Method for preparing fitness equipment part through hot stamping process

A technology for fitness equipment and components, which is applied in the field of hot stamping process to prepare fitness equipment components, which can solve the problems of wasting materials, complicated production process, and waste, and achieve the effects of reducing manufacturing costs, improving forming performance, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

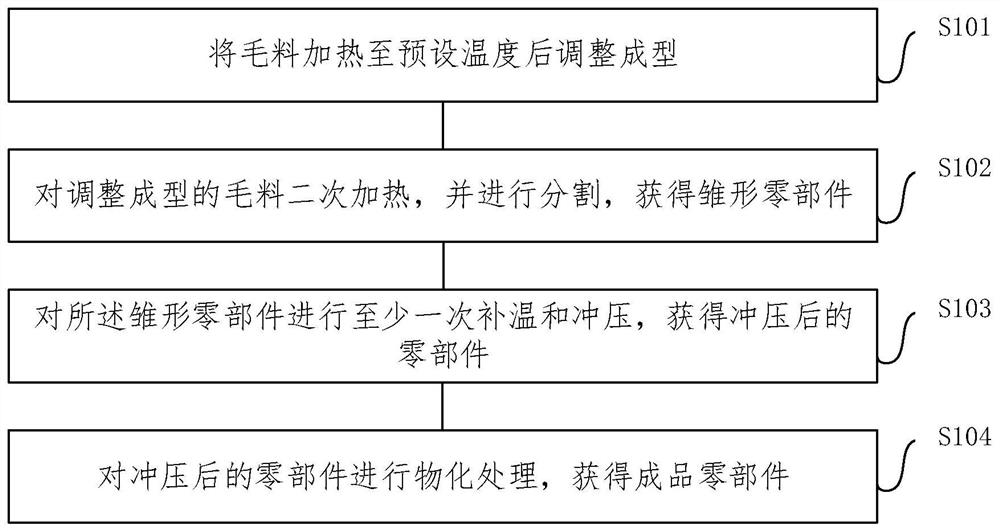

[0031] This embodiment discloses as figure 1 A method for preparing fitness equipment parts by a hot stamping process includes the following steps:

[0032] S101. Adjust the molding after heating the wool to a preset temperature;

[0033] S102, reheating the adjusted and shaped wool material and dividing it to obtain prototype parts;

[0034] S103, performing at least one warming and stamping on the prototype parts to obtain stamped parts;

[0035] S104, performing physical and chemical treatment on the stamped parts to obtain finished parts.

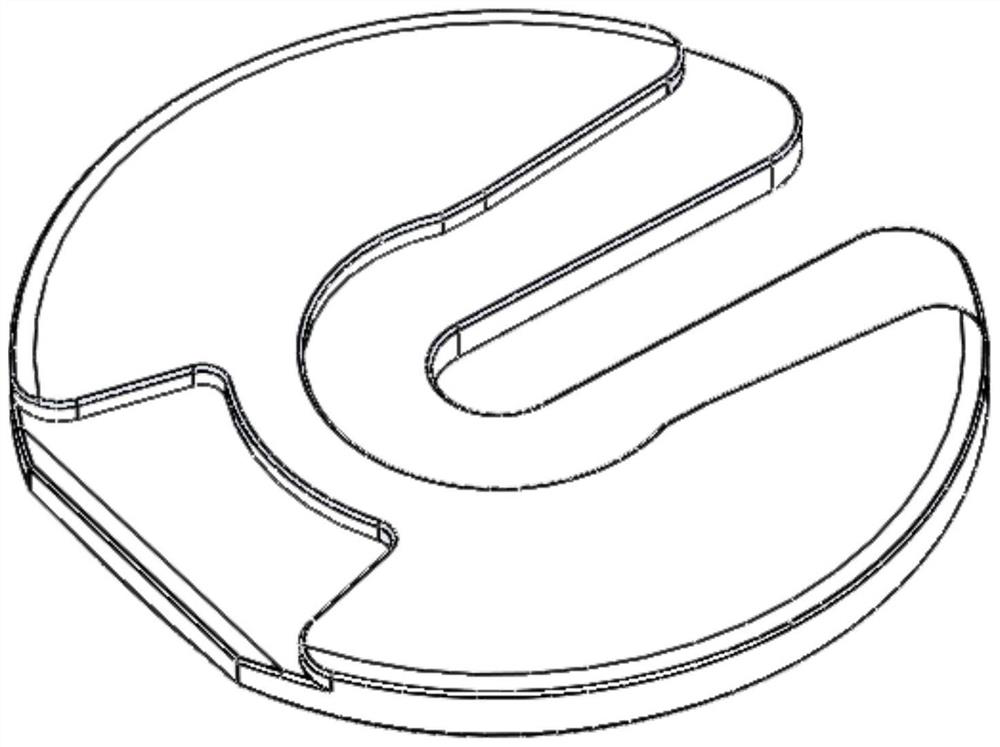

[0036] Wherein, in S101, the wool can be iron, steel or some alloys, etc., and the initial wool can be in any shape. After the wool material is heated to the preset temperature, it is easy to adjust the shape. Take the dumbbell plate for fitness equipment as an example. After heating, the wool material can be adjusted into a cylinder or a prism. different cylinders.

[0037] After adjusting the molding, the wool is heated again to ...

Embodiment 2

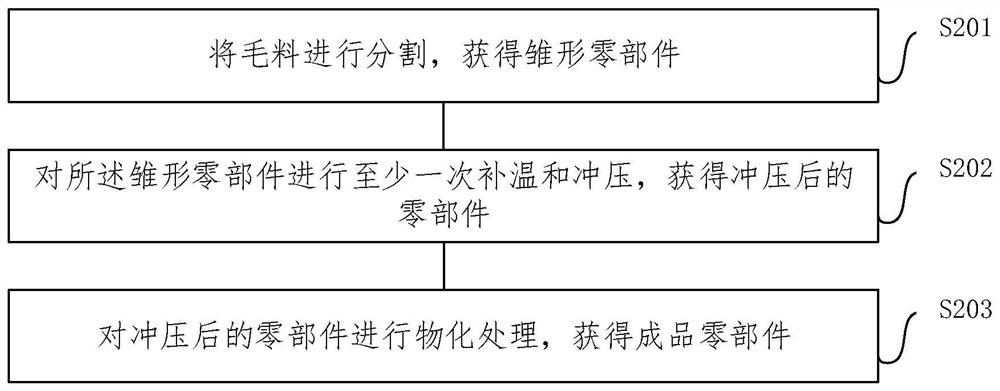

[0047] This embodiment discloses a method for preparing parts of fitness equipment by a hot stamping process. The method includes the following steps:

[0048] S201, dividing the wool to obtain prototype parts;

[0049] S202, performing at least one warming and stamping on the prototype parts to obtain stamped parts;

[0050] S203 , performing physical and chemical treatment on the stamped parts to obtain finished parts.

[0051] Compared with Example 1, the method disclosed in this embodiment saves the need to adjust the shape after heating the wool to a preset temperature. This is because the wool itself is a cylinder or a prism wool, which can be directly divided and stamped. Thereby more process steps are saved.

[0052]Specifically, the divided wool is blanked. That is to put other raw metal materials such as iron, steel ingot, steel column or aluminum alloy into the blanking machine; austenitization includes two stages of heating and heat preservation. The purpose of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com