Forming method of L-shaped ring type products

A product, L-shaped technology, applied in the field of forming L-shaped ring products, can solve the problems of large blank weight, large cutting volume, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

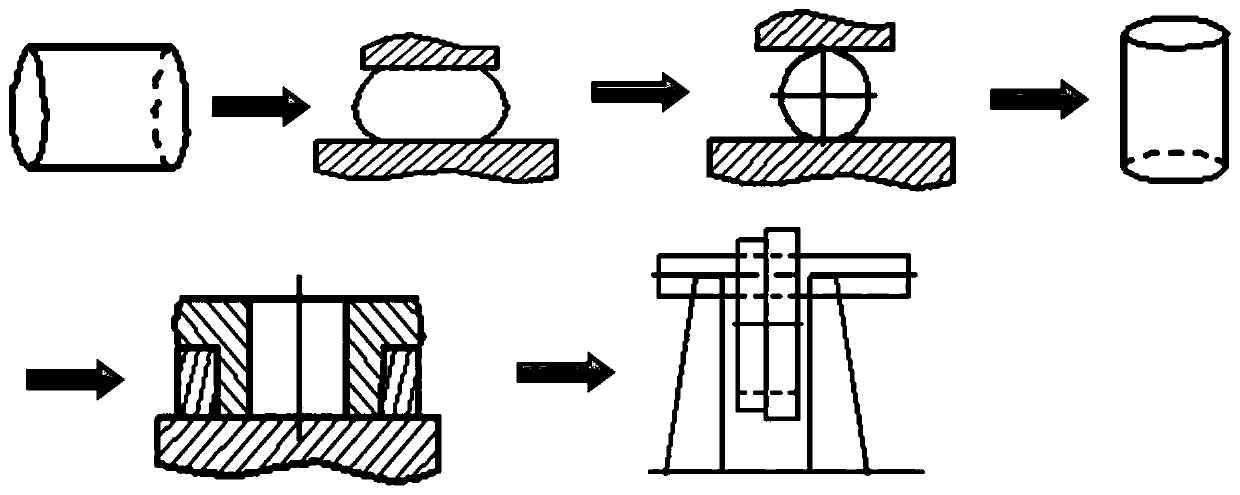

[0014] For the molding method of L-ring products, see figure 1 , figure 2 , the specific process is as follows: blanking - upsetting - drawing and lengthening - blanking - pre-forming - horse frame reaming + trimming and forming, the specific steps are as follows: loading and unloading from raw materials, and then the obtained blanking Carry out upsetting, and then lengthen to obtain the corresponding blank, and then place the blank in the corresponding drain pan for upsetting, punching, and pre-forming. The formed blank has an L-shaped section, and then the L-shaped blank is placed. The reaming correction is carried out on the horse frame to form the designed L-ring products.

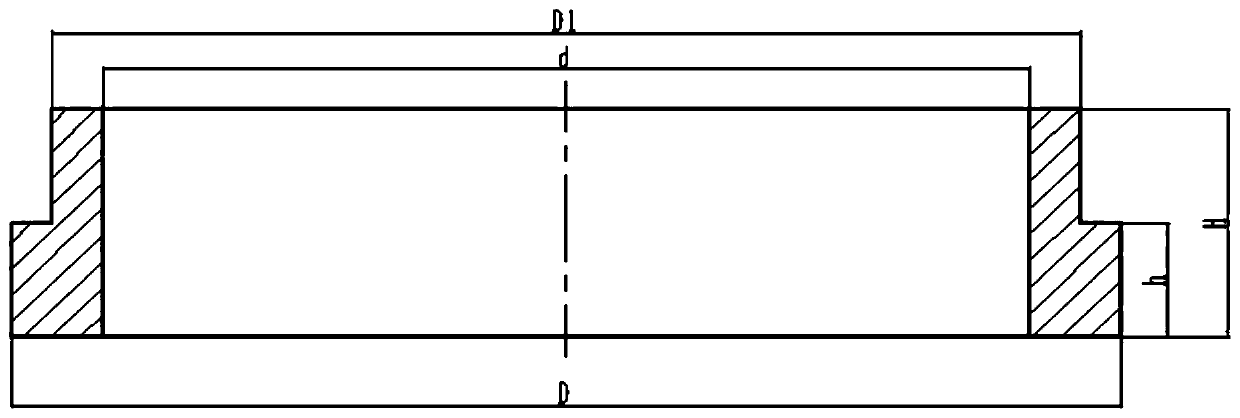

[0015] The final molding state of L-ring products is obtained by reaming, in which the diameter of the center hole must be greater than or equal to half the outer diameter of the product to ensure the accuracy of molding;

[0016] The shape of the blank preformed by upsetting and punching through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com