Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Post-manufacturing circuit processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transient electronic devices comprising inorganic or hybrid inorganic and organic substrates and encapsulates

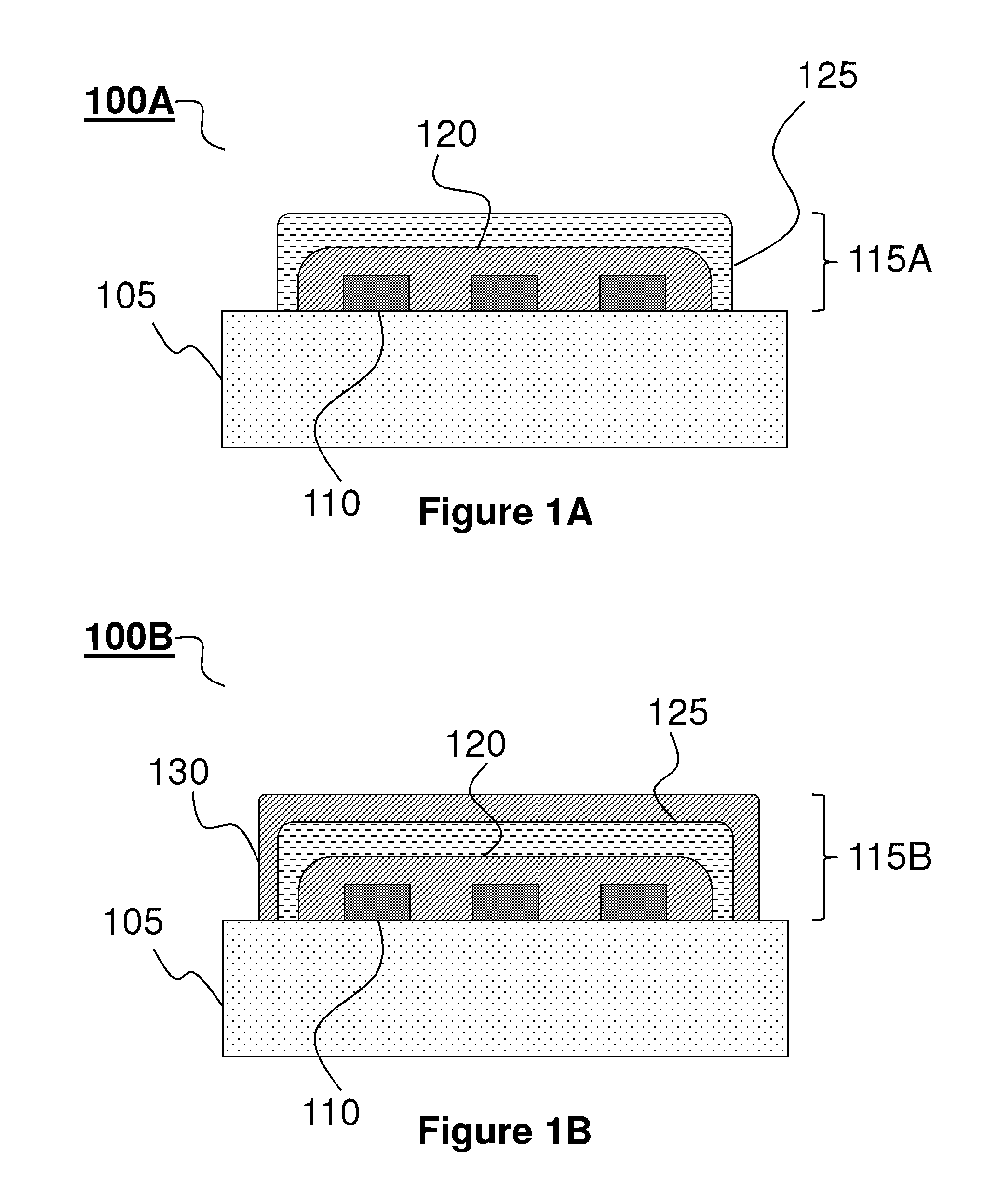

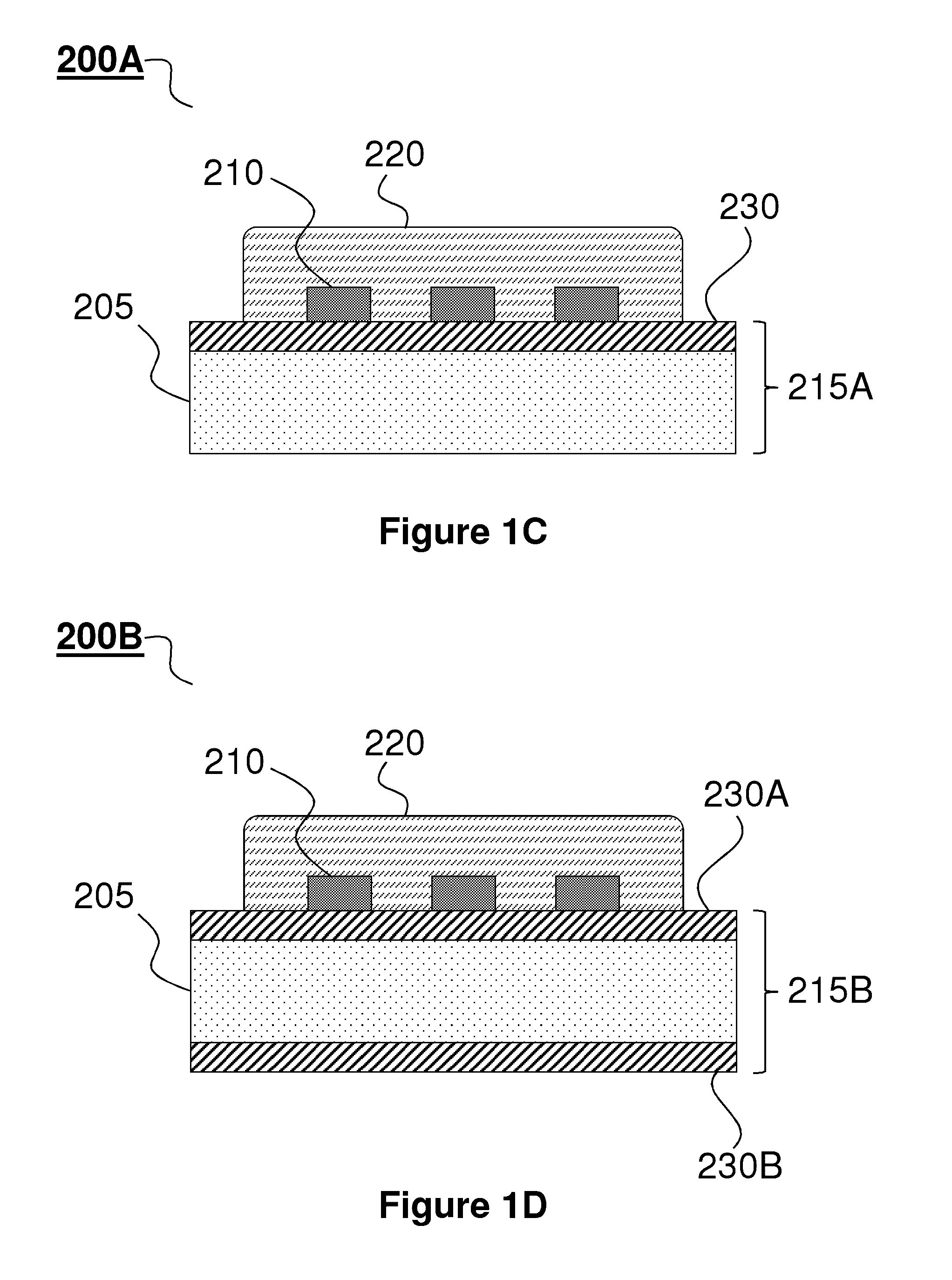

ActiveUS20140305900A1Effective fabrication of deviceUseful overall permeabilityLayered productsFinal product manufactureSingle crystalInorganic materials

