Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Accurately formed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

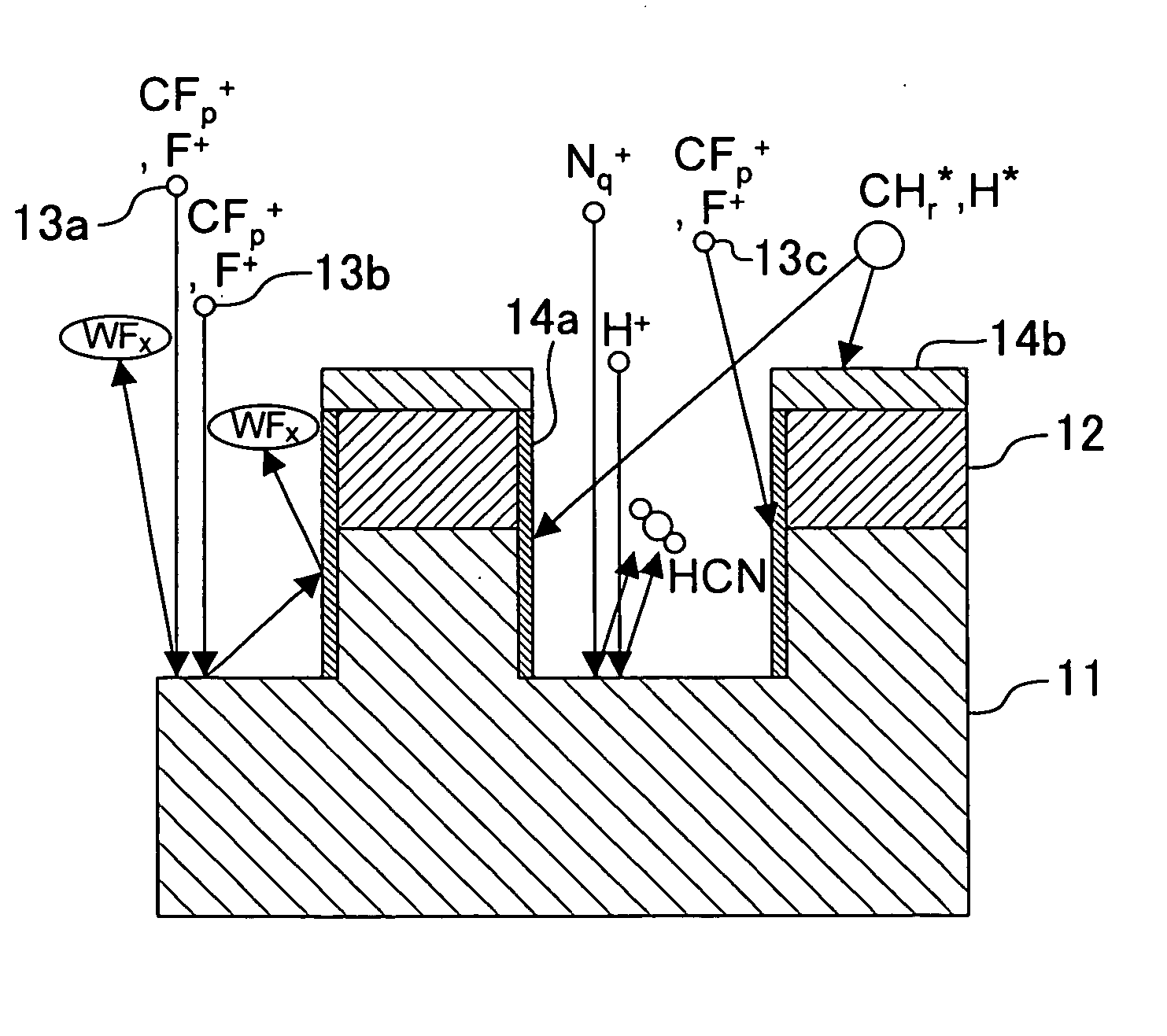

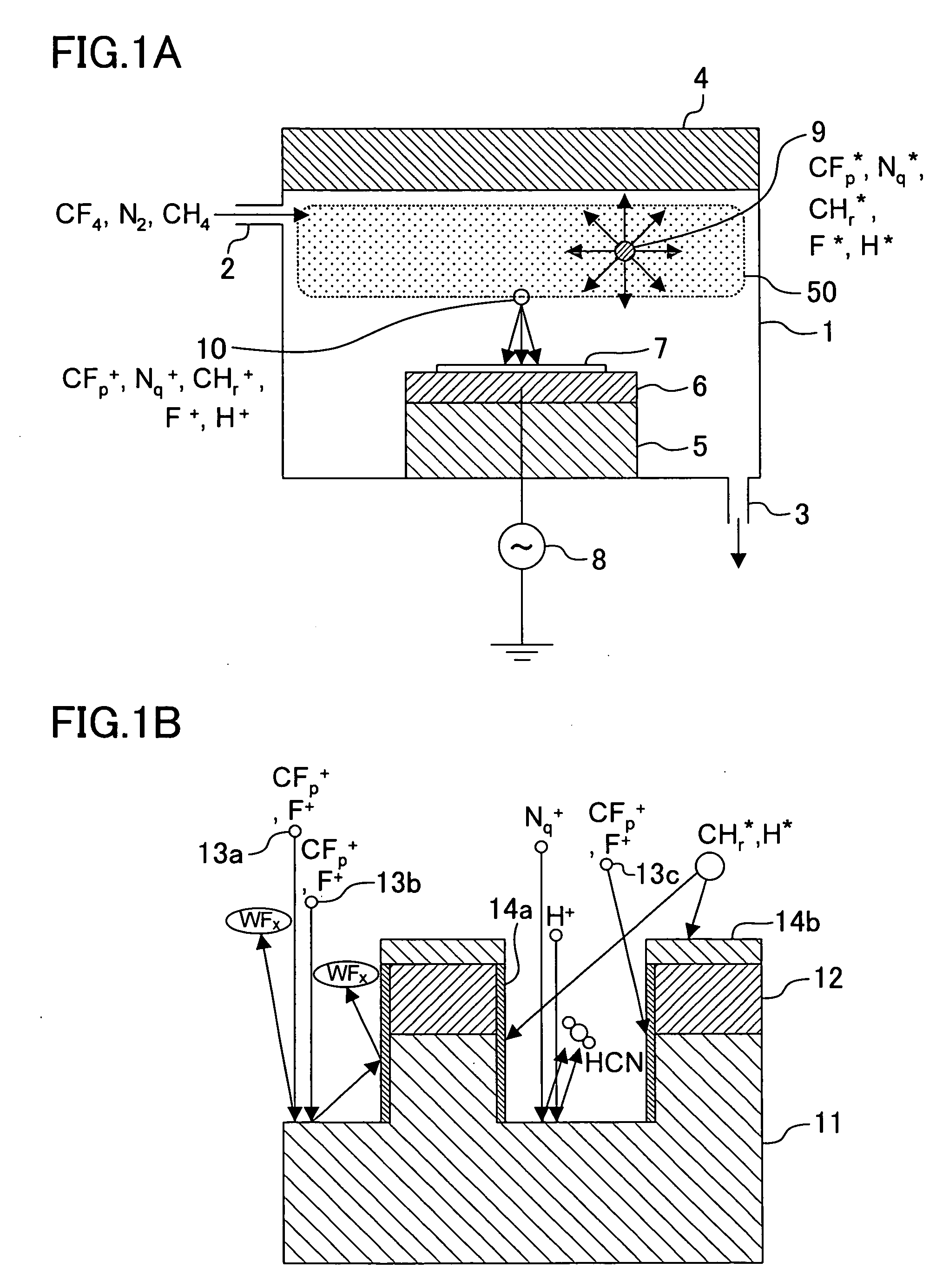

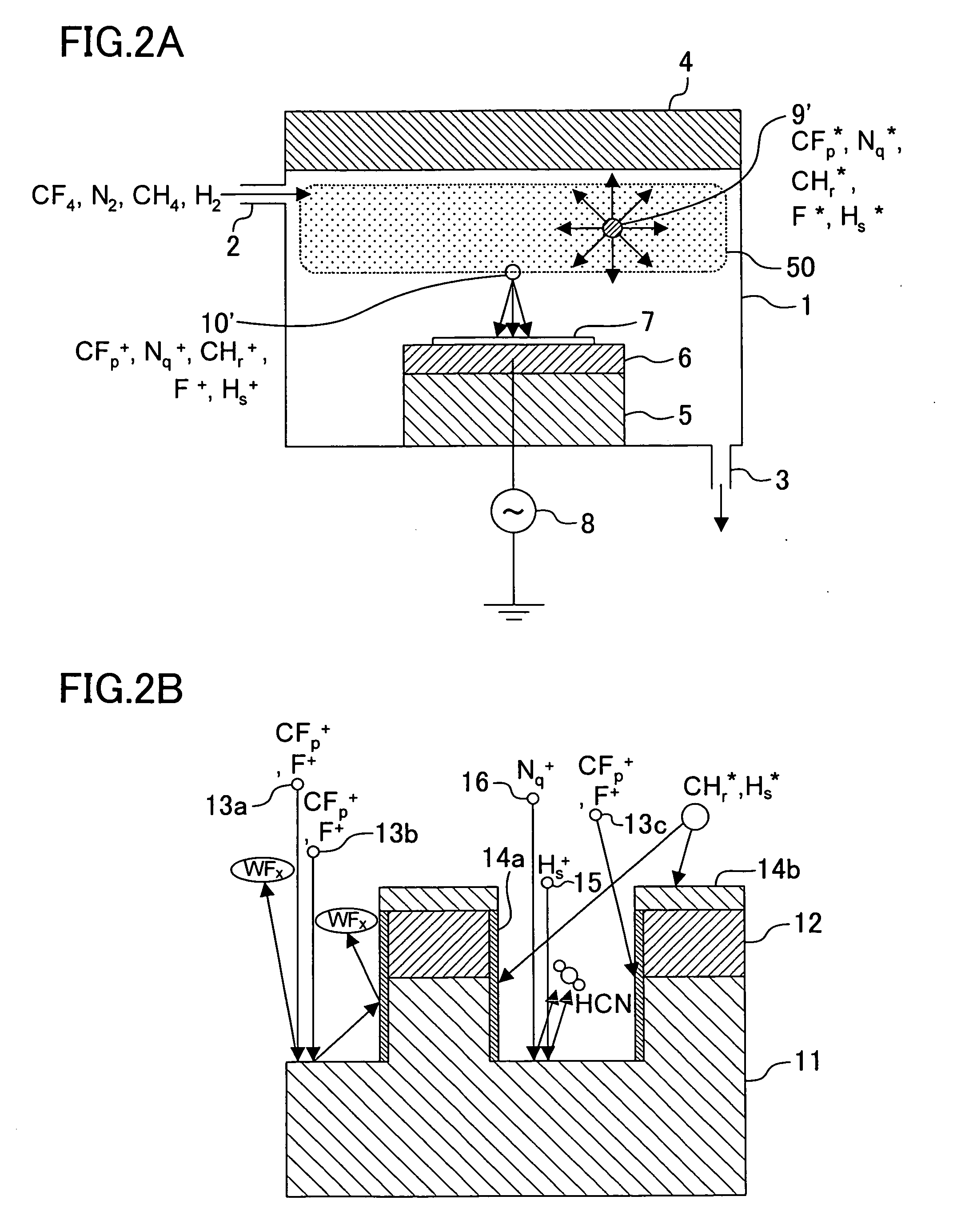

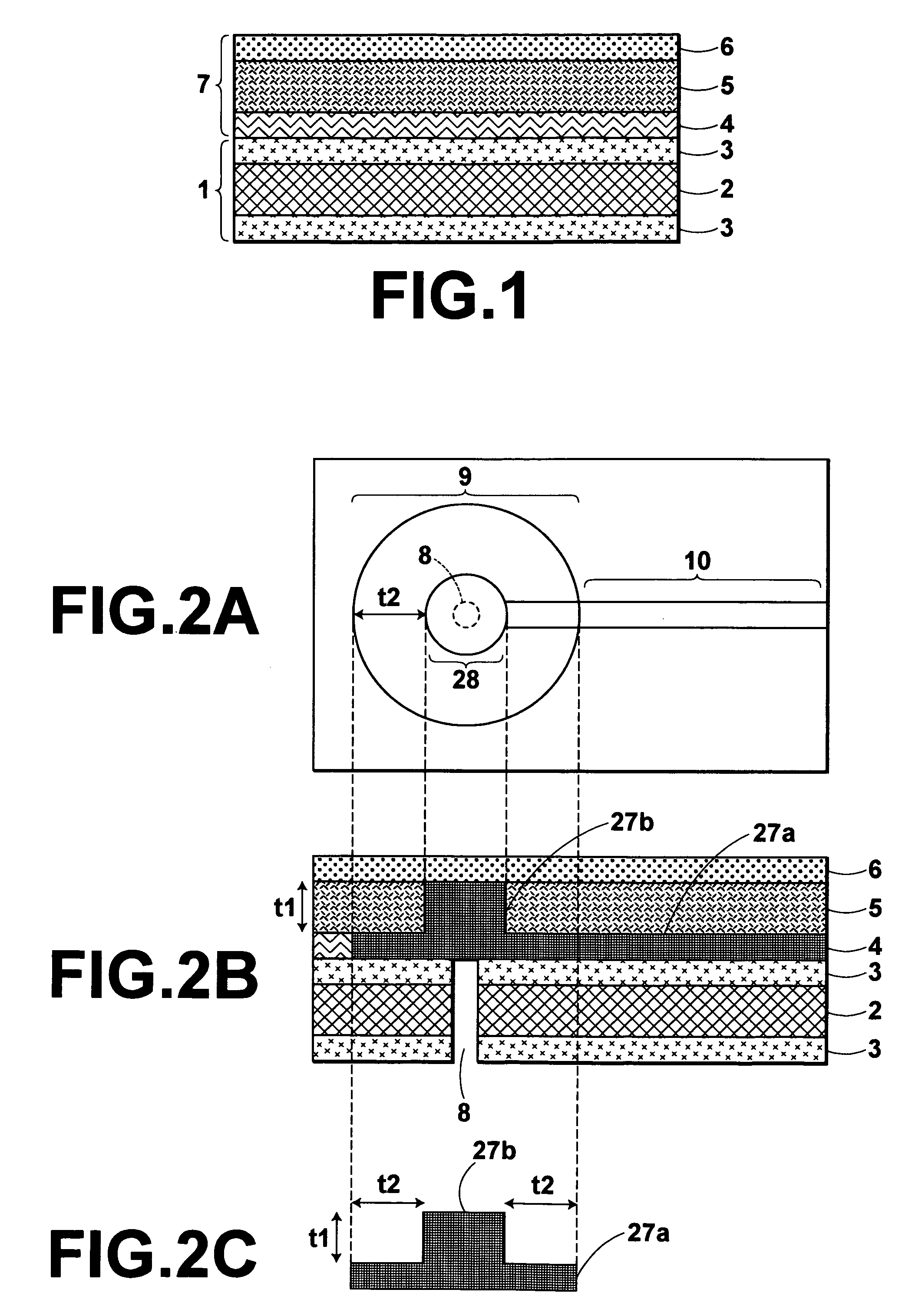

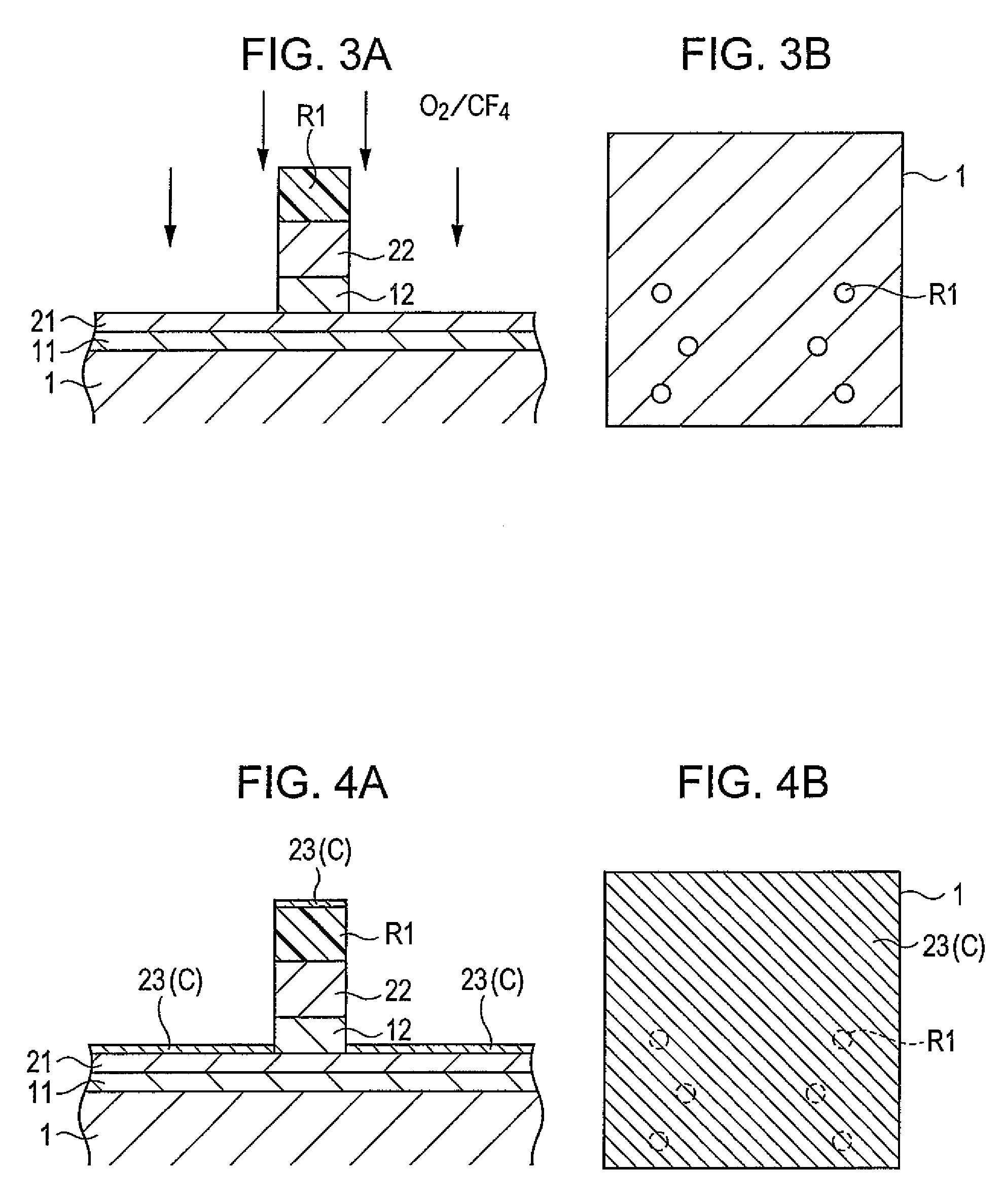

Dry etching method, fine structure formation method, mold and mold fabrication method

InactiveUS20070187362A1Increase preciseness and easinessAccurately formedDecorative surface effectsOptical light guidesNitrogen atomTungsten

