Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about "Refining by particle radiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing biomass

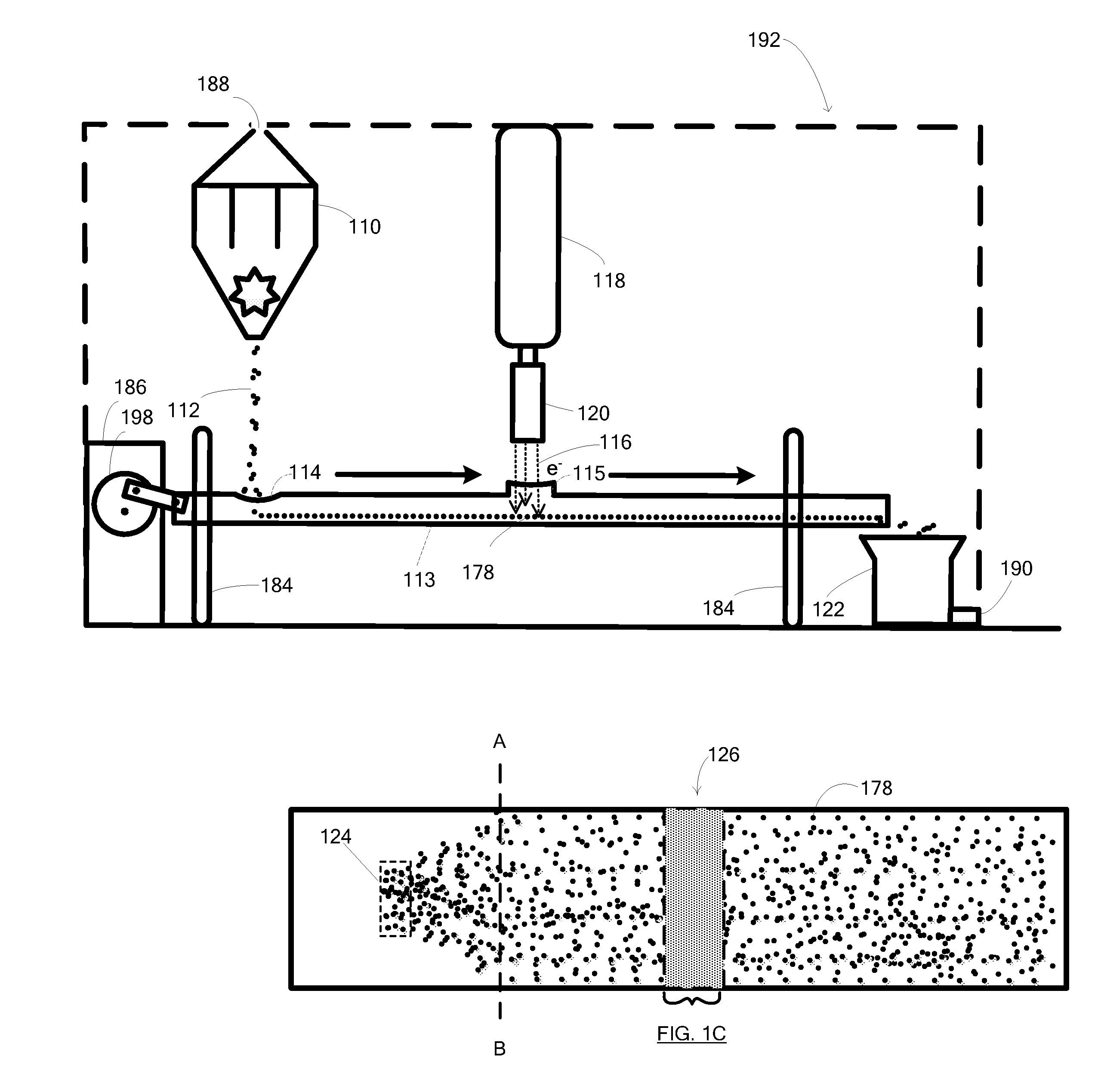

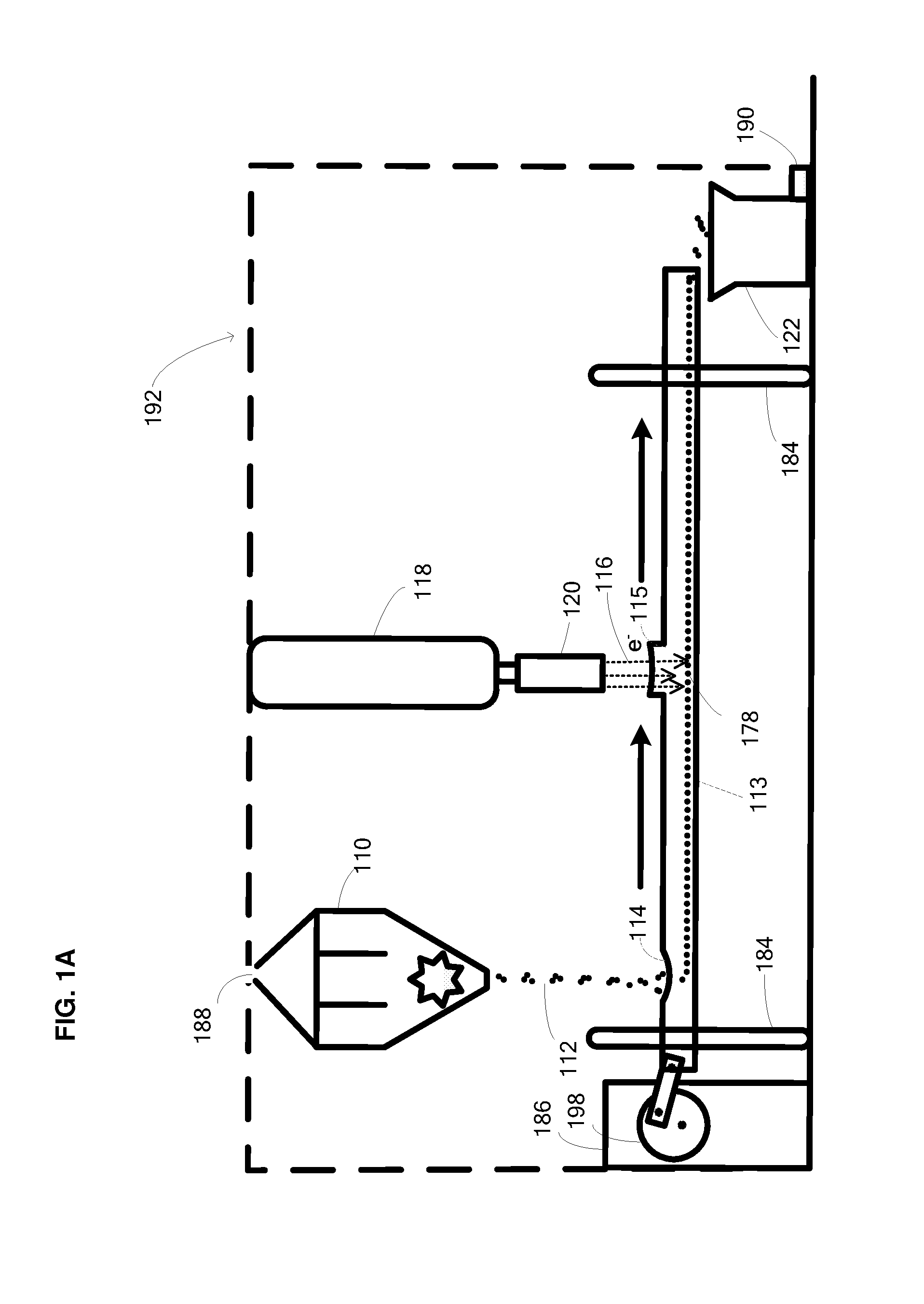

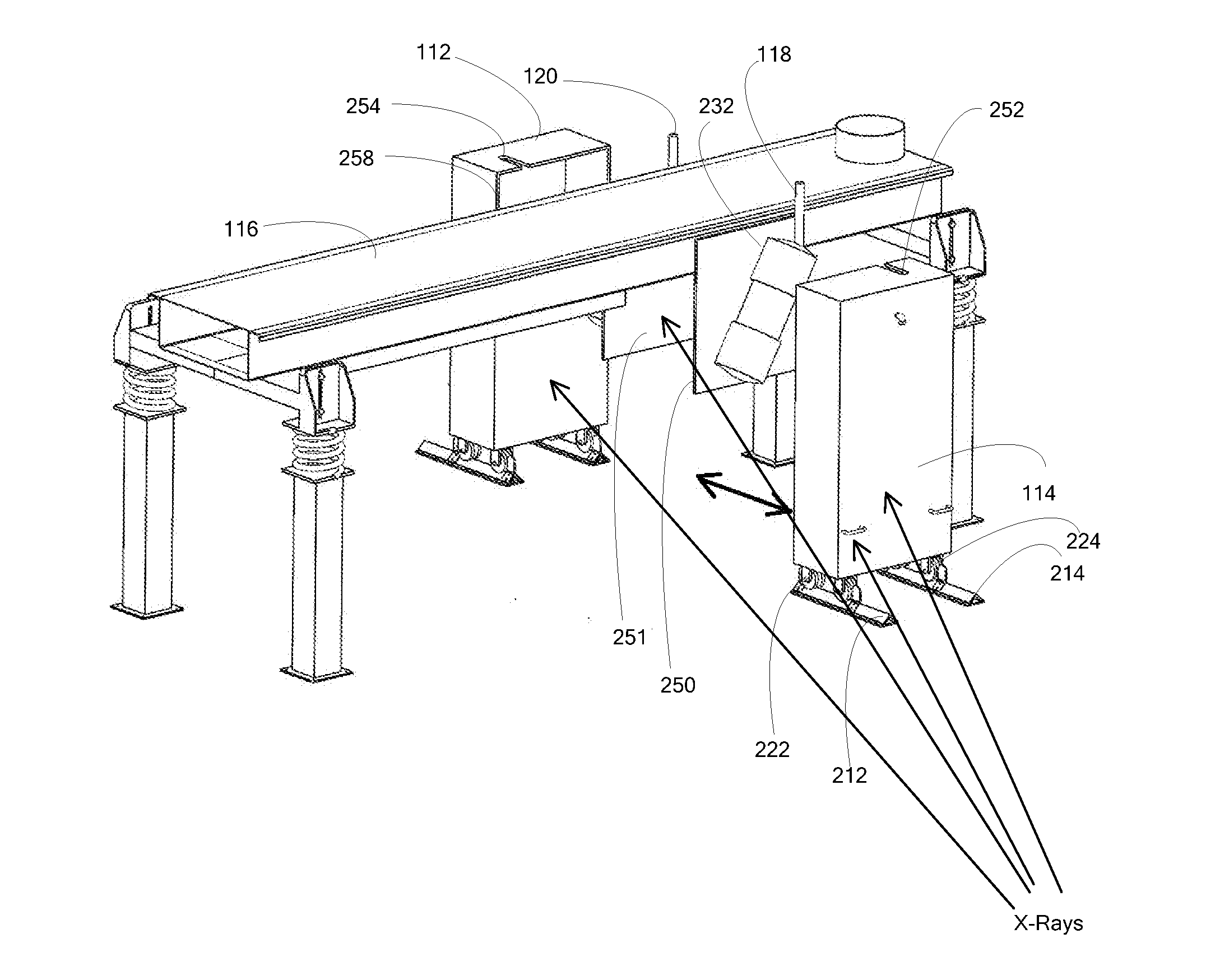

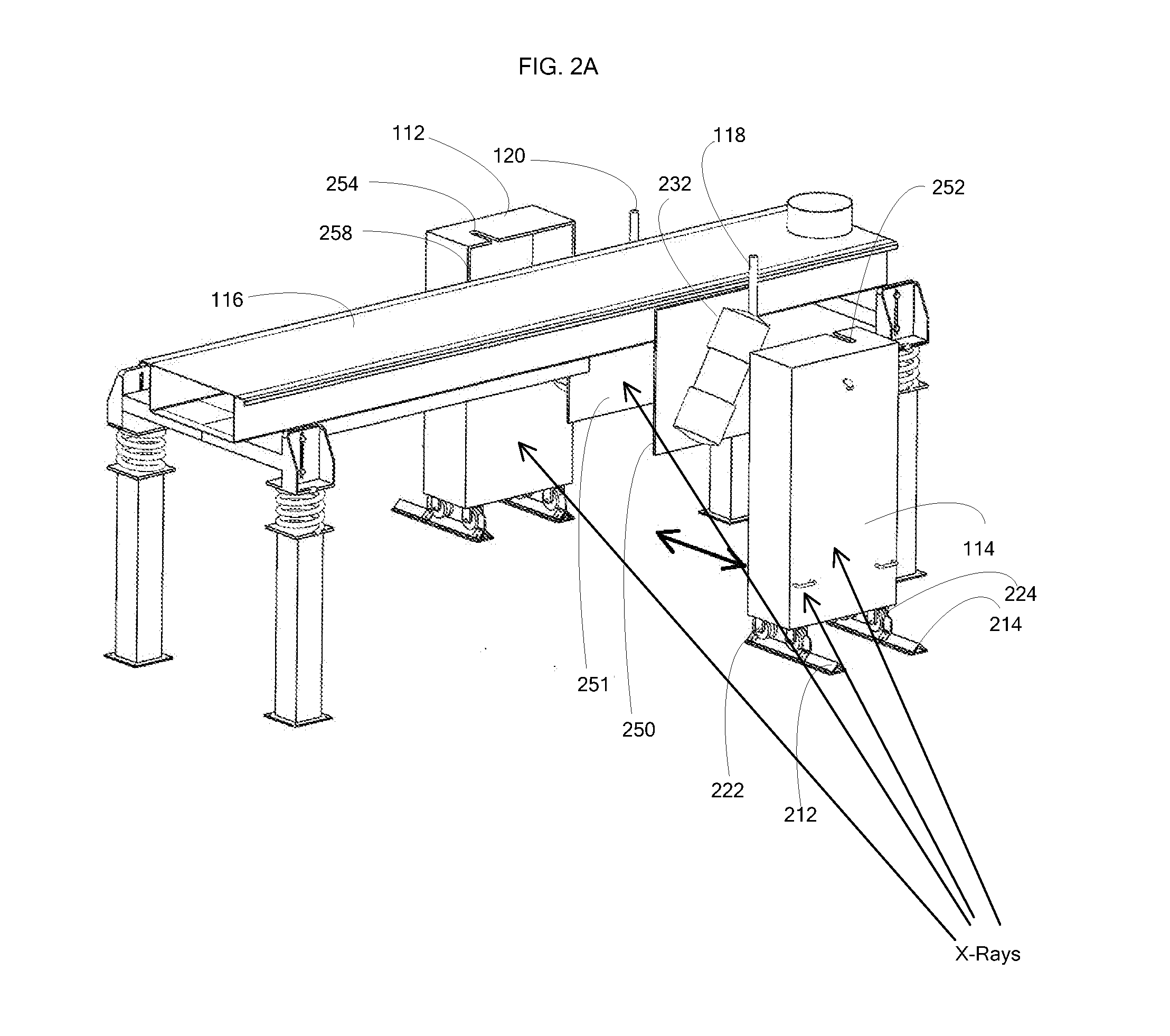

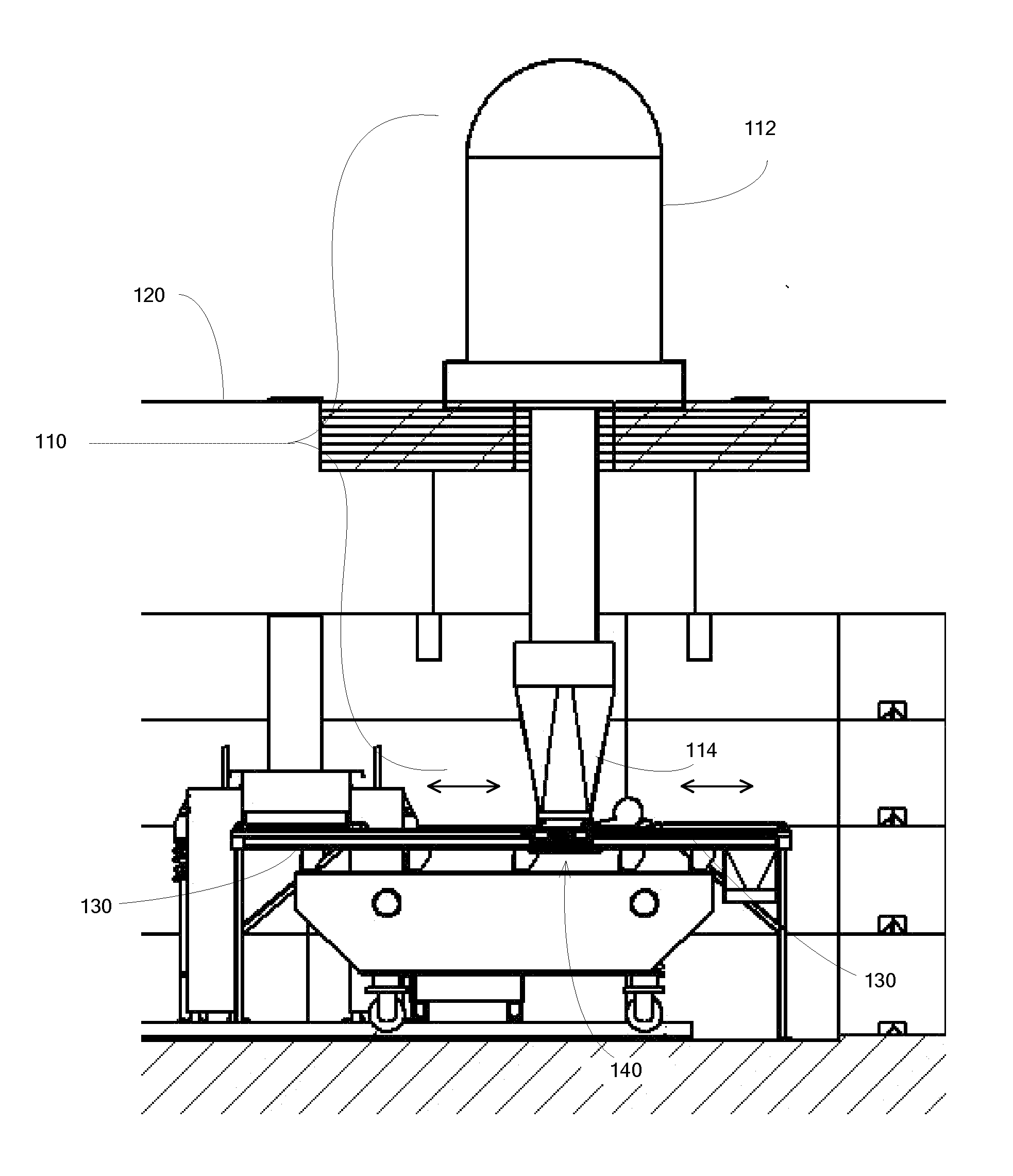

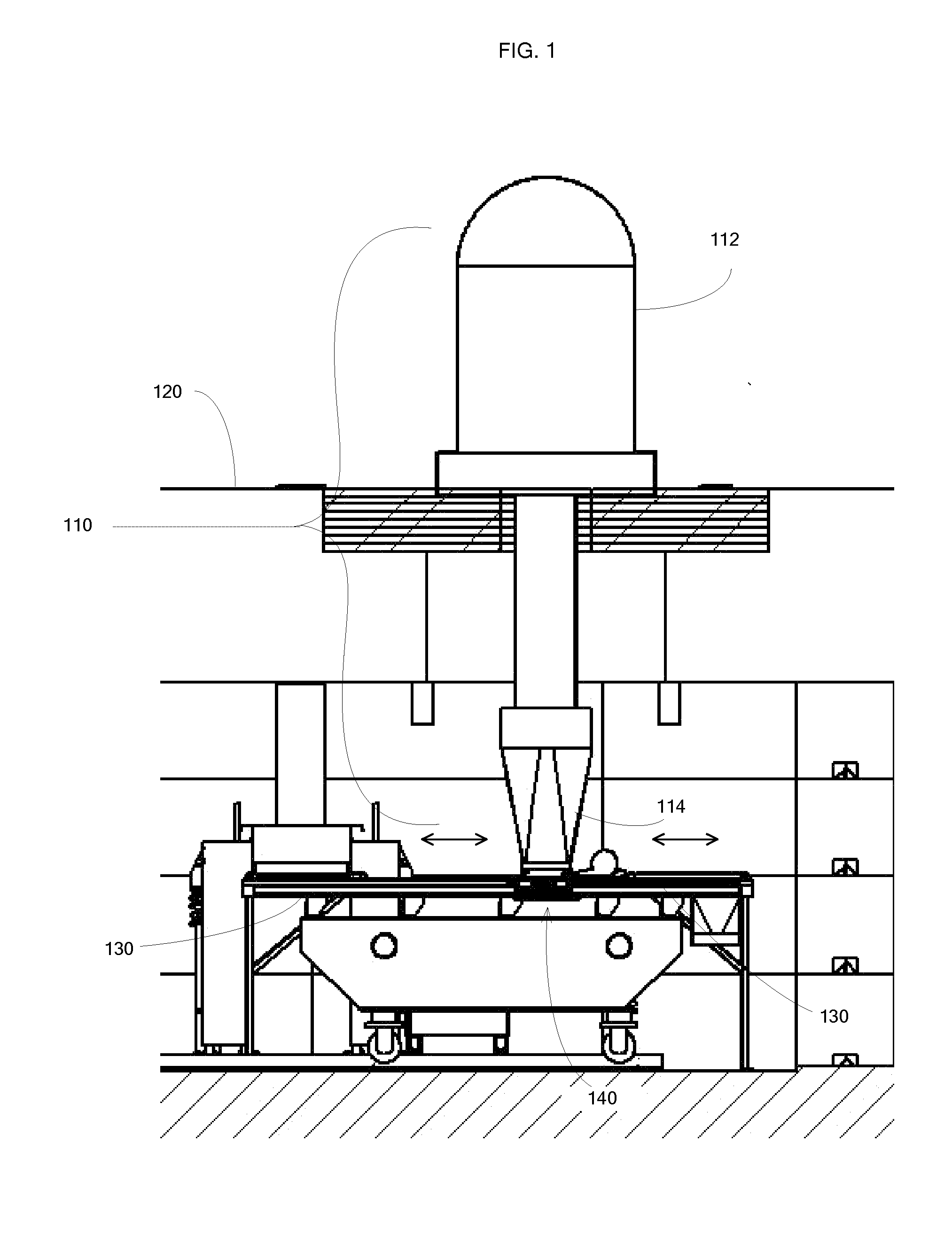

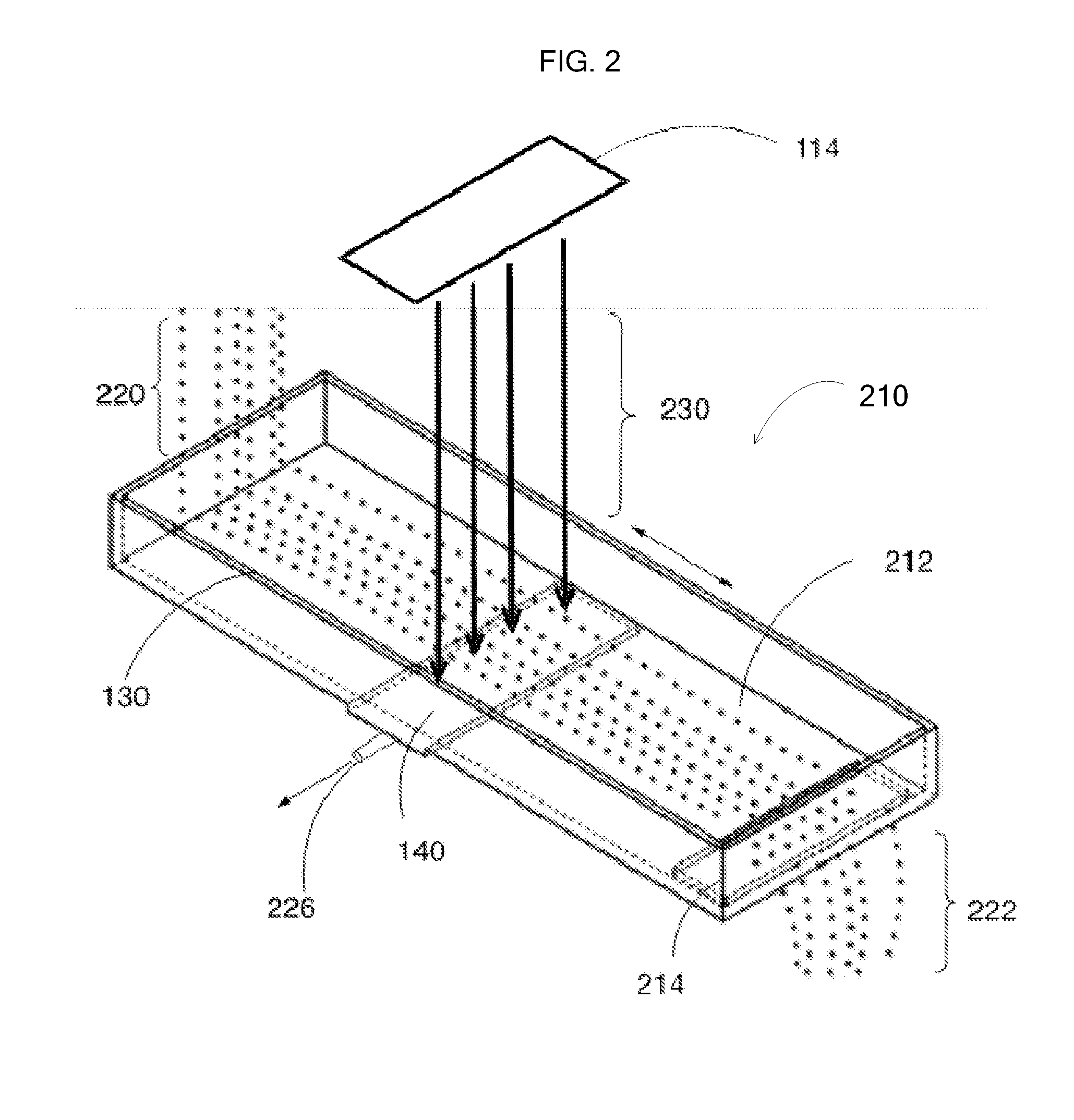

Methods and systems are described for processing cellulosic and lignocellulosic materials into useful intermediates and products, such as energy and fuels. For example, conveying systems and methods, such as highly efficient vibratory conveyors, are described for the processing of the cellulosic and lignocellulosic materials.