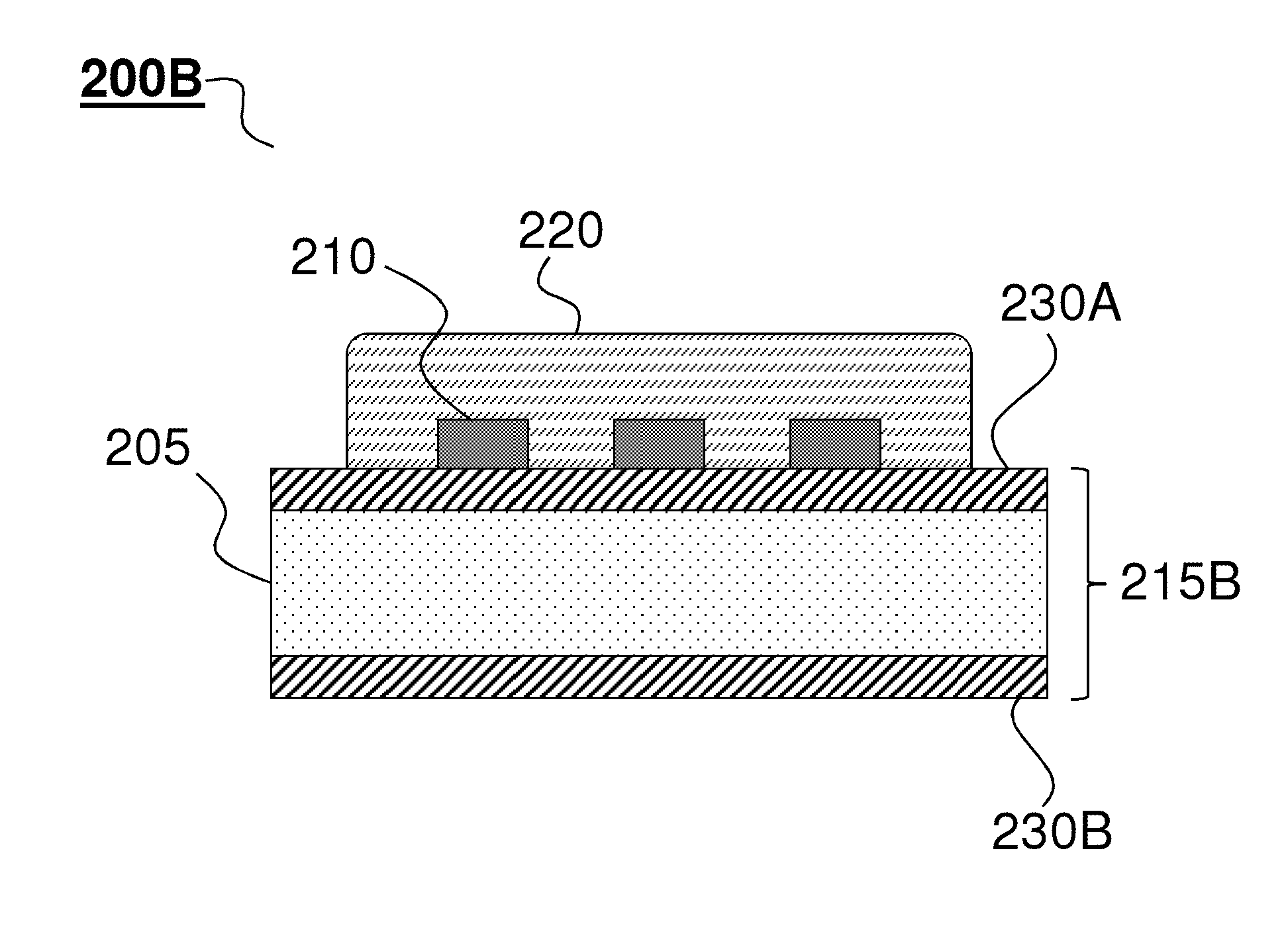

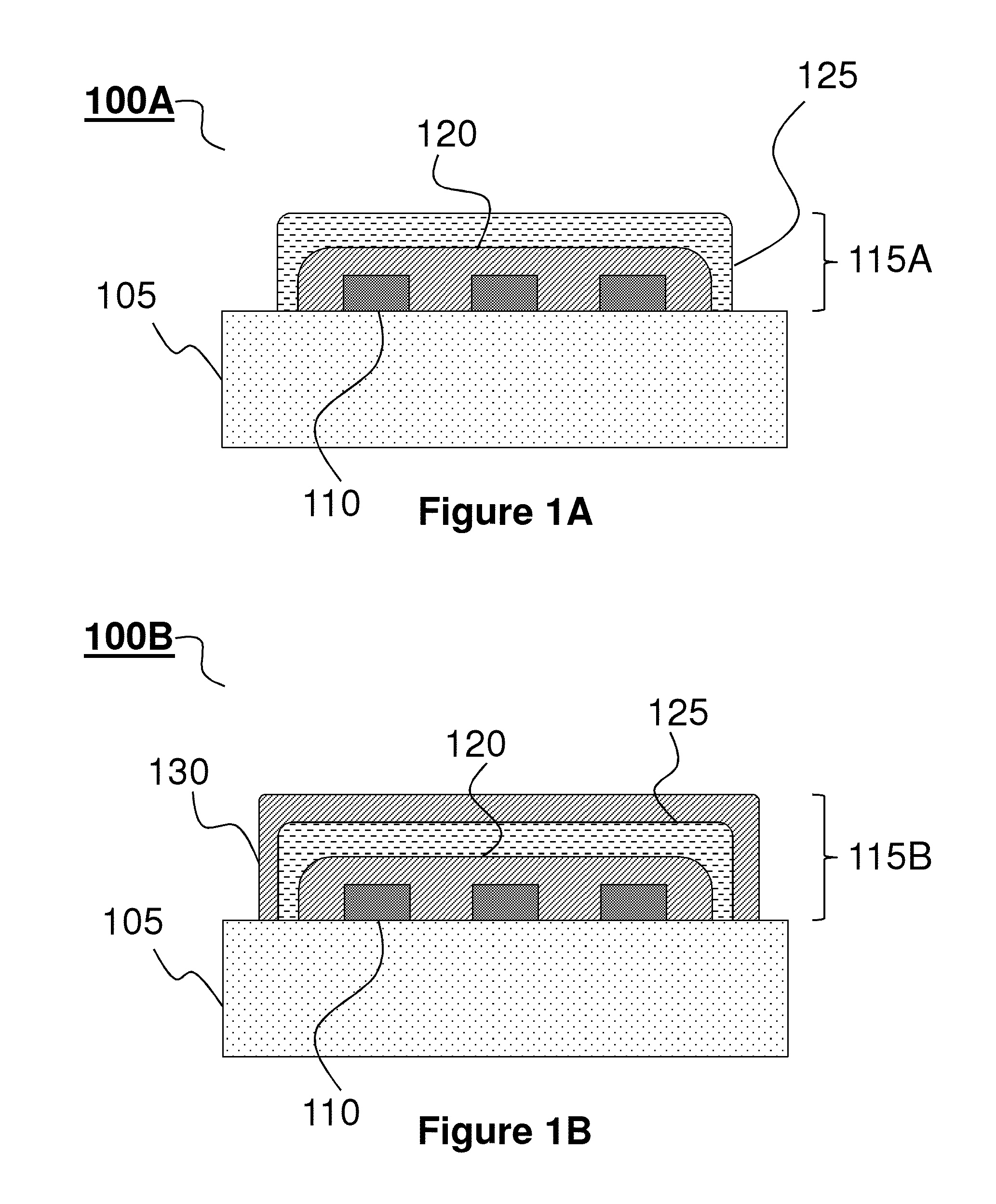

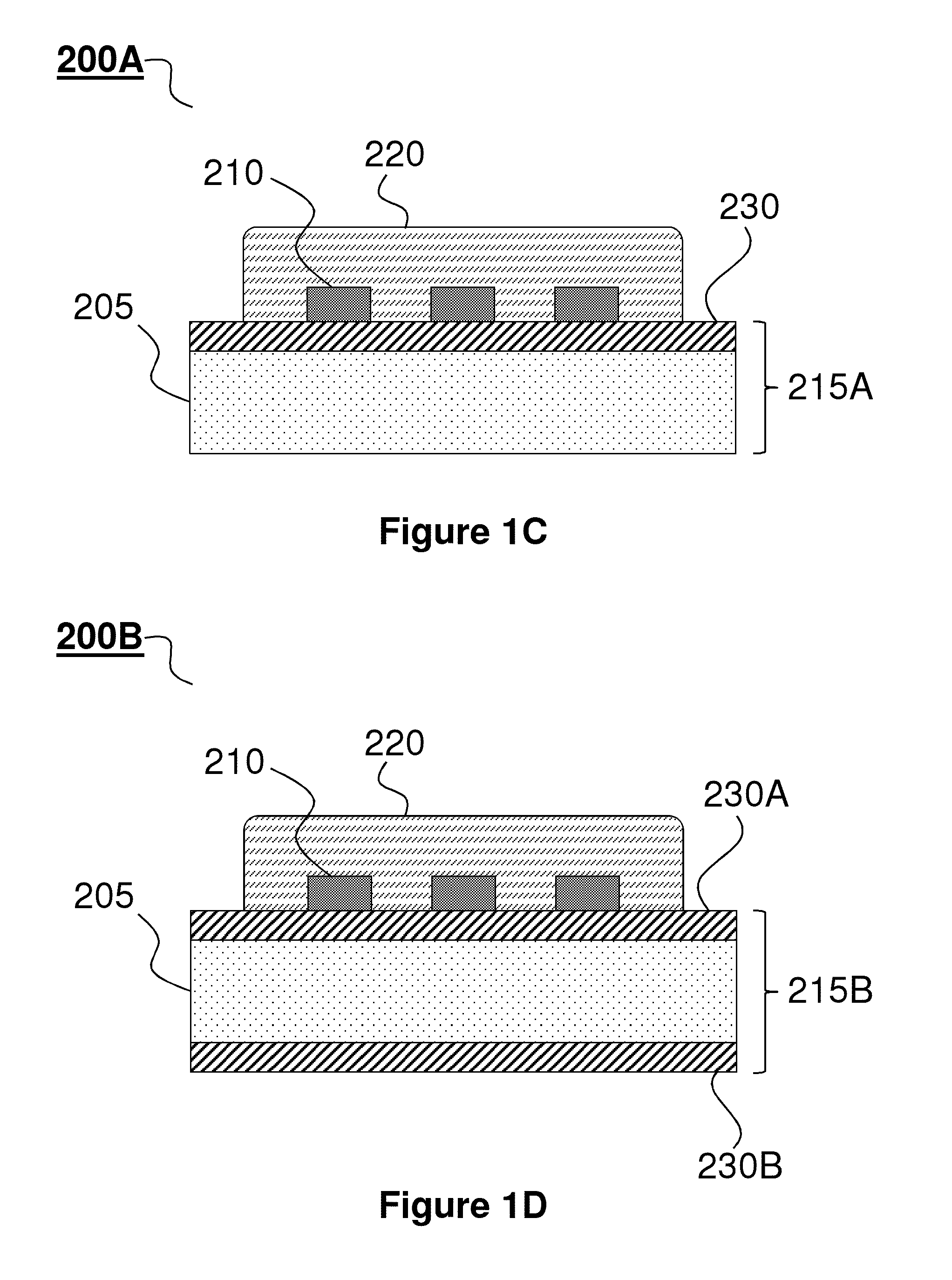

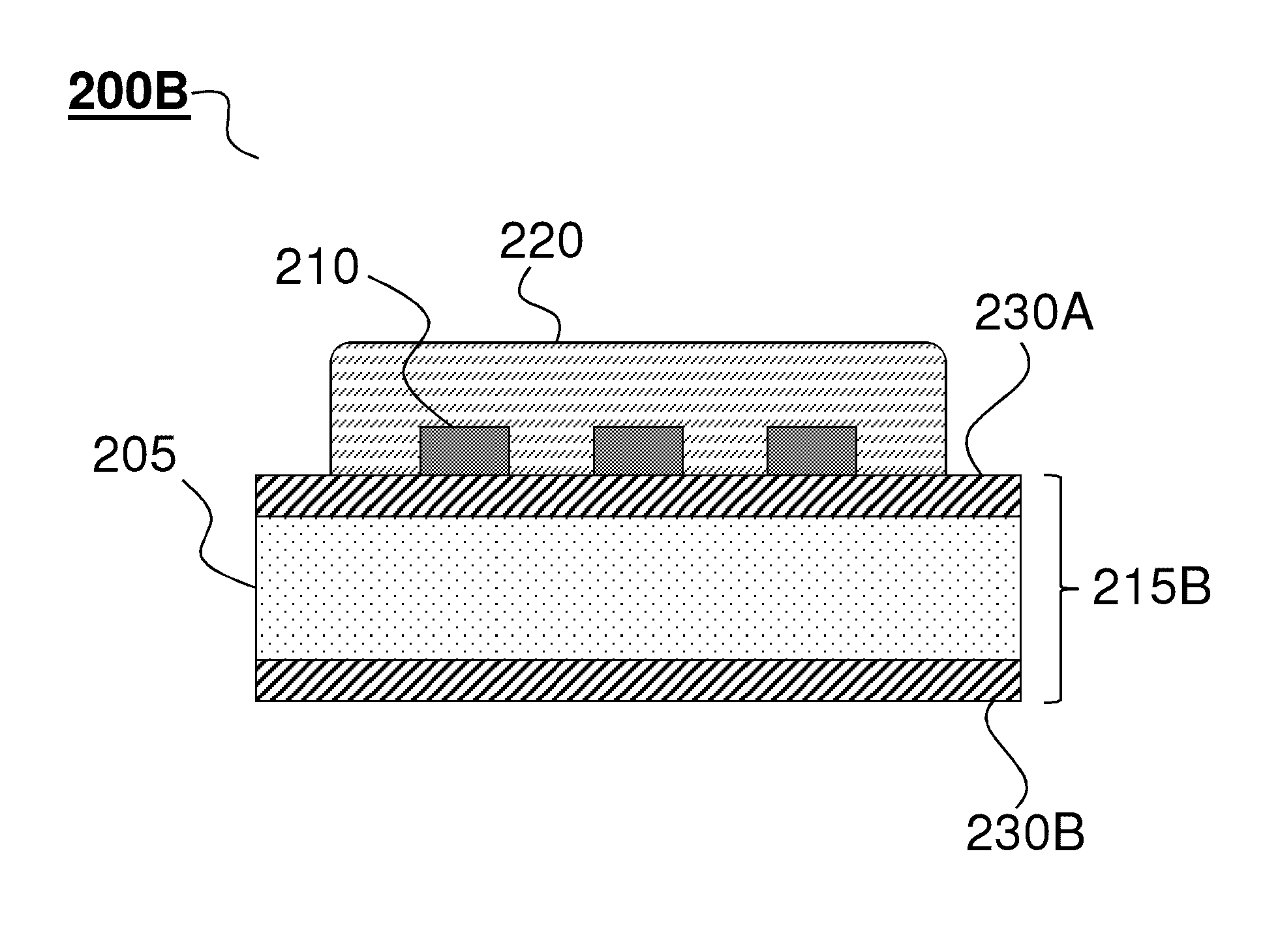

The invention provides transient devices, including active and passive devices that physically, chemically and / or electrically transform upon application of at least one internal and / or external stimulus. Incorporation of degradable device components, degradable substrates and / or degradable encapsulating materials each having a programmable, controllable and / or selectable degradation rate provides a means of transforming the device. In some embodiments, for example, transient devices of the invention combine degradable high performance single crystalline inorganic materials with selectively removable substrates and / or encapsulants.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Transient electronic devices comprising inorganic or hybrid inorganic and organic substrates and encapsulates

