Electric melting device for full-automatic continuous feeding, deslagging, metal pouring and recovery

A melting device, fully automatic technology, applied in the direction of electric charge control, lighting and heating equipment, furnace components, etc., can solve the problems of large amount of flue gas, complicated tail gas treatment, high maintenance cost, etc., and achieve high heating efficiency, fast speed, The effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

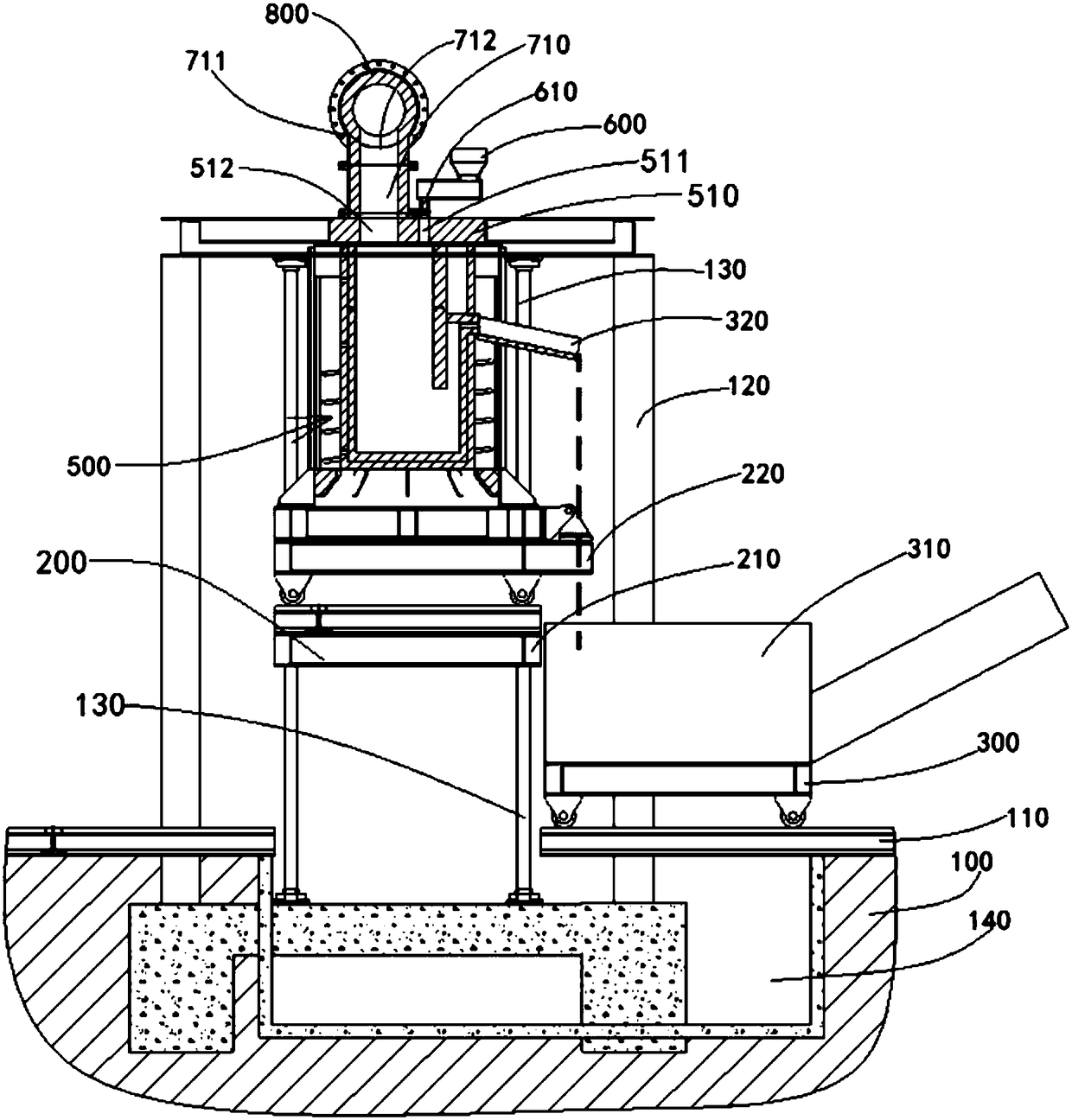

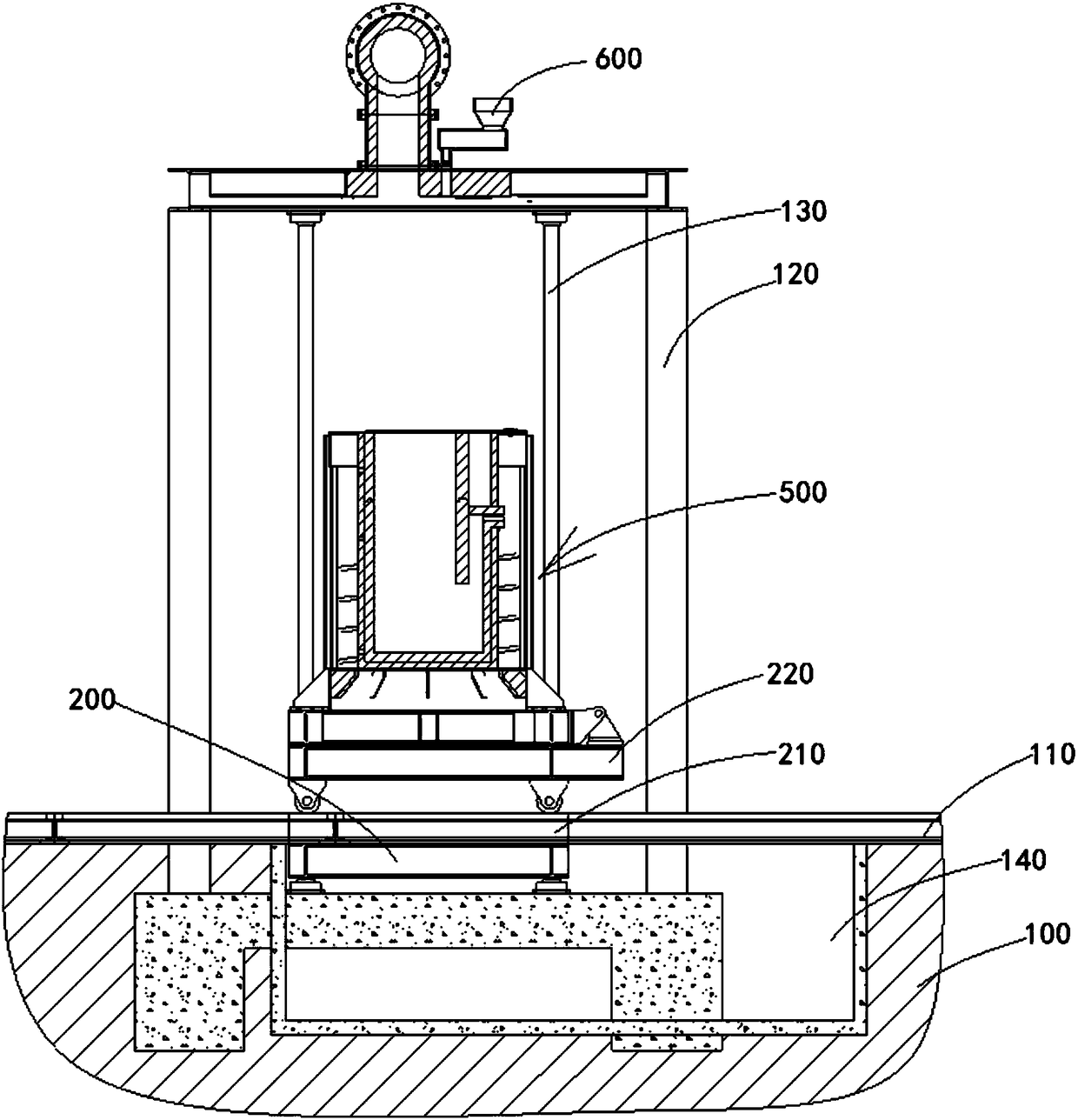

