Method for inhibiting cracks of aluminum alloy self-piercing rivet joint

A technology for riveting joints and aluminum alloys, which is applied in the field of suppressing cracks in aluminum alloy self-piercing riveting joints, can solve the problems of high heating cost, easy cracking, poor operability, etc., achieve reliable macro cracks and micro cracks, and improve plastic deformation capacity , the effect of stabilizing shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

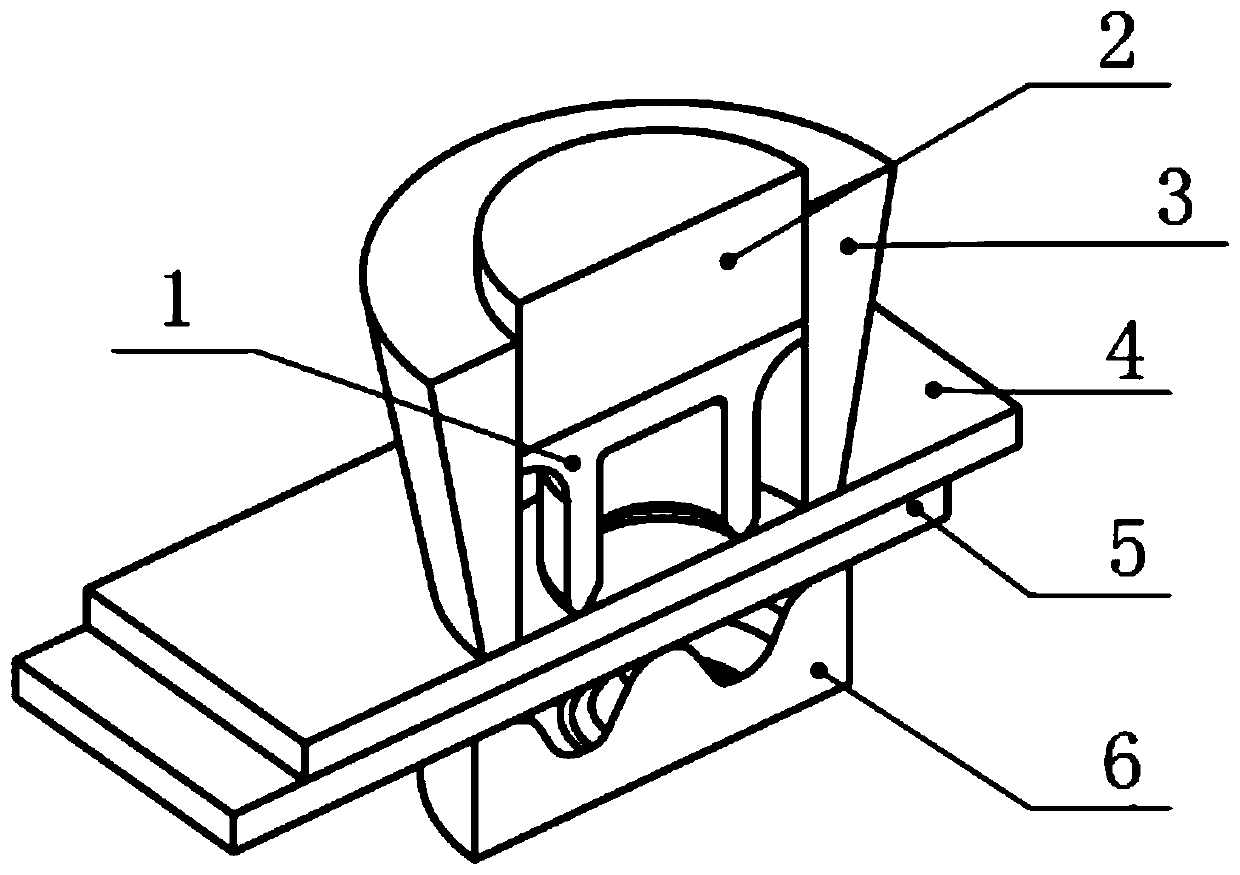

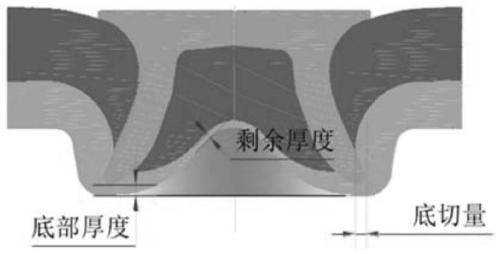

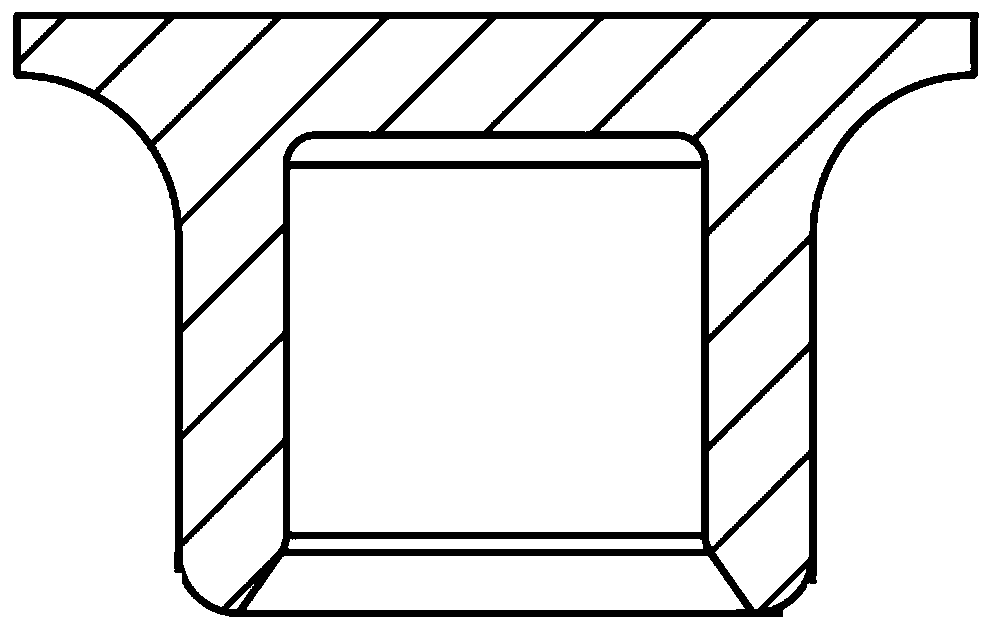

[0067] Take the 0.65mm 340 low carbon steel plate and the AlSi10Mg cast aluminum parts with the joint part of 2.5mm for SPR lap joint on the steel and under the aluminum. Among them, the diameter of the leg of the rivet is Φ5.3mm and the length is 5mm, and a higher riveting speed is adopted. 300mm / s, the riveting equipment adopts Henrob electric servo self-piercing riveting equipment. Details of the riveting process can be found in figure 1 , that is, the upper plate 4 (that is, the steel plate) and the lower plate 5 (that is, the cast aluminum part) are laminated and placed on the die 6, and then the riveting position on the upper surface of the laminate of the upper plate 4 and the lower plate 5 is set The blank holder 3 and the punch 2 punch the rivet 1 to realize riveting. The structure of the rivet see image 3 Shown, the shape of the die see Figure 4 shown.

[0068] When the pre-heat treatment before riveting is not carried out, it is found that the lower surface o...

Embodiment 2

[0080] Compared with Example 1, most of them are the same, except that in this example, the process condition of the pre-heating treatment is: heating at a temperature of 530° C. and keeping it warm for 12 hours.

Embodiment 3

[0082] Compared with Example 1, most of them are the same, except that in this example, the process condition of the pre-heating treatment is: heating at a temperature of 550° C. and keeping it warm for 3 hours.

[0083] In the above embodiments, the material of the cast aluminum parts used can be replaced as required by "Al-Si-Mg three-phase aluminum alloy, the melting range is 570-590°C, the tensile strength is ≥ 100Mpa, and the thickness is 1.5mm-3.0 mm” in other arbitrary forms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com