Tank-cover-free type forevacuum heat treatment furnace

A heat treatment furnace and pre-vacuum technology, applied in heat treatment furnaces, heat treatment baths, bell-type furnaces, etc., can solve the problems of low efficiency, poor effect, difficulty in dealing with large-scale, large-volume material heat treatment, etc., to improve uniformity The effect of ensuring the effect of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

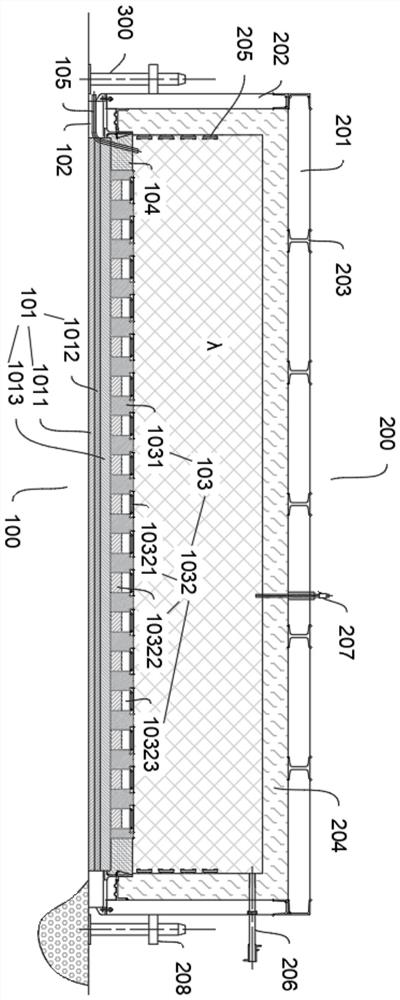

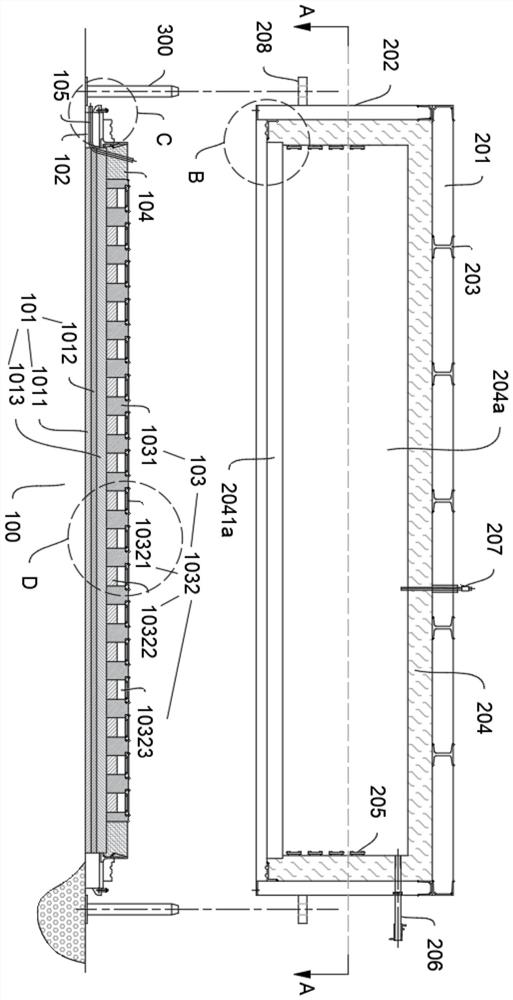

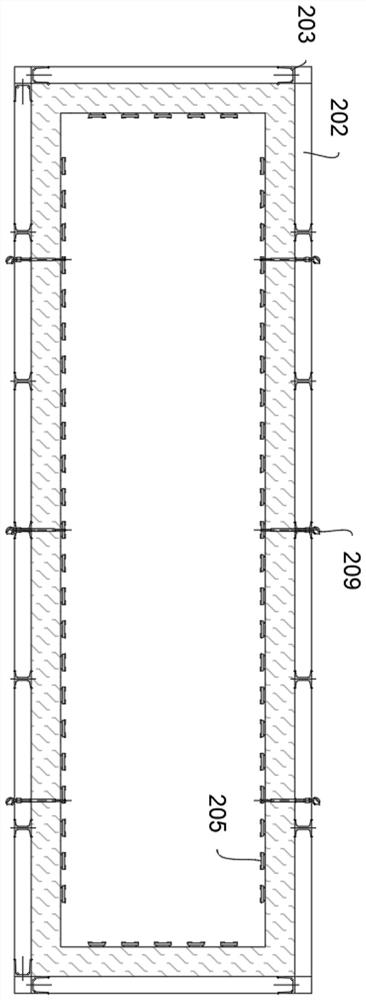

[0057] a kind of like figure 1 , figure 2 and image 3 The shown tankless cover type pre-vacuum heat treatment furnace specifically includes:

[0058] The furnace bottom 100 and the furnace cover 200 are two parts. The furnace cover 200 is detachably covered on the upper end of the furnace bottom 100 to form a closed space λ, and the closed space λ is used to store metal or alloy workpieces and plates to be heat treated;

[0059] The furnace bottom 100 includes two parts, a substrate 101 and a furnace lining 103. The furnace lining 103 is fixed on the upper end of the substrate 101 and the edge of the substrate 101 extends beyond the edge of the furnace lining 103, that is, the vertical projection of the furnace lining 103 falls into the substrate completely. 101, forming an overall gradient structure;

[0060]The outer periphery of the edge of the substrate 101 is fixedly provided with a support base 102, and the support base 102 is used to receive and install the furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com