ActiveUS9496229B2Useful overall permeabilityInhibition of volume changeFinal product manufactureSemiconductor/solid-state device detailsElectricitySingle crystal

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Method for manufacturing characters of printed circuit board

InactiveCN105208791AImprove alignment accuracyReduce bad problems such as easy blurDecalcomaniaPost-manufacturing circuit processesCooking & bakingScreen printing

The invention discloses a method for manufacturing characters of a printed circuit board. The method includes the following steps that S1, in the pre-process, a solder mask of the printed circuit board is manufactured; S2, solder resist ink with the same color as the needed characters is selected, and the viscosity of the solder resist ink is adjusted to an appropriate value; S3, a screen printing plate is prepared, and whole-plate screen printing is performed; S4, pre-baking is performed; S5, exposure and development are performed to obtain the characters of the printed circuit board; S6, after-baking is performed. The solder resist technological process is adopted for replacing a traditional character manufacturing process to manufacture the characters; the alignment accuracy of a solder resist exposure machine can reach the tolerance range of + / -20 micrometers which is far accurate than the tolerance range of + / -100 micrometers of human eye alignment, so that the alignment accuracy of the characters is greatly improved, and the undesirable phenomenon that the characters deviate or are printed on a bonding pad or become fuzzy easily is effectively reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

