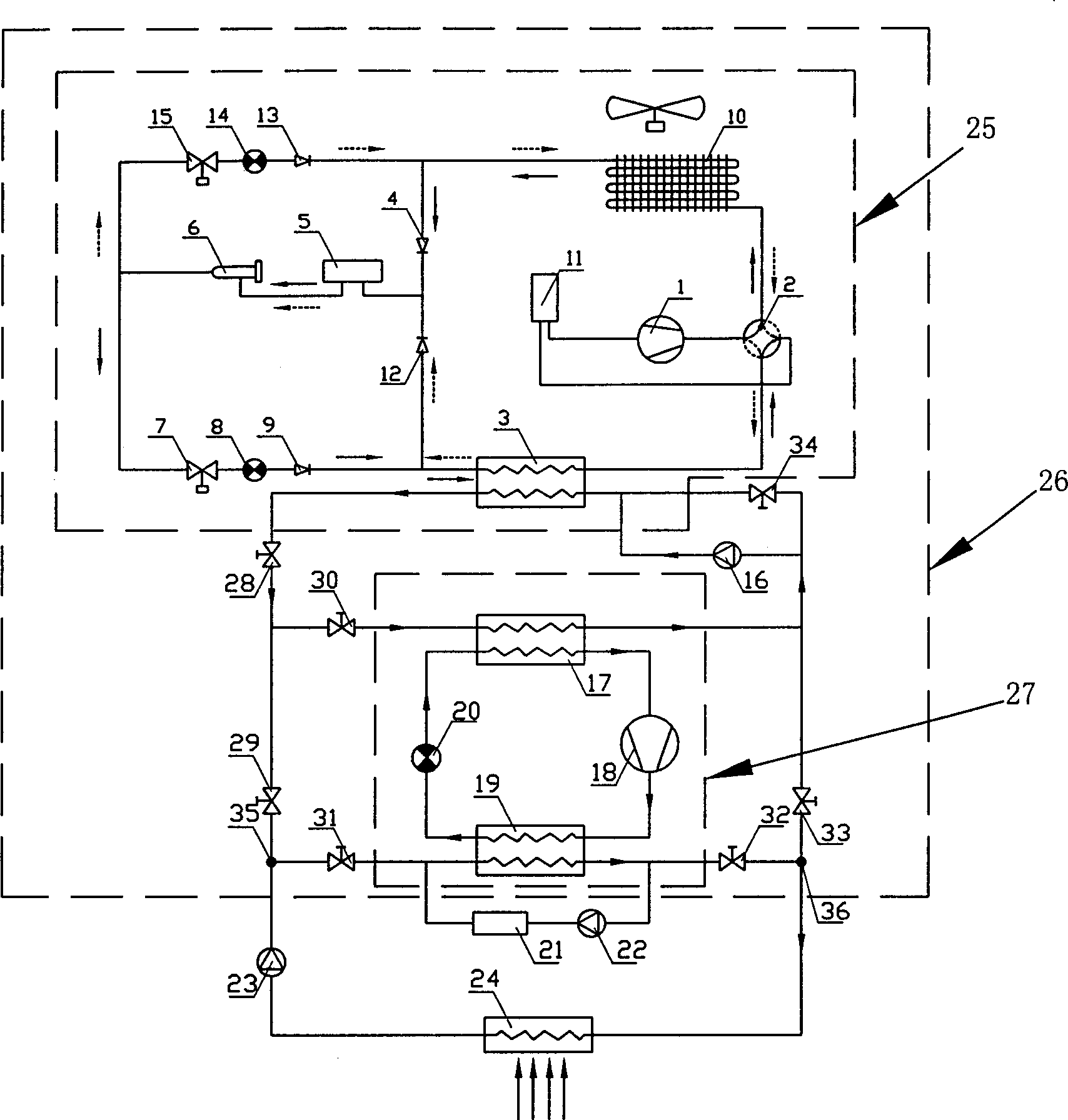

Compound air-cooled heat pump set

InactiveCN1451935AWide operating temperature rangeSolve the heating problem in autumn and winterHeat pumpsWater source heat pumpWater source

A combined air-cooled heat pump set is characterized by that the water-source heat pump set is combined with the air cooled heat pump set via water circulating mechanism to form a whole. In the summer, both heat pump sets are respectively used for refrigeration. In the winter, the air cooled heat pump set is used to heat water to 21 deg.C and then the water-source heat pump set is used to furtherheat the water to 45 deg.C for heating indoor air.

Owner:华夏幸福基业股份有限公司

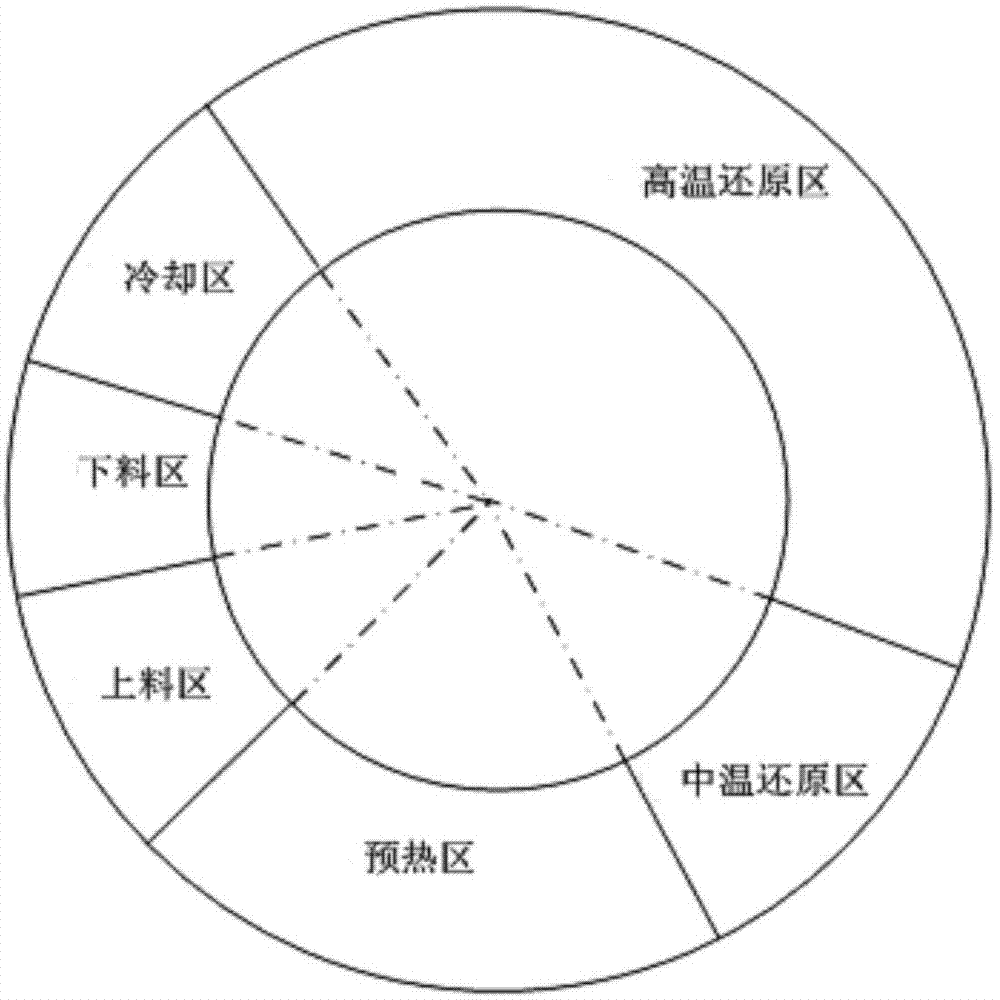

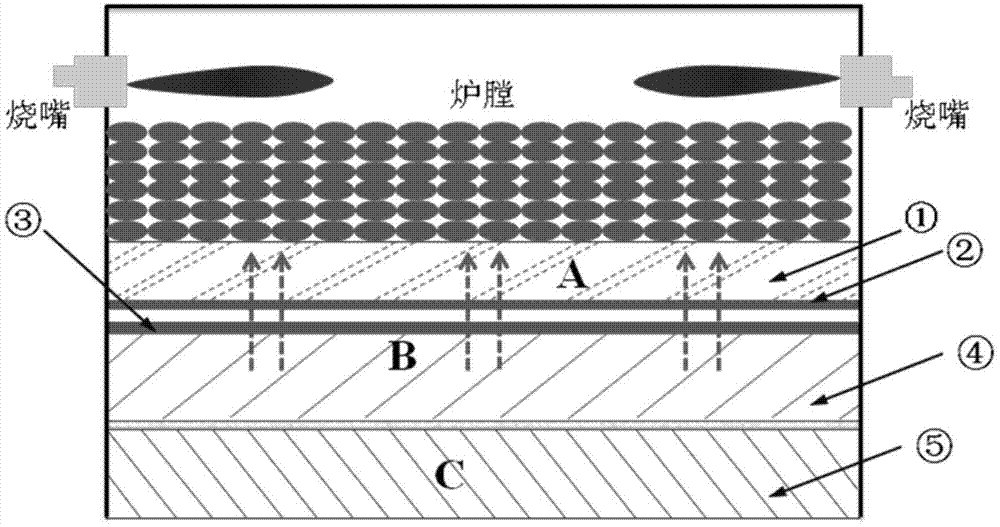

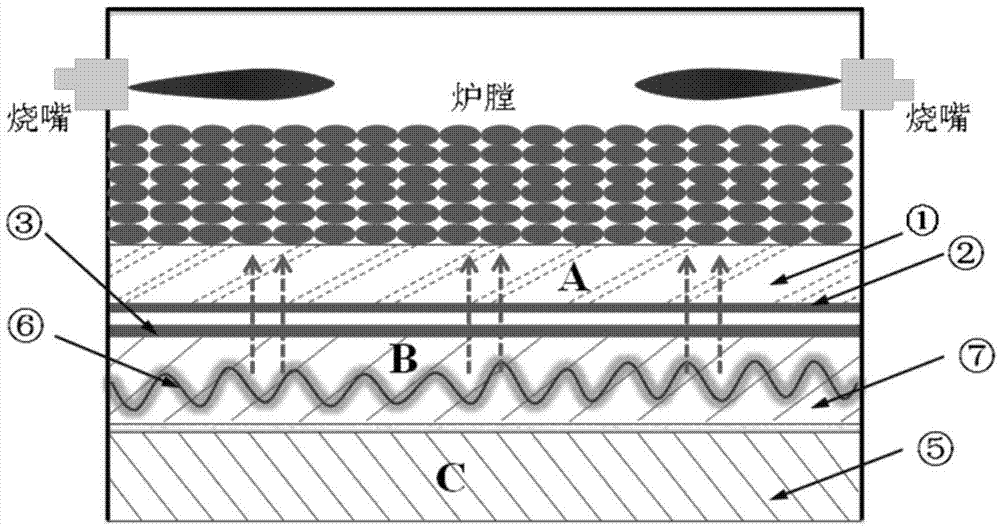

Furnace bottom structure capable of realizing reduction of deep bed for rotary hearth furnace

The invention provides a furnace bottom structure for a rotary hearth furnace. The furnace bottom structure comprises a heat preserving layer, a heating layer and an anti-slag-corrosion heat transfer layer in sequence from bottom to top, wherein the heat preserving layer and the heating layer are fixed; the anti-slag-corrosion heat transfer layer can rotate relative to the heat preserving layer and the heating layer; resistance wires are buried in the heating layer; the inside of the rotary hearth furnace is partitioned into a plurality of regions; the quantity of the resistance wires in the heating layer correspondsing to each region is set in advance; a layer of second steel plate is fixed on the upper part of the heating layer; a layer of first steel plate is fixed on the lower part of the anti-slag-corrosion heat transfer layer; a certain gap is kept between the first steel plate and the second steel plate, so that radiation heat transfer can be realized, and friction is prevented. By adopting the furnace bottom structure for the rotary hearth furnace provided by the invention, effective heat transfer and rapid reduction of a deep bed in a reduction process can be realized.