Owner:XYLECO INC

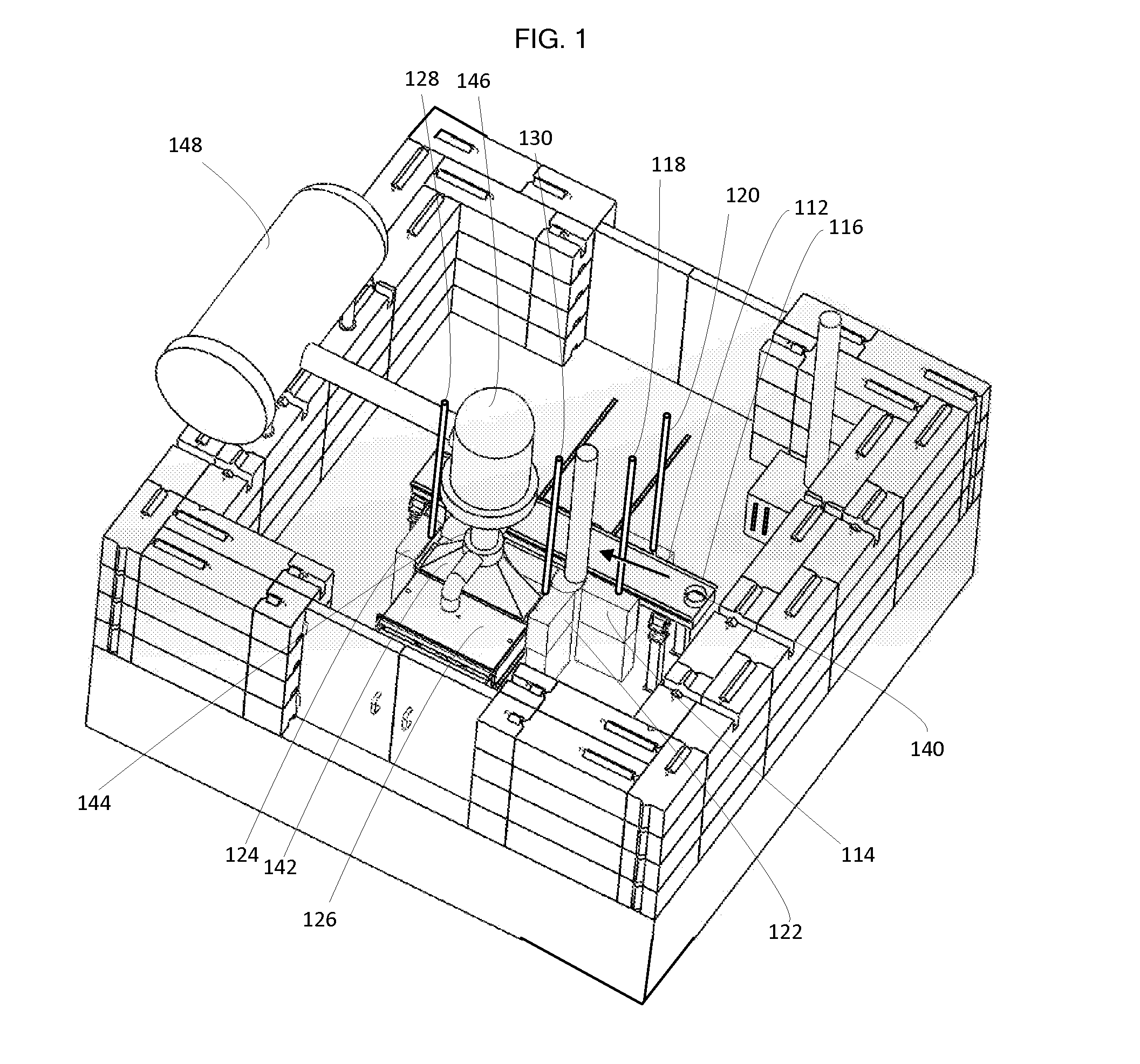

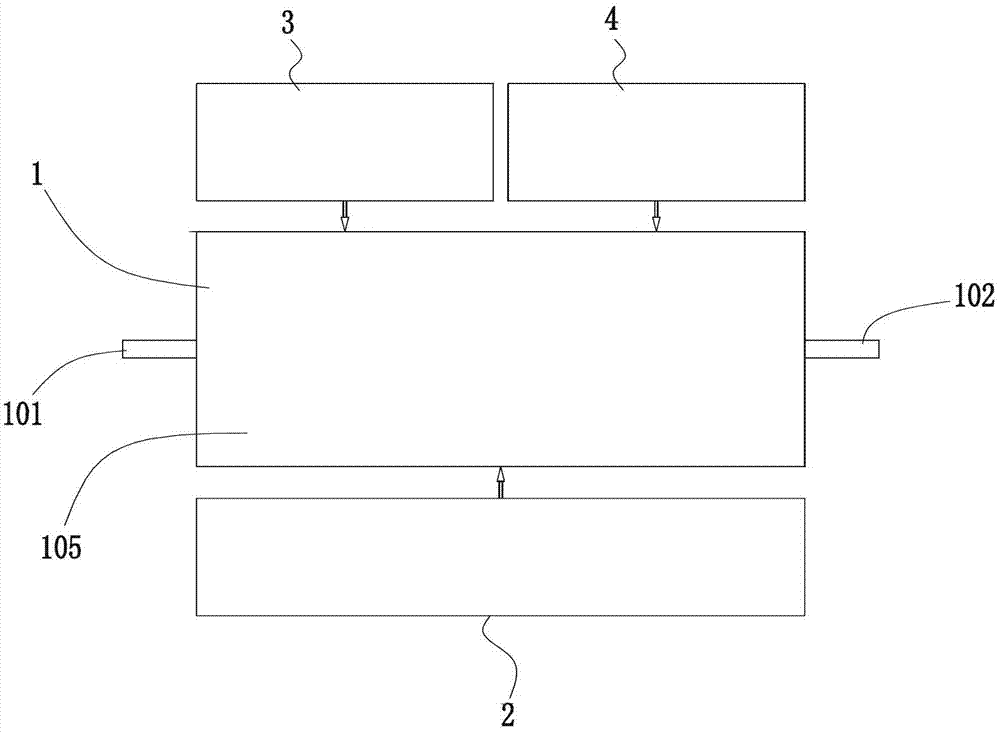

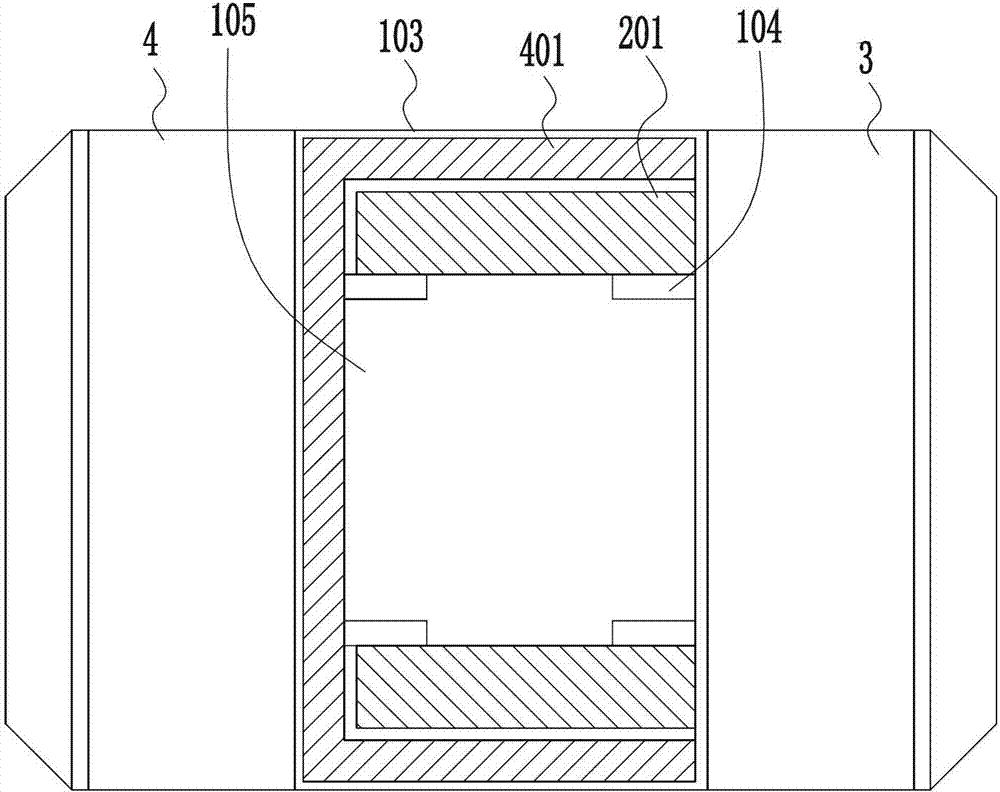

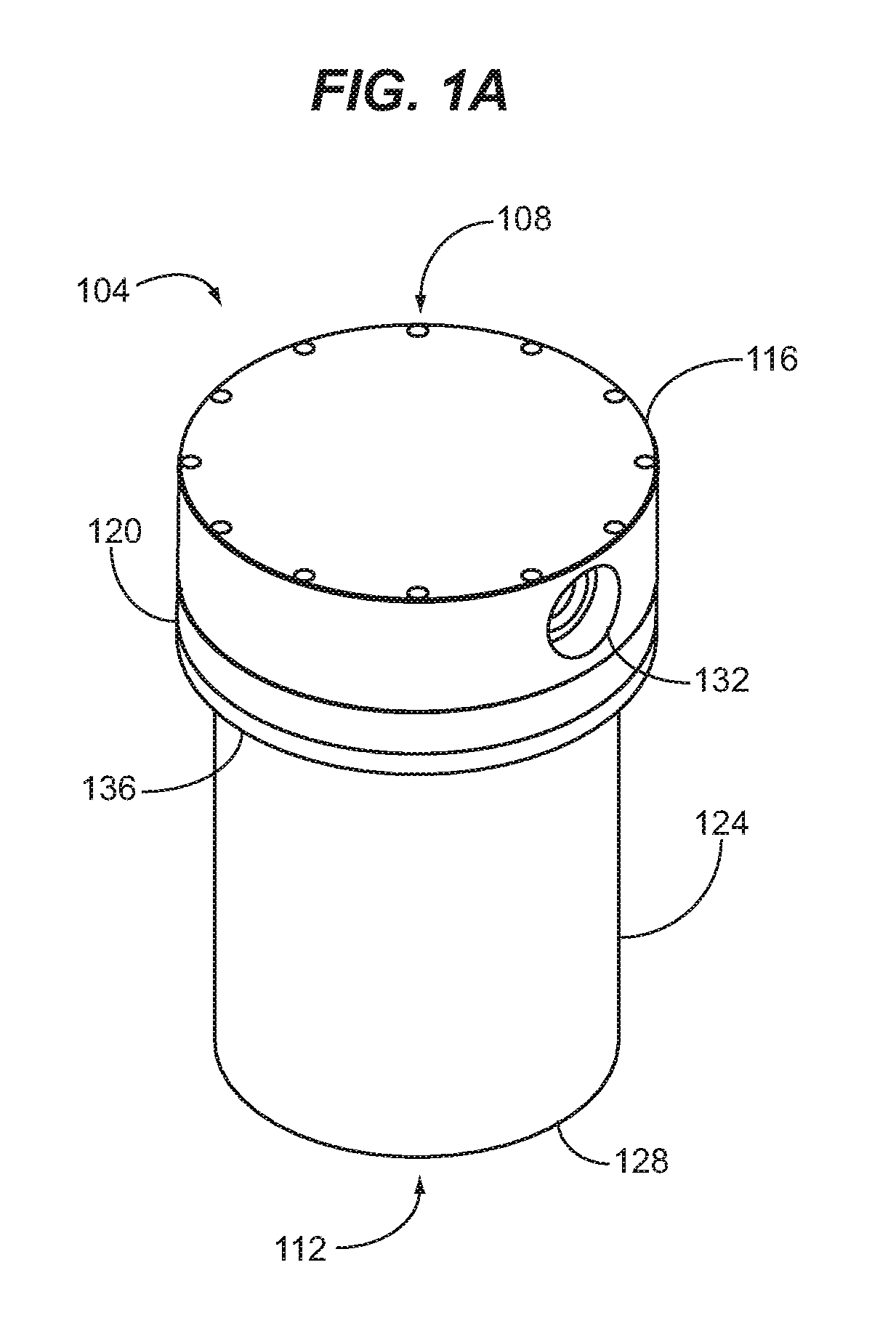

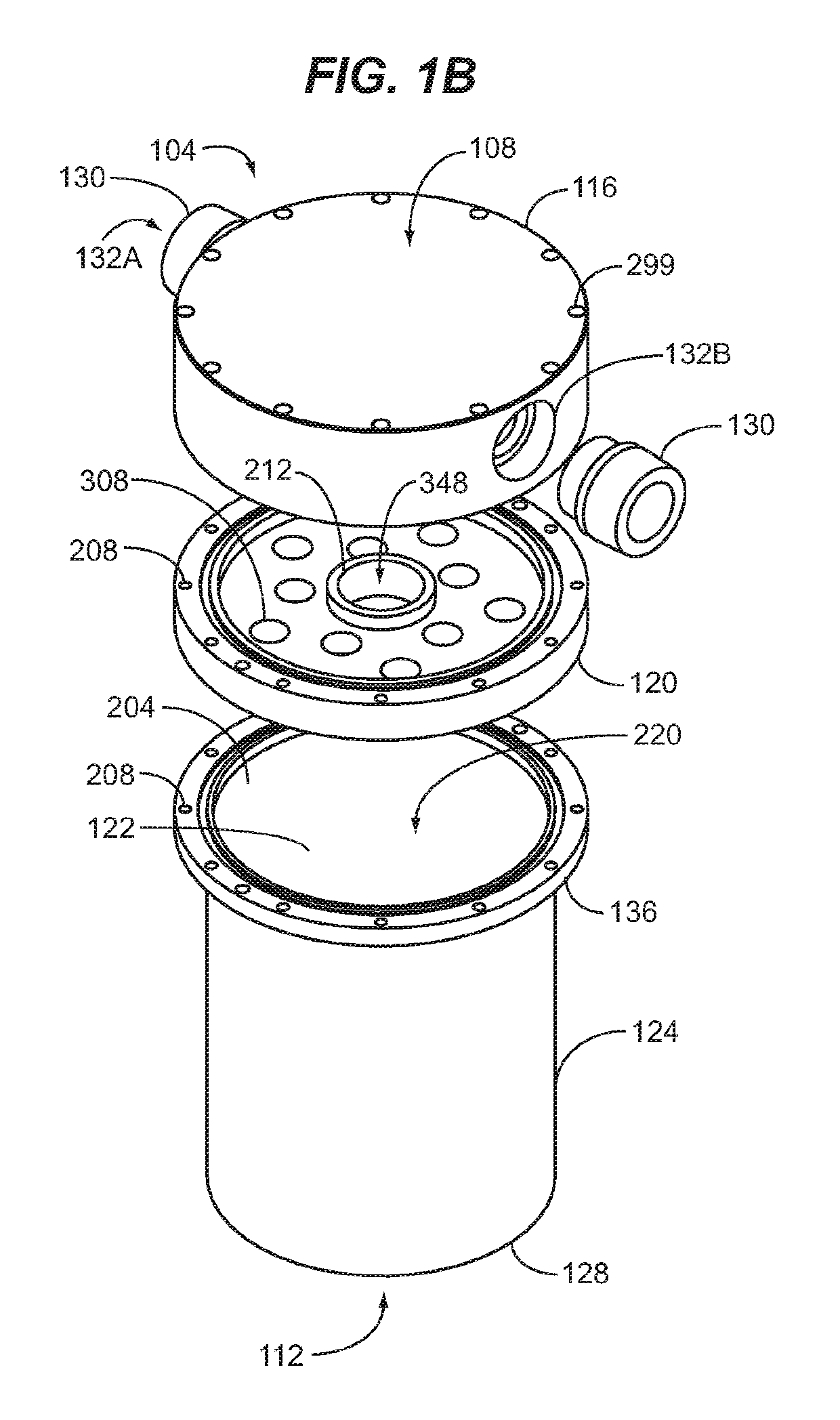

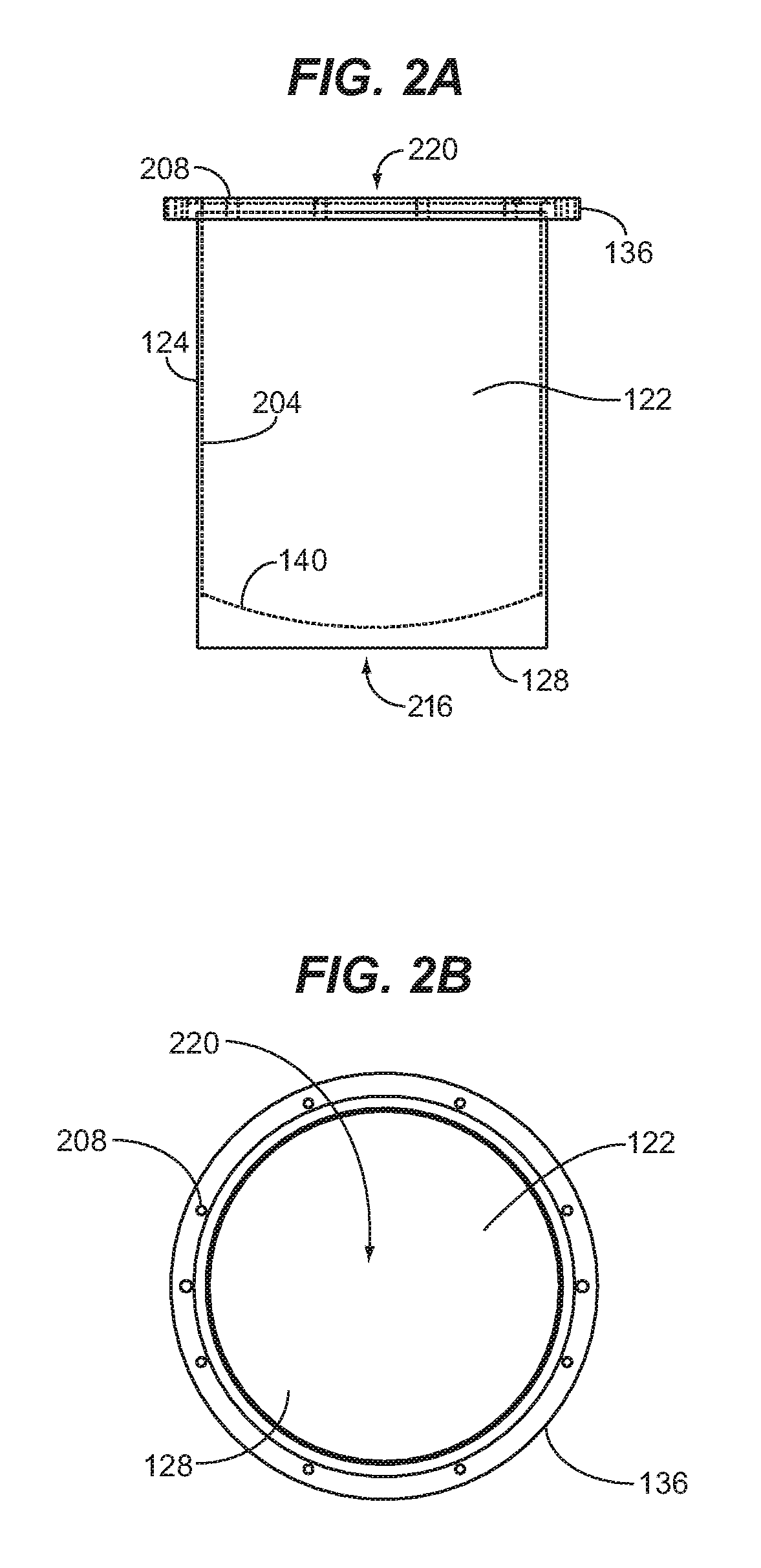

Equipment protecting enclosures

InactiveUS20150287487A1Promote sportsReduce exposureElectrical coke oven heatingBiofuelsCelluloseProduct gas

Biomass (e.g., plant biomass, animal biomass, and municipal waste biomass) is processed to produce useful intermediates and products, such as energy, fuels, foods or materials. For example, systems and methods are described that can be used to treat feedstock materials, such as cellulosic and / or lignocellulosic materials, in a vault in which the equipment is protected from radiation and hazardous gases by equipment enclosures. The equipment enclosures may be purged with gas.

Owner:XYLECO INC

Processing materials

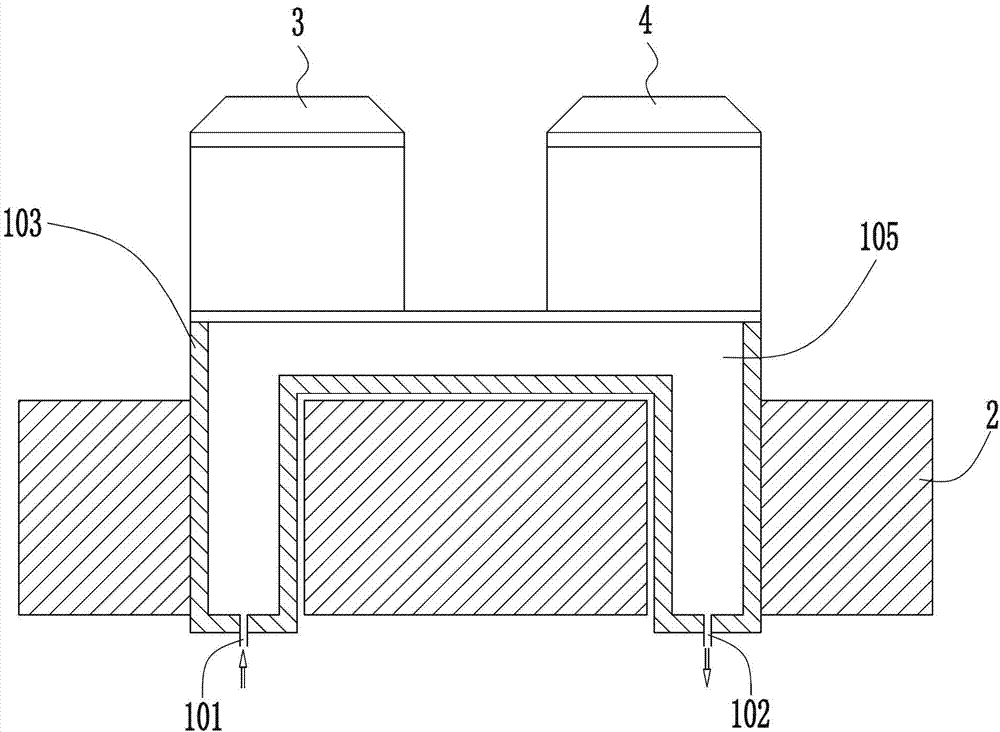

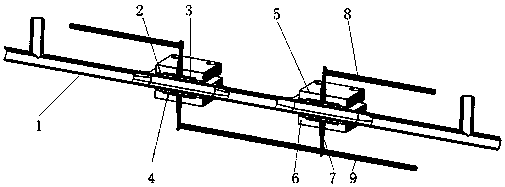

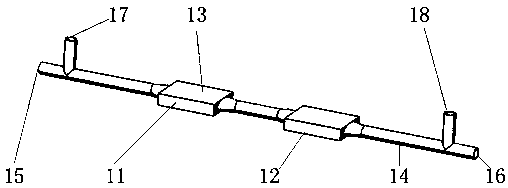

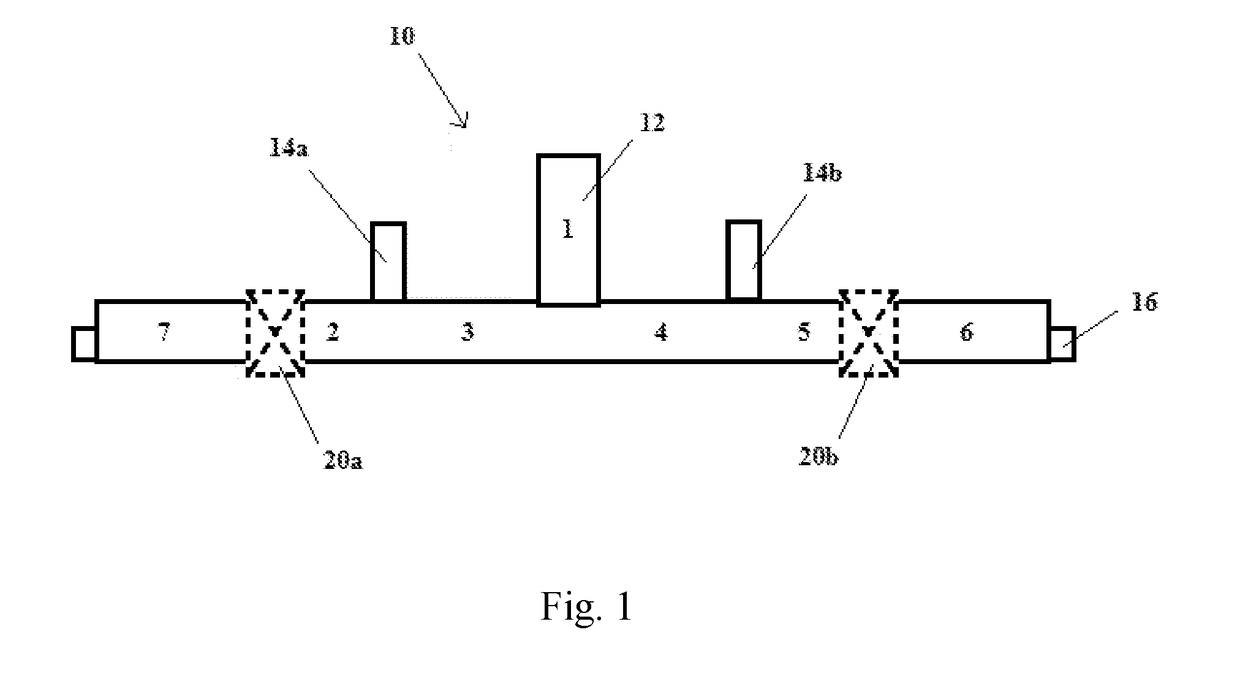

ActiveUS20150284907A1Avoid degradationAvoid destructionElectrical coke oven heatingBiofuelsProcess engineeringCooling fluid

Biomass (e.g., plant biomass, animal biomass, and municipal waste biomass) is processed to produce useful intermediates and products, such as energy, fuels, foods or materials. For example, systems and methods are described that can be used to treat feedstock materials, such as cellulosic and / or lignocellulosic materials, while cooling equipment and the biomass to prevent overheating and possible distortion and / or degradation. The biomass is conveyed by a conveyor, which conveys the biomass under an electron beam from an electron beam accelerator. The conveyor can be cooled with cooling fluid. The conveyor can also vibrate to facilitate exposure to the electron beam. The conveyor can be configured as a trough that can be optionally cooled.

