Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Achieve heat treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

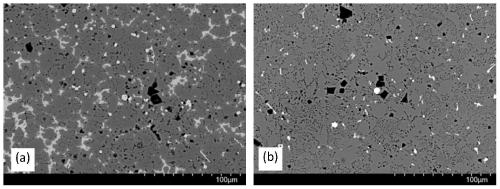

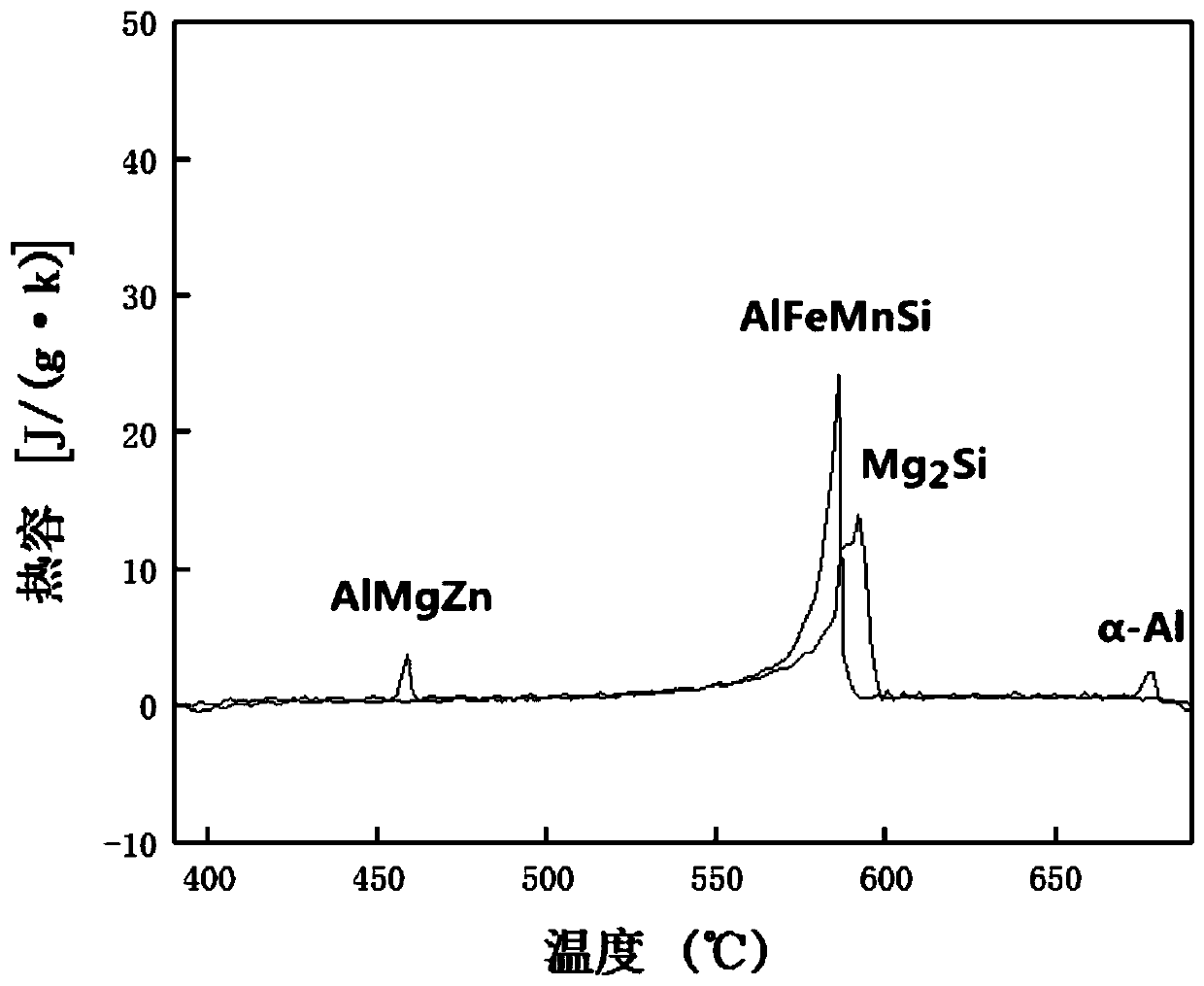

Smelting low-temperature solid-solution heat treatment method for die-casting aluminum alloy

InactiveCN109763080AImprove performanceAvoid blistering and deformationFoundry mouldsFoundry coresDie castingHardness

The invention relates to a smelting low-temperature solid-solution heat treatment method for a die-casting aluminum alloy. The smelting low-temperature solid-solution heat treatment method has significantly advancement compared with the background technology, and aims to solve the problem that the heat treatment cannot be conducted on a conventional die-cast aluminum alloy. The solid-solution temperature of the AlMgZnSi die-casting aluminum alloy is reduced by 60-100 DEG C, the heat treatment of the die castings is achieved, foaming and deformation of the castings are avoided, the hardness isimproved from127.02 HV before the heat treatment to 171.96 HV, the yield strength is improved from 253.58 Mpa before the heat treatment to 407.07 Mpa, the tensile strength is improved from 314.55Mpa before the heat treatment to 460.12 Mpa, the elongation rate is improved from 3.59% before heat treatment to 4.33%. The process method is accurate and informative in data, the fact that the low-temperature solid-solution heat treatment can be conducted on the die-casting aluminum alloy is represented, the mechanical performance is greatly improved after the low-temperature heat treatment, and the limitation of a traditional die-casting aluminum alloy is broken through.

Owner:ZHONGBEI UNIV

Production method of cast-state ductile iron QT800-5 by using fired mold precision casting

InactiveCN108796355AIncreased pearlite contentImprove mechanical propertiesFoundry mouldsFoundry coresManganeseCopper

The invention discloses a production method of a cast-state ductile iron QT800-5 by using fired mold precision casting. The method comprises the following steps of fired mold precision casting of shell and shell making, molten iron smelting, spheroidizing treatment, inoculation treatment, mold shell casting and module cooling so as to obtain the QT800-5, wherein the requirements that the tensile strength Rm is larger than or equal to 800 MPa and the elongation percentage after fracture A is larger than or equal to 5% can be met. The production method of cast-state ductile iron QT800-5 by usingthe fired mold precision casting has the beneficial effects that low-cost copper and manganese are added to improve a pearlite content in a cast-state ductile iron matrix, the structure is strengthened and refined, the mechanical property of a material is improved, the cost can be effectively reduced, and the cast-state heat-free treatment is realized; and meanwhile, deformation is avoided afterthe heat treatment of a casting is avoided.

Owner:DONGFENG PRECISION CASTING CO LTD

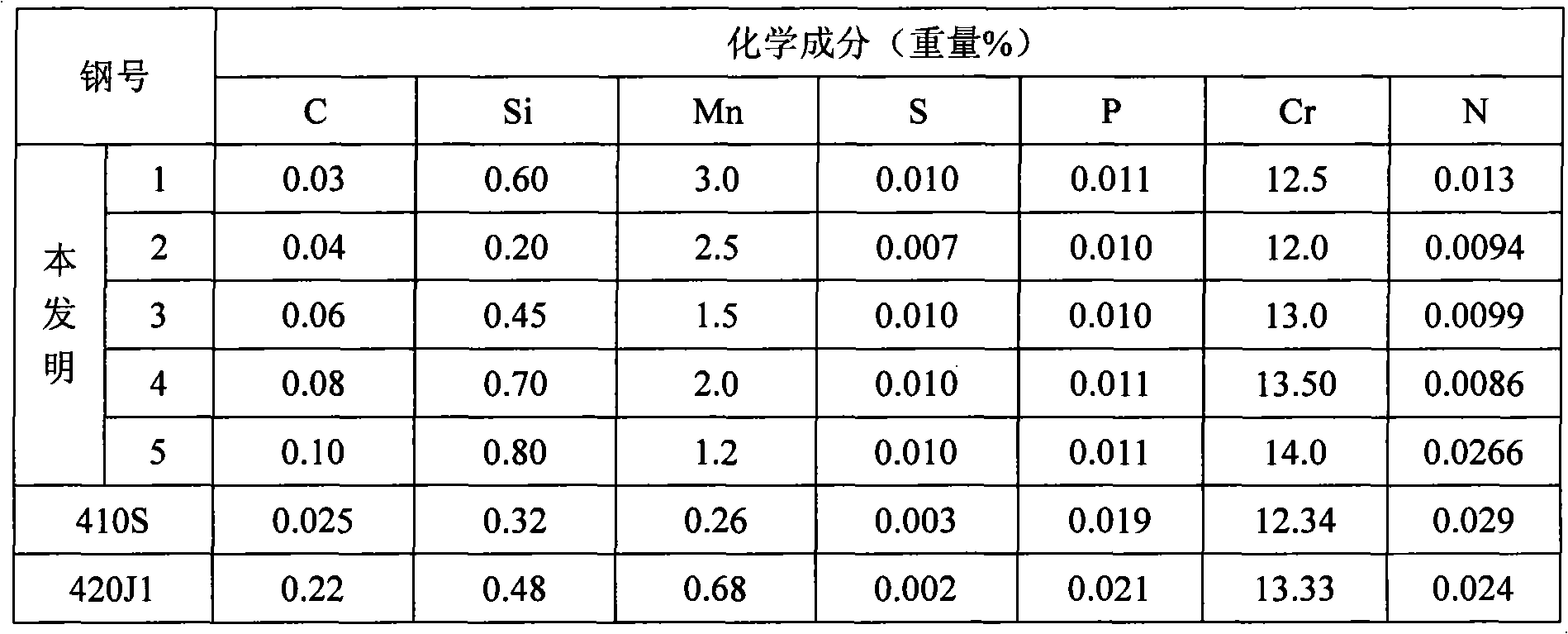

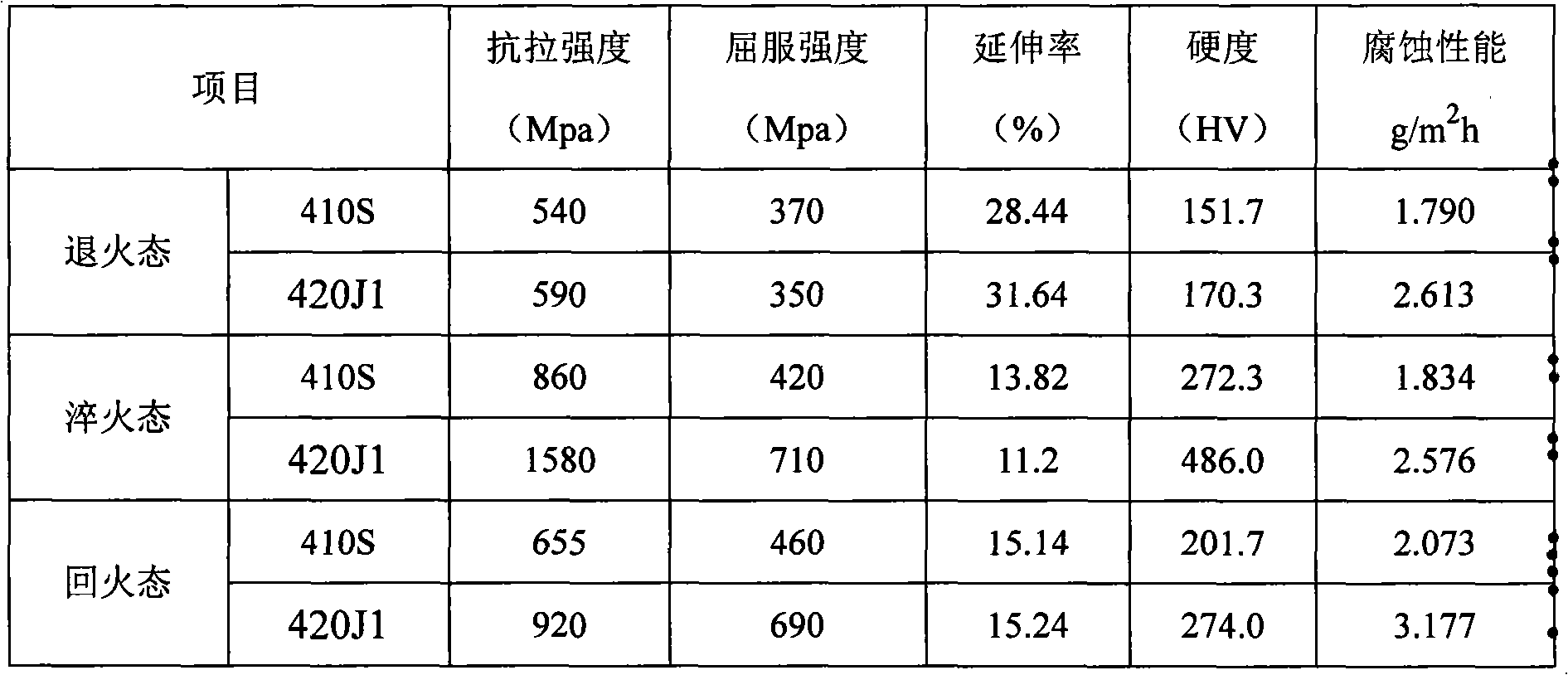

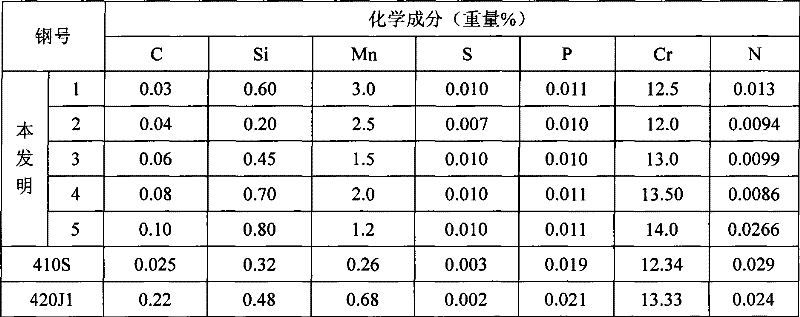

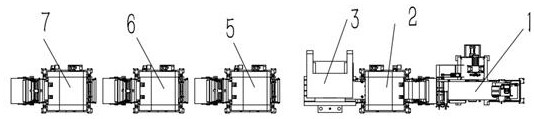

Martensitic stainless steel with high Mn content

The invention provides a martensitic stainless steel with high Mn content, which comprises the following chemical compositions in percentage by weight: 0.03-0.1% of C, 0.20-0.80% of Si, 1.2-3.0% of Mn, 12-14% of Cr, 0.008-0.03% of N, the balance Fe and unavoidable impurities. By improving Mn content in steel, adding proper amount of N and utilizing Mn and N to strengthen, the invention improves the strength and the rigidity of the martensitic stainless steel. Compared with other alloys, the cost of Mn is lower and the resource is richer. The low-carbon martensitic stainless steel after being strengthened by utilizing Mn and N only needs quenching heat treatment to obtain martensitic stainless steel materials with favorable strength, tenacity and corrosion resistance, and has more convenient use and superior performance compared with commonly used tempered martensitic stainless steel.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

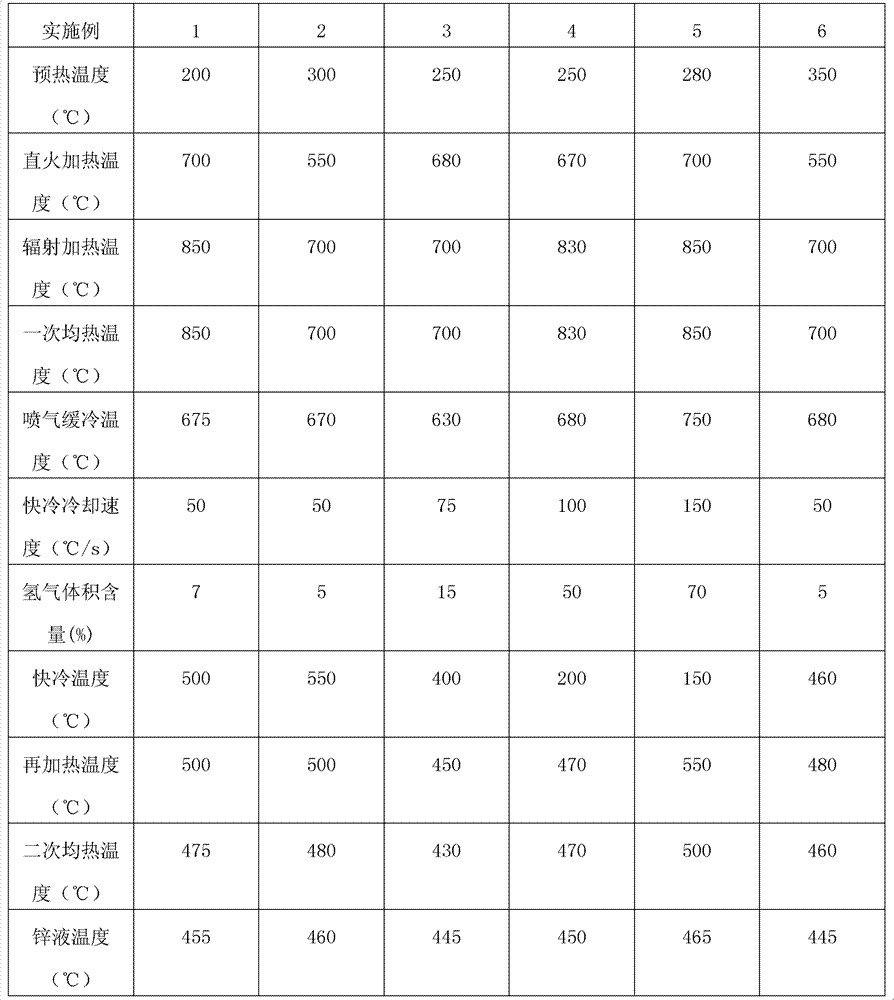

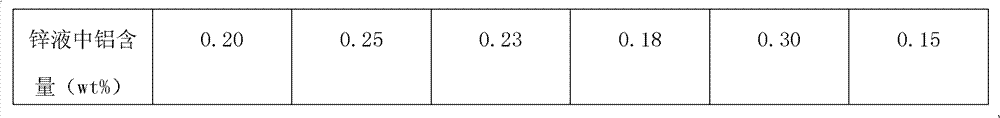

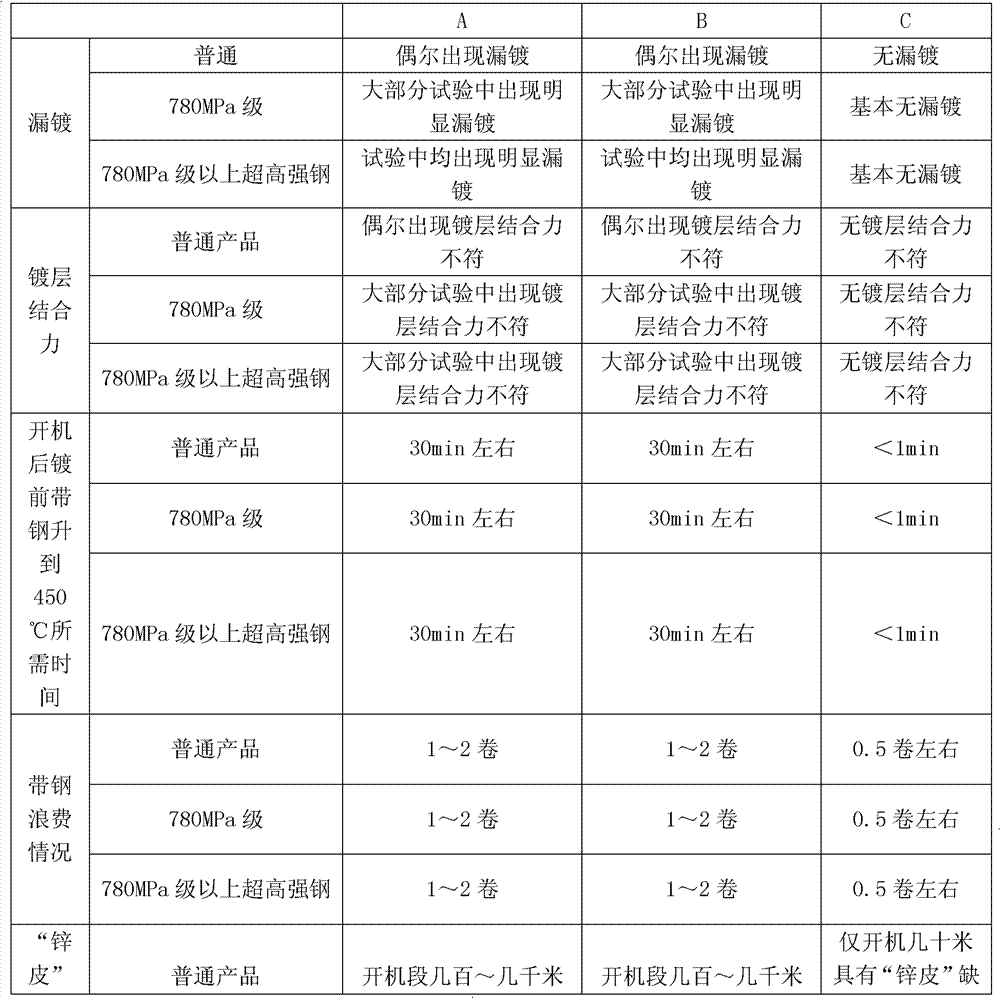

Strip steel continuous hot galvanizing method

InactiveCN102816986AImprove PlatabilityAchieve heat treatmentHot-dipping/immersion processesHydrogenStrip steel

The invention discloses a strip steel continuous hot galvanizing method. The strip steel continuous hot galvanizing method sequentially comprises the following steps of washing and pre-heating strip steel, adopting short flame to heat the strip steel to be at the temperature of 550-700 DEG C in a strip steel directly contacted mode, adopting a radiant tube heating method to continue to heat the strip steel to be at the temperature of 700-850 DEG C, sequentially soaking and slowly cooling the strip steel, adopting nitrogen and hydrogen mixed gas with 5-70% of hydrogen volume to quickly cool the strip steel to be at the temperature of 150-550 DEG C, heating the strip steel again to be at the temperature of 450-550 DEG C, performing secondary soaking to the strip steel and performing hot galvanizing treatment to the strip steel. By means of the method, the platability of ultrahigh strong steel can be obviously improved, various annealing curves can be achieved flexibly, and annealing processes which cannot be achieved by a traditional hot galvanizing unit can be achieved. In addition, the 'zinc scale' detect in starting of the unit can be obviously overcome.