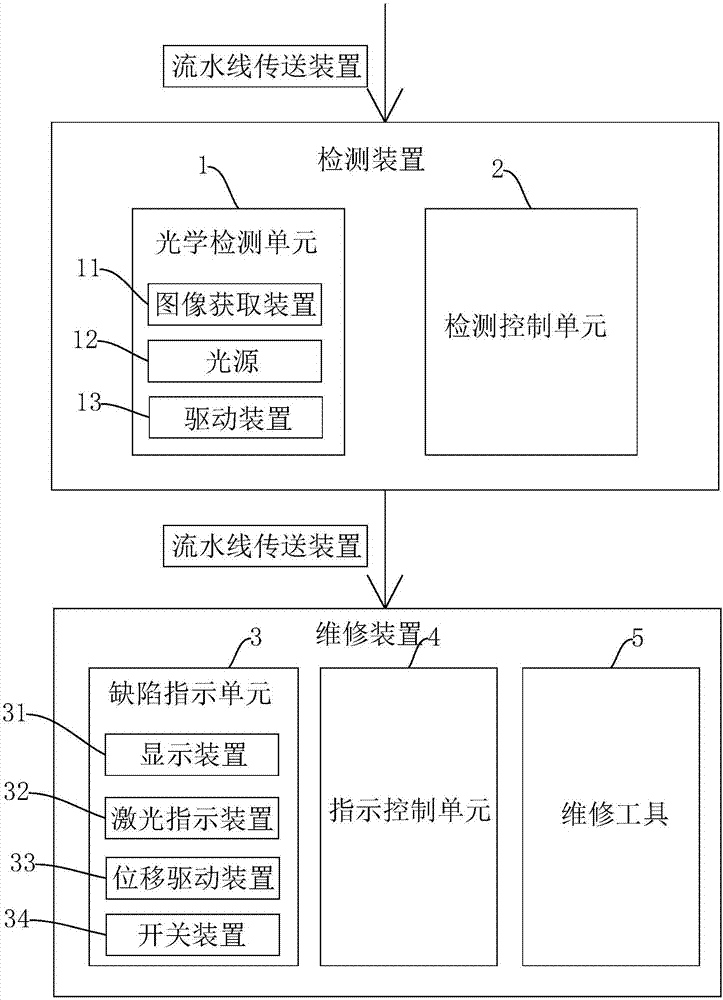

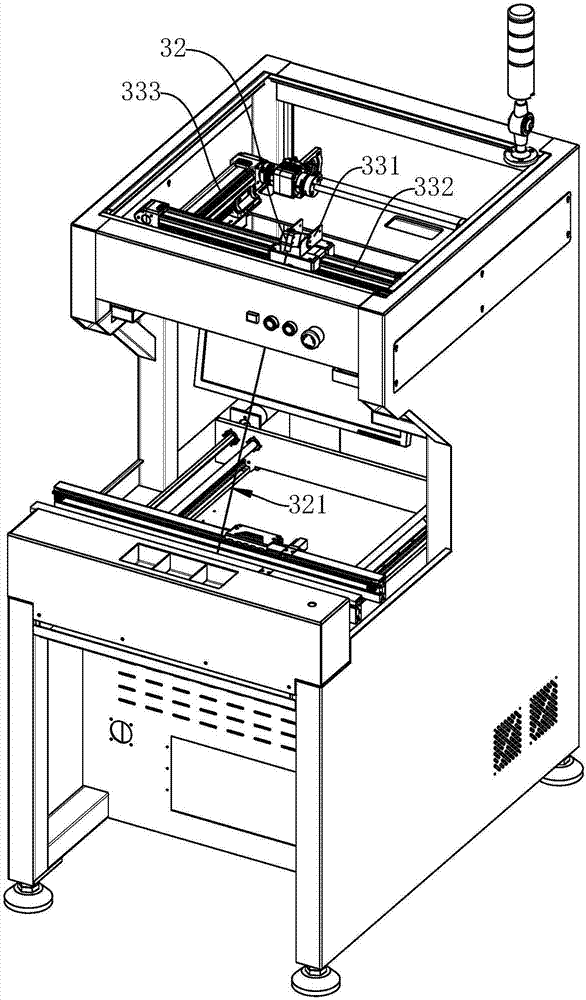

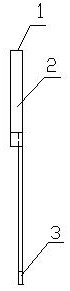

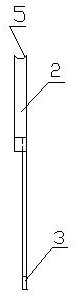

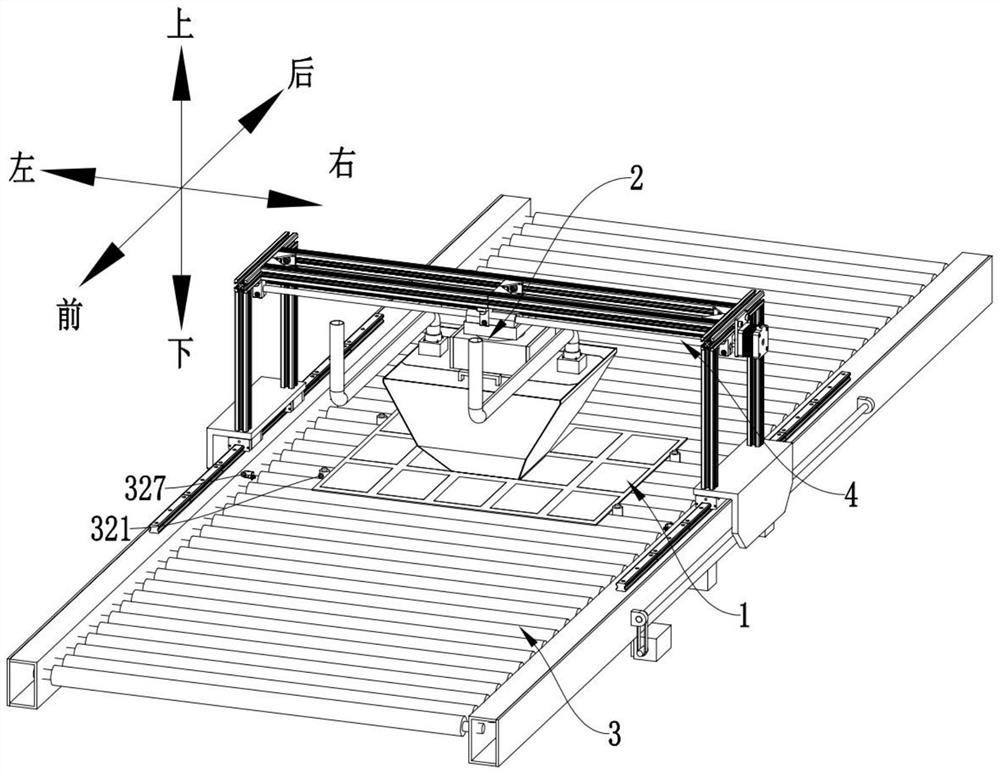

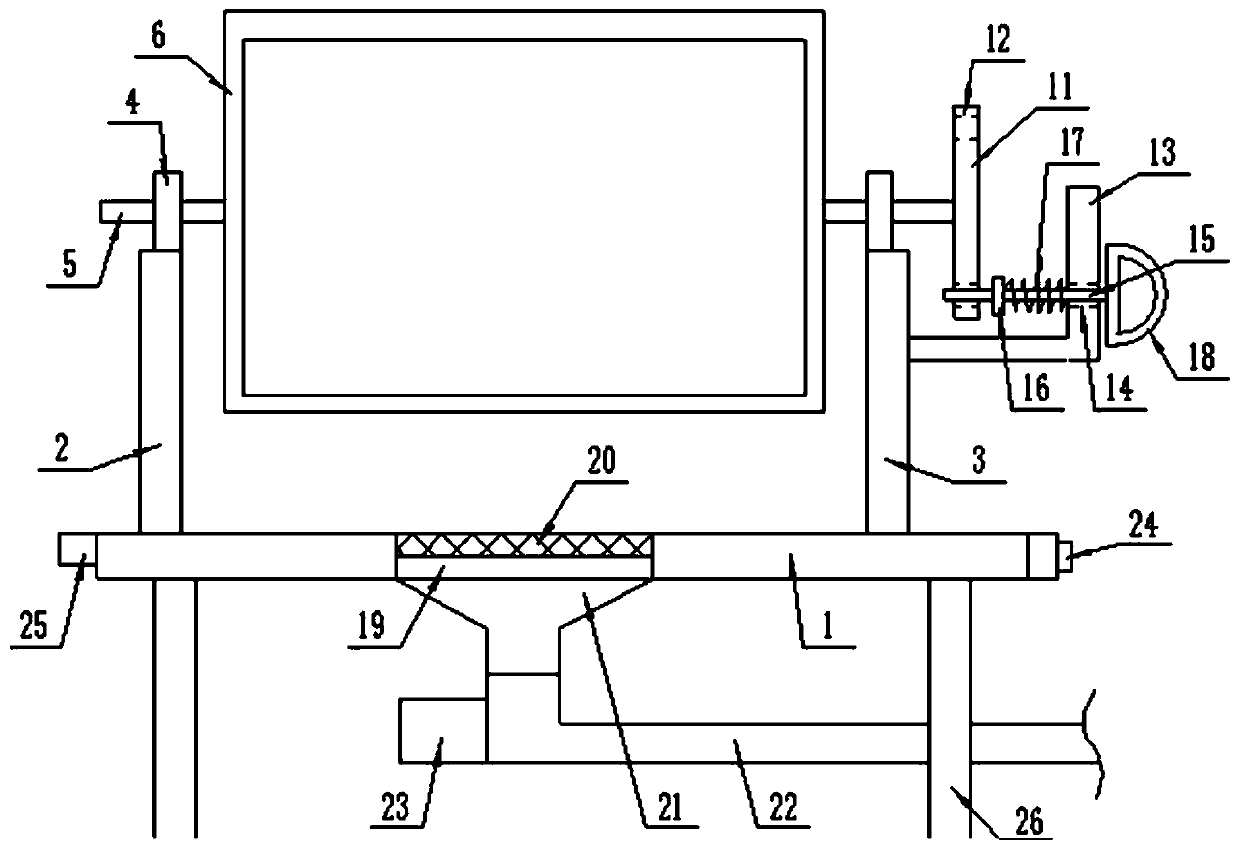

Defect inspection and maintenance system, method and maintenance device

PendingCN107478979AEasy maintenanceReduce wastePrinted circuit assemblingElectronic circuit testingComputer hardwareInformation control

The present invention discloses a defect inspection and maintenance system, a method and a maintenance device. The defect inspection and maintenance system comprises an optical detection unit for acquiring a complete image of the product to be tested; a detection control unit for receiving the image obtained by the optical detection unit and analyzing the image to find out whether the product to be detected is a defective product or not and to find the position of defects on the defective product; a defect indicating unit, comprising a laser indicating device and a displacement driving device, wherein the laser indicating device is adapted to generate laser light, and the displacement driving device is configured to drive the laser indicating device to move; and an indication control unit in signal connection with the detection control unit and the defect indicating unit for obtaining the soldering defect position information of the defective product from the detection control unit and controlling the displacement driving device of the defect indication unit to move according to the defect position information so that the laser indicating device generates a laser indication on the location of the soldering defect point.

Owner:深圳市阿拉玎光电自动化有限公司

Method for re-washing solder resist plug hole

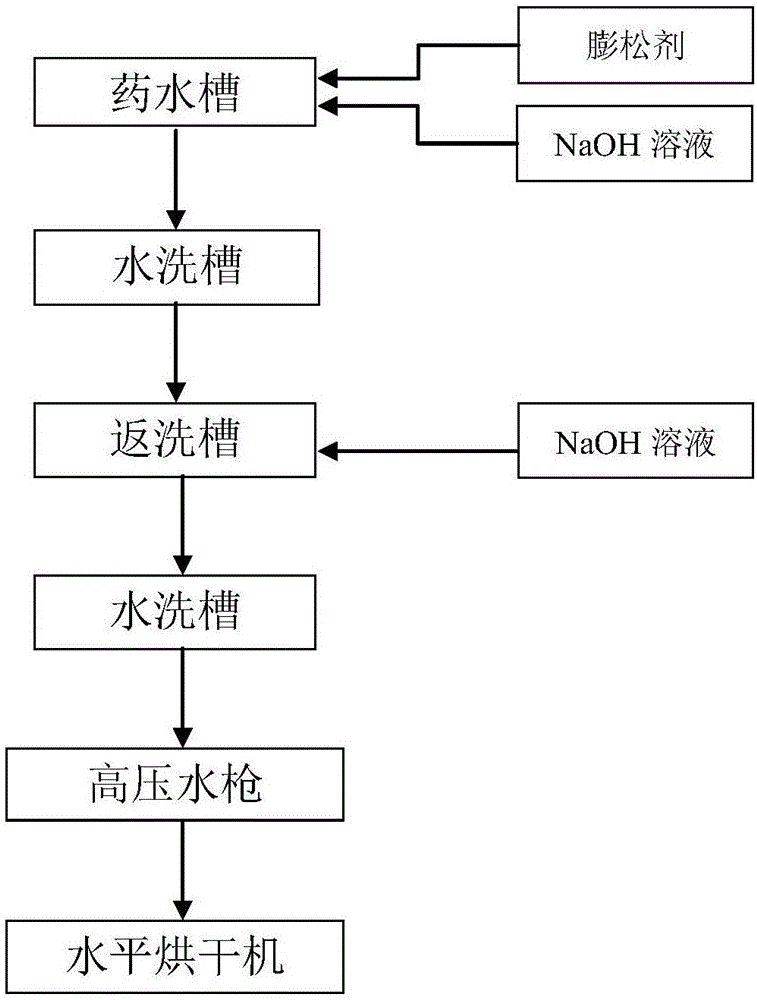

InactiveCN106413276AEasy to cleanAvoid blushingPost-manufacturing circuit processesNon-metallic protective coating applicationResistPrinting ink

The invention discloses a method for re-washing a solder resist plug hole, belonging to the technical field of manufacturing of circuit boards. The method comprises the following steps of: (a), putting a plug hole board to be re-washed in a liquid medicine groove containing a swelling agent to immerse and perform swelling treatment; (b), putting the plug hole board immersed by the swelling agent in a water washing groove to wash, and removing the swelling agent on the surface of the board; (c), putting the plug hole board in a re-washing groove containing NaOH solution to immerse; (d), putting the plug hole board processed in the step (c) in the water washing groove to wash; and (e), washing the fetched plug hole board by using a high-voltage water gun, and removing printing ink and NaOH solution on the surfaces of the plug hole and the board. By means of the method disclosed by the invention, solder resist printing ink in the hole of the plug hole board can be effectively removed; and thus, the quality problem that printing ink in small holes cannot be re-washed cleanly after solder resist solidification can be thoroughly solved.