Owner:SHENWU TECH GRP CO LTD

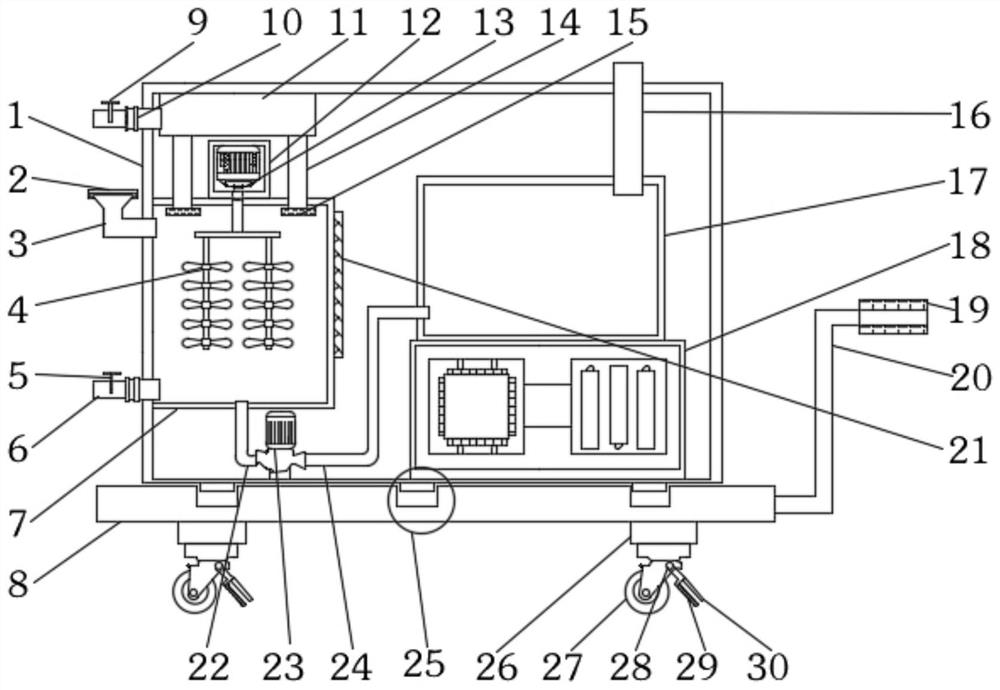

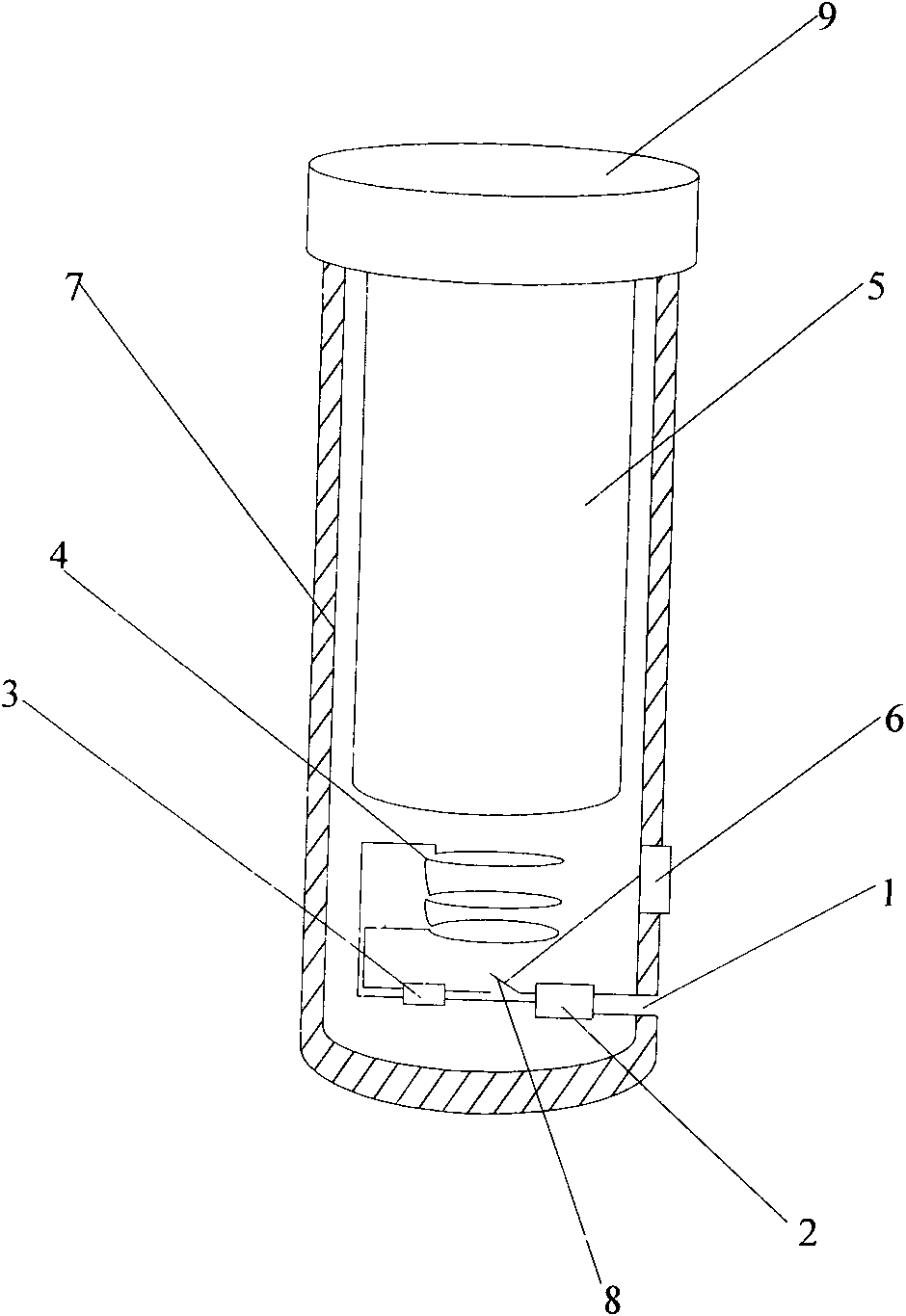

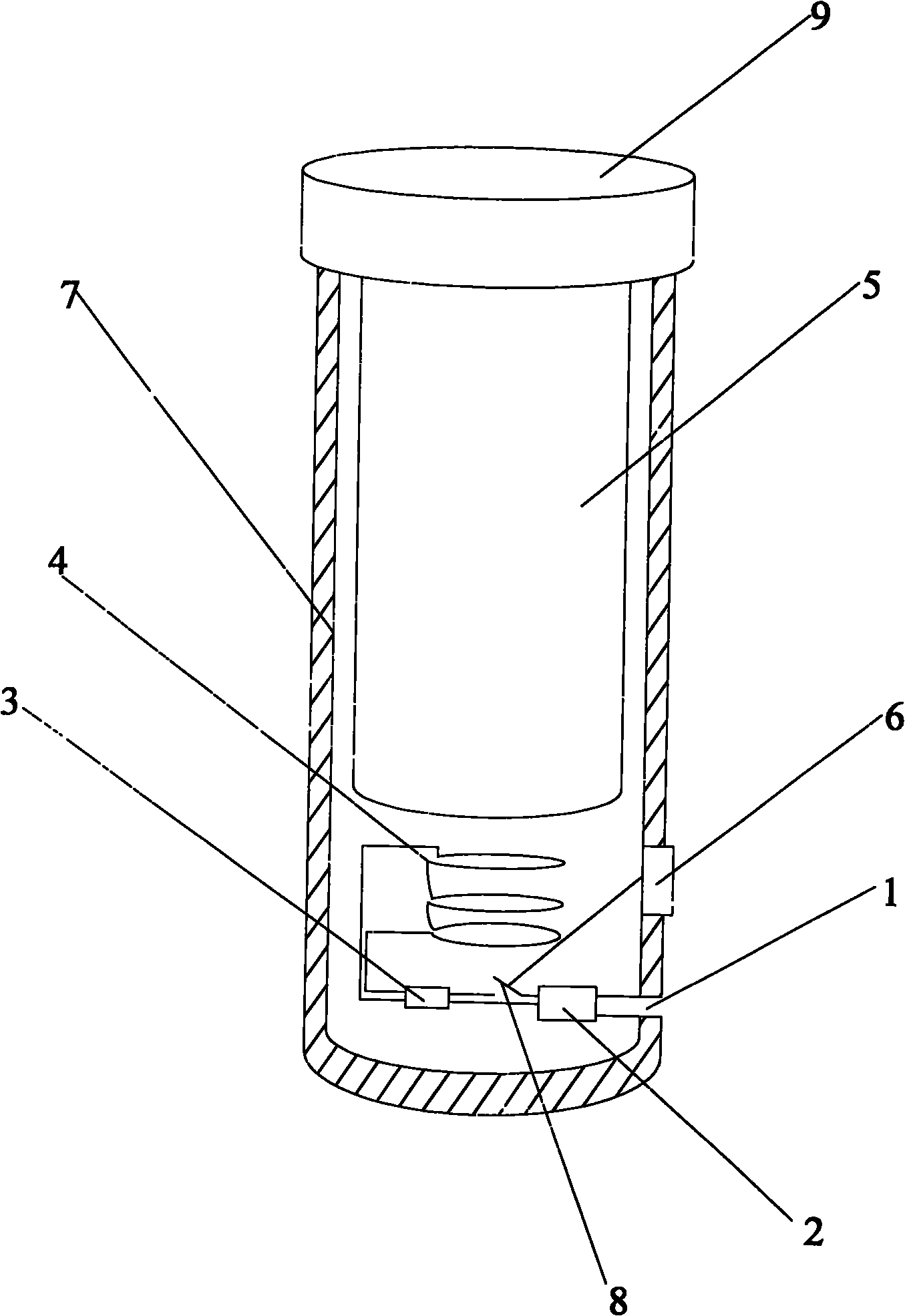

Atomizer for respiratory medicine department

InactiveCN112156289AAchieve the purpose of heatingUse impactRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention discloses an atomizer for the respiratory medicine department, and belongs to the technical field of medical equipment. The atomizer comprises a shell, a water pipe B is inserted into the top end of the left side of the shell, a valve B is detachably connected to the upper portion of the water pipe B, a water tank is fixedly installed on the right side of the water pipe B, a water pipe C is inserted into the lower portion of the water tank, the water pipe C extends into the interior of a box body, a high-pressure spray head is in clearance connection with the lower portion of thewater pipe C, a motor is fixedly installed on the left side of the water pipe C, the power output end of the motor is connected with the power input end of a rotating shaft, a stirring rod is detachably connected with the lower portion of the rotating shaft, a heating plate is in clearance connection with the left side of the box body, a water pipe A is inserted into the bottom end of the left side of the box body, and a valve A is detachably connected with the upper portion of the water pipe A. According to the atomizer for the respiratory medicine department, the motor, the rotating shaft,the stirring rod and the box body are installed, and liquid medicine in the box body is stirred, so that the liquid medicine is prevented from being precipitated, the pesticide effect is prevented from being influenced, good practicability is achieved, and popularization is suggested.

Owner:李月浩

Heating water cup

InactiveCN102151048AGuaranteed to drinkSimple structureWater-boiling vesselsDrinking vesselsEngineeringThermal water

The invention relates to a water cup, in particular to a heating water cup. The heating water cup comprises a cup shell, a cup body and a cup cover, wherein the cup shell has a hollow structure, and the stainless steel cup body is embedded into the cup shell; the lower part of the stainless steel cup body is provided with a coil, a micro inverter and a lithium battery sequentially connected through a lead, and a switch is arranged between the lithium battery and the micro inverter; and the lower end of the exterior of the cup shell is provided with a control button connected with the switch and a charge socket connected with the lithium battery. The heating water cup has simple structure; by adopting the heating water cup, a user is free from the limitation of time and space and can drink hot water at any time and any place; and the heating water cup is more convenient, safer and quicker to use.

Owner:顾帅杰

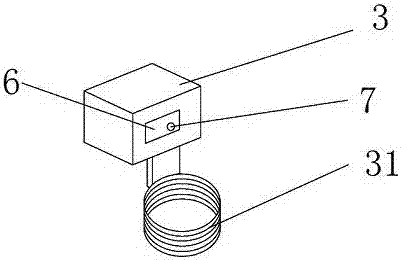

Guide pipe welding equipment

PendingCN107498172ALess smokeReduce leakageHigh frequency current welding apparatusPipe weldingLeakage rate

The invention provides guide pipe welding equipment. The guide pipe welding equipment comprises an operating table, a high-frequency heating device and an induction coil, wherein the high-frequency heating device is mounted on the upper rear portion of the operating table. The induction coil is a spiral copper pipe. The two ends of the spiral copper pipe are correspondingly connected with the positive electrode and the negative electrode of the high-frequency heating device. When the guide pipe welding equipment is used for welding guide pipes, the less smoke and the less welding leakage are generated; the leakage rate is lowered remarkably and is stabilized about 200 PPM; the operations depend on the equipment without depending on the skills of staff, and the stability is good; and the machining efficiency is high, and the purpose of 3,500 pieces per person per day is achieved.

Owner:无锡市华琳制冷设备有限公司

Tea leaf de-enzyming barrel with internal heating function

InactiveCN103461548AImprove processing efficiencyQuality improvementPre-extraction tea treatmentElectrical resistance and conductanceEngineering

The invention discloses a tea leaf de-enzyming barrel with an internal heating function. The tea leaf de-enzyming barrel comprises a charging hole, a barrel body, a radiating pipe, a resistance heating wire, a temperature detection element and a humidity detection element, wherein the charging hole is formed in the upper part of the outer wall of the barrel body, the temperature detection element and the humidity detection element are symmetrically arranged at left and right sides of the inside of the barrel body in a symmetrical manner, the temperature detection element can detect the temperature inside the barrel body in real time, the radiating pipe is arranged at the central position inside the barrel body, and the resistance heating wire is arranged inside the radiating pipe. According to the tea leaf de-enzyming barrel, the resistance heating wire is arranged inside the barrel body, compared with the traditional barrel type tea leaf de-enzyming machine, the tea leaf de-enzyming barrel can achieve the purpose of heating inside the barrel body, so as to improve the tea leaf processing efficiency; besides, the de-enzymed tea leaves are uniform and have the high quality, and therefore, the tea leaf de-enzyming barrel has a wide application prospect.

Owner:常熟市新艺机械厂

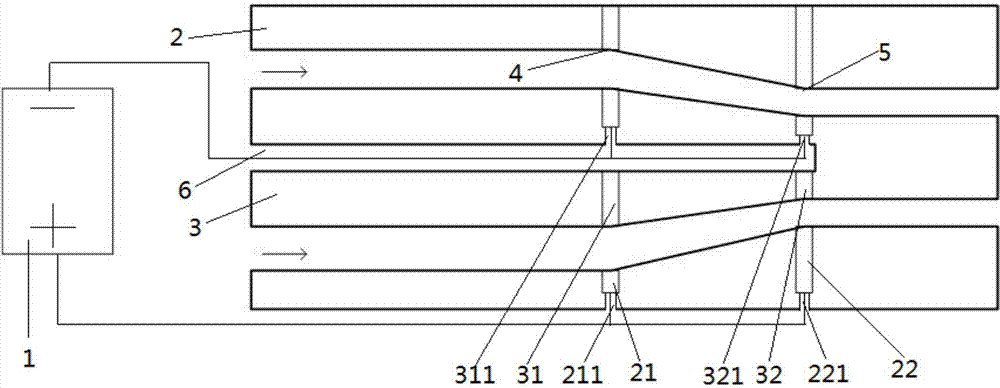

Auxiliary processing device for electric pulse pipe fitting

The invention discloses an auxiliary processing device for an electric pulse pipe fitting. The auxiliary processing device comprises a pulse power supply, a concave die, a core rod, insulating layers, a first positive electrode, a second positive electrode, a first negative electrode and a second negative electrode, wherein the first positive electrode and the second positive electrode are arranged on the inner surface of the concave die; the first negative electrode and the second negative electrode are arranged on the outer surface of the core rod; the first positive electrode, the second positive electrode, the first negative electrode and the second negative electrode are annular electrodes; the first positive electrode, the second positive electrode, the first negative electrode and the second negative electrode are connected with a pulse power supply; the insulating layers are uniformly distributed on the surfaces of the concave die and the core rod except the positive electrodes and the negative electrodes. According to the auxiliary processing device for the electric pulse pipe fitting, pulse current is introduced and an electro-plastic effect is used for enabling a raw material pipe fitting to be easily extruded and molded; the device disclosed by the invention is simple in structure, rapid in heating and high in working efficiency, and the cost loss and the energy source loss are reduced.