Owner:XYLECO INC

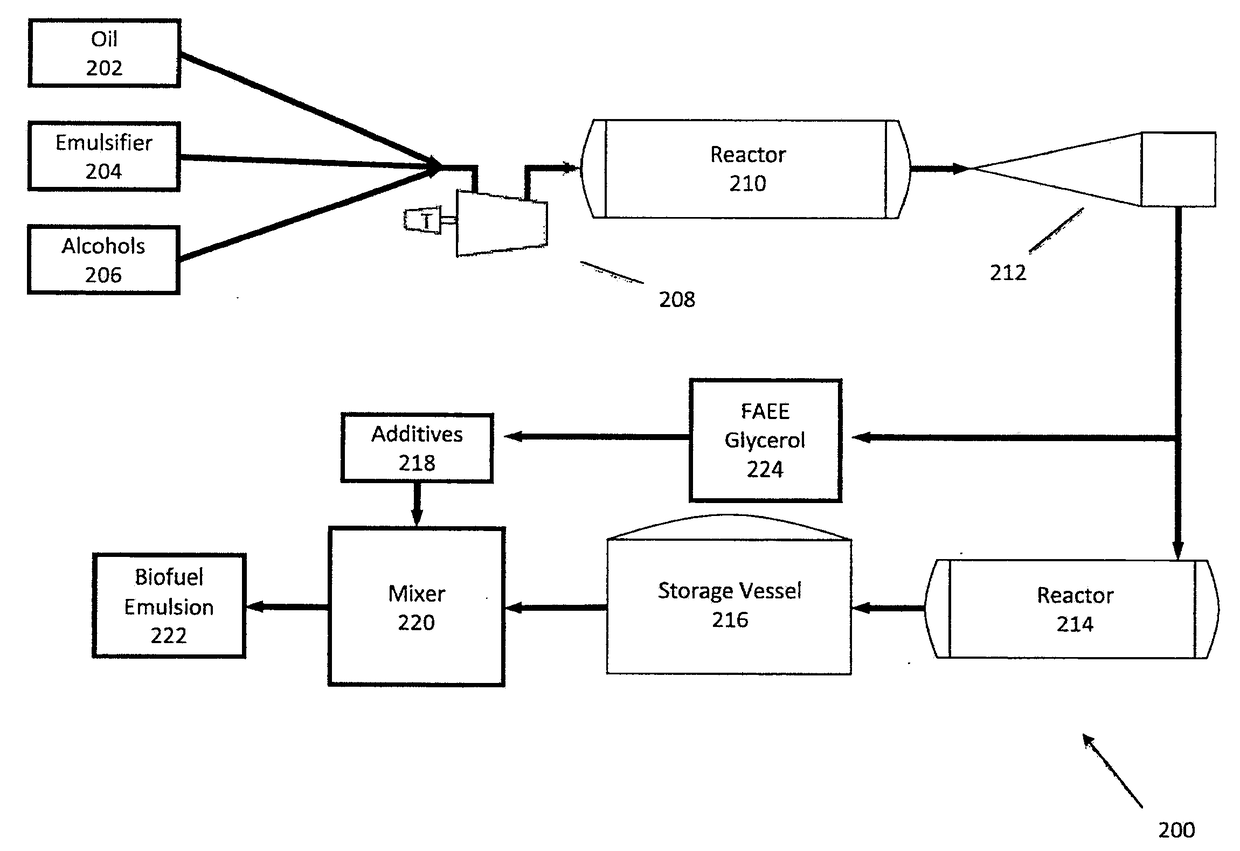

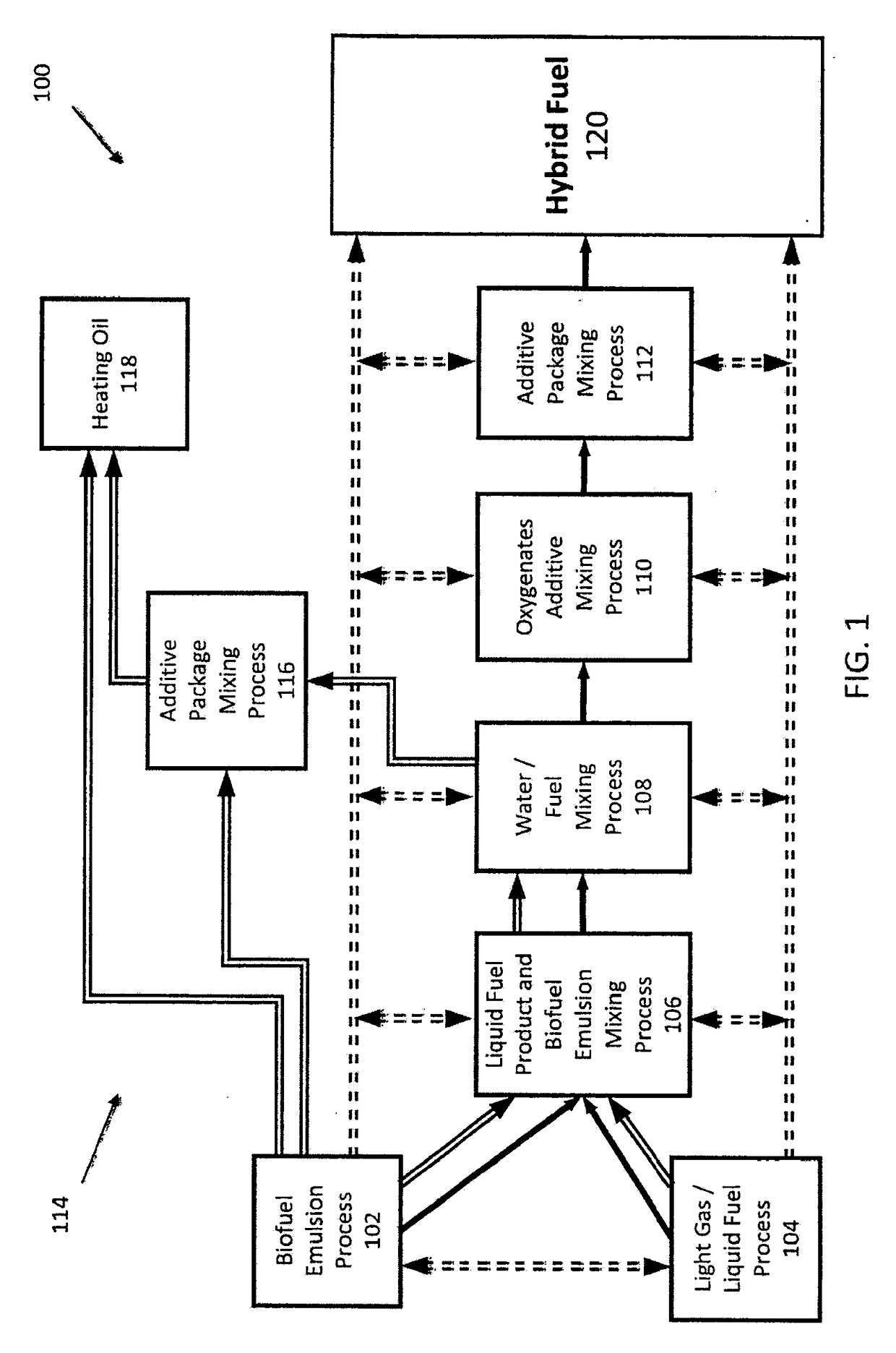

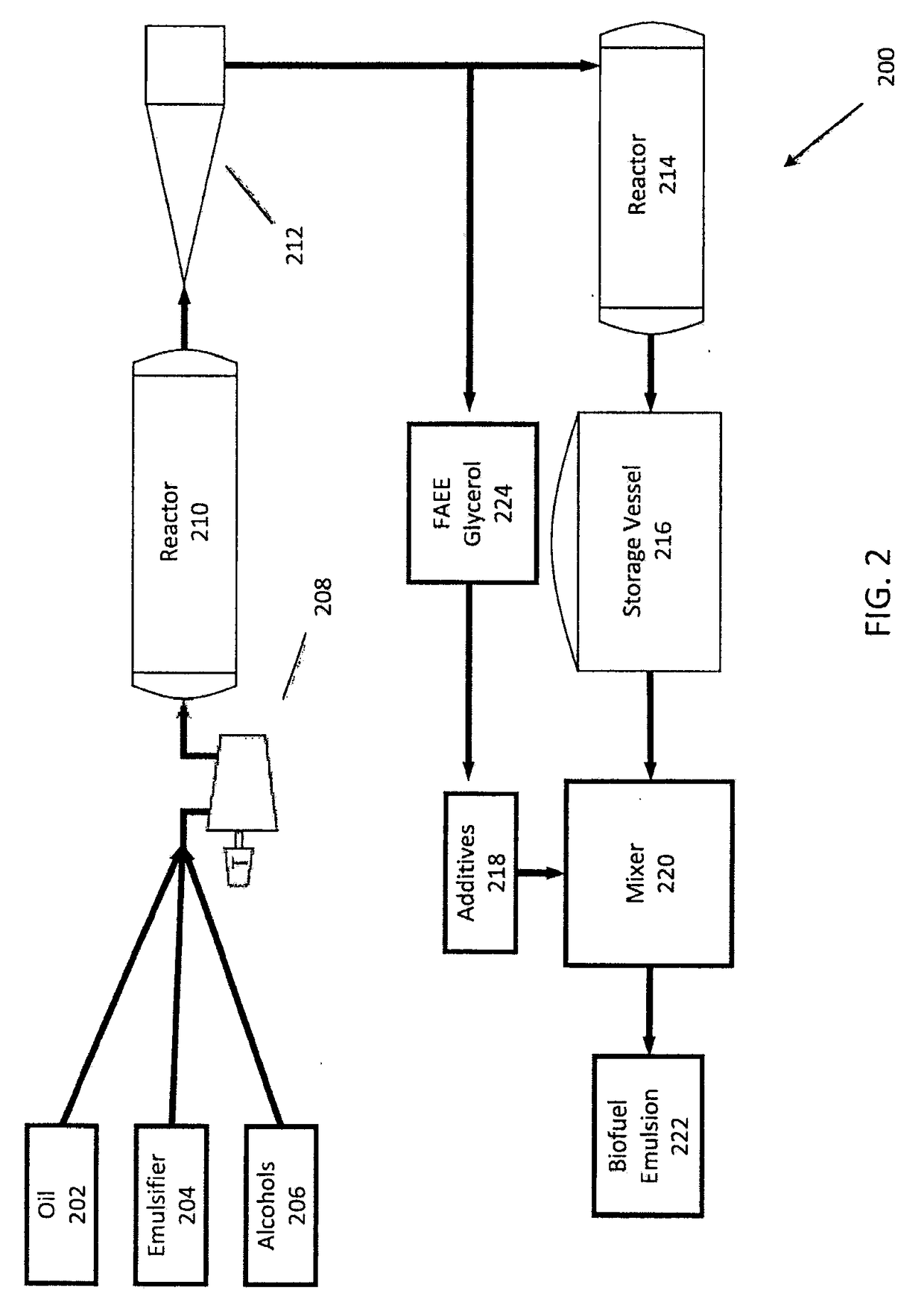

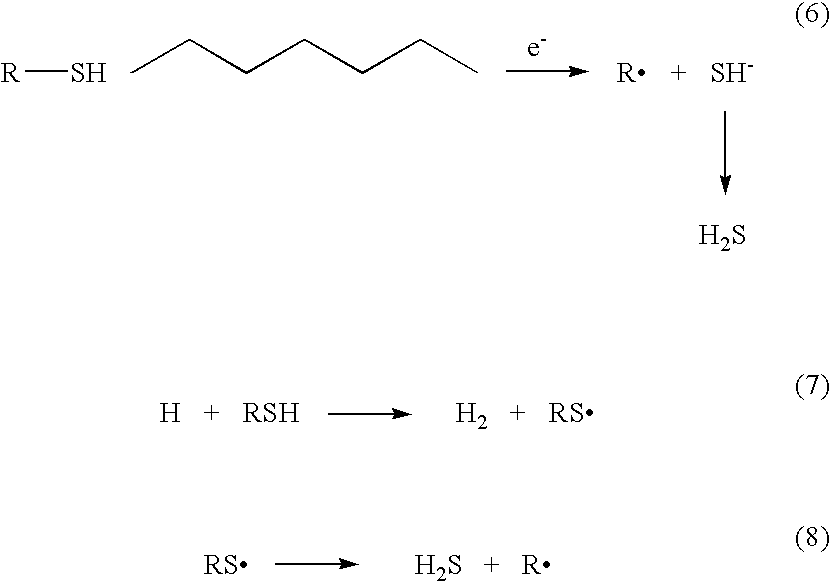

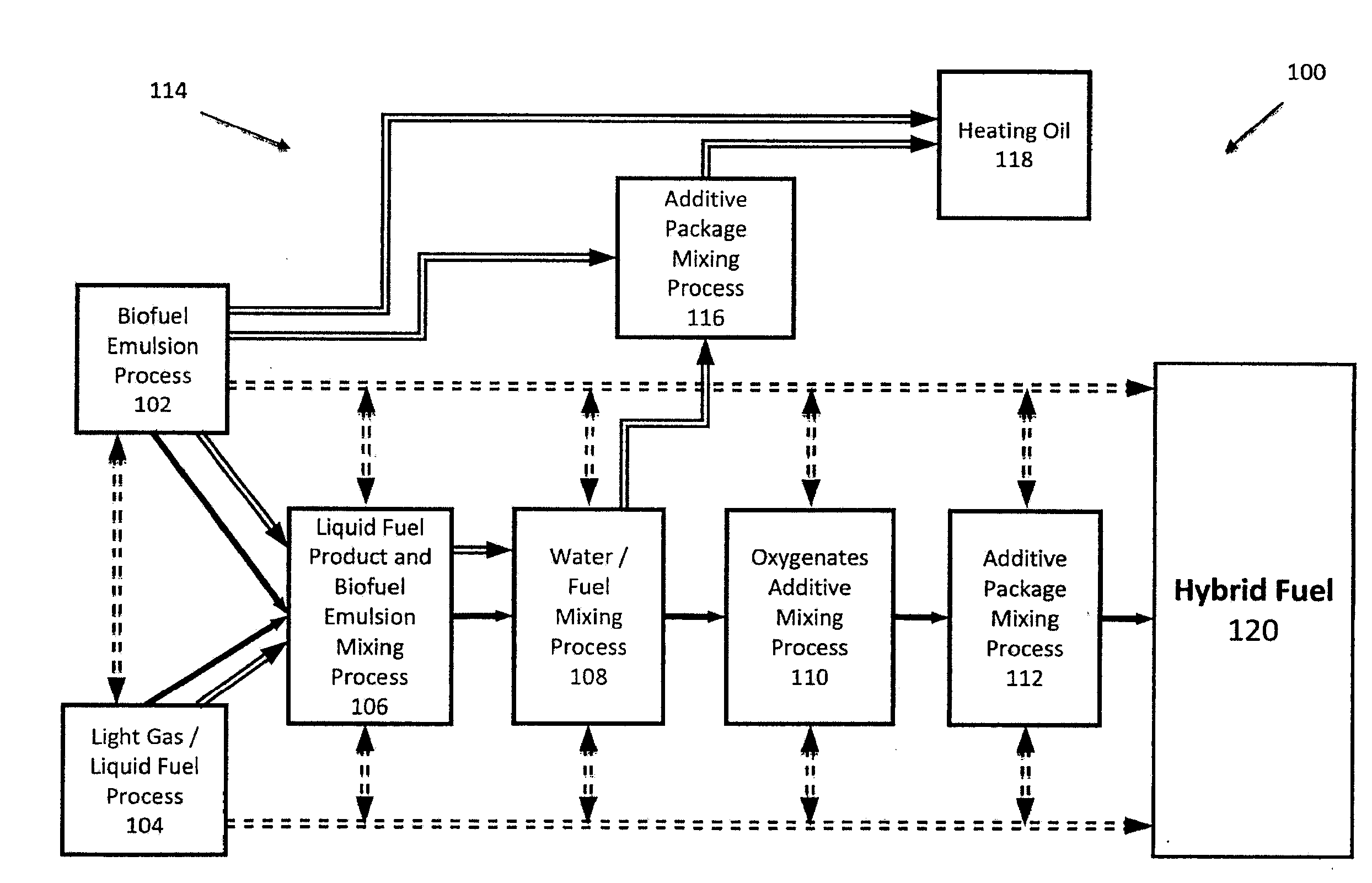

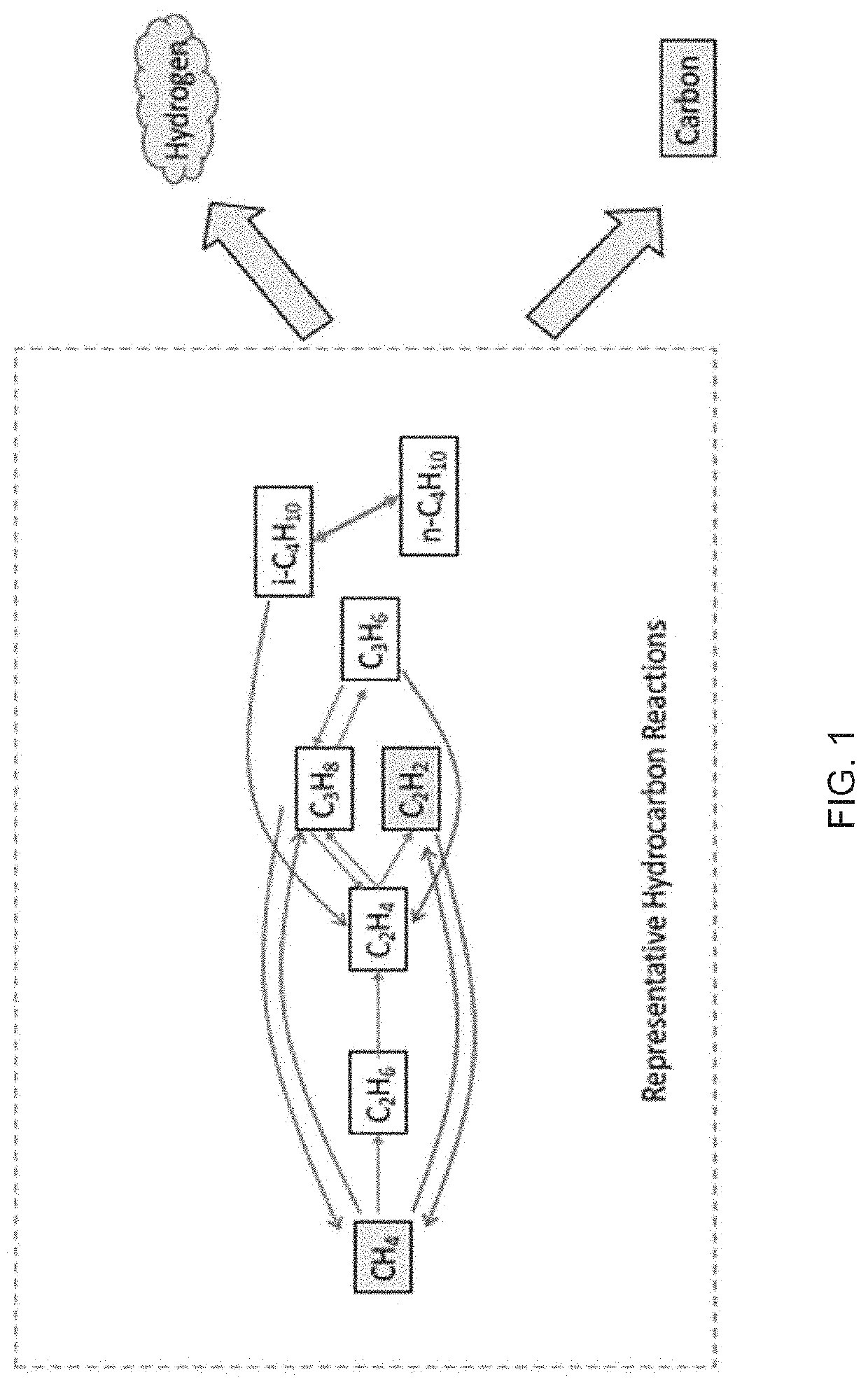

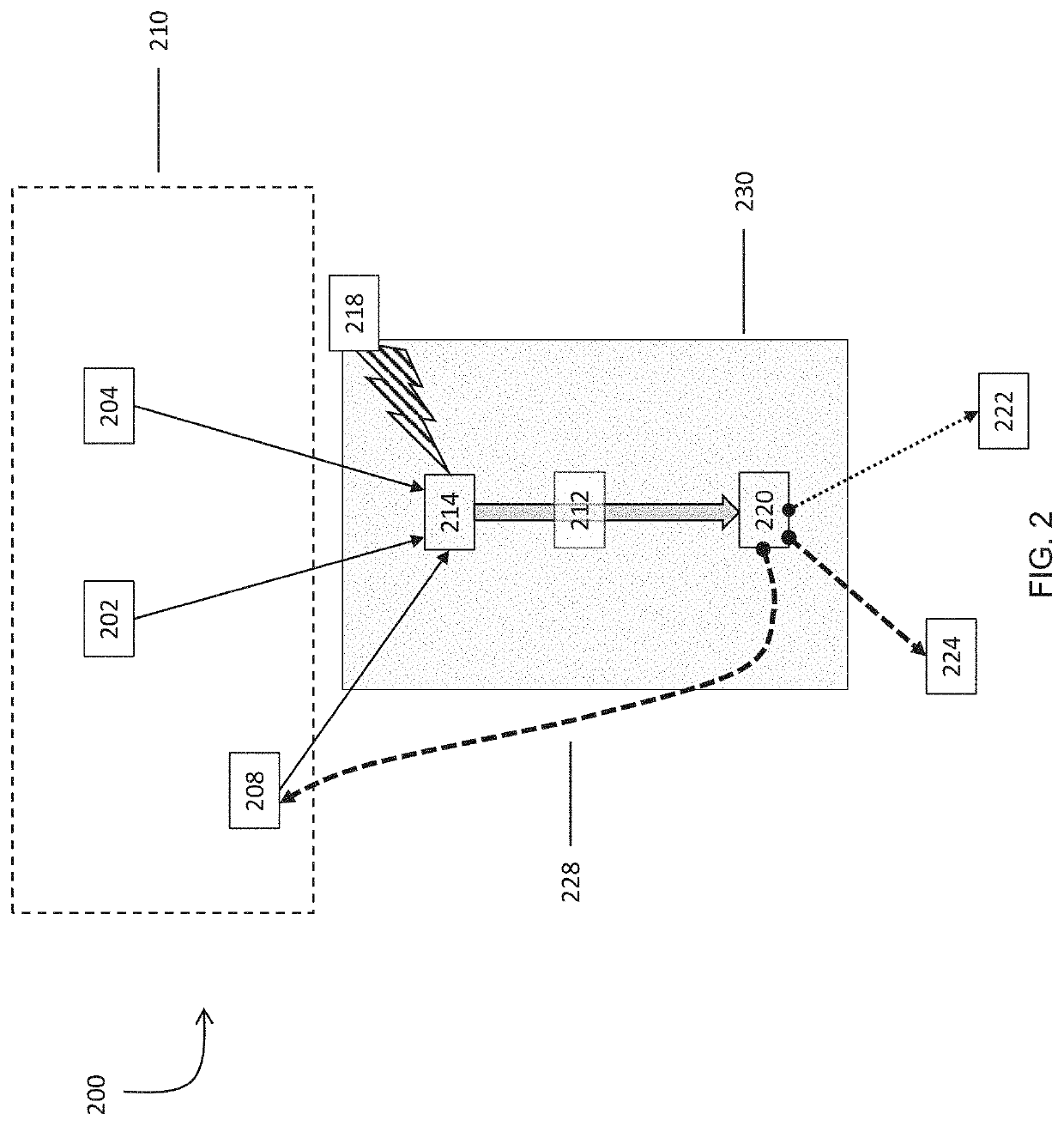

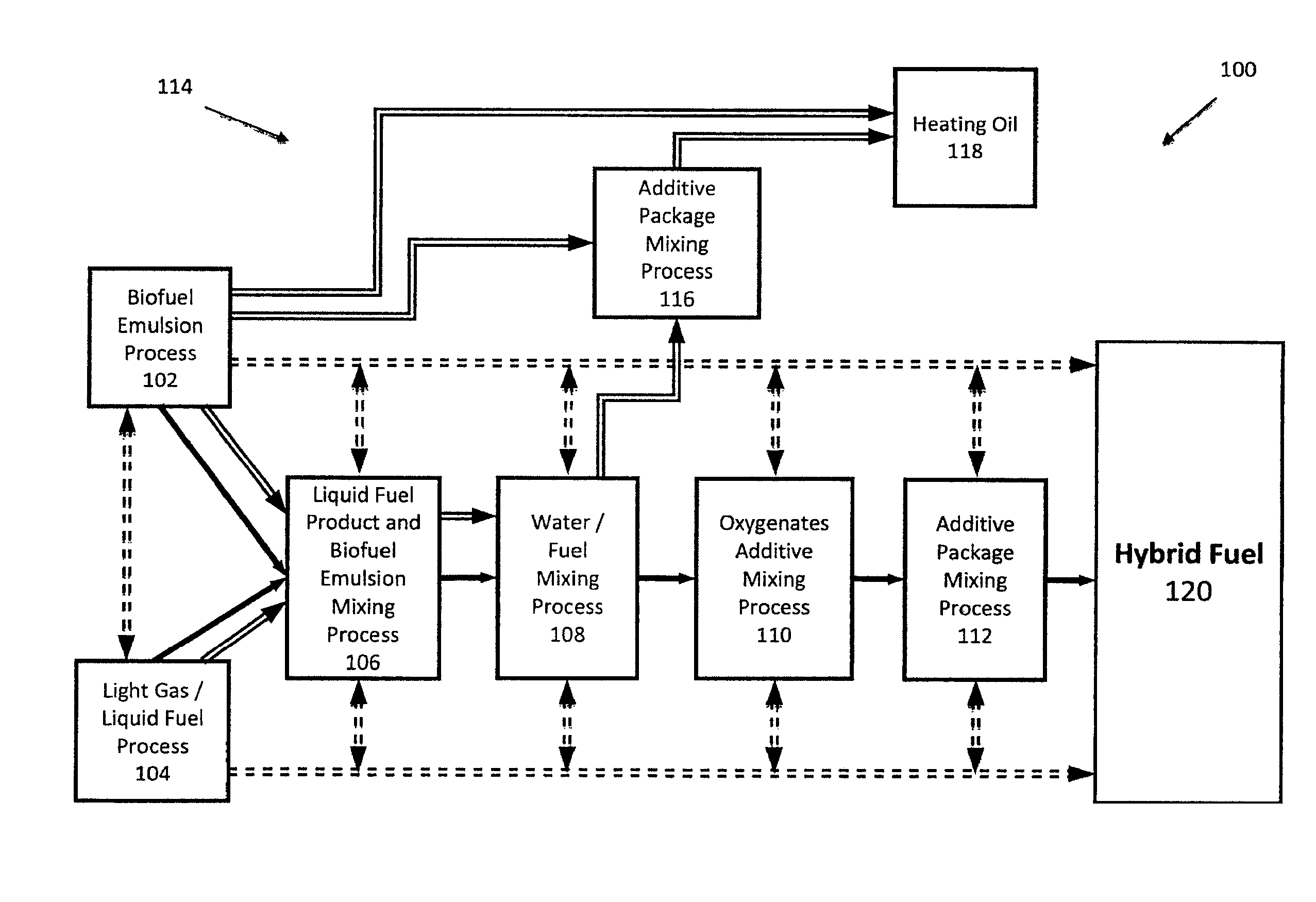

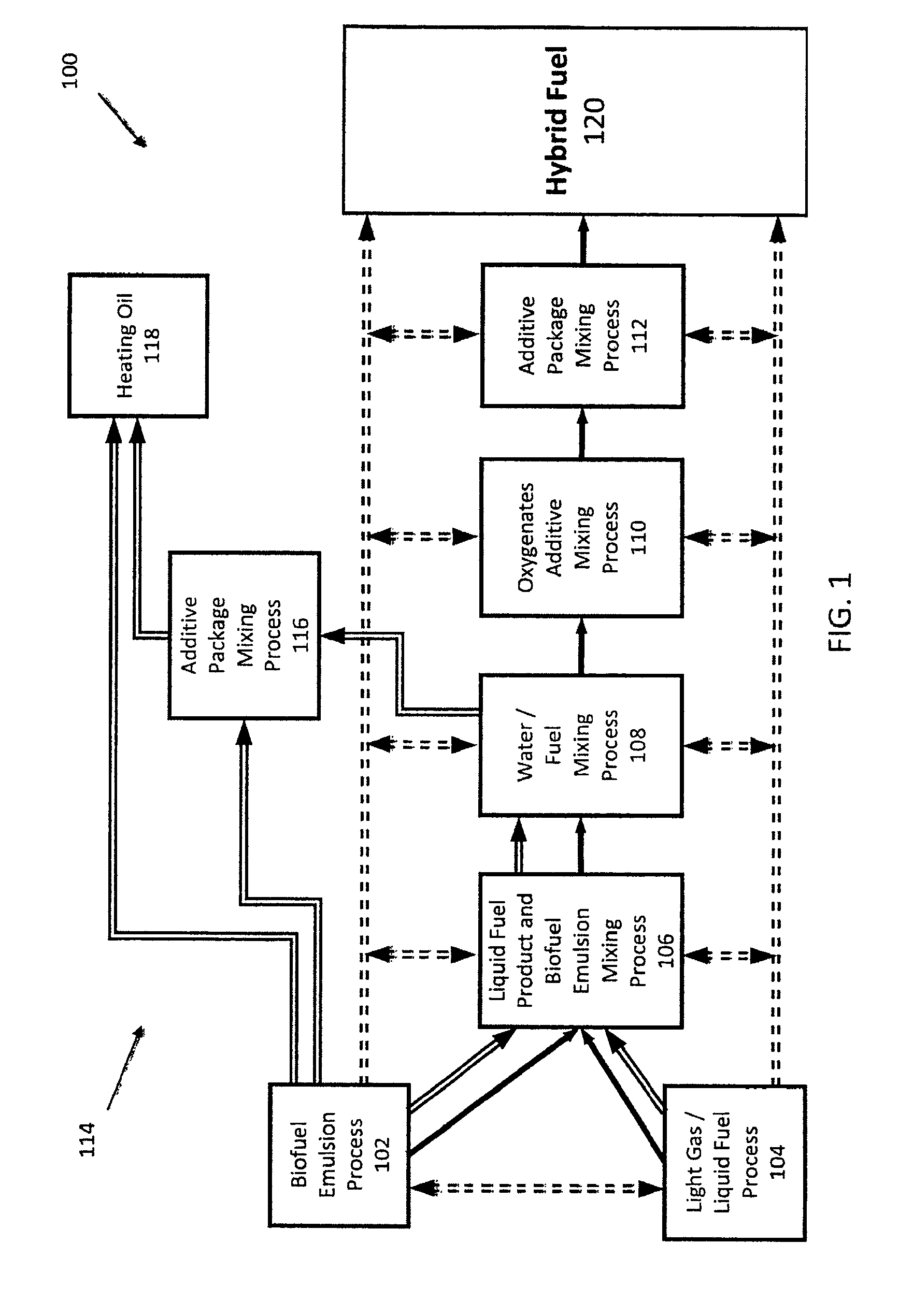

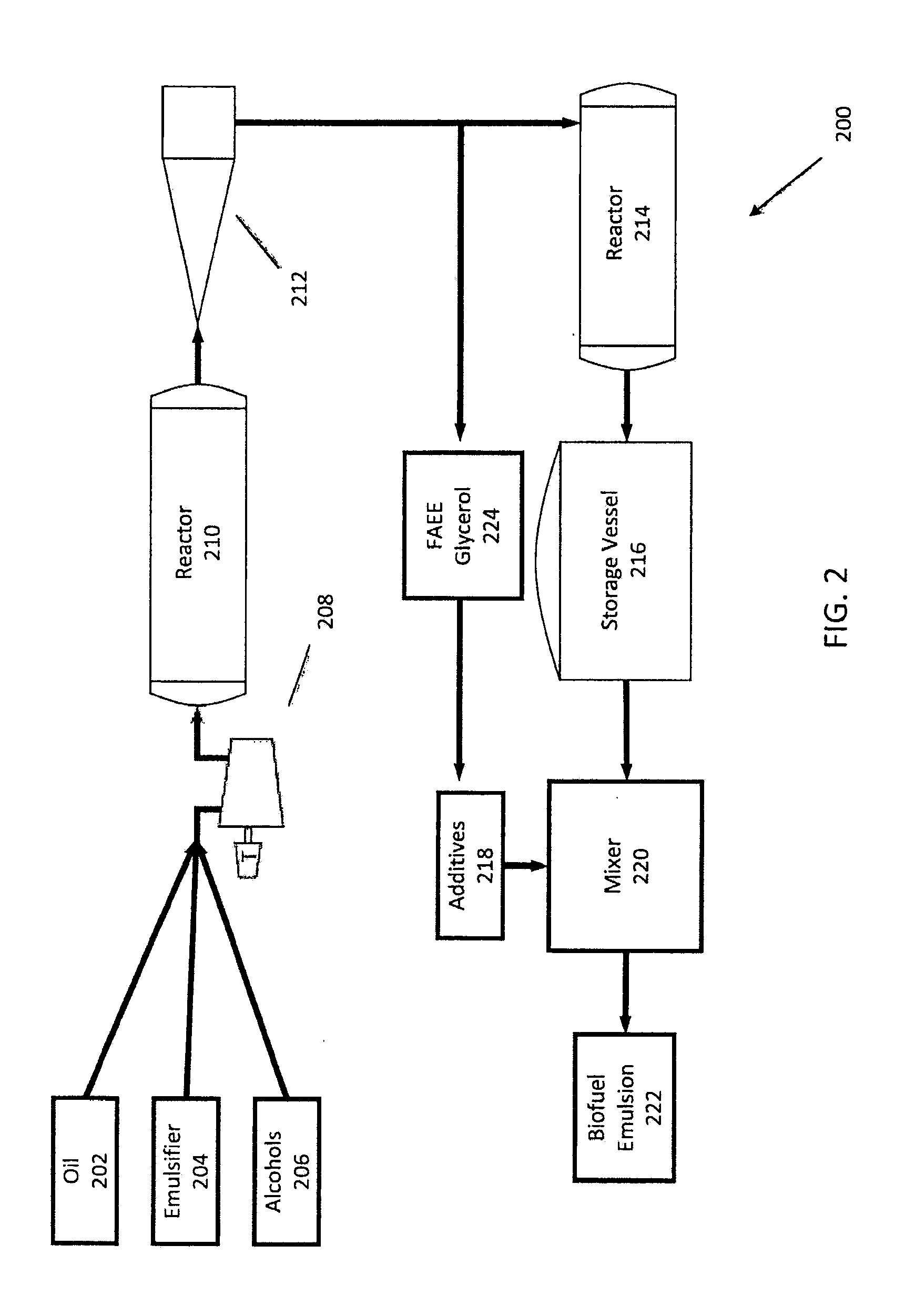

Hybrid fuel and method of making the same

InactiveUS20170152453A1High densitySpeed up the flowInternal combustion piston enginesBiofuelsBiofuelLiquid fuel

A hybrid fuel and methods of making the same. A process for making a hybrid fuel includes the steps of combining a biofuel emulsion blend and a liquid fuel product to form a hybrid fuel. Optionally, the hybrid fuel can be combined with water in a water-in-oil process and include oxygenate additives and additive packages. A hybrid fuel includes blends of biofuel emulsions and liquid fuel products, including light gas diesel. Optionally, the hybrid fuel can include water, oxygenate additives, and other additive packages.