Owner:珠海杰赛科技有限公司

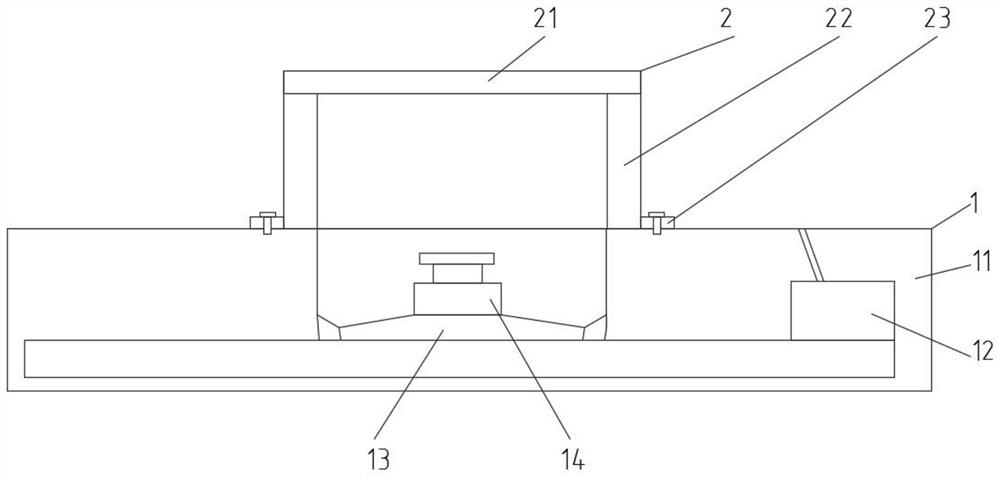

Fixing frame capable of facilitating maintenance of circuit board

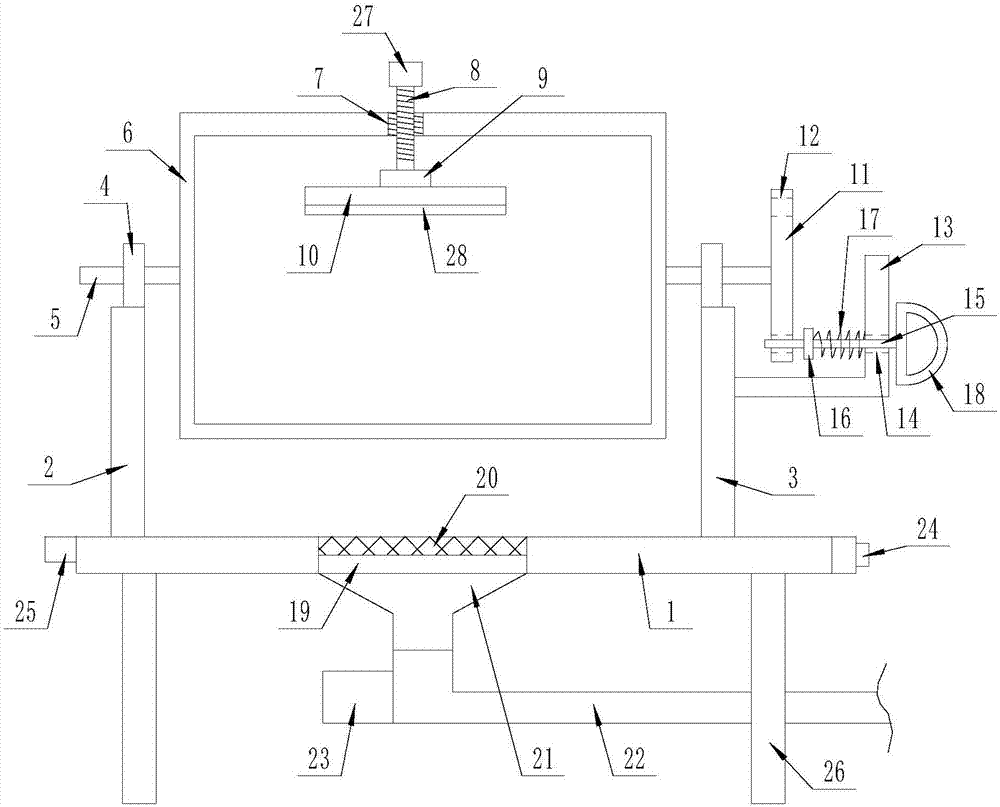

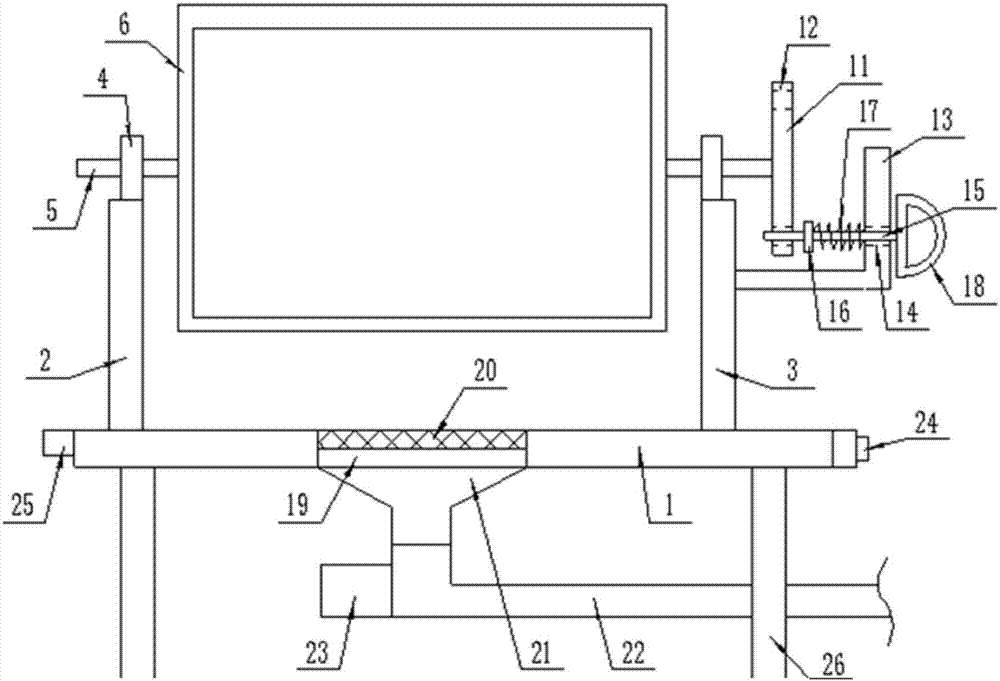

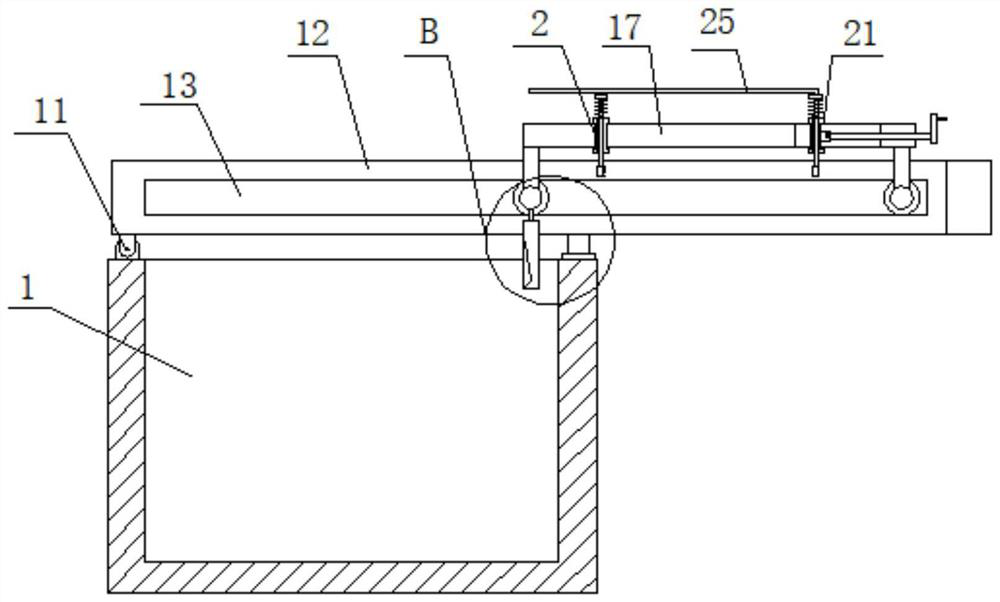

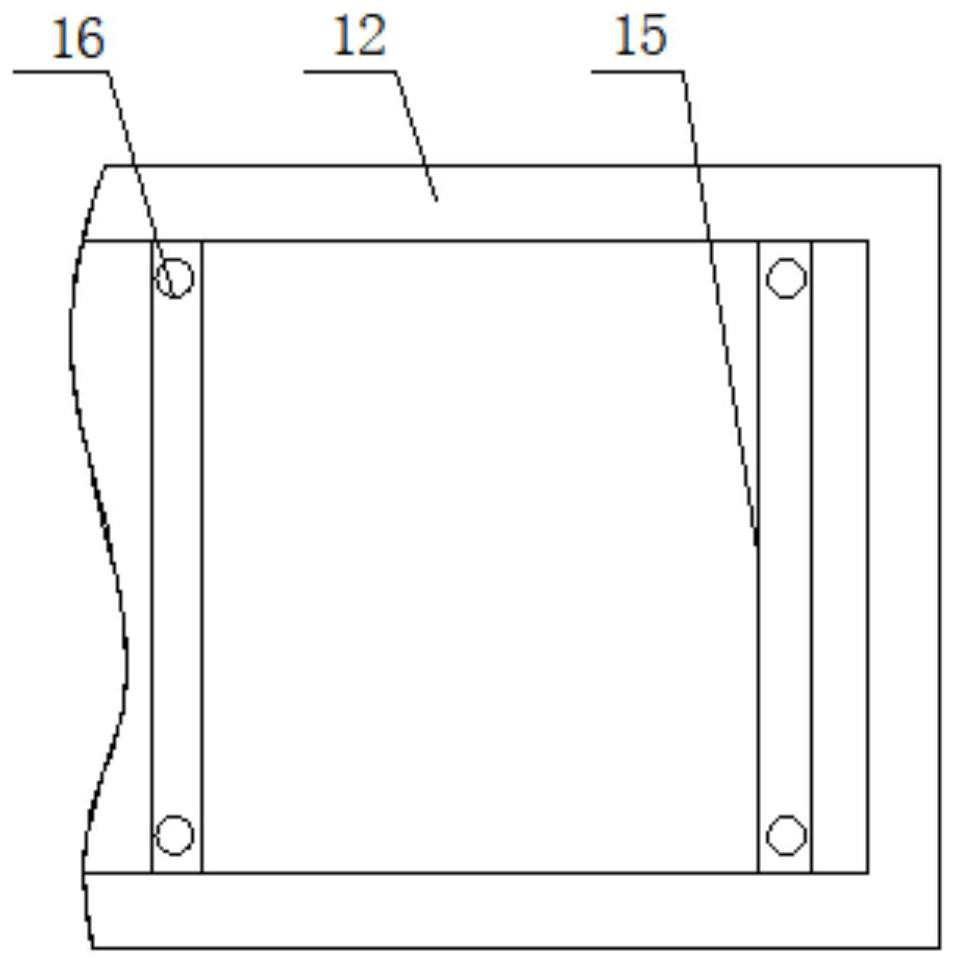

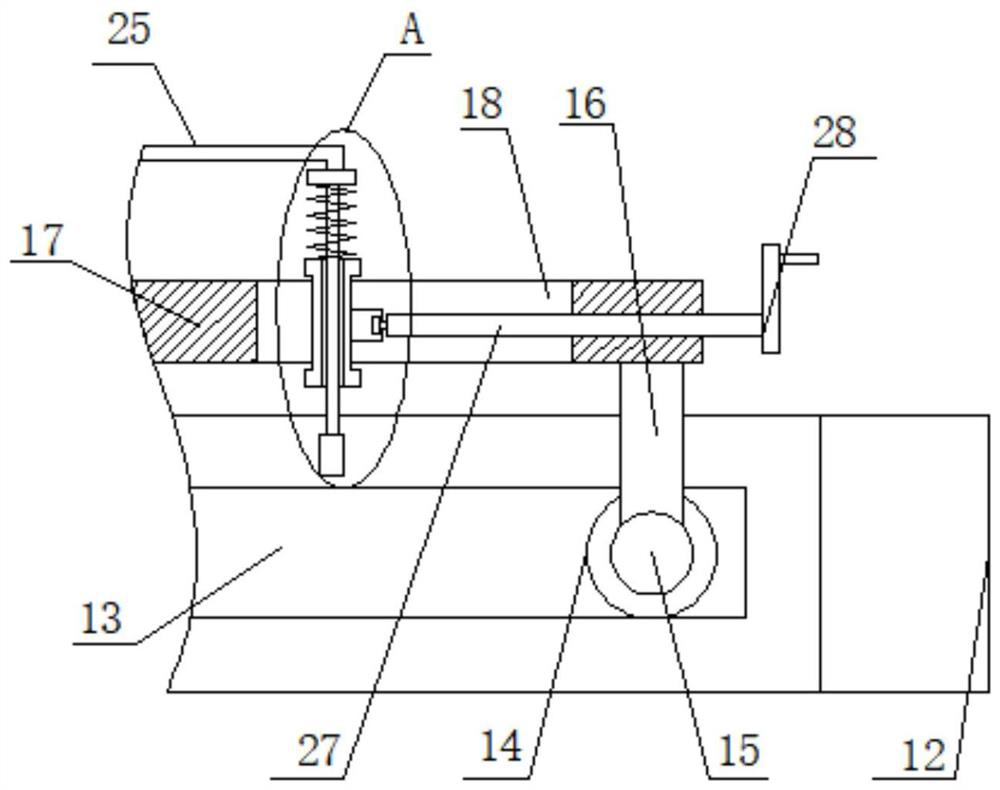

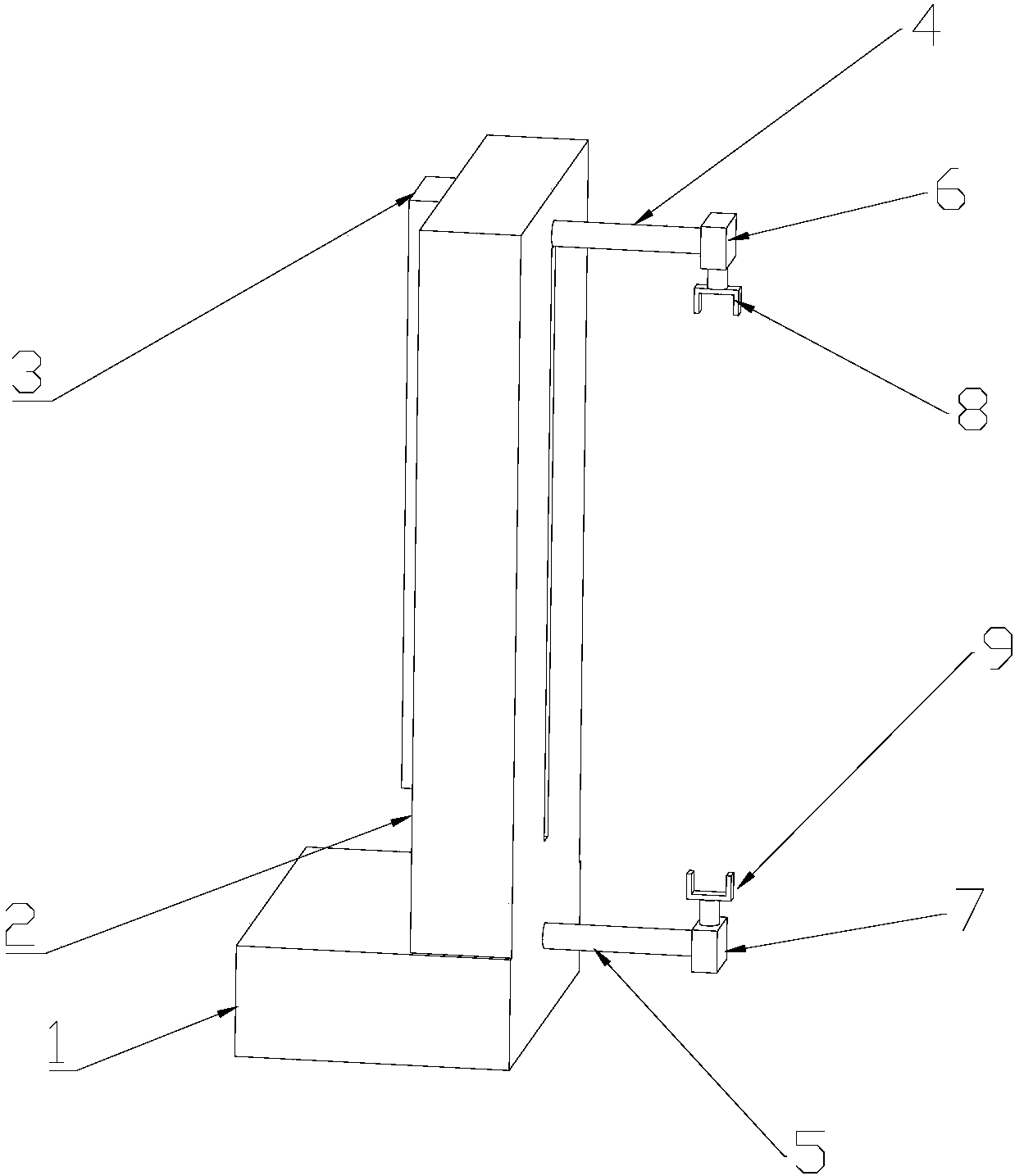

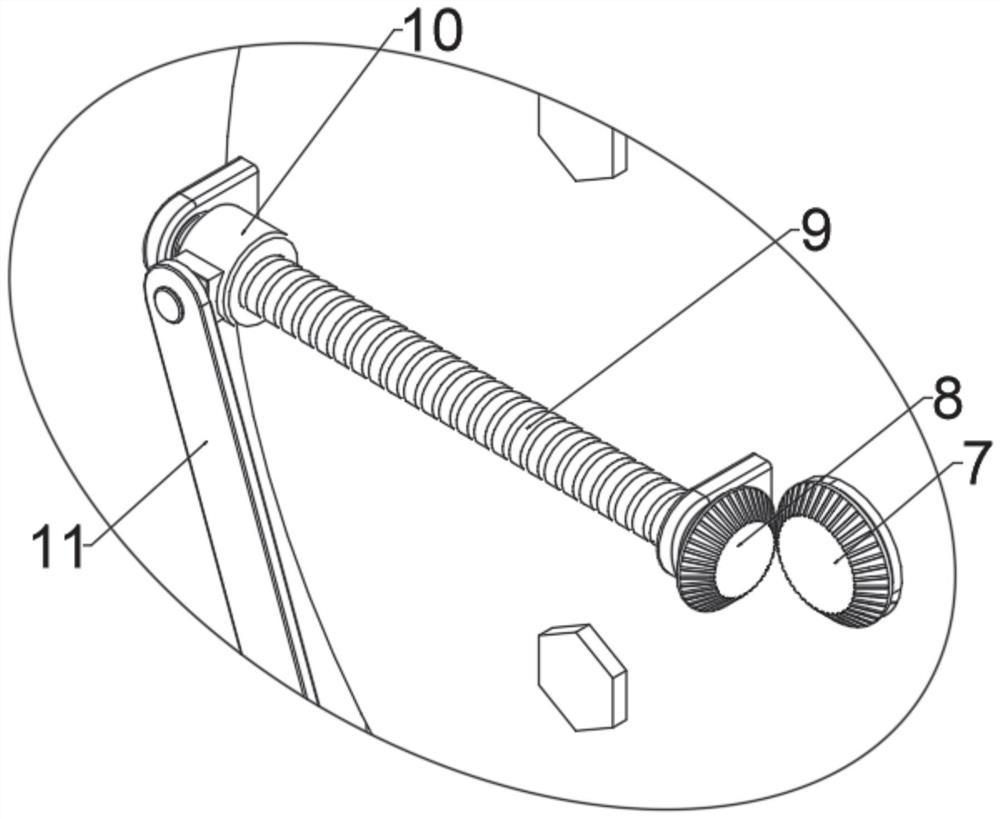

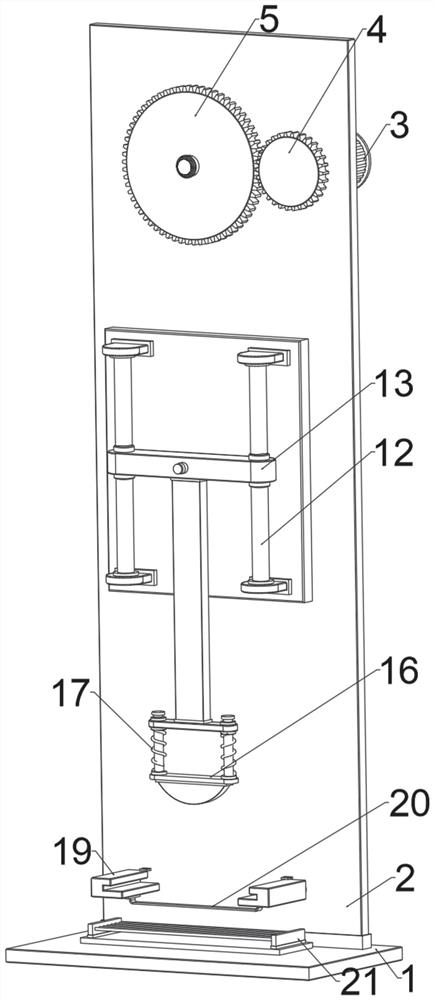

InactiveCN108012440AEasy maintenanceAvoid damagePost-manufacturing circuit processesPrinted circuits repair/correctingFixed bearingFixed frame

The invention discloses a fixing frame capable of facilitating maintenance of a circuit board. The fixing frame comprises a rectangular base, wherein a first portal bracket and a second portal bracketare arranged at two sides of the upper surface of the rectangular base separately; fixed bearings are arranged on the upper surfaces of the first portal bracket and the second portal bracket; a horizontal rotating shaft is arranged in each fixed bearing; a rectangular fixing frame fixedly connected with the horizontal rotating shafts is arranged between the first portal bracket and the second portal bracket; a threaded through hole is processed in the upper surface of the rectangular fixing frame; a threaded rod is embedded into the threaded through hole; and a rotating bearing sleeves one end, at the inner side of the rectangular fixing frame, of the threaded rod. The fixing frame has the beneficial effects that the circuit board is fixed by adopting a method of extruding and fixing theside of the circuit board, so that the damage of a fixing clamp to the surface of the circuit board is avoided; and the fixing angle of the circuit board can be adjusted and the circuit board can be turned over at any time, so that maintenance of the circuit board is facilitated.