Owner:SHANGHAI JIAO TONG UNIV

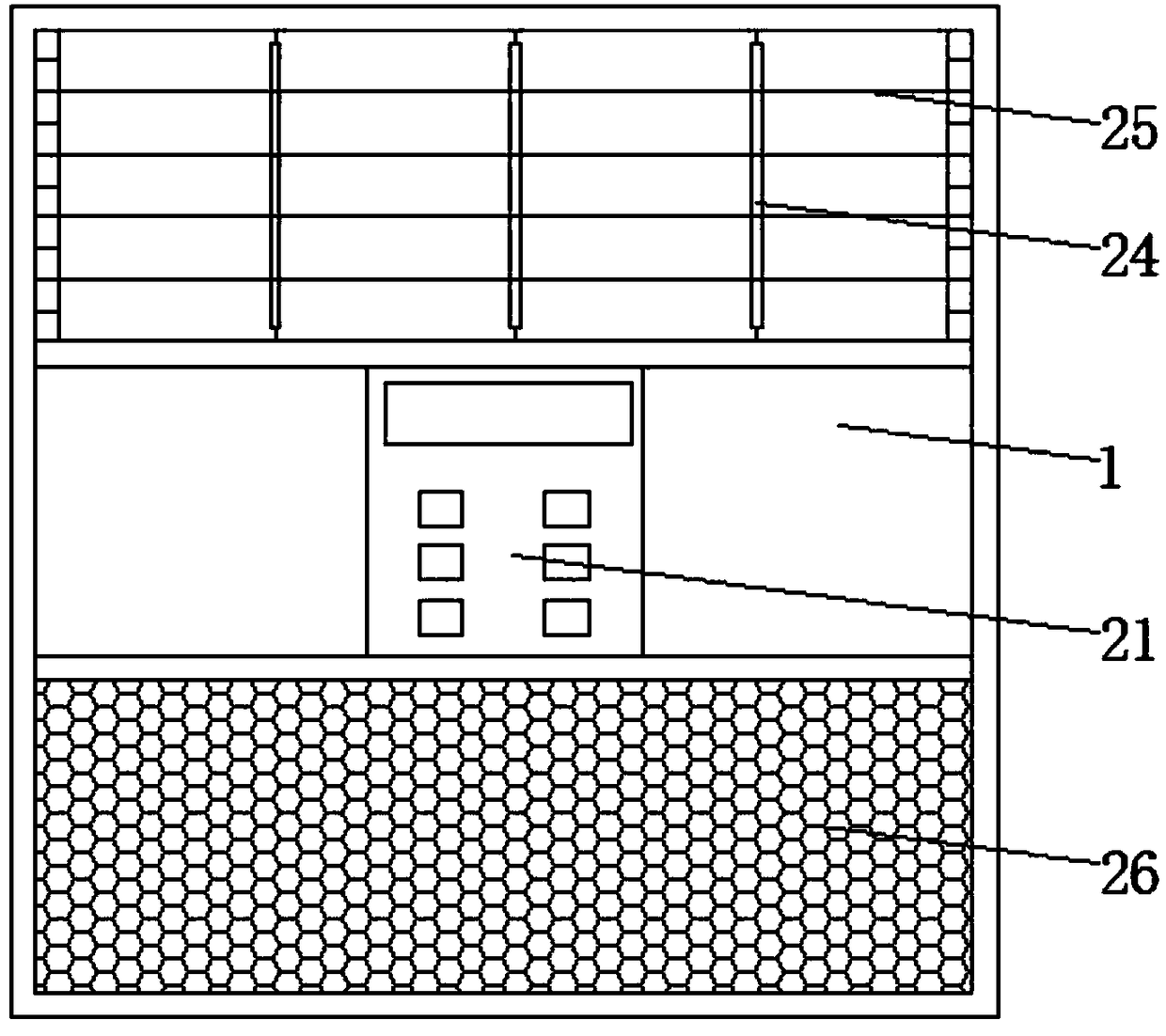

New energy vehicle anti-haze purifying device

InactiveCN108297653AEasy to take out or clampEasy to replace and maintainHuman health protectionAir-treating devicesEngineeringNew energy

The invention discloses a new energy vehicle anti-haze purifying device, and relates to the technical field of new energy vehicle air purifying equipment. The new energy vehicle anti-haze purifying device comprises a box body, an air outlet through hole and an air inlet through hole are formed in the upper part and the lower part of one side of the box body, and a first ventilation fixing plate isfixedly connected between the upper part and the lower part of the middle of the inner wall of the air inlet through hole; and the center of the first ventilation fixing plate is fixedly connected with a first motor, an air inlet fan is rotatably connected to the side, away from the air inlet through hole, of the first motor through an output shaft, and a motor box is fixedly connected with the side, away from the air inlet fan, of the bottom of the inner wall of the box body. The new energy vehicle anti-haze purifying device solves the problem that an original new energy vehicle internal space is relatively small and closed, the situation that internal air becomes dirty is easily caused due to the fact that no anti-haze purifying device is arranged, and consequently, the health of humanbodies is damaged, the purpose of efficient removing of haze and particulate matter impurities is achieved, turbid air is extracted through the negative pressure, the haze removing efficiency is effectively improved, later replacement maintenance is convenient, and the simple and practical effects are achieved.