Owner:PANASONIC CORP

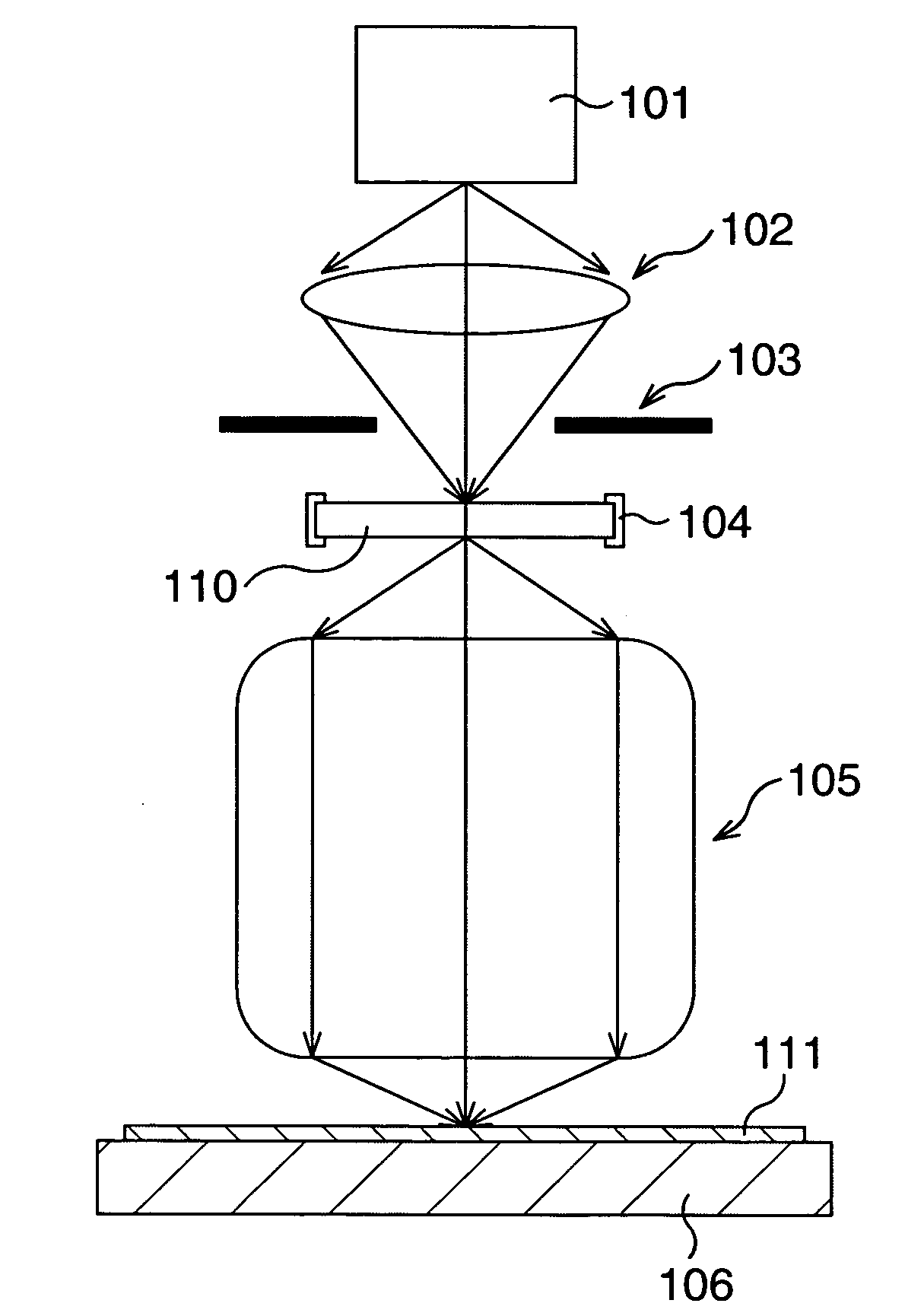

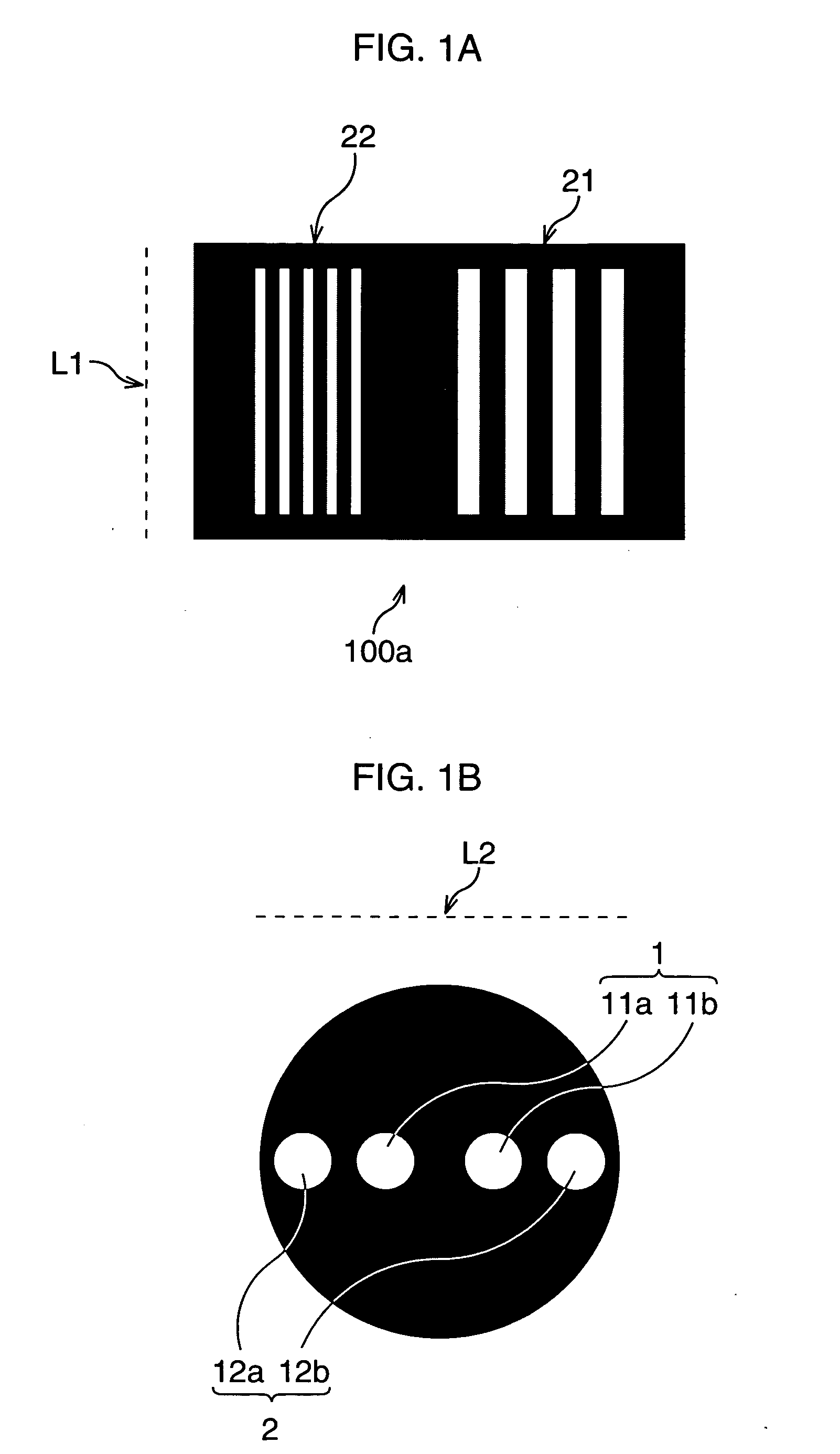

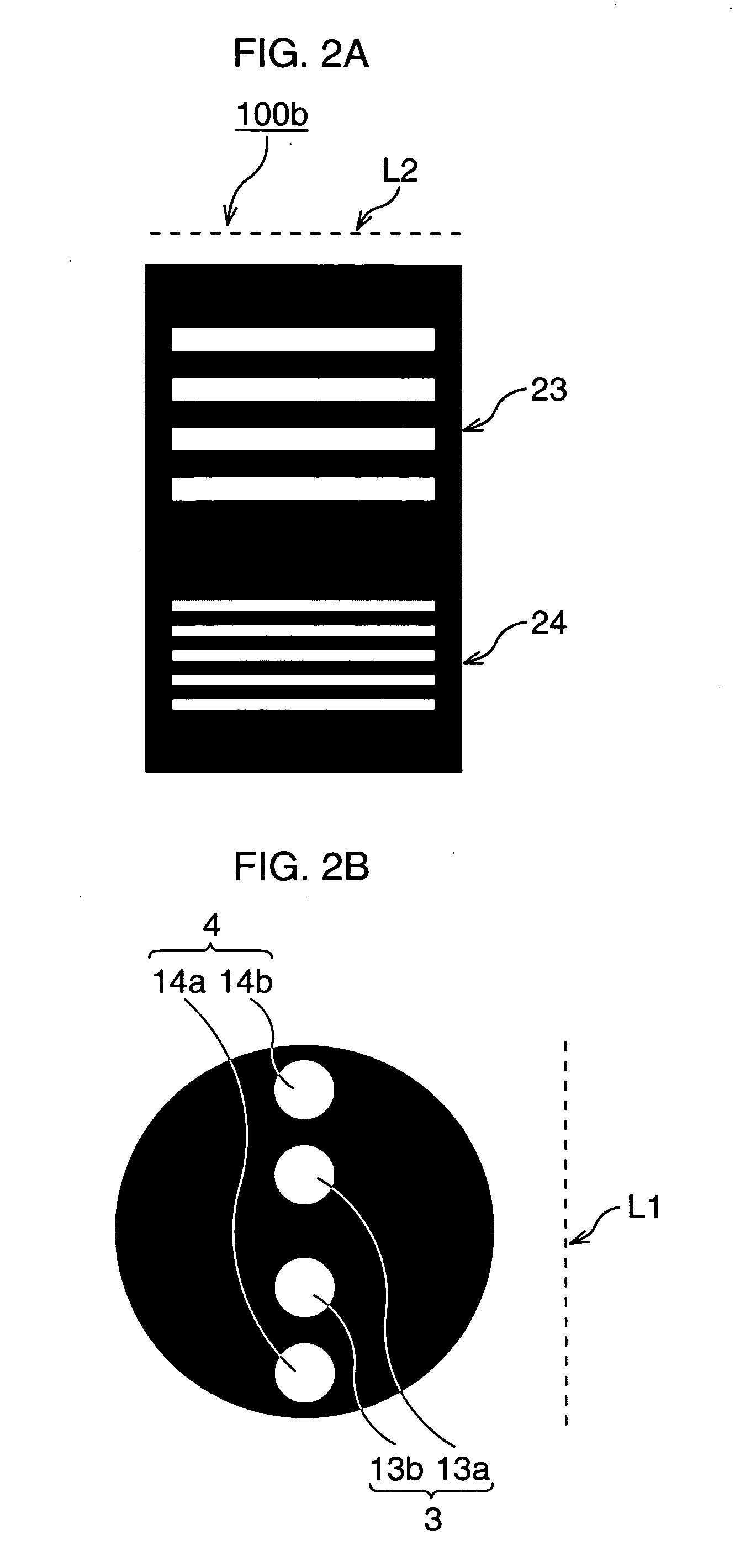

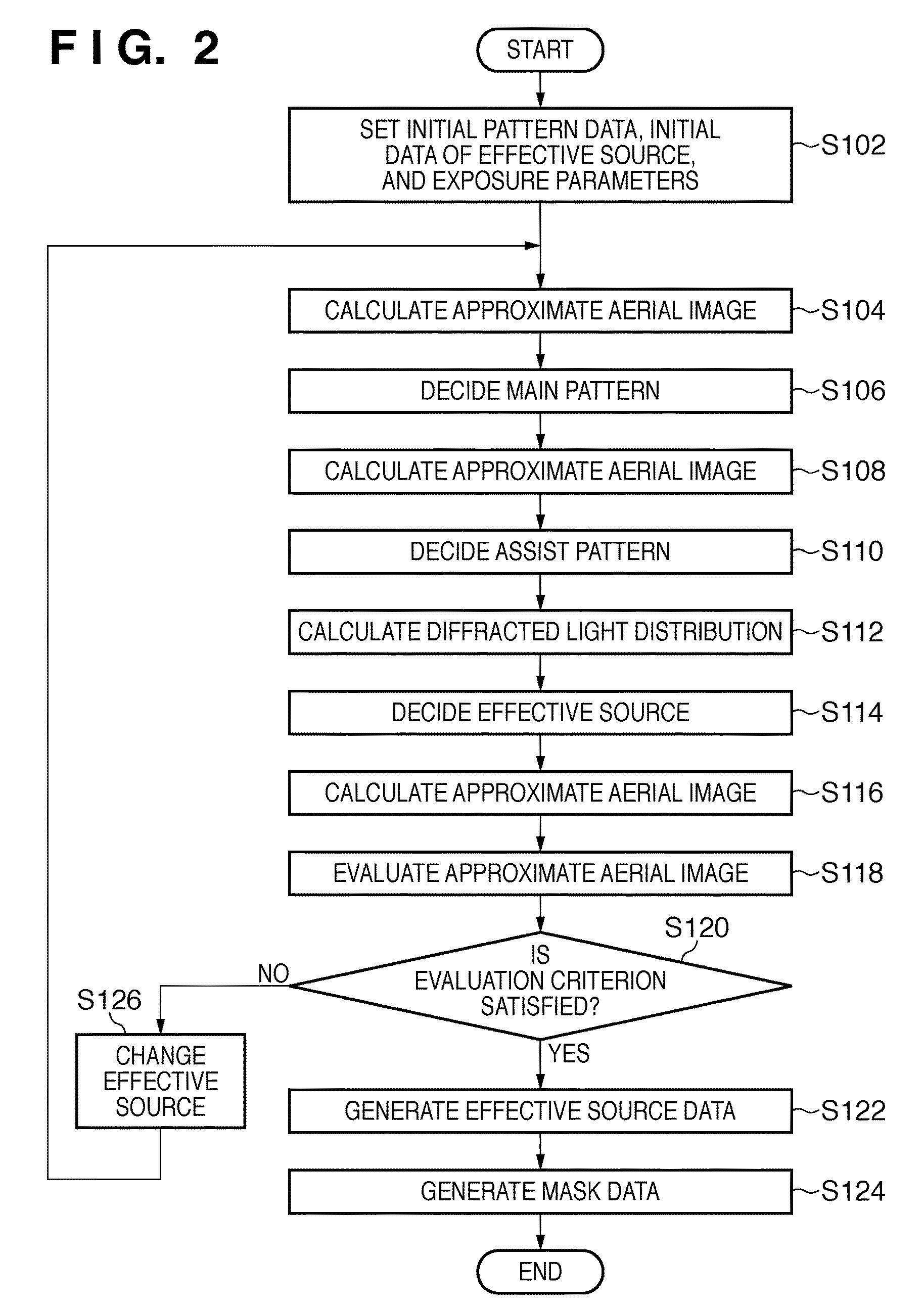

Illumination optical system, exposure method and designing method

InactiveUS20080030706A1Improve reliabilityForming accuratelyPhotographic printingPhysicsOptoelectronics

Exposure for performing patterning in which micropatterns differing in pitch exist in close vicinity to one another is handled, and micropatterns are formed with high accuracy with sufficient manufacture process margins without using a photomask complicated in manufacturing process at high manufacture cost like an alternating phase shift mask. A light intensity distribution of irradiation light constituted of double pole illuminations is formed to correspond to L&S patterns. The double pole illumination is constituted of a pair of illumination modes, and the double pole illumination is constituted of a pair of illumination modes.