Owner:信丰明新电子科技有限公司

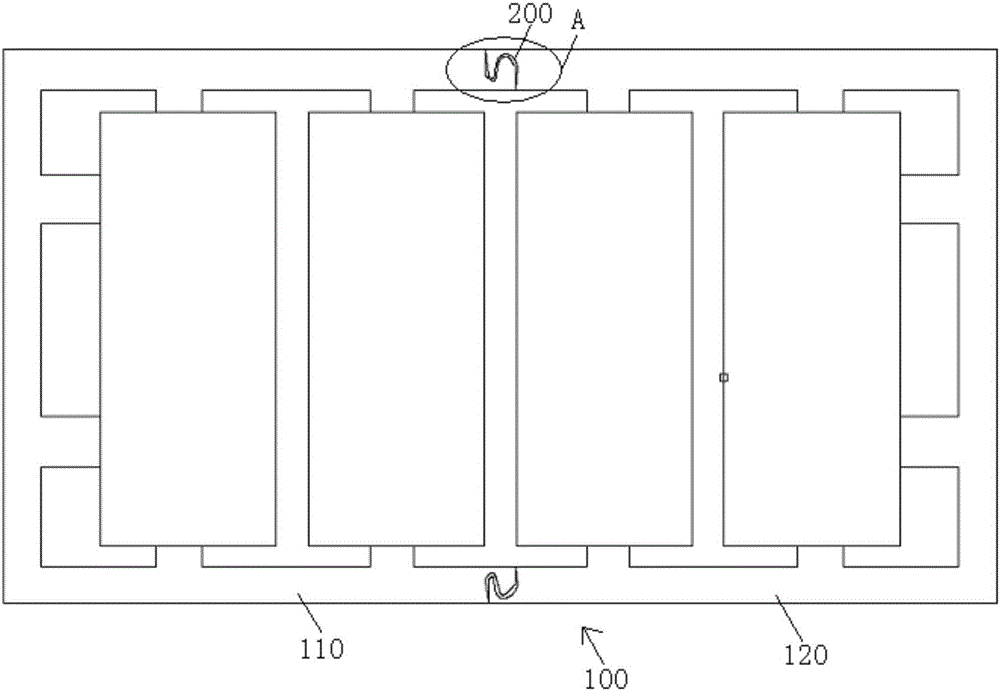

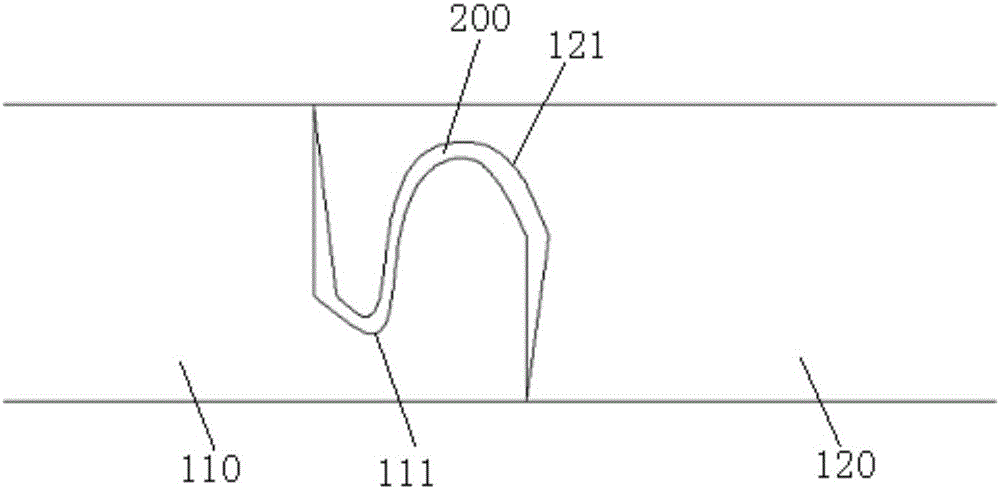

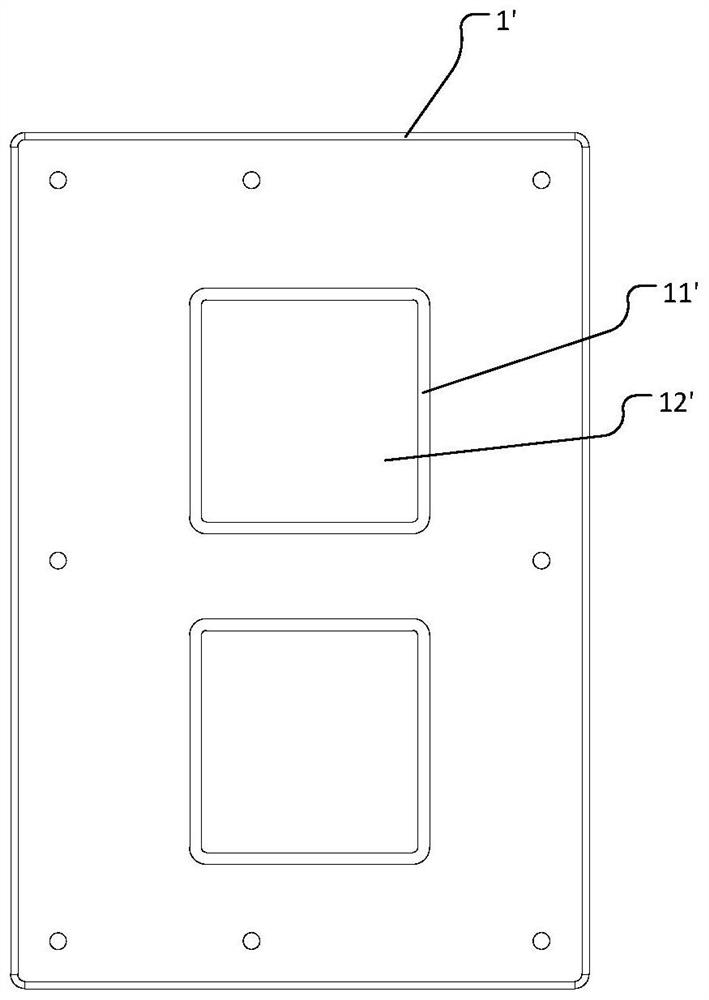

Splicing structure of printed circuit board and splicing method

PendingCN106793493AImprove stitching qualityReduce splicing costsPrinted circuit assemblingPost-manufacturing circuit processesAdhesiveEngineering

The invention discloses a splicing structure of a printed circuit board. The splicing structure includes a mother board and a child board spliced at one end of the mother board, the end, spliced with the child board, of the mother board is provided with a mother board splicing surface, the end, spliced with the mother board, of the child board is provided with a child board splicing surface, the mother board splicing surface is spliced with the child board splicing surface to form the splicing structure, the two ends of the splicing structure are in butt joint, and the middle of the splicing structure is provided with a cavity used for pouring thermocuring adhesives. The splicing structure of the printed circuit board not only can improve the splicing quality of the printed circuit board, but also can reduce the splicing cost and achieve environmental protection.