Owner:FUELINA TECH

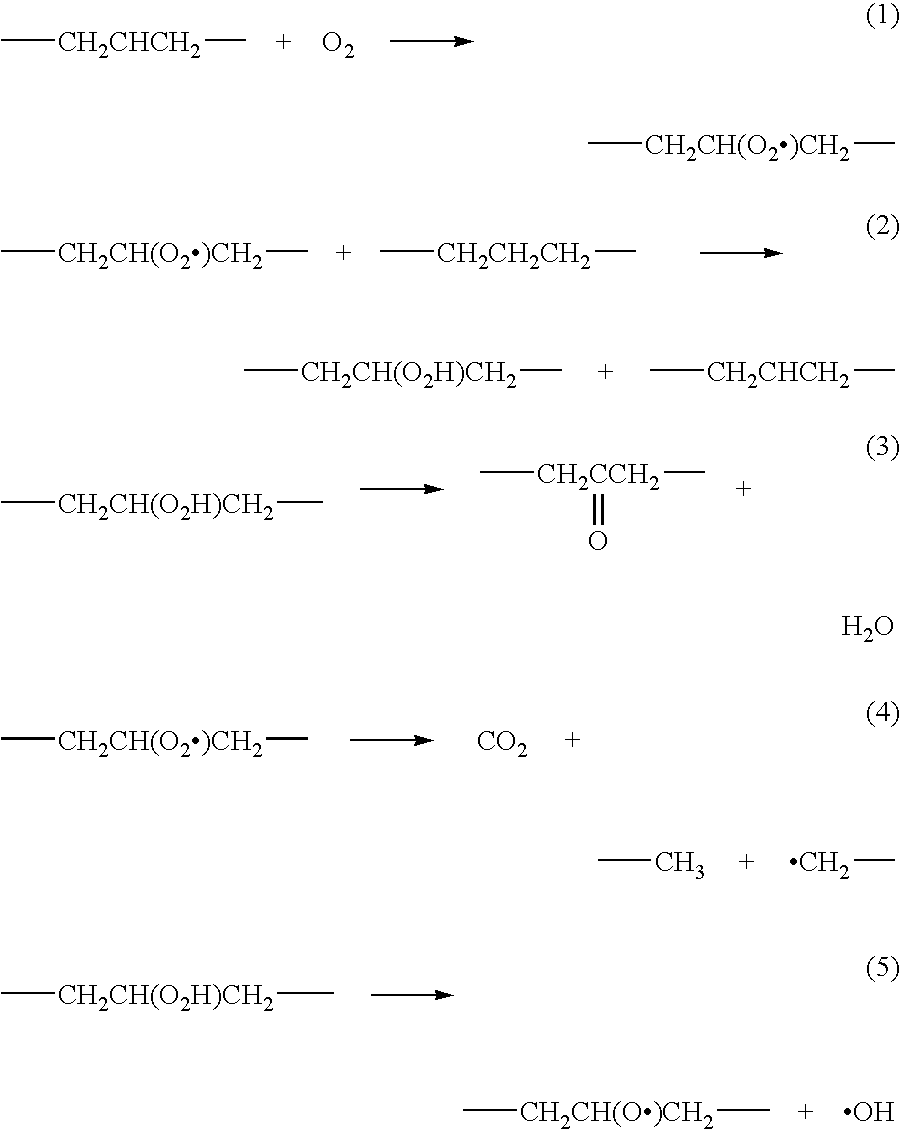

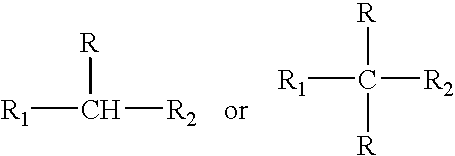

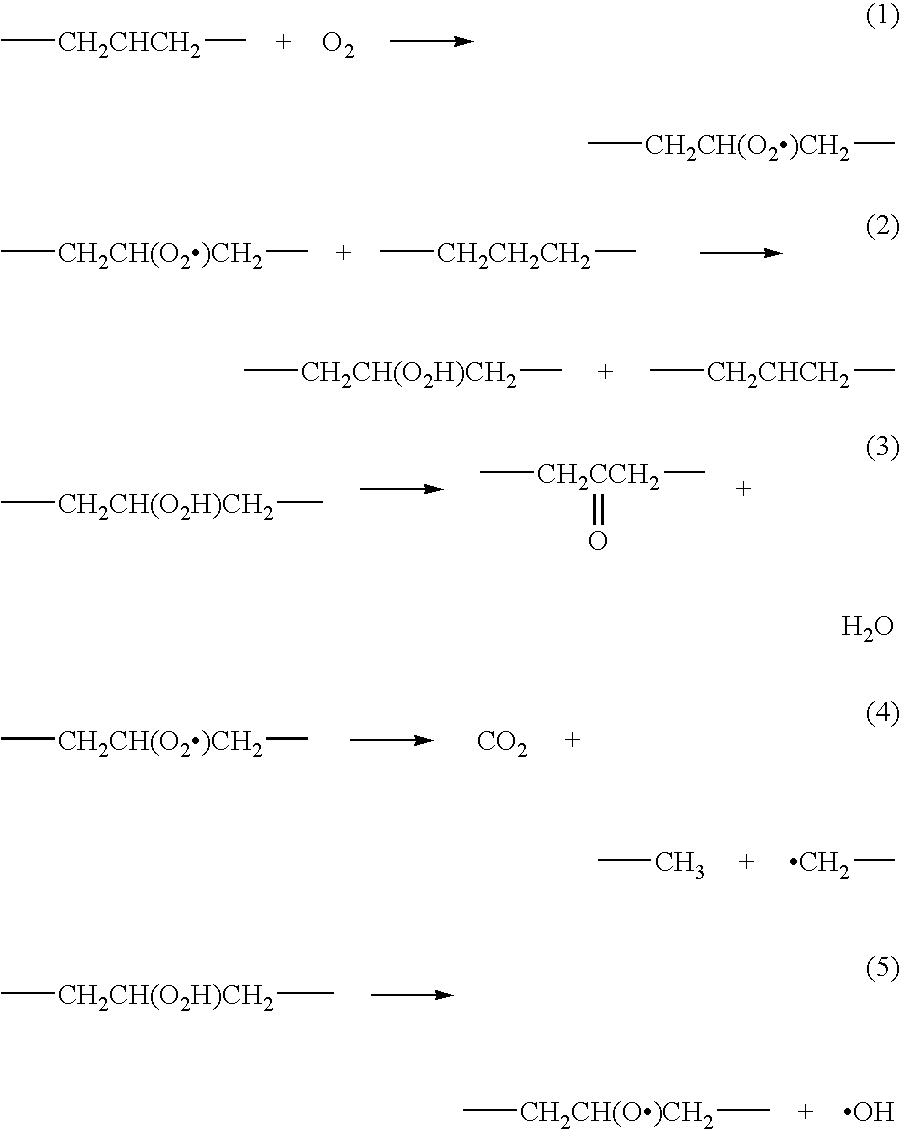

Radiation processing of heavy oils

InactiveUS20090308789A1Maximize roleIncrease productionRefining with oxygen compoundsFluid removalRadiation chemistryPetroleum product

The present invention is drawn to a method of processing heavy paraffinic oils or heavy aromatic oils using radiation chemistry of polyethylene under oxidizing conditions. The process of the invention will result in a chain reaction for oxidative scission as the basis for a radiation processing for heavy paraffinic or aromatic oils. The method of the invention will allow for the cost-efficient and environmentally-friendly processing of heavy oils into lighter petroleum products.

Owner:PETRORADIANT

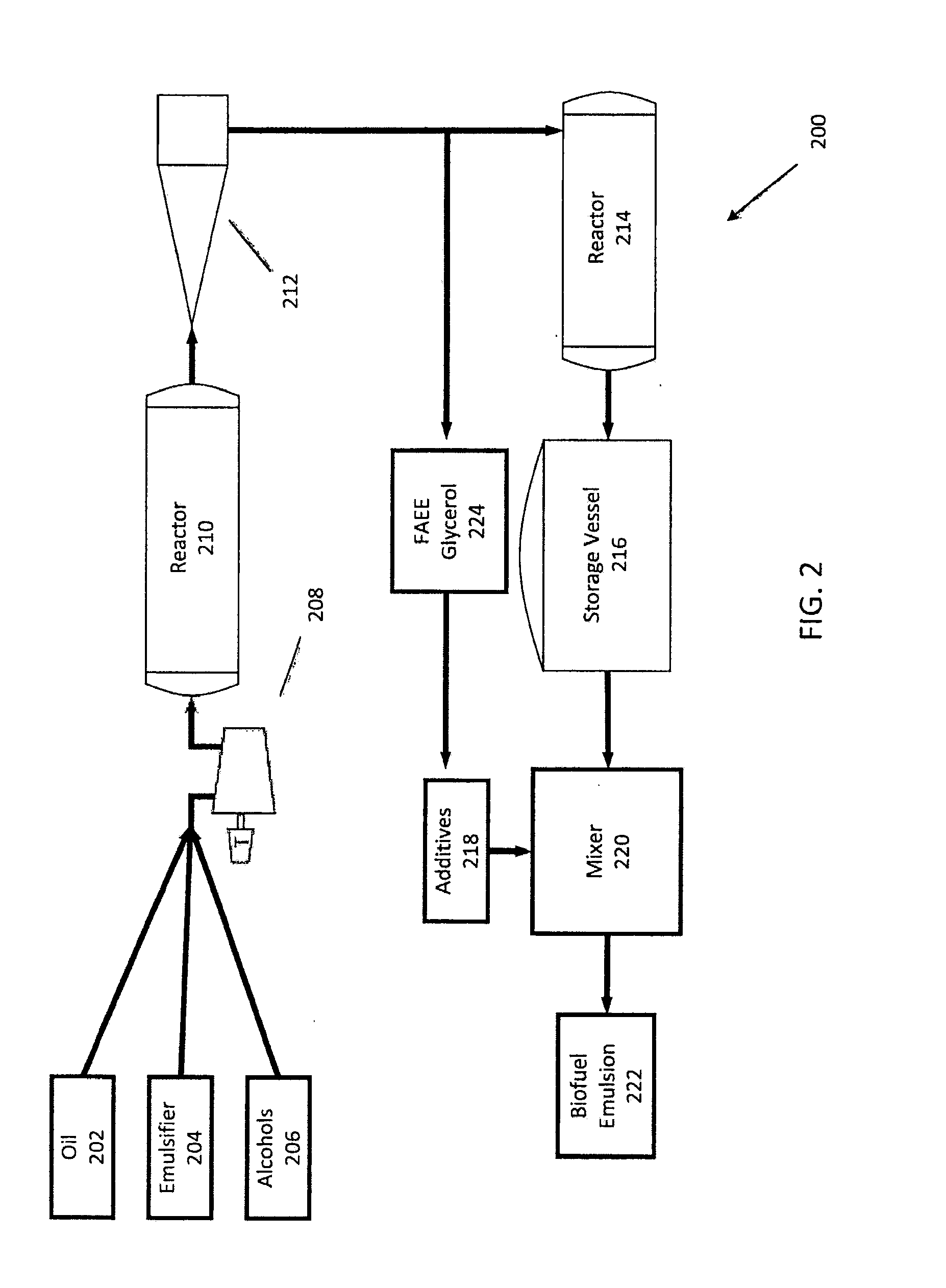

Process and apparatus for the conversion of methane gas to higher hydrocarbons

InactiveUS20050189212A1High dissociationLiquid hydrocarbon mixtures productionHydrocarbonsUltraviolet lightsLiquid hydrocarbons

A process and apparatus are provided for converting methane to higher hydrocarbons, especially for converting economically stranded natural gas to a transportable liquid hydrocarbon product mainly comprised of C3+ hydrocarbons, comprising applying ultraviolet light to and / or causing an electrical discharge in the presence of methane (or the natural gas containing the methane) under conditions effective to cause its dissociation and polymerization to C2+ and higher hydrocarbons.

Owner:KERR MCGEE OIL & GAS CORP

Hybrid Fuel and Method of Making the Same

InactiveUS20150047252A1Low viscosityLow levelInternal combustion piston enginesBiofuelsBiofuelEngineering

A hybrid fuel and methods of making the same. A process for making a hybrid fuel includes the steps of combining a biofuel emulsion blend and a liquid fuel product to form a hybrid fuel. Optionally, the hybrid fuel can be combined with water in a water-in-oil process and include oxygenate additives and additive packages. A hybrid fuel includes blends of biofuel emulsions and liquid fuel products, including light gas diesel. Optionally, the hybrid fuel can include water, oxygenate additives, and other additive packages.

Owner:FUELINA TECH

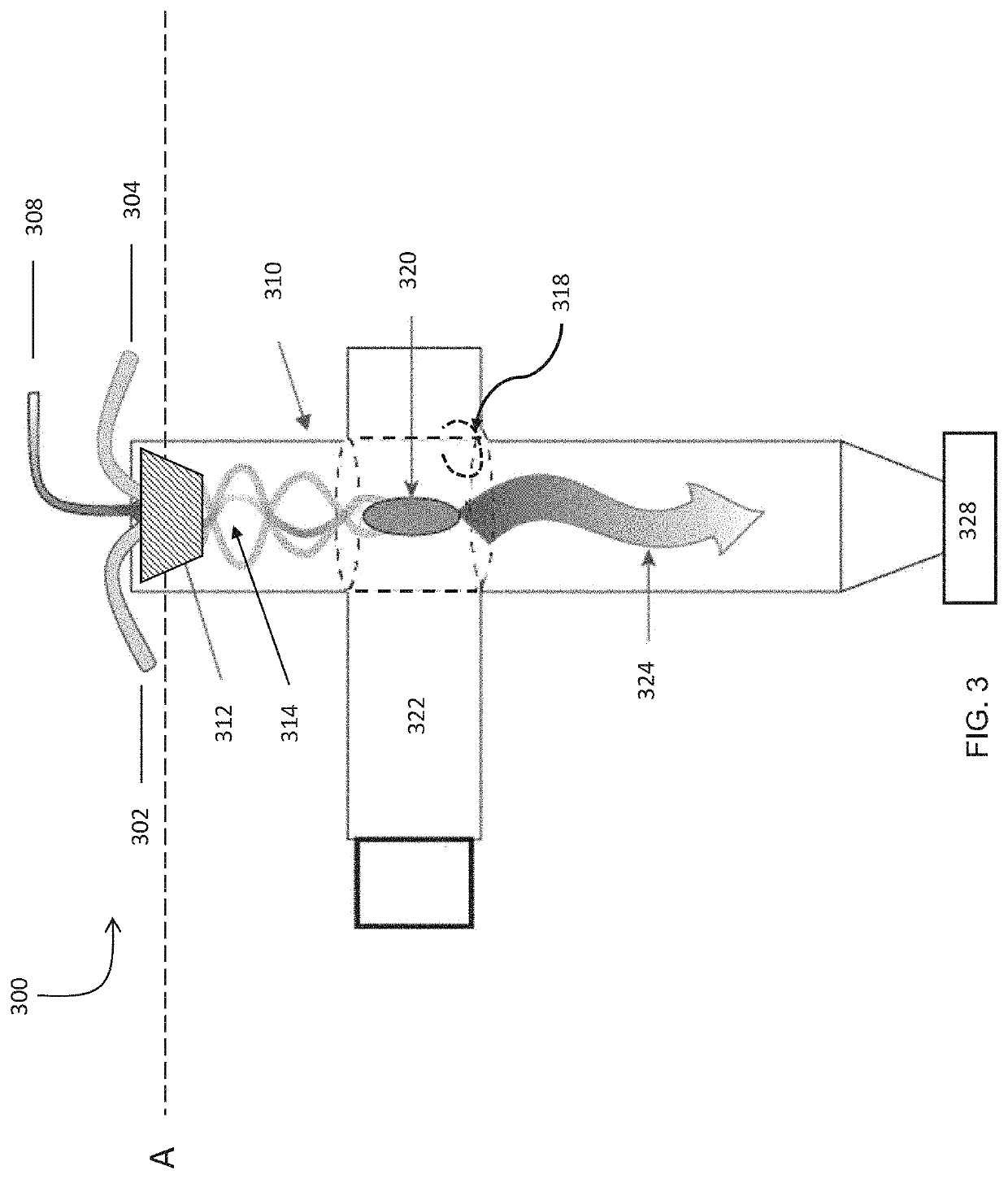

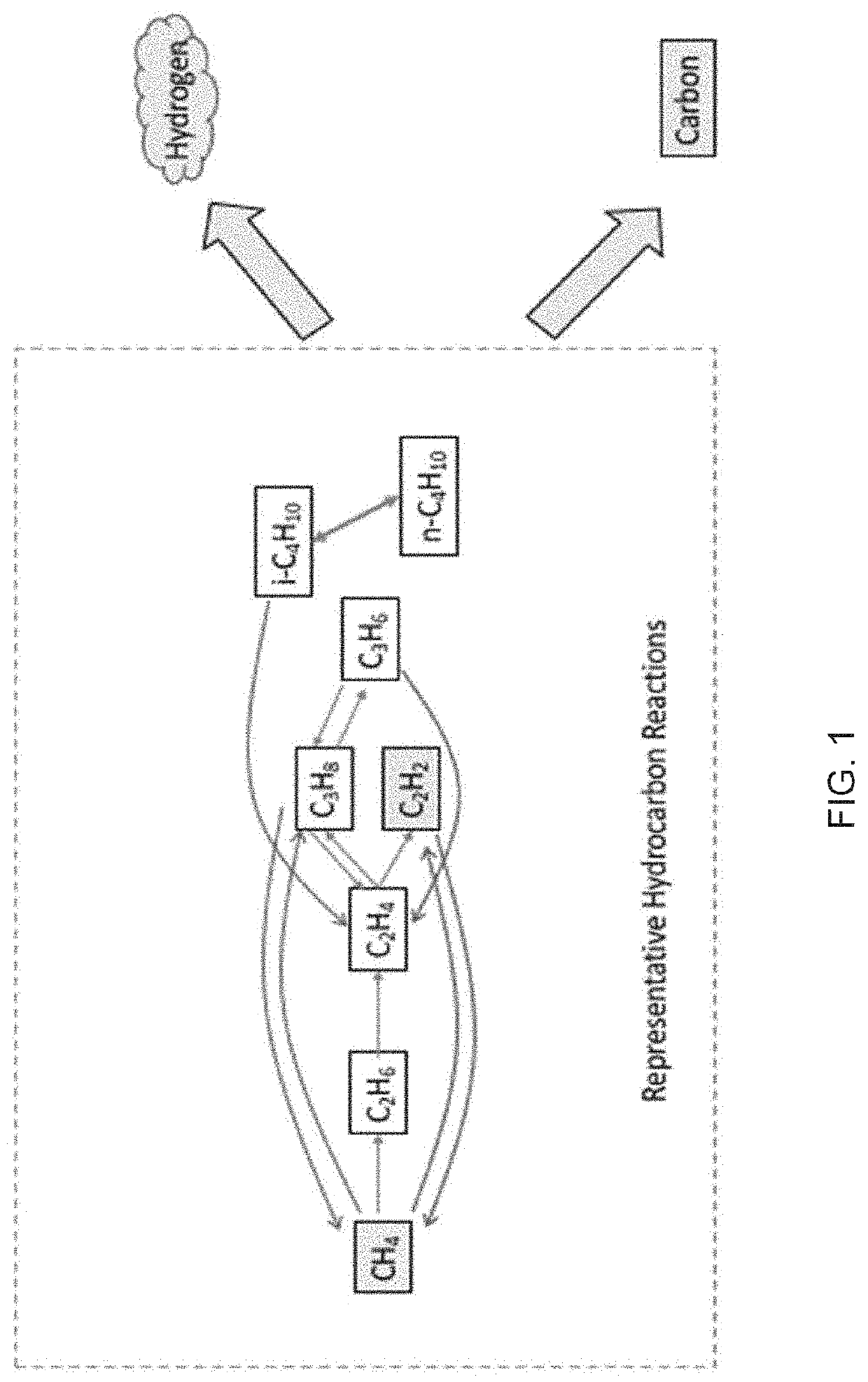

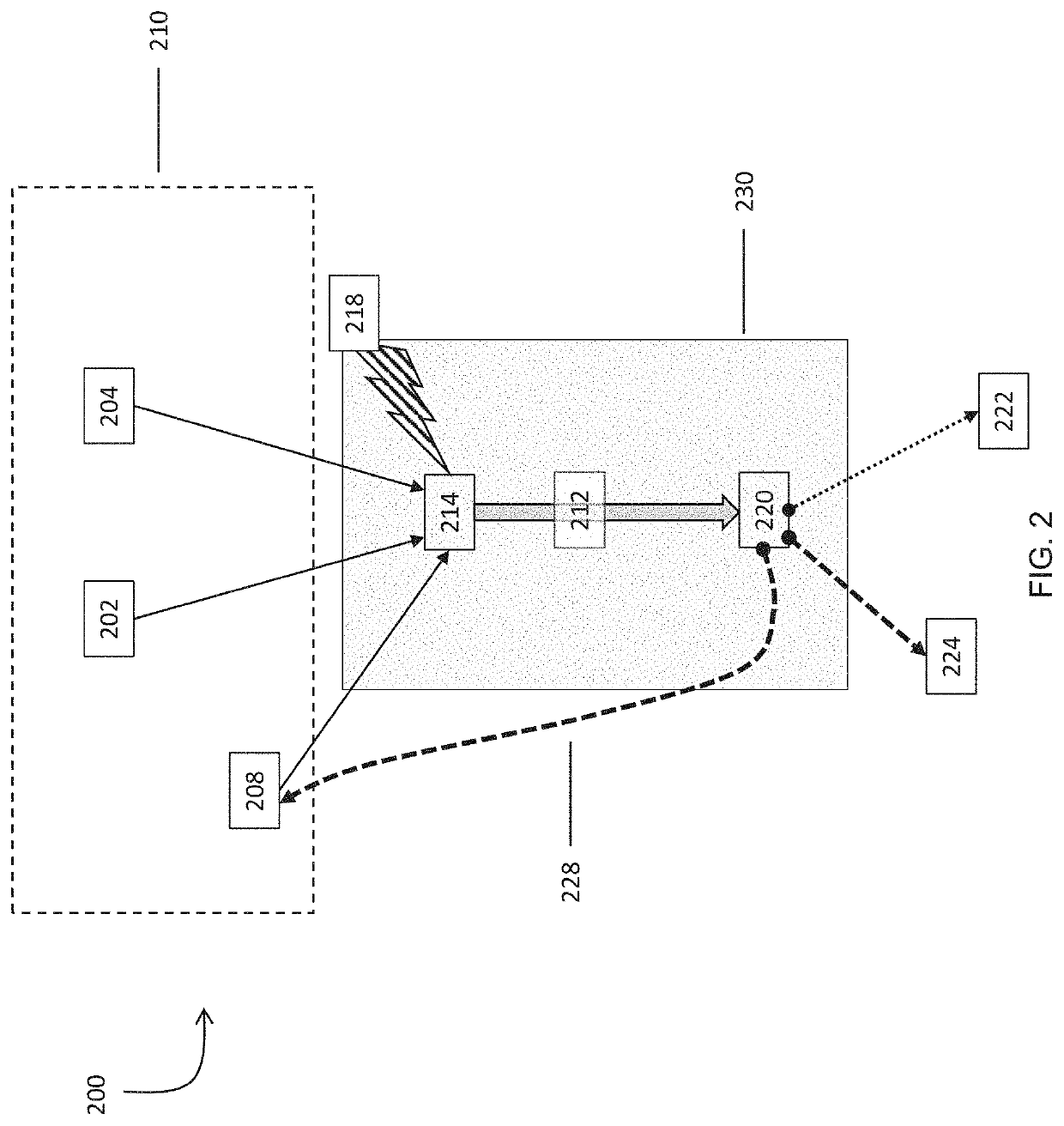

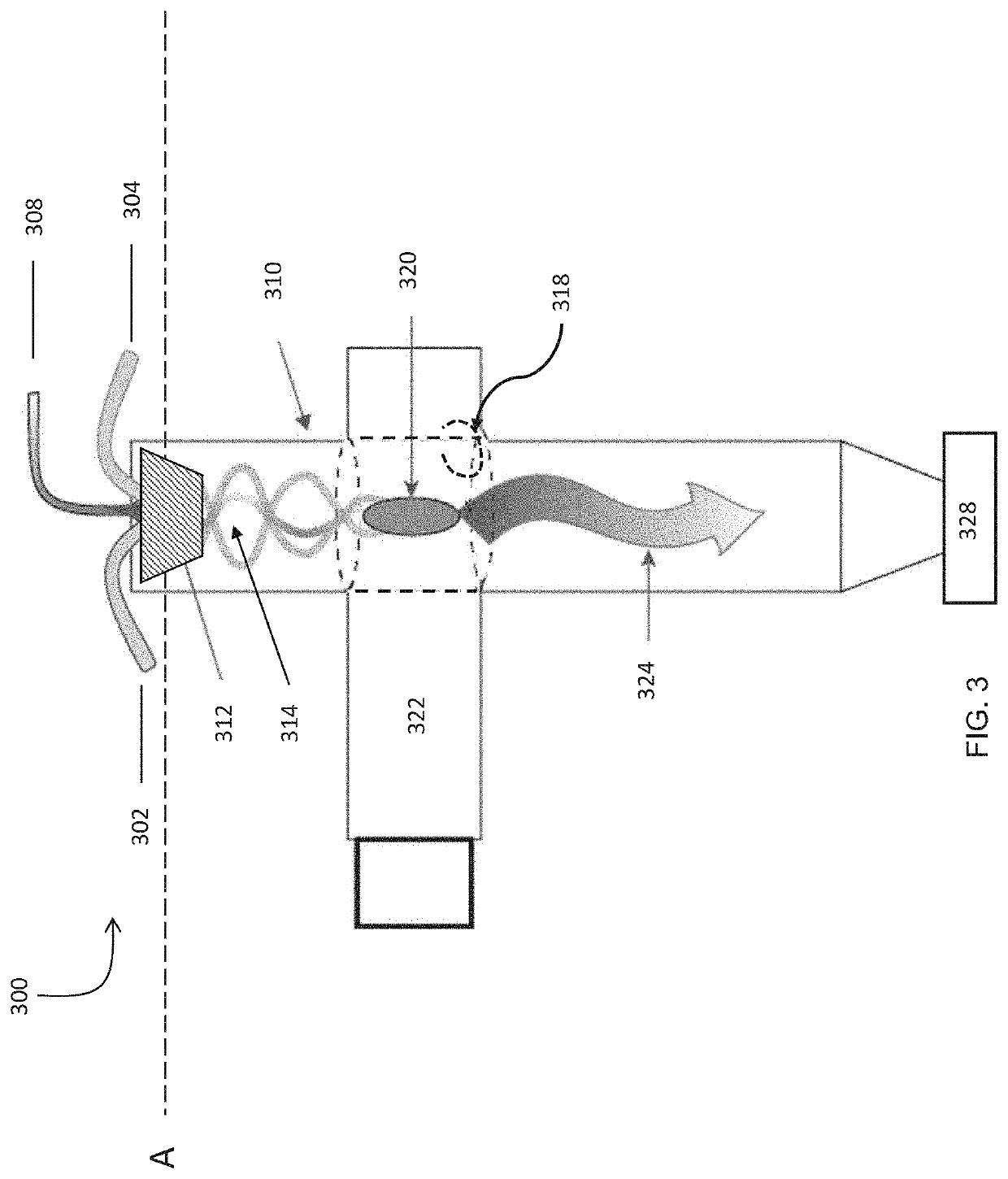

Systems and methods for processing gases

ActiveUS20210245133A1Carbon compoundsHydrocarbon oil cracking processChemical physicsPhysical chemistry

The invention includes a gas processing system for transforming a hydrocarbon-containing inflow gas into outflow gas products, where the system includes a gas delivery subsystem, a plasma reaction chamber, and a microwave subsystem, with the gas delivery subsystem in fluid communication with the plasma reaction chamber, so that the gas delivery subsystem directs the hydrocarbon-containing inflow gas into the plasma reaction chamber, and the microwave subsystem directs microwave energy into the plasma reaction chamber to energize the hydrocarbon-containing inflow gas, thereby forming a plasma in the plasma reaction chamber, which plasma effects the transformation of a hydrocarbon in the hydrocarbon-containing inflow gas into the outflow gas products, which comprise acetylene and hydrogen. The invention also includes methods for the use of this gas processing system.