Owner:佛山杰致信息科技有限公司

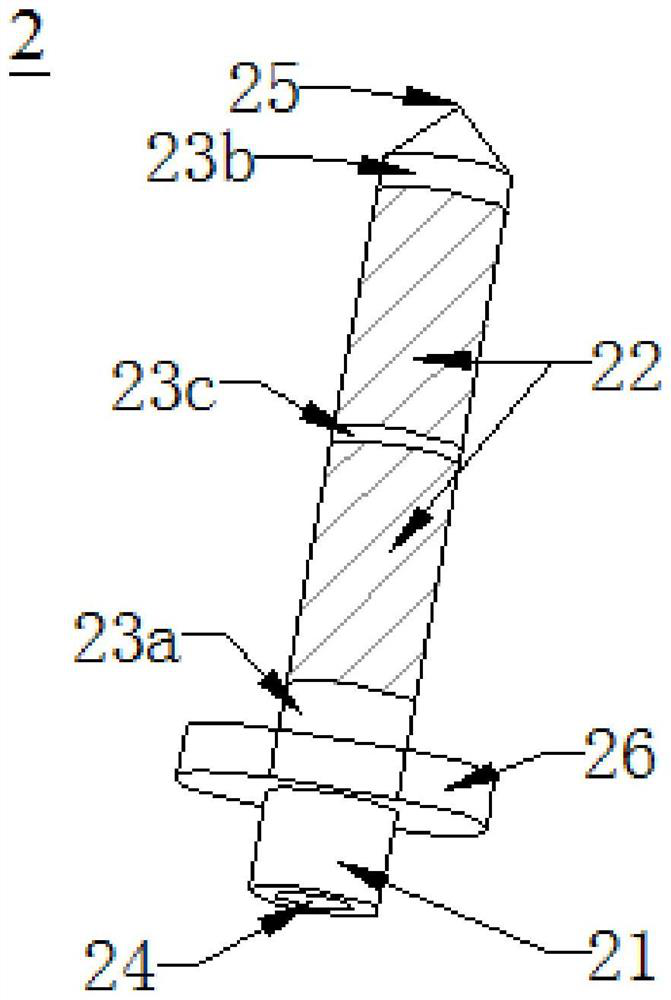

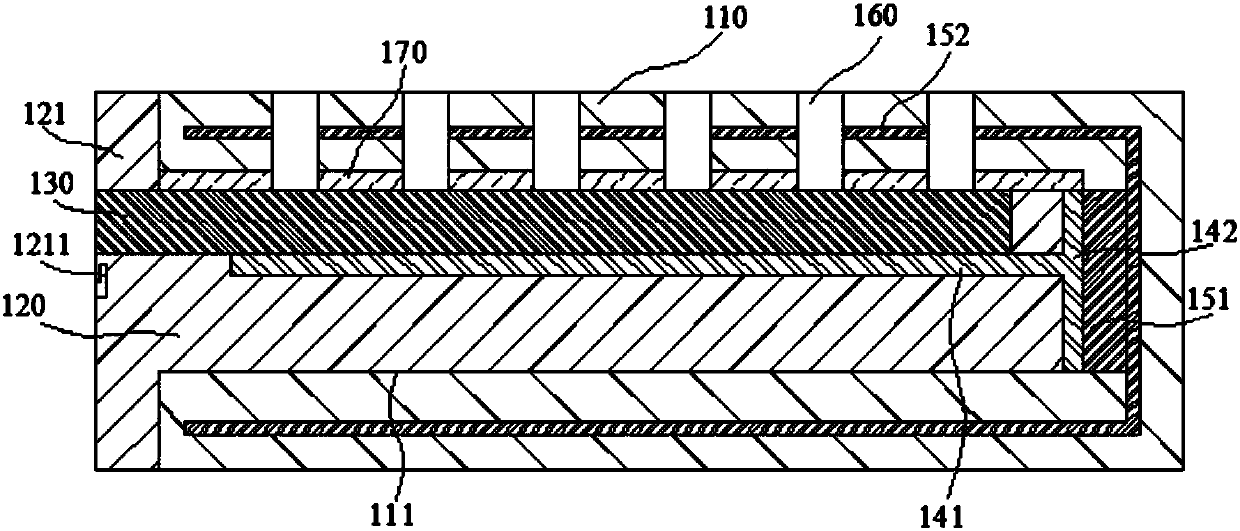

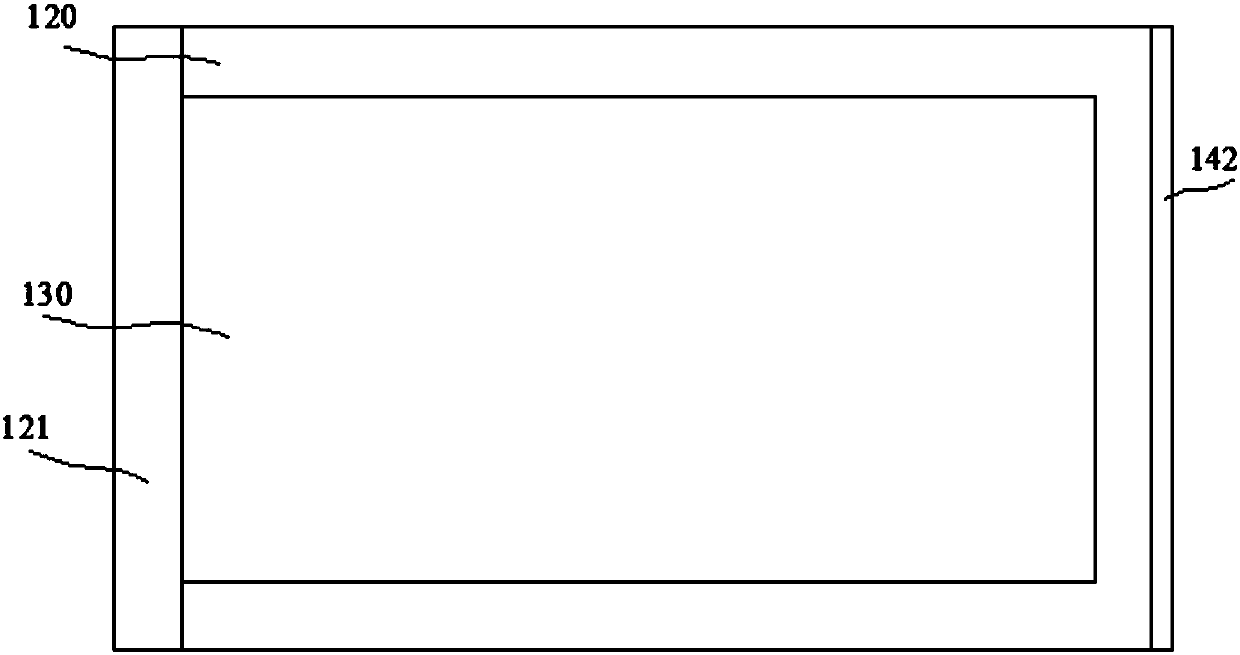

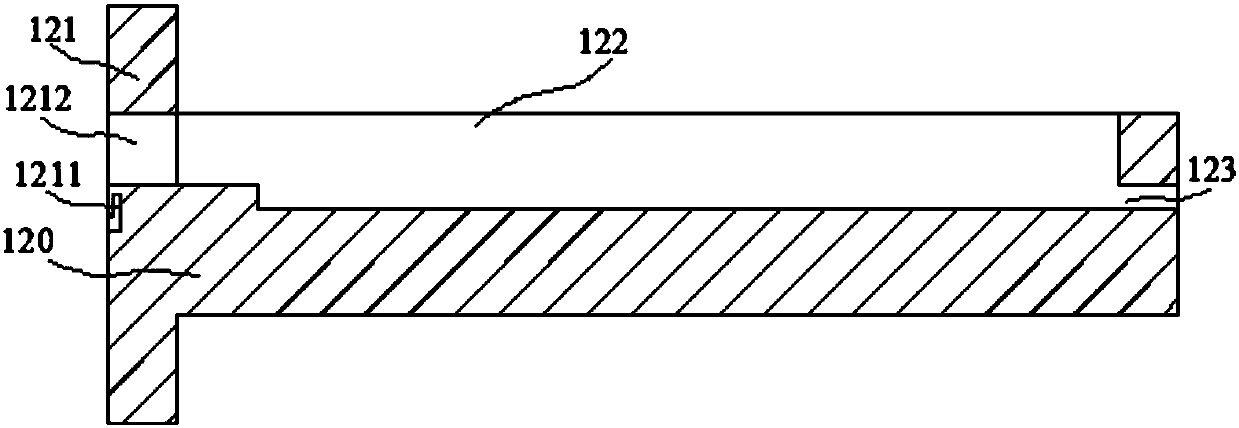

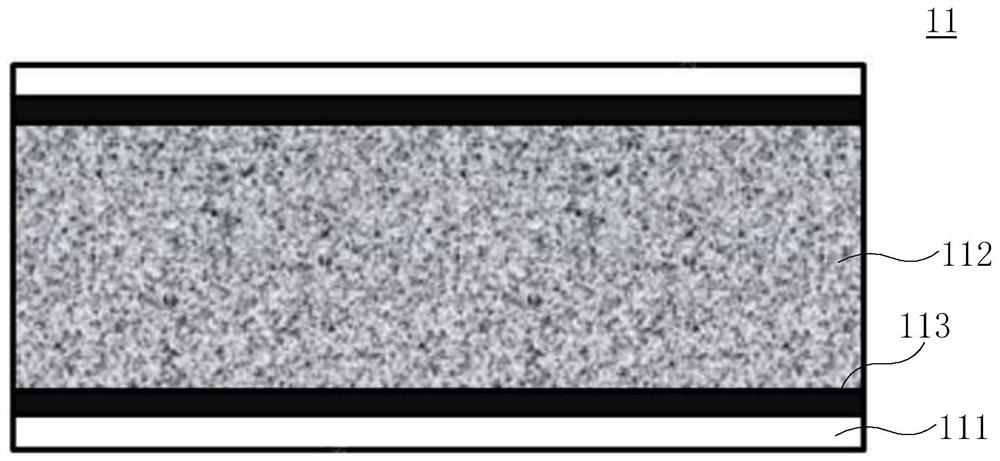

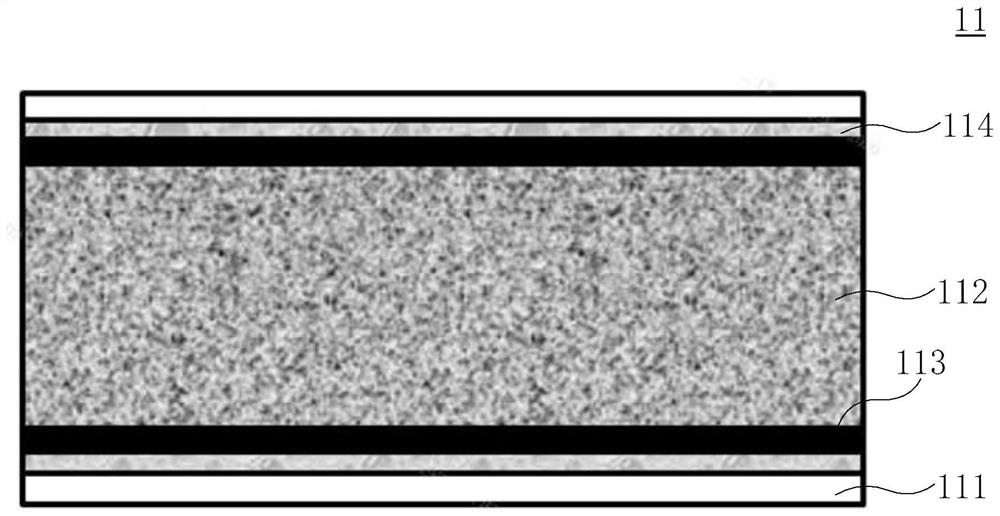

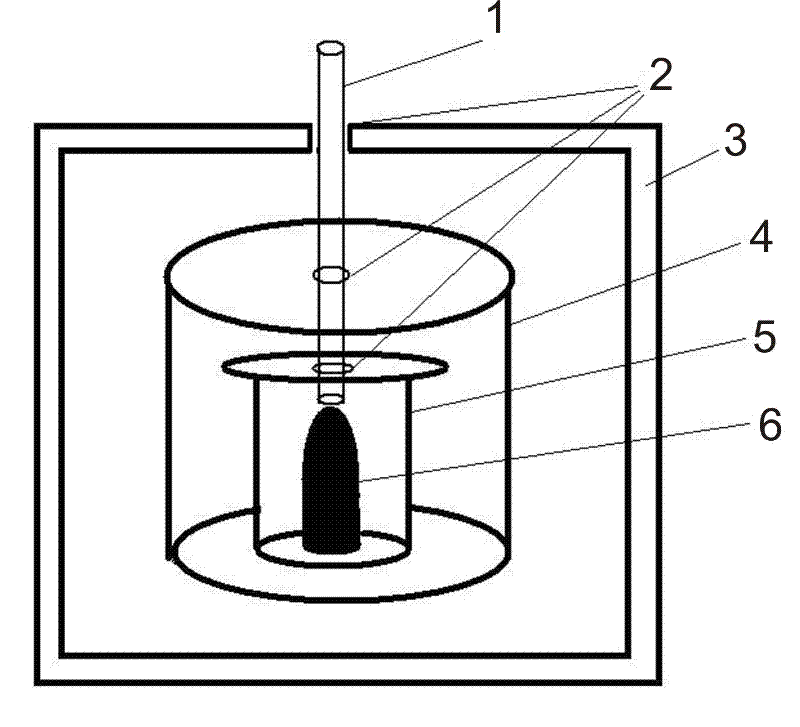

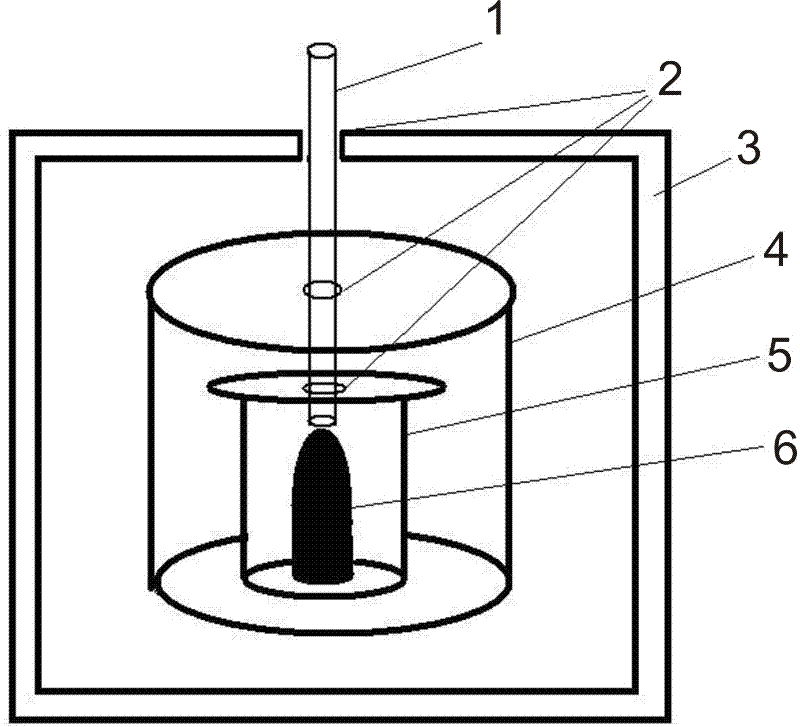

Heat-not-burn device

The invention provides a heat-not-burn device. The device comprises a heating cavity and an infrared heater, wherein an inserting hole is formed in the bottom wall of the heating cavity, and the inserting hole is located in the middle area of the bottom wall; and the infrared heater comprises a columnar carrier, an infrared coating located on the outer side face of the carrier and an electrode electrically connected with the infrared coating. The top surface of the carrier is closed, and the top surface of the carrier and the part, opposite to the infrared coating, of the carrier are insertedinto the heating cavity from the inserting hole; and an electrode electrically connected with the infrared coating is led out of the heating cavity. By using the device, the tobacco materials are heated more uniformly and fully, and the generated smoke is more sufficient.

Owner:HUBEI CHINA TOBACCO IND

Heating device employing graphene generate heat

ActiveCN107911882AStuffing is effectiveEasy to insertOhmic-resistance electrodesHeating element materialsElectricityEngineering

The invention relates to the technical field of graphene, and relates to a heating device employing graphene to generate heat. An installation cavity is formed in a protection layer of the heating device, a support plate is plugged in the installation cavity and is provided with a baffle plate, a graphene electric heating film is arranged in a first accommodating cavity in the support plate, convex strips are respectively arranged at a left side and a right side of the graphene electric heating film, the convex strips are blocked by baffle strips, a first energization contact is arranged at aleft side of each convex strip, a second energization contact is arranged in the first accommodating cavity and is matched with the first energization contact, the second energization contact is connected with a metal energization rod, a left side of the metal energization rod is in threaded connection with two fastening nuts, a lower part of the first accommodating cavity communicates with a second accommodating cavity, a metal plugboard is arranged in the second accommodating cavity, a top surface of the metal plugboard is attached to the graphene electric heating film, the metal plugboard is connected with a metal lamination plate, the metal lamination plate is attached onto a metal heat conduction plate, and the metal heat conduction plate is connected with two metal network plates. Bythe heating device, the graphene can be used for generating heat and can be protected, and the heating speed is fast.

Owner:NINGBO COLLEGE OF HEALTH SCI

Smoking product

PendingCN113100493AAvoid uneven heatingImprove the taste of smokingFireproof paintsCigar manufactureMouthfeelSmoke

The invention relates to the technical field of tobaccos, and provides a smoking product. The smoking product comprises a smoke generation section, which comprises a tube wall and a tube cavity, wherein the tube cavity is used for containing an aerosol forming substrate; and an infrared radiation layer, which is formed on at least part of the inner surface of the tube wall, and is used for being heated by a smoking set to generate infrared rays and heating the aerosol forming substrate at least in a radiation mode. Through the infrared radiation layer arranged on the inner surface of the pipe wall, the infrared radiation layer is heated by the smoking set to generate infrared rays, and aerosol is heated at least in a radiation mode to form a substrate; and the infrared rays are long in wavelength, can penetrate through substances, resonate with molecules and atoms in the substances and generate strong vibration and rotation, so that the temperature of the substances rises, the purpose of heating is achieved, the overall temperature of the substances rises, the phenomenon that an existing smoking product is heated unevenly is avoided, and the smoking taste of a user is improved.