Owner:FUJITSU SEMICON LTD

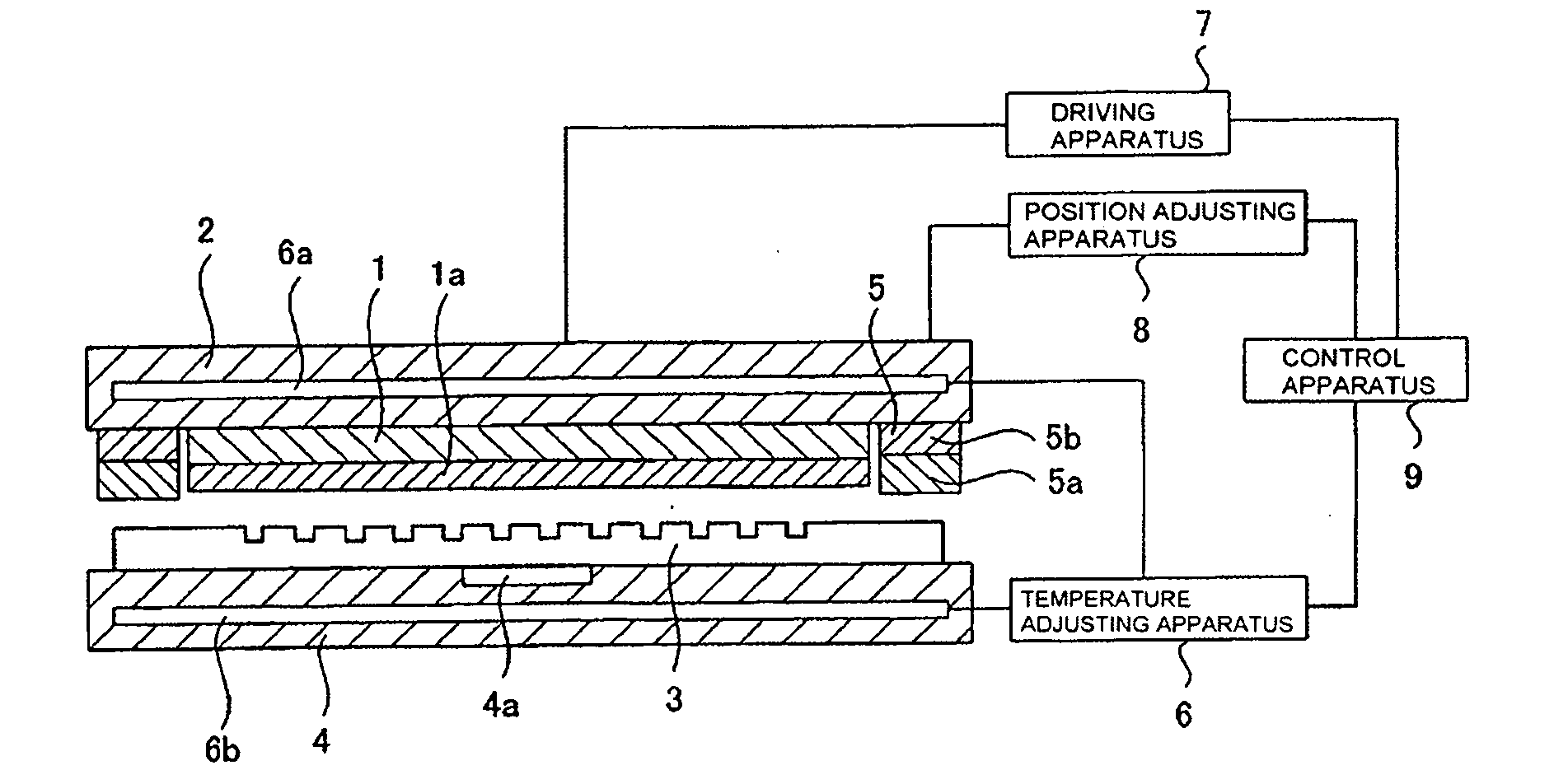

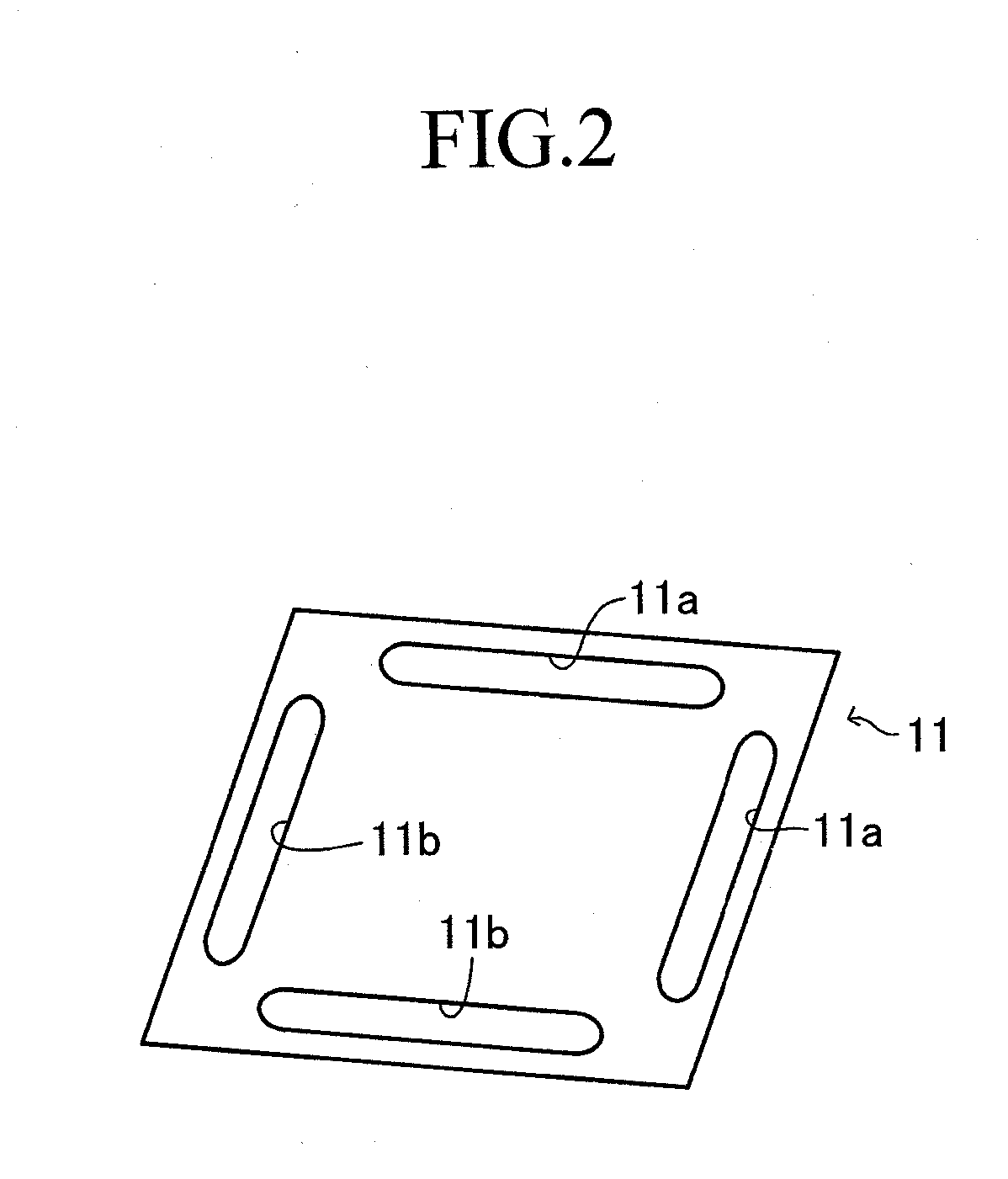

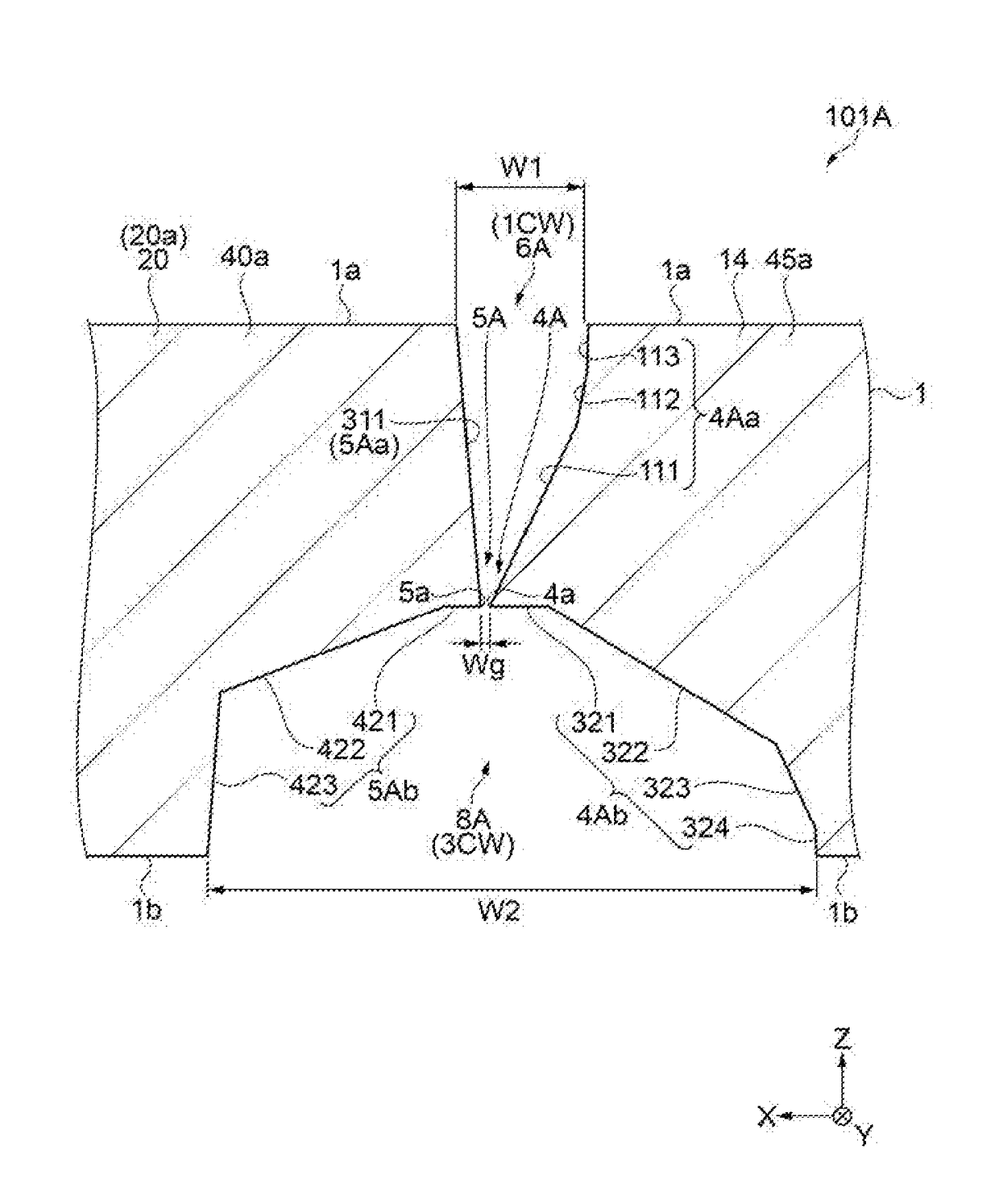

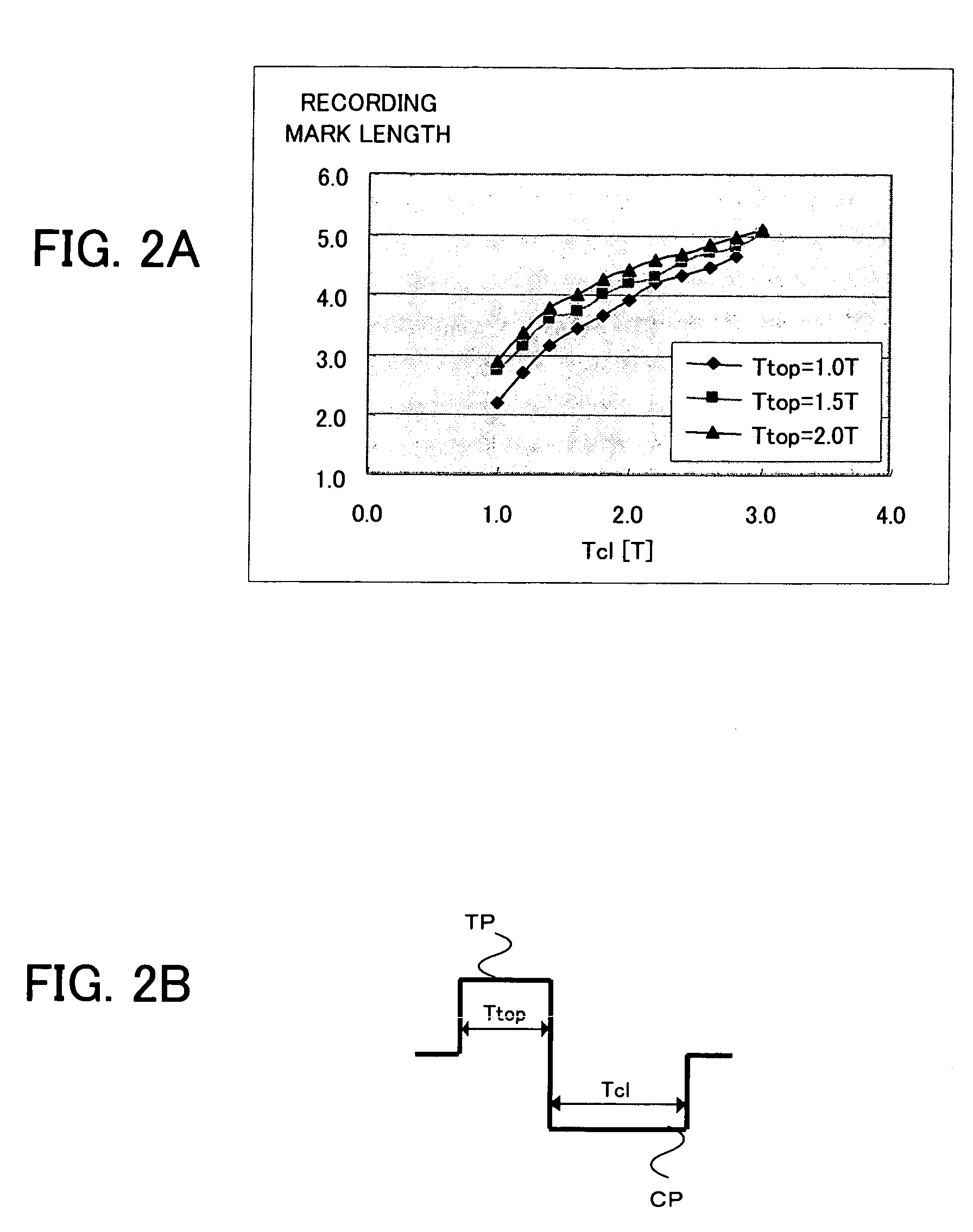

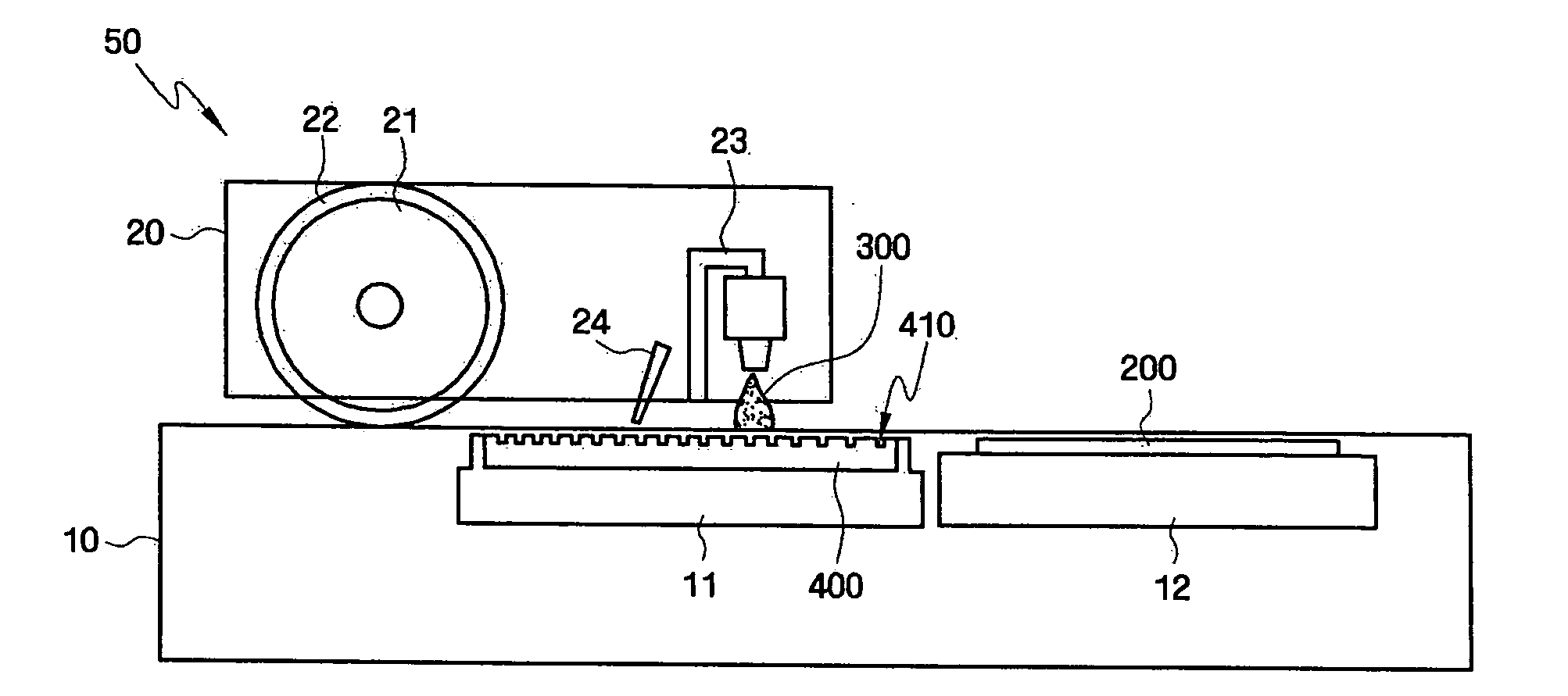

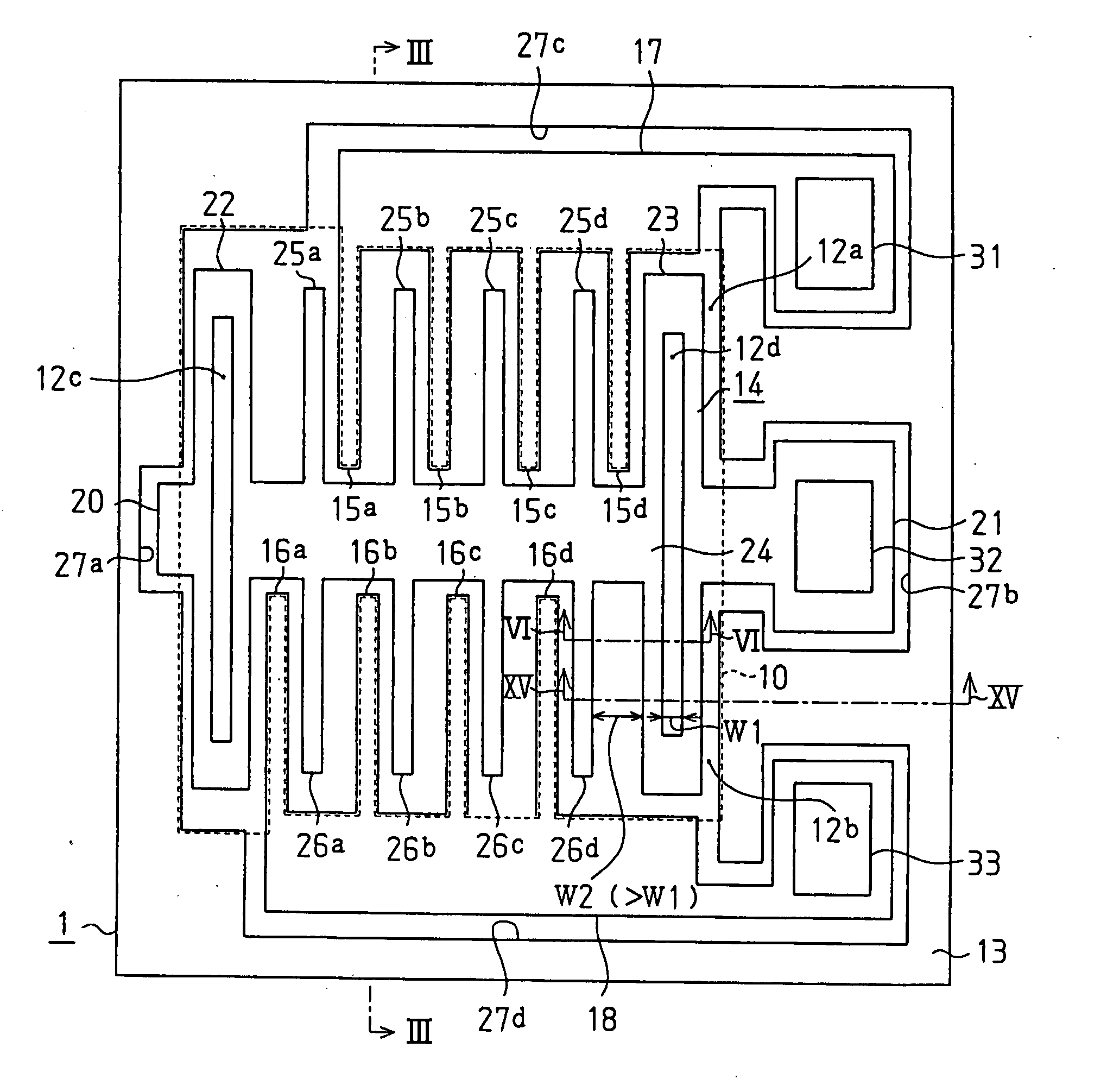

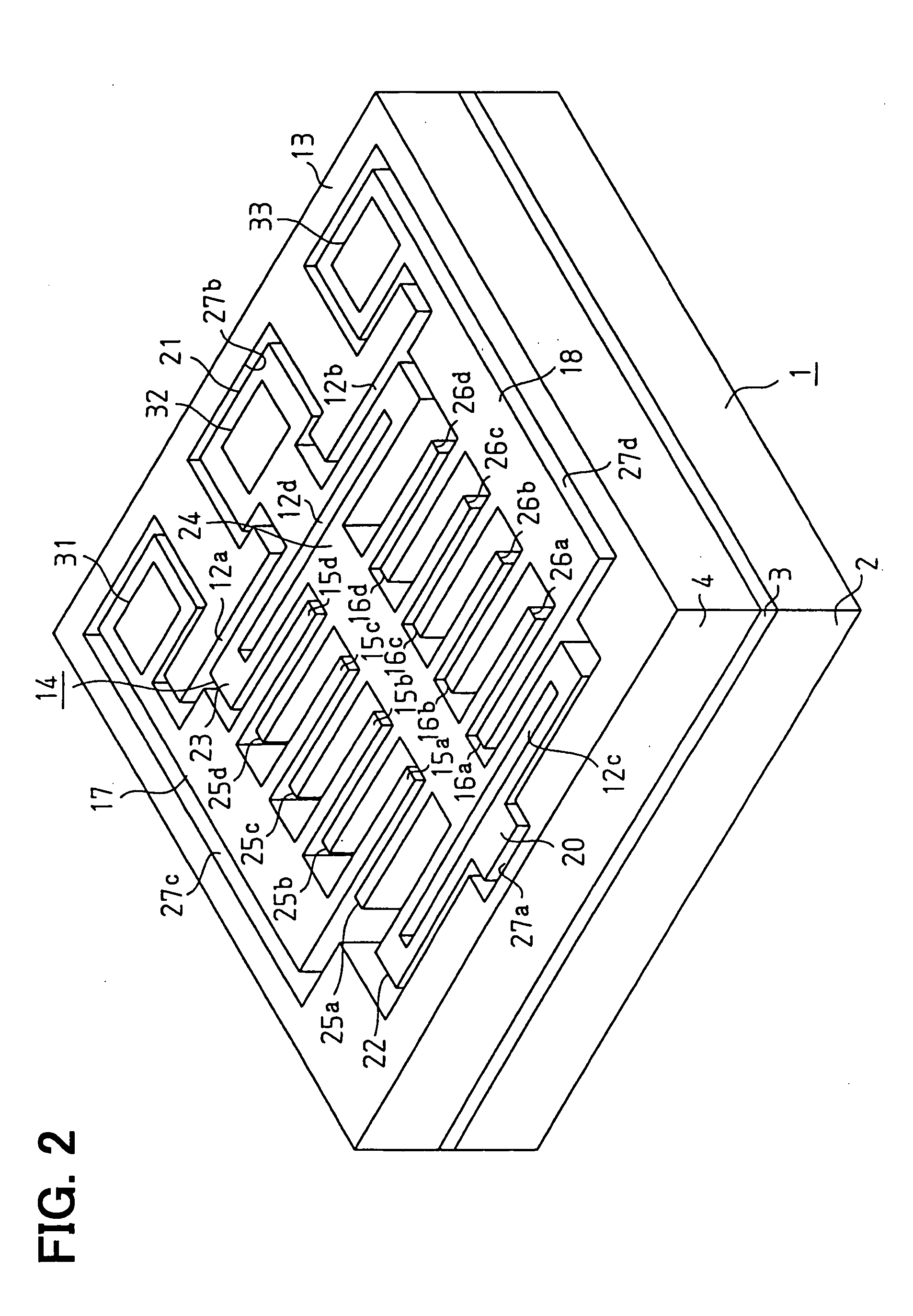

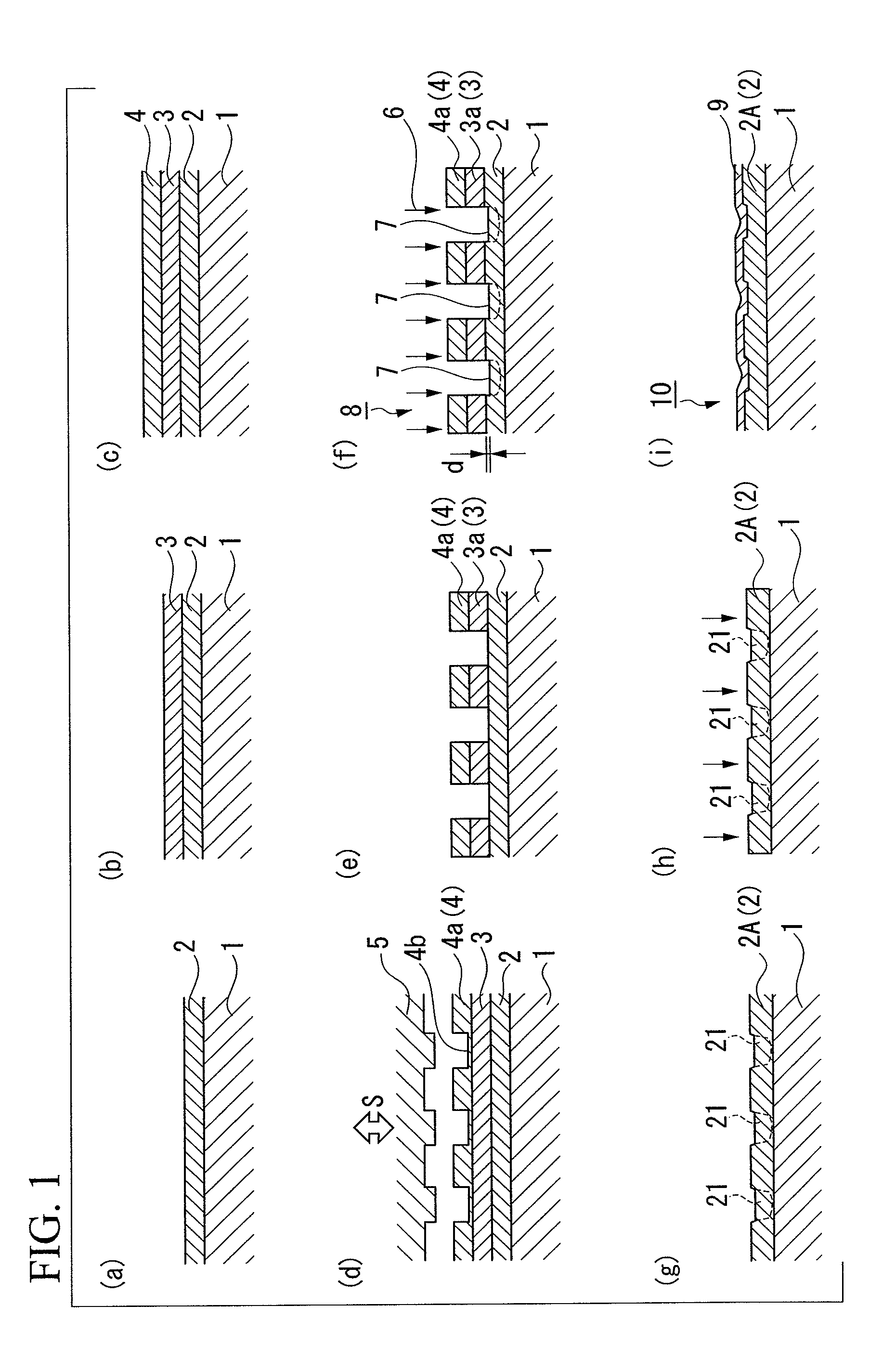

Imprint Method and Imprint Apparatus

InactiveUS20090273119A1Accurately pattern shapePrecise positioningNanoinformaticsConfectioneryThermal deformationMaterials science

[Problems] In an imprint method, any displacement of a pattern shape due to thermal deformation of a mold is prevented and the pattern shape is formed accurately on a substrate.[Solving Means] The present invention provides an imprint method for pressing a mold 3 having a pattern formed on a surface thereof against a transfer layer 1a on a substrate 1 to replicate the shape of the pattern of the mold 3 to the transfer layer 1a. A peripheral portion of the surface of the mold 3 is held by a retaining component 5 onto a mold holding component 4, and in this state, the mold 3 is pressed against the transfer layer 1a on the substrate 1.