Owner:TRANSFORM MATERIALS LLC

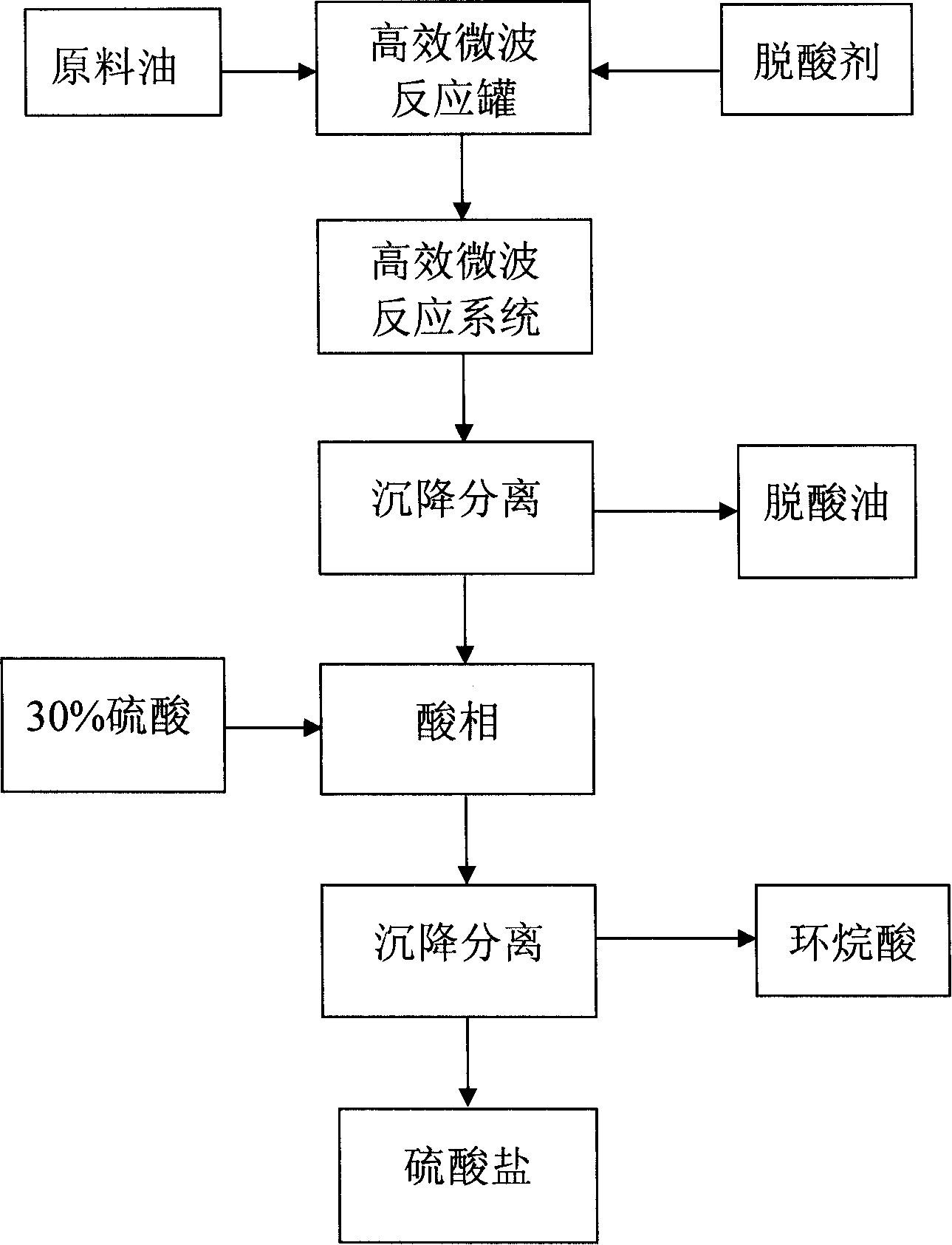

Technological process of eliminating naphthenic acid from diesel oil

InactiveCN1740276ATo achieve the purpose of deacidification and refiningImprove escape rateRefining with aqueous alkaline solutionsRefining by particle radiationSulfatePetroleum product

The present invention relates to acid matter eliminating technology for petroleum product, and is technological process of eliminating naphthenic acid from diesel oil. After fraction oil and deacidifying agent are added directly into microwave reactor, the microwave reactor is transferred into efficient microwave reaction system for microwave radiation. After deposition separating, the deacidifying agent with carried naphthenic acid is separated completely from the oil phase in deacidifying rate over 98 % and oil product recovering rate over 99.0 %. The separated acid phase is mixed with 30 % concentration sulfuric acid in the same volume for depositing separation into the upper layer of naphthenic acid and lower layer of sulfate solution. The said process has raised oil product quality and output, no emulsification, low production cost and environment friendship.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Process and apparatus for the conversion of methane gas to higher hydrocarbons

InactiveUS20050189211A1Liquid hydrocarbon mixtures productionHydrocarbonsLiquid hydrocarbonsUltraviolet lights

A process and apparatus are provided for converting methane to higher hydrocarbons, especially for converting economically stranded natural gas to a transportable liquid hydrocarbon product mainly comprised of C3+ hydrocarbons, comprising applying ultraviolet light to methane (or to the natural gas containing the methane) under conditions effective to cause its photodissociation and polymerization to C2+ and higher hydrocarbons.

Owner:KERR MCGEE OIL & GAS CORP

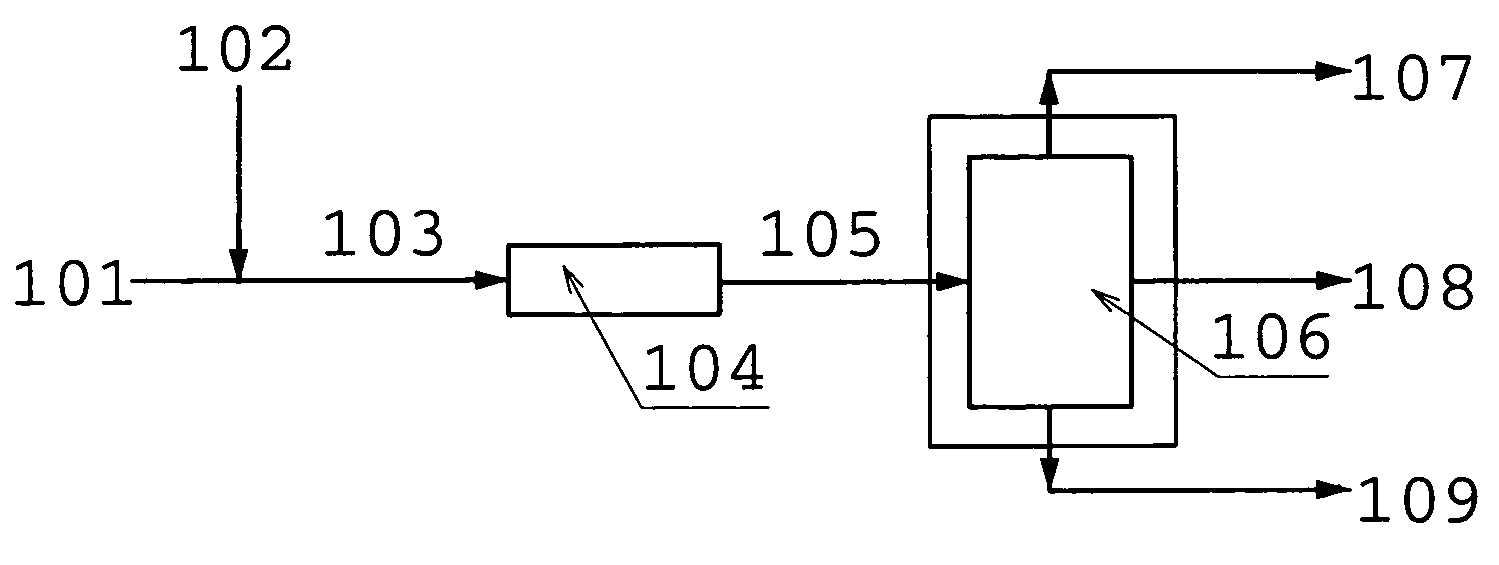

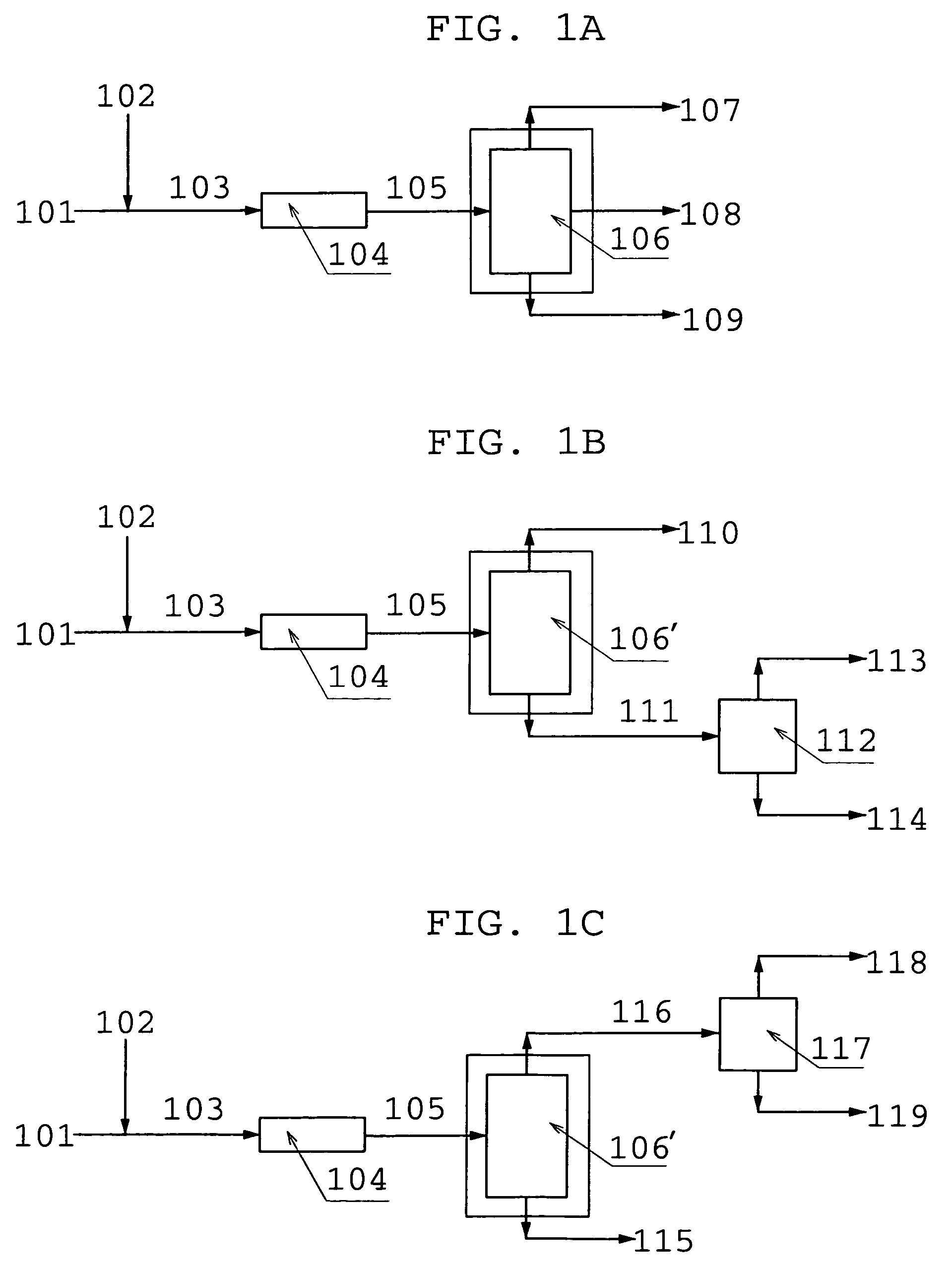

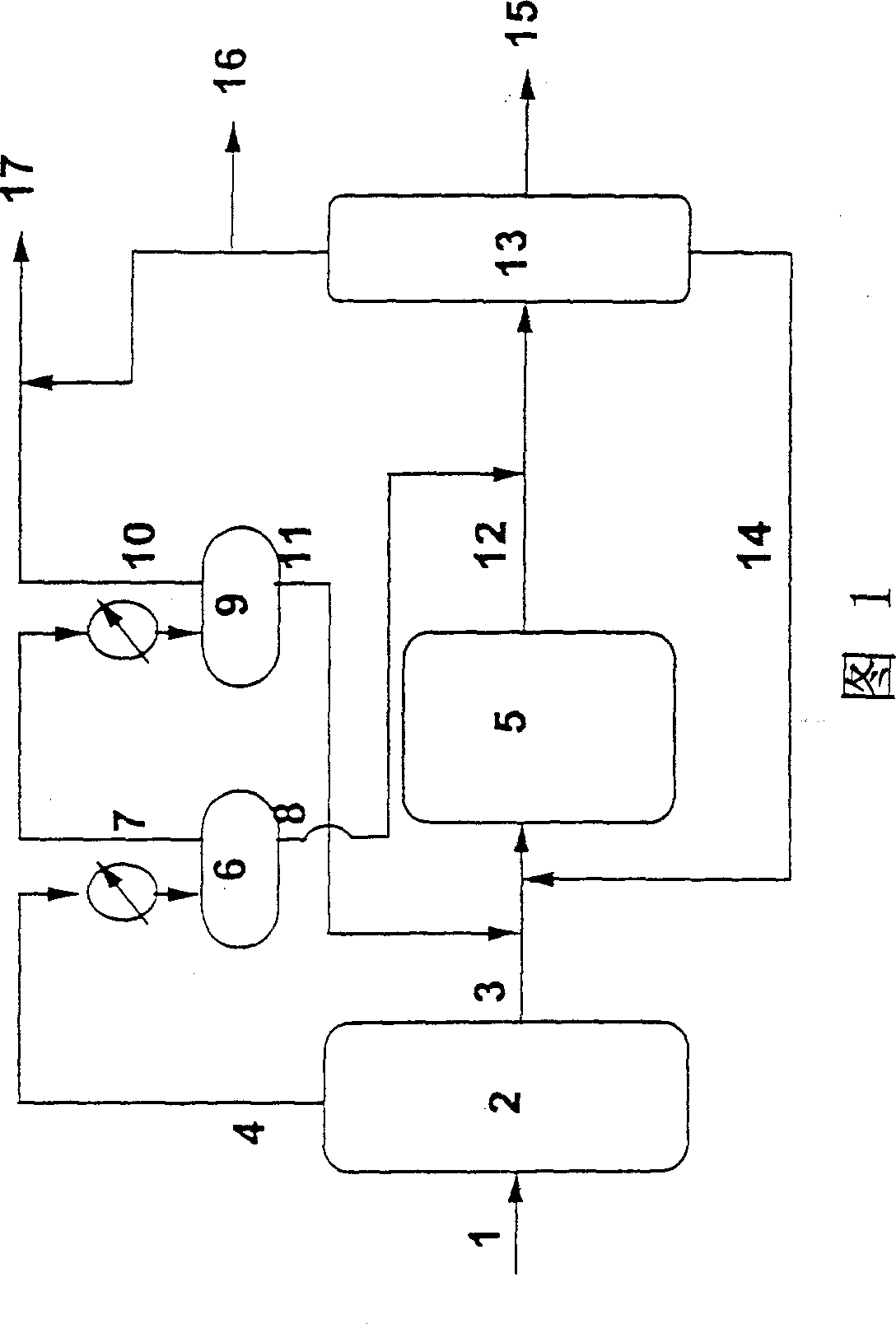

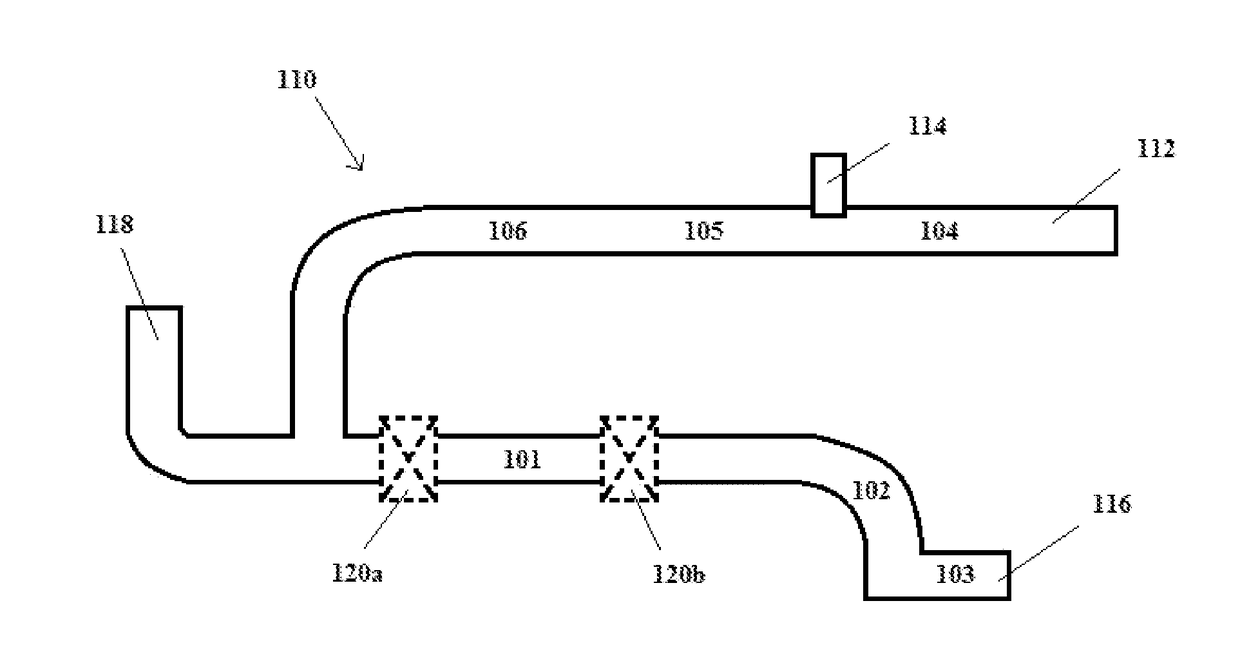

Process for reducing the naphthenic acidity of petroleum oils or their fractions

InactiveUS7507329B2High acid strengthReduce the numberLiquid separation by electricityRefining by electric/magnetic meansGas phaseDecomposition

A process for reducing the naphthenic acidity of petroleum oils or their fractions is described, said process comprising providing a hydrocarbon feed 103 / 203 / 303 having between 0.1 and 99 wt % of emulsified / dispersed water in oil, said feed containing salts and a content of naphthenic acids measured as TAN between 0.1 and 10 mg KOH / g oil; directing the said petroleum oil feed and emulsified / dispersed water towards an energy emitter device in the microwave range and submitting said feed 103 / 203 / 303 in liquid phase, under pressure between 0.7 and 4.5 MPa at temperatures between 50° C. and 350° C. to the microwave radiation, applied in the range of 1 mm to 30 cm to said feed so that the presence of salts, the applied temperature and the high dielectric constant of the water droplets make that the heat is absorbed on the spot by the water and heat said water preferentially to the oil, while the naphthenic compounds at the interface between the droplets and the oil catch said heat; effecting the decomposition of the carboxylic acids responsible for the naphthenic acidity in the petroleum feed at temperatures around 320° C. and generating CO2; separating with the aid of any known device 106 / 106′ / 112 / 117 / 208 / 208′ / 214 / 219 / 310 / 310′ / 316 / 321 any gas phase generated, water and oil; and recovering the hydrocarbon oil stream 108 / 113 / 119 / 210 / 215 / 221 / 312 / 317 / 323 having a reduced content in naphthenic acids. The process is designed to be applied to the reduction of naphthenic acids in feeds of petroleum oils and their fractions in the oil production step, in refineries or any industrial installation.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