Owner:SHENZHEN FIRST UNION TECH CO LTD

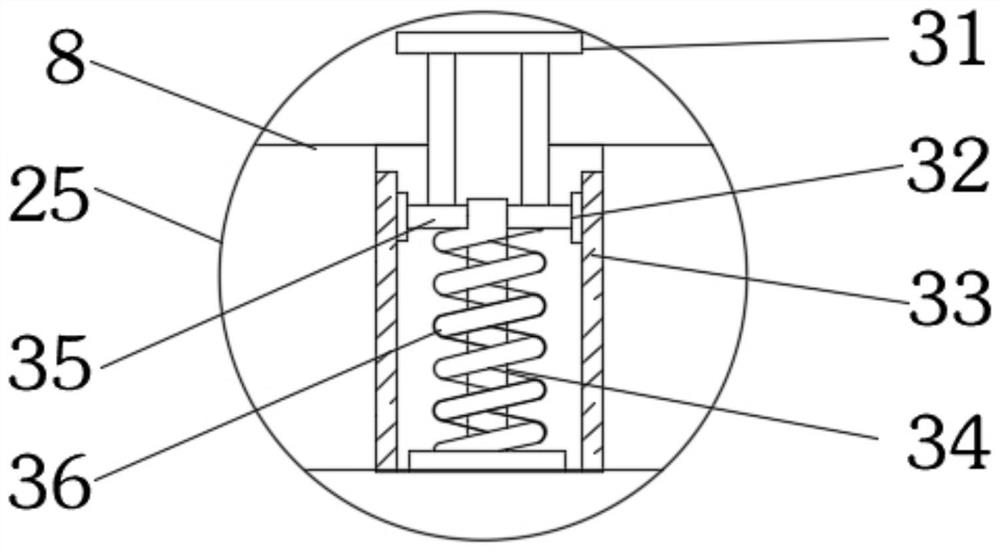

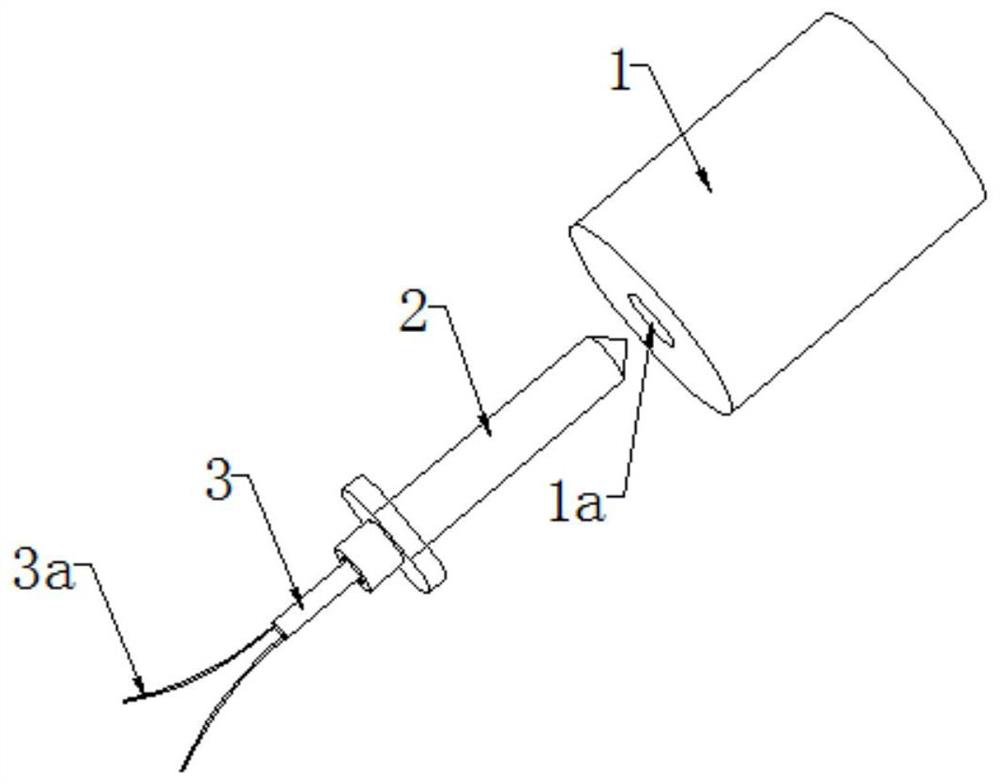

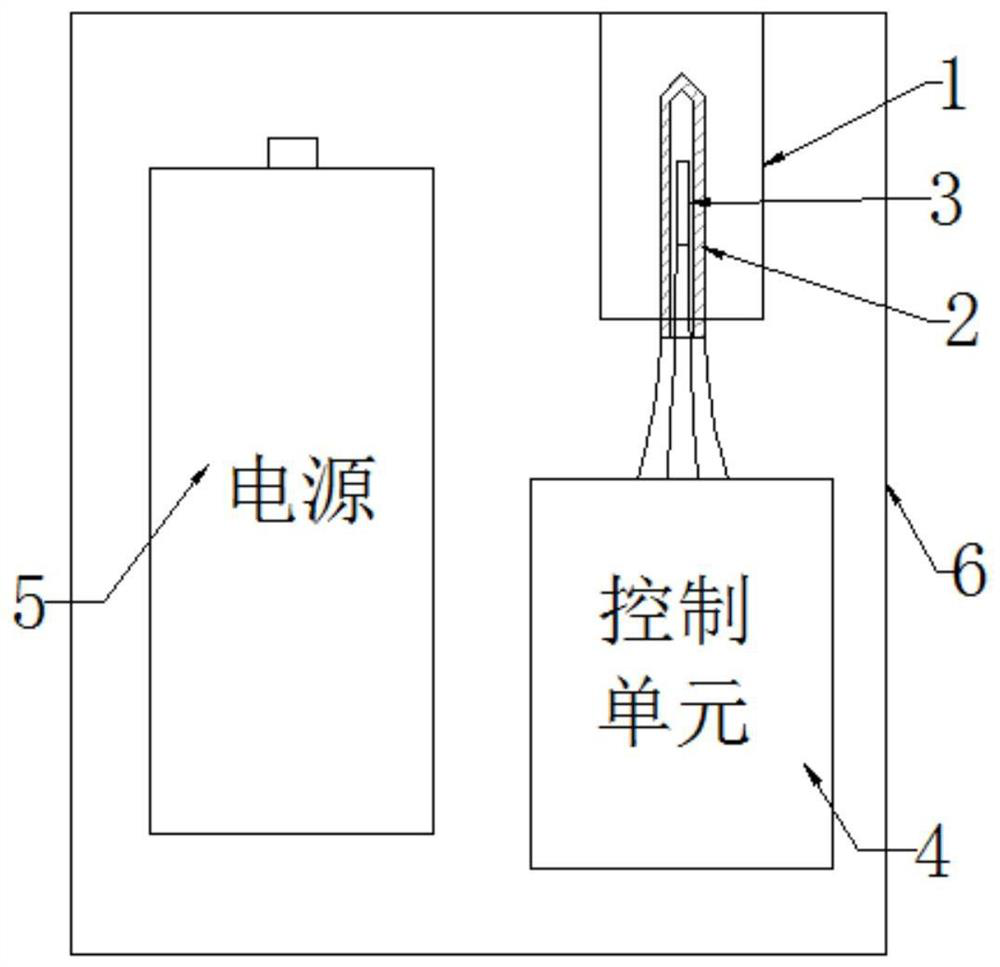

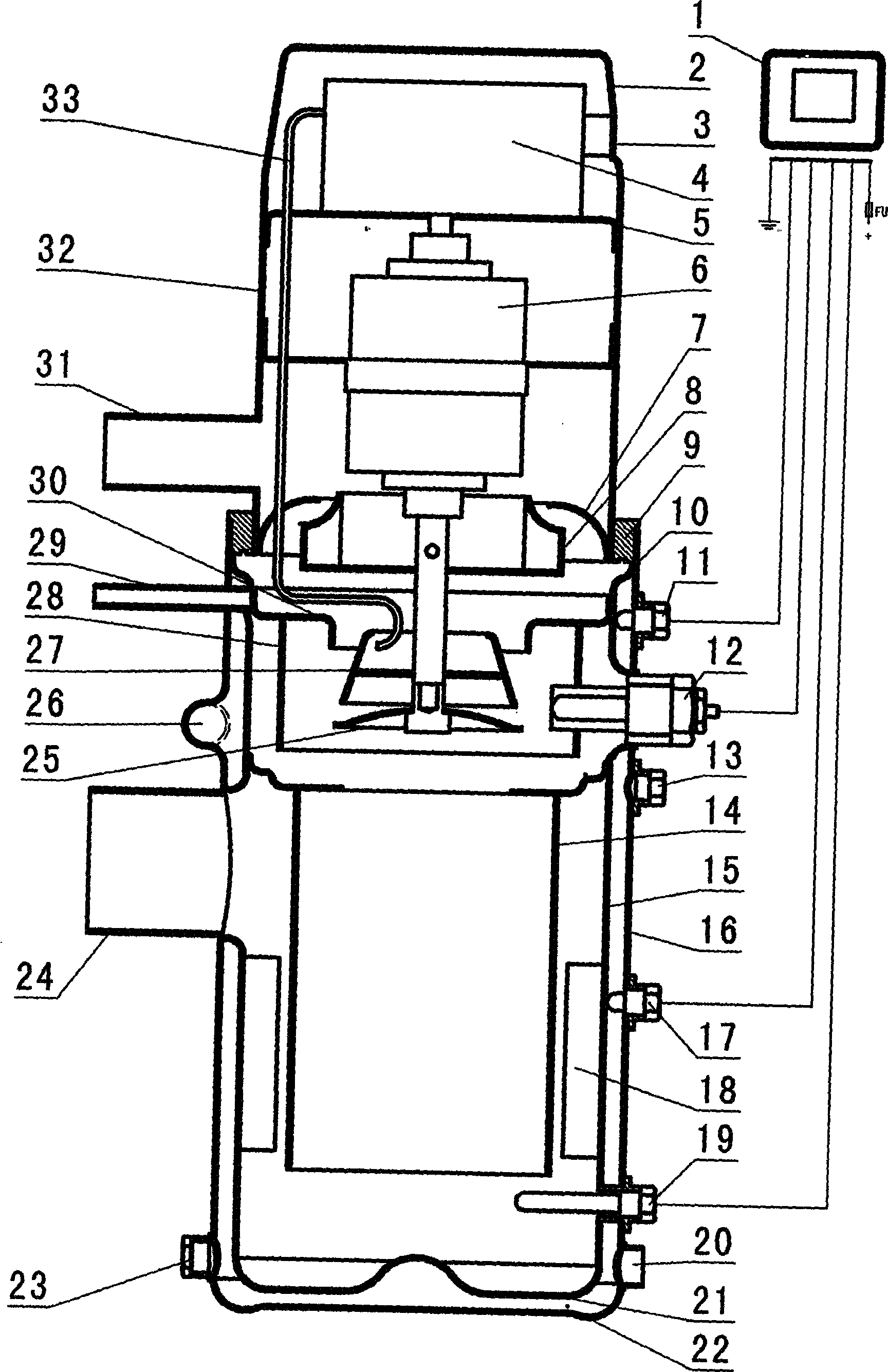

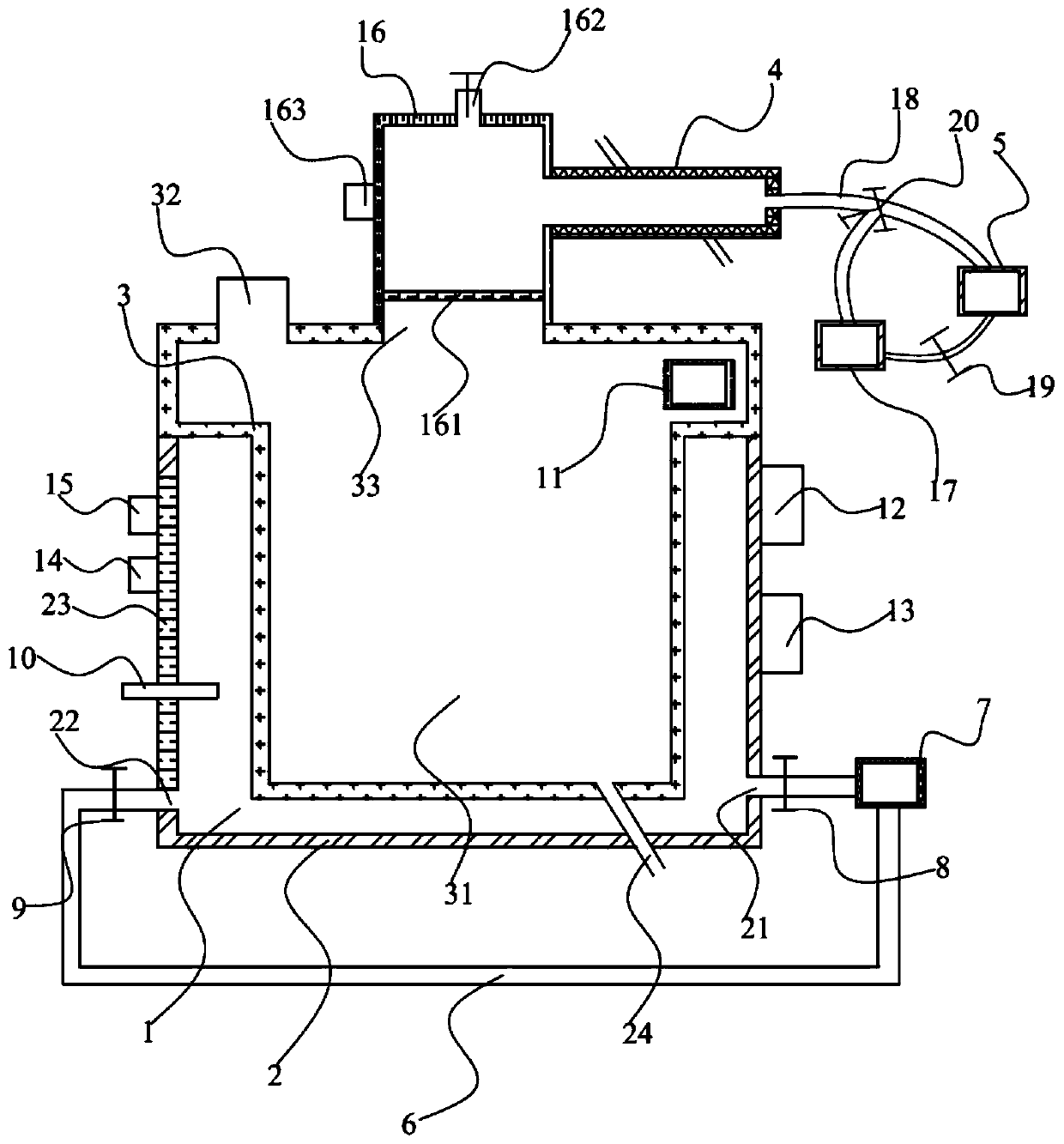

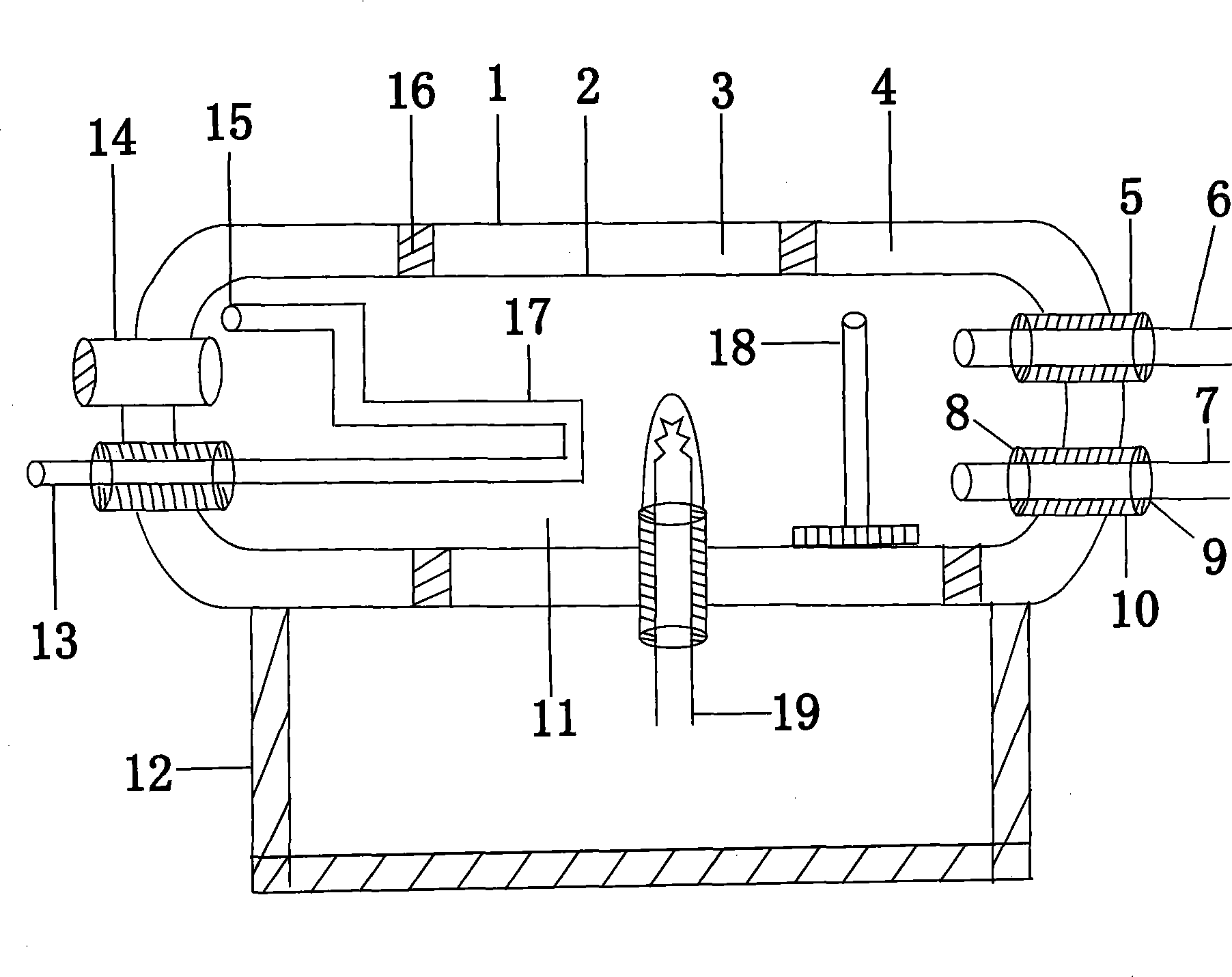

Low-temperature heating device for an engine

InactiveCN101532458AAchieve the purpose of heatingMachines/enginesEngine startersFuel oilEngineering

The invention relates to a heating device for an engine, in particular to a low-temperature heating device for the engine. The device consists of a sensor controller (1), an oil conveying pump (4), a direct current motor (6), an oil conducting pipe (33) and the like, wherein the oil conducting pipe is connected to the oil conveying pump and an atomizer to achieve the actions of oil supply and fuel oil atomization; a water temperature overheating sensor, a water temperature sensor, an ignition plug, a water temperature overheating sensor and an ignition sensor which run through an inner sleeve of a water chamber and are arranged on the lower end of an outer sleeve of the water chamber are connected with the sensor controller respectively, and achieve the functions of ignition, water temperature control, water temperature overheating protection and ignition burning respectively; and the device adopts the sensor controller to control the water temperature overheating protection and the ignition sensor, introduces cooling liquid in an engine body at low temperature into a low-temperature heating device of the engine for circular heating and reaches the temperature which is easy for the engine to start and is not overhigh, so that the engine can be normally started no matter how cold the weather is.