Owner:PIONEER CORP

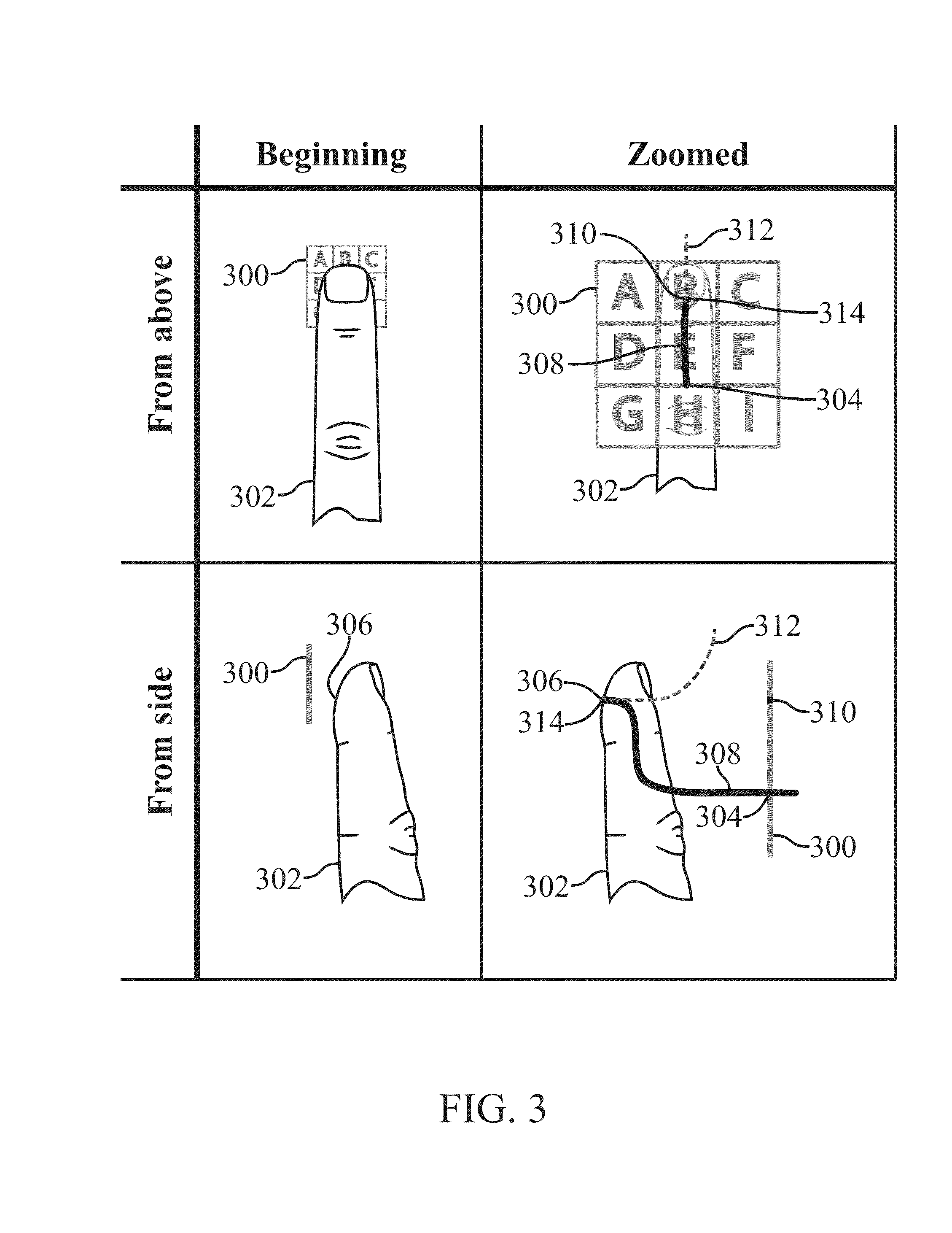

User interface enabled by 3D reversals

InactiveUS20160098094A1Eliminate performanceAccurately formedInput/output for user-computer interactionCathode-ray tube indicatorsUser interfaceHuman–computer interaction

A method and system are provided where a user can imitate a tap gesture with a fingertip in space without a physical surface to tap on and, if the trajectory of the fingertip is tracked in the course of movement, the tap gesture is performed by a 3D reversal. In a 3D reversal, the trajectory becomes substantially reversed.

Owner:GEEGUI

Mask fabrication method, exposure method, device fabrication method, and recording medium

InactiveUS20100009272A1Forming accuratelyAccurately formedSemiconductor/solid-state device manufacturingCharacter and pattern recognitionComputer scienceRecording media

Owner:CANON KK

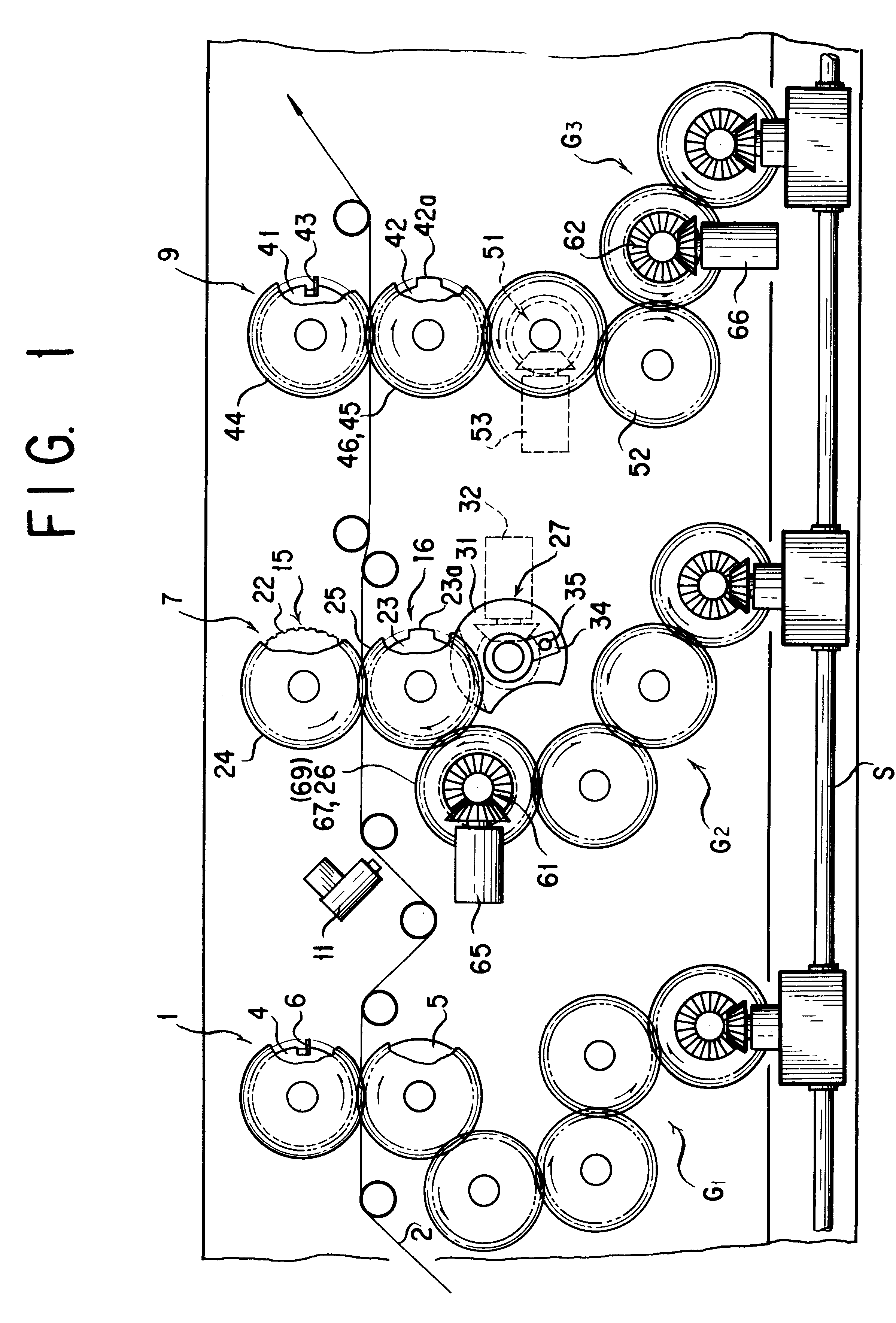

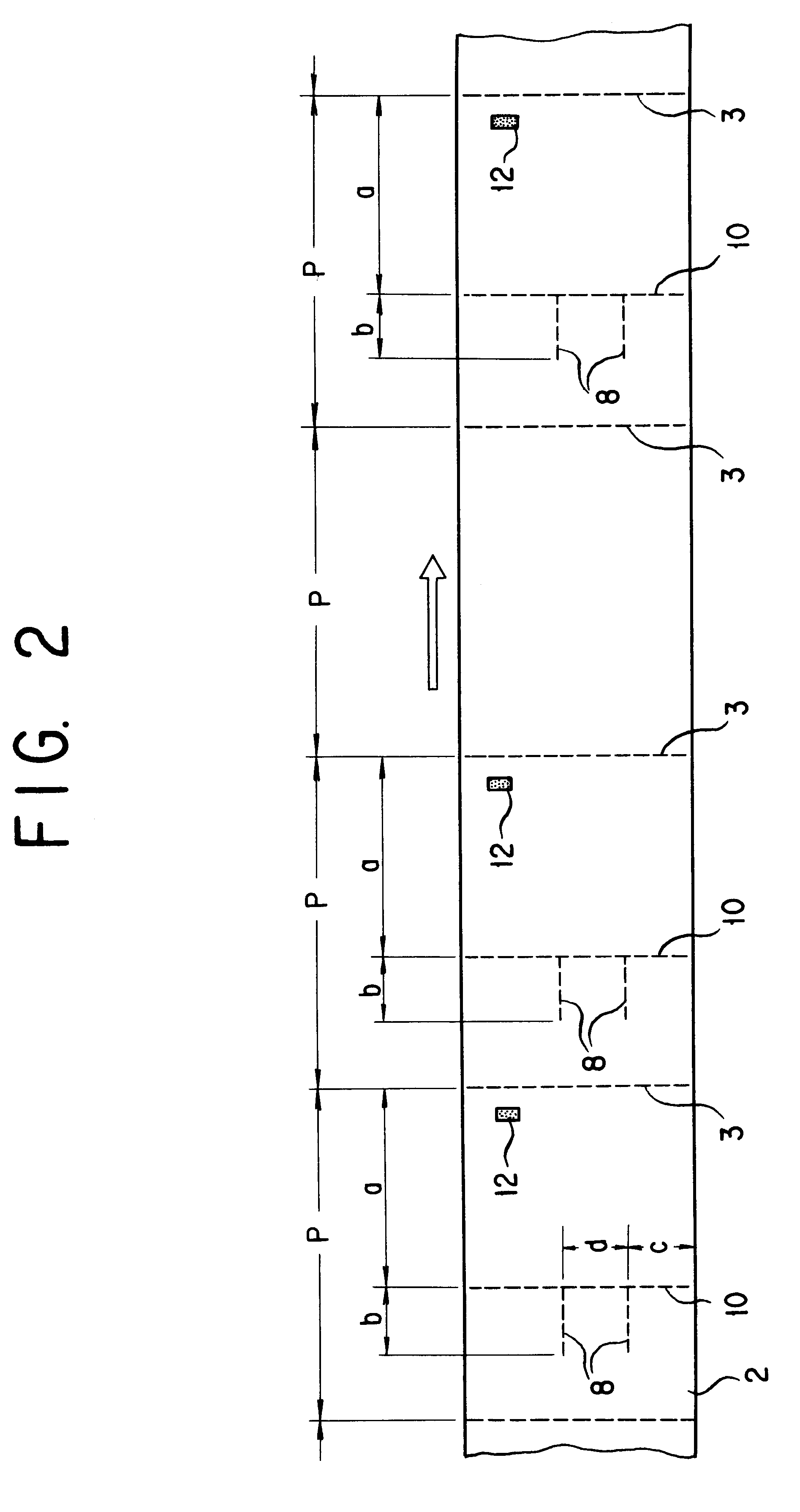

Arbitrarily positioned lateral perforation forming apparatus for form printing machine

InactiveUS6401583B1Simple control systemForming accuratelyStock shearing machinesRotary pressesControl systemEngineering

An arbitrarily positioned lateral perforation forming apparatus can form a lateral perforation at an arbitrary position or selected position in a continuous web paper at high precision by a simple control system with small control amount. A lateral roulette cylinder projecting a lateral roulette edge on its outer periphery, arranged on one side of the continuous web paper and rotating in a traveling direction of the continuous web paper; and a receptacle cylinder projecting an edge projecting portion opposing to the lateral roulette edge of the lateral roulette cylinder on its outer periphery, arranged on the other side of the continuous web paper, rotating in the traveling direction of the continuous web paper, and forming a lateral perforation in the continuous web paper when the edge receptacle portion opposes the roulette edge; are rotated in synchronism with traveling of the continuous web paper in the drive system. Furthermore, the arbitrarily positioned lateral-perforation forming apparatus includes a first differential mechanism disposed in an element connected to one of the lateral roulette cylinder and the receptacle cylinder in the drive system, causing difference in rotational phases of the lateral roulette cylinder and the receptacle cylinder by varying rotation of a differential shaft thereof for selectively placing the edge receptacle portion at a position opposing to the roulette edge and a position circumferentially offsetting from the roulette edge, and a first control unit for controlling rotation of the differential shaft of the first differential mechanism.