Owner:BAOSHAN IRON & STEEL CO LTD

Preferably pb-free and as-free optical glasses with tg less than or equal to 500 degree centigrade

InactiveCN1522977AAchieve heat treatmentEnsuring near net shape thermoformingOptical elementsRefractive indexGlass transition

Optical glass having a refractive index nd of 1.8-1.56, an Abbe number vd of 64-72 and a glass transition temperature Tg of not more than 500degrees C comprises (in wt.%) 53-58 SiO2, 11-15 B2O3, 16-20 Al2O3, 0-13 Na2O, 0-13 K2O, 9-13 SIGMA M2O, and 0.5-4 F.

Owner:SCHOTT AG

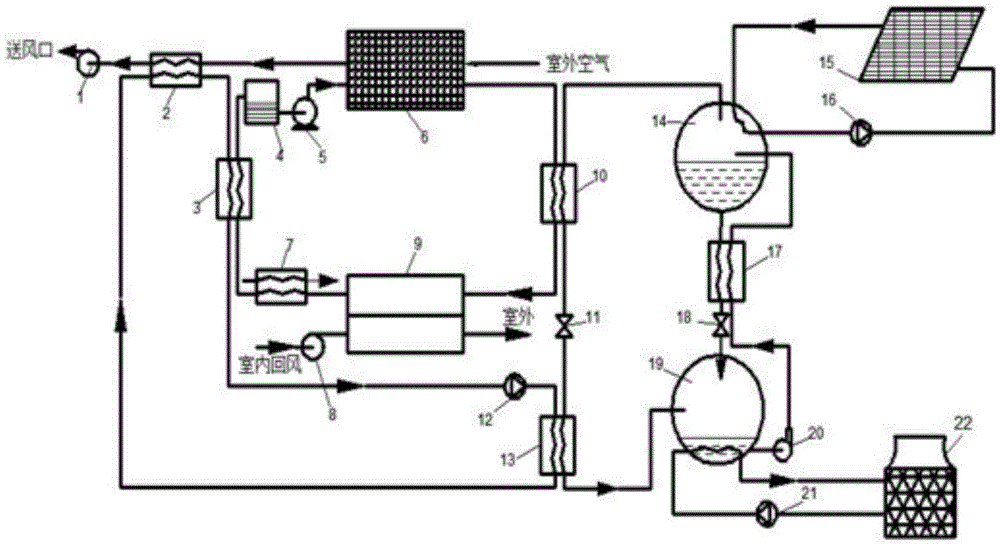

Solar thermally-driven independent temperature and humidity control air conditioning system

ActiveCN105627473AAchieve heat treatmentEffective combinationMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention relates to a solar thermally-driven independent temperature and humidity control air conditioning system. The system comprises a first heat exchanger, a second heat exchanger, a desiccant solution storage tank, a film dehumidifier, a regenerator, a condenser, a first throttling valve, an evaporator, a generator, a solar heat collector, a solution heat recovery device and an absorber. The system effectively combines a solar absorption refrigeration subsystem and a film solution dehumidifying subsystem, the solar absorption refrigeration subsystem provides heat required by regeneration of a solution in a dehumidifying system and cold required by cooling and performs heat treatment on air by using produced refrigerant water, and the film solution dehumidifying subsystem performs wet treatment on the air. Compared with the prior art, the system has the advantages that green energy, namely, solar energy, can be fully utilized, independent temperature and humidity regulation and control can be realized, and the system is energy-saving, low in emission and good in regulation and control performance, and the like.

Owner:SHANGHAI JIAO TONG UNIV

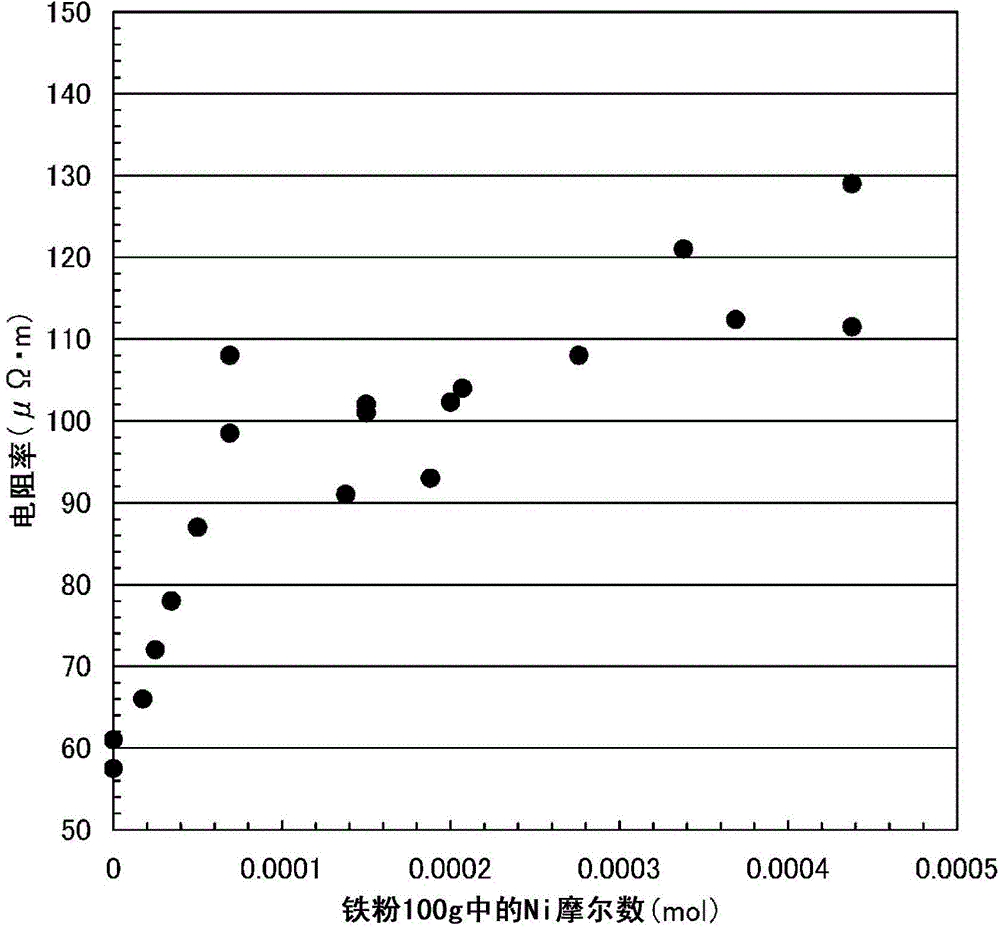

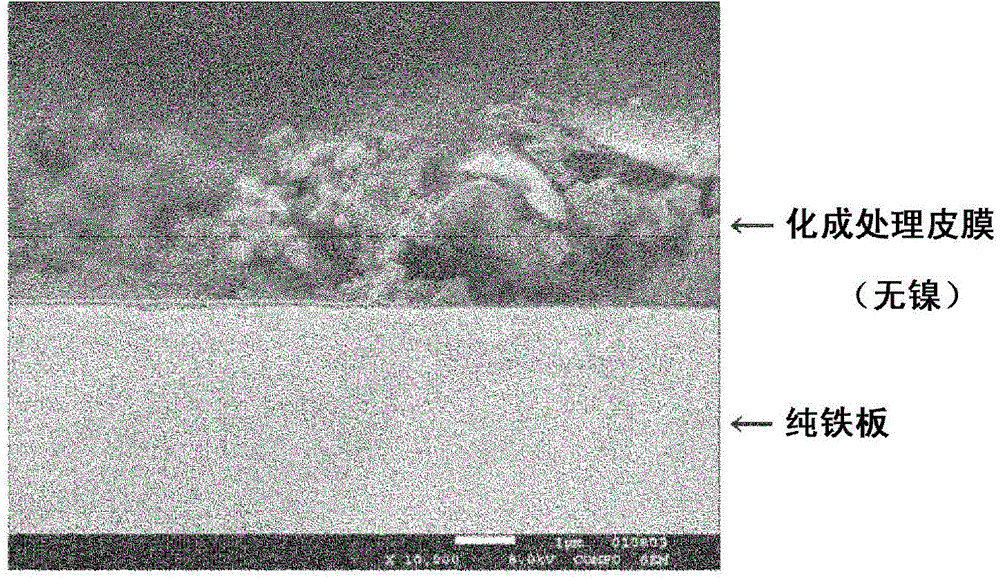

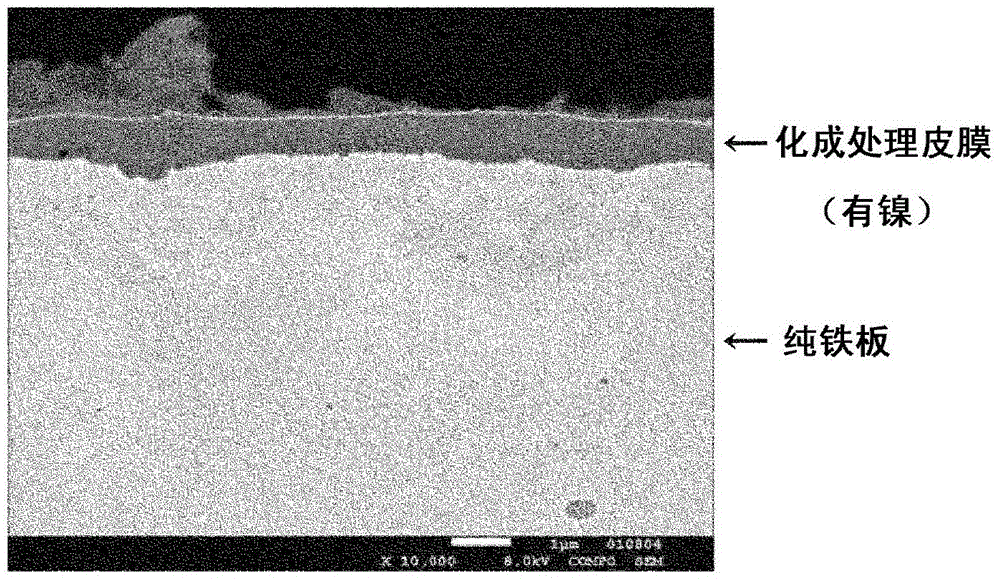

Iron-base soft magnetic powder for dust cores, manufacturing method thereof, and dust core

ActiveCN103608138AReduce iron lossImprove heat resistanceTransportation and packagingMetal-working apparatusPhosphatePhosphoric acid

This iron-base soft magnetic powder for dust cores comprises a phosphate conversion film formed on the surface of the iron-base soft magnetic powder, wherein the phosphate conversion film contains the element nickel, and the content ratio of the element aluminum in the phosphate conversion film is less than or equal to the content ratio of aluminum in the aforementioned powder. Excellent thermal stability enables maintaining electrical insulation properties even when subjected to high-temperature heat treatment.

