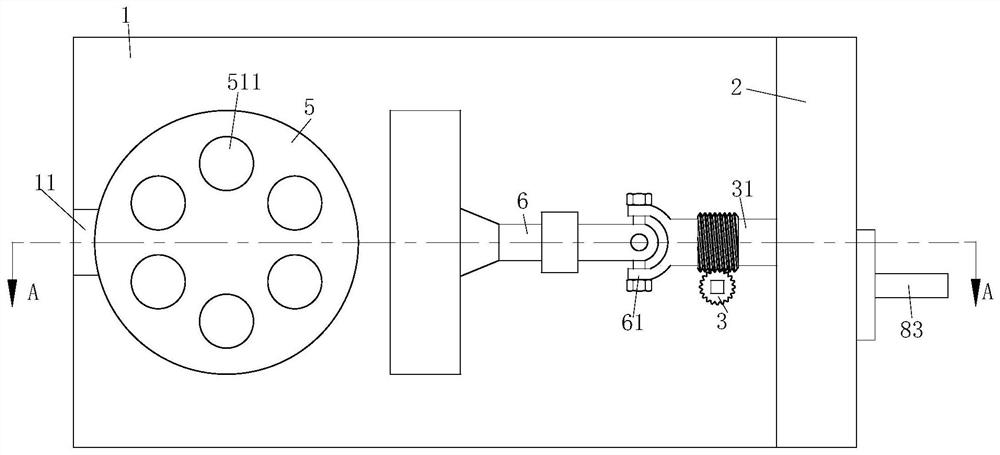

Stainless steel bar heat treatment equipment

A technology for heat treatment equipment and stainless steel bars, applied in heat treatment equipment, heat treatment furnaces, furnaces, etc., can solve problems such as difficult processing of bars, and achieve the effects of reducing emissions, protecting the environment, and reducing use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