Owner:MIYAKOSHI PRINTING MACHINERY

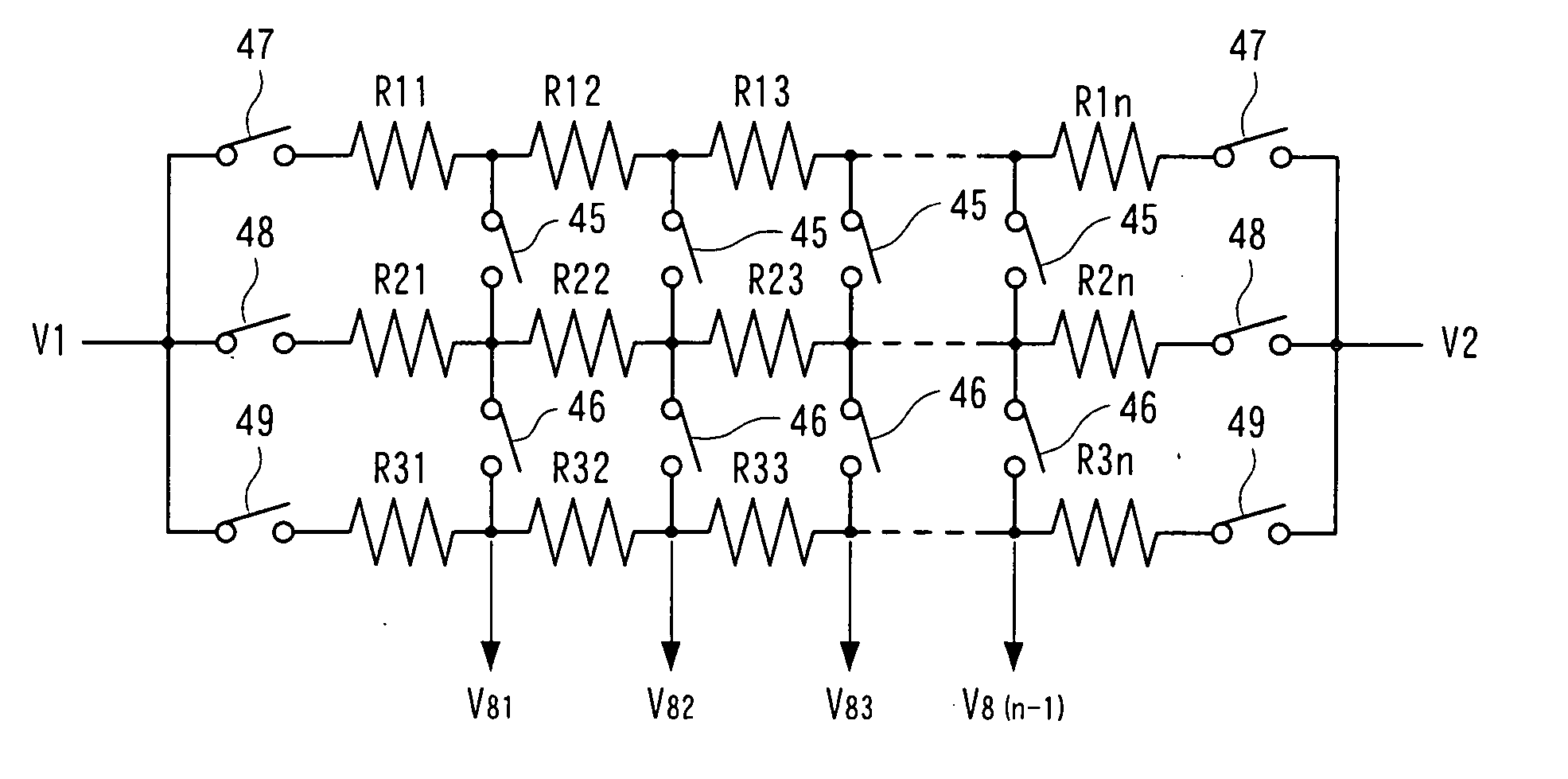

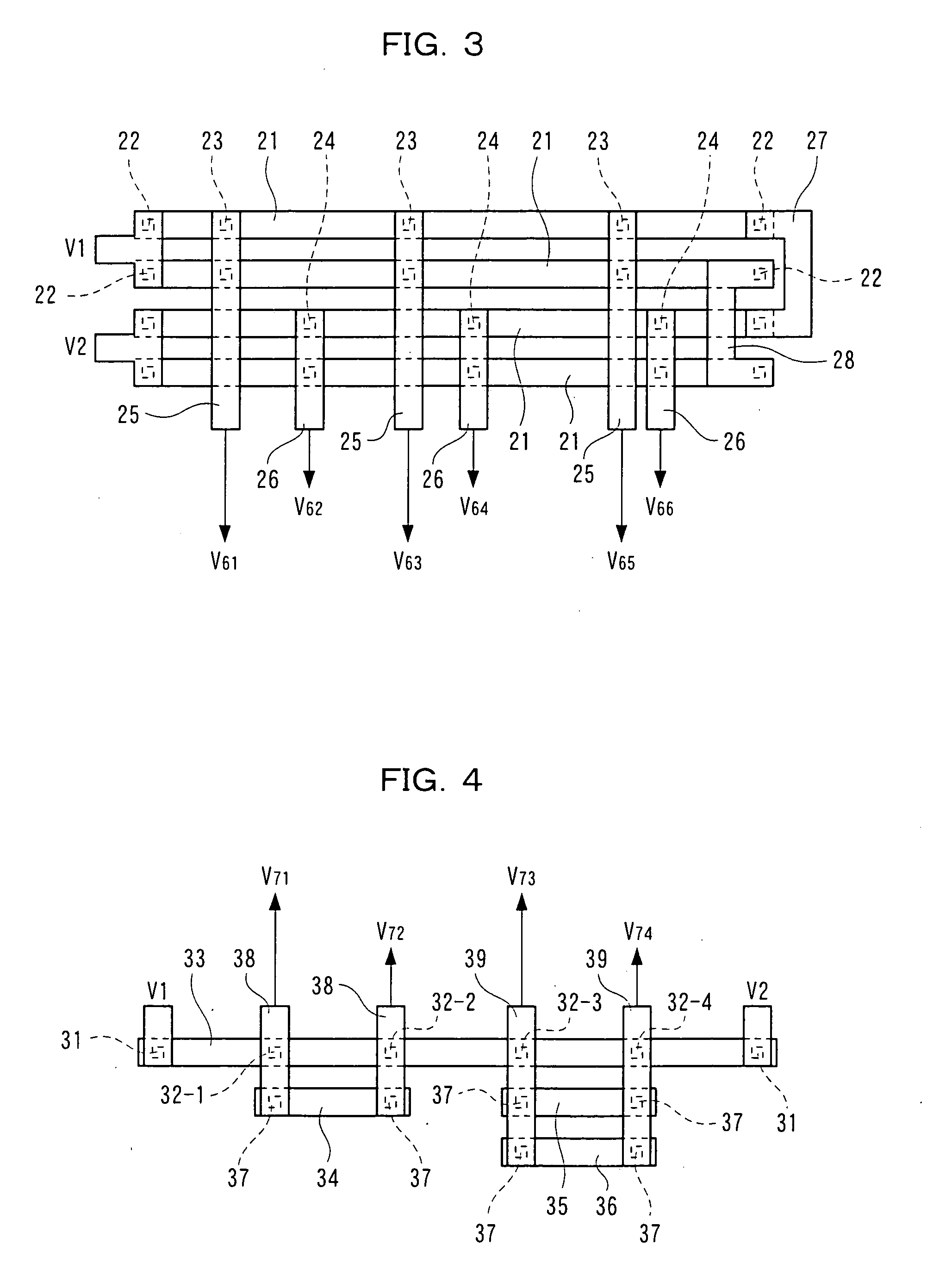

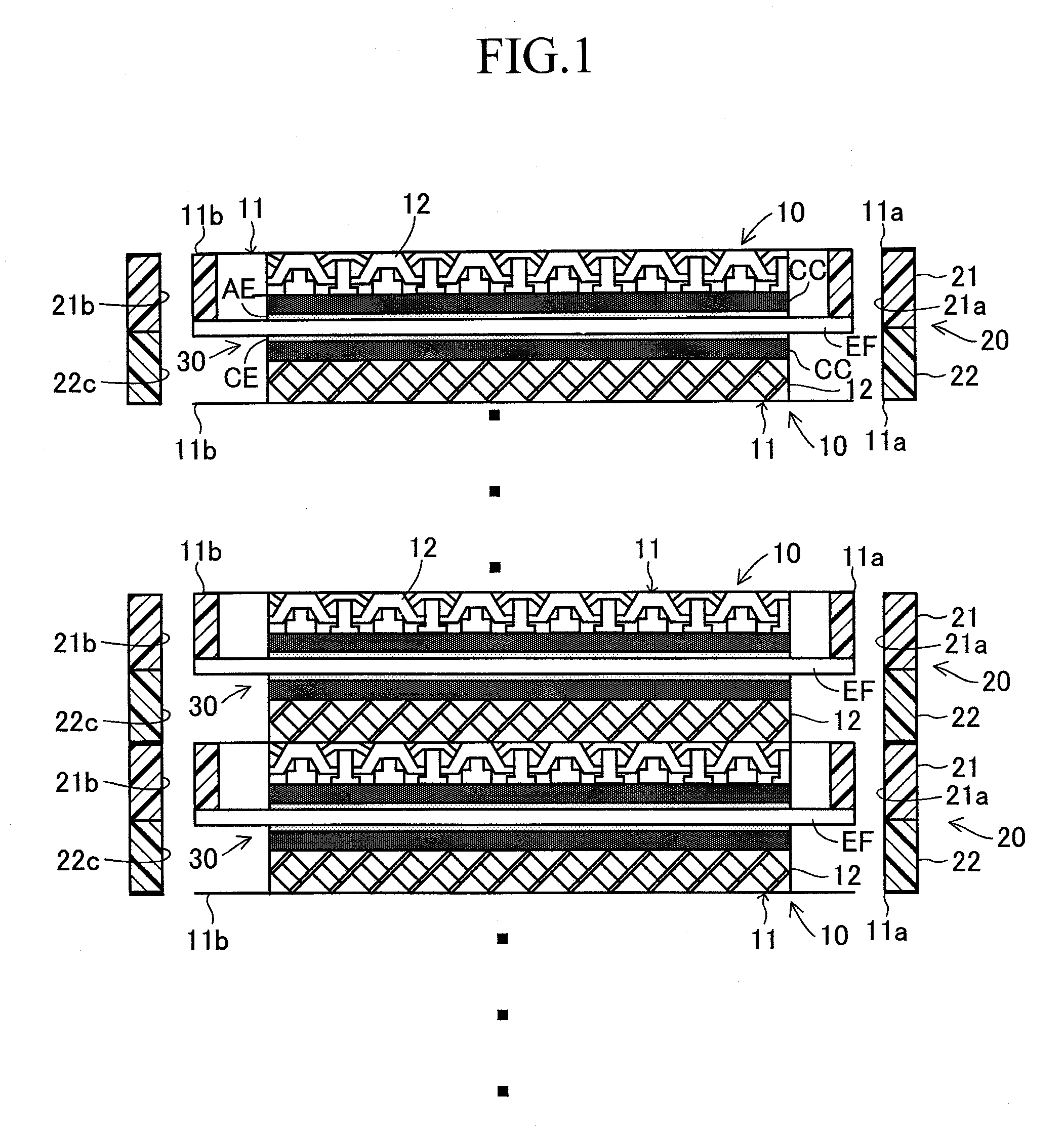

Resistance voltage divider circuit, liquid crystal display driving apparatus using resistance voltage divider circuit, and liquid crystal display apparatus

InactiveUS20050140534A1Accurate gradation voltageImprove gradation displayElectric signal transmission systemsStatic indicating devicesLiquid-crystal displayJunction point

A resistance voltage divider circuit of a gradation potential generation circuit for adjustment, which generates a gradation potential for driving a liquid crystal device. The circuit includes three resistors (11) which are equal in resistance value and have contacts (12) at equal positions. The contacts (12) at the equal positions of each resistors (11) are connected to one another so as to connect the resistors in parallel, reference potentials V1 and V2 are inputted across the resistors connected in parallel, and a gradation potential is generated on a junction point of the contact (12) according to a voltage divided by the resistors (11).

Owner:PANASONIC CORP

Ultrasound diagnostic system and method of forming Tx and Rx beams by using delay data

InactiveUS20070016049A1Forming accuratelyAccurately formedUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsLight beamEngineering

The present invention relates to an ultrasound diagnostic system including: a memory unit for storing transmit (Tx) delay data and receive (Rx) delay data necessary for forming a Tx beam and a Rx beam; a Tx beam forming unit for adjusting delays of Tx signals by referencing the Tx delay data stored in the memory unit to form the Tx beam; a probe for converting the Tx signals into ultrasound signals and transmitting the ultrasound signals into a target object, the probe being configured to receive ultrasound echo signals reflected from the target object to output electrical Rx signals; and a Rx beam forming unit for adjusting delays of the Rx signals by referencing the Rx delay data stored in the memory unit to form the Rx beam.

Owner:MEDISON CO LTD

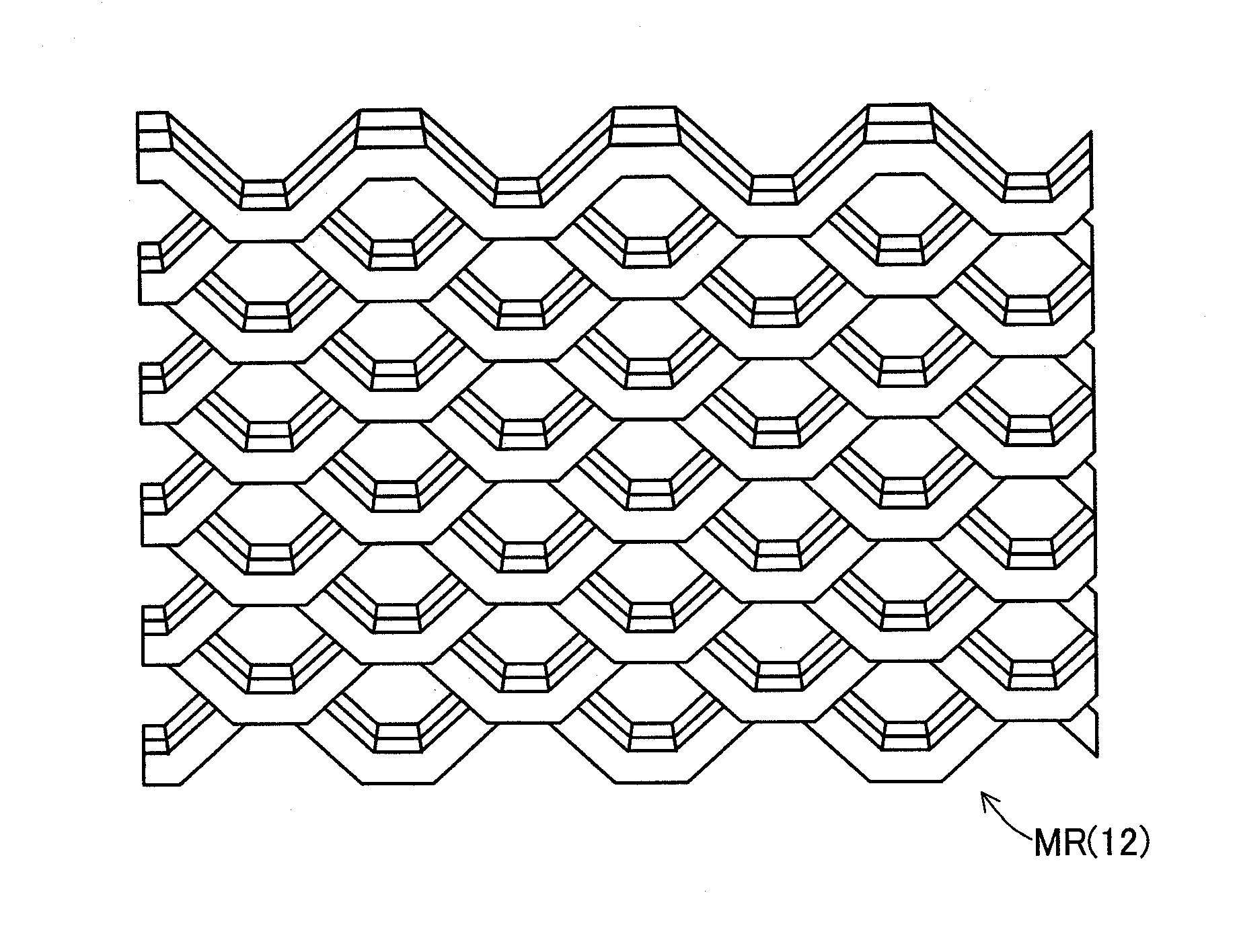

Method of forming gas diffusion layer for fuel cell

InactiveUS20090089989A1Forming accuratelyUniform shapeFinal product manufactureElectrode carriers/collectorsFuel cellsForming gas

A collector 12 which serves as a gas diffusion layer for a fuel cell; i.e., a metal lath MR, is formed by a method consisting of a first step and a second step. In the first step, while an upper blade UH is positioned at a first machining position along the width direction of a stainless steel sheet S, generally hexagonal through holes are formed in the stainless steel sheet S at two positions which are biased from each other by a machining pitch. In the second step, while the upper blade UH is positioned at a second machining position along the width direction of the stainless steel sheet S, generally hexagonal through holes are formed in the stainless steel sheet S at two positions which are biased from each other by the machining pitch. The first step and the second step are alternated repeatedly, thereby forming the metal lath MR having a uniform shape and a predetermined thickness.

Owner:TOYOTA SHATAI KK +1

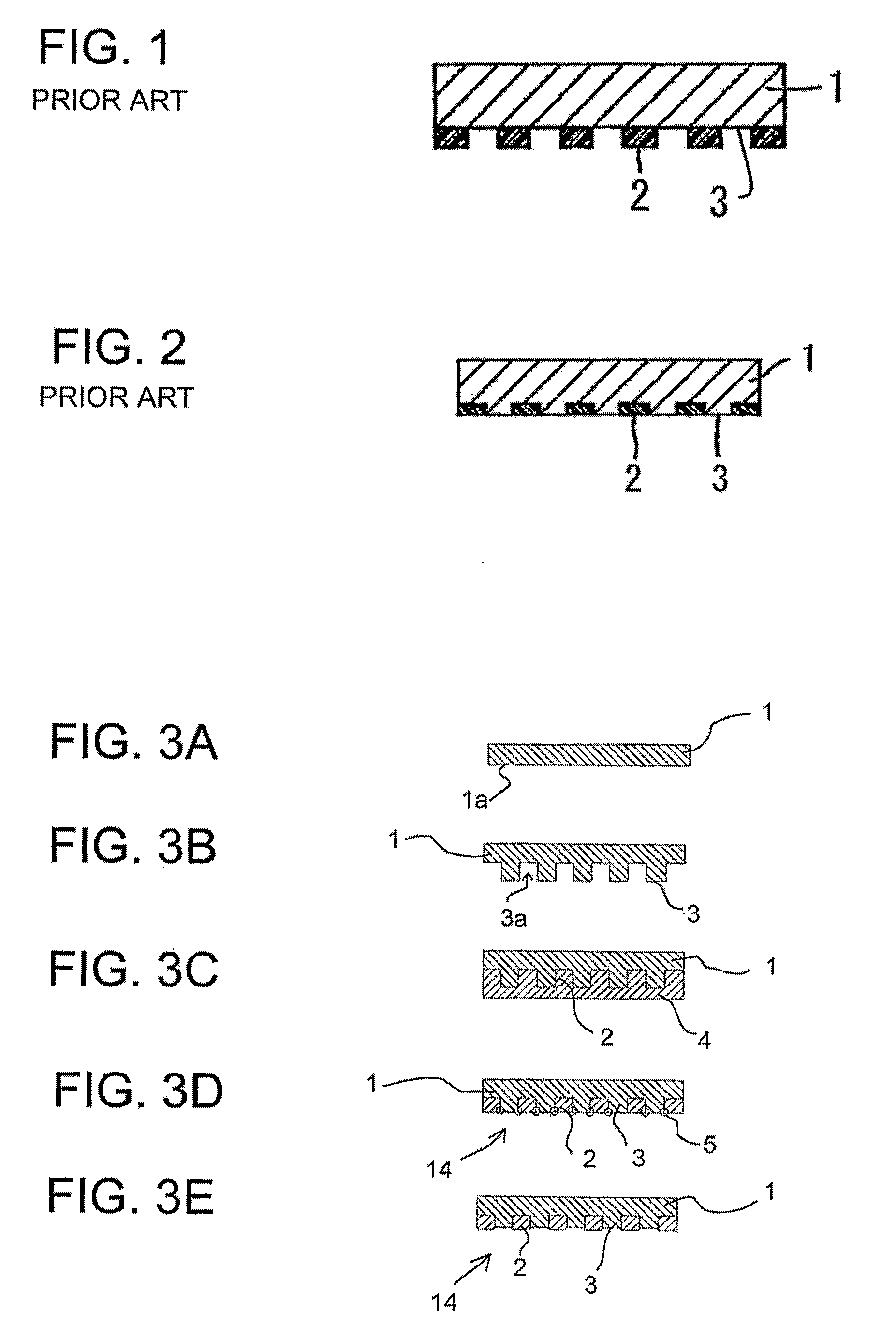

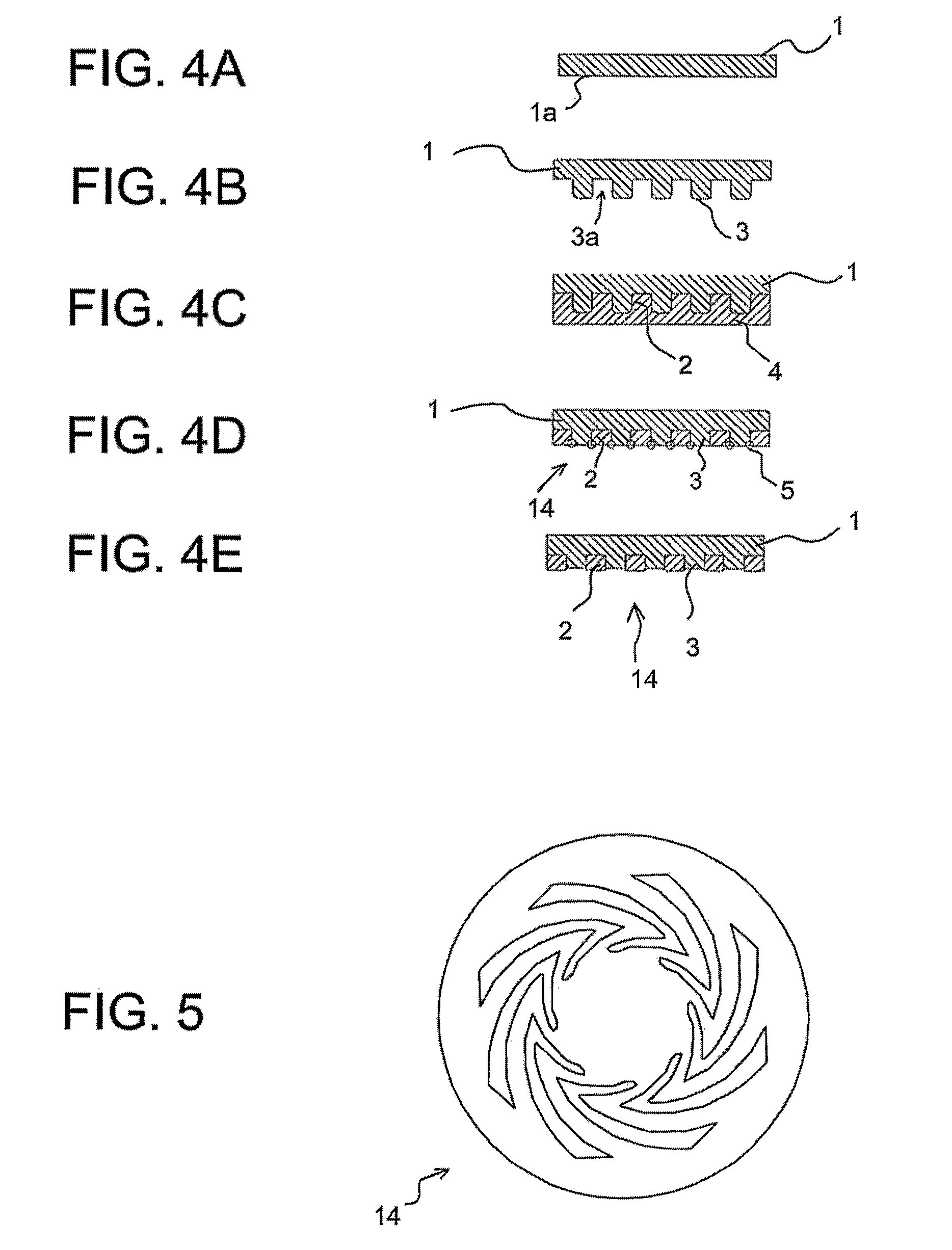

Electrode tool for electrochemical machining and method for manufacturing same

InactiveUS20070144917A1Good reproducibilityAccurately formMachining electrodesAutomatic control devicesEngineeringHeight difference

An electrode tool for electrochemical machining includes a machining electrode surface (1a). The machining electrode surface (1a) includes a conductive pattern defined by lands (3) and grooves (3a) that are formed by groove machining the electrode surface (1a). The machining electrode surface (1a) is then molded with a hard insulating resin layer (4), and a surface of the hard insulating resin layer (4) is mechanically polished to expose the lands (3) of the conductive pattern. The lands (3) are chemically dissolved to obtain a conductive pattern (14) having a surface that is formed below a resulting insulating resin surface (2), with the height difference between the two surfaces being between 1 and 5 pm. The electrode tool allows precise surface machining of work pieces and can withstand prolonged use.

Owner:MINEBEAMITSUMI INC

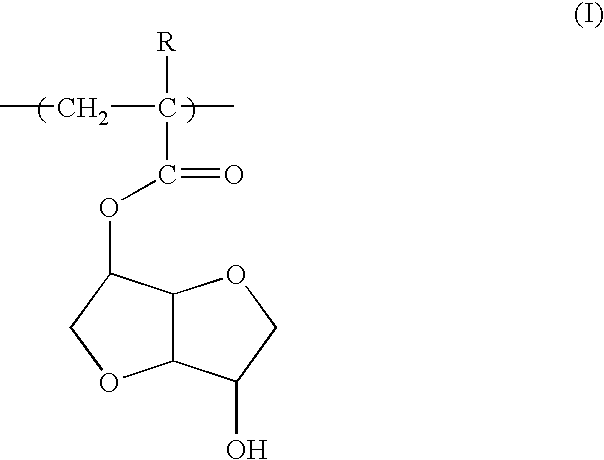

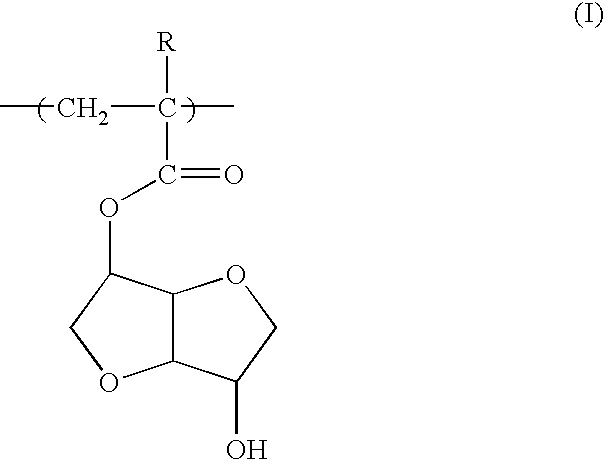

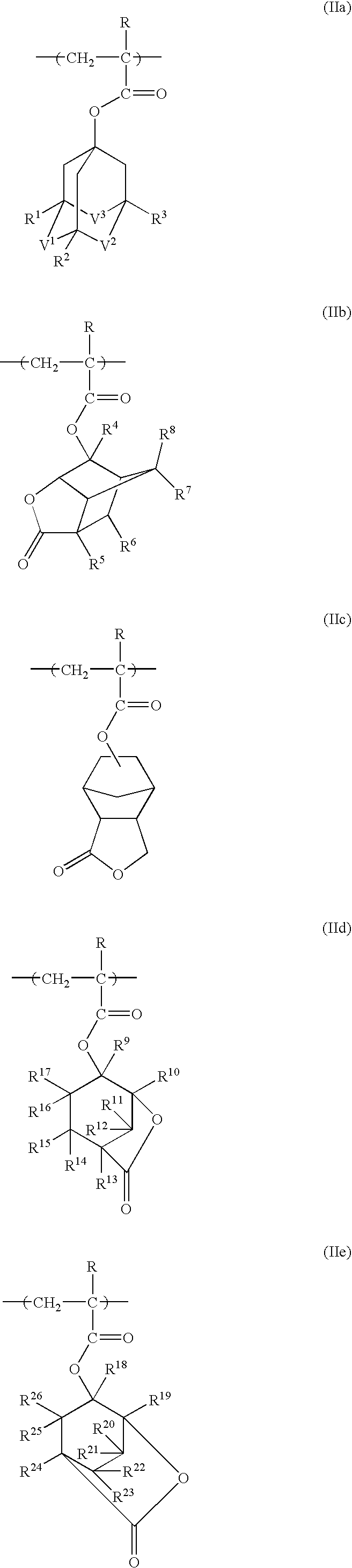

Photoresist polymeric compound and photoresist resin composition

InactiveUS20050014087A1Well-balanced solubilityForming accuratelyRadiation applicationsPhotomechanical apparatusResistSolubility

A polymeric compound for photoresist of the present invention includes a monomer unit having 2,6-dioxabicyclo[3.3.0]octane skeleton in the structure. The monomer unit having 2,6-dioxabicyclo[3.3.0]octane skeleton includes a monomer unit represented by the following Formula (I): wherein R is a hydrogen atom or a methyl group. The polymeric compound for photoresist may include a monomer unit having 2,6-dioxabicyclo[3.3.0]octane skeleton, a monomer unit having a group of adhesion to substrate, and a monomer unit having an acid-eliminating group. The polymeric compound for photoresist of the present invention exhibits not only adhesion to substrate, acid-eliminating property and resistance to dry-etching but also has well-balanced solubility in solvents for photoresist and alkali-soluble property.