Owner:KOBE STEEL LTD

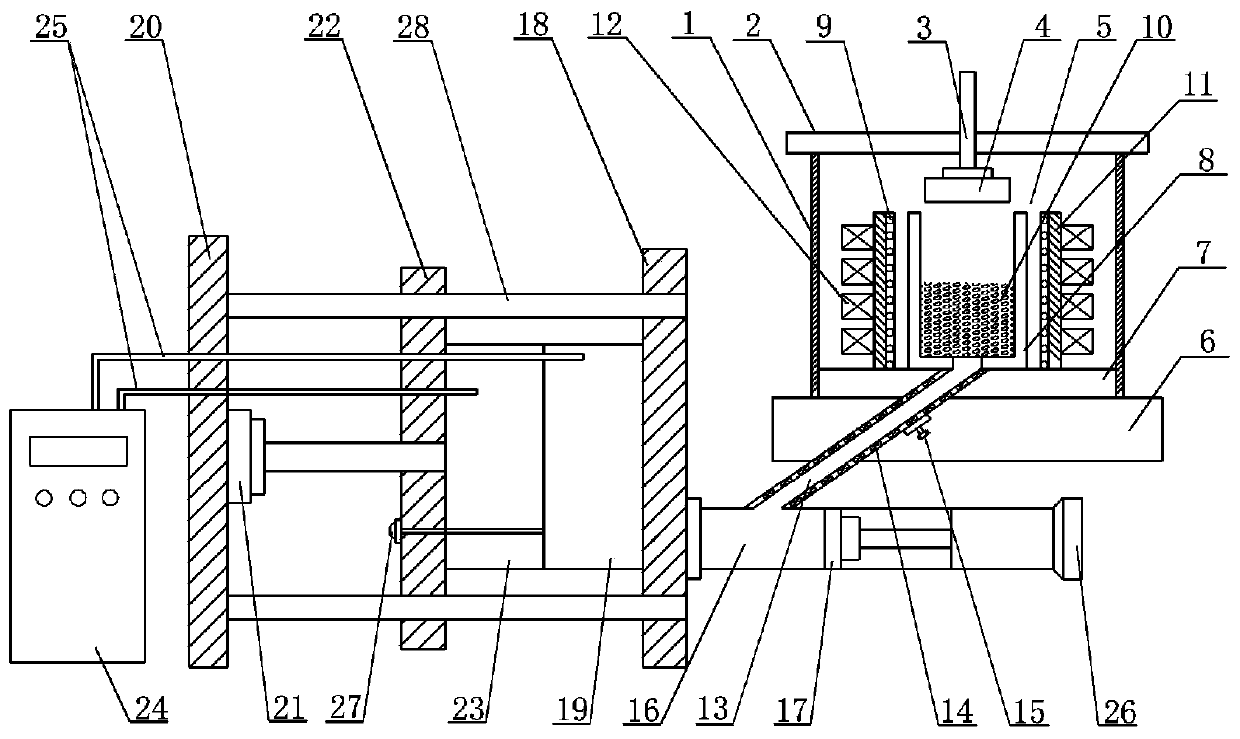

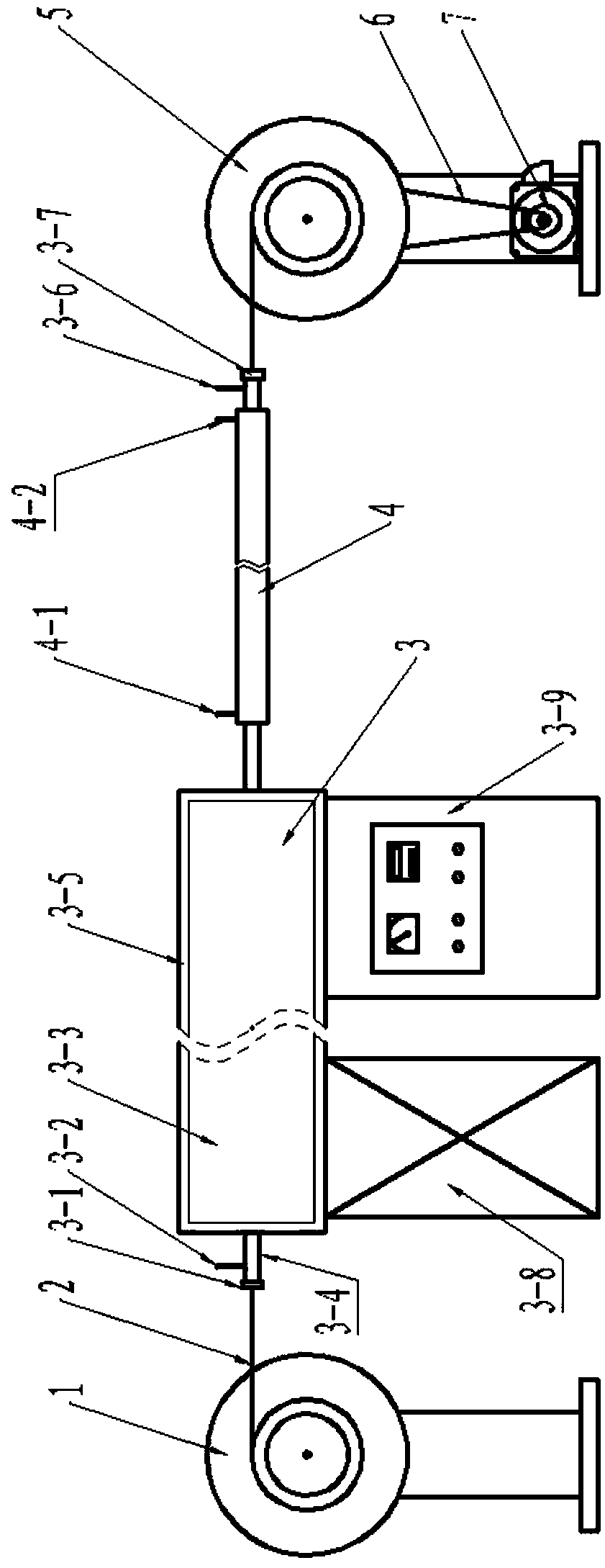

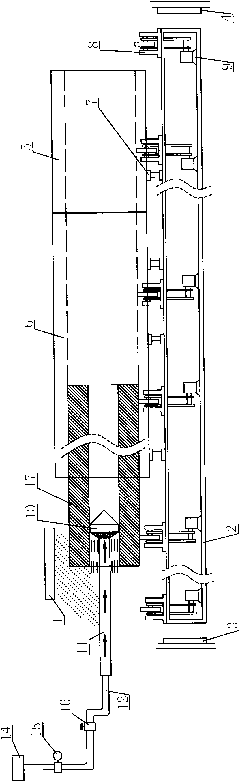

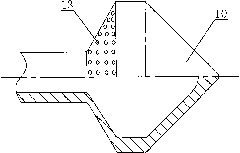

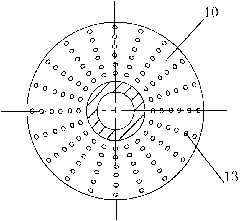

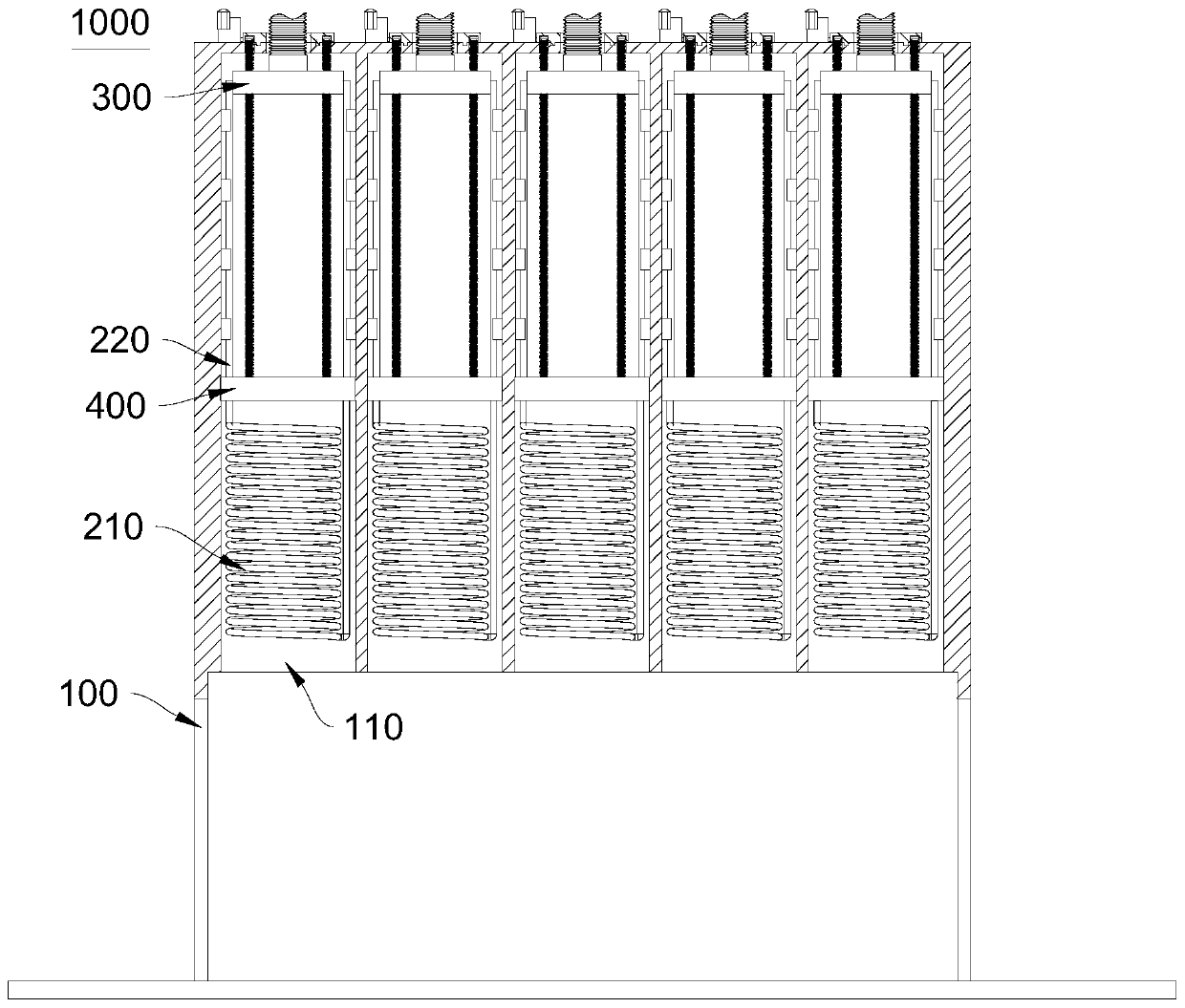

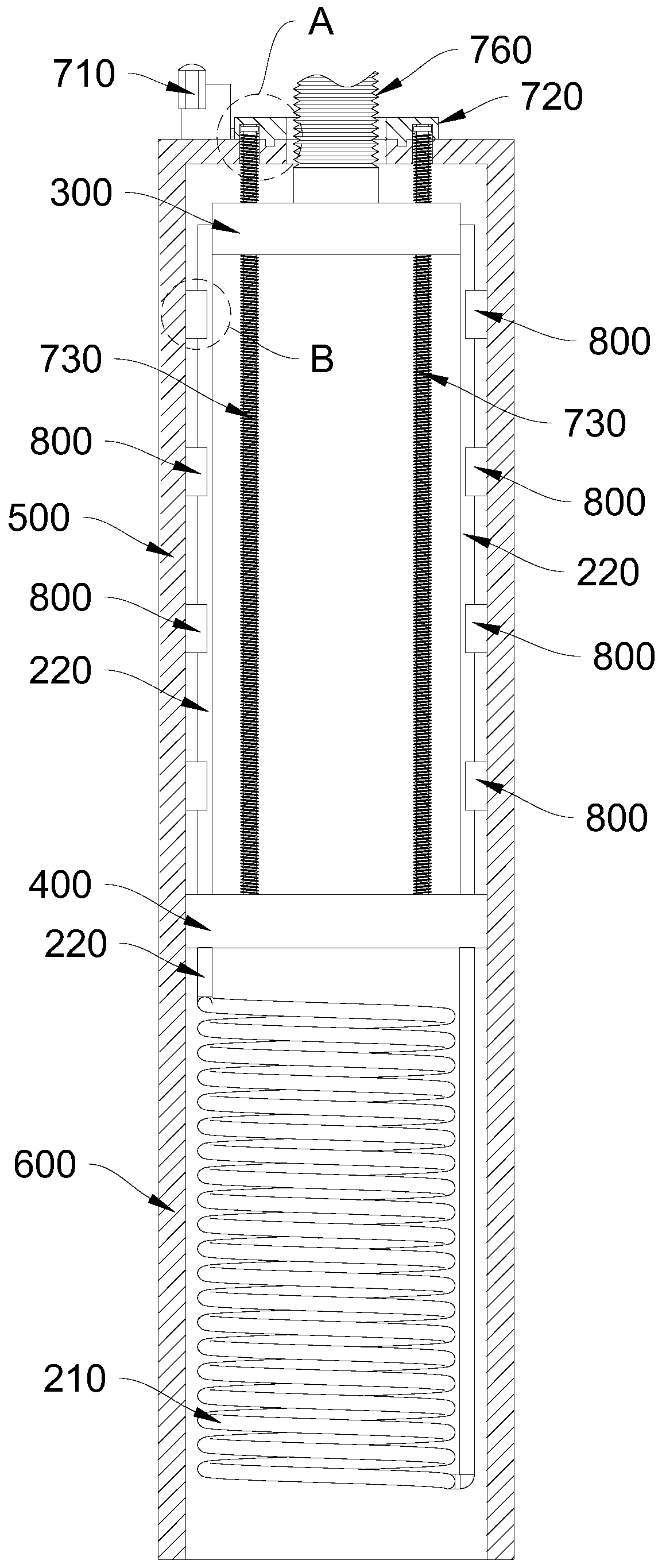

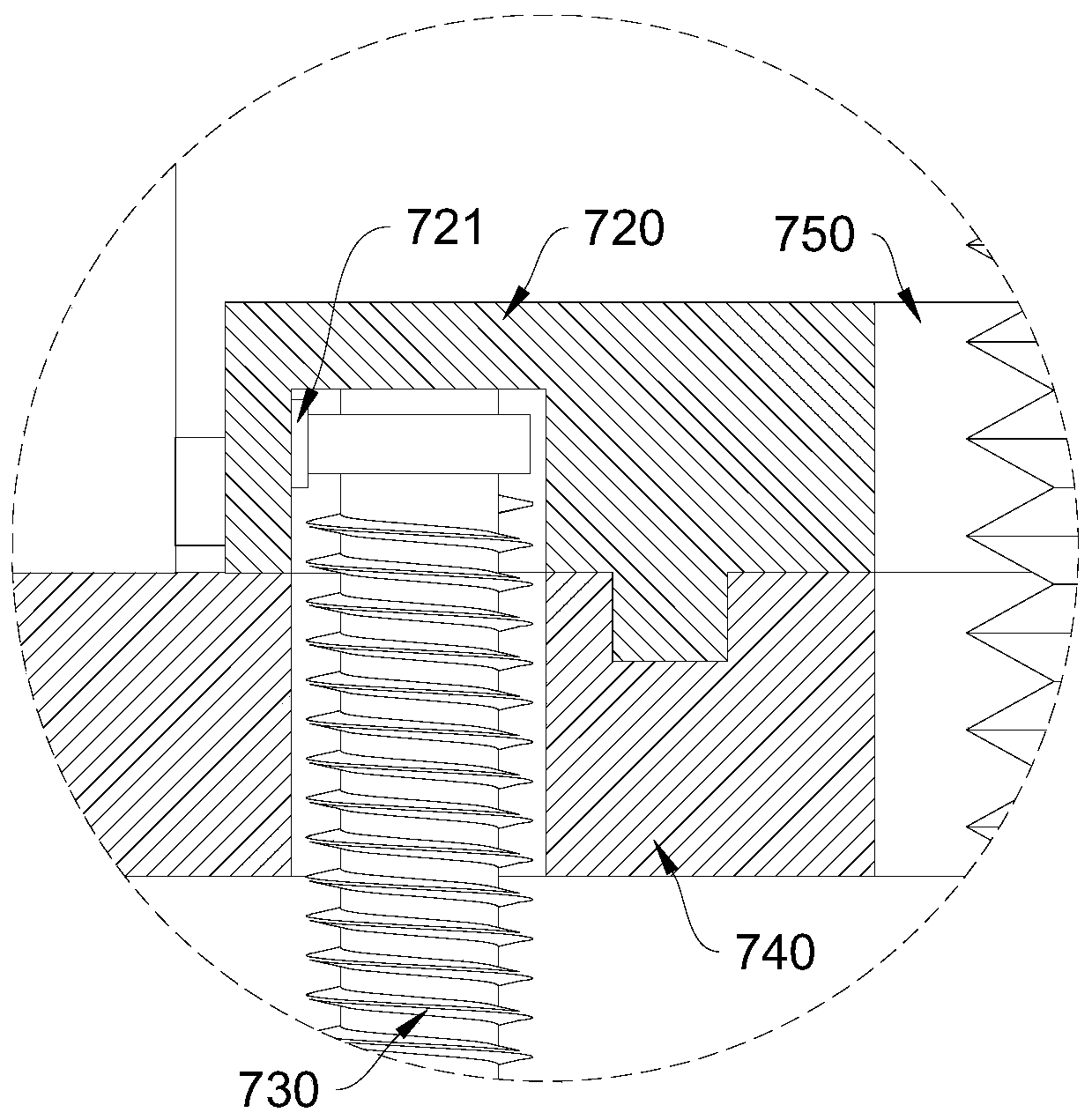

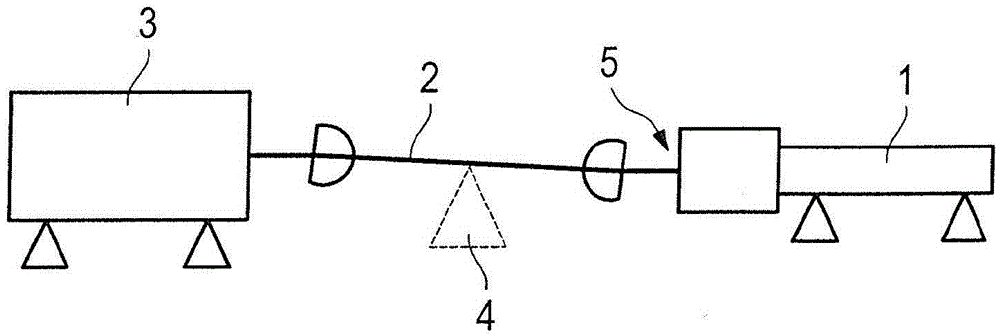

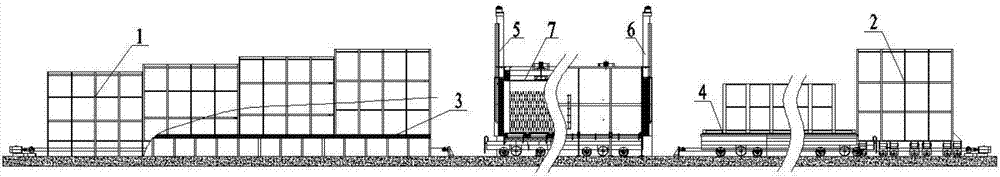

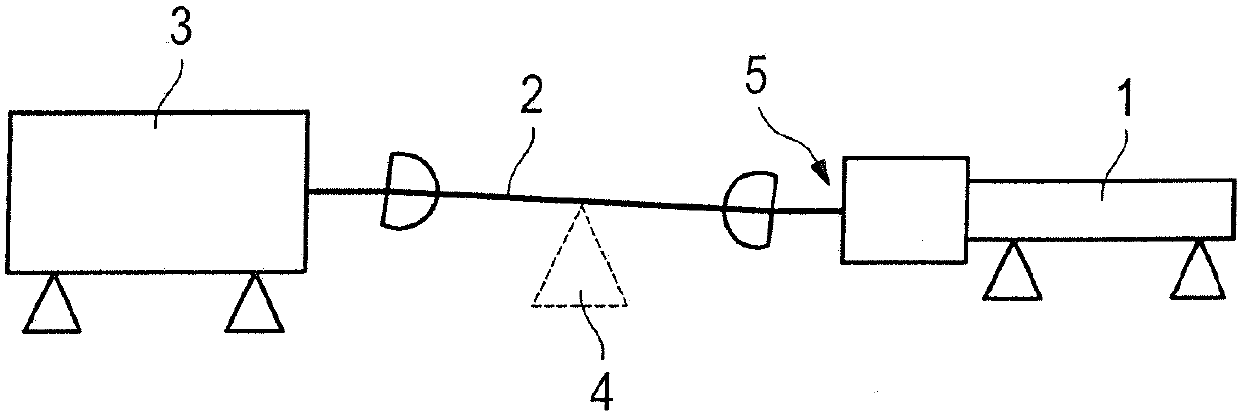

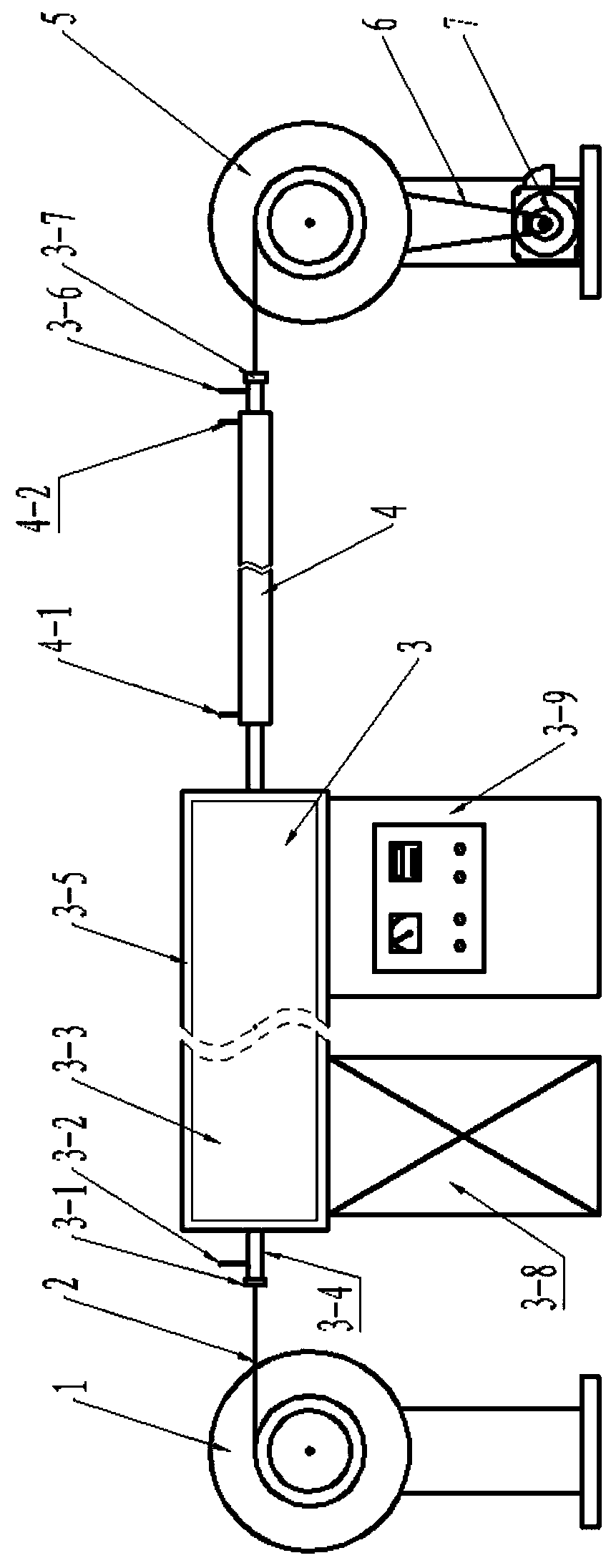

Continuous thermal processing device and thermal processing method of MgB2 superconduction wire/strip

ActiveCN107799235AReduce temperature differenceRapid heating and coolingApparatus for heat treatmentSuperconductor device manufacture/treatmentTransmission beltEngineering

The invention discloses a continuous thermal processing device. In the device, a take-up wheel is driven to rotate through a transmission belt by a motor, a lead is driven to pull a material to be thermally processed to sequentially pass through a heating region and a cooling region of the thermal processing device, dynamic continuous thermal processing and cooling processing are performed, rapidtemperature rising and reduction of the material is achieved in one step, the temperature difference of the material at different positions during the thermal processing process is reduced, the thermal processing quality is improved, and the application range of the device is expanded. The invention also discloses a thermal processing method of an MgB2 superconduction wire / strip. By the method, the MgB2 superconduction wire / strip is placed in the thermal processing device, continuous and rapid temperature rising and reduction thermal processing under inert gas production is performed, a non-super conduction impurity phase is prevented from being generated from an MgB2 superconduction core wire, an adhesion phenomenon among MgB2 lines / strips is prevented, and the continuous thermal processing device is flexible, controllable, convenient and efficient.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Medium-frequency heat treatment system and heat treatment process for petroleum tool irregular materials

ActiveCN101824526AEven heating inside and outsideCompact structureFurnace typesIncreasing energy efficiencyThermodynamicsSprayer

The invention discloses a medium-frequency heat treatment system and heat treatment process for petroleum tool irregular materials. The heat treatment system comprises a medium-frequency heater, a discharge rack, a feed rack, a sprayer and a circulating air cooler, wherein the discharge rack and the feed rack are respectively arranged at the left end and the right end of the medium-frequency heater; the sprayer is arranged above the middle part of the medium-frequency heater; and the circulating air cooler cooperates with the sprayer for use. The heat treatment process comprises the following steps: (1) cleaning the petroleum tool irregular materials; (2) heating the petroleum tool irregular materials, soaking, and water-cooling and air-cooling at the same time; (3) heating the petroleum tool irregular materials, soaking, and air-cooling; and (4) inspecting before warehousing. The invention has the advantages of simple process steps, favorable process parameters, reasonable system structure, high heat treatment efficiency and simple control operation. The invention can effectively avoid the phenomena of cracking and laminating at the end of the petroleum tool irregular material, prevent cooling water from entering the inner bores and ensure that the inside and the outside thereof are uniformly heated. The whole treatment process does not have oxidation or decarbonization, thereby having no pollution.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司 +1

