One-die multi-cavity full-automatic laminating machine

A multi-cavity, fully automatic technology in one mold, used in layered products, lamination devices, lamination and other directions, can solve the problems of reduced processing efficiency, unfavorable timely material retrieval, low lamination efficiency, etc., to improve lamination efficiency. , Good cooling effect and high bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

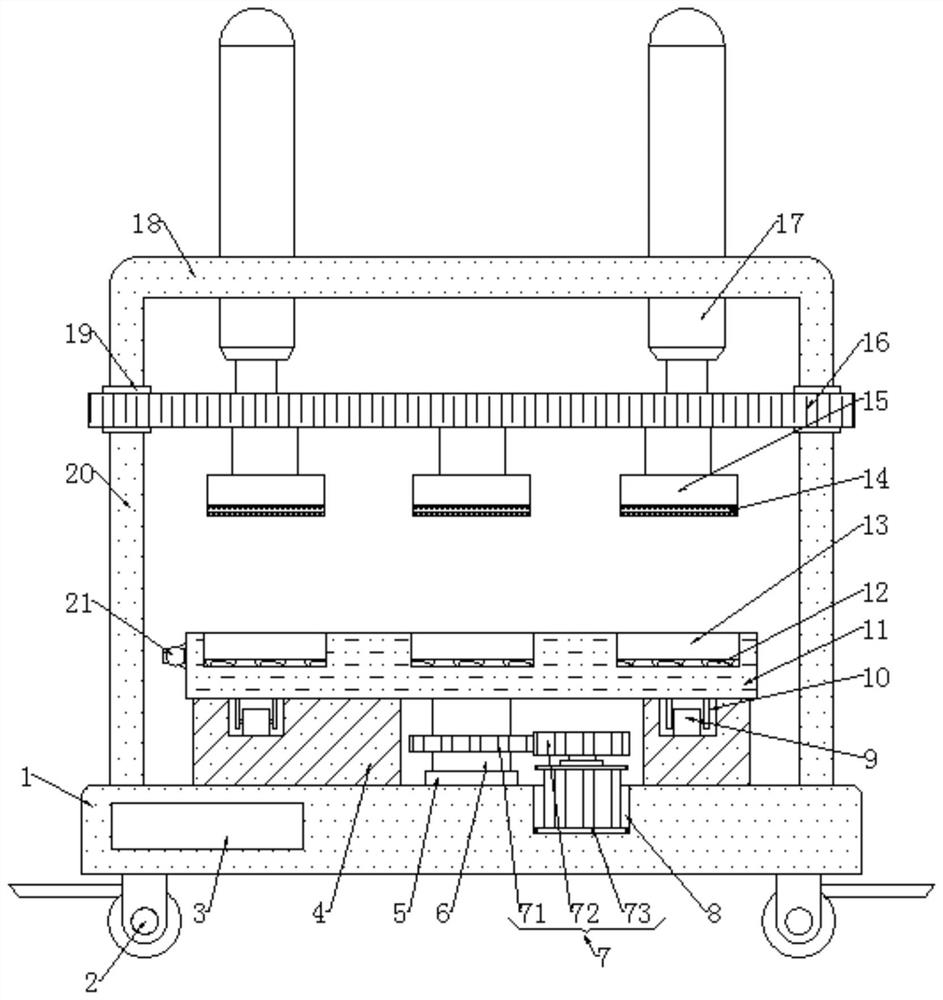

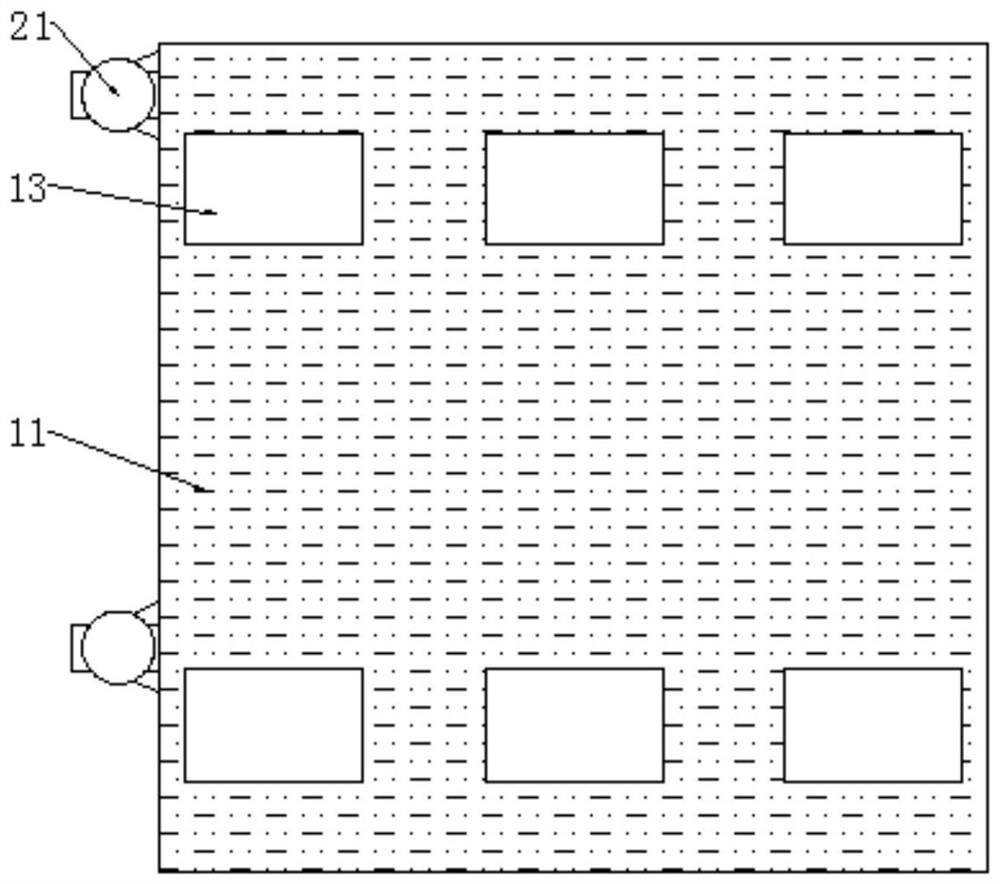

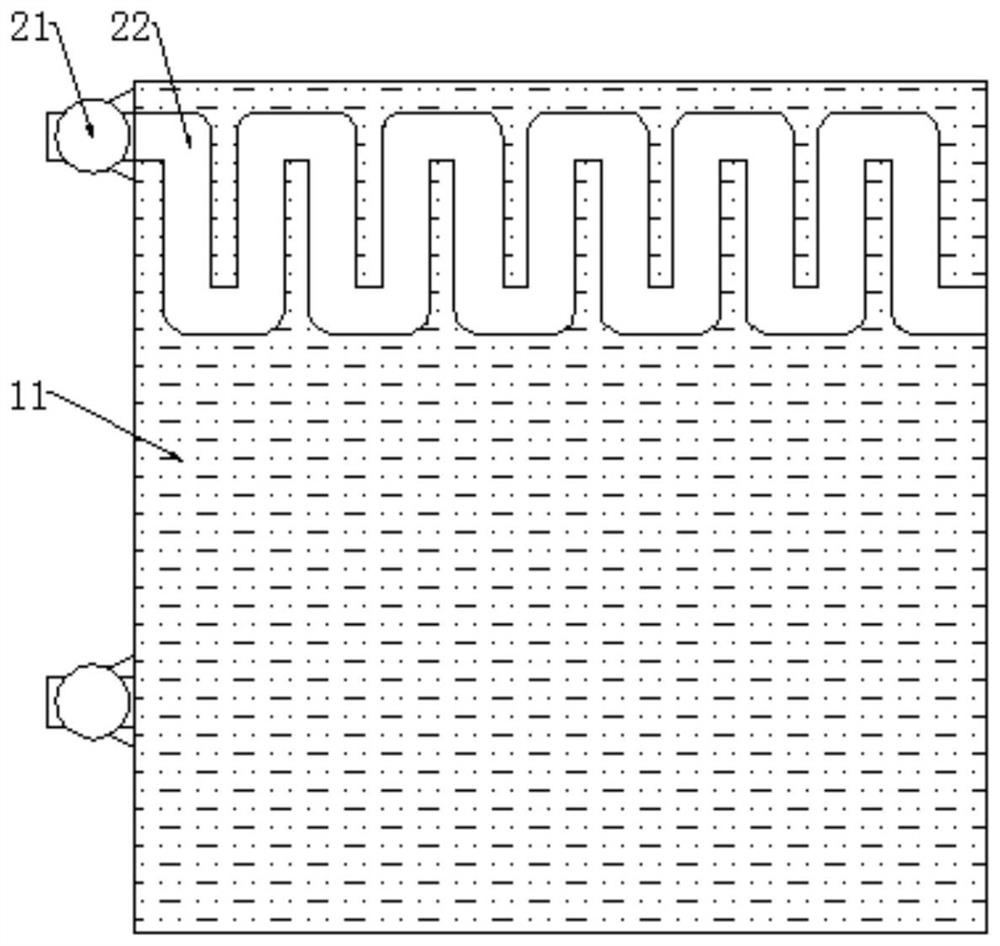

[0019] see Figure 1-3 , the present invention provides the following technical solutions: a one-mold multi-cavity automatic laminating machine, including a base 1, a groove 8 is opened on the top of the base 1, and a drive assembly 7 is fixedly connected to the bottom of the inner wall of the groove 8 , the top of the base 1 is fixedly connected with a bearing 5, the bearing 5 is pierced with a rotating shaft 6, the top of the rotating shaft 6 is fixedly connected with a processing table 11, and the top of the processing table 11 is provided with a plurality of bonding Cavity 13, by setting multiple laminating cavities 13, the lamination of one mold and multiple cavities is realized. At the same time, with the help of the turning of the processing table 11, the conversion of laminating cavities 13 at different positions is achieved, which greatly improves the laminating efficiency. The top of the base 1 is fixedly connected with a support platform 4. By setting the support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com