Owner:DAICEL CHEM IND LTD

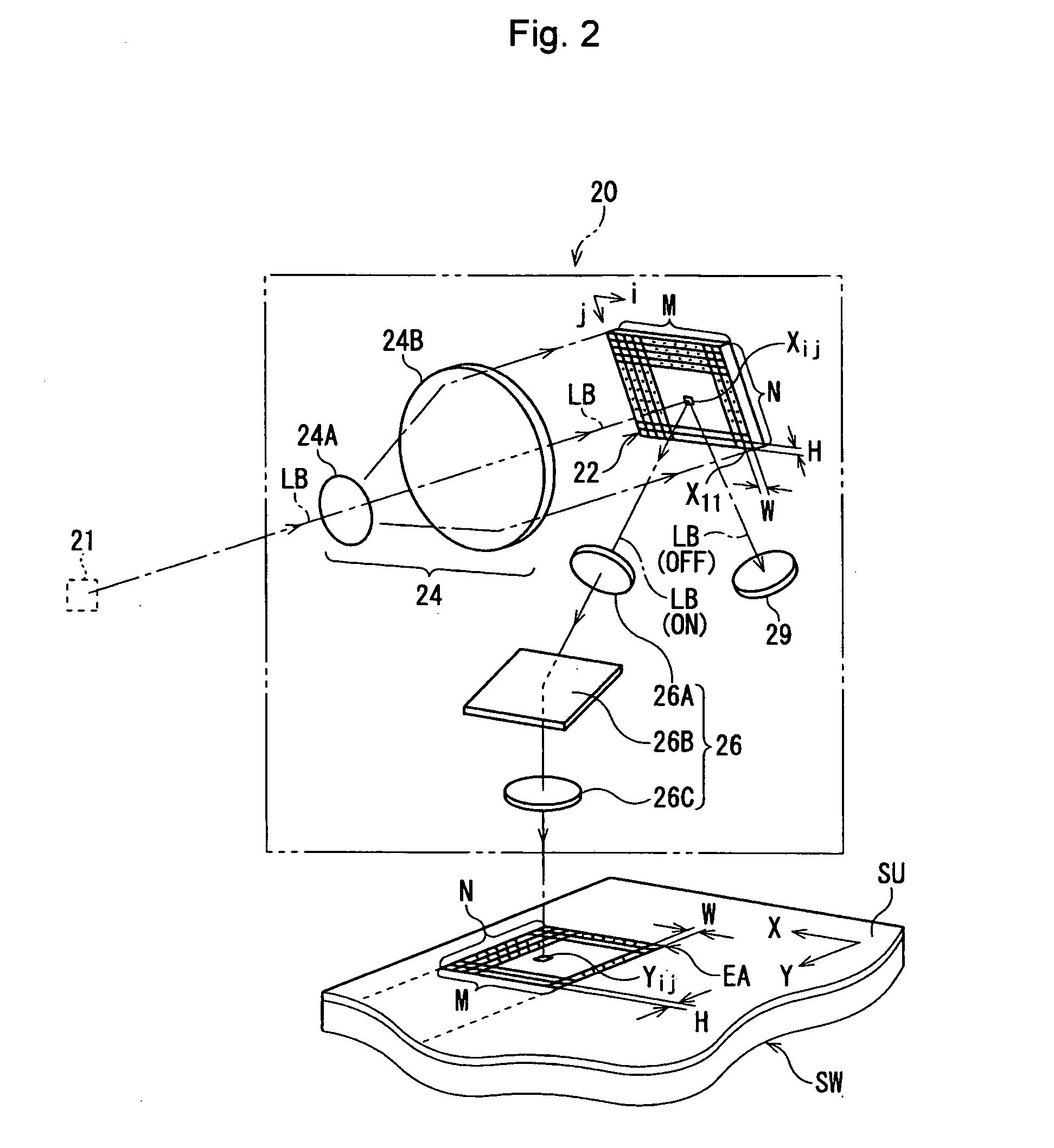

Apparatus for forming pattern

InactiveUS20060033897A1Accurately formedForming accuratelyElectric discharge tubesPhotographic printingPosition errorData matching

An apparatus for forming a pattern has a light-modulating unit, a scanner, a pattern data processor, a light modulating controller, a position-error detector, and a correction value calculator. The pattern data processor generates band-pattern data corresponding to each scanning band on the basis of pattern data matching a preceding pattern that is repeatedly and regularly formed on the photo-sensitive material. The position-error detector detects a position-error of the preceding pattern relative to a pattern area. The correction value calculator calculates an alignment correction value in each pattern area on the basis of the position-error, so as to overlay the pattern on the preceding pattern. The pattern data processor corrects the band-pattern data in accordance with the alignment correction value while classifying each exposure data of the band-pattern data into a corresponding pattern area.

Owner:ORC MFG

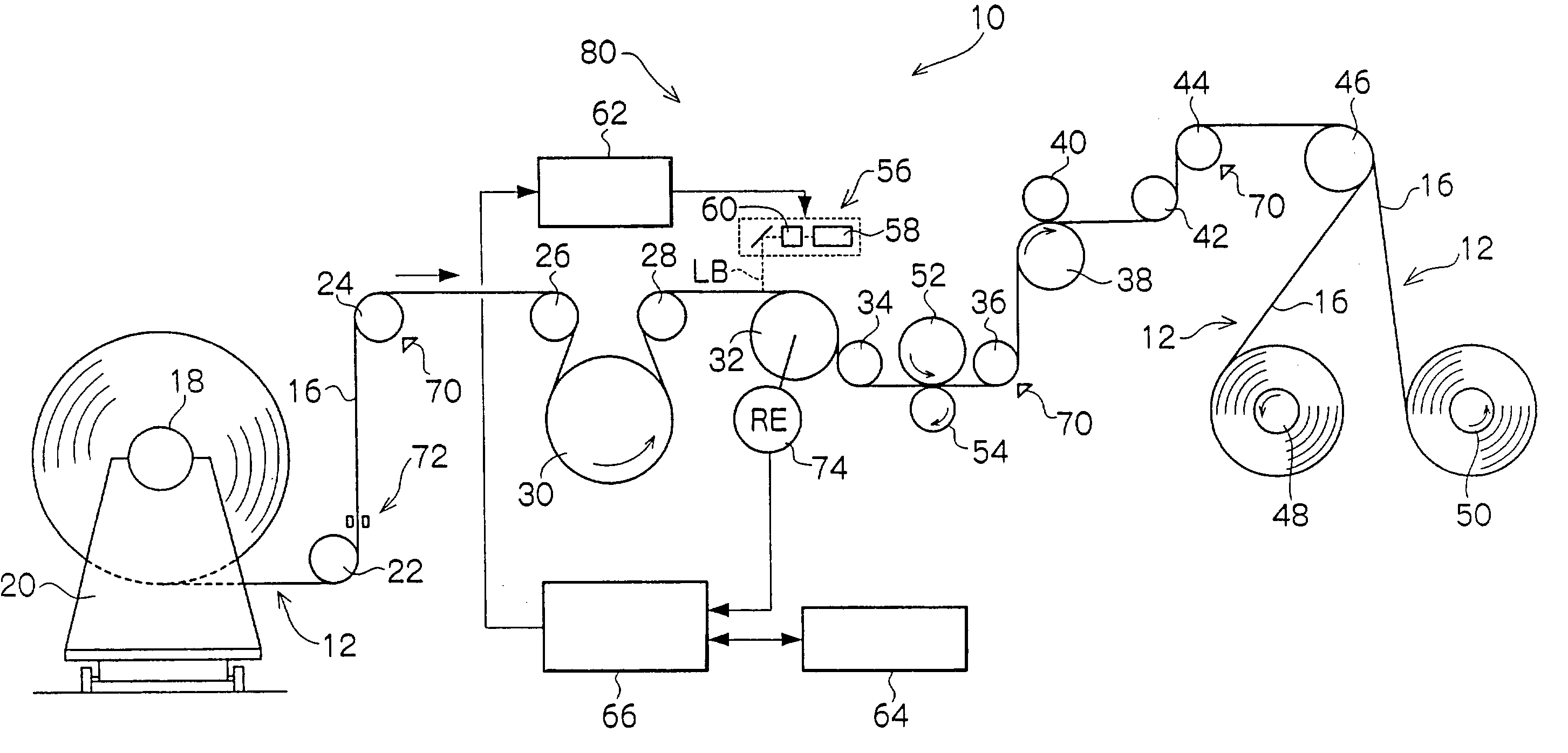

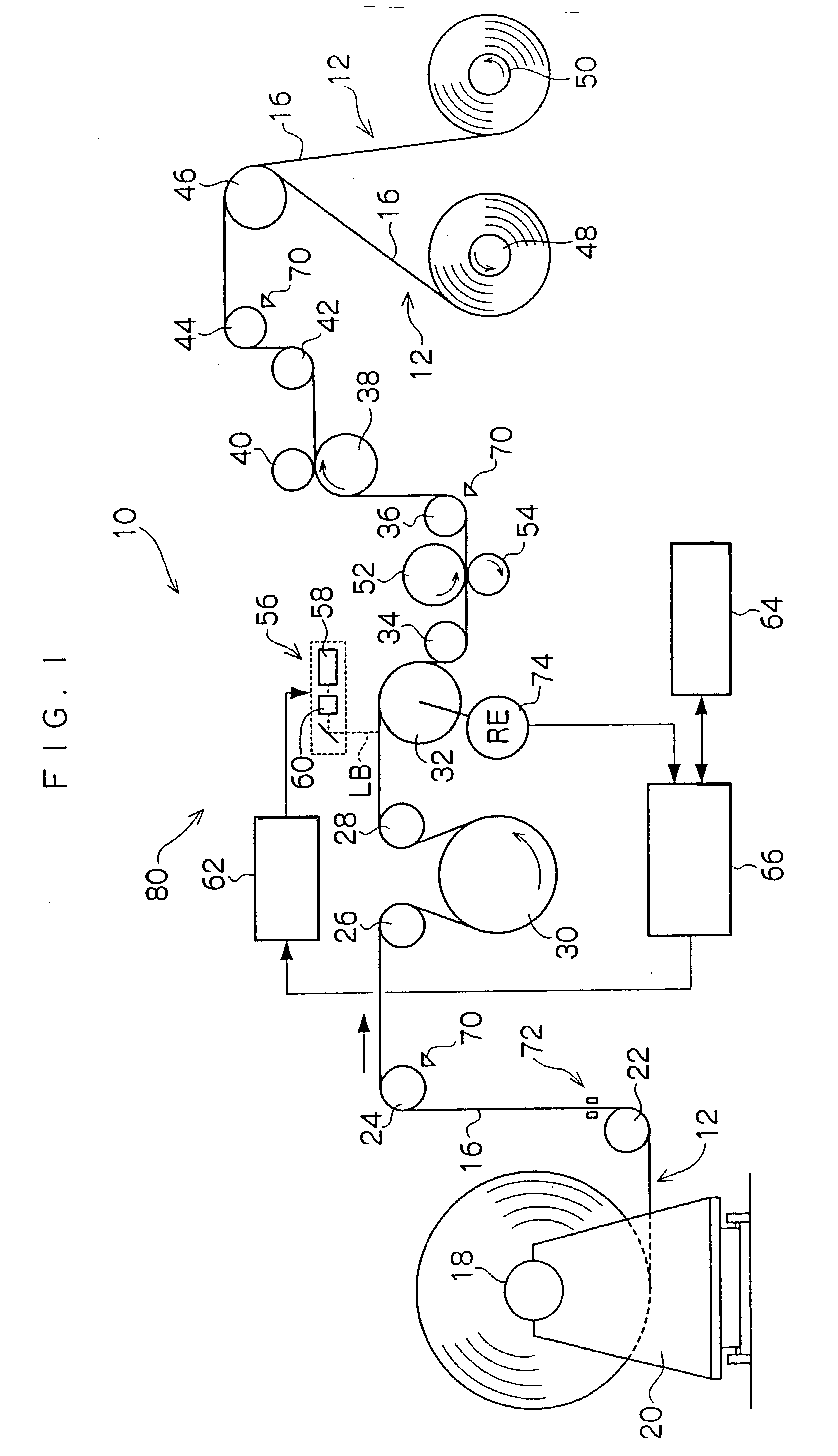

Web processing method and web processing device

InactiveUS20030222971A1Accurately formedImprove work efficiencyDevelopersDigital marking by photographic/thermographic registrationDevice formX-ray

In a web processing device, a marking head is disposed so as to oppose an X-ray film which is trained about a print roller which is at an upstream side of slitting blades. Within a scanning range of a laser beam of a marking head, two printing regions are disposed with a non-printing region therebetween. The non-printing region is disposed so as to oppose a cutting line which is cut by the slitting blades. Before cutting the X-ray film, the web processing device forms marking patterns on both sides of the cutting line.

Owner:FUJIFILM HLDG CORP +1

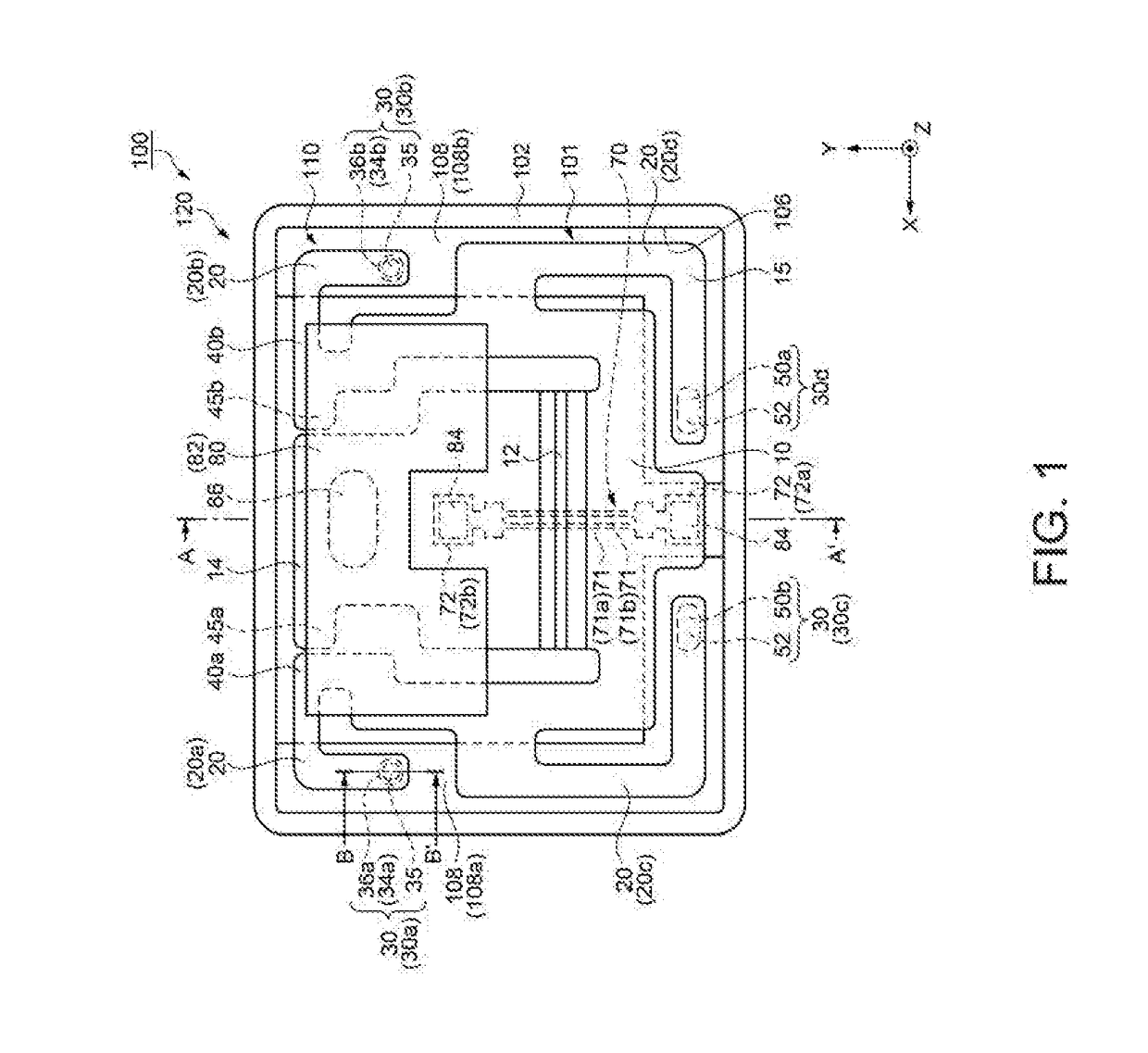

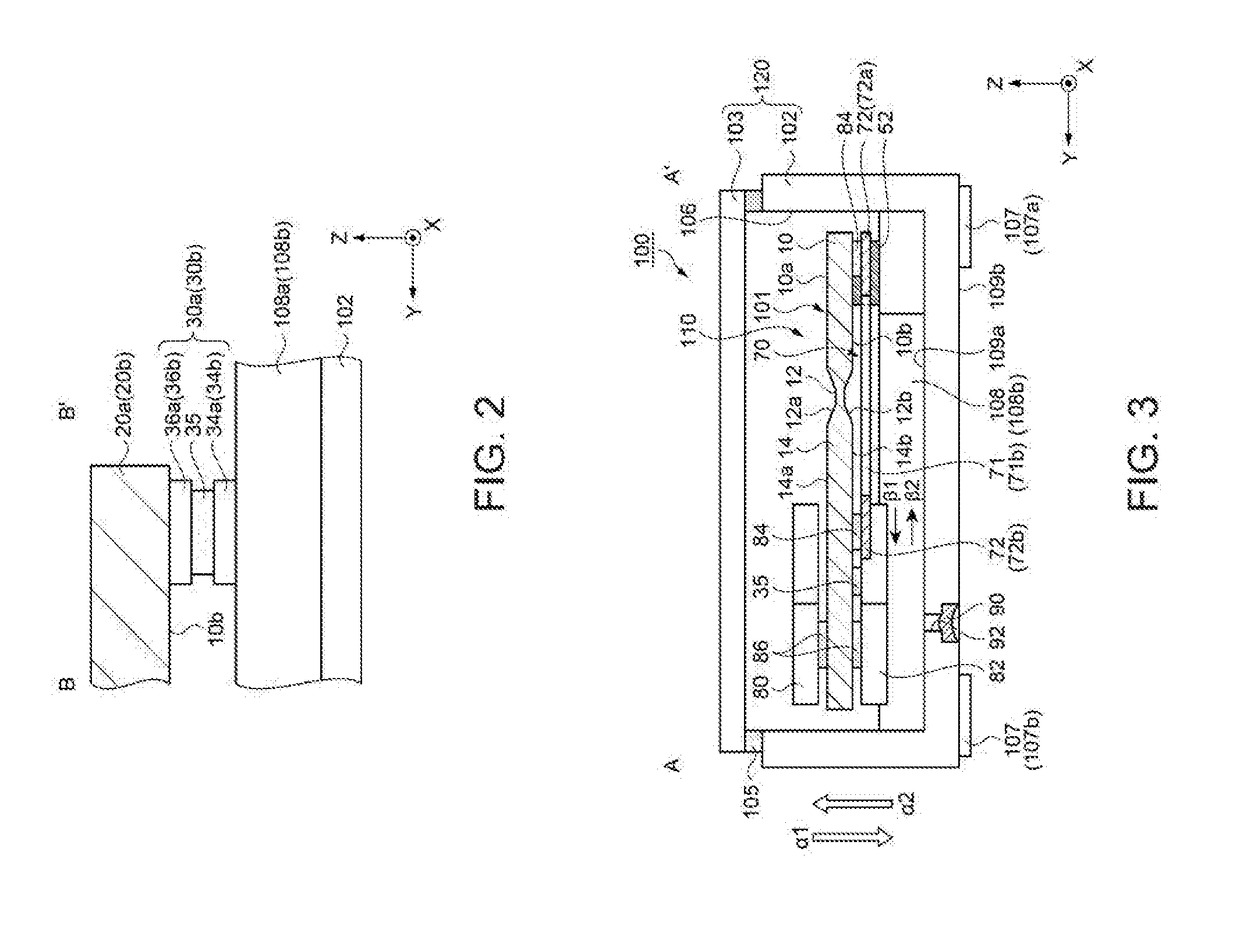

Substrate for sensor, physical quantity detection sensor, acceleration sensor, electronic apparatus, vehicle, and method of manufacturing substrate for sensor

ActiveUS20180065840A1Accurately formedImprove accuracyAcceleration measurement using interia forcesDecorative surface effectsEngineeringCantilever

A cantilever section as a substrate for a sensor includes: a base section; a movable section connected to the base section; an arm portion as a support portion extending along the movable section from the base section when viewed in a planar view as viewed from a thickness direction of the movable section; and a gap portion formed to have a predetermined gap between the movable section and the arm portion when viewed in the planar view, in which a ridge portion formed as an etching residue having a top portion on the side facing the gap portion is provided on each of facing surfaces of the movable section and the arm portion in the gap portion, and the predetermined gap is a gap between a top portion of a first ridge portion which is the ridge portion formed at one of the movable section and the arm portion, and a top portion of a second ridge portion which is the ridge portion formed at the other of the movable section and the arm portion.