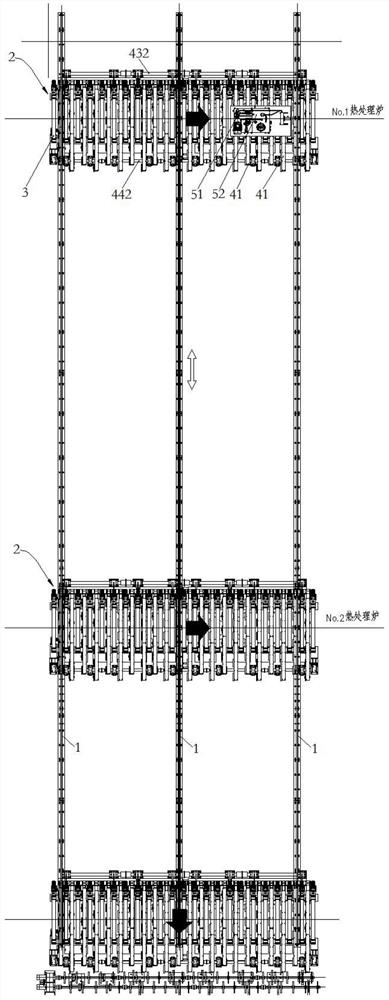

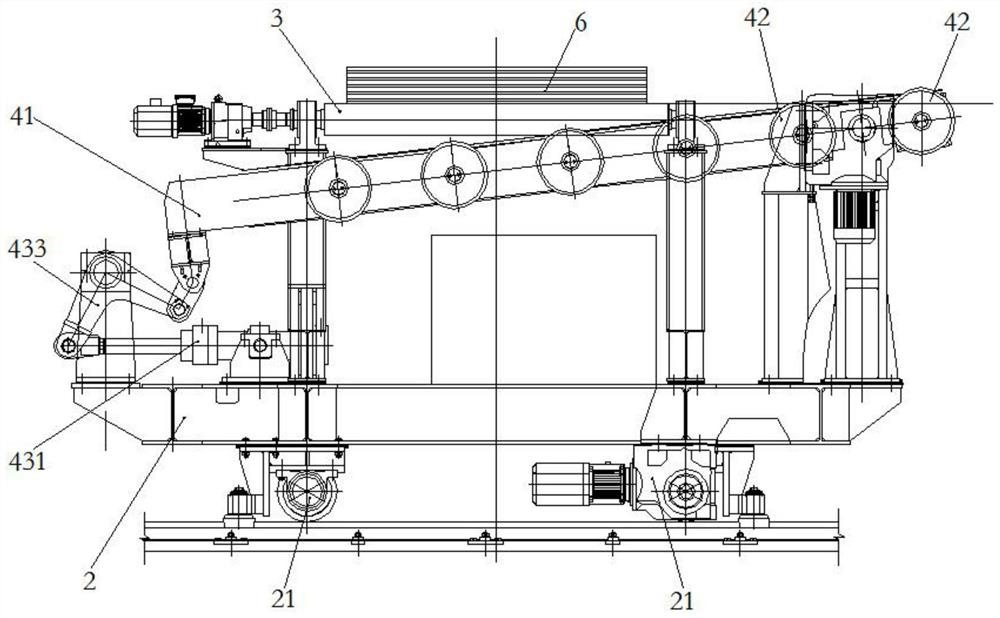

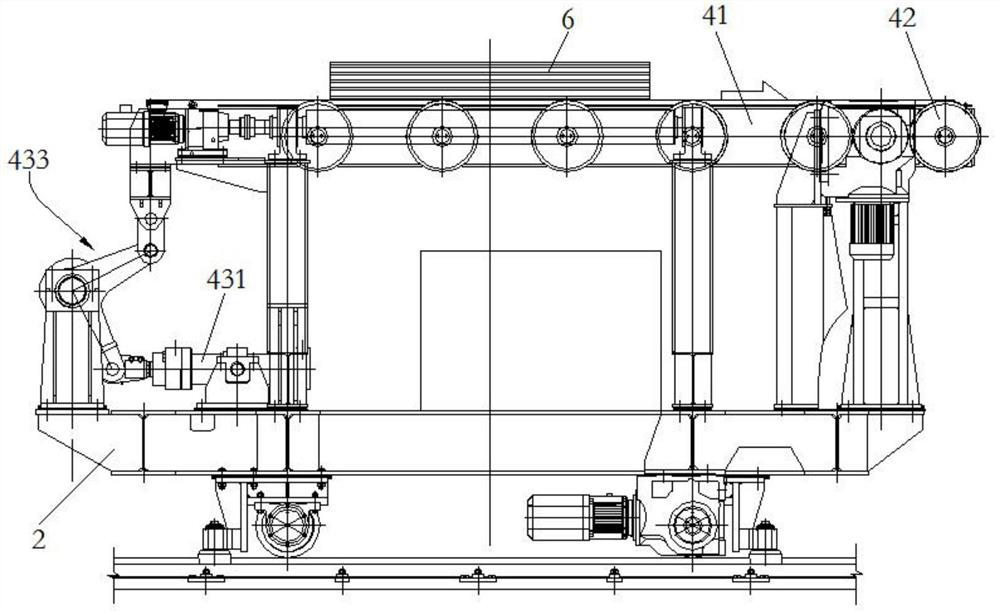

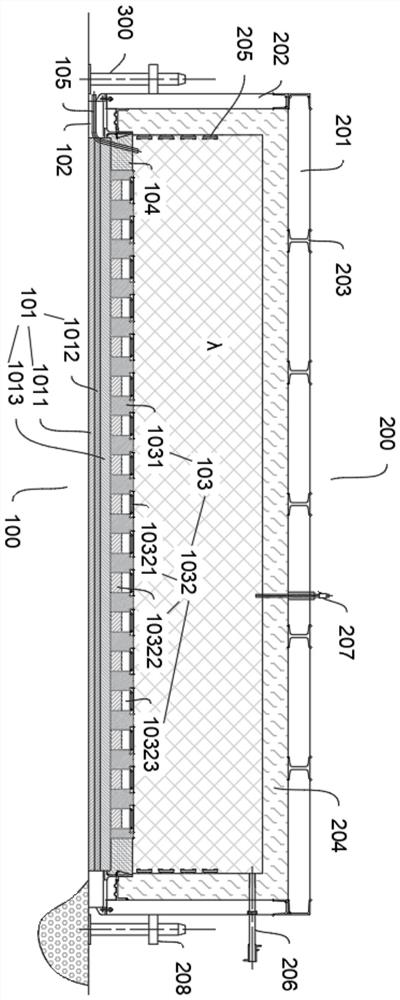

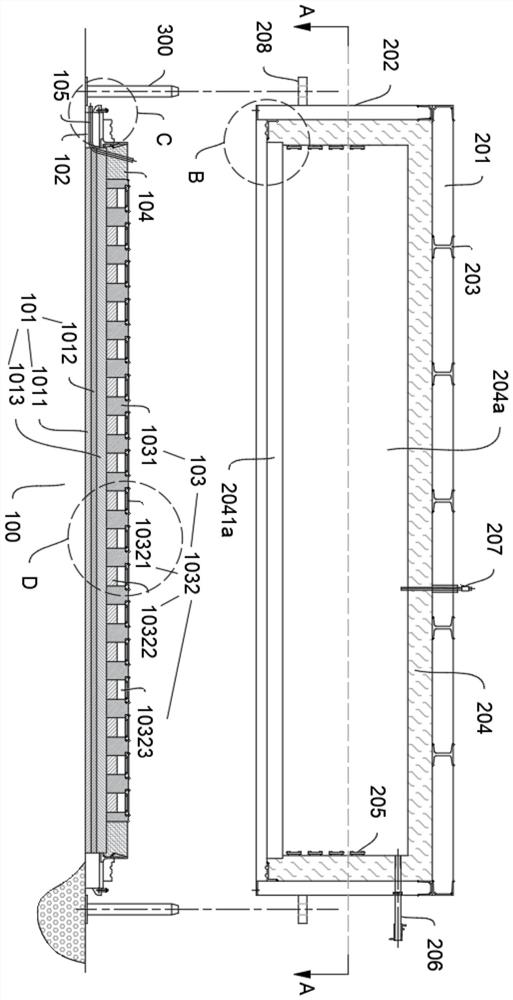

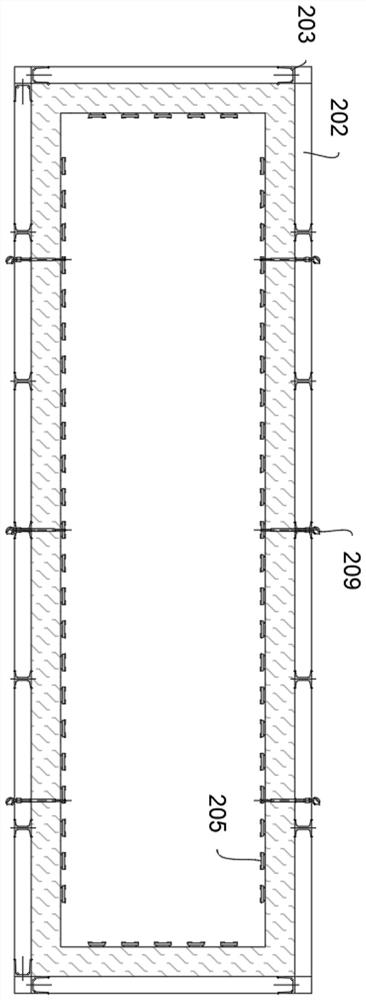

Stacked steel plate conveying system and hot rolled plate continuous heat treatment method

ActiveCN113981201AShorten the conveying distanceImprove stabilityFurnace typesProcess efficiency improvementTransit systemStructural engineering

The invention relates to a stacked steel plate conveying system which comprises a transverse moving rail and a steel plate conveying vehicle running on the transverse moving rail. The guide stroke of the transverse moving rail covers each matched heat treatment station; the steel plate conveying vehicle is provided with a side-moving lower vehicle roller way suitable for bearing steel plate stacks, and the conveying direction of the side-moving lower vehicle roller way is perpendicular to the guiding direction of the transverse moving rail. In addition, the invention further provides a hot rolled plate continuous heat treatment method. The method comprises the following steps: after continuously quenching a steel plate, performing fixed-length cutting and stacking; using the stacked steel plate conveying system for conveying the steel plate stacks formed by stacking a plurality of steel plates to a downstream heat treatment station. The steel plate conveying vehicle is adopted as steel plate conveying equipment, whole-pile transportation of steel plate stacks can be achieved, namely batch steel plate heat treatment is achieved, the steel plate conveying efficiency and the steel plate heat treatment efficiency can be remarkably improved, particularly in long-distance transportation, the steel plate transportation stability can be improved, and the equipment investment cost is obviously reduced.

Owner:WISDRI ENG & RES INC LTD

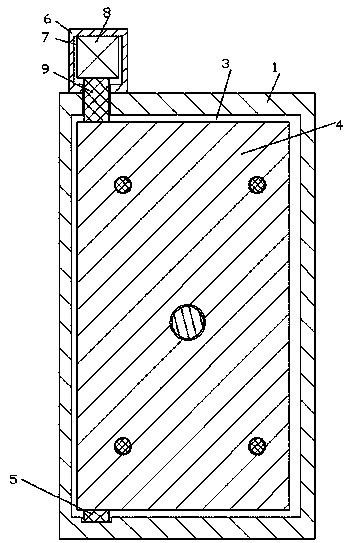

Wood modification device

InactiveCN109049228AImprove insulation effectEasy to put inWood treatment detailsThermal wood treatmentAir pumpEngineering

The invention discloses a wood modification device. The wood modification device comprises a fixed box body. The fixed box body is internally provided with a heat preservation space, and a sealing shell is fixedly disposed on the lower end wall of the heat preservation space, and the sealing shell is internally provided with a sealing space, an induction air pump is arranged on the lower end of the left end surface of the fixed box body, a steam inlet pipe is arranged at the left end of the induction air pump, and a stable clamp is fixedly disposed on the end surface, close to the movable plate, of the fixed plate. A monitoring shell is fixedly disposed at an upper end of the right end surface of the sealing shell. In the working of the wood modification device, the stability of the processing process is ensured by elastic connection, and a wood board can be taken out by drawing upwards, convenient use is achieved, and during the circulation of gas, the temperature of the exhaust gas is monitored by a second temperature sensor; and the information is fed back to the induction air pump, the flow rate of the steam is adjusted according to the loss of heat, the uniformity of heating of wood is ensured, and the utilization of energy is increased.

Owner:嵊州市诺米克进出口有限公司

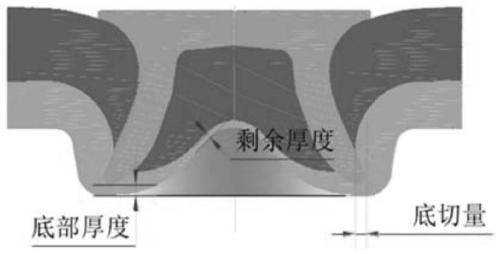

Method for inhibiting cracks of aluminum alloy self-piercing rivet joint

The invention relates to a riveting method for inhibiting cracks of an aluminum alloy self-piercing rivet joint. The method comprises the steps that a cast aluminum component is preheated, SPR riveting with the cast aluminum located below is conducted on a steel plate or other high-extensibility materials, and the method is completed. Compared with the prior art, the cast aluminum component is preheated before riveting to further improve the plasticity deformation capability of the cast aluminum component, surface eutectic silicon segregation and the like of the cast aluminum component can beimproved and eliminated to allow the organization of the cast aluminum component to be more uniform, the formation of riveting cracks is inhibited, and therefore the service life of the joint is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

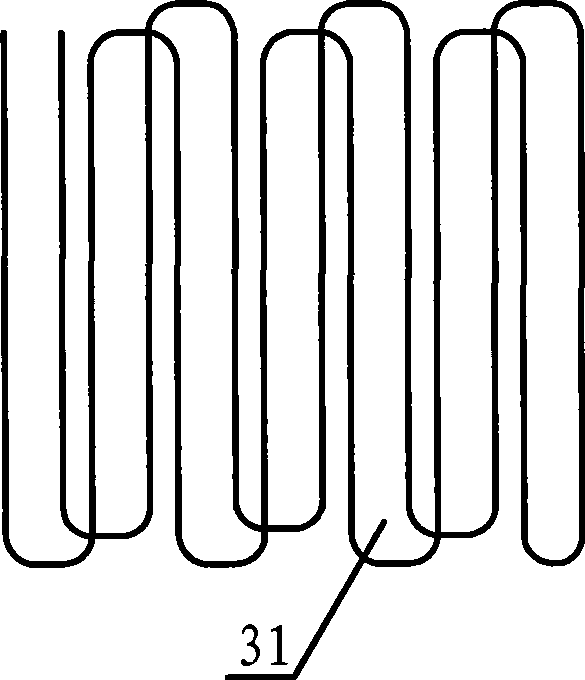

Heating improved heat treatment equipment for alloy steel strip and alloy steel strip heat treatment process

ActiveCN111363894ASimple structureComprehensiveFurnace typesIncreasing energy efficiencyEngineeringConductive materials

The invention discloses heating improved heat treatment equipment and an alloy steel strip heat treatment process, and relates to the technical field of alloy steel strip heat treatment. The equipmentcomprises a heat treatment bin, an induction coil, a first base, a partition plate, a first guide pipe, a second guide pipe and a first lifting assembly, wherein the first guide pipe and the second guide pipe are connected, the partition plate is mounted at the connecting part between the first guide pipe and the second guide pipe; the induction coil comprises a coil body and an extension section, wherein the extension section is made of a conductive material and connected with the coil body; the coil body is contained in the second guide pipe, and the extending section penetrates through thepartition plate and coopertates with the partition plate in a slidable mode; the extension section extends to the first guide pipe and is connected with the first base; the first base is driven by the first lifting assembly so that the coil body can stretch into the heat treatment bin to cover a steel strip roll; and the first base, the partition plate, the first guide pipe and the second guide pipe are all made of insulating materials. The equipment has the advantages of being simple in structure, high in comprehensiveness and wider in application range. The process has the advantages of being simple to operate, wide in application range and very convenient.

Owner:丰城市顺达五金制品有限公司

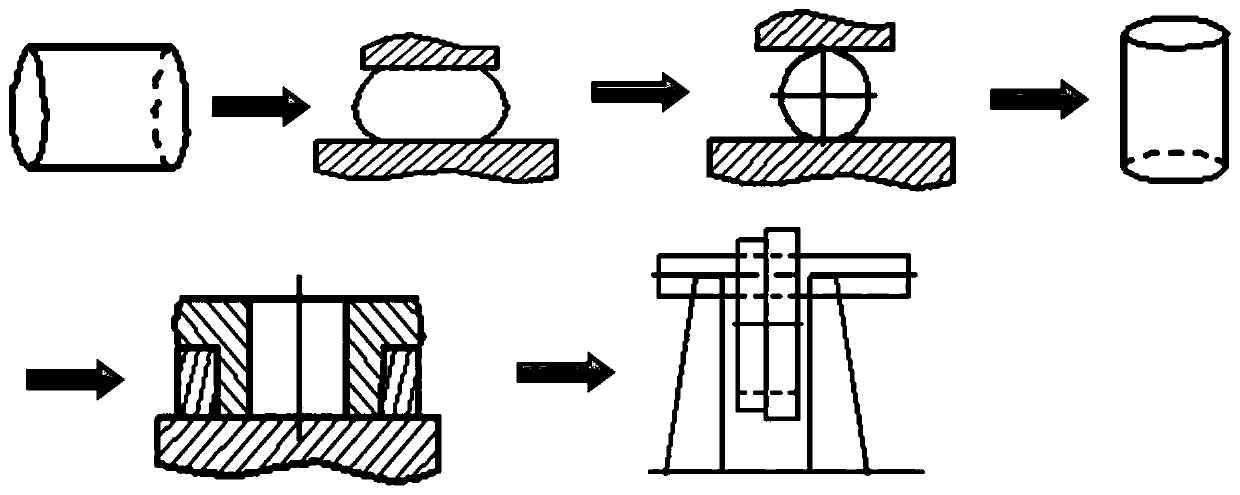

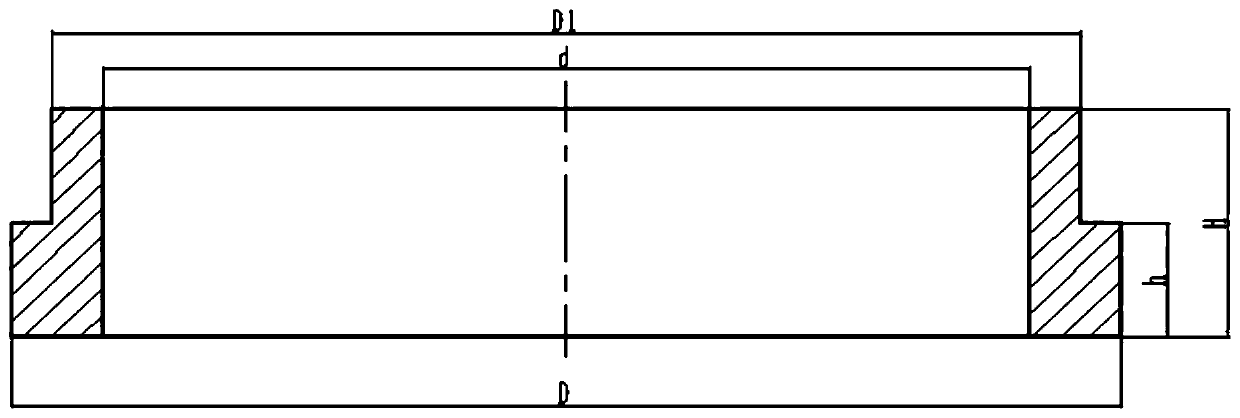

Forming method of L-shaped ring type products

InactiveCN110640075AAchieve heat treatmentAchieve near net shapeMetal-working apparatusWheelsManufactured materialMechanical engineering

The invention provides a forming method of L-shaped ring type products. The forming method of the L-shaped ring type products realizes near-net forming of the L-shaped ring type products by improvingthe blank production technology and performing step chambering so as to realize processing little in cutting or free of cutting and realize heat treatment for rough blanks, thereby realizing the purpose of reducing production cost. The forming method of the L-shaped ring type products includes the steps: performing blanking on raw materials, then preforming upsetting on materials obtained throughthe blanking, then obtaining the corresponding rough blanks through drawing, next placing the rough blanks in corresponding leaking plates for upsetting, punching and preforming, forming blanks with L-shaped sections, and afterwards placing the blanks with the L-shaped sections on a mandrel supporter for performing chambering amendment so as to form the designed L-shaped ring type products.

