Tempering heat treatment equipment and technique for bainite high-strength finish-rolled thread steel bars

A technology for finishing thread rolling and processing equipment, applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., can solve the problems of strict production process control requirements, large residual stress, easy occurrence of brittle fracture, etc., and reduce the sensitivity of hydrogen-induced cracks. , Reduce the residual stress of the structure, the effect of uniform strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

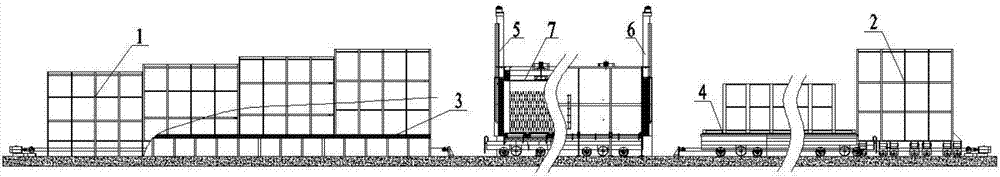

[0021] The tempering heat treatment equipment for bainite high-strength finish-rolled threaded steel bars of the present invention includes a heat treatment furnace 7, a trolley, and a heat preservation cover, and the trolley and the heat preservation cover are located on the track leading into the heat treatment furnace 7. The trolley and the heat preservation cover are two groups, namely 1# trolley 3, 2# trolley 4 and 1# heat preservation cover 1, 2# heat preservation cover 2.

[0022] As shown in the figure, 1# trolley 3 and 2# trolley 4 are respectively located on both sides of heat treatment furnace 7, and there are respectively 1# heat treatment furnace door 5, 2# heat treatment furnace door 6 and 1# trolley 3 on both sides of heat treatment furnace 7 , 2# trolley 4 is relative.

[0023] As shown in the figure, 1# heat preservation cover 1 and 2# heat preservation cover 2 are respectively located on the outside of 1# trolley 3 and 2# trolley 4, and the two sets of trolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com