Owner:舒漫

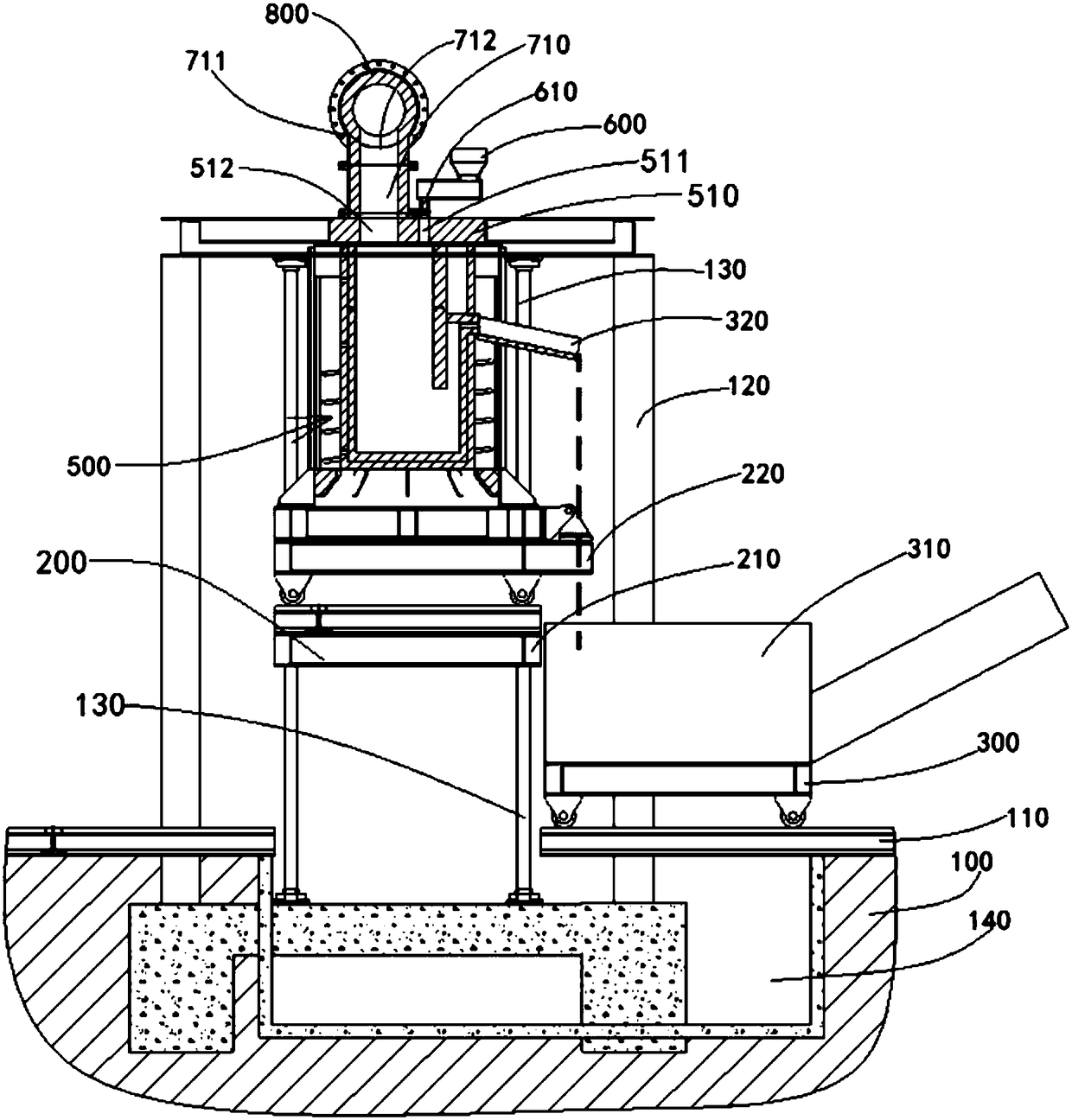

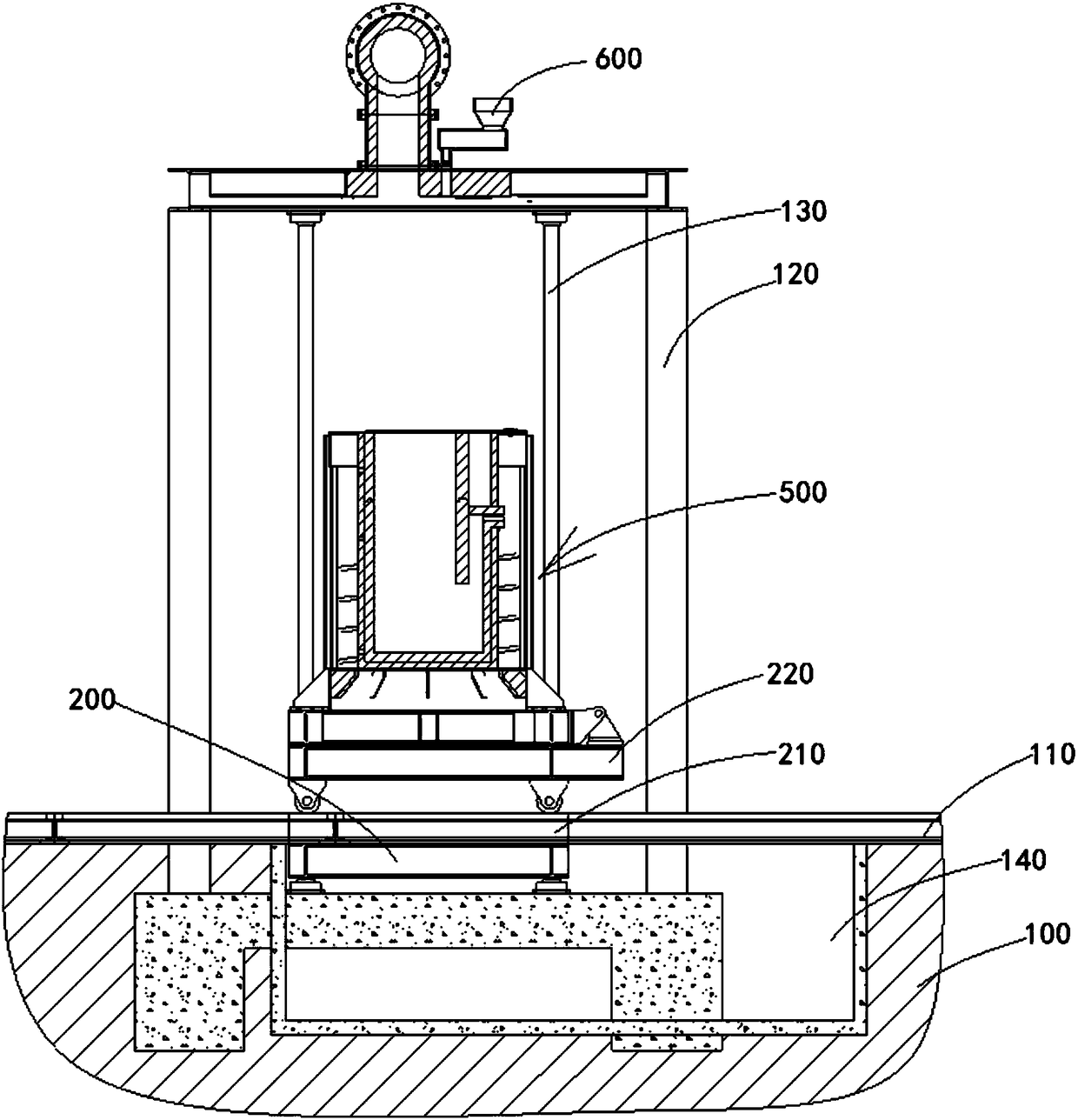

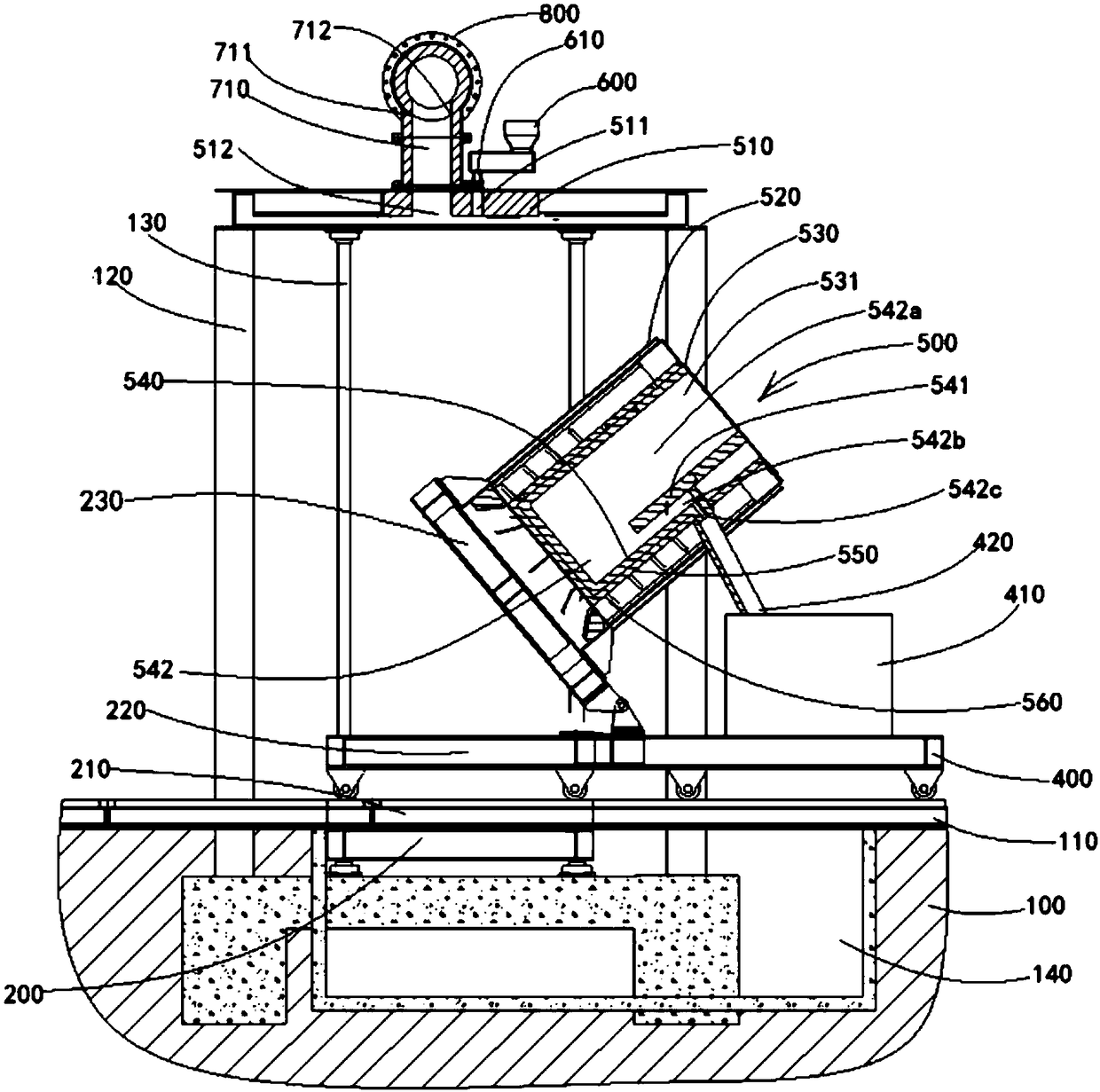

Electric melting device for full-automatic continuous feeding, deslagging, metal pouring and recovery

ActiveCN108302941ASmooth and airtight feedingIncrease the cross-sectional areaCharge manipulationProcess efficiency improvementElectricityMolten state

The invention discloses an electric melting device for full-automatic continuous feeding, deslagging, metal pouring and recovery. The device comprises of a foundation surface, a guide rail and a furnace cover support, wherein the foundation surface is paved on the foundation, the guide rail is laid on a mechanical lifting platform, and the furnace cover support is laid on the foundation surface ofthe foundation; an electric smelting furnace body travelling trolley, a water-cooled type slag discharging machine travelling trolley and a steel ladle travelling trolley are arranged on the guide rail; a water-cooled type slag discharging machine and a steel ladle are correspondingly arranged on the water-cooled type slag discharging machine travelling trolley and the steel ladle travelling trolley; the electric smelting furnace body traveling trolley is provided with an electric smelting furnace body hydraulic pressure pouring mechanism, when the electric smelting furnace body discharges molten steel, the molten steel are poured out by means of the electric smelting furnace body hydraulic pressure pouring mechanism; and a furnace cover and a vibration type feeder are installed on the furnace cover support, wherein a feeding hole and a smoke outlet are formed in the furnace cover, a discharging hole in the vibration feeding machine is in butt joint with a feeding hole in the furnacecover, in the molten state, the electric smelting furnace body is located below the furnace cover, and the furnace cover covers a furnace opening of the electric smelting furnace body.

Owner:上海煜工环保科技有限公司

Cr2Nb phase containing CuCr contact material preparing method

The invention discloses a Cr2Nb phase containing CuCr contact material preparing method. The Cr2Nb phase containing CuCr contact material preparing method comprises the following steps that S1, burdening is conducted, and raw materials are matched according to the proportion; S2, vacuum induction smelting is conducted, prepared raw materials are arranged in a ceramic crucible, under vacuum conditions, gradient heating is conducted, and the raw materials are melted; S3, casting cooling is conducted, when the raw materials are completely melted, components are uniform under the action of electromagnetic stirring, molten liquid in the ceramic crucible is poured into a water cooling die, and cooling and furnace discharging are conducted; S4, hot forging deformation and heat treatment are conducted, the hot forging technology is adopted for deforming a cast ingot to the needed size, and then heat treatment is conducted; and S5, machining is conducted, and machining equipment is adopted formachining the cast ingot into the needed contact shape according to a drawing. By means of the Cr2Nb phase containing CuCr contact material preparing method, the strength and the hardness of a contactcan be effectively improved, meanwhile, the high-temperature-resisting performance of the material is greatly improved, the contact is better resistant to ablation and high-temperature deformation, and meanwhile the service life of the contact is greatly prolonged.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Microwave sintering method of clay-graphite crucible

The invention relates to a microwave sintering method of a clay-graphite crucible, which comprises the following steps: mixing materials, aging, forming, glazing, carrying out vacuum drying to obtain a sample, putting the sample into a thermal insulator, and sintering in a microwave oven. The invention utilizes microwaves to heat and sinter the clay-graphite crucible so as to maximally increase the utilization ratio of energy sources, thereby greatly shortening the sintering time. In addition, since microwave heating has favorable uniformity, the invention can greatly enhance the quality stability of the sintered product.

Owner:宜昌浩诚工贸有限公司

Industrial energy-saving and environment-friendly dust removal device

InactiveCN113440946AAchieve recyclingImprove filtering effectGas treatmentDispersed particle filtrationActivated carbonThermodynamics

The invention provides an industrial energy-saving and environment-friendly dust removal device, and relates to the technical field of dust removal devices. An industrial energy-saving and environment-friendly dust removal device comprises a heat exchange assembly, the heat exchange assembly comprises a heat exchange box, the heat exchange box is provided with a flue gas inlet pipe and a flue gas outlet pipe which are communicated with an inner cavity of the heat exchange box, a heat exchange pipe is arranged in the heat exchange box, and the two ends of the heat exchange pipe penetrate through the outer side of the heat exchange box; a dust removal assembly comprises a dust removal box, the dust removal box is provided with an inlet and an outlet, the inlet of the dust removal box is communicated with the opening end of the flue gas outlet pipe, and a filter screen and an activated carbon adsorption screen are sequentially arranged in the dust removal box in the direction from the inlet to the outlet of the dust removal box. According to the flue gas dust removal device, dust removal of flue gas can be achieved, and waste heat in the flue gas can be recycled.

Owner:齐珍

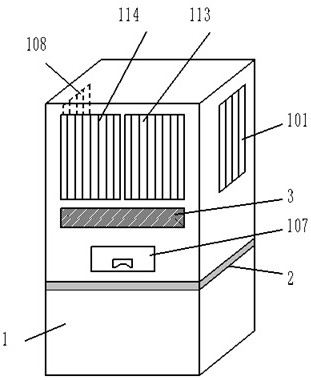

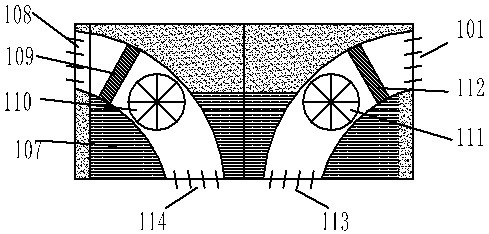

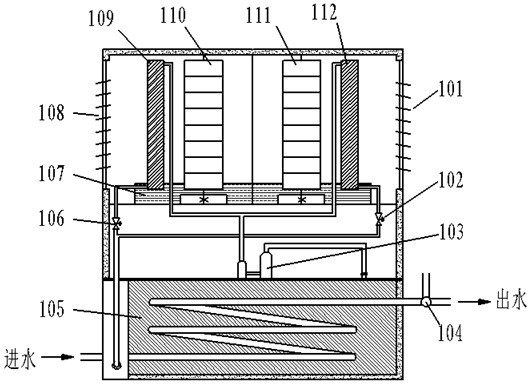

Kitchen air conditioner structure and kitchen air conditioner

InactiveCN112594788ACompact distributionSimple structureLighting and heating apparatusSpace heating and ventilation detailsMechanical engineeringPhysics

The invention provides a kitchen air conditioner structure which comprises a machine body. A partition plate is arranged in the middle of the machine body, a first side air inlet and a second side airinlet which are symmetrically formed are formed in the side face of the upper portion of the machine body, a first air outlet and a second air outlet which are symmetrically distributed are formed inthe front side of the upper portion of the machine body, an evaporator, a cross-flow fan I and a cross-flow fan II are arranged in the machine body, the evaporator and the cross-flow fan are positioned in the air duct between the corresponding side air inlet and the air outlet, a touch control panel and a water collecting tank are arranged on the front side of the machine body, a compressor is arranged in the machine body, a condenser is arranged on the lower portion of the machine body, a first throttling device and a second throttling device are arranged between the water collecting tank and the condenser, and a flow mixing valve is arranged at the water outlet end of one side of the condenser. The kitchen air conditioner comprises the kitchen air conditioner structure.