Owner:WUXI HONGDA HEAVY IND

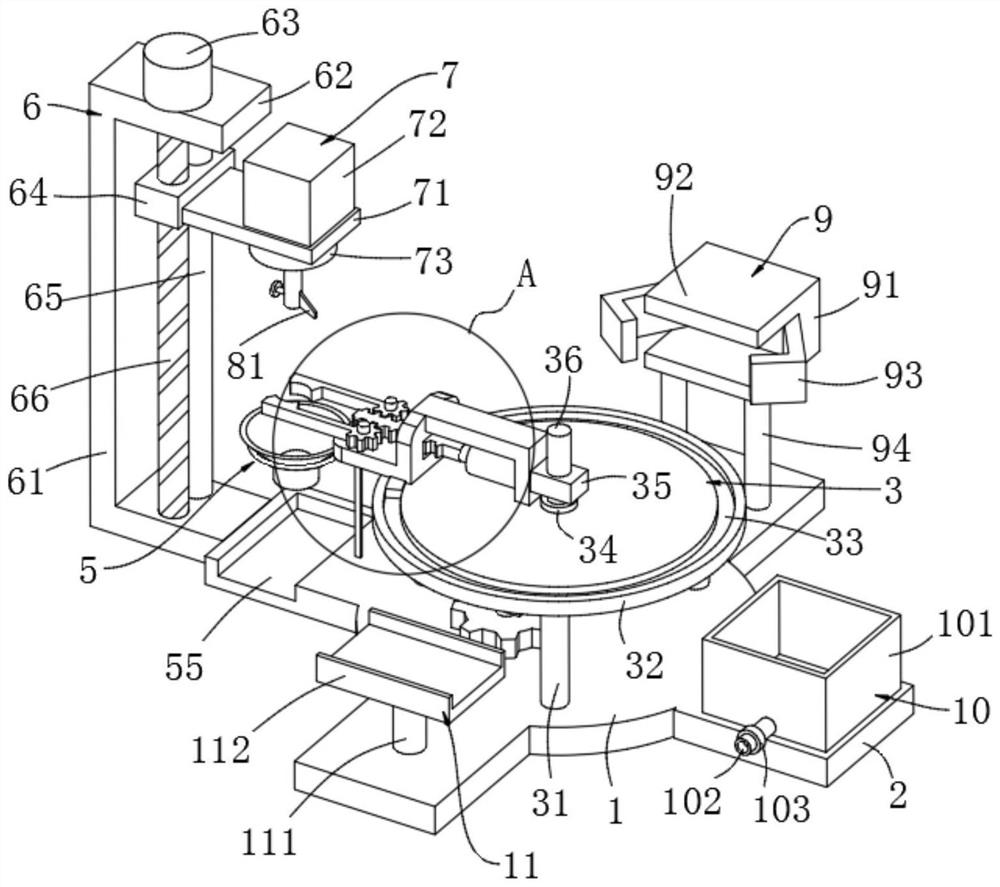

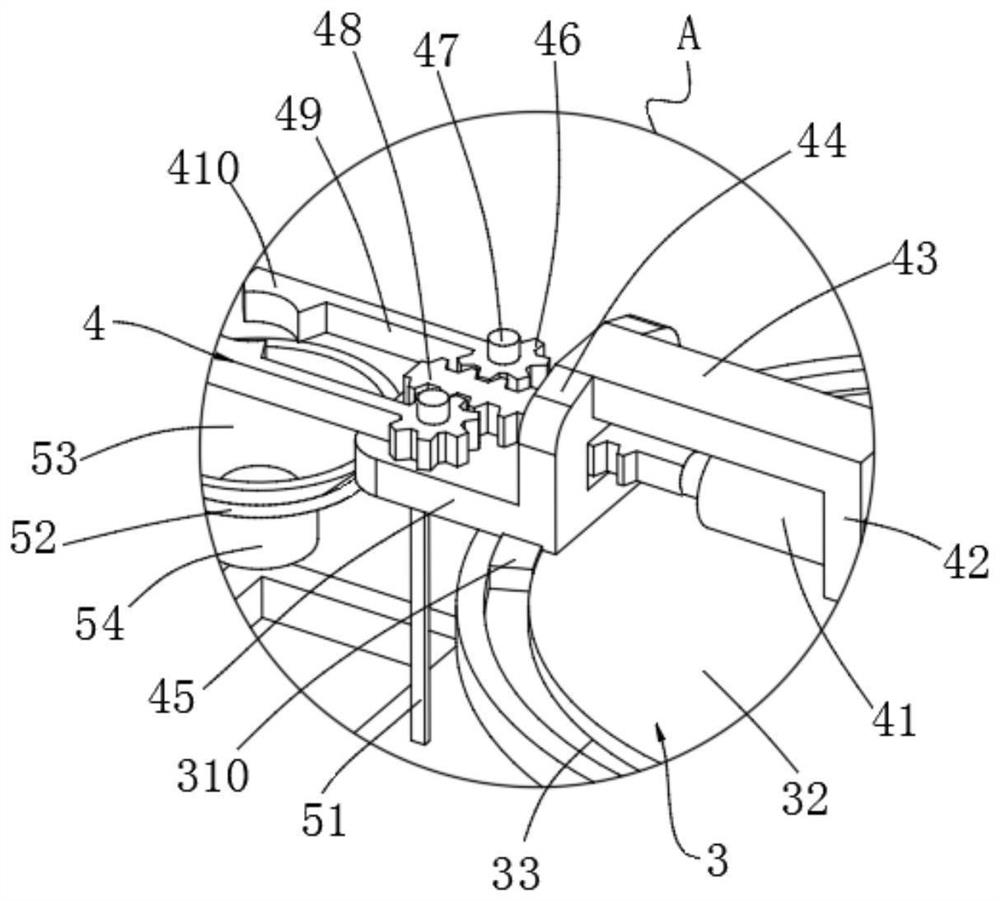

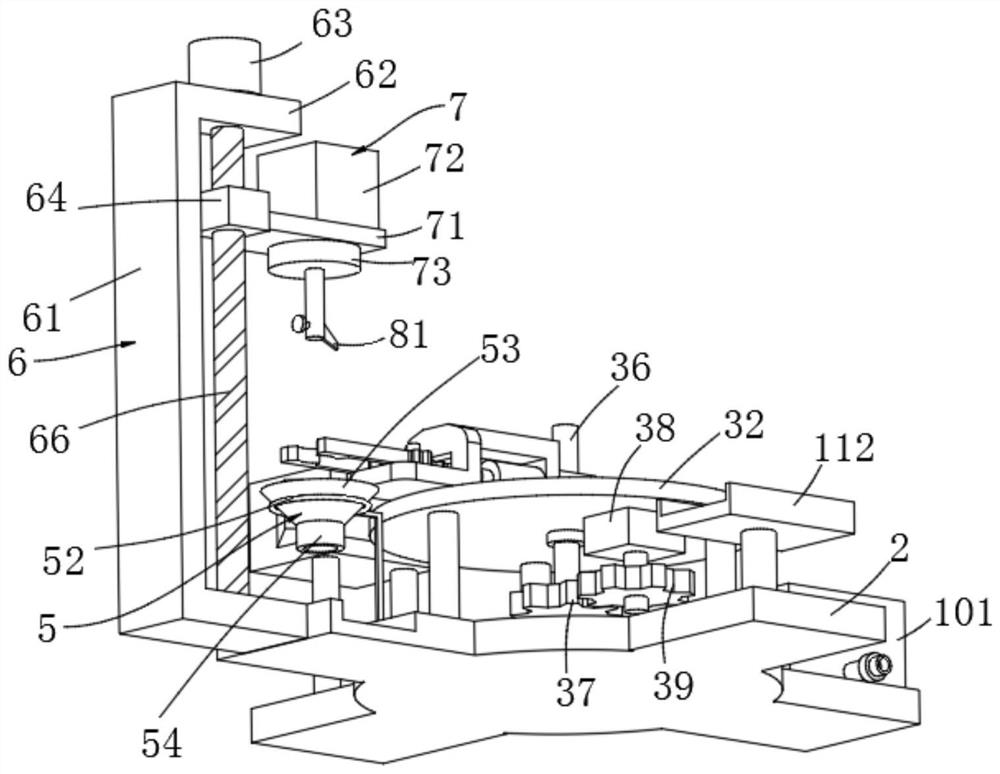

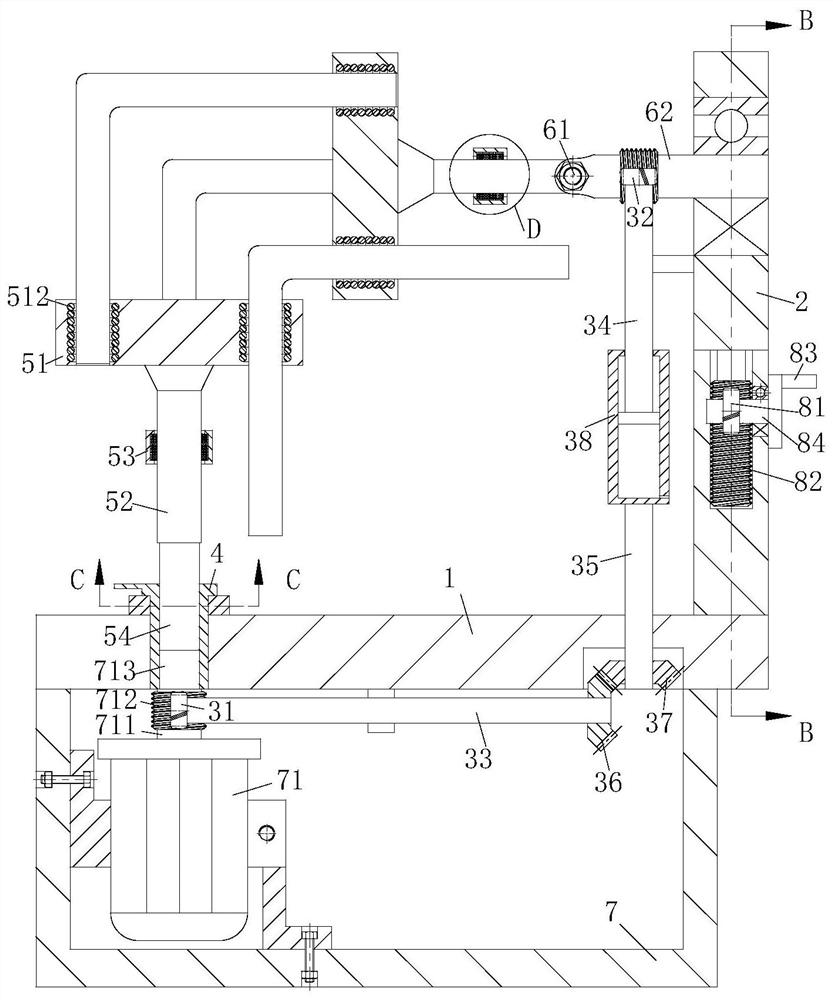

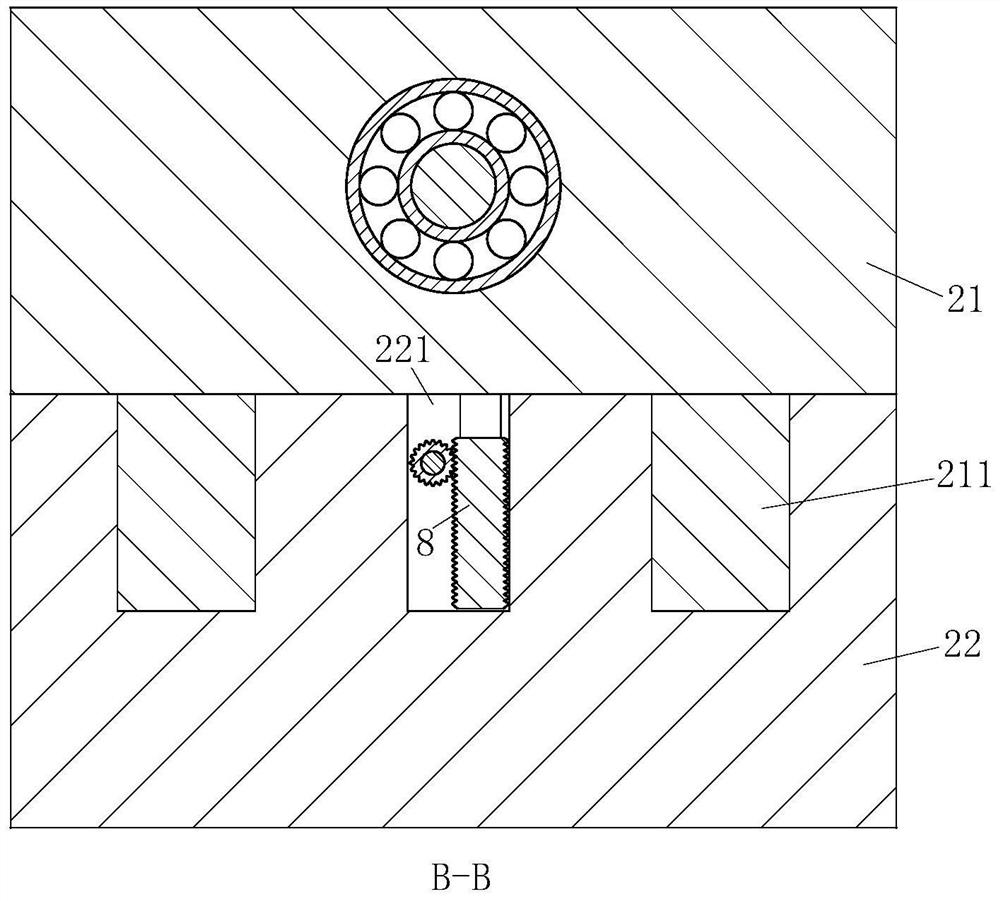

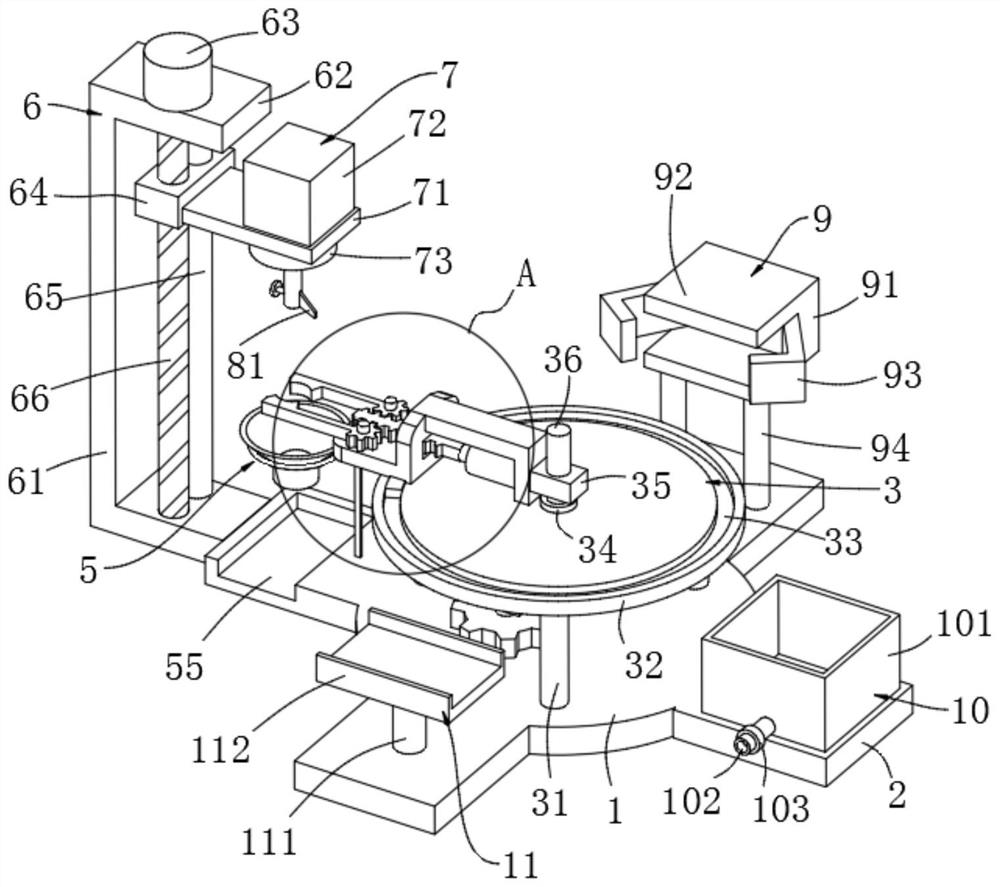

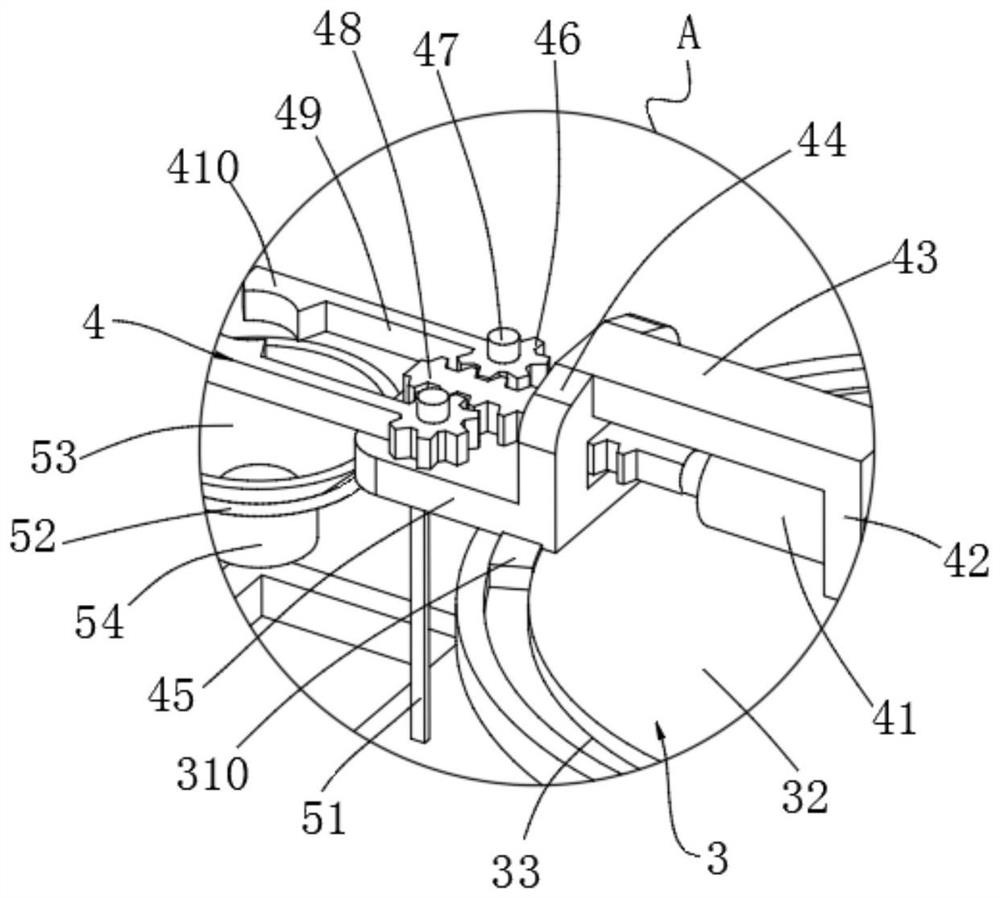

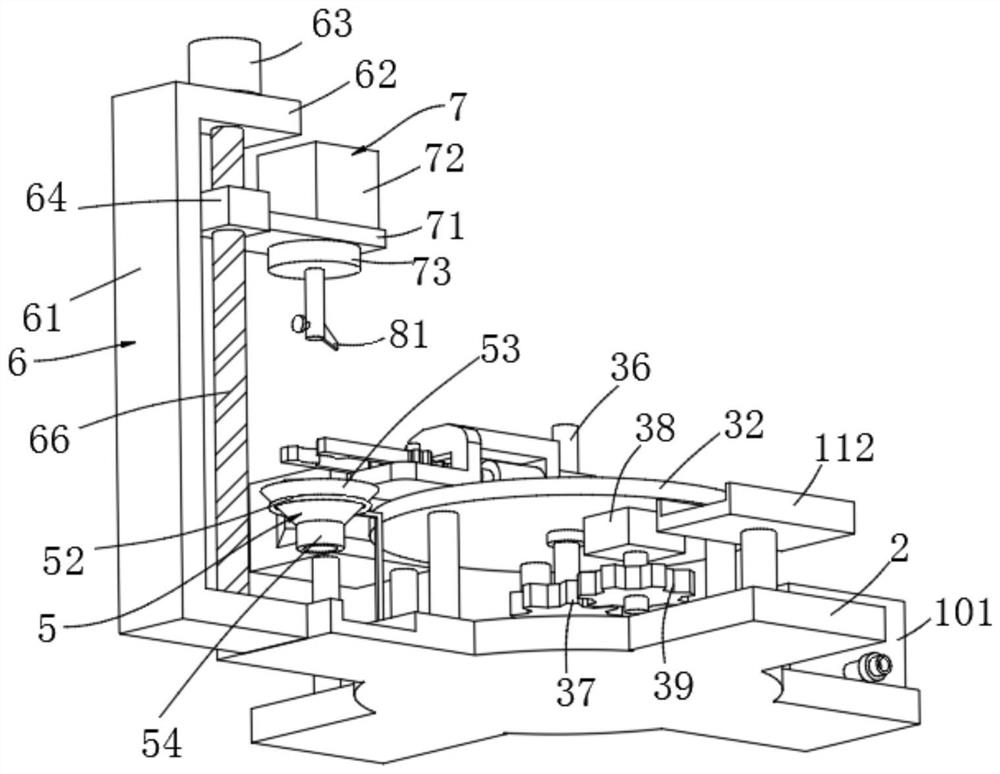

Treatment mechanism of engine cylinder

ActiveCN112475895AAchieve heat treatmentStress reliefFurnace typesFeeding apparatusMotronicPower unit

The invention discloses a treatment mechanism of an engine cylinder. The treatment mechanism comprises a chassis, an angle adjusting unit, a clamping unit, a height adjusting unit, a boring power unit, an adjustable boring cutter unit and a heat treatment unit; the clamping unit is mounted at the top of the chassis through the angle adjusting unit; four mounting plates are arranged on the side surface of the chassis at equal angles; the boring power unit is mounted on the mounting plate on the left side through the height adjusting unit; the adjustable boring cutter unit is mounted at the bottom of the boring power unit; the heat treatment unit is mounted on the mounting plate on the back side; and the heat treatment unit comprises a heat treatment equipment box, a baffle plate, an L-shaped door plate, equipment box legs, an electric push rod, a support rod, an end rod, a through hole, a door plate shaft, a push-pull block, a hinge support, a heat conducting circular plate, a circularblind groove and an electric heating wire. The treatment mechanism can continuously perform the production steps of the engine cylinder, improves the production continuity, effectively improves the production efficiency, reduces the manual participation, and reduces the labor cost.