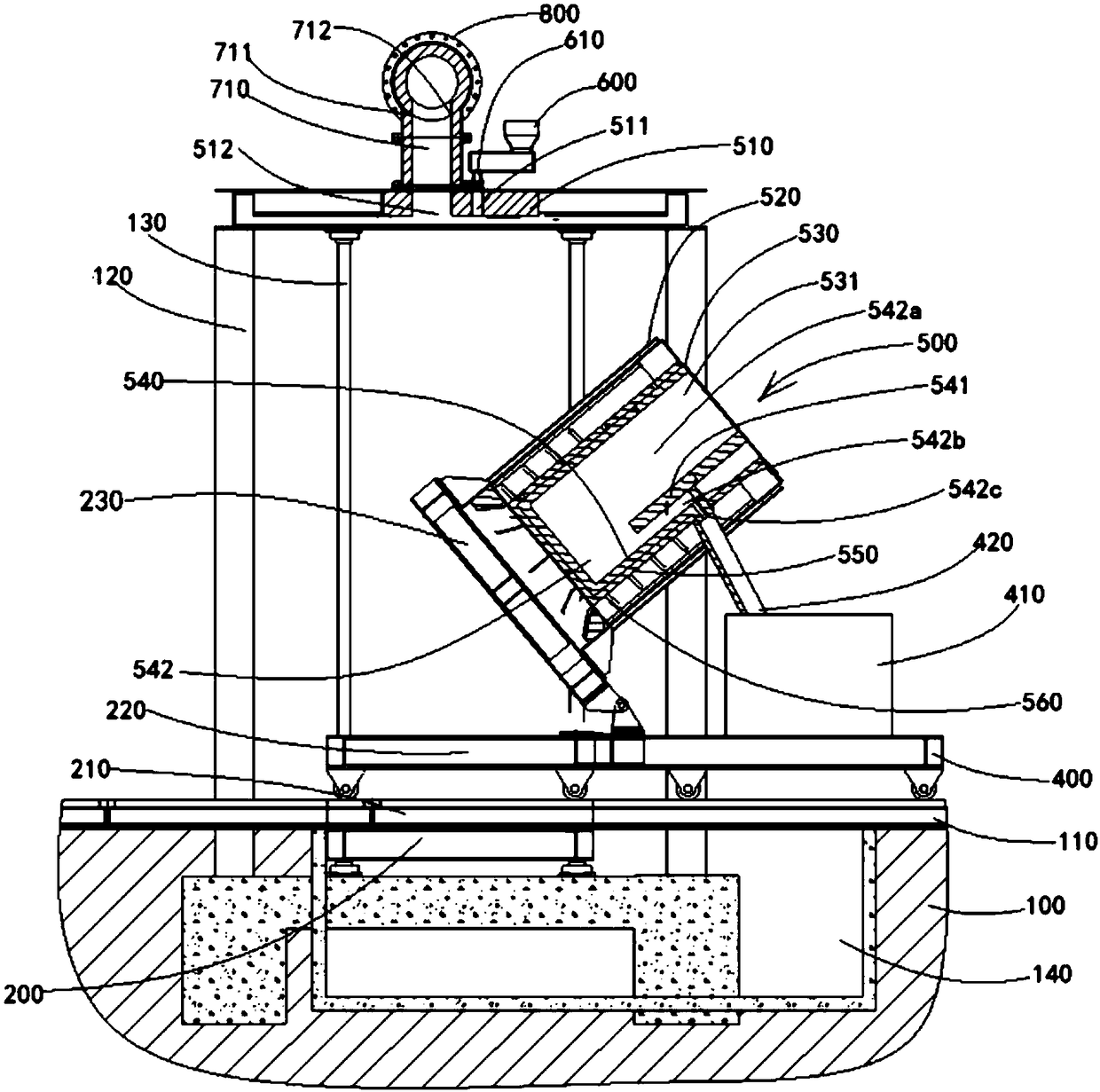

[0046] see Figure 1 to Figure 4 , the fully automatic continuous feeding slagging and dumping metal recovery electrofusion device shown in the figure includes a foundation 100 and a mechanical lifting platform 200 installed on the foundation 100, and a platform on the foundation surface of the foundation 100 and the mechanical lifting platform 200 A pair of parallel guide rails 110, 210 are laid on the surface, and the guide rail 210 on the platform surface of the mechanical lifting platform 200 is connected with the guide rail 110 on the base surface when the mechanical lifting platform 200 is lowered to the lowest position, so that the electric melting furnace can be moved Body 500, easy to repair and maintain.

[0047] On a pair of parallel guide rails 110, 210, a traveling trolley 220 for an electric melting furnace body, a traveling trolley 300 for a water-cooled slag extractor, and a traveling trolley 400 for a ladle are provided. Electric melting furnace body travelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com