Smelting low-temperature solid-solution heat treatment method for die-casting aluminum alloy

A technology of solid solution heat treatment and casting aluminum alloy, which is applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., and can solve problems such as limiting the application range, deformation, and surface bubbling of aluminum alloy die castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with accompanying drawing:

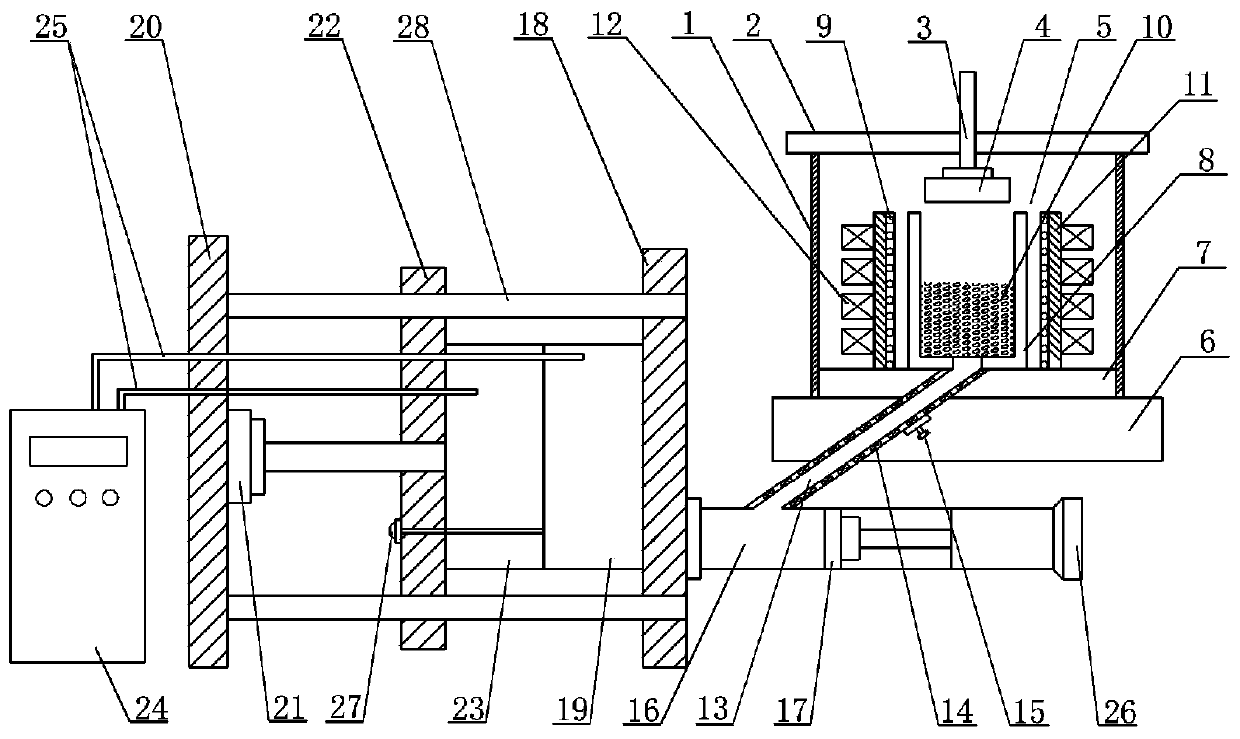

[0059] figure 1 As shown in the figure, the smelting and die-casting state diagram of die-casting aluminum alloy, the position and connection relationship of each part are correct, the installation is firm, and the operation is performed in sequence.

[0060] The amount of chemical substances used in preparation and smelting is determined according to a preset range, with grams and milliliters as measurement units.

[0061] The smelting of die-casting aluminum alloy is carried out in an electromagnetic stirring melting furnace, which is completed in the process of heating, smelting, heat preservation, electromagnetic stirring, and compaction; the pressing of die-casting aluminum alloy is carried out in a die-casting machine. Completed during the pressure holding process;

[0062]Above the electromagnetic stirring melting furnace 1 is the furnace cover 2, and the hydraulic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com