Owner:芜湖钻石航空发动机有限公司

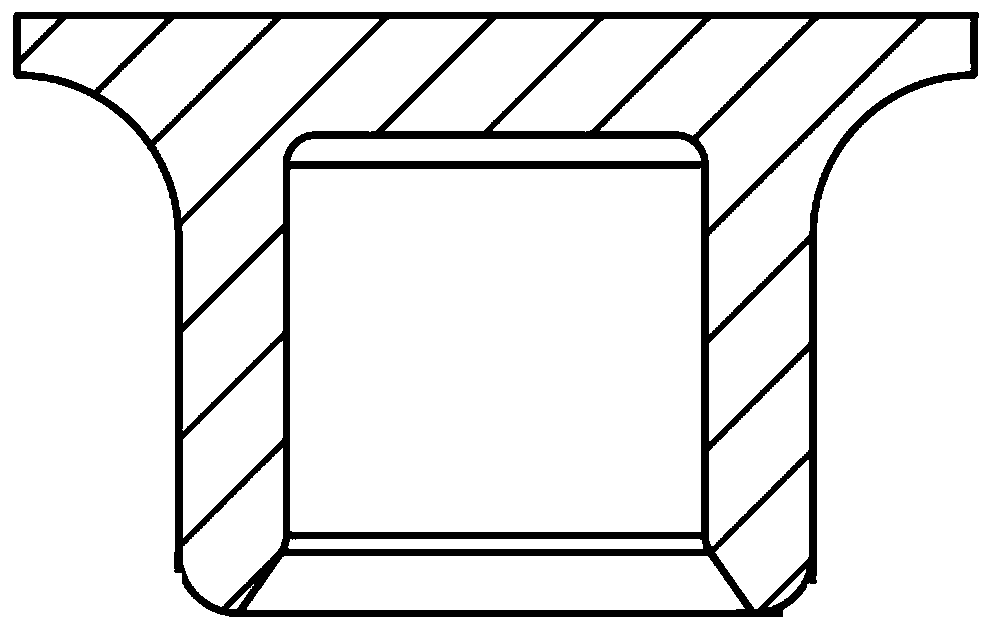

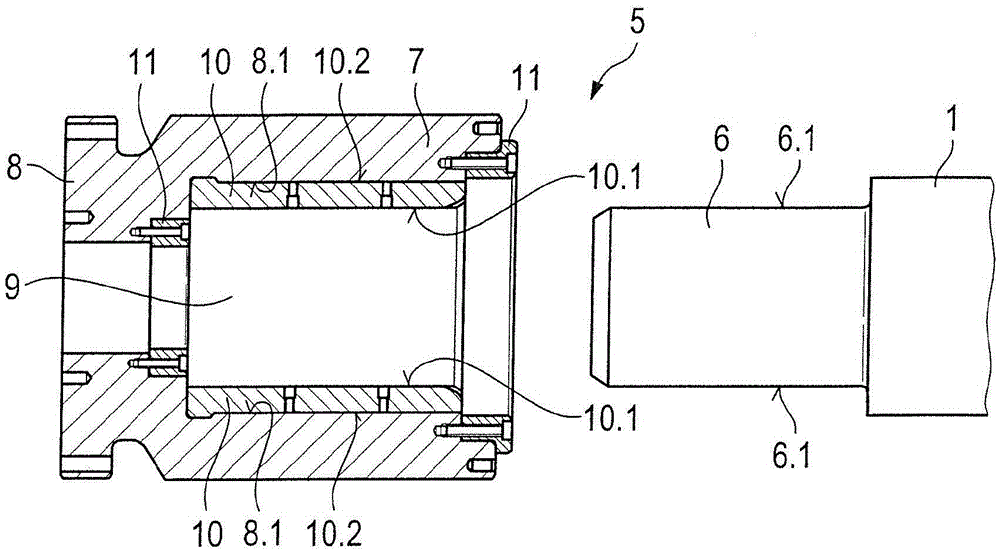

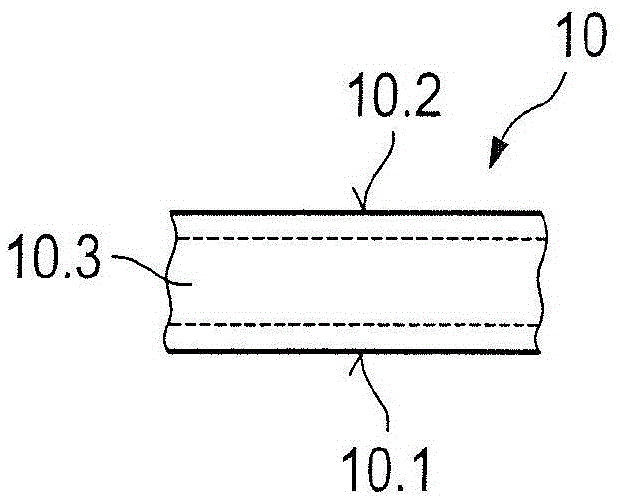

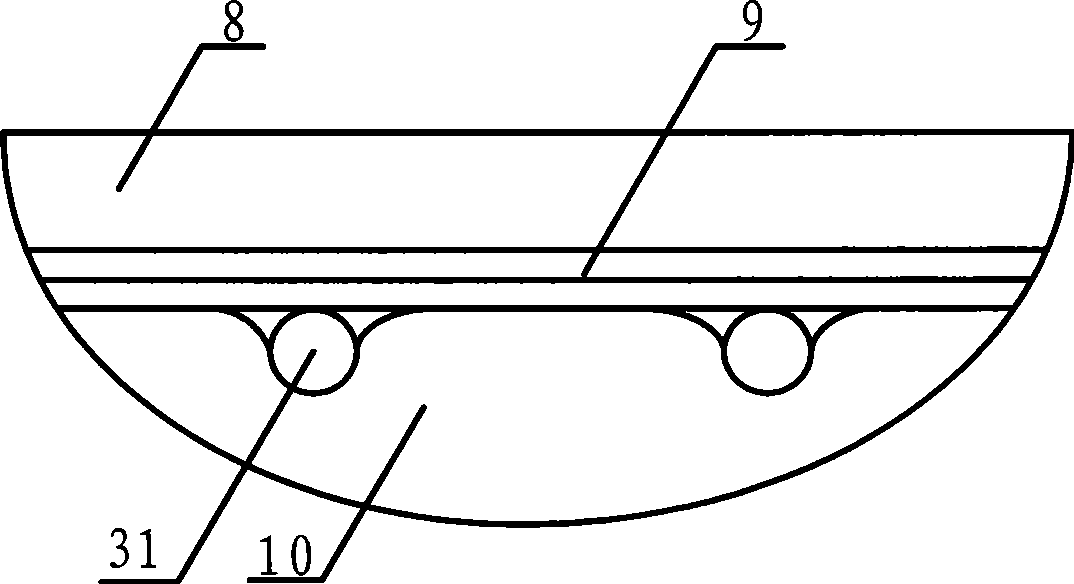

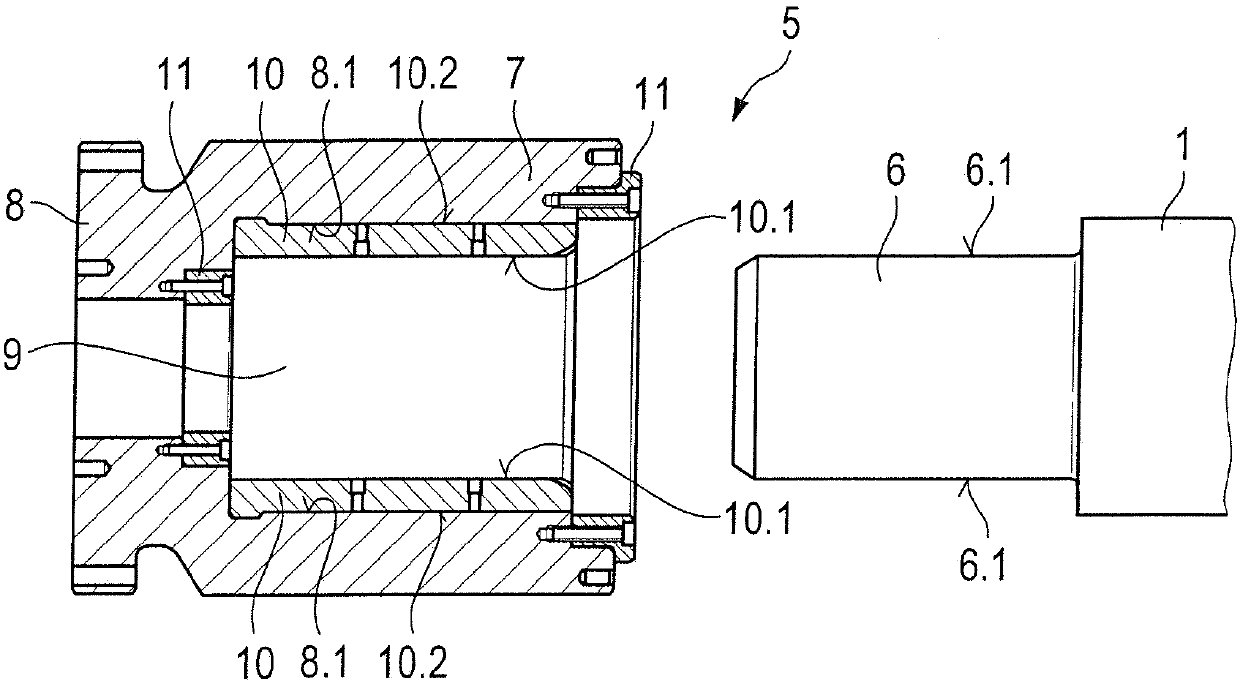

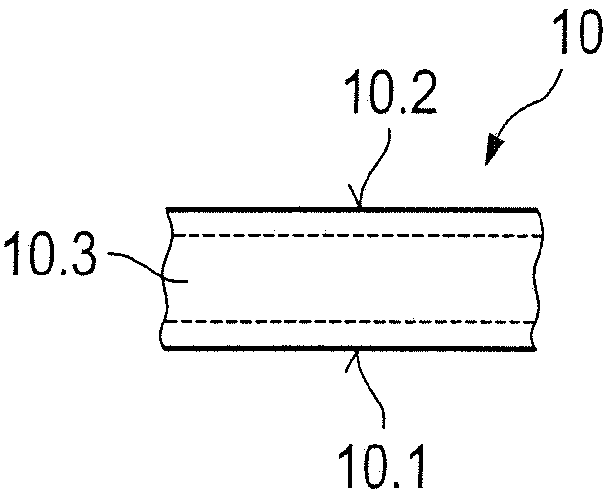

Pin receiving portion for a hub, in particular in a rolling mill

ActiveCN105636714AReduce hardnessExtended service lifeCouplings for rigid shaftsRolling mill drivesHardnessRolling mill

The invention relates to a pin receiving portion (7) for a hub for receiving the pin (6) of a connection unit, in particular of a roller (1), said pin receiving portion (7) having a main part (8) with an opening (9), which is at least partly lined with at least one wear plate (10), for inserting the pin (6). The wear plate (10) has a front surface (10.1) for bearing on the pin (6), said front surface delimiting the opening for the pin (6), and the wear plate (10) has a rear surface (10.2) which faces away from the front surface (10.1) and which rests against a receiving surface (8.1) of the main part (8) at least temporarily. The wear plate (10) has a lower hardness on the wear plate rear surface (10.2) than the receiving surface (8.1) of the main part (8).

Owner:VOITH PATENT GMBH

Heat treatment process of long shaft

ActiveCN111304430AUniform coolingAchieve heat treatmentFurnace typesHeat treatment furnacesTemperingMaterials science

The invention relates to a heat treatment process of a long shaft. The heat treatment process comprises the following steps that S1, a heat treatment device is selected, and the long shaft is fed to the heat treatment device; S2, quenching is carried out, wherein the quenching temperature ranges from 830 DEG C to 850 DEG C; S3, cooling is conducted, wherein the long shaft is cooled in a spraying mode, and the cooling temperature ranges from 24 DEG C to 26 DEG C; S4, tempering is conducted, wherein the tempering temperature is divided into first-stage tempering temperature and second-stage tempering temperature, the first-stage tempering temperature ranges from 710 DEG C to 750 DEG C, and the second-stage tempering temperature ranges from 500 DEG C to 600 DEG C; and S5, discharging is carried out. The heat treatment process has the effects of reducing bar damage and being good in heat treatment effect.

