Iron-base soft magnetic powder for dust cores, manufacturing method thereof, and dust core

A powder magnetic core and manufacturing method technology, applied in the direction of inductance/transformer/magnet manufacturing, inorganic material magnetism, transformer/inductance parts, etc., can solve the problems of high-density pigments, improve heat resistance, The effect of low iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

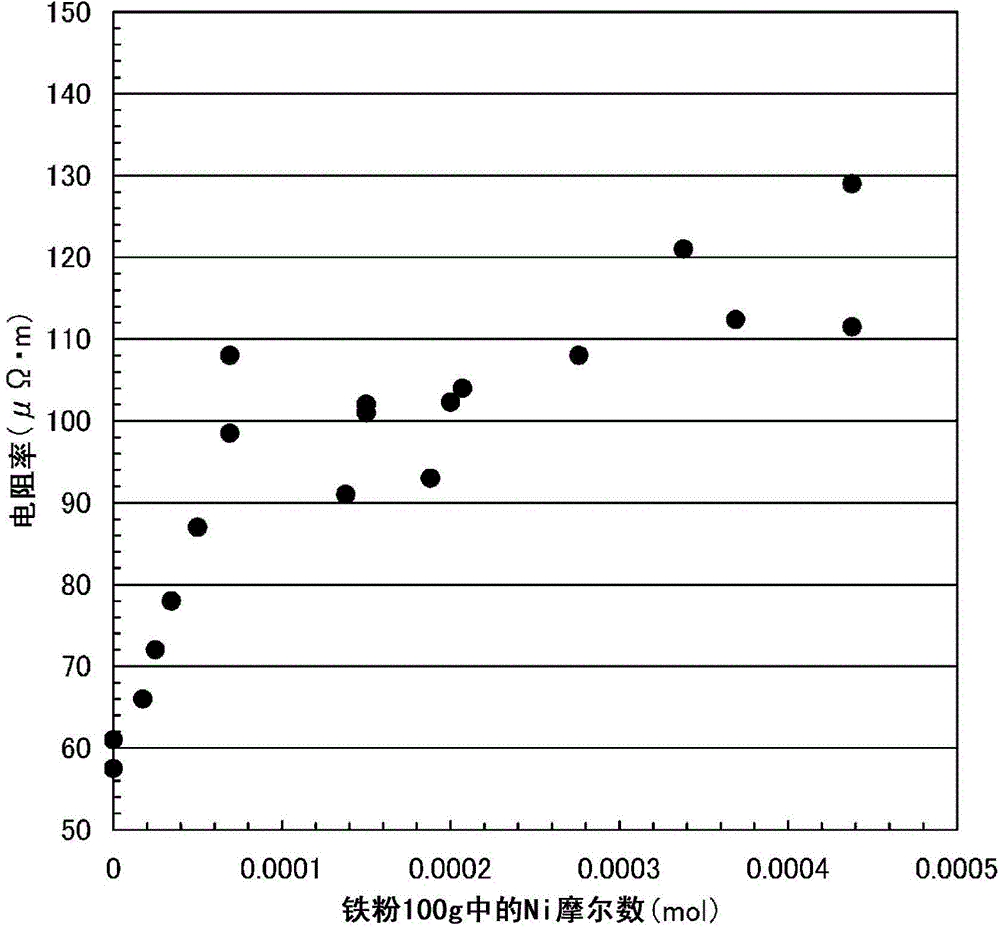

experiment example 1~12、16~20

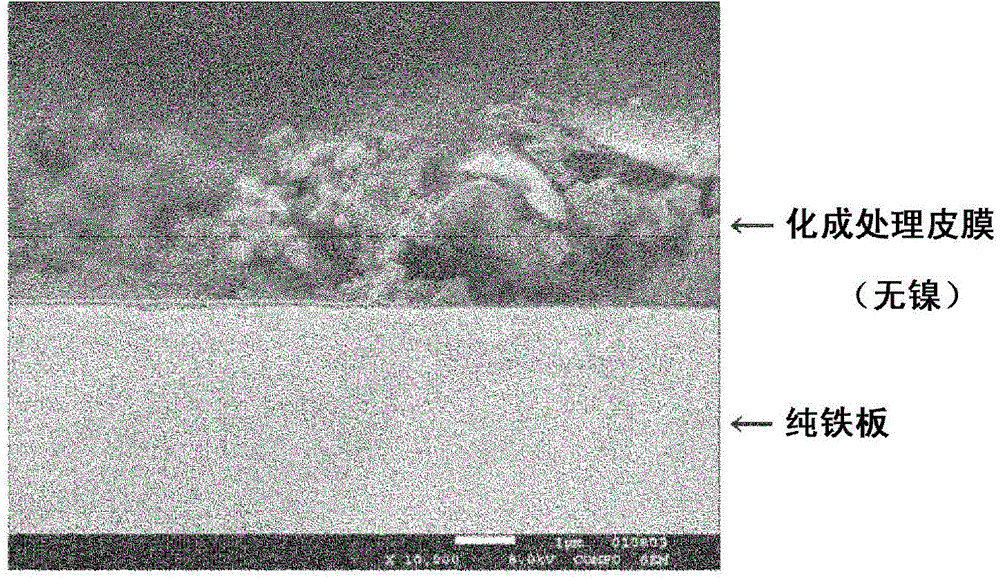

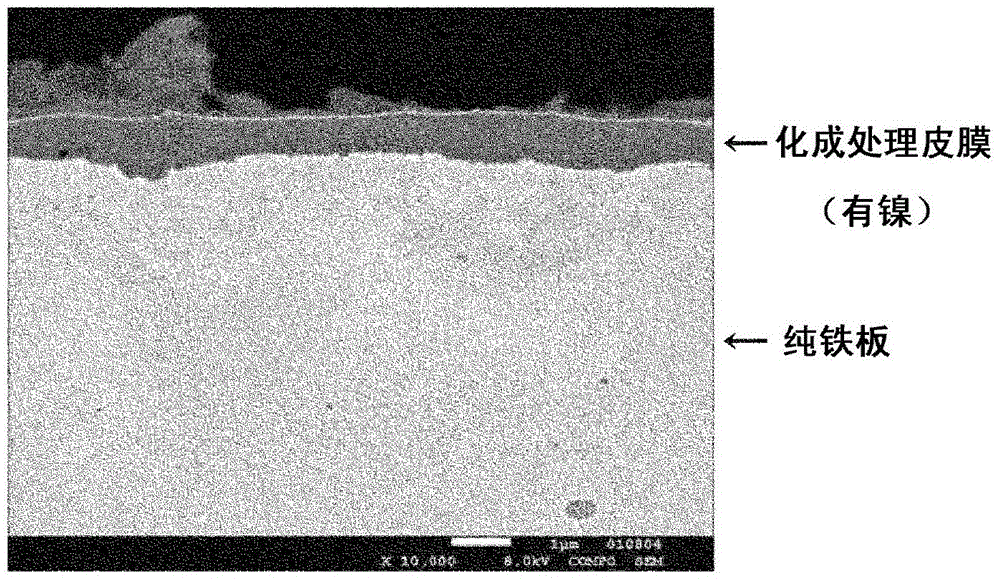

[0084] (formation of phosphoric acid-based chemical film)

[0085] As the soft magnetic powder, pure iron powder (manufactured by Kobe Steel Works; ATMEL (registered trademark) ML35N; average particle diameter 140 μm; iron-based soft magnetic powder containing 0% by mass of aluminum element and nickel element) was used.

[0086] In addition, as the phosphoric acid solution, the following treatment solution was used: in the water: 50 parts, KH 2 PO 4 : 35 parts, H 3 PO 4 : 10 copies, (NH 2 Oh) 2 ·H 2 PO 4 : Into 100ml of matrix drug A obtained by mixing 10 parts, mix a compound containing nickel element (nickel pyrophosphate and / or nickel nitrate) with the formulation shown in Table 1, and further dilute to 10 times with water to obtain the treatment solution 1~ 12. 16 to 20 (the content of the aluminum element is 0% by mass). It should be noted that Experimental Example 1 is an example in which the compound containing nickel element is not mixed with the base drug A. ...

experiment example 13~15、21