Owner:SEIKO EPSON CORP

Substrate for sensor, physical quantity detection sensor, acceleration sensor, electronic apparatus, and moving object

InactiveUS20170184626A1Accurately formedExcellent impregnationAcceleration measurement using interia forcesEngineeringMechanical engineering

A substrate for a sensor includes: a base section; a movable section connected to the base section; an arm portion as a support portion extending along the movable section from the base section; a first gap portion having a protrusion portion in which one of the movable section and the arm portion protrudes toward the other of the movable section and the arm portion, and having a predetermined gap between the protrusion portion on one side and the other of the movable section and the support portion; and a second gap portion which is located further toward the base section side than the first gap portion has a gap wider than the predetermined gap, in which in the first gap portion, one of the movable section and the arm portion has a ridge portion on the side facing the first gap portion.

Owner:COLUMBIA PEAK VENTURES LLC

Driver/Fastener Inter-engagement System

InactiveUS20180106286A1Reduce manufacturing costAccurately-formedBoltsSpannersDriver/operatorEngineering

Embodiments of the present invention provide a screw and driver system comprising a range of screws and a driver for said range. Each screw comprises a head having a driving recess in its surface for engagement by said driver. Each recess has a recess longitudinal axis. The recess of larger screws in the range has a plurality of superimposed recess-tiers of decreasing size with increasing depth from said surface, each recess-tier except the smallest having substantially parallel driving surfaces substantially parallel said recess longitudinal axis. The driving head of the driver has a driver longitudinal axis and a plurality of superimposed drive-tiers of decreasing size towards a tip of the driver, each drive-tier except the smallest having substantially parallel driving surfaces substantially parallel said longitudinal axis. The driver and recess are shaped so that, when the driver is engaged with the recess of any screw in said range, torque applied to the driver is transmitted to the screw through said driving surfaces. The smallest recess-tier of larger screws has a mouth in a floor of an adjacent recess-tier and has recess flanks that are all tapered from the mouth towards the recess longitudinal axis at a recess taper angle between 1.91 and 6.85°. The smallest drive-tier of the driver has a root in a base of an adjacent drive-tier and has drive flanks that are all tapered from the root towards the driver longitudinal axis at a tier taper angle between minus 1.5 and plus 2.5° difference with respect to said recess taper angle. The diameter of the drive-tier at the root and the diameter of the recess-tier at the mouth are such that, on insertion of said driver head in the screw recess, said drive and recess flanks inter-engage to deform and stick together through frictional engagement before said base engages said floor.

Owner:CONSOLIDATED FASTENERS LLC

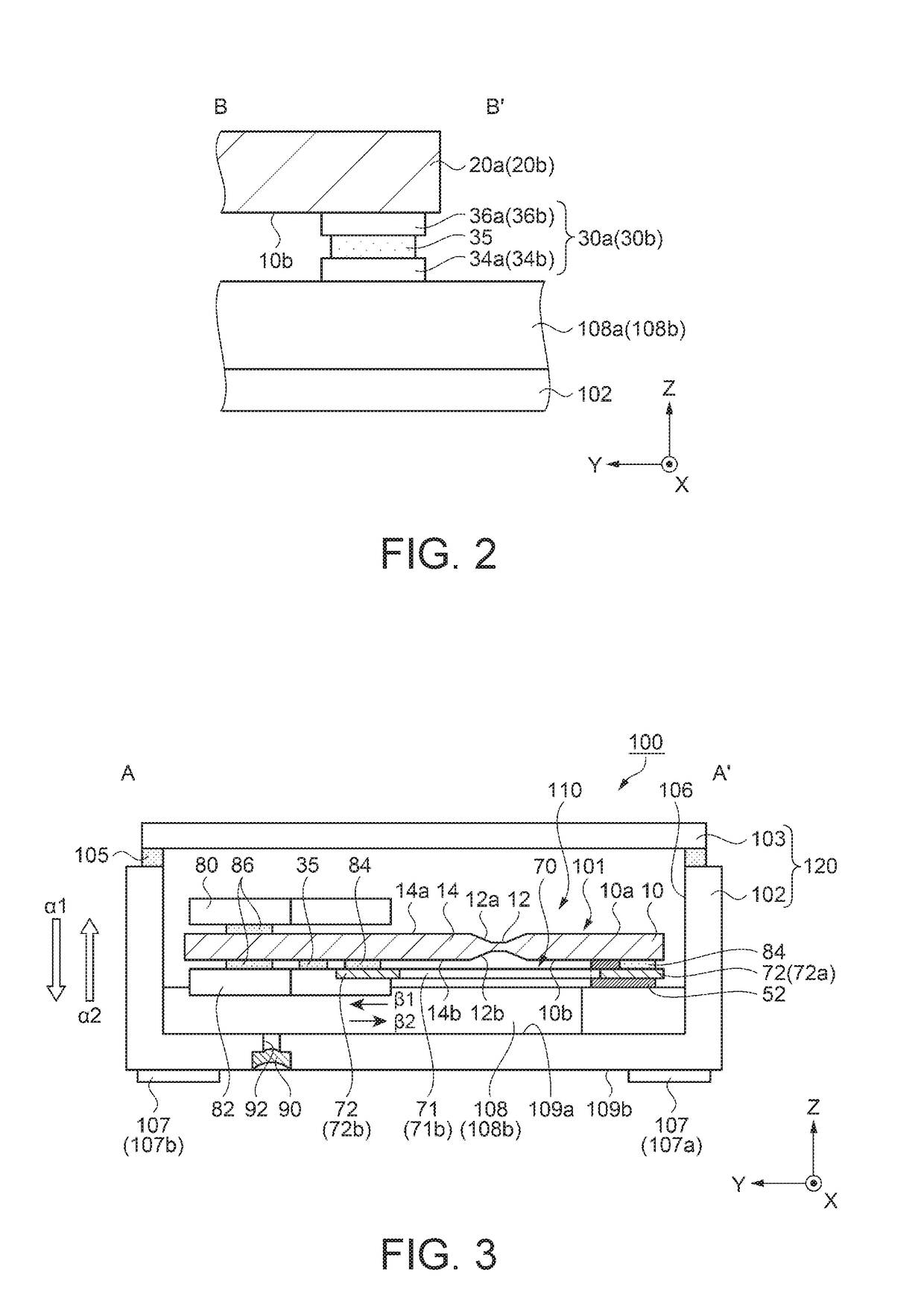

Information recording device and information recording method

InactiveUS20060153038A1Accurately formedTelevision system detailsRecording strategiesMultiple pulseLaser

In a recording strategy suitable for high-speed recording, a laser driving signal includes a top pulse having a pulse width corresponding to a recording mark length and multi-pulses having a period 3-times larger than a base clock period of a recording mark. The top pulse is has the first identical-shape top pulses when the recording mark length is 3 nT (“n” is a natural number), the second identical-shape top pulses when the recording mark length is (3 n+1)T, and the third identical-shape top pulses when the recording mark length is (3n+2)T.

Owner:PIONEER CORP

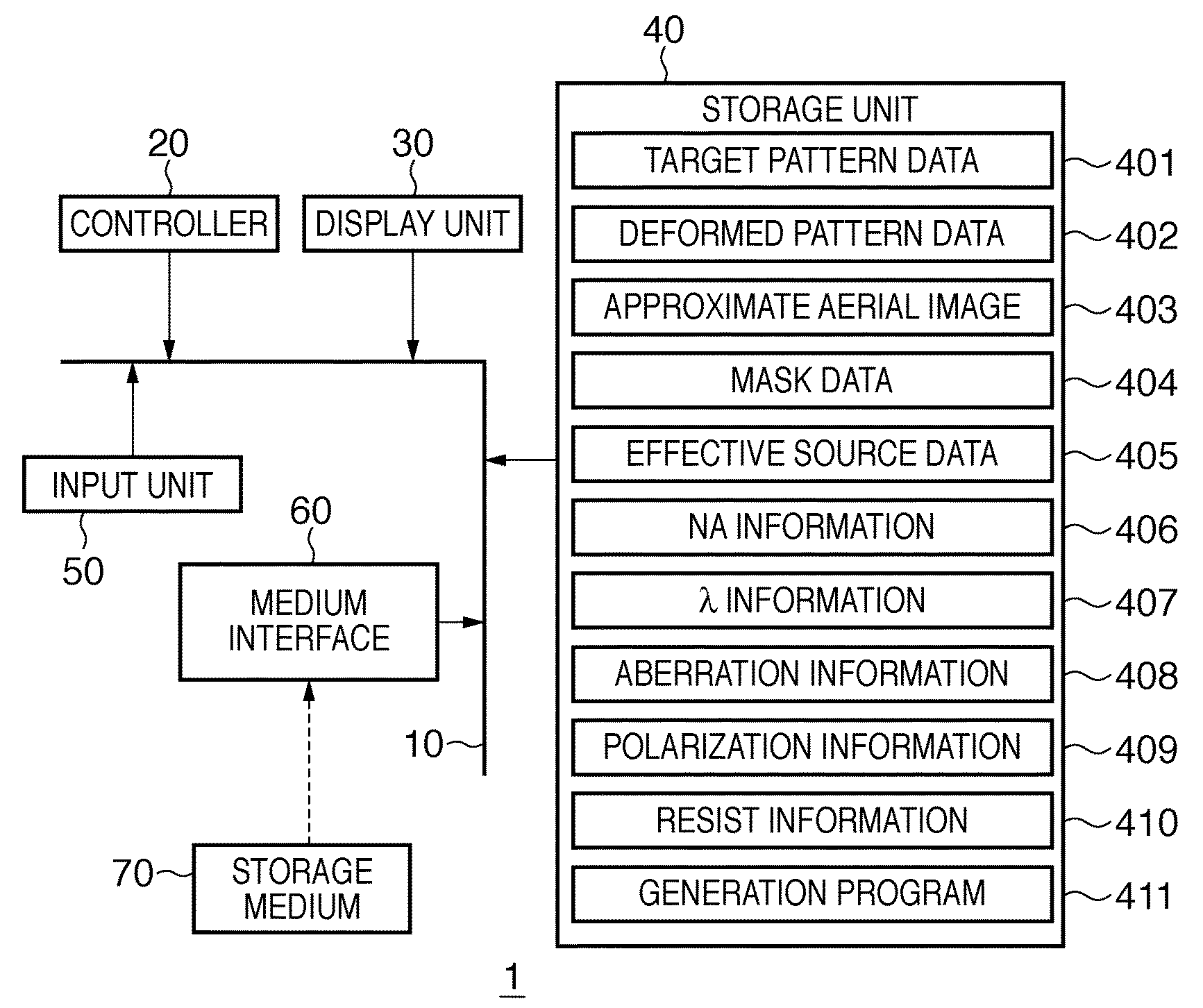

Method for optimization of light effective source while target pattern is changed

InactiveUS8365106B2Accurately formedPhotomechanical apparatusSemiconductor/solid-state device manufacturingOptics

Owner:CANON KK

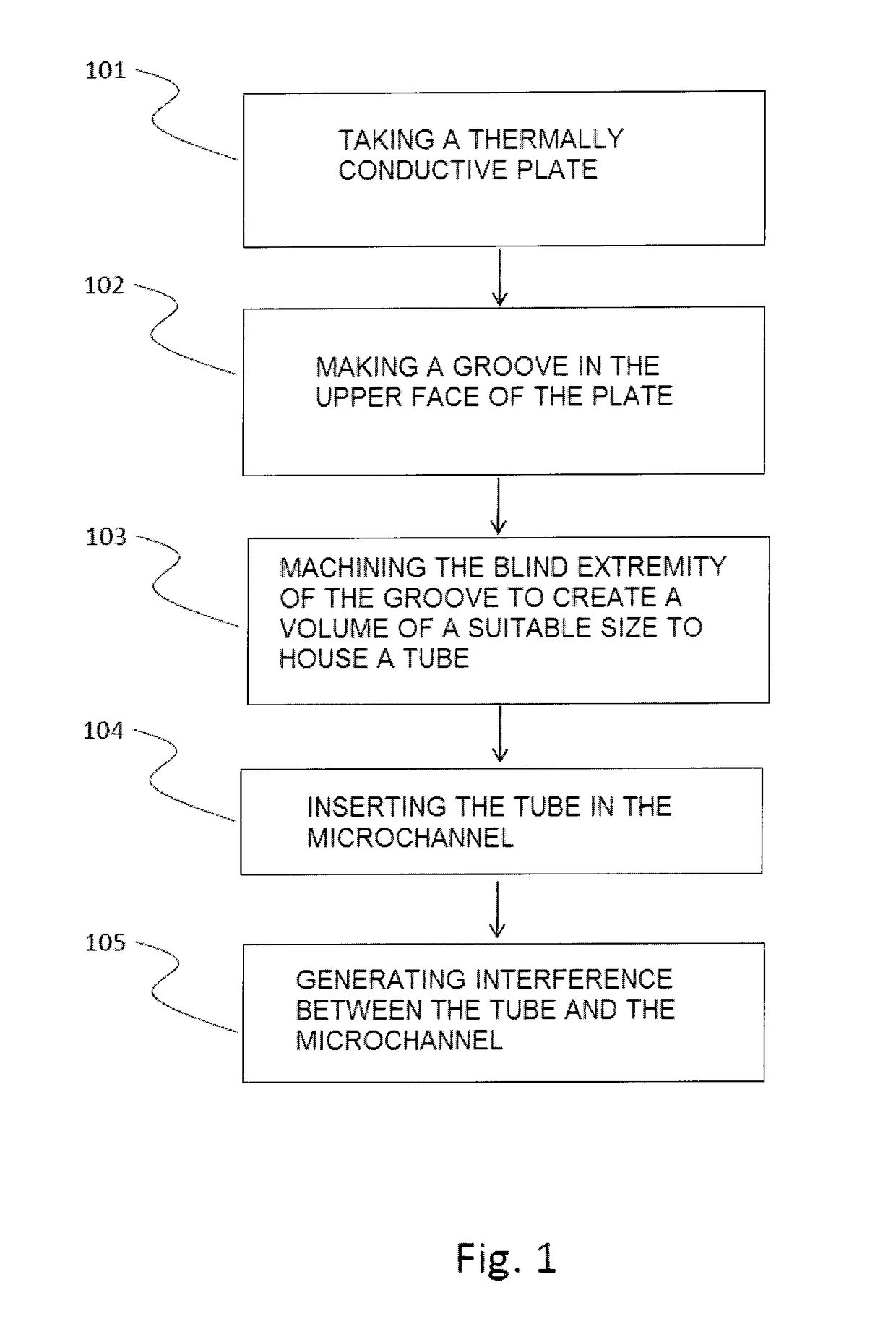

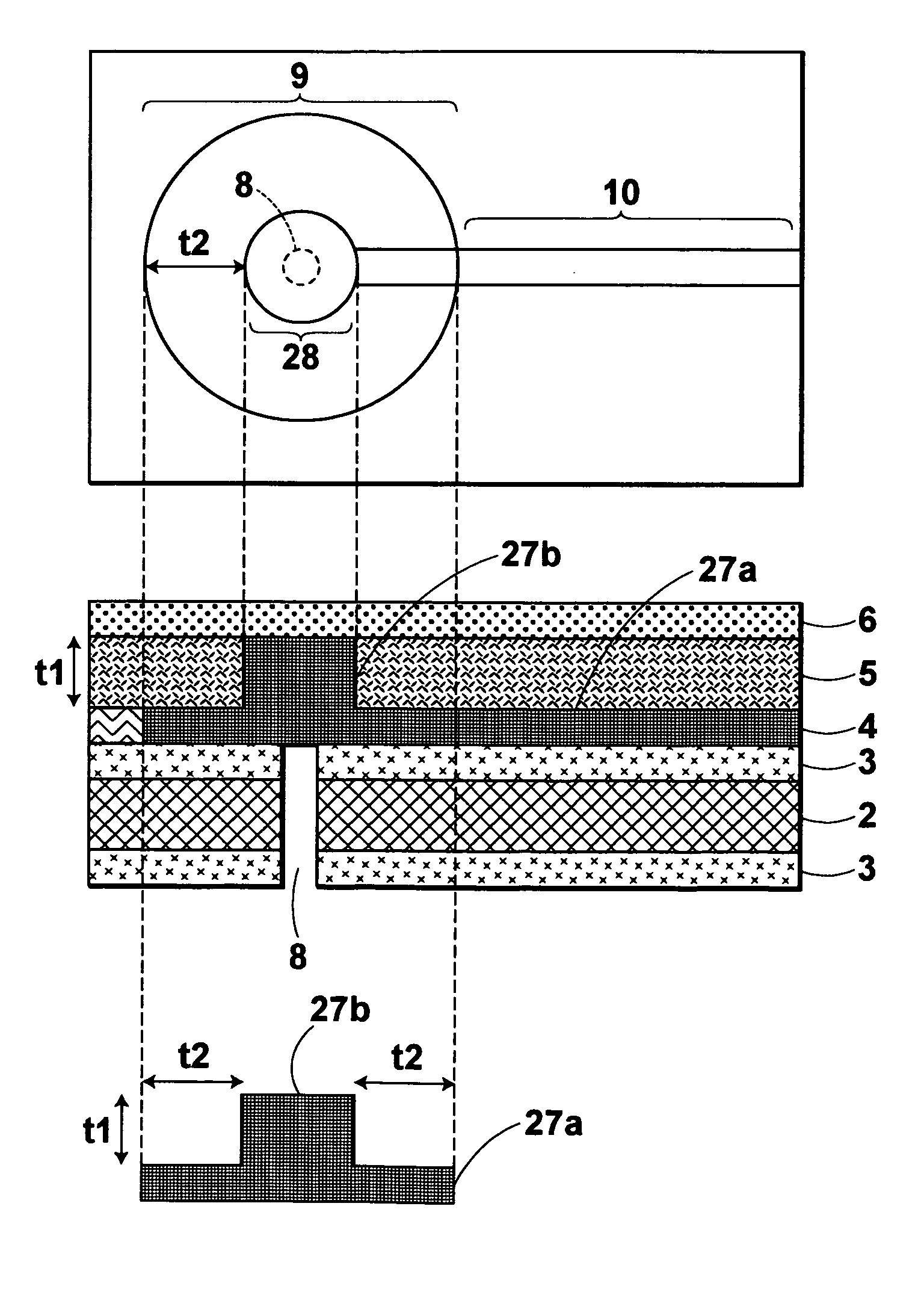

Method for producing a heat exchanger and relevant heat exchanger

InactiveUS20170082382A1Reduced dimensionImprove efficiencyLiquid coolingConversion outside reactor/acceleratorsEngineeringLower face

The invention relates to a method for producing a heat exchanger, wherein at least one microchannel, placed within a plate having an upper face and a lower face and precisely arranged between said upper face and lower face is obtained by making a groove on the upper face of the plate, said groove extending between an open extremity facing on the upper face and a blind extremity placed inside the plate, and machining the blind extremity of the groove to create a volume of a suitable size to house a tube inserted in the microchannel, said tube being fixed inside the microchannel by generating an interference between the tube and the microchannel. The invention relates also to a heat exchanger obtained by such method.

Owner:IST NAZ DI FISICA NUCLEARE

Manufacturing method of thin film transistor in which a total film thickness of silicon oxide films is defined

InactiveUS6867075B2Forming accuratelyAccurately formedTransistorSolid-state devicesSilicon oxideSemiconductor

On a transparent substrate to which a gate electrode is arranged, a silicon nitride film and a silicon oxide film to be gate insulating films are deposited, and further, a polycrystalline silicon film as a semiconductor film to be an active region is formed. On the polycrystalline silicon film corresponding to the gate electrode, a stopper is arranged, and a silicon oxide film and a silicon nitride film to be an interlayer insulating films are deposited so as to cover this stopper. The film thickness T0 of the stopper is set in a range of 800 angstroms to 1200 angstroms. Furthermore, the film thickness T0 of the stopper is set in the range to fulfill the following expression:T0+T1≦(T2×8000 Å)where T1 is the film thickness of the silicon oxide film and T2 is the film thickness of the silicon nitride film.