Owner:杭州大路金属热处理有限公司

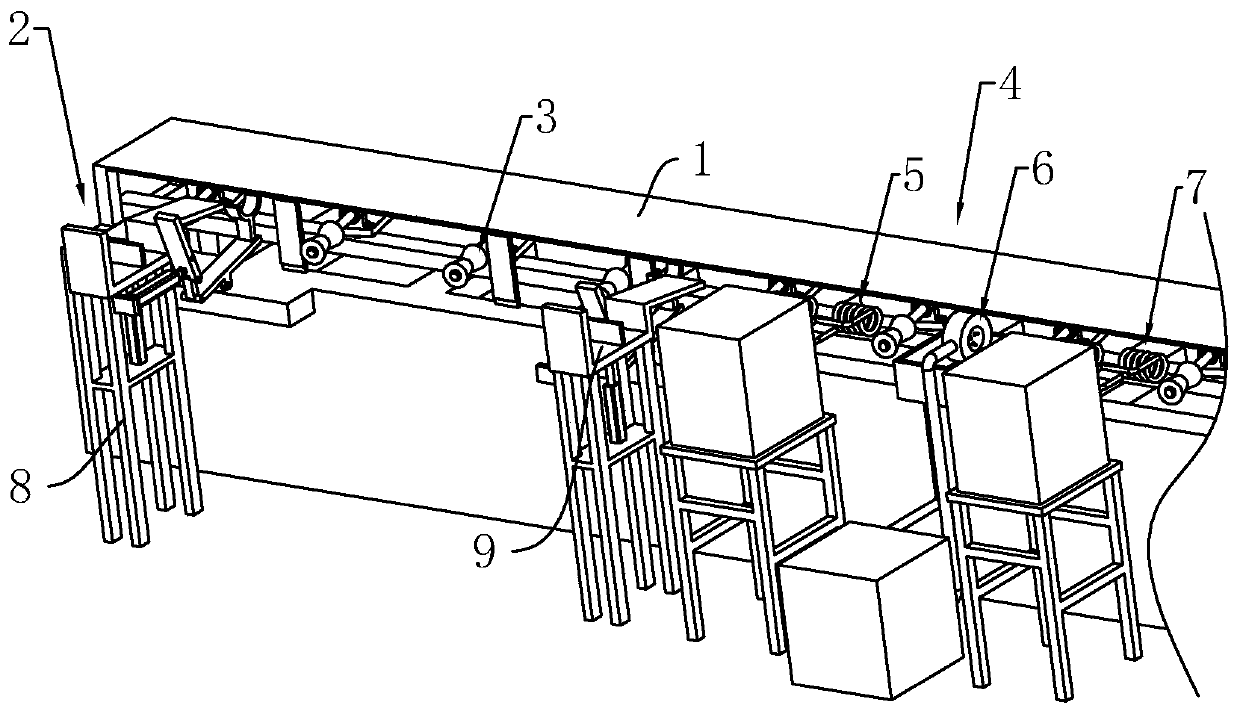

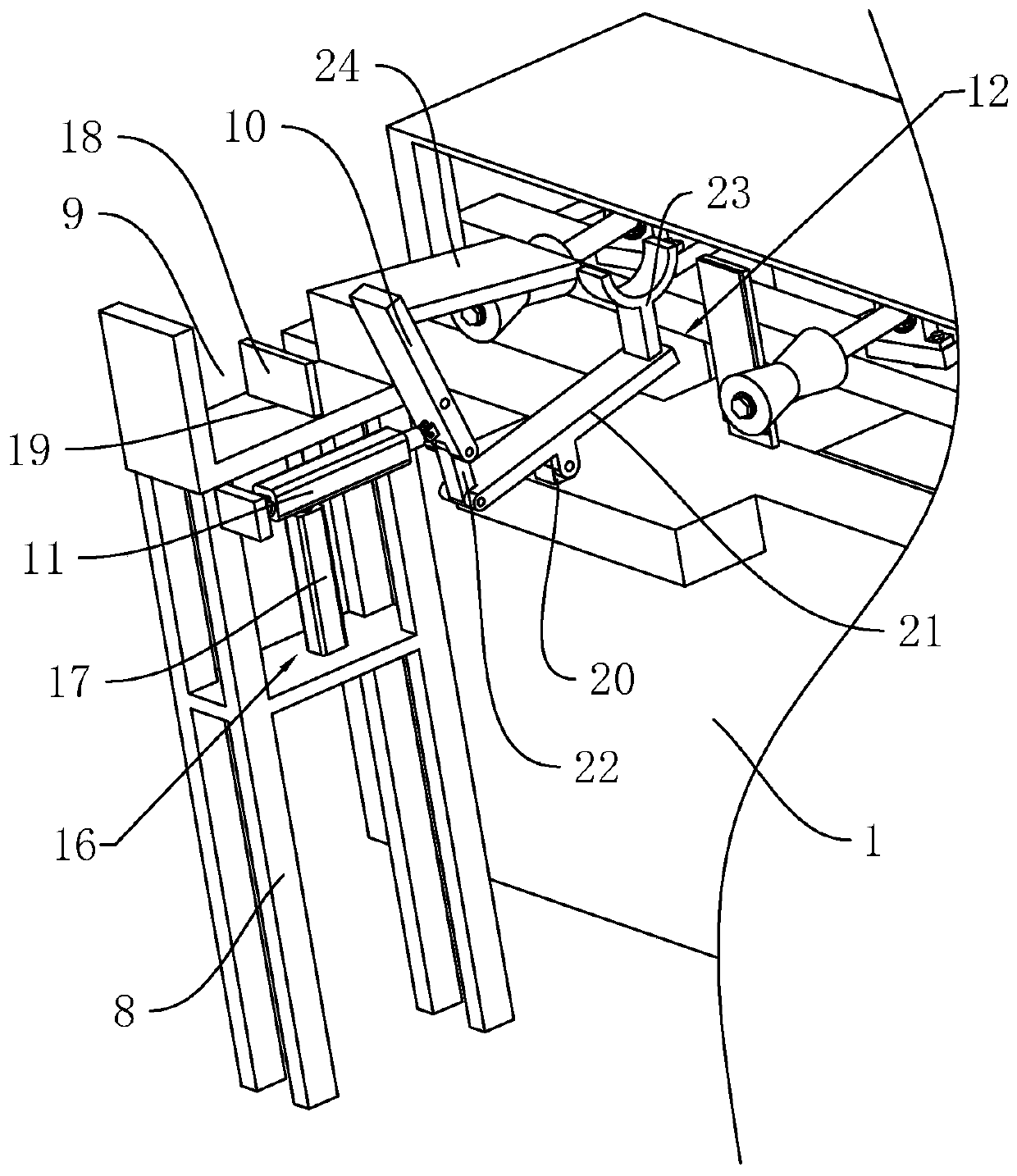

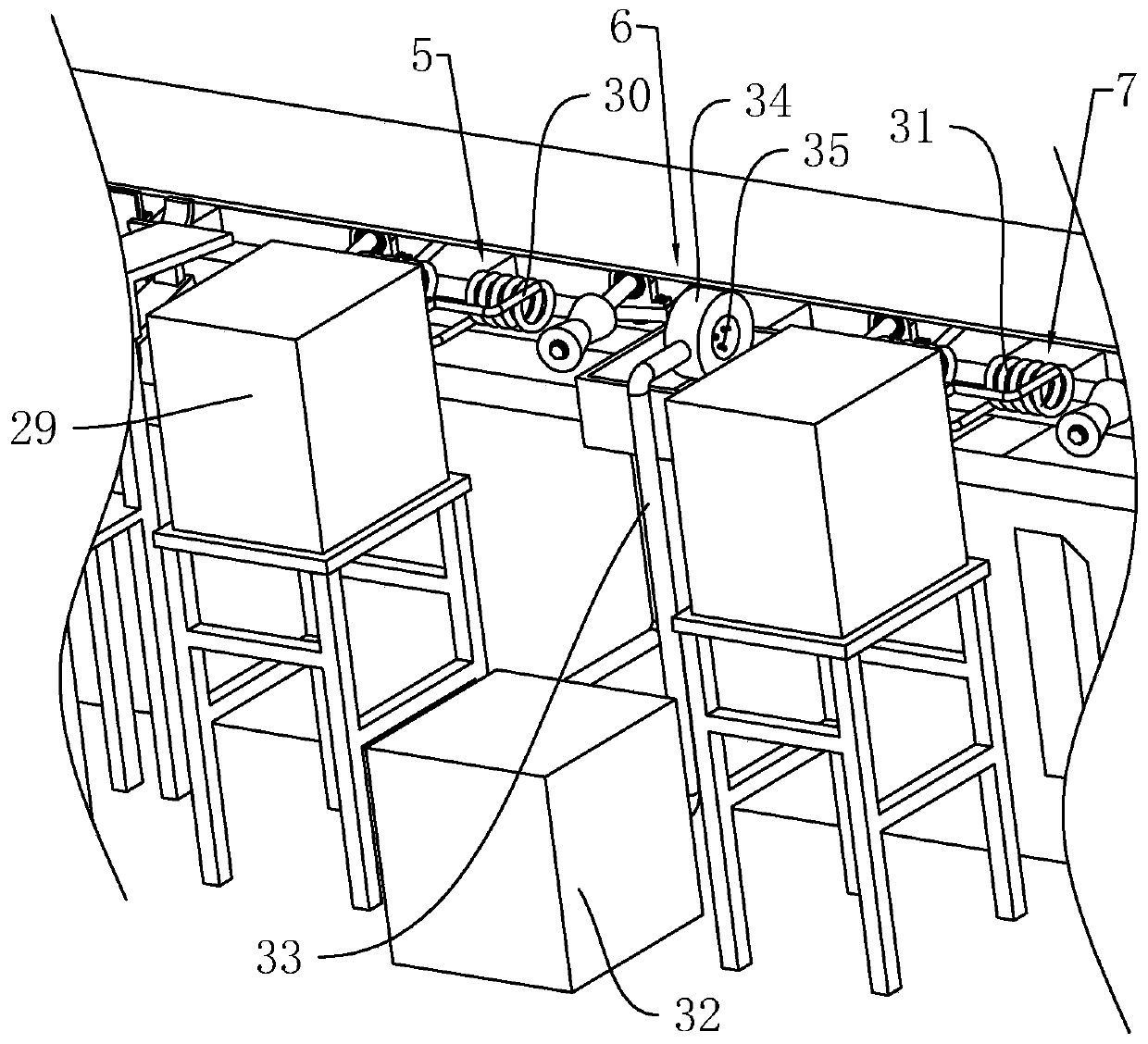

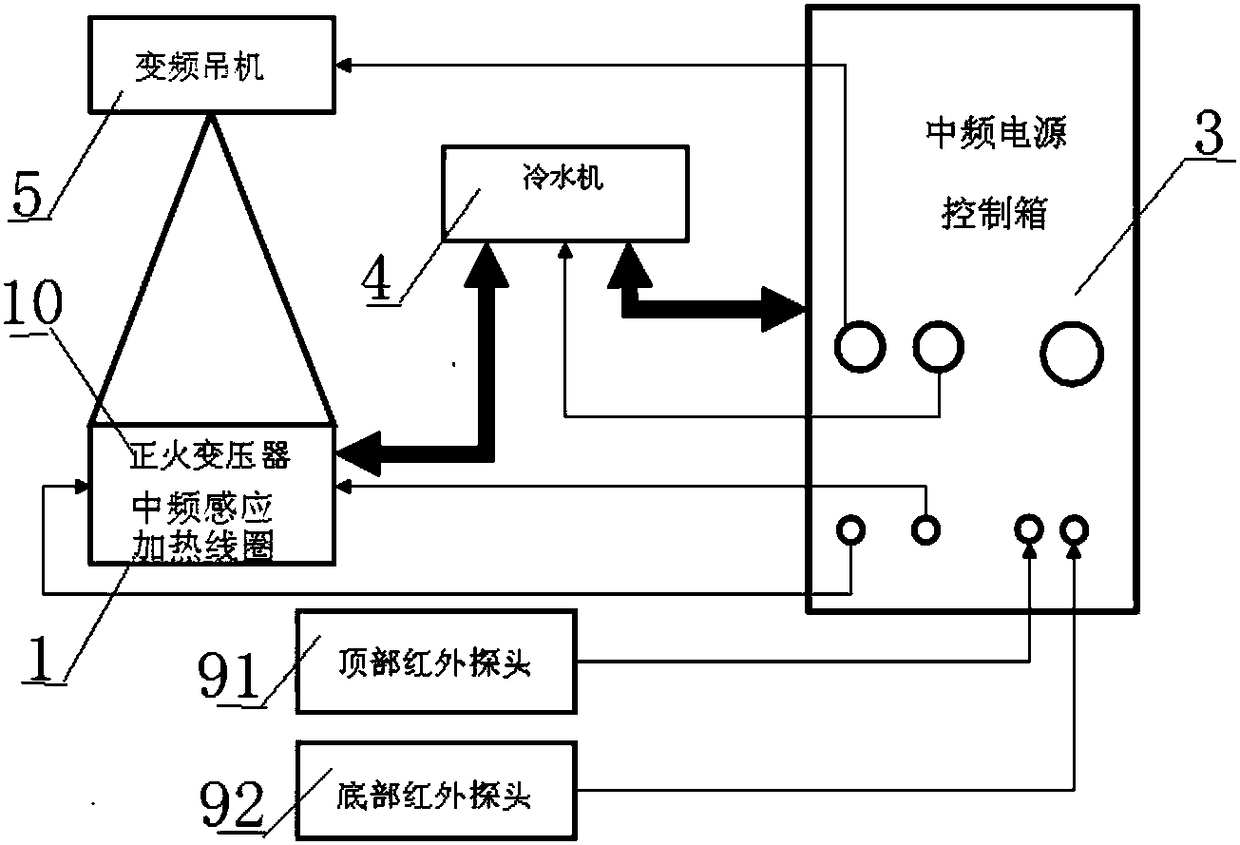

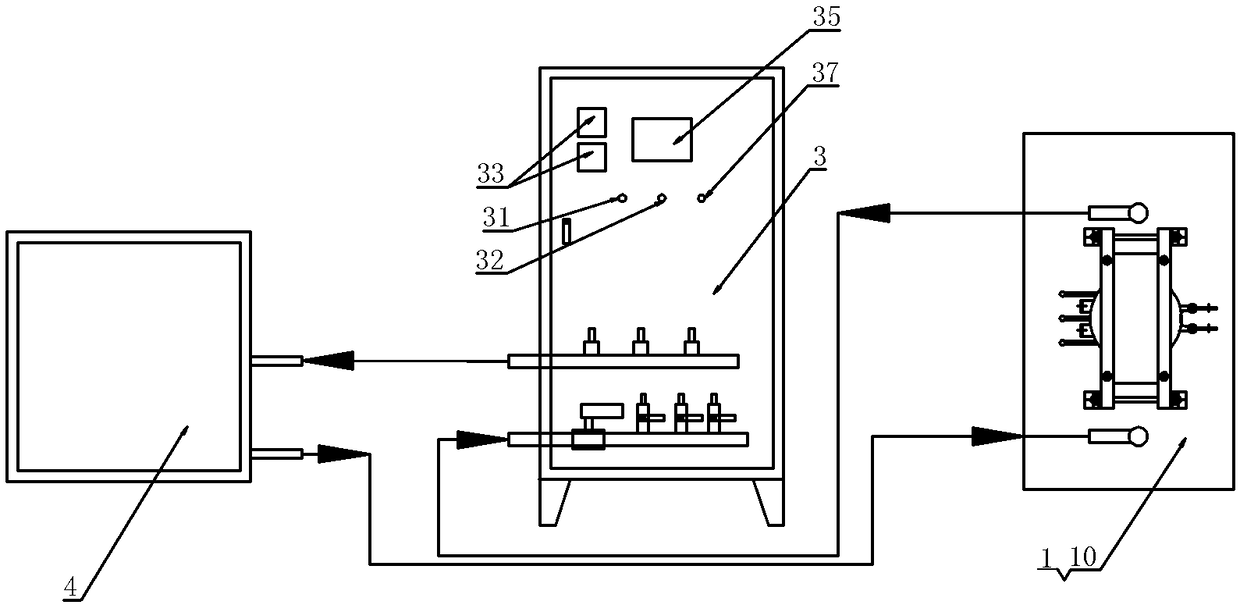

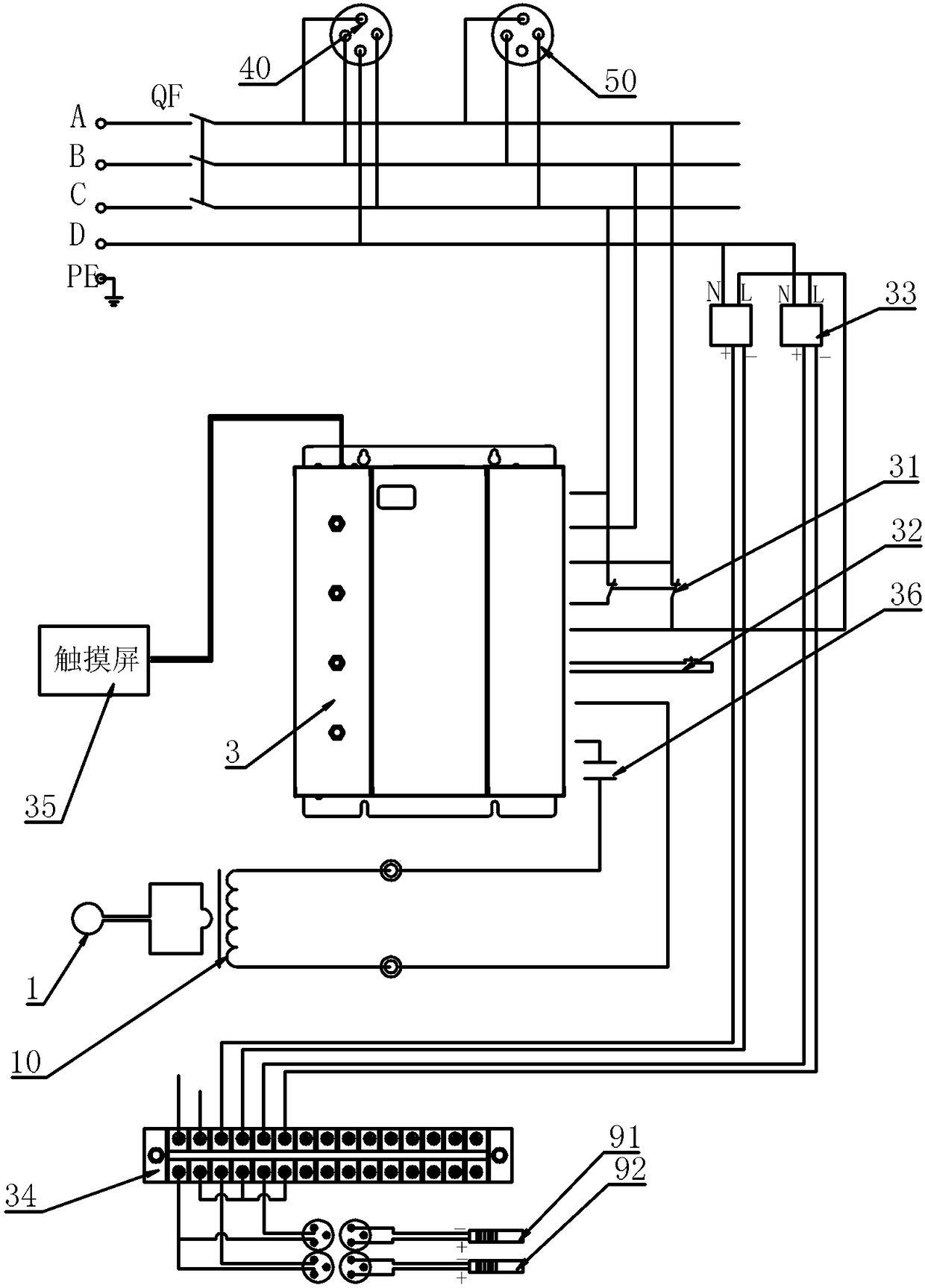

Rail welding head normalizing system

PendingCN108220571ARealize normalizingImprove the performance of metal structureFurnace typesHeat treatment furnacesTransformerBusbar

The invention discloses a rail welding head normalizing system in the field of metal heat treatment. The rail welding head normalizing system comprises a medium-frequency power source control cabinet,a normalizing transformer and a medium-frequency induction heating coil. The input end of the normalizing transformer is connected with the output end of the medium-frequency power source control cabinet. The medium-frequency induction heating coil comprises a first active coil and a second active coil. A closed loop coil with a T-shaped vertical cross section is defined by the first active coiland the second active coil. The top of the first active coil is connected with a first busbar, the top of the second active coil is connected with a second busbar, the top of the first busbar and thetop of the second busbar correspondingly pass through a top electrode plate to be connected with the output end of the normalizing transformer, and so that a closed loop circuit is formed among the first busbar, the first active coil, the second active coil, the second busbar and the normalizing transformer.

Owner:SHANGHAI UNIV OF ENG SCI

Heating system and heating means

ActiveCN101481750AHeating evenlyControllable heating temperatureFurnace typesHeat treatment furnacesHeating systemEnergy loss

The invention relates to a heating system and a heating method; wherein, the system comprises a shuttering; and the system also comprises a heating cabinet used for storing liquid to be heated, a main pipe line connected with the heating cabinet and used for transporting the liquid, at least a heating unit composed of copper tubes with fixed shape arranged in a line, connected in parallel on the main pipe line and connected with the part where the shuttering is not contacted with a die body, and a basic valve arranged at the main pipe line and used for controlling the connection or the disconnection between the heating cabinet and the main pipe line. The system can effectively correct the defects of bad heating effect, high cost, heavy energy loss and the like in the prior art of heat treatment, and can realize heating. The system has the advantages of controllable heating temperature, low cost and good safety.

Owner:保定华翼风电叶片研究开发有限公司

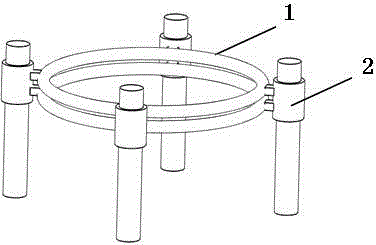

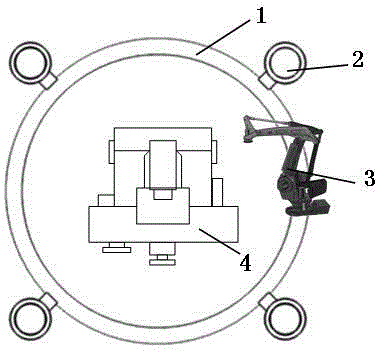

Processing method for heat-preservation heat treatment of large workpiece by adopting circular rail heating robot

InactiveCN104593574ASize limitAchieve heat treatmentFurnace typesHeat treatment process controlRobotic armEngineering

A processing method for heat-preservation heat treatment of a large workpiece by adopting an circular rail heating robot comprises the technical schemes that for the large workpiece which is difficultly accommodated by an ordinary heat treatment furnace, a circular rail which can move up and down is arranged at the periphery of the workpiece, and the industrial robot walks on the rail and can quickly arrive at any position of the periphery of the workpiece. A mechanical arm is provided with a burner for heating the large workpiece. At the same time, the temperature of the workpiece surface is sensed through a heat sensor, to a part with the lower temperature, the robot automatically moves to the part to heat the part automatically through the rail, the large workpiece temperature is kept in a constant range, and thus the process of heat treatment is completed. The method provided by the invention breaks the restriction of the traditional heat treatment device on the processed workpiece size, can achieve heat treatment of the large workpiece with relatively low cost, and is especially suitable for heat treatment of the large workpiece with fewer number and huge size.

Owner:安徽省库仑动力自动化科技有限公司

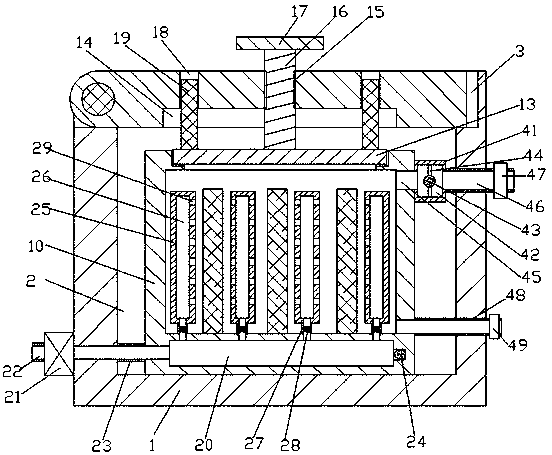

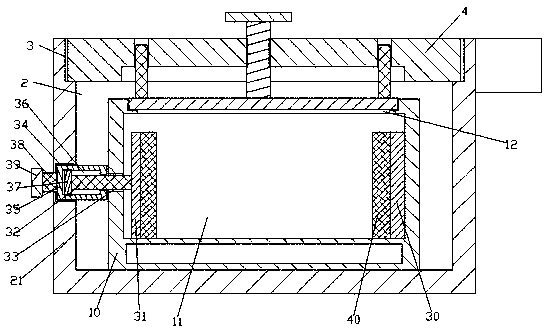

Tank-cover-free type forevacuum heat treatment furnace

PendingCN114410905AAchieve heat treatmentImprove uniformityMaintainance of heating chambersSolid state diffusion coatingExhaust valveEngineering

The invention belongs to the field of metallurgical equipment, and particularly relates to a tank-cover-free type forevacuum heat treatment furnace. Comprising a furnace bottom and a furnace cover detachably mounted on the furnace bottom, and a closed space is formed after the furnace cover covers the furnace bottom; the furnace bottom is composed of a substrate and a furnace lining which is arranged above the substrate and completely located within the range of the substrate, a heating body is arranged on the furnace lining, and a supporting bottom is further arranged on the periphery of the substrate; the furnace cover is composed of an outer cover and a lining, a heating piece is arranged on the inner side wall of the lining, and after the furnace cover is closed, the outer cover is buckled downwards to abut against the supporting bottom. The furnace cover is provided with an exhaust valve used for vacuumizing, and the exhaust valve is externally connected with a vacuum pump to work, so that vacuumizing treatment of the heat treatment furnace is achieved. According to the invention, large-batch plate heat treatment can be quickly and efficiently realized, the size of the furnace body can be adjusted according to actual use requirements, and heat treatment of materials with different specifications and sizes can be realized.

Owner:浙江精瑞工模具有限公司

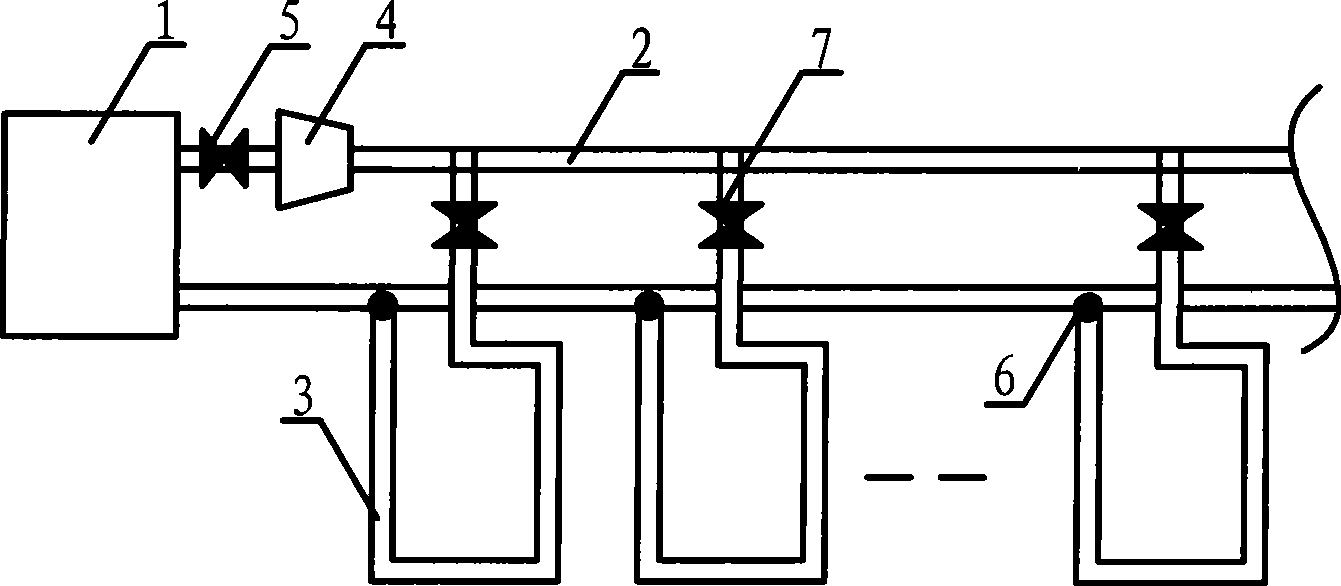

Tempering heat treatment equipment and technique for bainite high-strength finish-rolled thread steel bars

ActiveCN107385180AImprove heat treatment efficiencyRealize mass productionFurnace typesHeat treatment furnacesHydrogenRebar

The invention discloses tempering heat treatment equipment and technique for bainite high-strength finish-rolled thread steel bars and belongs to the technical field of metal heat treatment equipment and techniques. The tempering heat treatment equipment and technique are used for conducting batched tempering heat treatment on the bainite high-strength finish-rolled thread steel bars. According to the technical scheme, the tempering heat treatment equipment adopts the structure of a double-station trolley and a double-station heat preservation hood. Alternate loading heat treatment can be achieved through the double-station trolley, the heat preservation time in a heat treatment furnace within a certain temperature range can be shared by the double-station heat preservation hood, the heat treatment efficiency of the heat treatment furnace is greatly improved through the alternate heat treatment process, energy resources are saved, and batch production of products is achieved. According to the heat treatment technical method, on the basis that uniform biphase structures and reasonable strength and toughness matching of the bainite high-strength finish-rolled thread steel bars are guaranteed, and the residual stress of the structures and the sensitivity of a hydrogen-induced crack are reduced, small-batch production can be organized, heat treatment of short materials is achieved with a certain fixed length range, and the application is wide and flexible.

Owner:HEBEI IRON AND STEEL

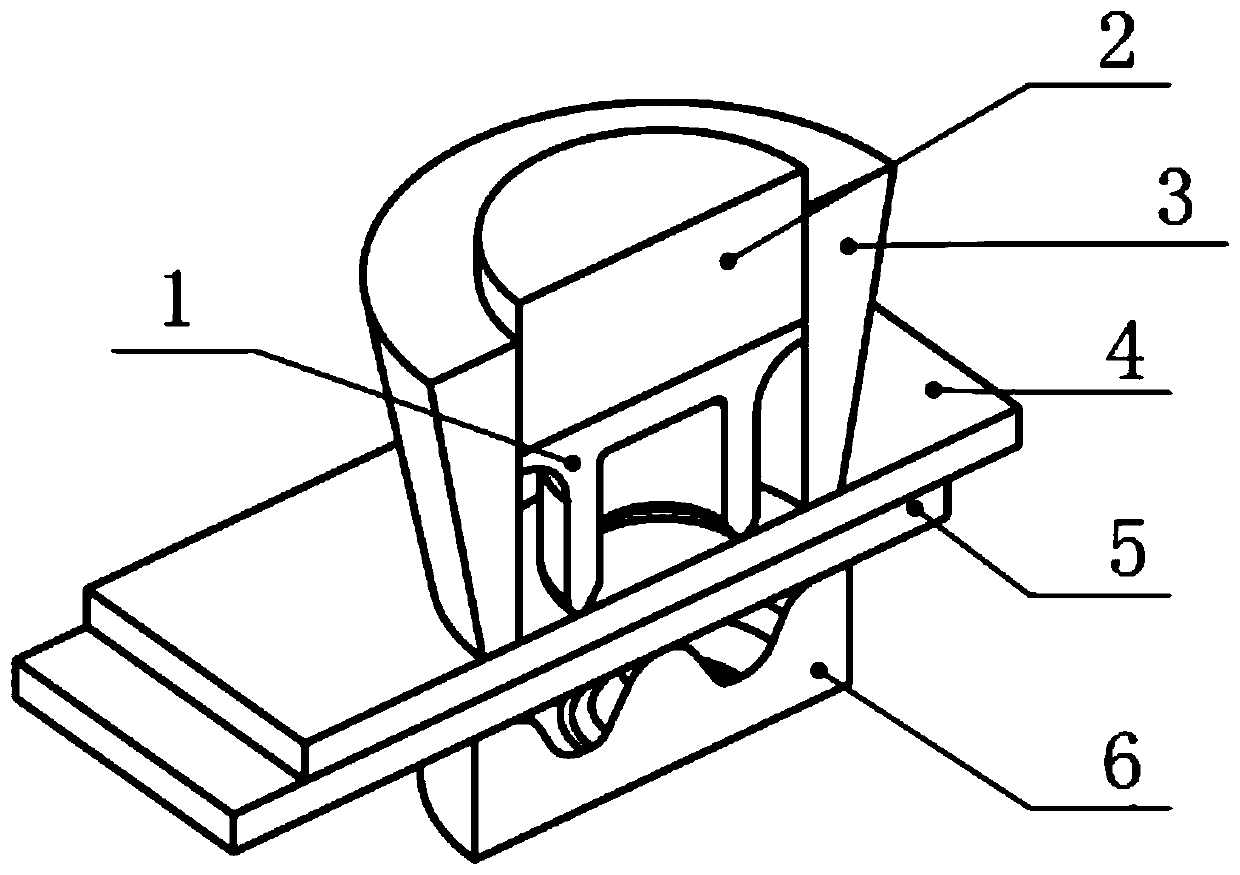

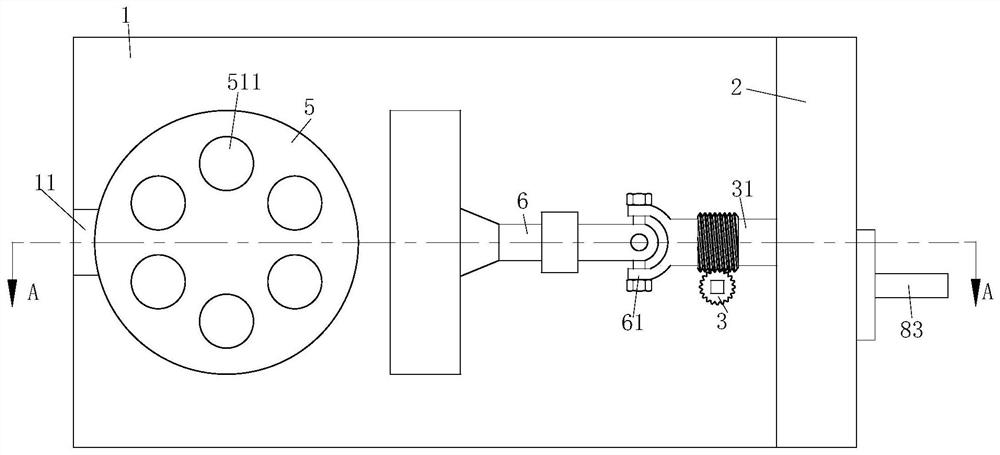

Stainless steel bar heat treatment equipment

ActiveCN113462875AReduce usageProtect environmentFurnace typesHeat treatment furnacesPhysicsElectric machinery

The invention relates to the technical field of heat treatment equipment, in particular to stainless steel bar heat treatment equipment. The equipment comprises a mounting plate, a first rotating arm and a second rotating arm, a groove is formed in one end of the mounting plate, the first rotating arm is rotationally connected into the groove, a side plate is fixed to the side, away from the groove, of the top end of the mounting plate, the second rotating arm is rotationally connected to the side plate, a motor box is fixed to the bottom end of the mounting plate, a motor is fixed to the side wall of the motor box through a fixing frame, an output shaft of the motor drives the first rotating arm to rotate through a connecting piece, spiral teeth are arranged on the outer surface of the output shaft, power is transmitted between the output shaft and the second rotating arm through a power transmission mechanism, and the power transmission mechanism is arranged in the motor box. The first rotating arm and the second rotating arm are driven by the motor to rotate, and heat treatment of a bent stainless steel bar is achieved in the rotating process of the first rotating arm and the second rotating arm which are specially designed.