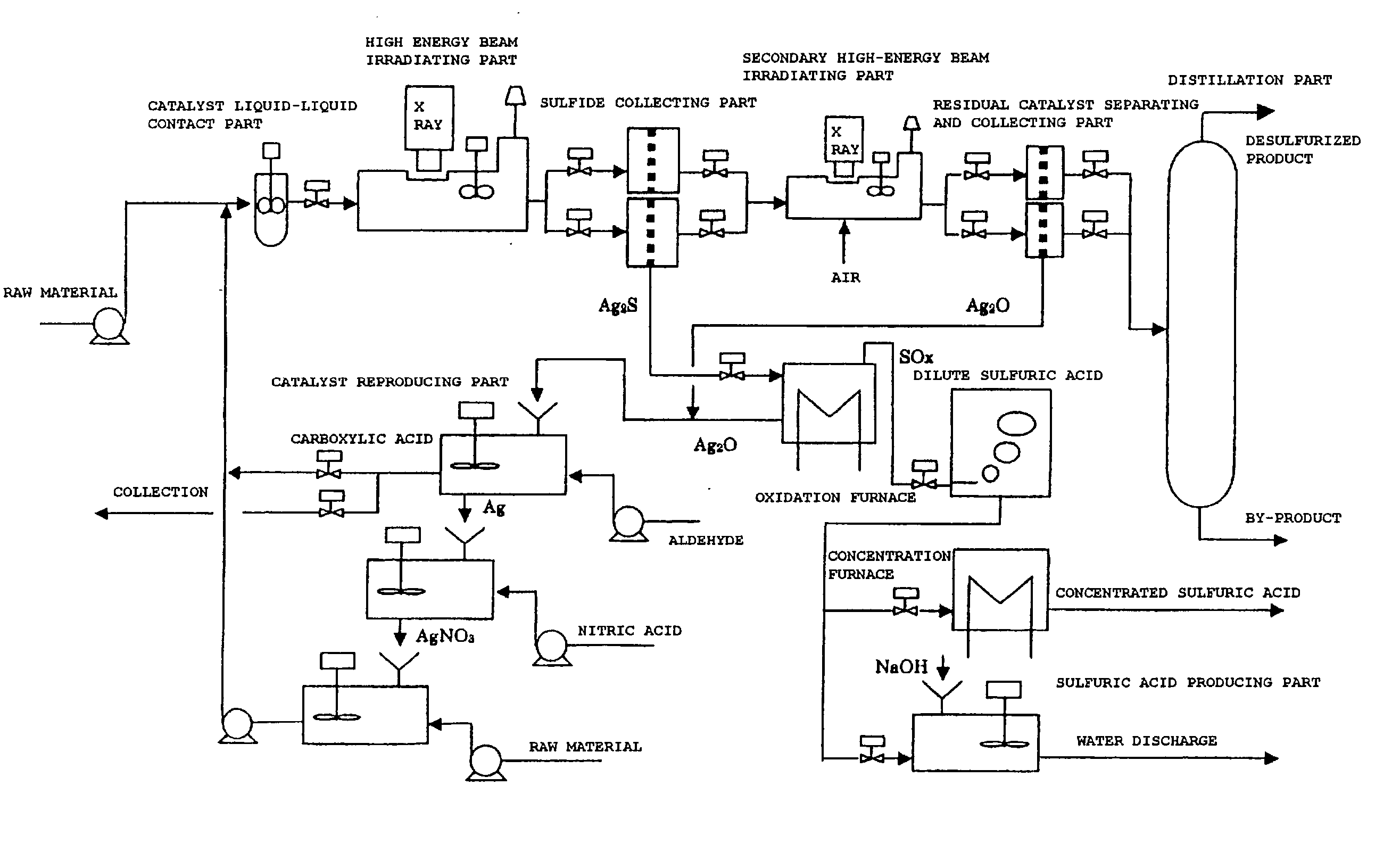

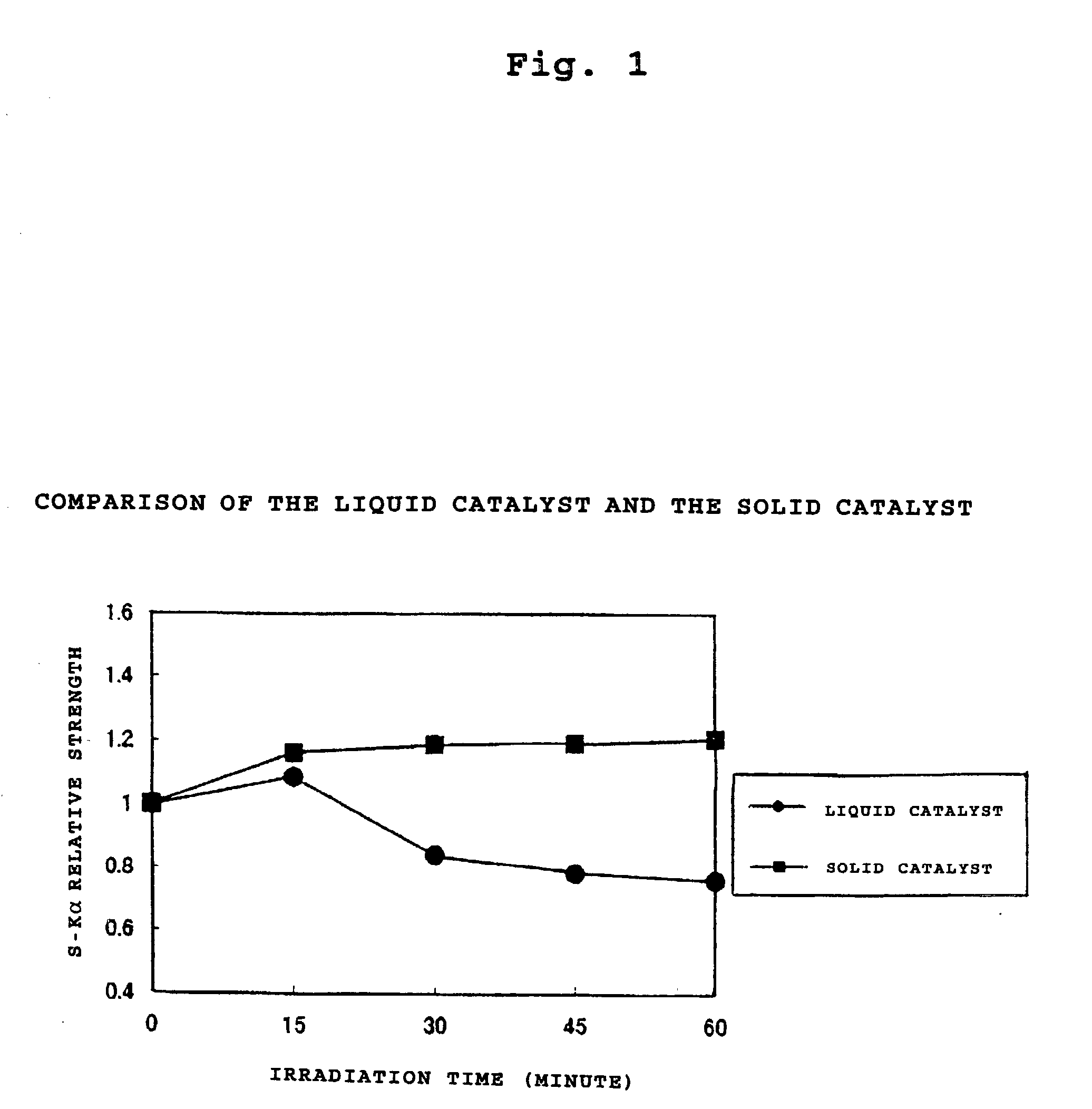

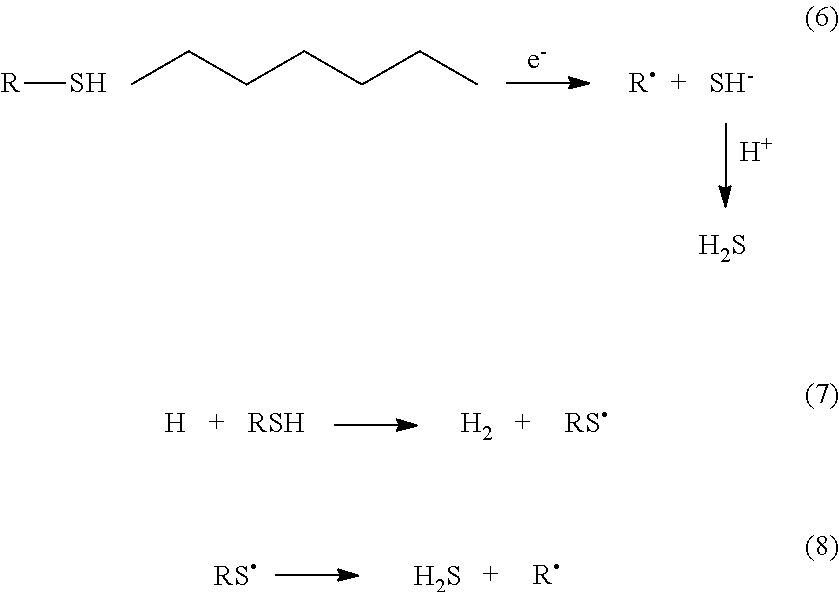

High-energy beam irradiating desulfurization device

InactiveUS20030017091A1Improve efficiencyHighly practicalRefining with metal saltsRefining by filtrationPetroleum productSulfide

The present invention is to provide an efficient and highly practical novel desulfurization device capable of executing the depth desulfurization. A high-energy beam irradiating desulfurization device for a petroleum product or a petroleum semimanufactured product, comprising a catalyst liquid-liquid contact part for contacting a metal compound solution as a catalyst and the petroleum product or the petroleum semimanufactured product, a high-energy beam irradiating part, and a sulfide collecting part for separating and collecting sulfide of the metal produced by the high-energy beam irradiation, is provided.

Owner:RIGAKU CORP

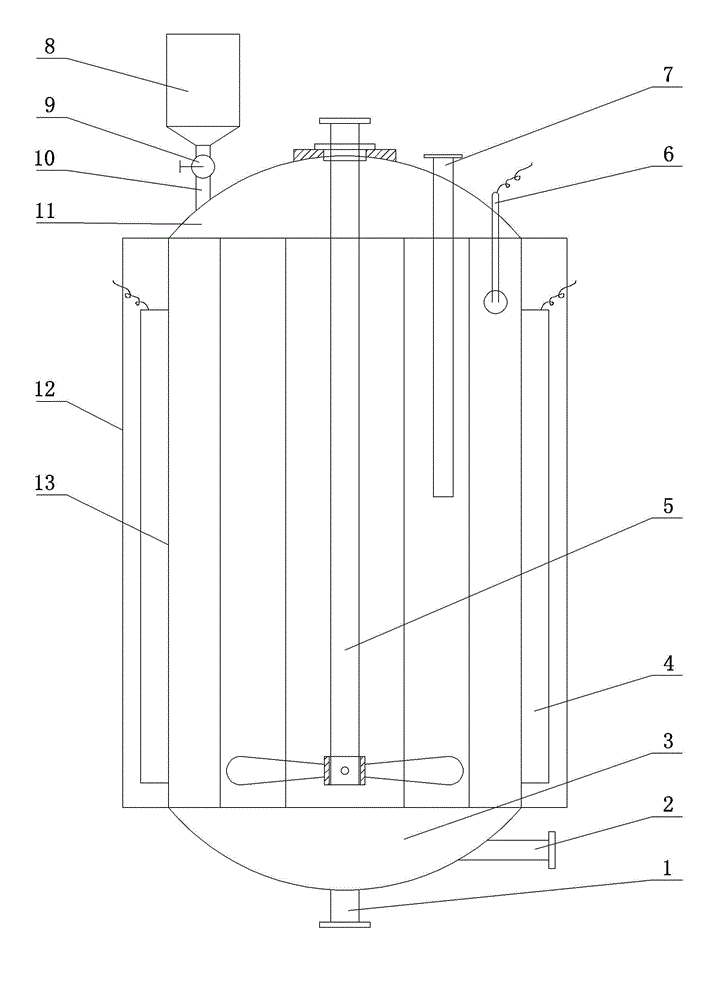

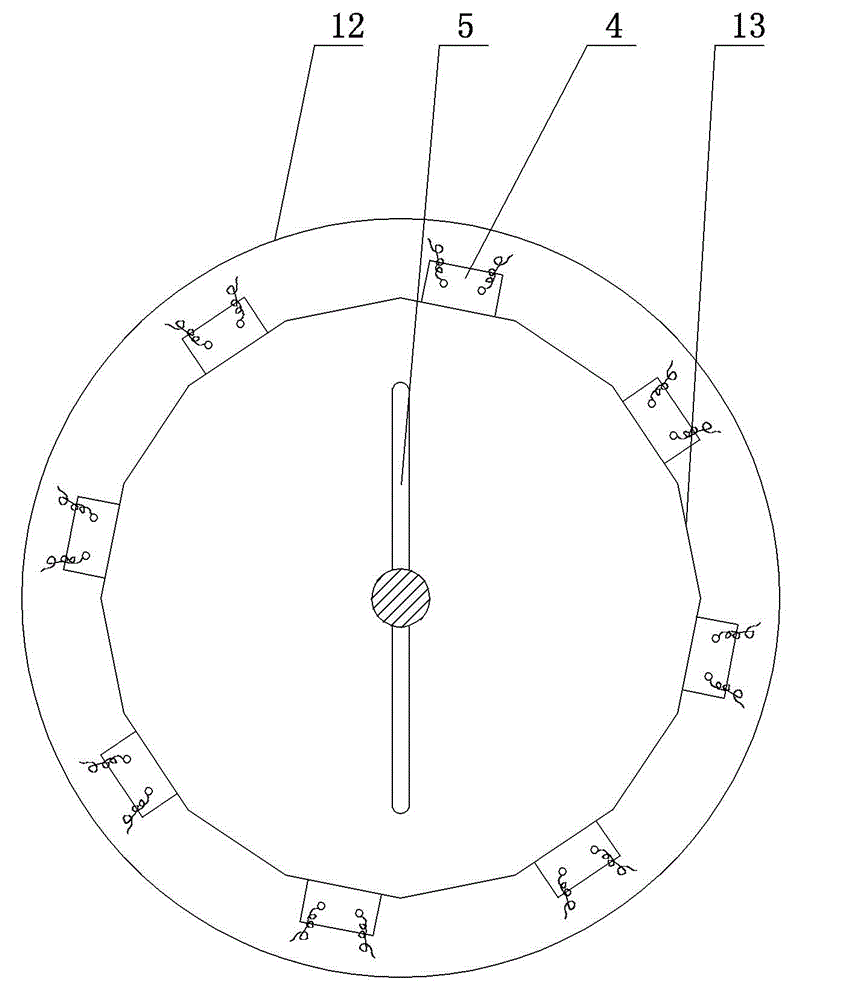

Ultrasonic resonance desulfurization electrochemical technology reactor and reaction technology thereof

ActiveCN104694155ANo safety hazardRefining by electric/magnetic meansRefining by filtrationWaste processingHazardous substance

The invention relates to an ultrasonic resonance desulfurization electrochemical technology reactor and a reaction technology thereof, and belongs to the technical field of organic matter waste processing. The ultrasonic resonance desulfurization electrochemical technology reactor and the reaction technology have the advantages of good removal effect of harmful substances in an oil product, and high working safety. The ultrasonic resonance desulfurization electrochemical technology reactor comprises a cylinder body, the upper end of the cylinder body is an upper seal head, the lower end of the cylinder body is a lower seal head, the upper seal head is provided with an oil inlet tube and a reagent feeding tube, a stirrer is arranged in the cylinder body, the upper end of the stirrer is arranged at the middle portion of the upper seal head, and the lower seal head is provided with an oil outlet tube. The reactor is characterized in that the cylinder body comprises an inner layer cylinder body and an outer layer cylinder body, and the outer sidewall of the inner layer cylinder body is provided with an ultrasonic transducer.

Owner:铜陵华兴精细化工有限公司

Hybrid fuel and method of making the same

InactiveUS9567542B2High densitySpeed up the flowInternal combustion piston enginesBiofuelsBiofuelLiquid fuel

Owner:FUELINA TECH

Method for preparing biomass based automotive diesel oil by quickly co-pyrolyzing bamboo waste and waste tires through microwave-assisted double-bed catalysis

InactiveCN107652999AHigh yieldImprove qualityBiofuelsLiquid hydrocarbon mixture productionAlkaneMolecular sieve

The invention provides a method for preparing biomass based automotive diesel oil by quickly co-pyrolyzing bamboo waste and waste tires through microwave-assisted double-bed catalysis. The method comprises the steps: 1) according to a mass ratio of (1 to 1) to (1 to 10), weighing bamboo waste and waste tires and evenly mixing; 2) according to a mass ratio of HZSM-5 molecular sieve catalyst to a bamboo waste and waste tire mixture equal to (1 to 1) to (1 to 10), putting the catalyst into a U-shaped quartz tube connected with a pyrolysis steam outlet of a quartz double-neck bottom and adding a microwave absorbent into a quartz cup; 3) burying the quartz double-neck bottom and the U-shaped quartz pipe into the quartz cup, putting into a microwave pyrolyzing instrument, heating to 450 to 650 DEG C, quickly adding the bamboo waste and waste tire mixture into the quartz double-neck bottle, catalyzing and reforming generated pyrolysis steam by the catalyst in the U-shaped quartz tube and condensing into hydrocarbon-rich biomass based automotive diesel oil by a condensation pipe. The method disclosed by the invention greatly shortens carbonizing time, improves bio-oil yield and quality andremarkably improves contents of alkane and arene in hydrocarbon-rich bio-oil.

Owner:NANCHANG UNIV

Fuel synchronous superposition treatment device and method

InactiveCN103113915AImprove stabilityReduce surface tensionDewatering/demulsification with electric/magnetic meansRefining by electric/magnetic meansPhysical approachEngineering

The invention discloses a fuel synchronous superposition treatment device and method. A magnetic field with intensity of 0.4MT, ultrasonic waves with the frequency of 1.25 MHz and the intensity of 70W / cm<2>, and electromagnetic waves with the wavelength of 7.0 mu m and the radiating power of 400W are simultaneously utilized to synchronously perform superposition treatment on fuel. After performing superposition treatment on the fuel, the fuel becomes cleaner, and the activity of the fuel can be better enhanced; and thus, the intermolecular cohesion of the fuel is lowered, the molecular configuration is changed, the viscosity and surface tension of the fuel are lowered, colloids and other impurities in the fuel are effectively removed, and the flowability, combustibility and cleanness of the fuel are enhanced, thereby greatly enhancing the combustion speed of the fuel, the temperature of the combustion zone and the complete combustion coefficient. The fuel is treated by a physical method, thereby basically avoiding the problem of secondary pollution due to use of chemical additives.

Owner:郑晓牧 +1

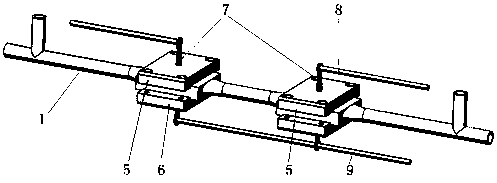

Series plasma pyrolysis flow reactor and operation method thereof

ActiveCN109351300ACompact structureReasonable designEnergy based chemical/physical/physico-chemical processesRefining by particle radiationEngineeringOperational approach

The invention discloses a series plasma pyrolysis flow reactor and an operation method thereof, which comprises a series flow pipe, a dielectric layer, a high-pressure copper plate, a low-pressure copper plate, an upper electrode shell, a lower electrode shell, an electrode connecting ear, a high-pressure electrode and a grounded electrode; the series flow pipe comprises a first-stagepyrolysis device, a second-stagepyrolysis device, an electrode fixing surface, a round pipe, an observation window, a temperature measuring port, a fuel inlet and a product outlet, the first-stagepyrolysis deviceand the second-stagepyrolysis device are arranged in the middle of the series flow pipe with a proper distance. The reactor has a compact structure and reasonable design; the second-stage pyrolysis device can be arranged at the back of the first-stagepyrolysis device to control the airflow velocity to change the residence time of a treated species in the two pyrolysis zones, so that the state of the species which reaches the secondpyrolysis device after first pyrolysis is different. The effects of treatment of stable species and pyrolysis of intermediate species by plasma on final pyrolysis products are studied.

Owner:AIR FORCE UNIV PLA

Systems and methods for processing gases

ActiveUS20220080379A1Carbon compoundsHydrocarbon oil cracking processChemical physicsPhysical chemistry

The invention includes a gas processing system for transforming a hydrocarbon-containing inflow gas into outflow gas products, where the system includes a gas delivery subsystem, a plasma reaction chamber, and a microwave subsystem, with the gas delivery subsystem in fluid communication with the plasma reaction chamber, so that the gas delivery subsystem directs the hydrocarbon-containing inflow gas into the plasma reaction chamber, and the microwave subsystem directs microwave energy into the plasma reaction chamber to energize the hydrocarbon-containing inflow gas, thereby forming a plasma in the plasma reaction chamber, which plasma effects the transformation of a hydrocarbon in the hydrocarbon-containing inflow gas into the outflow gas products, which comprise acetylene and hydrogen. The invention also includes methods for the use of this gas processing system.

Owner:TRANSFORM MATERIALS LLC

Radiation processing of heavy oils

InactiveUS8470166B2Maximize roleIncrease productionRefining with oxygen compoundsFluid removalRadiation chemistryPetroleum product

The present invention is drawn to a method of processing heavy paraffinic oils or heavy aromatic oils using radiation chemistry of polyethylene under oxidizing conditions. The process of the invention will result in a chain reaction for oxidative scission as the basis for a radiation processing for heavy paraffinic or aromatic oils. The method of the invention will allow for the cost-efficient and environmentally-friendly processing of heavy oils into lighter petroleum products.

Owner:PETRORADIANT

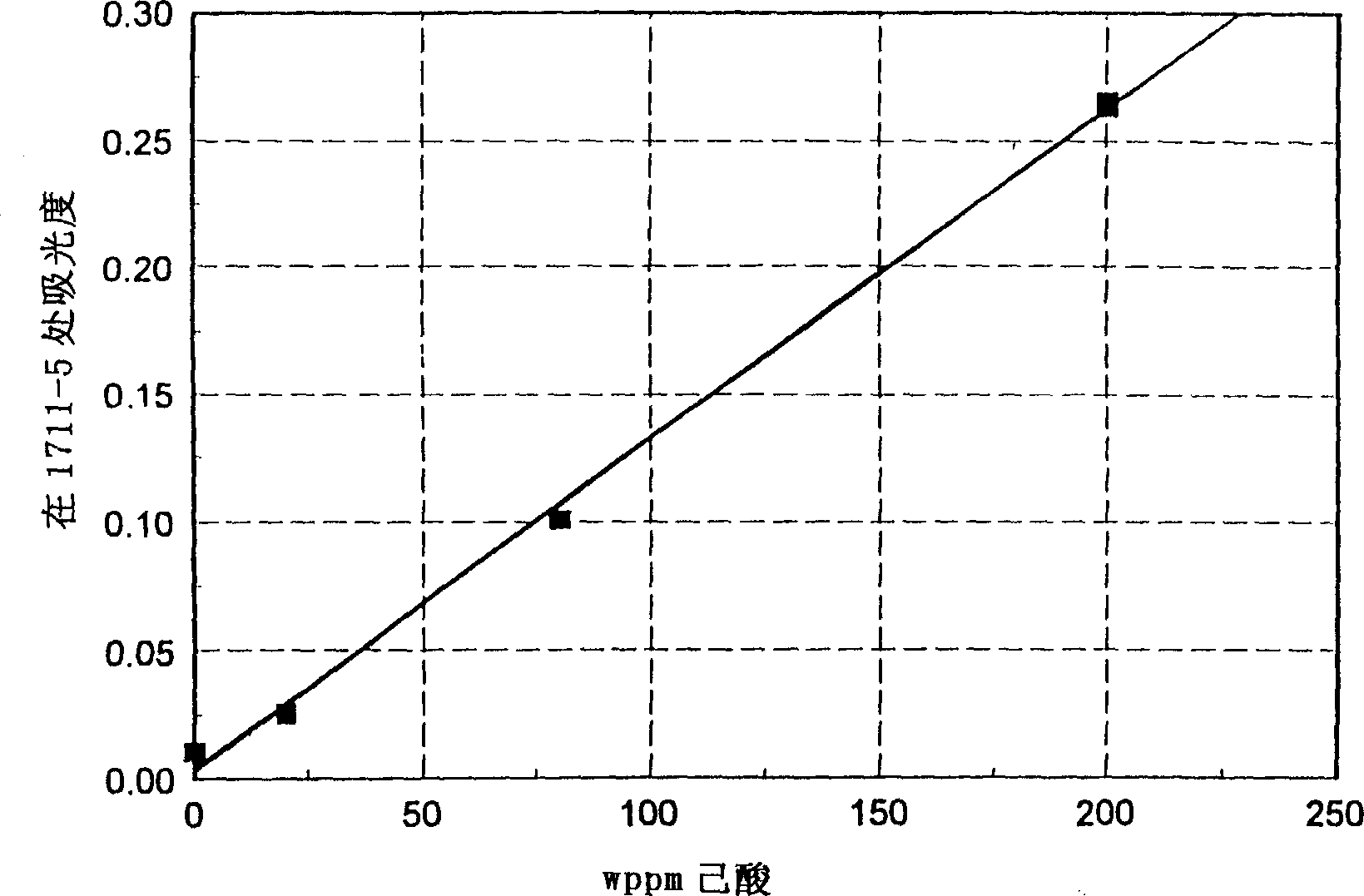

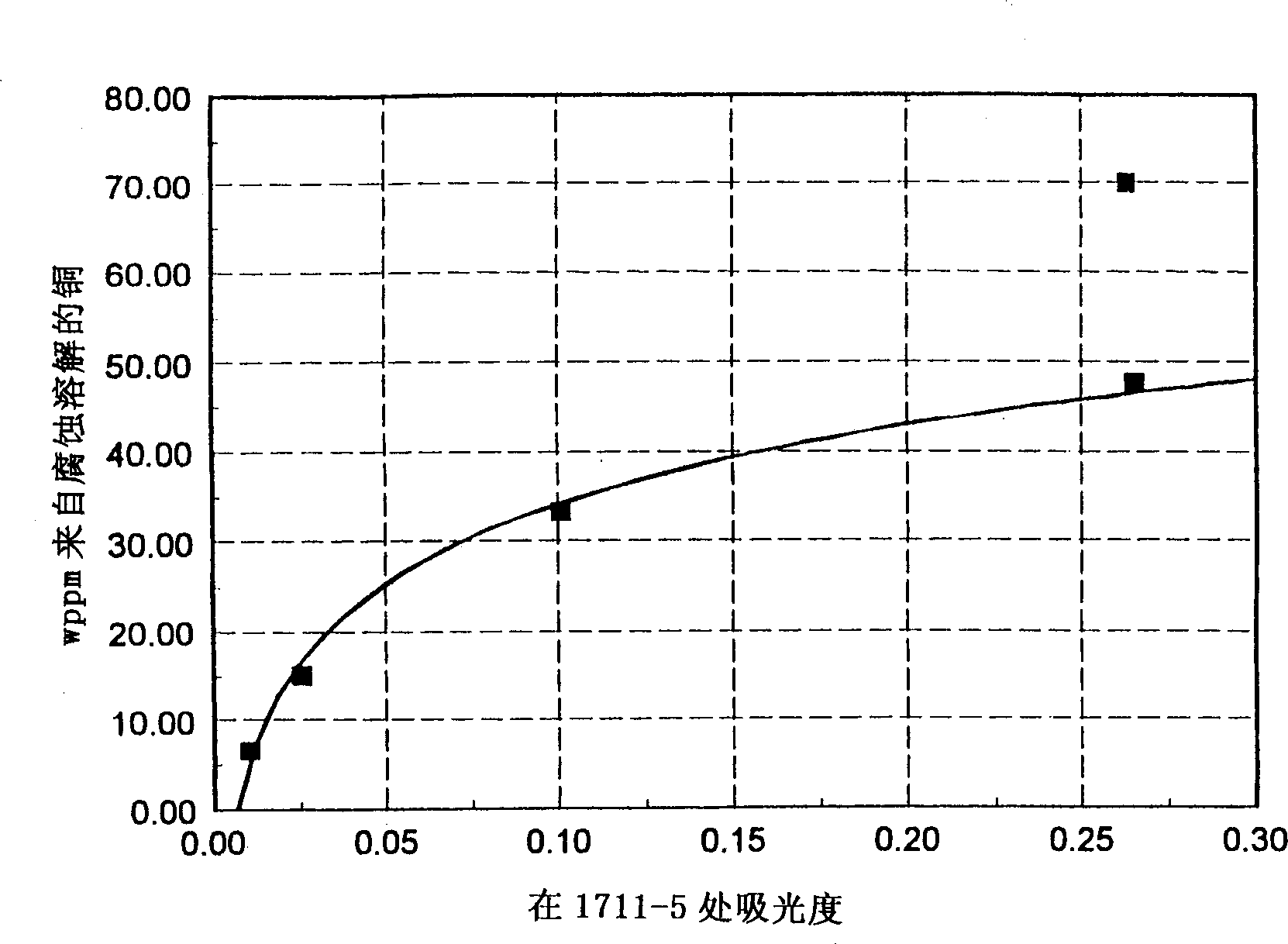

Use of infrared spectroscopy to produce high lubricity, high stability, Fischer-Tropsch diesel fuels and blend fuel

InactiveCN1293648AHydrocarbon distillation control/regulationHydrocarbon by hydrogenationAlcoholGasoline

The present invention is a method for controlling a process for producing a distillate fuel heavier than gasoline. The process includes several different fractions, streams, including alcohols, olefins, and acids. At least one of the streams or is irradiated with IR radiation, allowing the determination of the concentrations of at least one of alcohols, olefins and acids. The temperature of the separator or is then adjusted to change the concentrations to pre-determined values.

Owner:EXXON RES & ENG CO

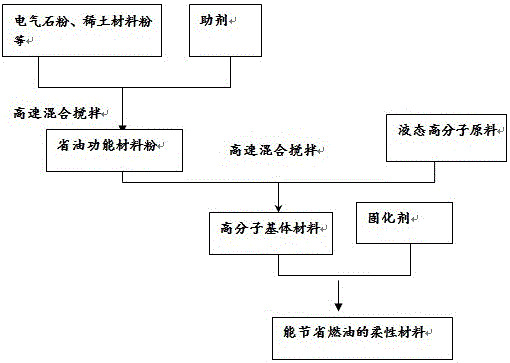

Flexible material capable of saving fuel

InactiveCN106635132AImprove performanceBurn fullyRefining by particle radiationSocial benefitsFuel tank

The invention discloses a flexible material capable of saving fuel. The flexible material mainly comprises tourmaline powder, rare earth material powder, auxiliaries and high-polymer materials. A process for preparing the flexible material includes A, uniformly stirring the quantitative tourmaline powder, the quantitative rare earth material powder, the quantitative auxiliaries and the like at the high speed to obtain oil-saving functional materials; B, stirring and dispersing the oil-saving functional materials into the high-polymer materials and carrying out molding, mold releasing and maintaining to obtain the oil-saving flexible material; C, winding the flexible material around oil delivery pipelines and mounting or adhering the flexible material around oil tanks. The flexible material has the outstanding advantages that the tourmaline powder and the rare earth material powder are used as main raw materials, appropriate quantities of synergists and stabilizers are added into the main raw materials, accordingly, far infrared rays can be continuously and stably emitted, generation of anions can be promoted, and the fuel can be sufficiently combusted; effects of the oil-saving functional materials can be sufficiently realized in a form of the flexible material, and accordingly outstanding oil-saving effects can be realized; the flexible material capable of saving the fuel is excellent in product performance, the process for preparing the flexible material is safe and reliable, the flexible material and the process have obvious economic and social benefits, and the like.