Owner:SANYO ELECTRIC CO LTD

Method of forming patterns

InactiveUS7223703B2Low yieldAccurately formedSecond resist patternSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringMechanical strength

In forming a mask pattern on a circuit board, a mask pattern of N-layer structure is formed in a region where the mechanical strength of the circuit board needs to be increased. N photosensitive layers are first stacked on a substrate so that they becomes lower in sensitivity from the first photosensitive layer toward the Nth photosensitive layer. In the first photosensitive layer (bottom layer), a first pattern is formed and has the same shape as a predetermined pattern to be formed on the circuit board. In the Kth photosensitive layer (N≧K≧2), a Kth pattern is formed so that the Kth pattern is smaller than a (K−1)st pattern formed in the (K−1)st photosensitive layer and arranged inside the (K−1)st pattern.

Owner:ADTEC ENG +1

Printing plate, method of manufacturing the printing plate, roll printing apparatus including the printing plate, and method of manufacturing display device using the roll printing apparatus

InactiveUS20070131124A1Accurately forming ink patternAccurately formedOther printing apparatusRotary letterpress machinesDisplay deviceEngineering

A printing plate, a method of manufacturing the printing plate, a roll printing apparatus including the printing plate, and a method of manufacturing a display device using the roll printing apparatus are provided. The roll printing apparatus includes a printing plate including an array of a plurality of grooves arranged equally spaced in a first direction, having substantially the same depth as a cell gap of a display panel including two opposing substrates, and extending in a second direction perpendicular to the first direction such that a distance between each of the plurality of grooves is greater at an end line than at a start line, and a transfer roller including a transfer sheet for transferring ink that is filled in the plurality of grooves to one of the substrates.

Owner:SAMSUNG ELECTRONICS CO LTD

Physical quantity sensor and method for manufacturing the same

InactiveUS20060008935A1Accurately formedAccurate shapeAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A physical quantity sensor includes: a semiconductor substrate; a cavity disposed in the substrate and extending in a horizontal direction of the substrate; a groove disposed on the substrate and reaching the cavity; a movable portion separated by the cavity and the groove so that the movable portion is movably supported on the substrate; and an insulation layer disposed on a bottom of the movable portion so that the insulation layer provides a roof of the cavity.

Owner:DENSO CORP

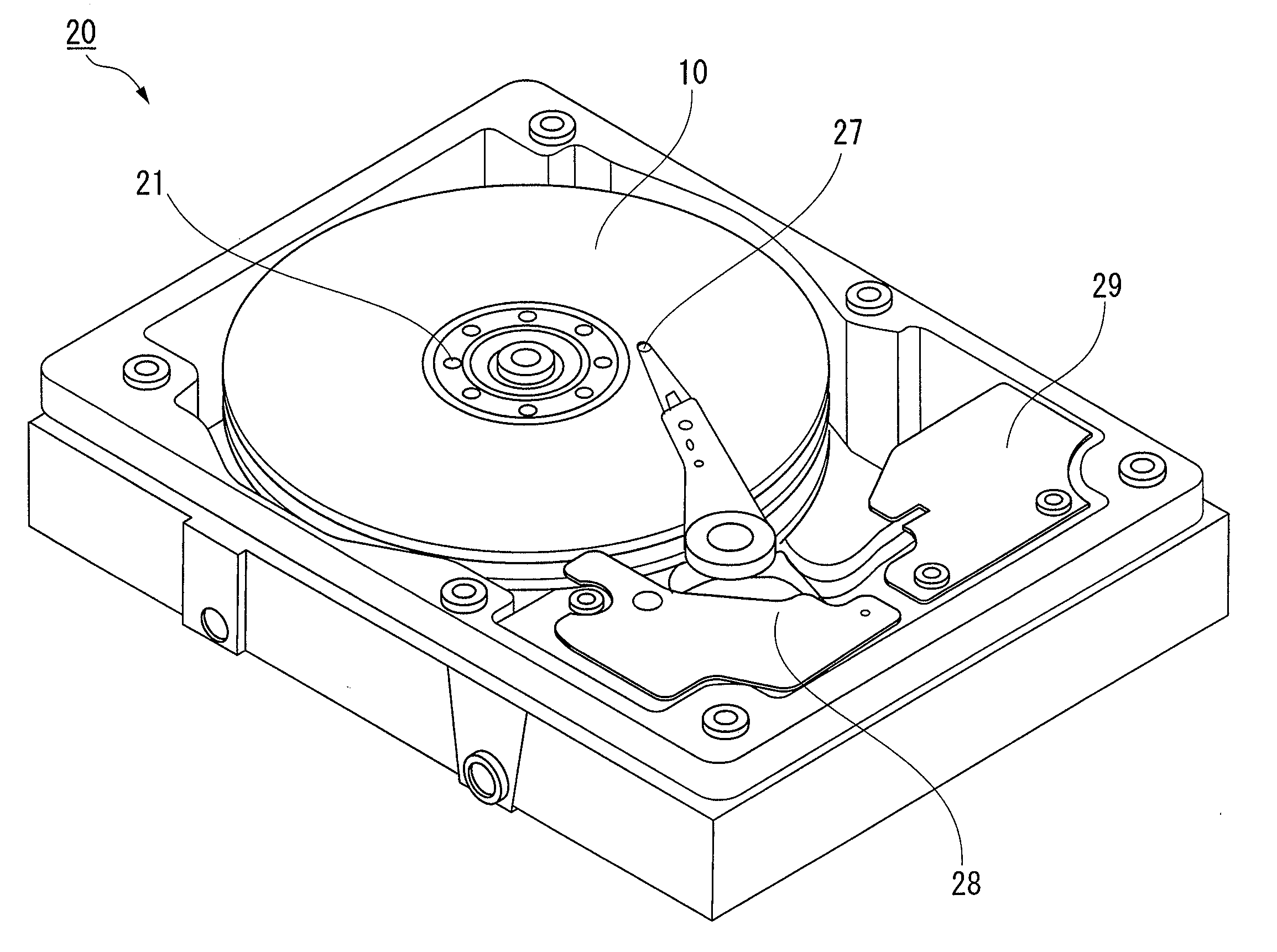

Air bearing surface of thin-film magnetic head slider and method of processing the same

InactiveUS7554770B2Improve adhesionAccurately formedFluid-dynamic spacing of headsRecord information storageResistCarbon film

Owner:TDK CORPARATION

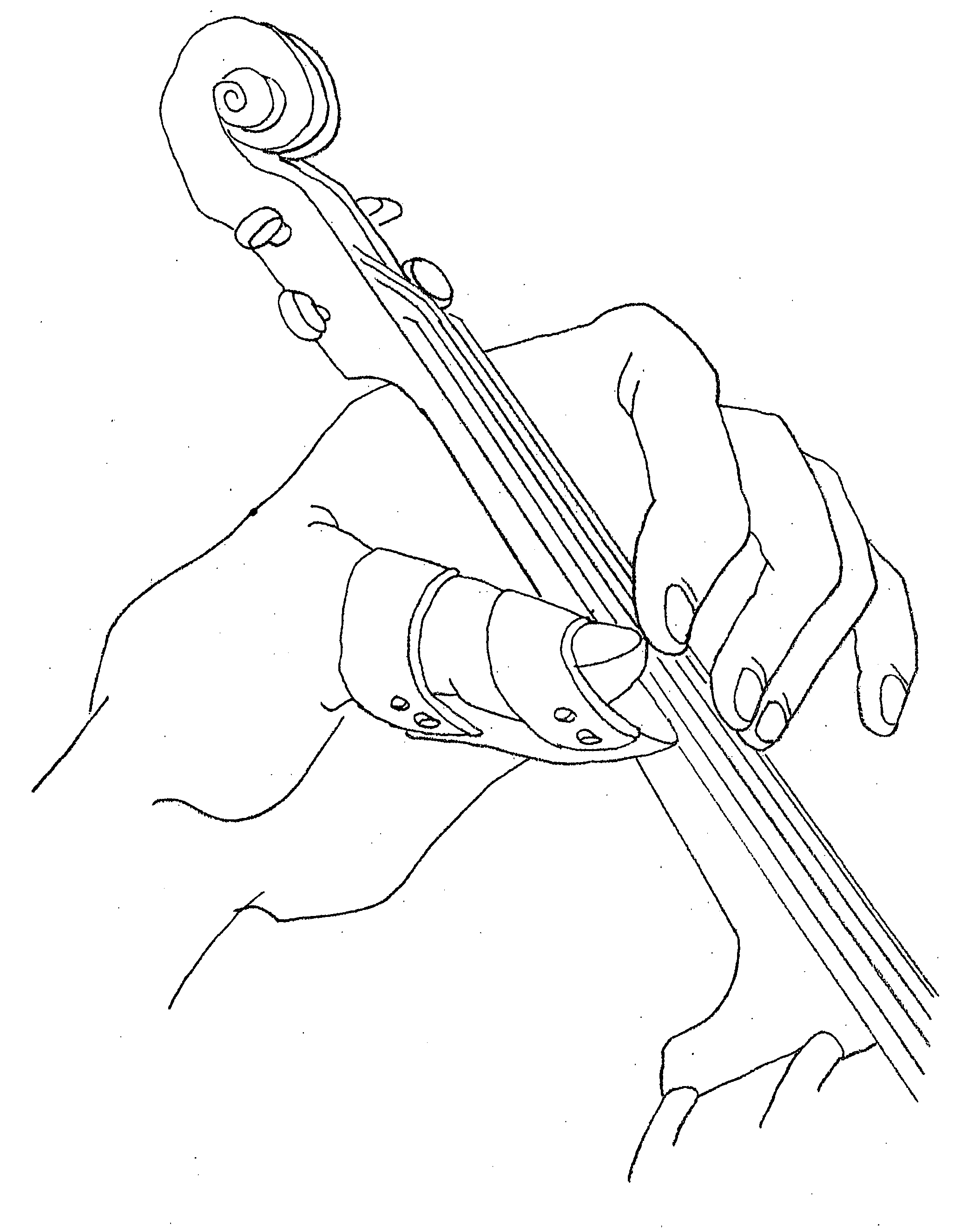

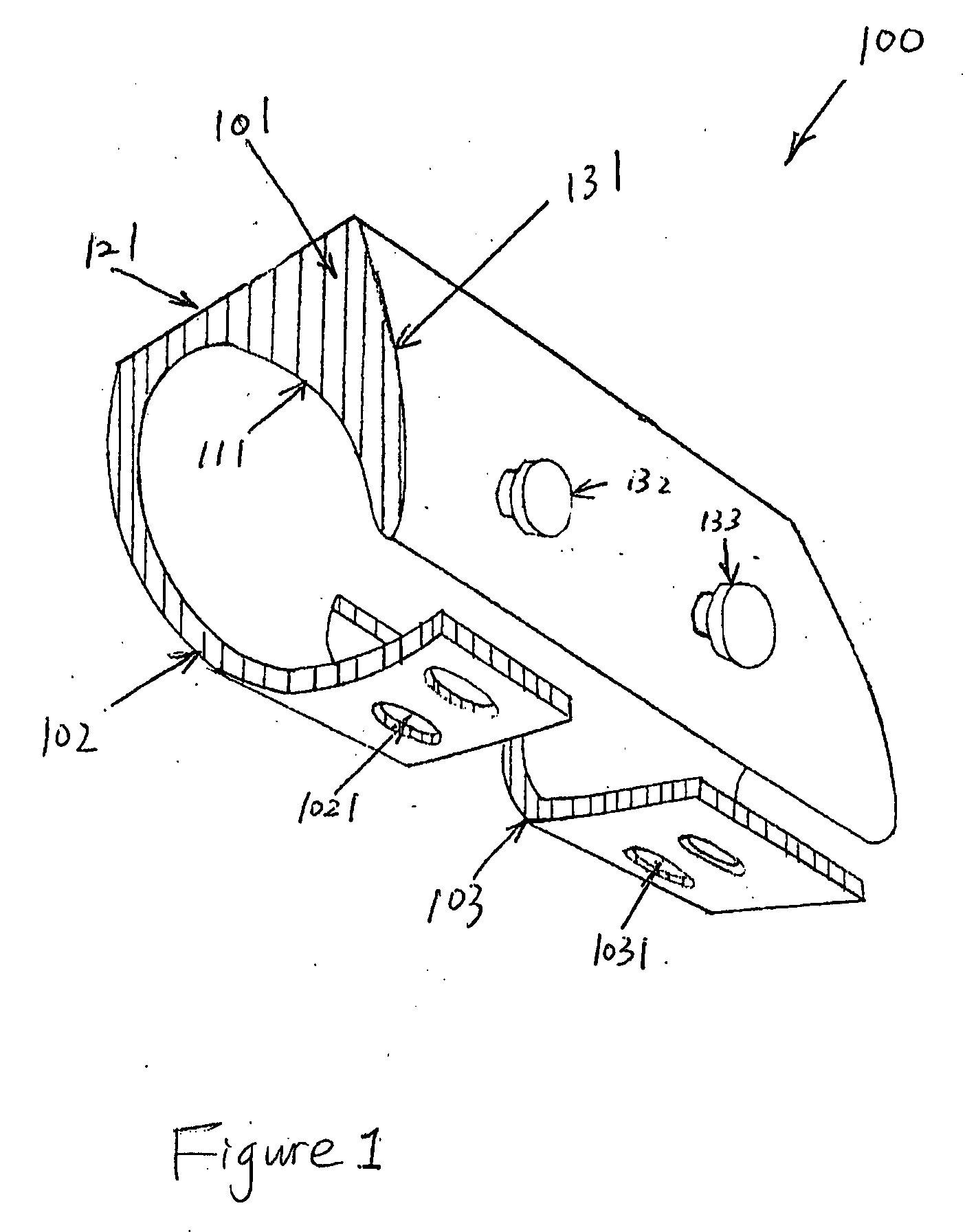

Violin Thumb Pad

A violin thumb pad that facilitates the optimal positioning of violin relative to the player's thumb supporting the violin neck, for teaching purpose and for increased comfort and reduced physical stress, is introduced. Assuming the violin player uses left hand to play the violin finger board, and used right hand to hold the bow, the violin thumb pad forces the left thumb and palm to turn towards the player so the player's fingers are inline with the violin string naturally. The violin thumb pad also forces the left thumb and to be comfortably straight. And it forces the left elbow to stay close with the player's body. The violin thumb pad also makes it easier to place the violin neck between the thumb and index finger and not letting the violin neck drop to the bottom of the thumb. The violin thumb pad comprises an elongated pad that has one side conformable to the thumb and one side conformable to the violin neck, and at least one harnesses or loops that fastens the pad to the thumb.

Owner:LUO TONG

Magnetic recording medium, method of manufacturing magnetic recording medium, and magnetic recording/reproducing apparatus

ActiveUS20110007414A1Increase productionAccurately formedDecorative surface effectsNanoinformaticsForeign matterEngineering

Disclosed is a method of manufacturing a magnetic recording medium capable of effectively and reliably removing foreign materials on the surface of a magnetic recording medium, preventing a mask layer from remaining on the surface of the magnetic recording medium, and forming the pattern of a magnetic layer with high productivity. The method of manufacturing a magnetic recording medium includes: a step of forming a magnetic layer on a non-magnetic substrate; a step of forming a mask layer on the magnetic layer; a step of patterning the mask layer to form a mask pattern; a step of forming a magnetic recording pattern on the magnetic layer using the mask pattern; a step of burnishing the surface of the mask pattern with an abrasive; and a step of removing the mask pattern.

Owner:RESONAC CORP

Web processing method and web processing device

InactiveUS6924829B2Increase in sizeAccurately formedDevelopersDigital marking by photographic/thermographic registrationDevice formX-ray

In a web processing device, a marking head is disposed so as to oppose an X-ray film which is trained about a print roller which is at an upstream side of slitting blades. Within a scanning range of a laser beam of a marking head, two printing regions are disposed with a non-printing region therebetween. The non-printing region is disposed so as to oppose a cutting line which is cut by the slitting blades. Before cutting the X-ray film, the web processing device forms marking patterns on both sides of the cutting line.

Owner:FUJIFILM HLDG CORP +1

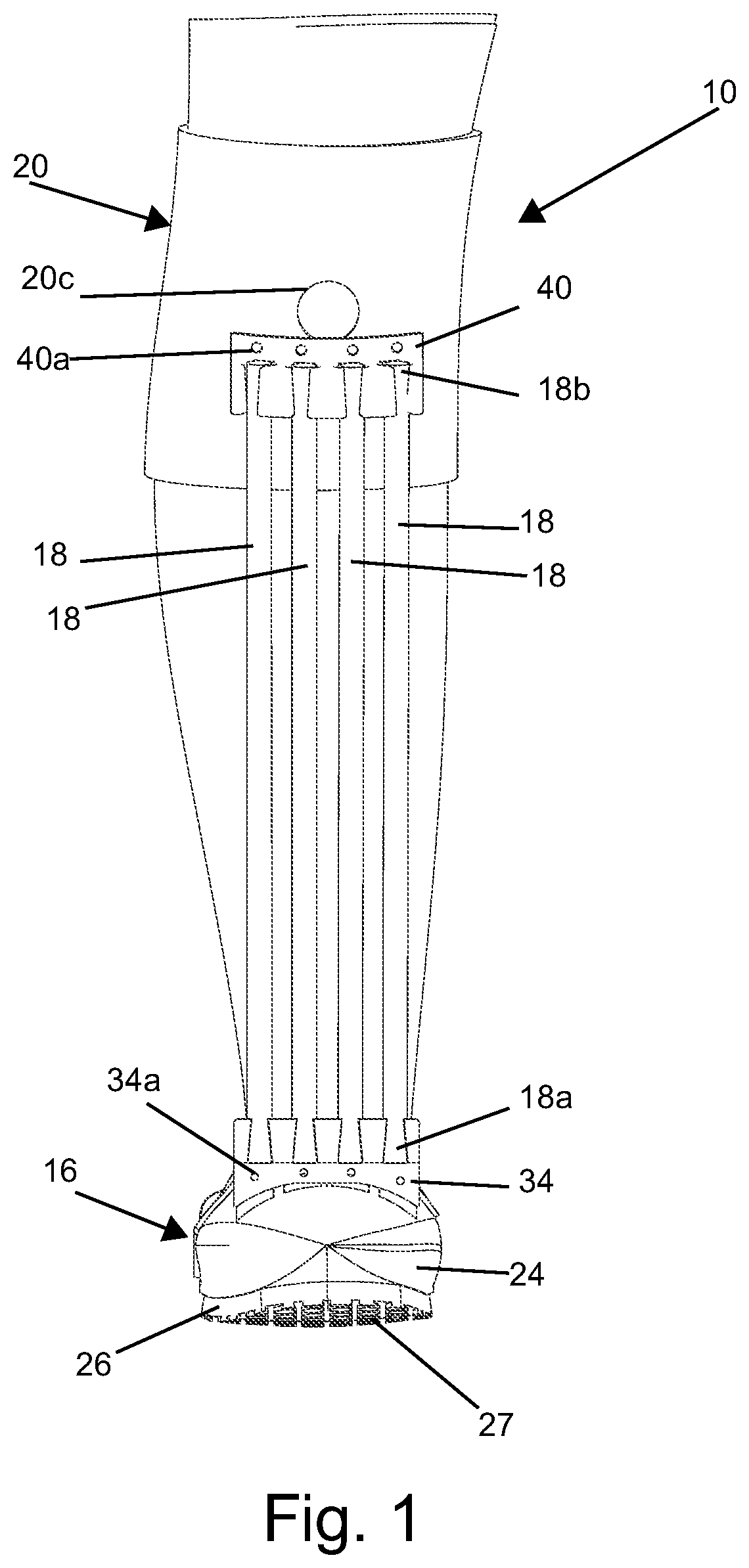

Exercise device

PendingUS20220184450A1Accurately formedImprove formFasteningsMuscle exercising devicesAerobic exerciseEngineering

An exercise device includes a footwear part, a brace part and at least one resistance band. The footwear part has a foot receiving portion configured to receive a front portion of a user's foot. The brace part is configured to be releasably attached to a knee area of the user. The at least one resistance band is configured to be releasably secured at opposite ends thereof to the footwear part and brace part, respectively. The exercise device can be used, among other things, for conditioning and strengthening, for aerobic exercises, and to help individuals maintain proper foot placement throughout an entire exercise and improve their form by helping them stay on their forefoot when performing an exercise dealing with brisk walking or running.

Owner:LOUIS ROOBENS

Information recording apparatus and information recording method

InactiveUS7586823B2Accurately formedRecording strategiesTelevision system detailsLaserElectrical and Electronics engineering

In a recording strategy suitable for high-speed recording, a laser driving signal includes a top pulse having a pulse width corresponding to a recording mark length and multi-pulses having a period 3-times larger than a base clock period of a recording mark. The top pulse is has the first identical-shape top pulses when the recording mark length is 3nT (“n” is a natural number), the second identical-shape top pulses when the recording mark length is (3n+1)T, and the third identical-shape top pulses when the recording mark length is (3n+2)T.

Owner:PIONEER CORP

Electrode tool for electrochemical machining and method for manufacturing same

InactiveUS7887678B2Good reproducibilityBurring of the lands can be preventedElectrical-based machining electrodesFeeding apparatusHeight differenceEngineering

Owner:MINEBEAMITSUMI INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com