Owner:GREE ELECTRIC APPLIANCES INC

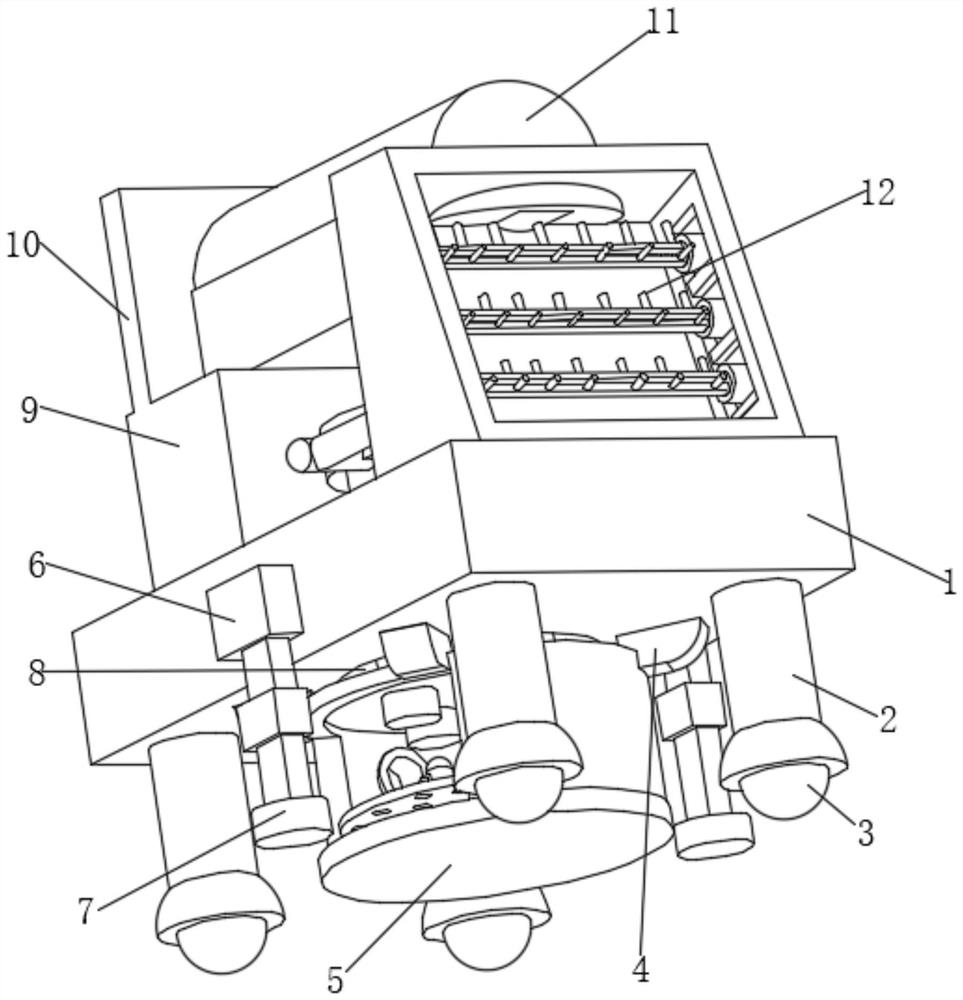

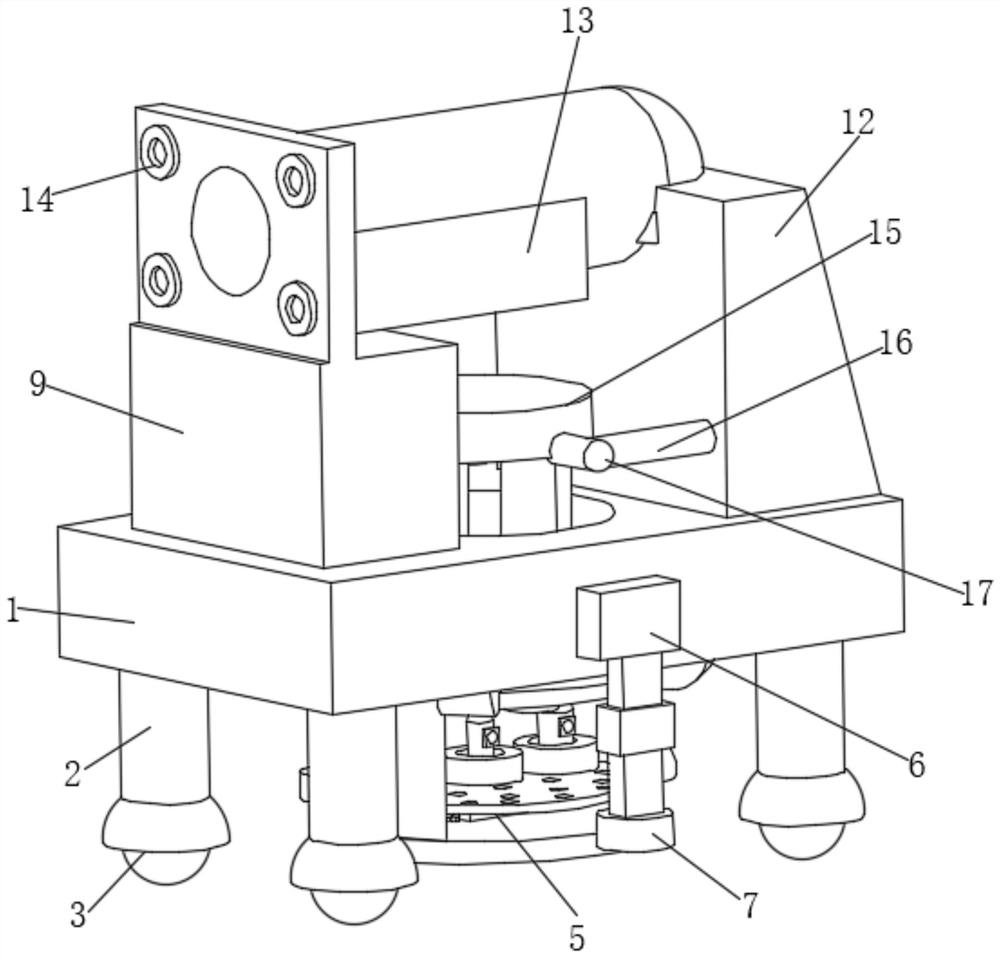

Rapid unloading device for petroleum asphalt tank container

PendingCN114834913AEasy to follow upIncrease water speedPackage recyclingCleaningStructural engineeringTank container

The invention discloses a petroleum asphalt tank container rapid unloading device which specifically comprises a fixed table, the fixed table is provided with a stable base and a control column arranged below the fixed table, rolling wheels are arranged below the control column, the lower portion of the fixed table is fixedly connected with a connecting assembly, and the connecting assembly is fixedly connected with the fixed table; a filtering water tank is fixedly connected to the middle of the connecting assembly, a reinforcing block is fixedly connected to the outer portion of the fixing table, a telescopic fixing column is fixedly connected to the lower portion of the reinforcing block, and a hollowed-out groove is formed in the middle of the fixing table; and the supporting table is provided with a height adjusting base and a connecting plate arranged above the supporting table, and the right side of the connecting plate is fixedly connected with a conveying channel. According to the rapid unloading device for the petroleum asphalt tank container, the unloading process is conducted in a sealed mode, the temperature in equipment is kept, the state of asphalt is kept, and the purposes of improving the unloading efficiency and keeping the state of the asphalt are achieved.

Owner:JIANGSU XINYUE HIGH-TECH CO LTD

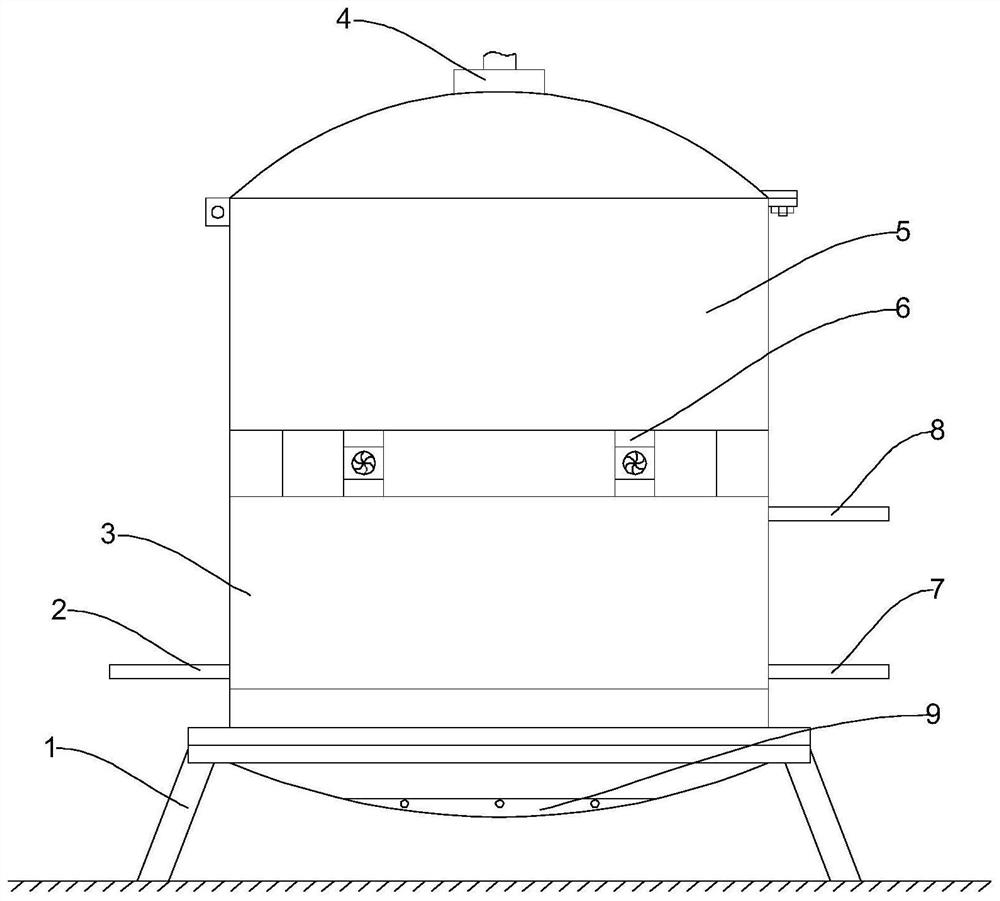

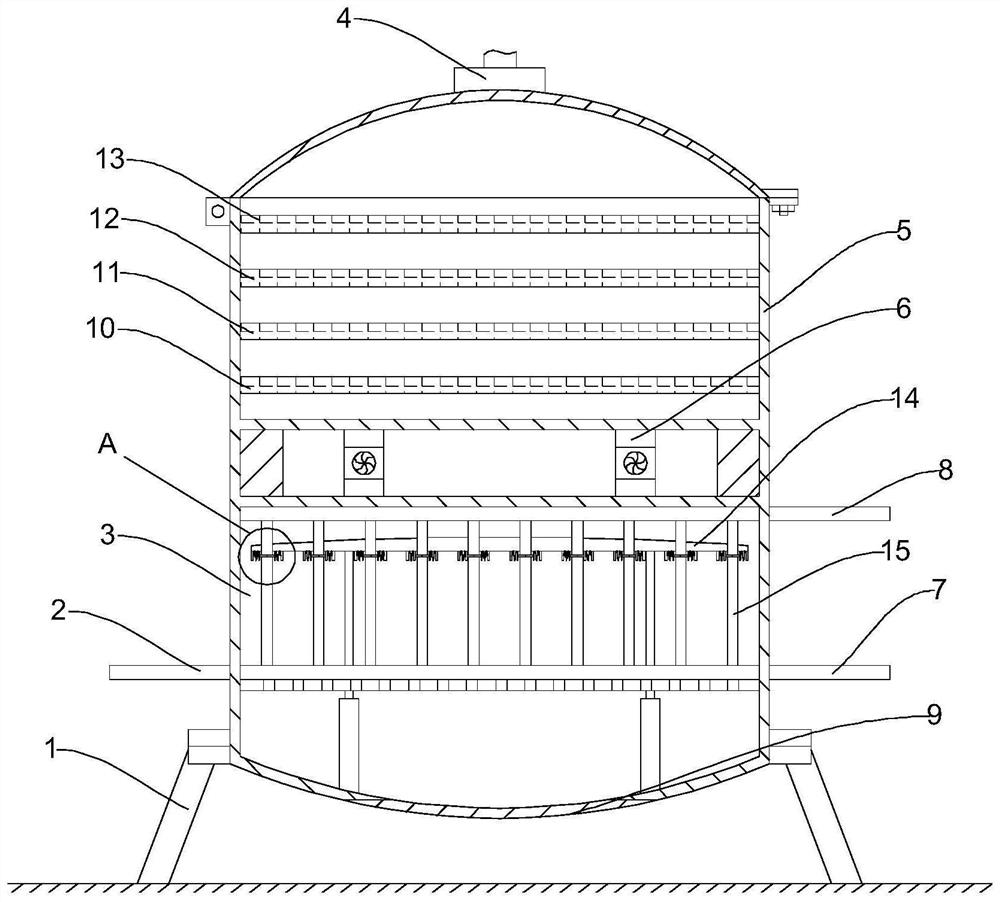

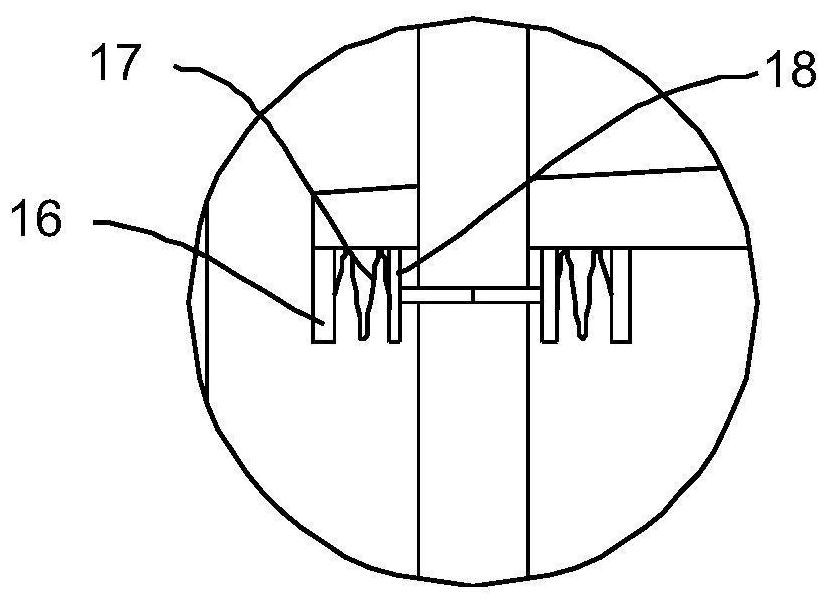

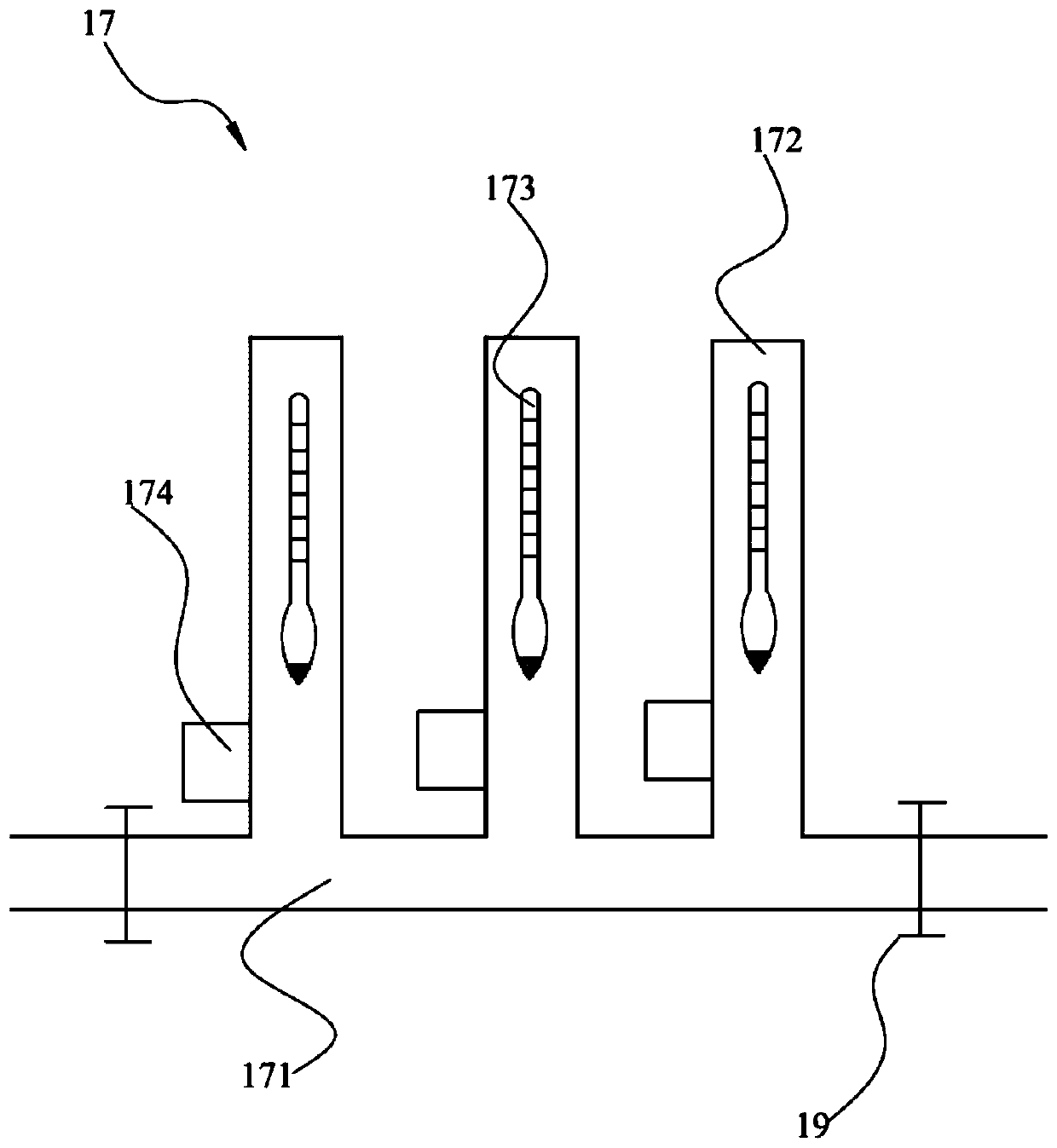

Distiller and distillation device

ActiveCN110129172AEasy to put inFully heatedAlcoholic beverage preparationGeneration rateDistillation