[0098] In Experimental Example 1, as the phosphoric acid solution, instead of the treatment liquid 1, the following phosphoric acid solution was used in water: 50 parts, NaH2 PO 4 : 30 parts, H 3 PO 4 : 10 parts, (NH 2 Oh) 2 ·H 2 SO 4 : In 100 parts of mixed base agent B100ml, mix nickel pyrophosphate and / or nickel nitrate with the formula shown in Table 1, and further dilute to 10 times with water to obtain the treatment solution 13~15, 21 (aluminum element Except that the content rate was 0% by mass), the same operation as in Experimental Example 1 was carried out to produce green compacts 13 to 15 and 21 . In addition, Experimental Example 13 is an example in which no nickel pyrophosphate and / or nickel nitrate was mixed with the base drug B.

[0099] Then, the powder compacts 13 to 15 were annealed at 600° C. for 30 minutes in a nitrogen atmosphere to produce the powder magnetic cores 13 to 15 . The rate of temperature increase when heating to 600°C was set to about ...

experiment example 22

[0101] In Experimental Example 1, as the phosphoric acid solution, the following phosphoric acid solution was used instead of the treatment liquid 1 in water: 50 parts, H 3 PO 4 : 40 parts, (NH 2 Oh) 2 ·H 2 SO 4 : In 100 ml of the matrix agent C100 ml obtained by mixing, nickel pyrophosphate was mixed with the formulation shown in Table 1, and further diluted with water to 10 times the obtained treatment solution 22 (the content rate of aluminum element was 0 mass %), except Otherwise, the same operations as in Experimental Example 1 were carried out to produce a green compact 22 . Next, the powder compact 22 was heat-treated at 400° C. for 120 minutes in the air atmosphere, and then annealed at 550° C. for 30 minutes to manufacture the powder magnetic core 22 . The temperature increase rate at the time of heating from 400°C to 550°C was set to about 10°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com