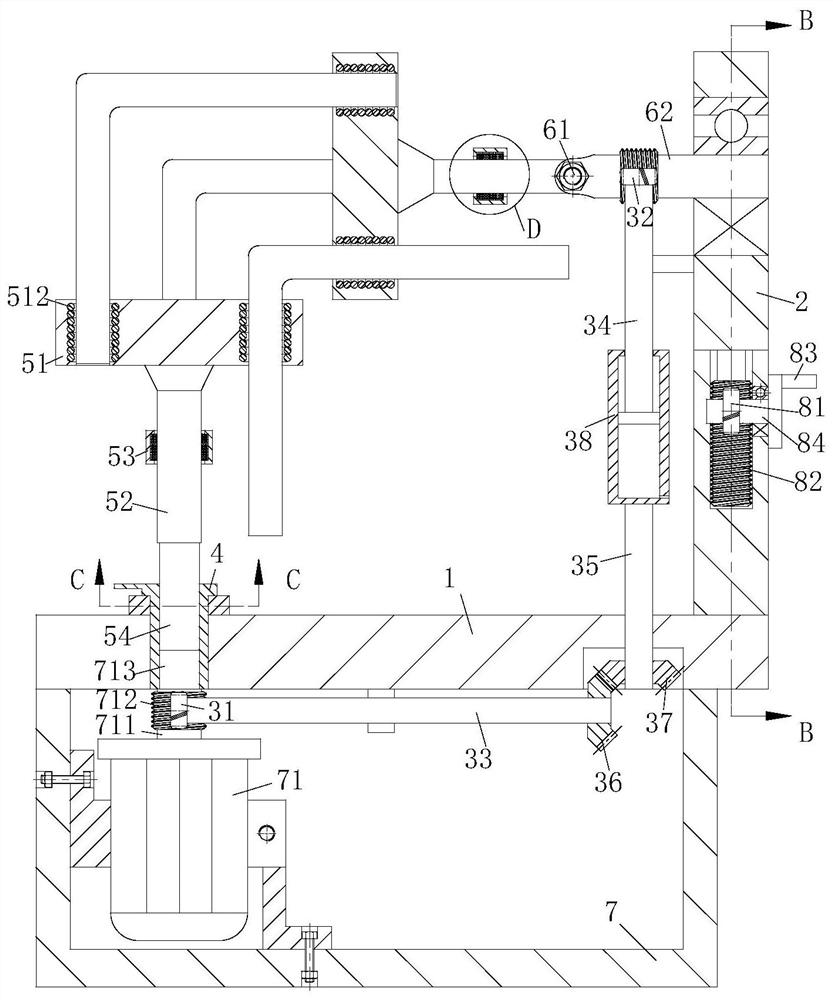

[0043] As a specific embodiment of the present invention, the brush plate 53 includes an inner ring 531 and an outer ring 532, the inner ring 531 is in interference fit with the connecting rod 52, and a plurality of copper rings are embedded in the inner ring 531 533, the copper ring 533 is electrically connected to the coil 512, the outer surface of the inner ring 531 is rotatably connected with an outer ring 532, and a plurality of copper sheets 534 are fixed on the side of the outer ring 532 close to the inner ring 531, a copper The sheet 534 is in contact with a copper ring 533, and the copper sheet 534 is electrically connected to an external power source. When the inner ring 531 and the outer ring 532 rotate relative to each other, the present invention contacts the copper ring 533 through the copper sheet 534 to realize the connection between the coil 512 and the outer ring 532. The external power source is always electrically connected.

[0044] As a specific embodimen...

Embodiment approach

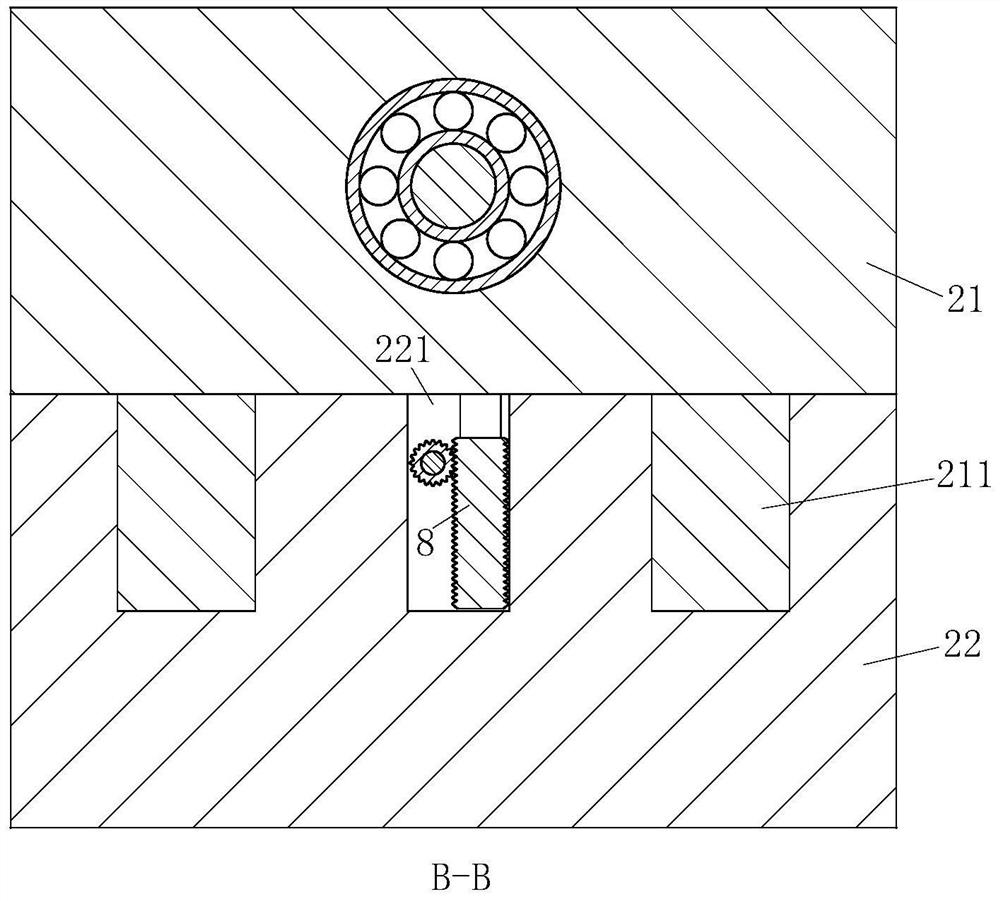

[0045] As a specific embodiment of the present invention, the side plate 2 includes a moving part 21 and a fixed part 22, the second rotating arm 6 is rotatably connected to the moving part 21, and the bottom end of the moving part 21 is fixed with a lift Mechanism 8 and a plurality of inserting blocks 211, the top of the fixed part 22 is provided with a plurality of slots 221, the lifting mechanism 8 and the inserting blocks 211 are arranged in the slots 221, the present invention drives the moving part 21 through the lifting mechanism 8 The insert block 211 at the bottom slides in the slot 221, thereby changing the height of the second rotating arm 6 on the moving part 21, and then cooperating with the universal coupling 61 on the second rotating arm 6 to change the height of the second rotating arm 6 The angle with the first rotating arm 5 realizes heat treatment of stainless steel rods with different bending angles.

[0046] As a specific embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com