The invention provides a distiller and a distillation device. The distiller comprises an inner cylinder and an outer cylinder; the interior of the inner cylinder is formed with an accommodating chamber suitable for accommodating fermented grains, and the inner cylinder is provided with a feed port and a discharge port which communicate with the accommodating chamber; the outer cylinder is providedwith a heat medium inlet, the inner cylinder is arranged in the outer cylinder, a flowing chamber is formed between the inner cylinder and the outer cylinder, and a flowing chamber coats the exteriorof the circumference wall and the bottom wall of the inner cylinder; the heat medium inlet communicates with the flowing chamber and a hot source suitable for supplying a heat medium, and the heat medium in a fluid form enters the flowing chamber from the heat medium inlet, so as to heat the fermented grains in the inner cylinder to evaporate into wine steam. The distiller can make the fermentedgrains in the inner cylinder heated more evenly, the fermented grains are evaporated fully, and the wine generation rate of the fermented grains is improved.

Owner:INST OF AGRI PROD QUALITY SAFETY & STANDARD JIANGXI ACAD OF AGRI SCI

One-die multi-cavity full-automatic laminating machine

InactiveCN111645397ATo achieve the purpose of heatingRealize the use of rotationLaminationLamination apparatusCooling effectAir pump

The invention belongs to the technical field of hot press molding equipment, and particularly relates to a one-die multi-cavity full-automatic laminating machine which comprises a base, a groove is formed in the top of the base, a driving assembly is fixedly connected to the bottom of the inner wall of the groove, a bearing is fixedly connected to the top of the base, and a rotating shaft is arranged in the bearing in a penetrating mode. The top end of the rotating shaft is fixedly connected with a machining table; according to the laminating machine, one-mold multi-cavity laminating use is achieved by arranging multiple laminating cavities, meanwhile, by means of overturning of the machining table, conversion of the laminating cavities in different positions is achieved, the laminating efficiency is greatly improved, a refrigeration air pump works, external air can be refrigerated and then conveyed to a heat dissipation channel, laminated materials are cooled, and part taking is convenient; according to the one-die multi-cavity full-automatic laminating machine, through cooperation of all structural parts, the purposes of high laminating efficiency and good cooling effect are achieved, and the whole one-die multi-cavity full-automatic laminating machine is reasonable in structure, convenient to use and high in practicability.

Owner:石门县达韵电子有限公司

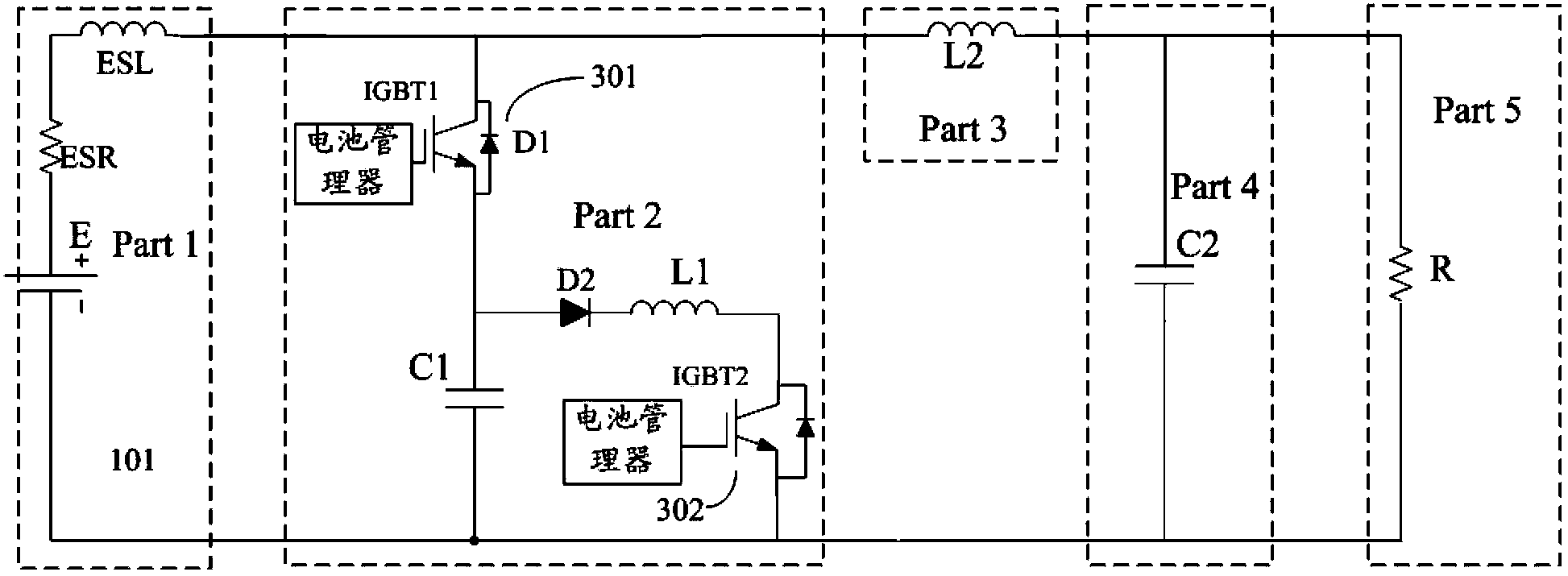

Electric vehicle, electric vehicle power system and battery heating method

ActiveCN103419662BAchieve the purpose of heatingReduce restrictionsSecondary cellsVehicular energy storageElectric machineElectrical battery

A power system of an electric vehicle, an electric vehicle comprising the electric vehicle and a method for heating a battery group of the electric vehicle are provided. The power system of the electric vehicle comprises: a battery group (101); a battery heater (102) connected with the battery group (101); a battery management device (103) connected with the battery group (101) and the battery heater (102) respectively, and configured to control the battery heater (102) to heat the battery group (101) when a temperature of the battery group (101) is lower than a first temperature threshold and a residual electric quantity of the battery group (101) is larger than an electric quantity threshold; an electric distribution box (104); a motor (105); a motor controller (106) connected with the motor (105) and the electric distribution box (104) respectively; and an isolation inductor (L2).

Owner:BYD CO LTD

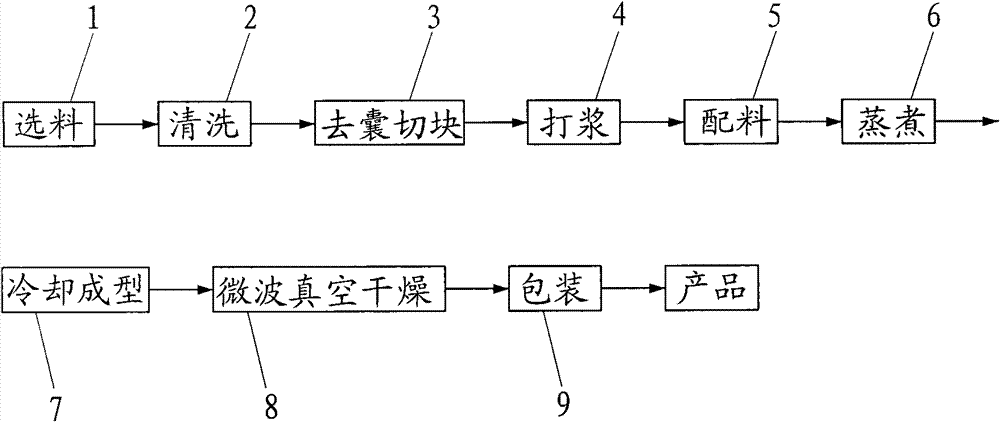

Preparation method of microwave vacuum puffing pumpkin chips

InactiveCN101816398BEffective combinationHigh nutritional valueFood shapingFood preparationMicrowavePreservative

Owner:JIMEI UNIV

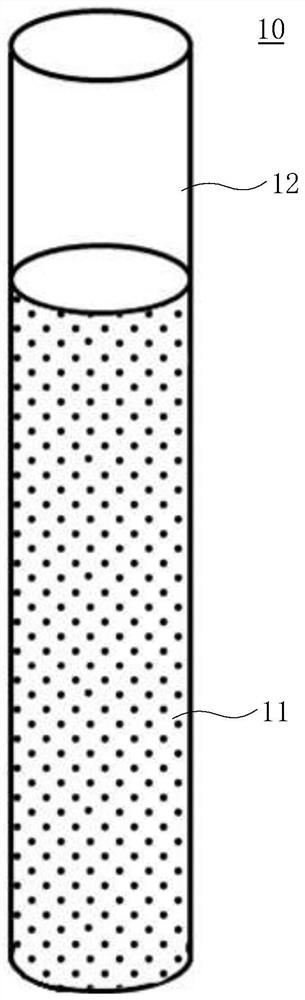

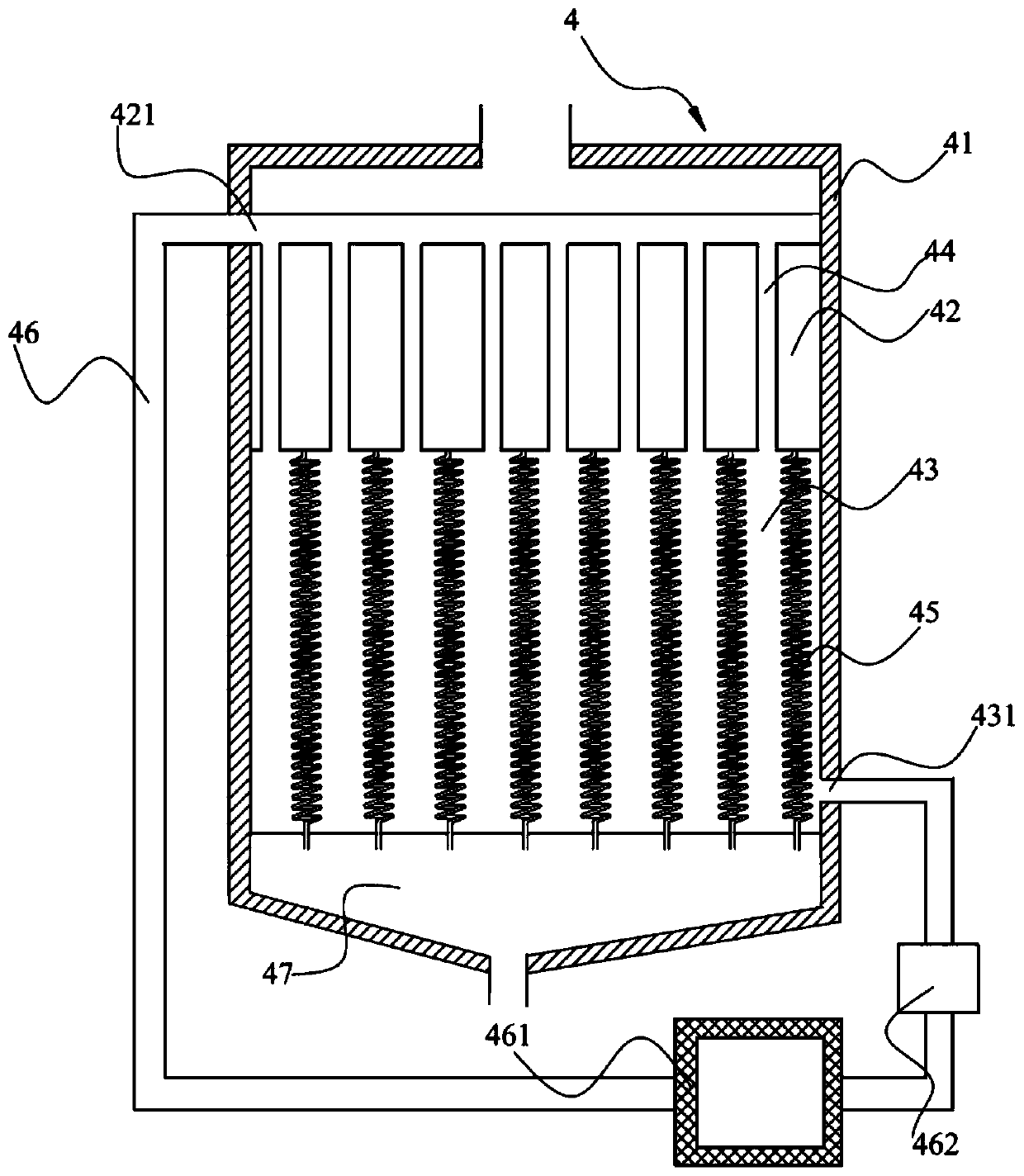

High heat solar water-heating cartridge

InactiveCN101059274AAchieve the purpose of heatingAbsorb moreSolar heating energySolar heat devicesElectricitySolar light

High-heat quantity solar hot water cylinder belongs to water-storing area. The outer cylinder (1) made by glass is nested out the inner cylinder (2) made by glass. Gaps (4) are left between the outer cylinder and the inner cylinder, and air in gaps is pumped into vacuum (3). The space (11) is equipped with bend tube (17), heat emission pipes (18) and electric heater (19), the outer cylinder and the inner cylinder are opened with hole (5) which is equipped with water inlet pipes. Cool water is injected into space (11), solar light irradiates the water in space through the outer cylinder, the inner cylinder and vacuum and heats the water. The vacuum insulates heat of water, the water in space is heated under the irradiating and heating of solar light and the insulating of vacuum. The warm water vapour in upper space and the heat quantity in upper water are transmitted into lower cool water through bend tube. Thereby the purpose of the water in high-temperature reflecting hot water cylinder namely in space is heated by solar light irradiating. In rainy weather, water is heated by electric heater, thereby the purpose of heating the water in space through electric heater in rain.

Owner:唐春芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com