Owner:魏昭荣

Fuel treatment module, system and method

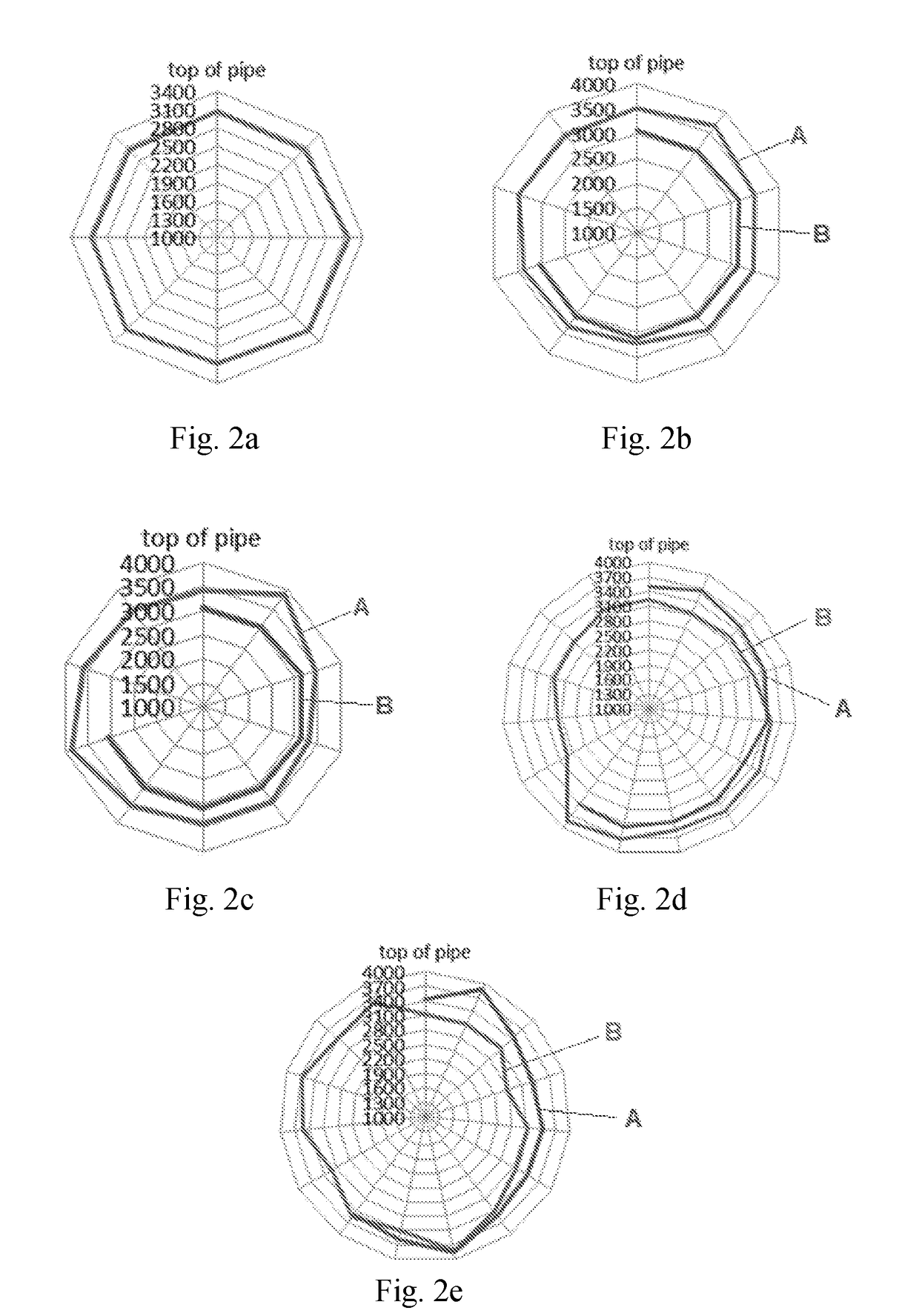

ActiveUS10371105B1Improve fuel efficiencyEmission reductionLiquid carbonaceous fuelsMachines/enginesFuel treatmentEngineering

A fuel treatment module treats fuel with infrared radiation from a plurality of infrared radiation emitting elements arranged in a structure configured to ensure sufficient exposure of the fuel to infrared radiation. Such structure includes a head cap and spacer having through bores providing a manifold through which fuel flows into multiple IR / shunt columns of infrared radiation emitting elements that are disposed within a canister. Then the fuel moves out of the multiple IR / shunt columns into the open area of the canister where the fuel then flows around the exterior of the columns, exposing the fuel to further infrared radiation treatment.

Owner:CAMERON DYNAMICS LLC

Desalting Method and Apparatus

InactiveUS20180086986A1Material analysis using wave/particle radiationRefining by water treatmentProduction lineNeutron backscattering

A method for optimizing a desalting process in which a hydrocarbon feedstock is passed to a desalter through a line under a set of conditions, the hydrocarbon feedstock containing a hydrocarbon fluid, water and a salt, said method comprising: obtaining spectra of the hydrocarbon feedstock under a plurality of environments in the line; comparing the spectra; and based on the comparison of the spectra, either modifying or maintaining the set of conditions under which the hydrocarbon feedstock is passed to the desalter; wherein the spectra are obtained using neutron backscattering.

Owner:BP CORP NORTH AMERICA INC

Method for removing water-soluble polymer in polymer-bearing crude oil

InactiveCN105349177ASolve efficiency problemsSolve the costRefining by filtrationRefining by particle radiationPolymer scienceMicrowave

The invention provides a method for removing a water-soluble polymer in polymer-bearing crude oil. The method comprises the following steps: uniformly adding a barium carbonate particle into the polymer-bearing crude oil, then radiating the obtained crude oil mixture in a microwave environment and carrying out filtering so as to effectively remove the water-soluble polymer in the polymer-bearing crude oil. The objective of the invention is to provide the method for removing the water-soluble polymer in the polymer-bearing crude oil to overcome the problems of difficult demulsification of the polymer-bearing crude oil produced after polymer flooding on the ground and during transporting, reduced efficiency of a heater, high cost of a de-emulsifier and the like. The method can remove the water-soluble polymer in the polymer-bearing crude oil and has the advantages of easiness in operation and realization and low cost; the barium carbonate particle used in the invention has the characteristics of regeneration performance and repeated usability, so cost of the method is reduced; and the method is applicable to technological treatment of polymer-bearing crude oil produced from a polymer flooded oil reservoir.

Owner:YANGTZE UNIVERSITY

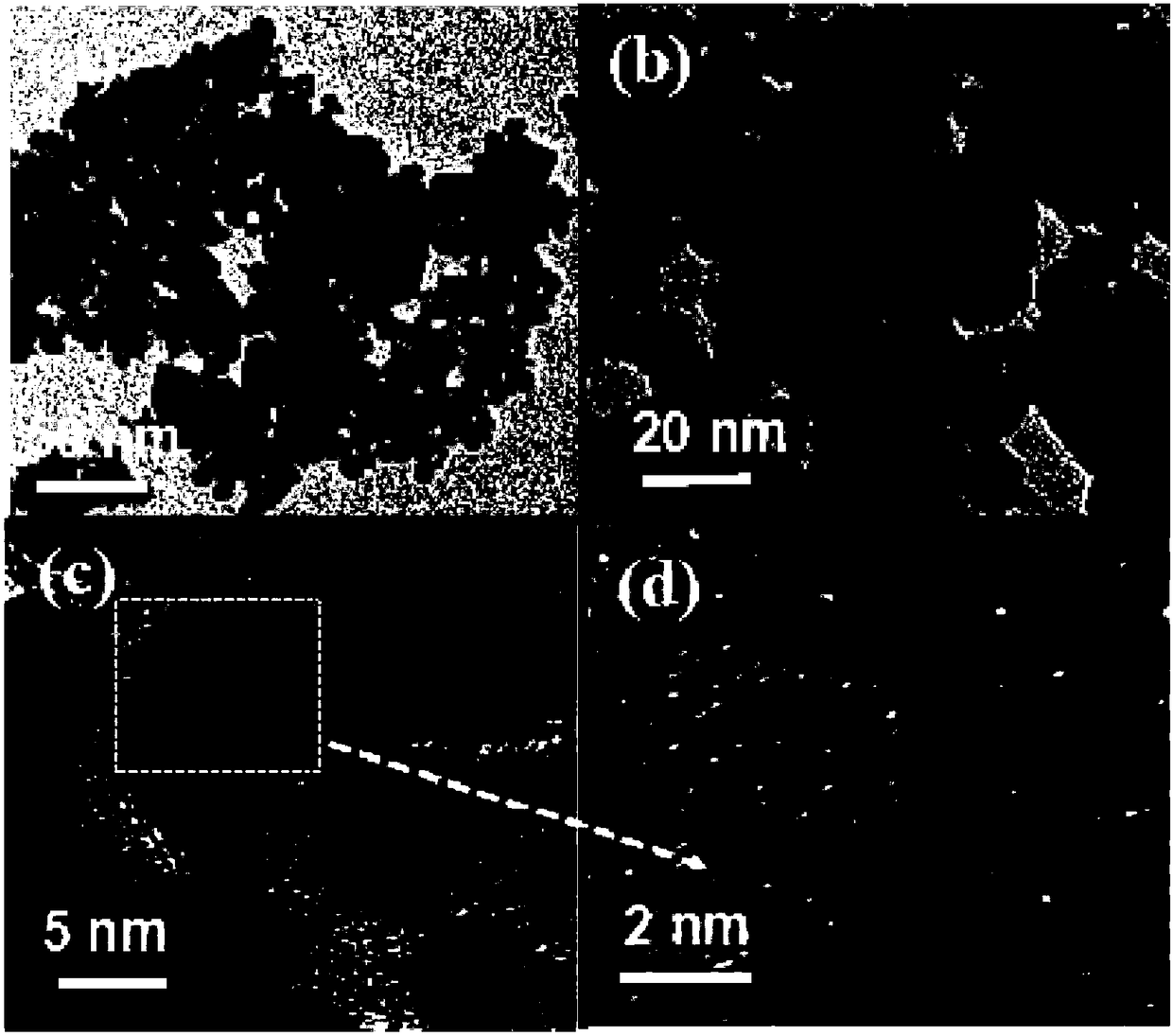

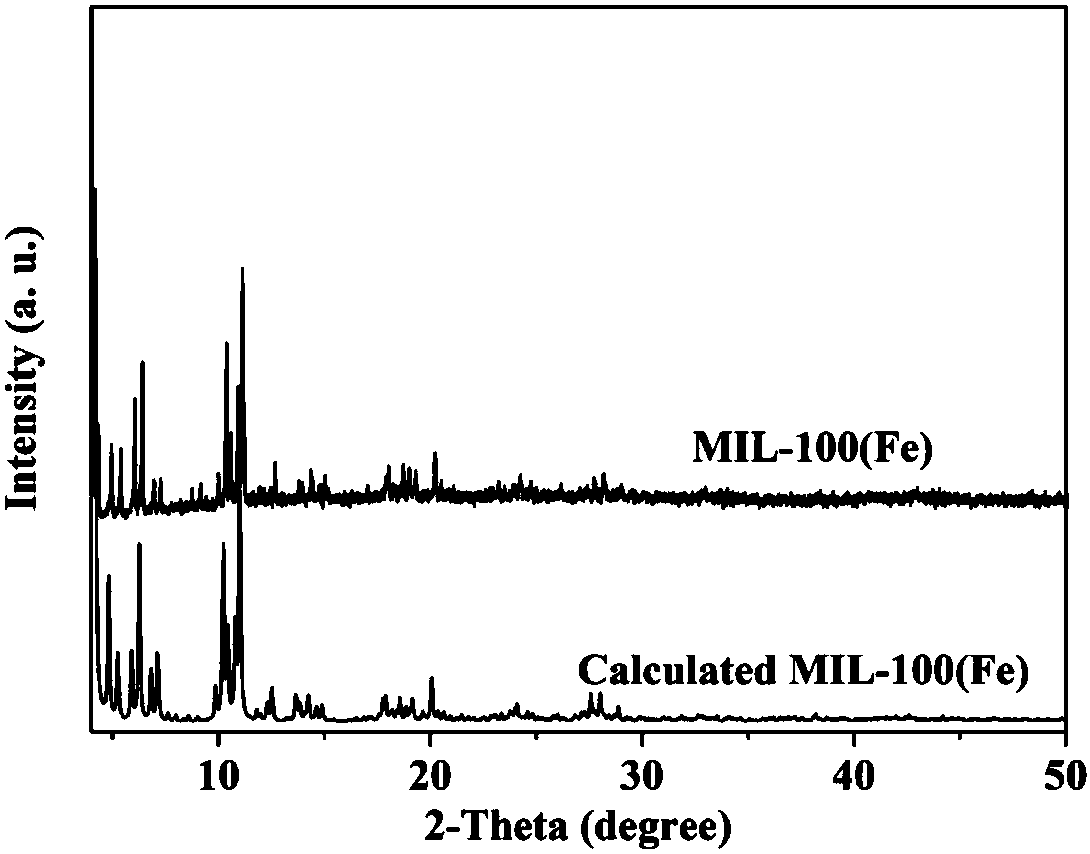

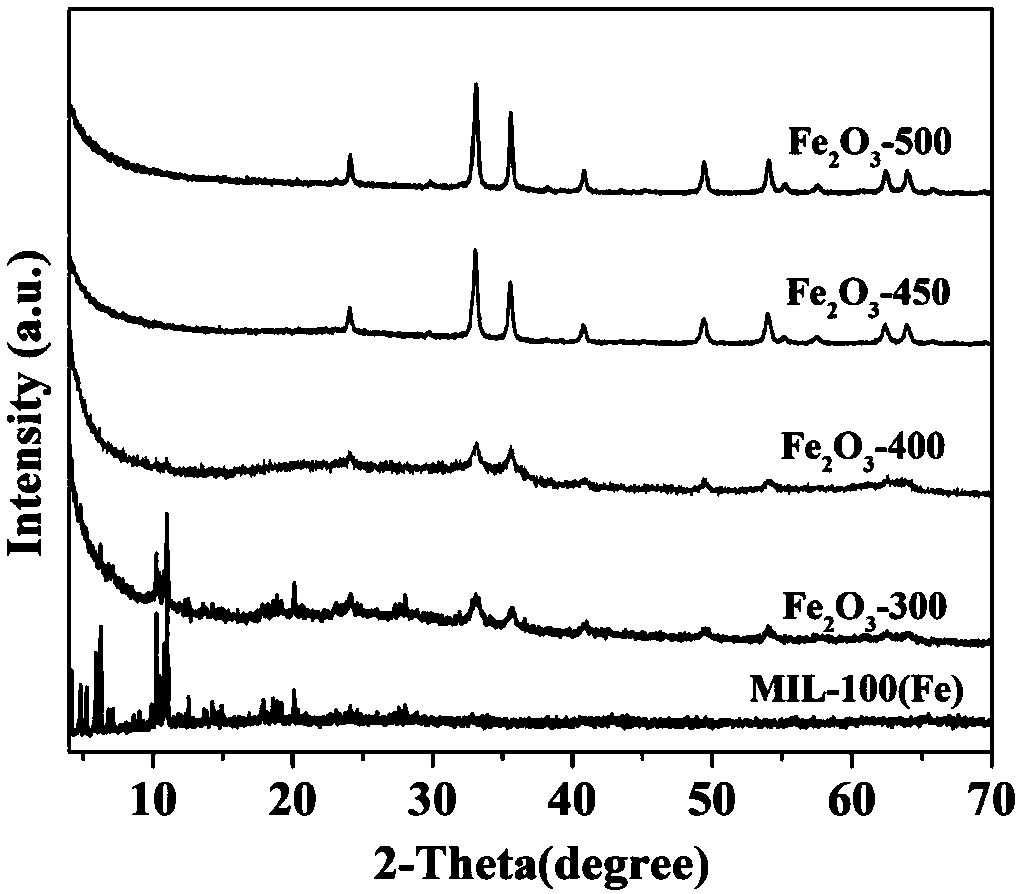

Supported type Fe2O3 composite photocatalyst

ActiveCN108273559AImprove lipophilicityGood dispersionOrganic-compounds/hydrides/coordination-complexes catalystsRefining with metal oxidesMetal frameworkNitrogen

The invention provides a supported type Fe2O3 composite photocatalyst, and relates to the technical field of photocatalysis. The supported type Fe2O3 composite photocatalyst comprises porous Fe2O3 andSDS which is supported on the porous Fe2O3, wherein the porous Fe2O3 is prepared by roasting an organic metal framework MIL-100; the porous Fe2O3 is dispersed into the SDS solution and is subjected to adsorption reaction for 1-3h; then the product is separated, washed and dried to obtain the supported type Fe2O3 composite photocatalyst. The composite photocatalyst is of a porous structure, high in photocatalyzing performance, and capable of effectively removing nitrogen-containing component in fuel oil; in addition, the preparation method is simple, and easy to implement, and has a good application prospect.

Owner:NINGDE NORMAL UNIV

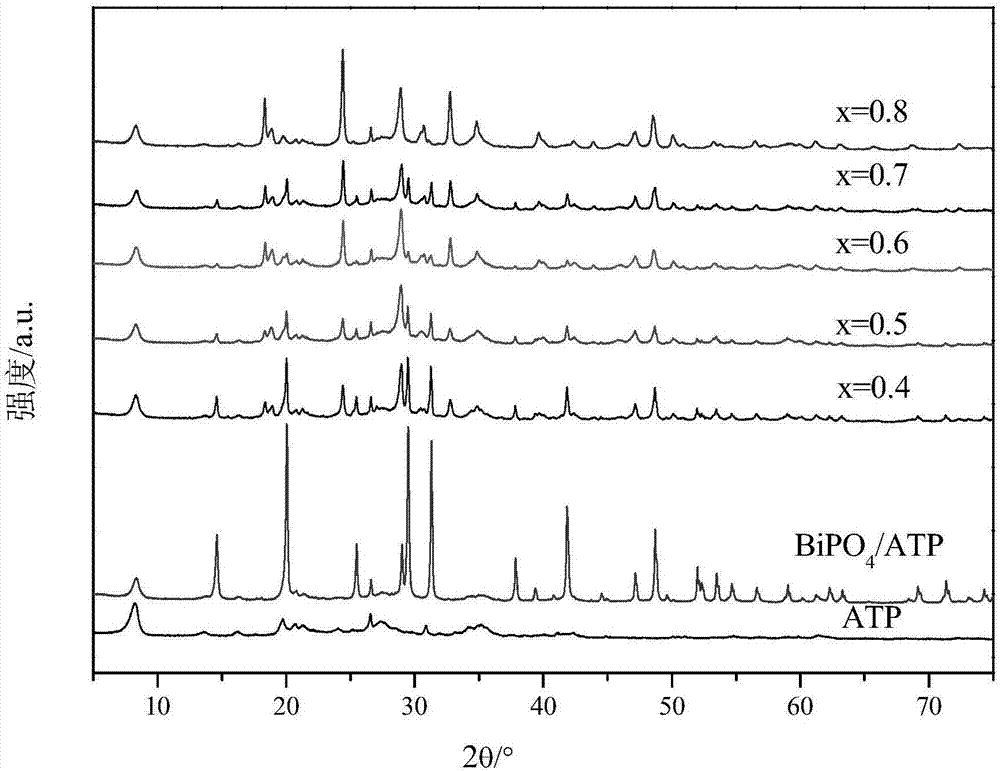

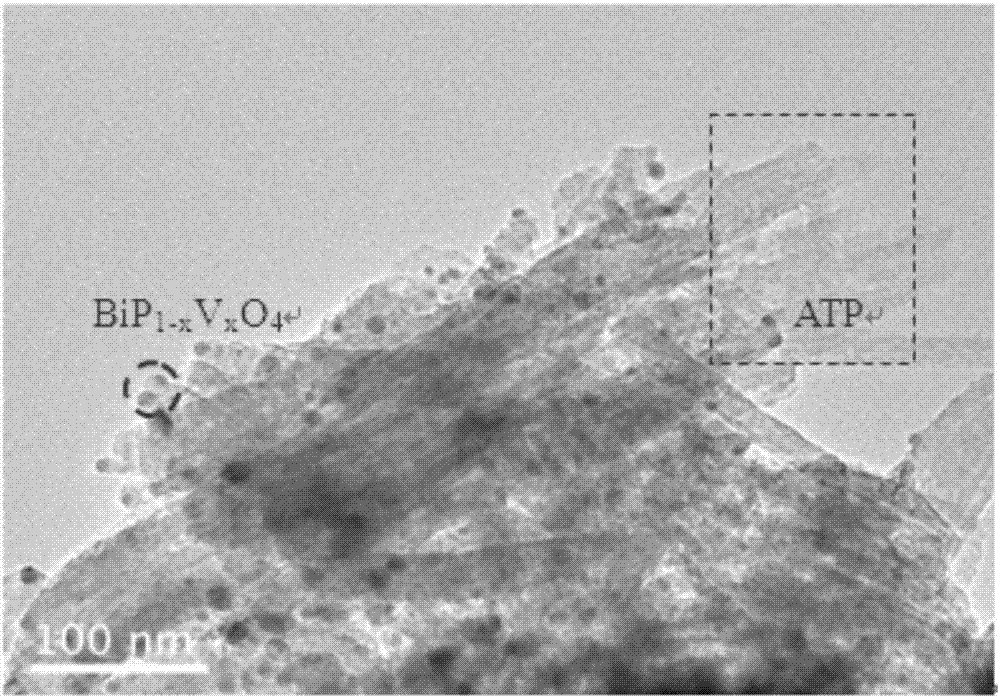

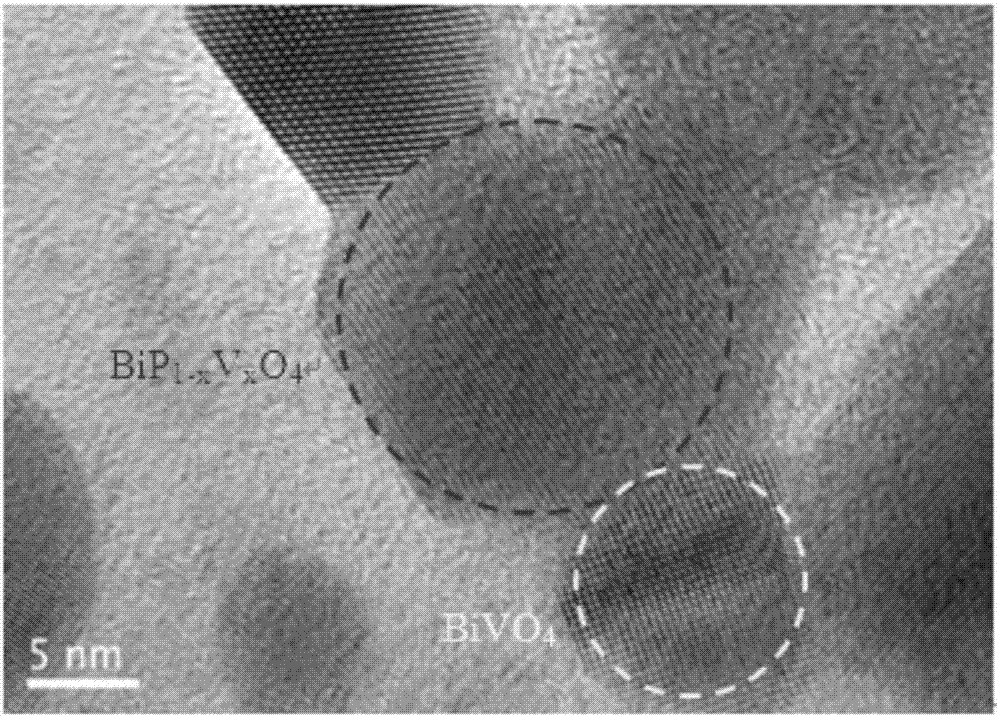

Vanadium-doped bismuth phosphate/attapulgite nanocomposite as well as preparation method and application thereof

ActiveCN106902855ALarge specific surface areaAvoid uneven loadPhysical/chemical process catalystsRefining by particle radiationVanadium dopingBismuth phosphate

The invention belongs to the field of novel chemical materials and particularly relates to a vanadium-doped bismuth phosphate / attapulgite nanocomposite as well as a preparation method and an application thereof. sodium dihydrogen phosphate, bismuth nitrate, ammonium metavanadate and attapulgite are added to deionized water to be fully stirred, a hydrothermal reaction, centrifugation, washing and drying are performed, the vanadium-doped bismuth phosphate / attapulgite nanocomposite is obtained, and the composite is used as a catalyst for photocatalytic desulfurization.