Owner:十堰高周波科工贸有限公司

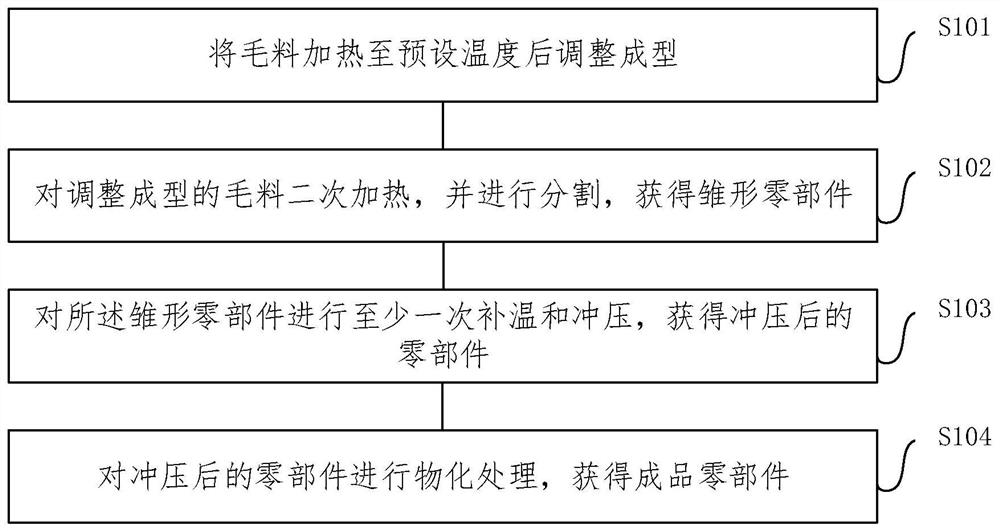

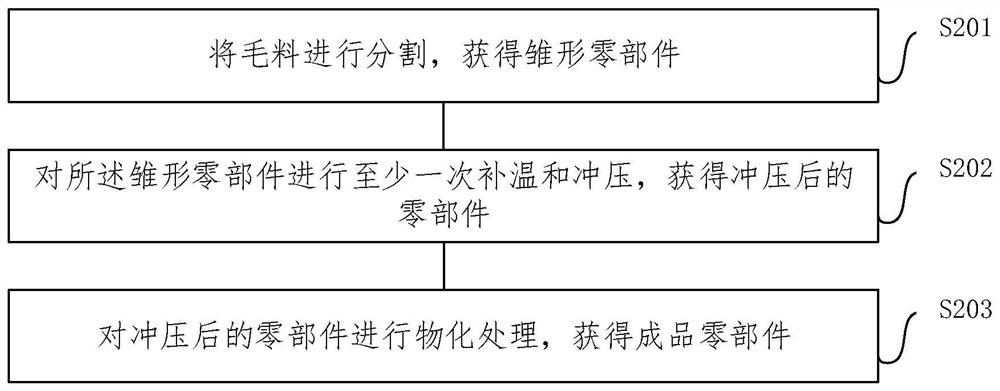

Method for preparing fitness equipment part through hot stamping process

The invention relates to the technical field of hot stamping, and in particular relates to a method for preparing a fitness equipment part through a hot stamping process. The method comprises the steps that: a blank is heated to a preset temperature and then adjusted to be formed; secondary heating is performed on the adjusted and formed blank; cutting is performed; a prototype part is obtained; the prototype part is subjected to at least one time of temperature supplementing and stamping, so that a stamped part is obtained; and the stamped part is subjected to physicochemical treatment, so that the finished part is obtained. According to the metal thermoplastic forming principle used in the invention, heat treatment of the blank is achieved while forming is performed; the forming performance of the material is improved; meanwhile, waste of the blank is reduced through stamping; resources are saved; environment friendliness and low carbon are achieved; and the manufacturing cost can be reduced.

Owner:刘平

Processing method of engine cylinder

InactiveCN112388258AEasy to collectAvoid affecting productionFurnace typesFeeding apparatusMotronicPower unit

The invention discloses a processing method of an engine cylinder. A processing mechanism of the engine cylinder comprises a chassis, an angle adjusting unit, a clamping unit, a height adjusting unit,a boring power unit, an adjustable boring cutter unit and a heat treatment unit; the clamping unit is installed at the top of the chassis through the angle adjusting unit; four mounting plates are arranged on the side face of the chassis at equal angles; the boring power unit is installed on the installing plate on the left side through the height adjusting unit; the adjustable boring cutter unitis installed at the bottom of the boring power unit, and the heat treatment unit is installed on the installing plate on the rear side; and the heat treatment unit comprises a heat treatment equipment box, a baffle, an L-shaped door plate, equipment box legs, an electric push rod, a supporting rod, an end rod, a through hole, a door plate shaft, a push-pull block, a hinged support, a heat conduction circular plate, a circular blind groove and a heating wire. The production steps of the engine cylinder can be continuously carried out, the production coherence degree is improved, the productionefficiency is effectively improved, manual participation is reduced, and the labor cost is reduced.

Owner:刘广芝

Martensitic stainless steel with high Mn content

The invention provides a martensitic stainless steel with high Mn content, which comprises the following chemical compositions in percentage by weight: 0.03-0.1% of C, 0.20-0.80% of Si, 1.2-3.0% of Mn, 12-14% of Cr, 0.008-0.03% of N, the balance Fe and unavoidable impurities. By improving Mn content in steel, adding proper amount of N and utilizing Mn and N to strengthen, the invention improves the strength and the rigidity of the martensitic stainless steel. Compared with other alloys, the cost of Mn is lower and the resource is richer. The low-carbon martensitic stainless steel after being strengthened by utilizing Mn and N only needs quenching heat treatment to obtain martensitic stainless steel materials with favorable strength, tenacity and corrosion resistance, and has more convenient use and superior performance compared with commonly used tempered martensitic stainless steel.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

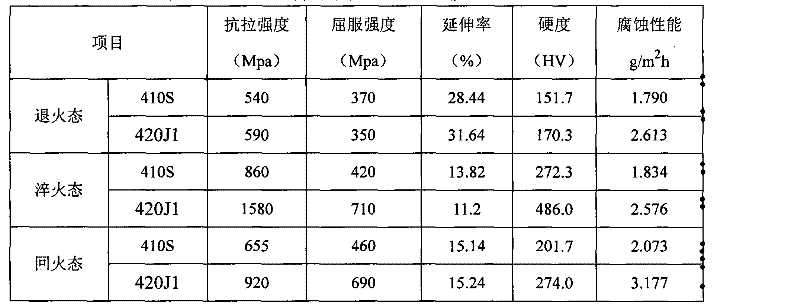

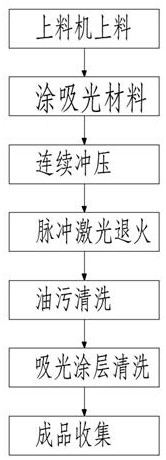

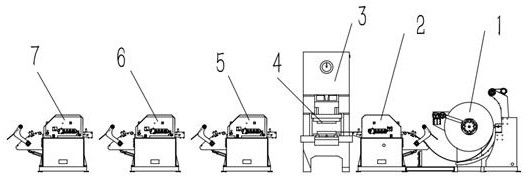

A kind of processing method of spring sheet for tuning fork type crystal resonator

ActiveCN112139360BQuick washNo pollution in the processShaping toolsLiquid surface applicatorsPunchingPhysical chemistry

The invention discloses a processing method for a spring piece used in a tuning fork type crystal resonator. After coating the surface of a strip-shaped zinc-nickel-nickel copper with a light-absorbing coating, a progressive die is used for continuous punching and forming, and a laser is used for annealing treatment, and finally a cavitation jet is used Wash to obtain the spring sheet for resistance welding. The beneficial effects of the invention are: to realize the collinear processing of each process in the production and processing of the spring sheet for tuning fork type crystal packaging, reduce the turnover process, and use the new heat treatment and cleaning method to achieve the purpose of energy saving and environmental protection.

Owner:日照皓诚电子科技有限公司

Pin neck receptacle for hubs, in particular in rolling mills

ActiveCN105636714BReduce hardnessExtended service lifeCouplings for rigid shaftsRolling mill drivesEngineeringRolling mill

The invention relates to a pin receiving portion (7) for a hub for receiving the pin (6) of a connection unit, in particular of a roller (1), said pin receiving portion (7) having a main part (8) with an opening (9), which is at least partly lined with at least one wear plate (10), for inserting the pin (6). The wear plate (10) has a front surface (10.1) for bearing on the pin (6), said front surface delimiting the opening for the pin (6), and the wear plate (10) has a rear surface (10.2) which faces away from the front surface (10.1) and which rests against a receiving surface (8.1) of the main part (8) at least temporarily. The wear plate (10) has a lower hardness on the wear plate rear surface (10.2) than the receiving surface (8.1) of the main part (8).

Owner:VOITH PATENT GMBH

A continuous heat treatment device and mgb 2 Superconducting wire/strip heat treatment method

ActiveCN107799235BReduce temperature differenceRapid heating and coolingApparatus for heat treatmentSuperconductor device manufacture/treatmentThermodynamicsElectric machine

The invention discloses a continuous heat treatment device, which uses a motor to drive the take-up wheel to rotate through a transmission belt, so as to drive the lead wire to pull the material to be heat treated to pass through the heating zone and cooling zone of the heat treatment device in sequence, and perform dynamic continuous heat treatment and cooling treatment. One step realizes the rapid temperature rise and fall of the material, reduces the temperature difference at different positions of the material during the heat treatment process, improves the quality of the heat treatment, and expands the application range of the device. The invention also discloses a MgB 2 Method for heat treatment of superconducting wire / strip, the method will MgB 2 The superconducting wire / strip is placed in the above-mentioned continuous heat treatment device, and then the heat treatment of continuous rapid temperature rise and fall is carried out under the protection of an inert gas, which avoids the MgB 2 The superconducting core wire generates non-superconducting impurity phases and MgB 2 The phenomenon of sticking between wires / strips is flexible and controllable, convenient and efficient.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

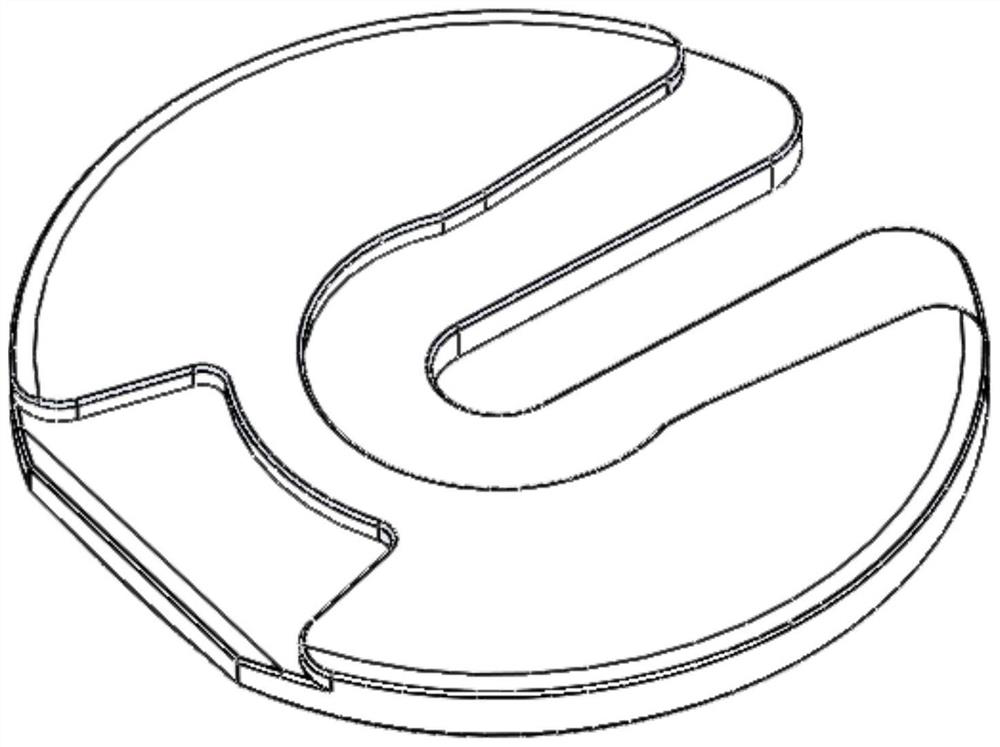

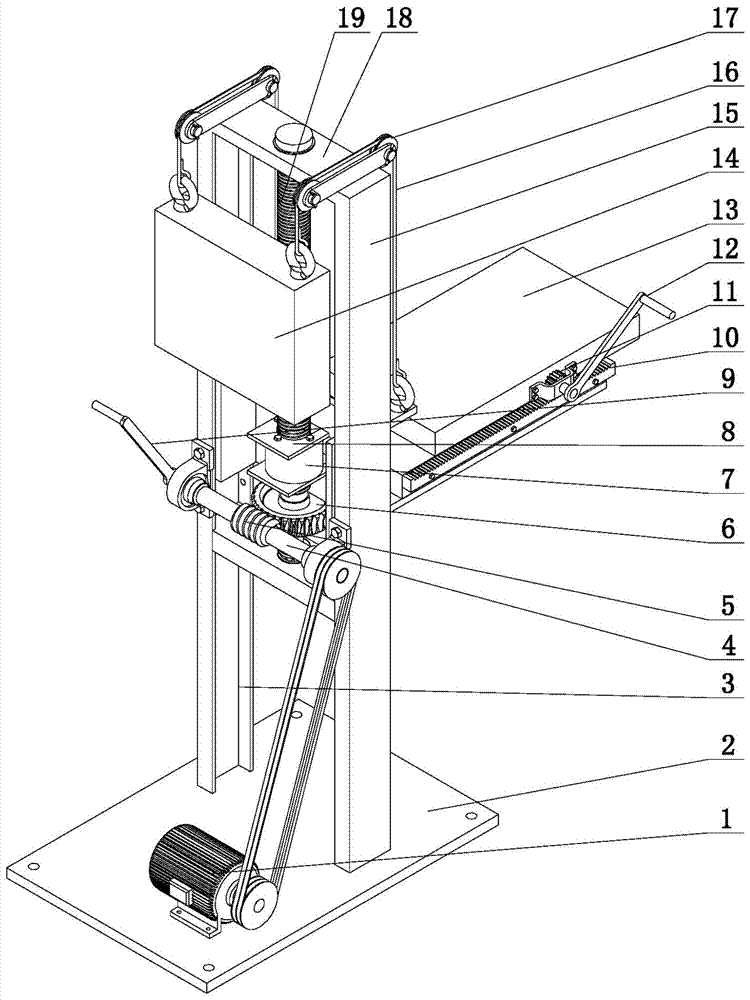

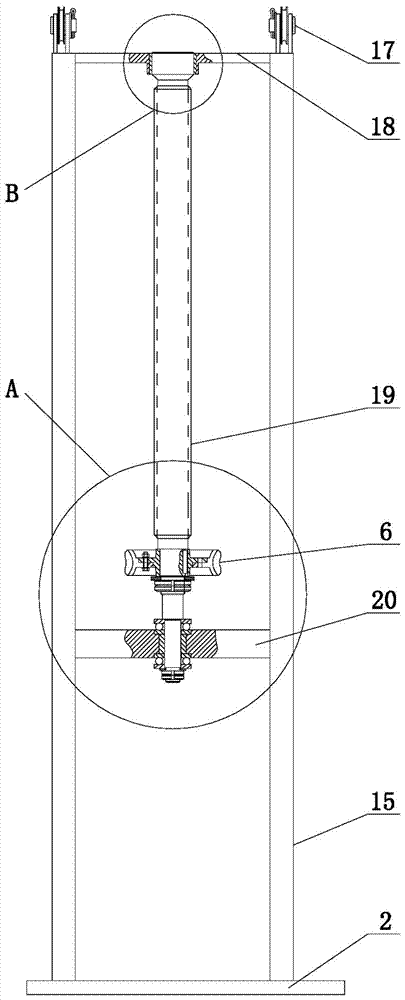

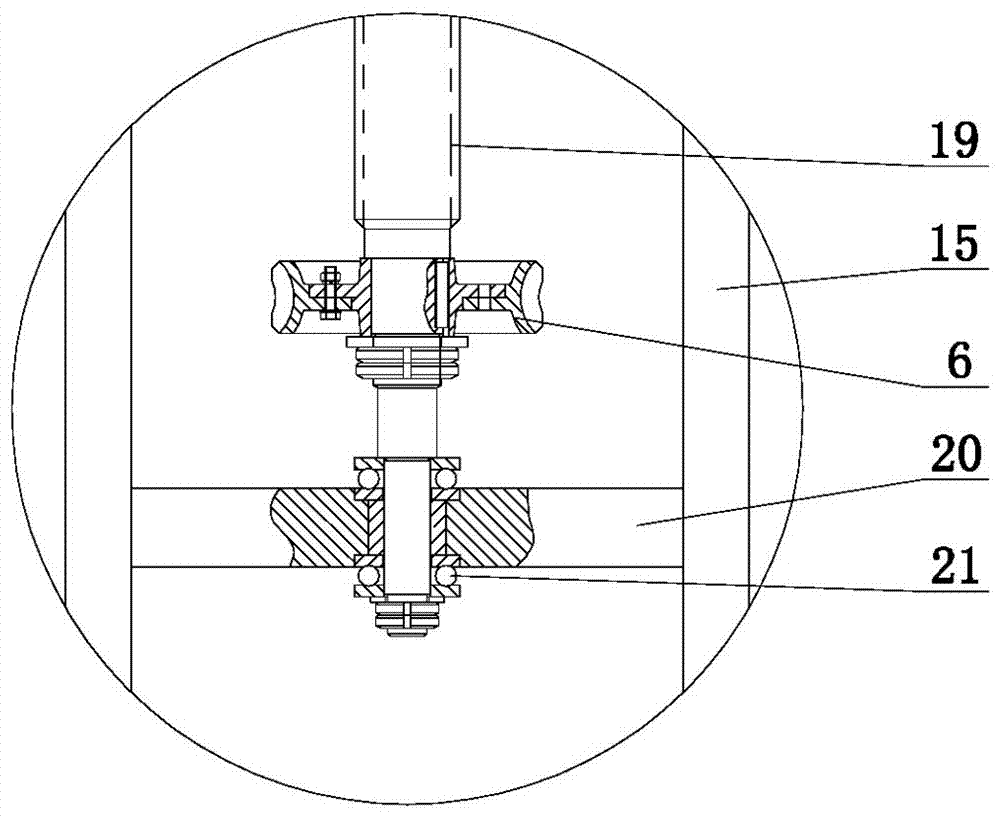

A simple lifting platform

A simple lifting platform belongs to the technical field of product heat treatment platforms, and in particular relates to a simple lifting platform for product heat treatment. The invention provides a simple lifting platform which is simple in structure, stable and reliable, and can realize vertical and lateral movement. The invention includes a base, on which two groove-shaped columns are arranged, and a crossbeam is arranged between the top ends of the two groove-shaped columns. A slider matching the groove is provided; the slider is connected to the vertical side of the same L-shaped lifting frame; a lead screw is arranged under the beam, and a screw nut is arranged on the lead screw, and a connecting screw is arranged on the screw nut. frame, the vertical side of the L-shaped lifting frame is provided with a connecting groove that matches the connecting frame; the horizontal side of the lifting frame is provided with a horizontal slide plate, and the horizontal slide plate is provided with a rotating gear; the lifting frame A toothed rack cooperating with the rotating gear is arranged on the horizontal side of the frame.

Owner:NFC (SHENYANG) METALLURGICAL MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com