High-strength and high-plasticity heat-resistant and fire-resistant magnesium alloy and manufacturing method thereof

A manufacturing method and high plasticity technology, applied in the field of high-strength, high-plasticity, heat-resistant and flame-resistant magnesium alloy and its manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 1-3

[0066] Table 1 lists the mass percentages of various chemical elements in the high-strength, high-ductility, heat-resistant and flame-resistant magnesium alloys of Examples 1-6 and the conventional magnesium alloys of Comparative Examples 1-3.

[0067] Table 1. (wt%, the balance is Mg and other unavoidable impurities)

[0068] Al Ca mn sn Zn Si Sr Example 1 2.5 2.0 0.25 1.0 2.5 0.15 0.5 Example 2 1.5 0.5 0.4 2.5 2.2 0.1 0.1 Example 3 0.5 1.0 0.15 1.5 2.0 0.3 0.2 Example 4 1.0 1.5 0.2 1.0 1.0 0.5 0.4 Example 5 2.2 0.8 0.5 2.0 1.5 0.4 0.3 Example 6 0.8 1.9 0.1 3.0 0.5 0.2 0.25 Comparative example 1 0.2

2.5

0.05

0.5

0.3

0.2 0.05

Comparative example 2 3.0

0.1

0.6

6

3

0.2 0.8

Comparative example 3 0.8 1.9 0.1 3.0 0.5 0.2 0.25

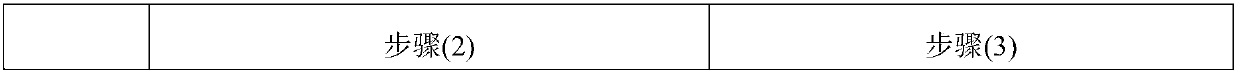

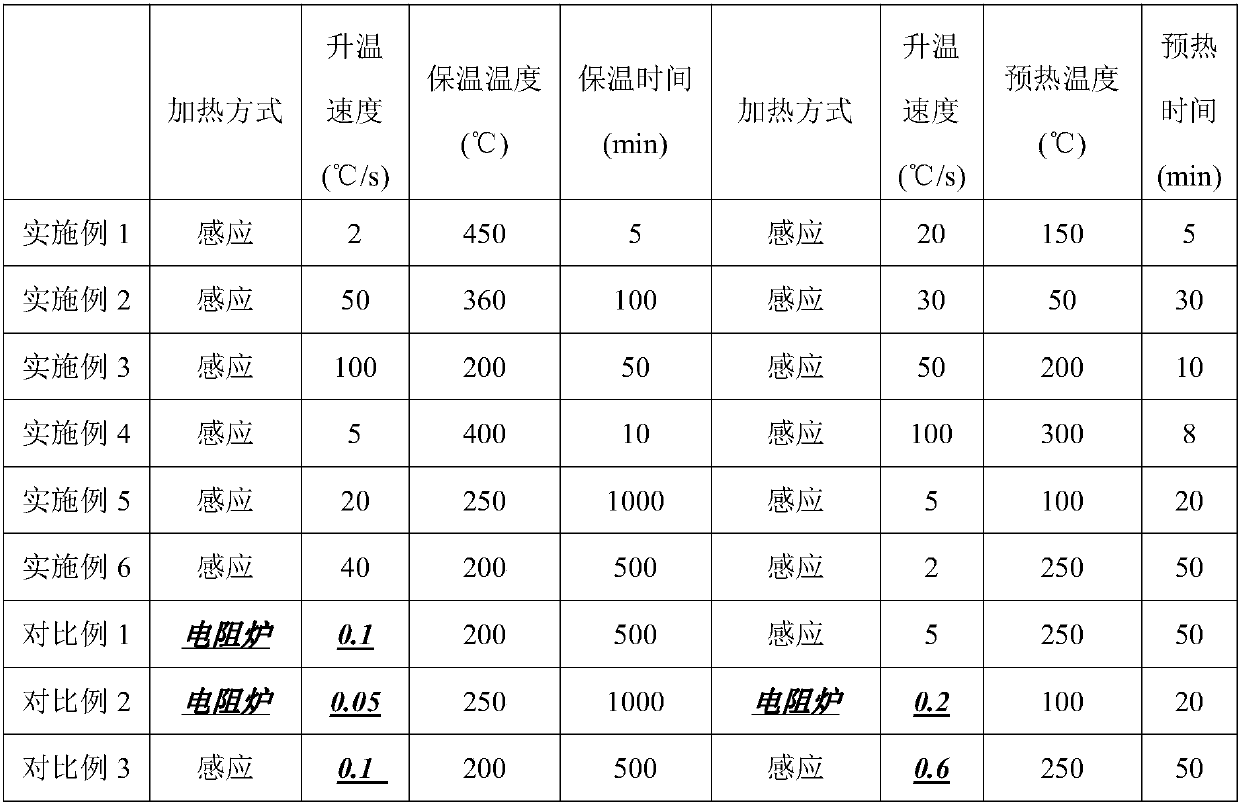

[0069] The manufacturing method of the high-strength, high-plasticity, heat-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com