Owner:CHANGZHOU UNIV

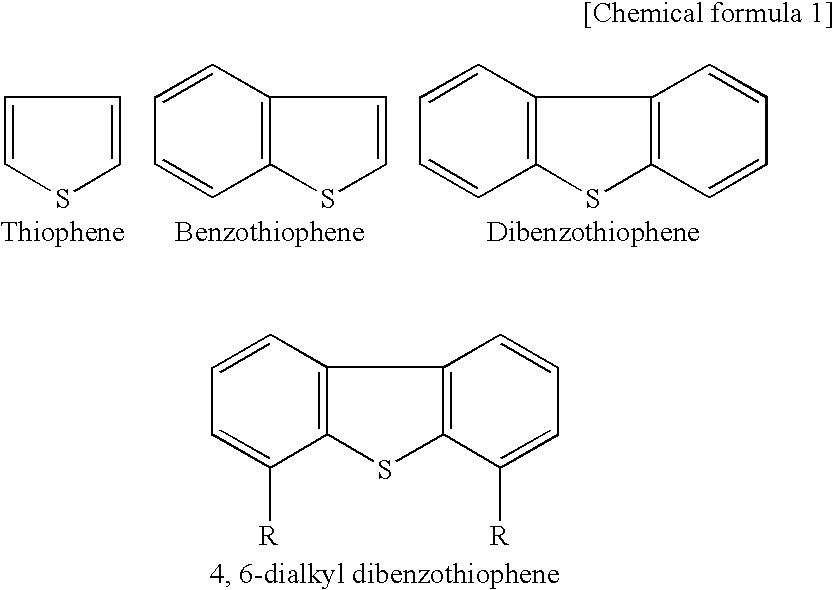

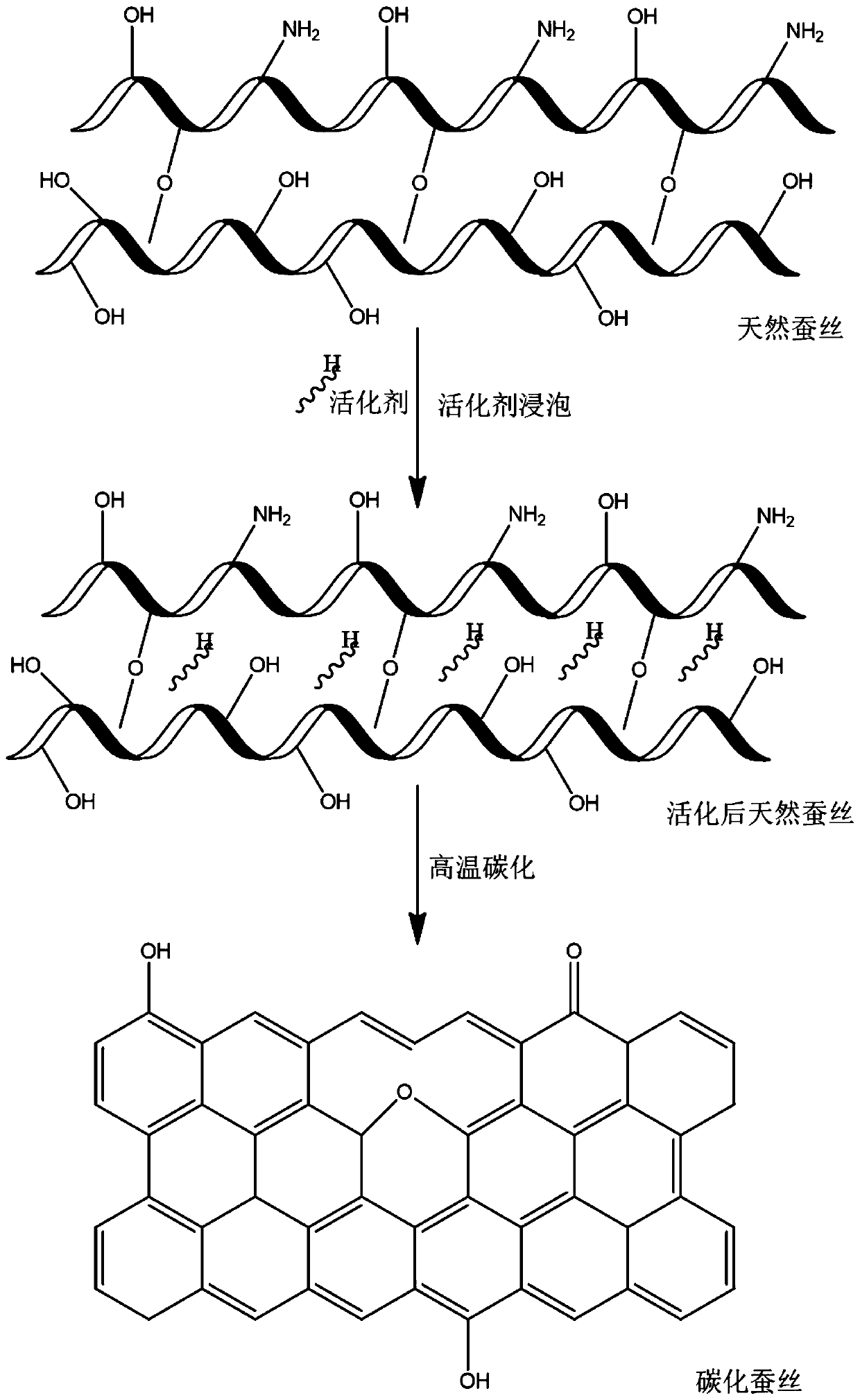

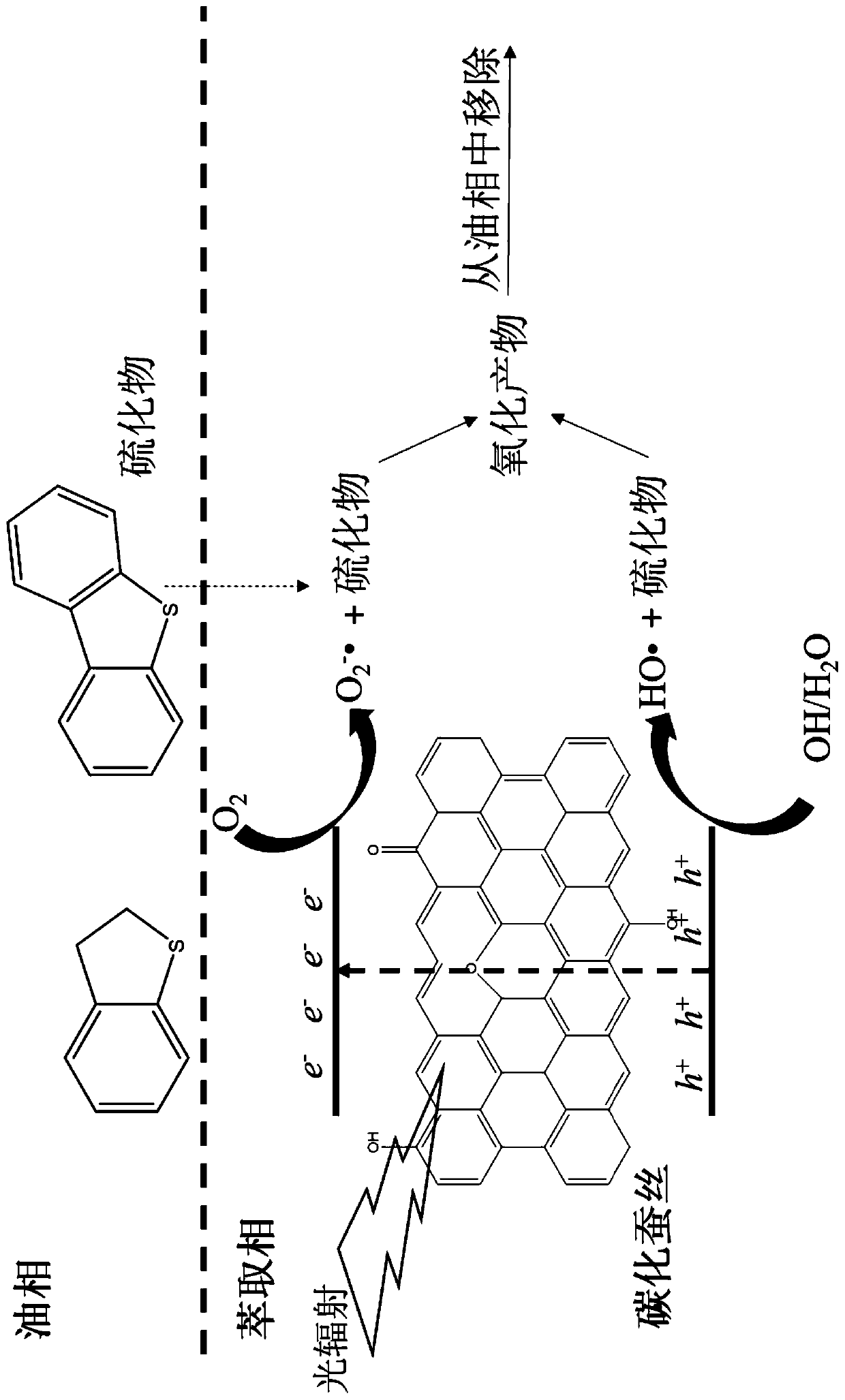

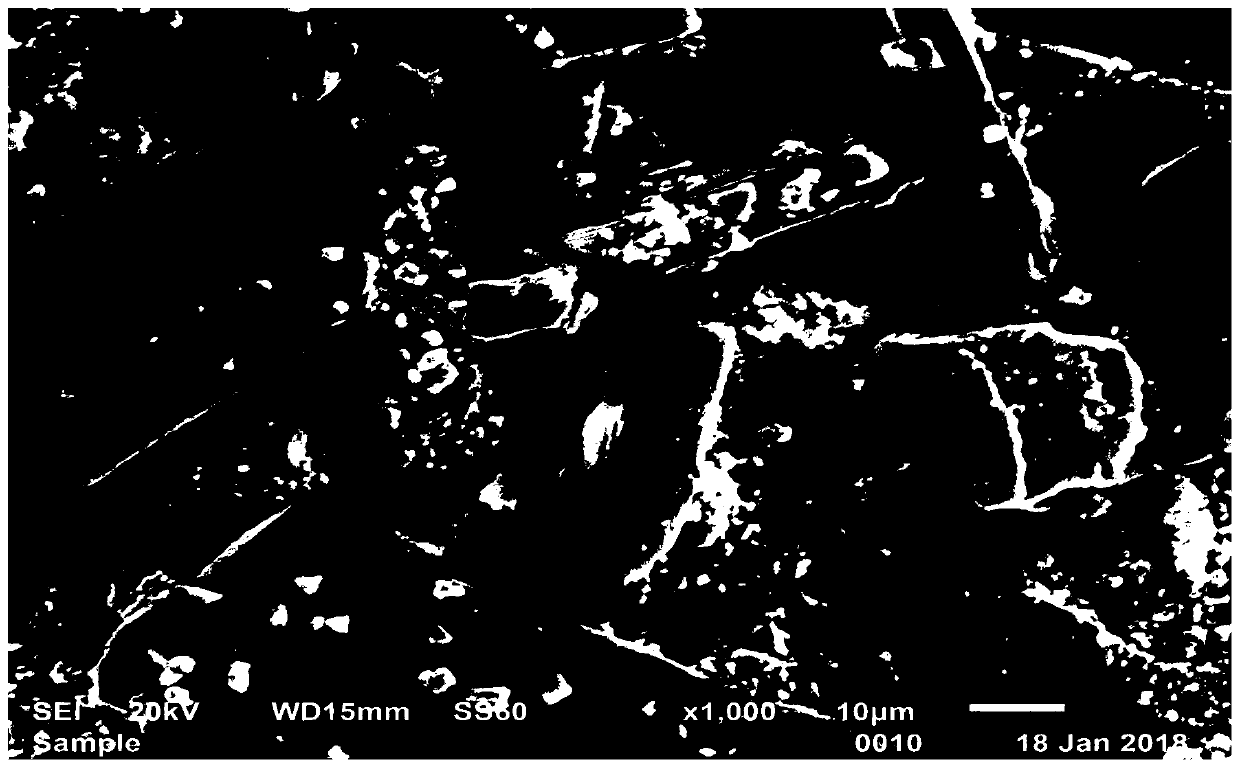

Preparation method and application of carbonized silk photocatalyst

ActiveCN110560177AIncrease useSimple preparation processOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsPhotocatalytic reactionRoom temperature

The invention discloses a preparation method and application of a carbonized silk photocatalyst. The carbonized silk photocatalyst is prepared by the following preparation steps: soaking natural silkand an activation agent into water, taking out the soaked silk, performing drying, and roasting the dried silk in the presence of an inert atmosphere. The invention further discloses a photocatalyticdesulfurization method of fuel oil. The photocatalytic desulfurization method comprises the following steps: mixing fuel oil to be desulfurized, an extraction agent and the carbonized silk photocatalyst, by taking air as an oxidant, performing a photocatalysis reaction under lighting, and separating an upper-layer oil phase, so as to obtain desulfurized fuel oil. The catalyst disclosed by the invention is simple in preparation process, and dibenzothiophene sulfides which are hard to remove in fuel oil can be effectively reduced under UV (ultraviolet) light radiation; desulfurization can be achieved in a desulfurization process at the room temperature, and reaction conditions are mild; air is adopted as the oxidant, and no explosive peroxide is used, so that potential security risks can bereduced. The catalyst disclosed by the invention has good application values in fuel oil desulfurization.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

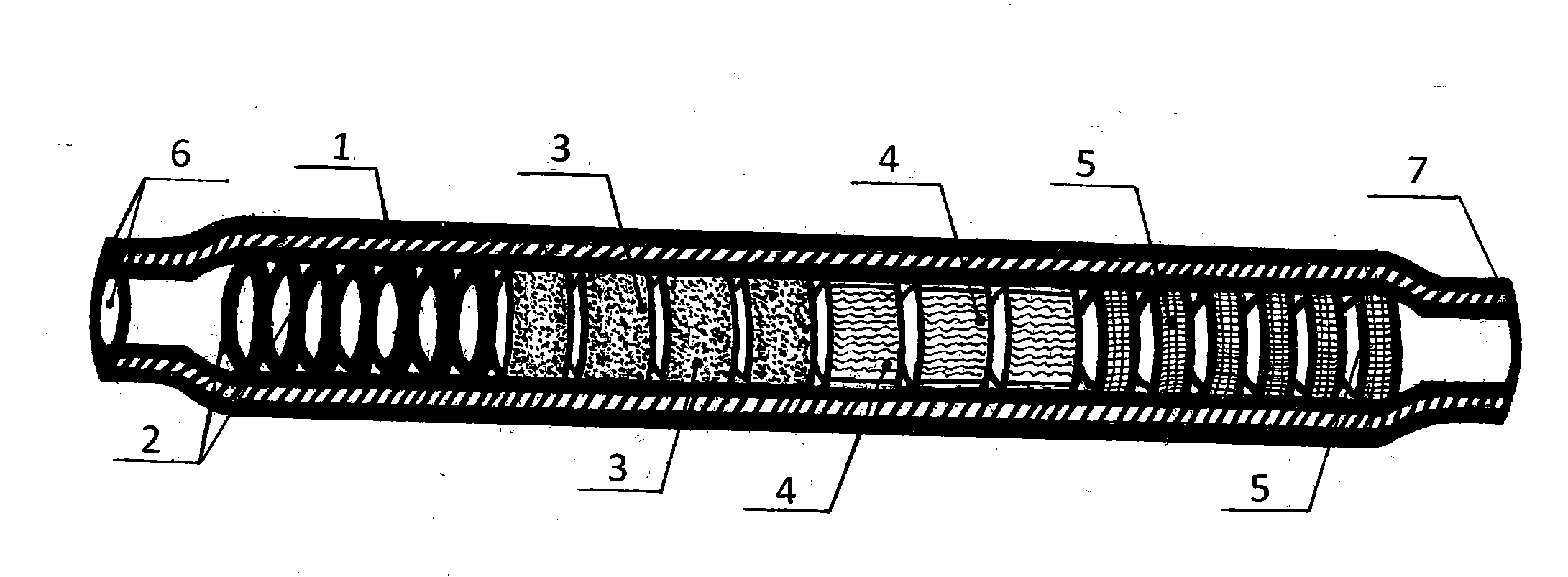

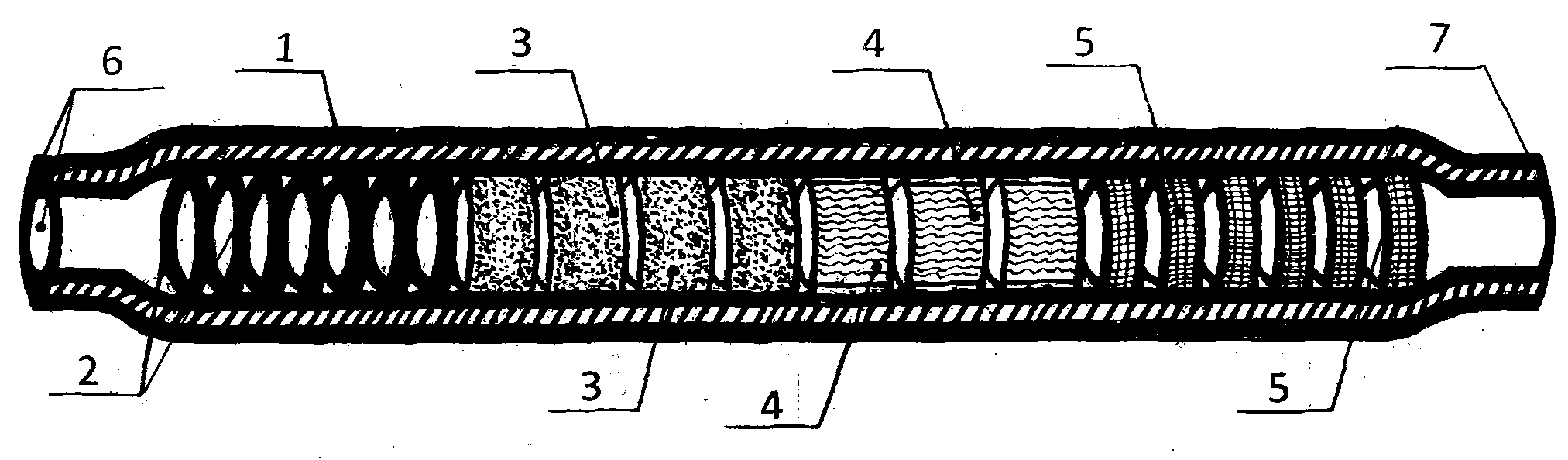

Supermolecular universal fuel saving pipe capable of step-by-step superstrong activation

InactiveCN102580648APass smoothlyImprove fuel saving effectInternal combustion piston enginesCombustion-air/fuel-air treatmentDecompositionFuel oil

The supermolecular universal fuel saving pipe capable of step-by-step superstrong activation adopts the step-by-step multiple decomposition and activation and the long-effective splitting technology. Due to the adoption of the fuel saving pipe, a fuel pipe used for various small car using diesel oil or gasoline, transport vehicles, coaches, buses, engineering vans, agricultural vehicles, motorcycles, military vehicles, radio cars, tanks, airplanes, trains, steamships, warships, generators, engines and the like is not only a fuel pipe for transporting fuel oil, but also a fuel pipe type fuel economizer. The functions of the far infrared and negative ions emitted by the fuel economizer and the functions of the activation and decomposition of a plurality of radial high-intensity activation rings are applied on the fuel oil directly, so that the fuel oil molecular group achieves the micro molecularization, the sufficient burning of the fuel oil is facilitated well, and the fuel saving and emission reduction effects are superior. According to the fuel saving pipe, the fuel saving ratio generally achieves 20-40%, the exhaust contaminant, namely CO and HC+NOx is reduced by 70-90% comprehensively, the power is increased by 15-30%, and the fuel saving pipe is most effective in fuel saving ratio, is suitable for being matched with various large-size and small-size new and old cars and ships and various machines for use, and is extremely perfect.

Owner:北京中能国泰能源技术研究院 +1

Method for removing water-soluble polymer in crude oil containing poly

InactiveCN105349177BSolve efficiency problemsSolve the costRefining by filtrationRefining by particle radiationMicrowavePolymer science

The invention provides a method for removing a water-soluble polymer in polymer-bearing crude oil. The method comprises the following steps: uniformly adding a barium carbonate particle into the polymer-bearing crude oil, then radiating the obtained crude oil mixture in a microwave environment and carrying out filtering so as to effectively remove the water-soluble polymer in the polymer-bearing crude oil. The objective of the invention is to provide the method for removing the water-soluble polymer in the polymer-bearing crude oil to overcome the problems of difficult demulsification of the polymer-bearing crude oil produced after polymer flooding on the ground and during transporting, reduced efficiency of a heater, high cost of a de-emulsifier and the like. The method can remove the water-soluble polymer in the polymer-bearing crude oil and has the advantages of easiness in operation and realization and low cost; the barium carbonate particle used in the invention has the characteristics of regeneration performance and repeated usability, so cost of the method is reduced; and the method is applicable to technological treatment of polymer-bearing crude oil produced from a polymer flooded oil reservoir.

Owner:YANGTZE UNIVERSITY

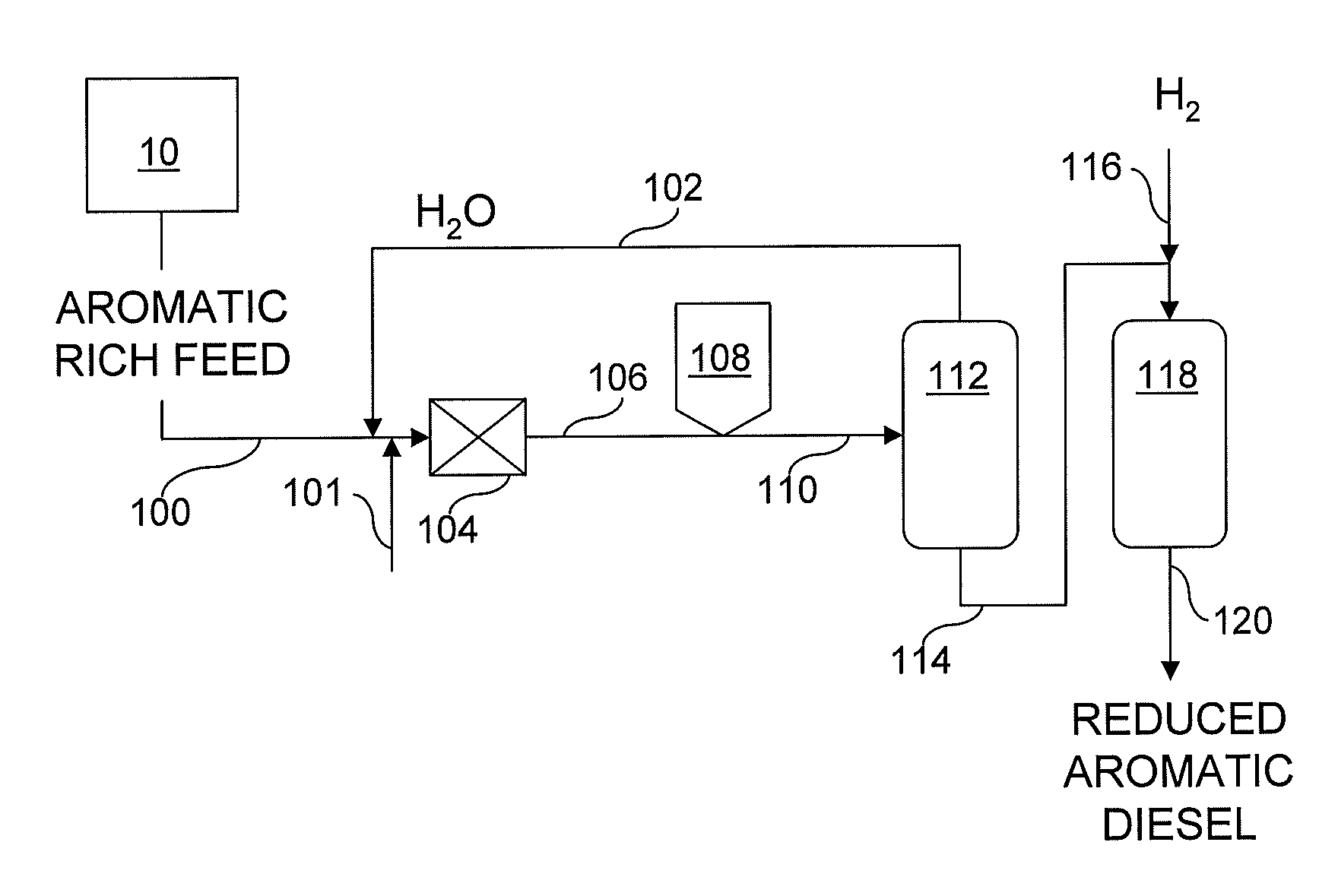

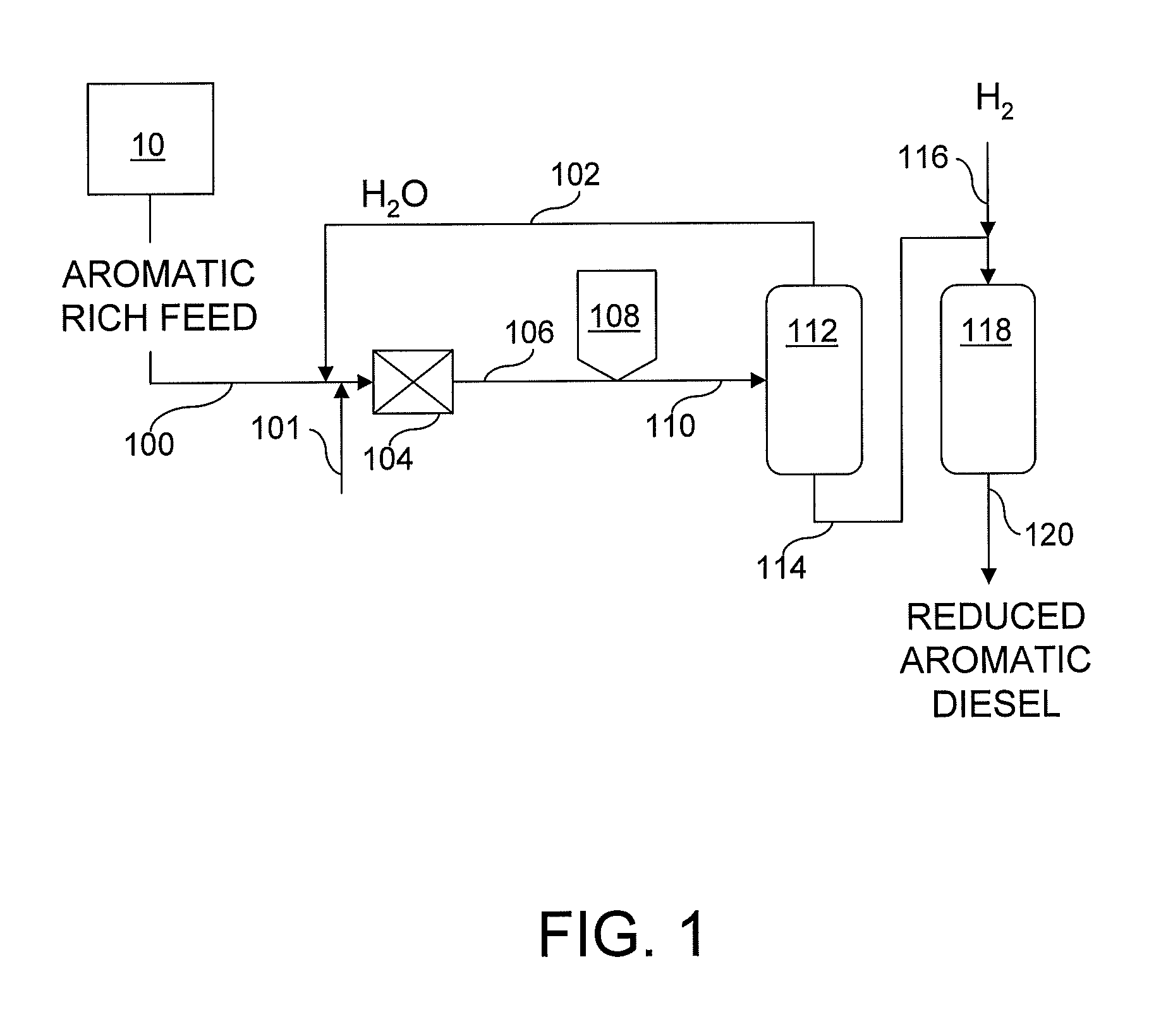

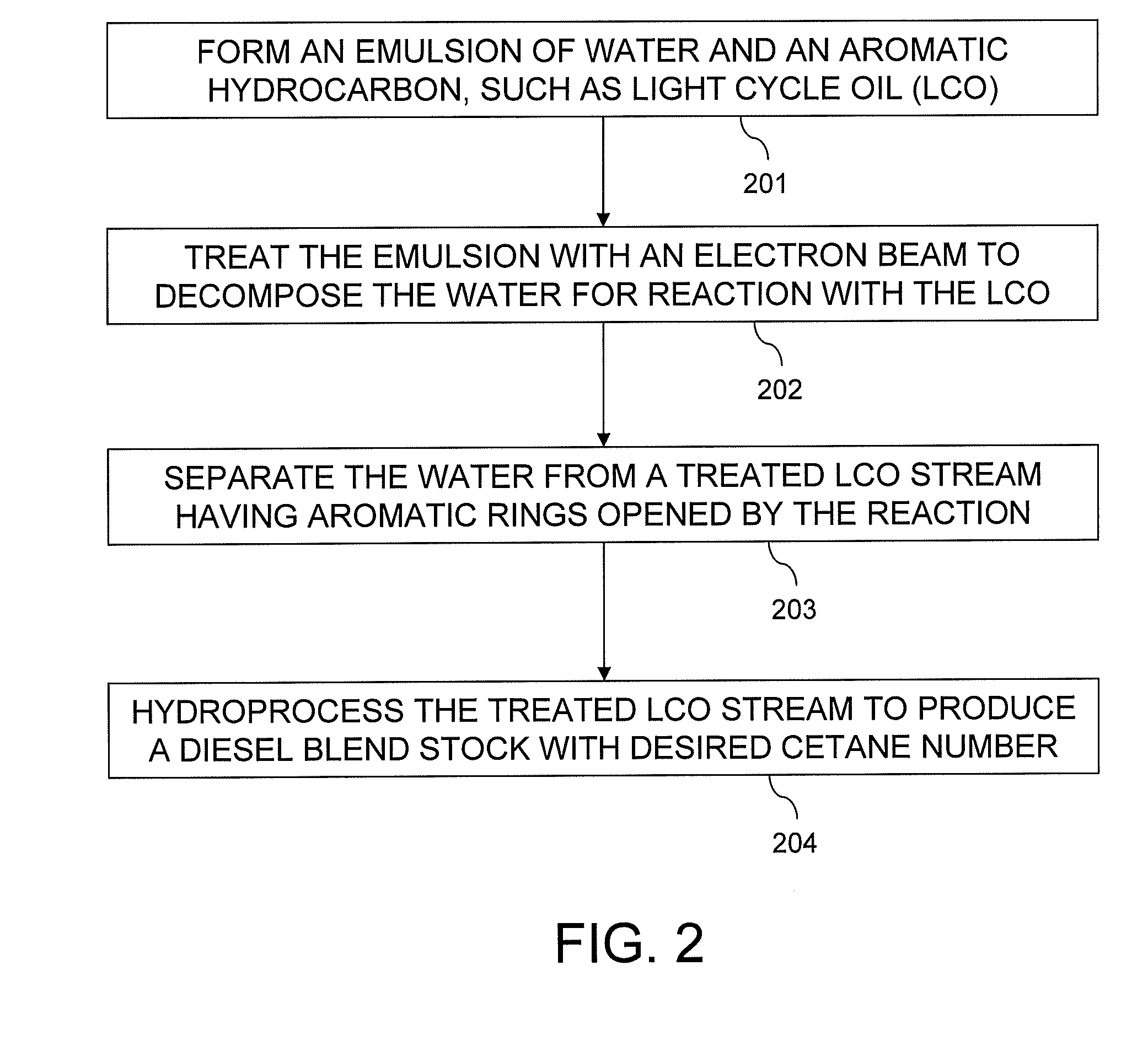

E-beam treatment to increase cetane

ActiveUS8920634B2More ring openingThermal non-catalytic crackingTreatment with plural serial stages onlyPhotochemistryHydrocarbon

Methods and systems relate to treating an oil-in-water emulsion with an electron beam to decrease aromatic content therein for subsequent recovery of diesel products with upgraded cetane number. The method includes passing the emulsion formed of water and a hydrocarbon stream, such as light cycle oil, through an electron beam. The electron beam causes radiolysis of the water into intermediates that react with and open rings of aromatic compounds from the hydrocarbon stream. Separation of the water from the emulsion after the treating with the electron beam provides the diesel products, which may be hydroprocessed to remove oxygenates.

Owner:PHILLIPS 66 CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com