Owner:SHANGHAI UNITECH ELECTRONICS CO LTD

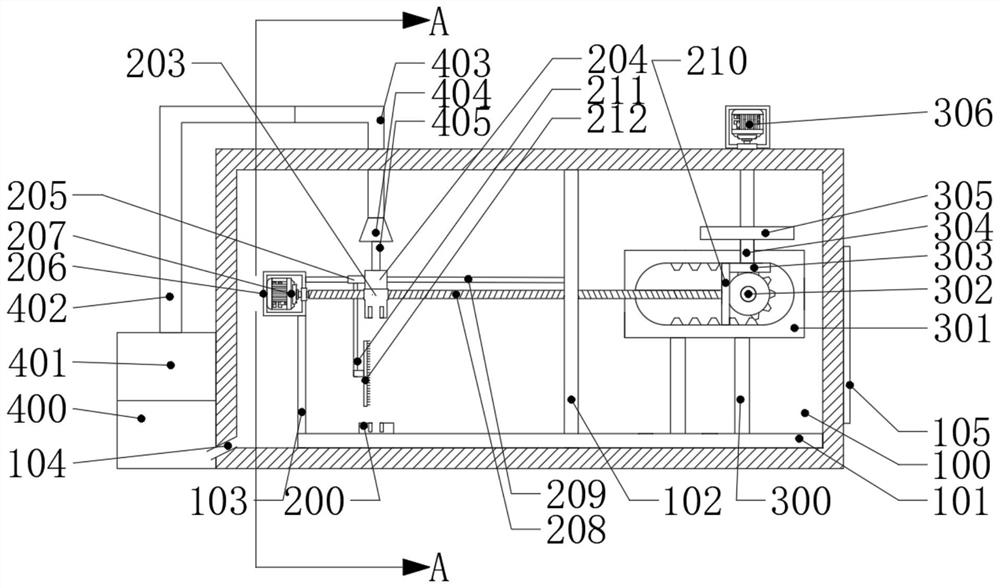

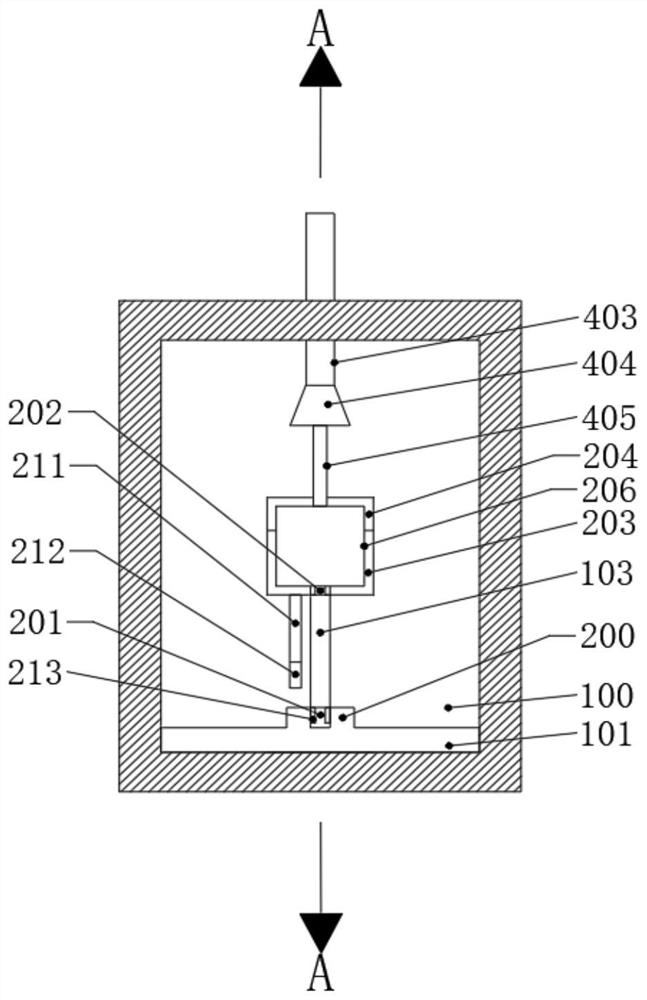

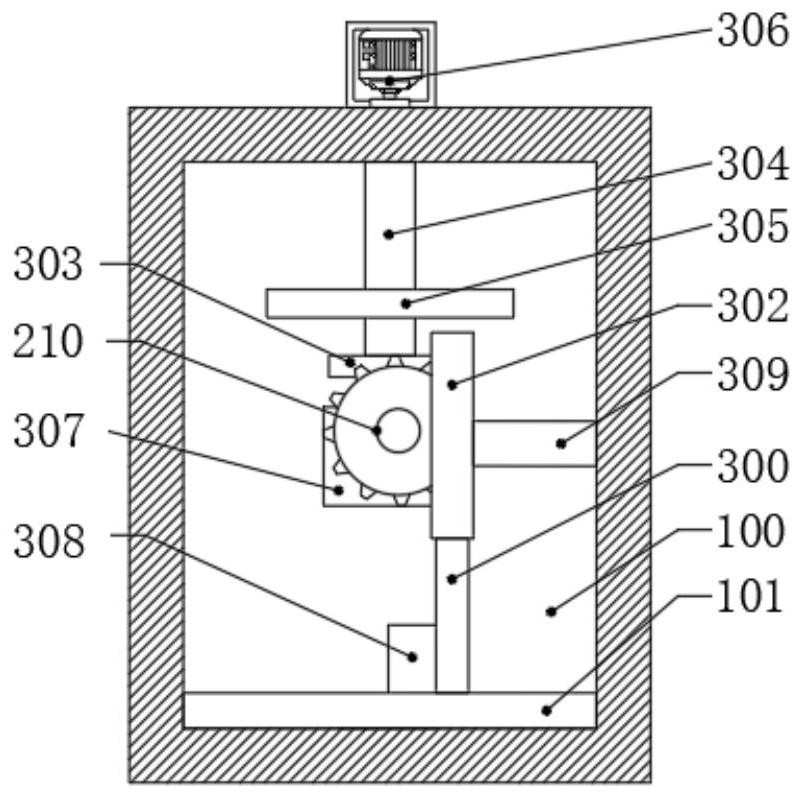

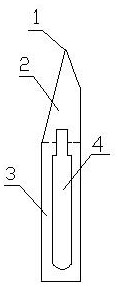

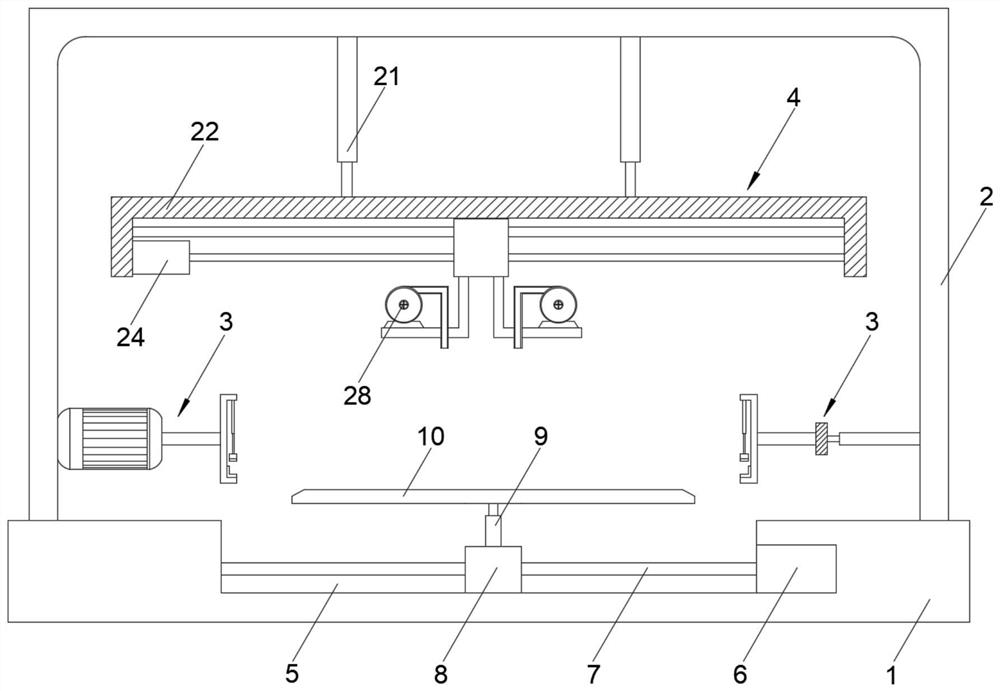

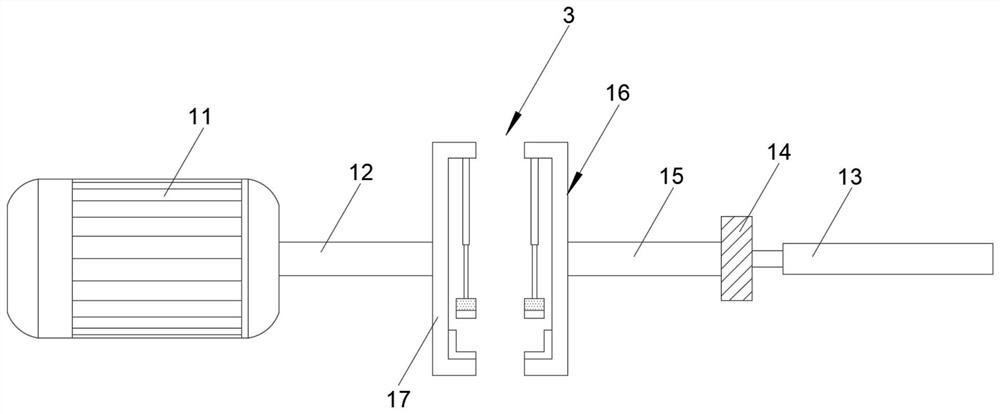

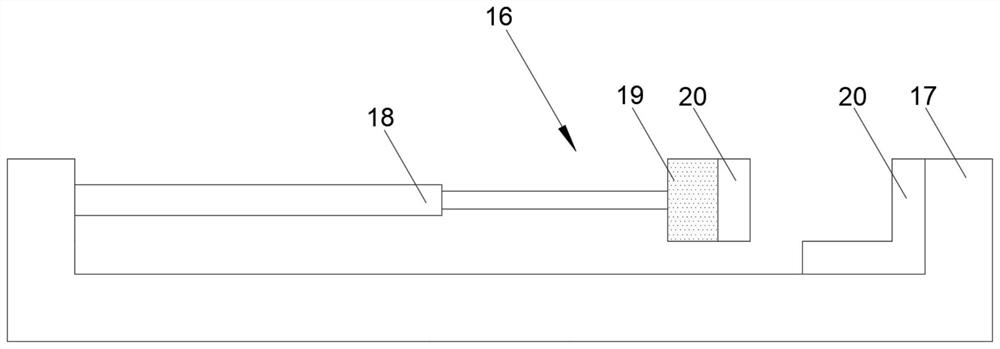

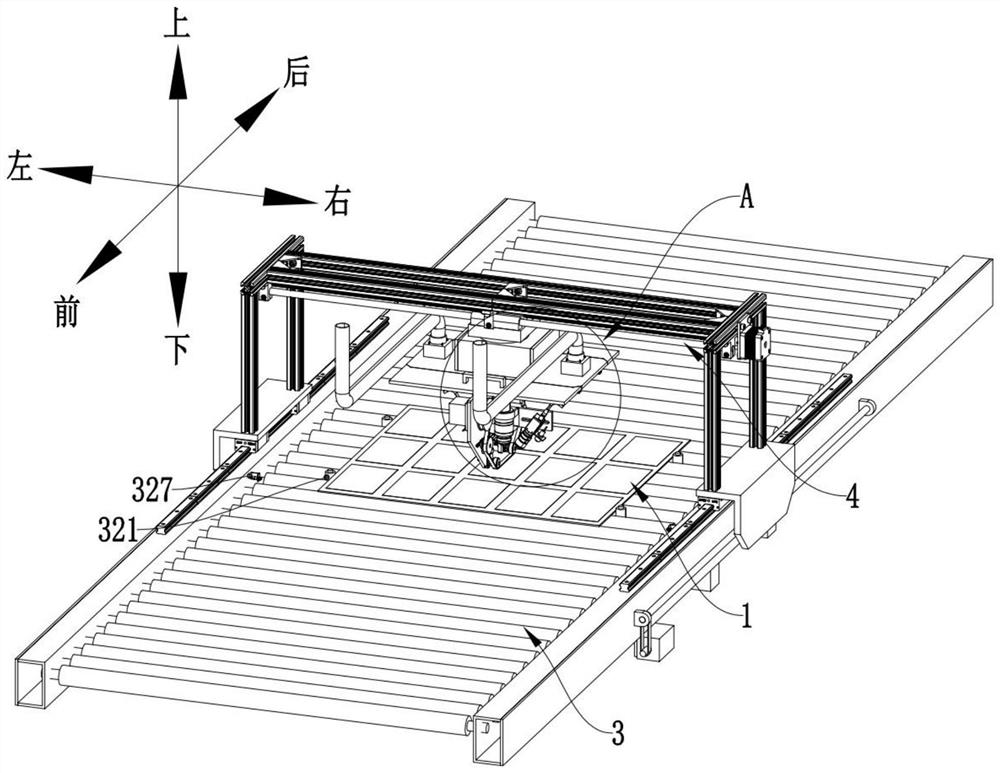

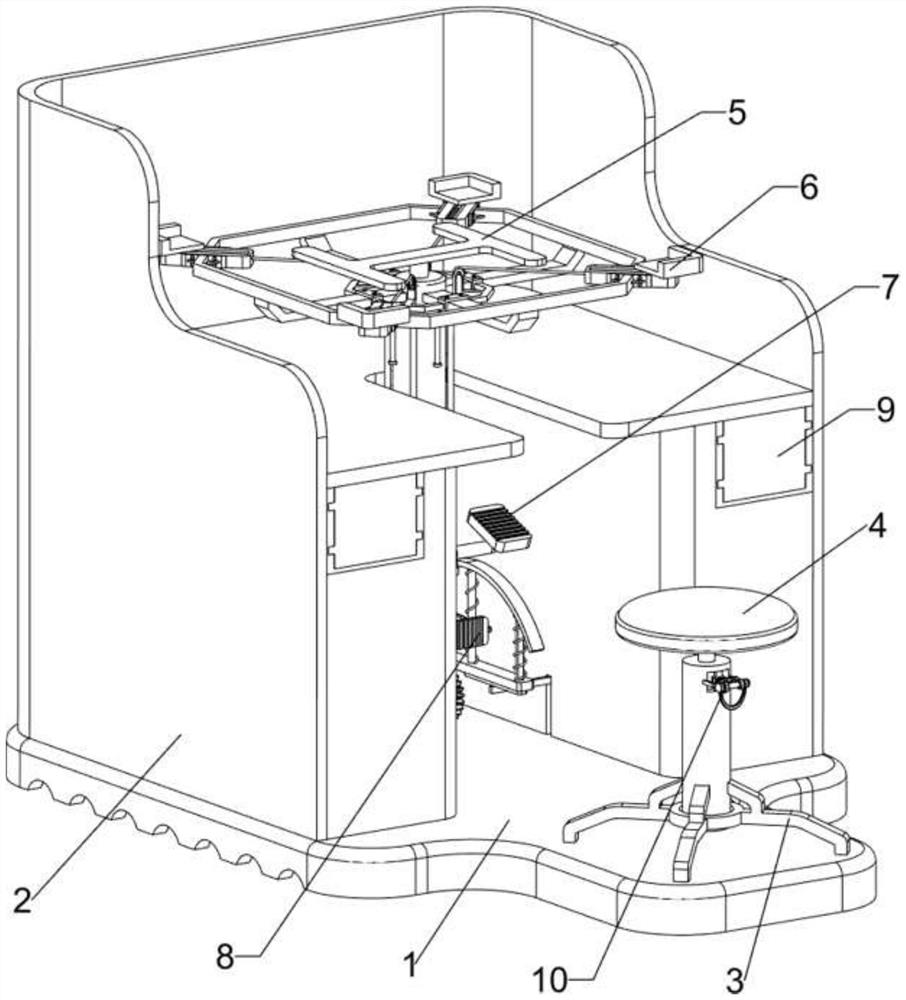

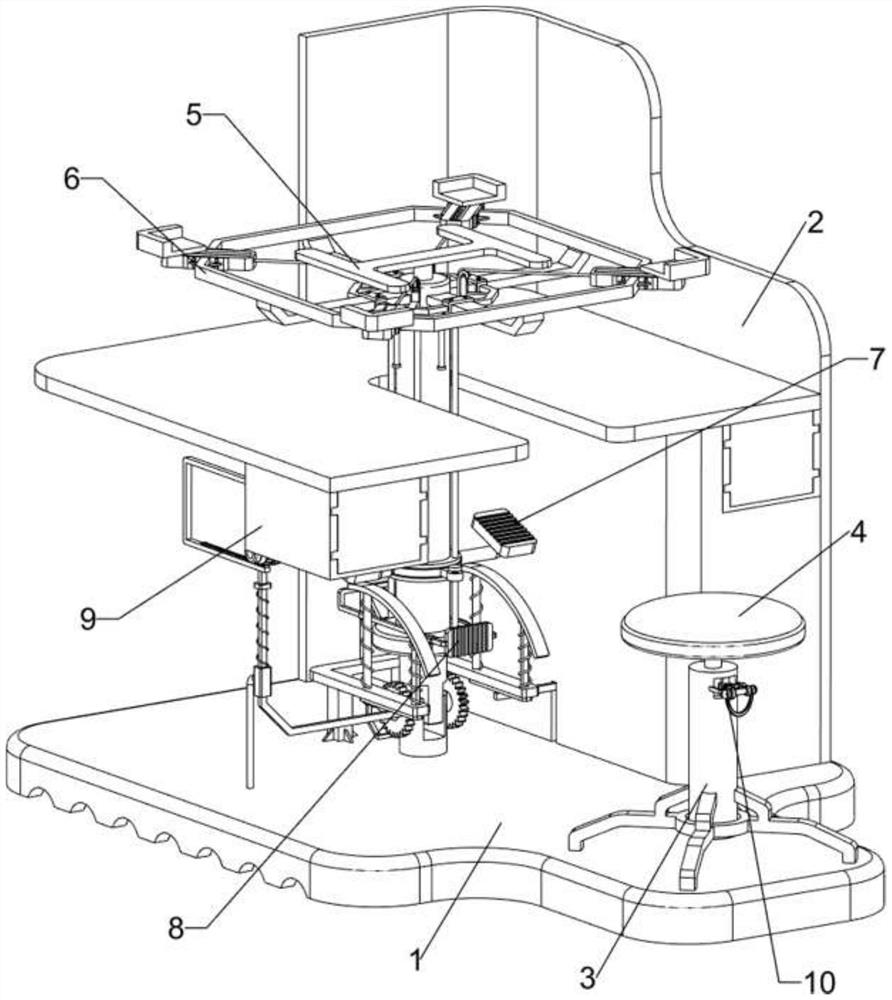

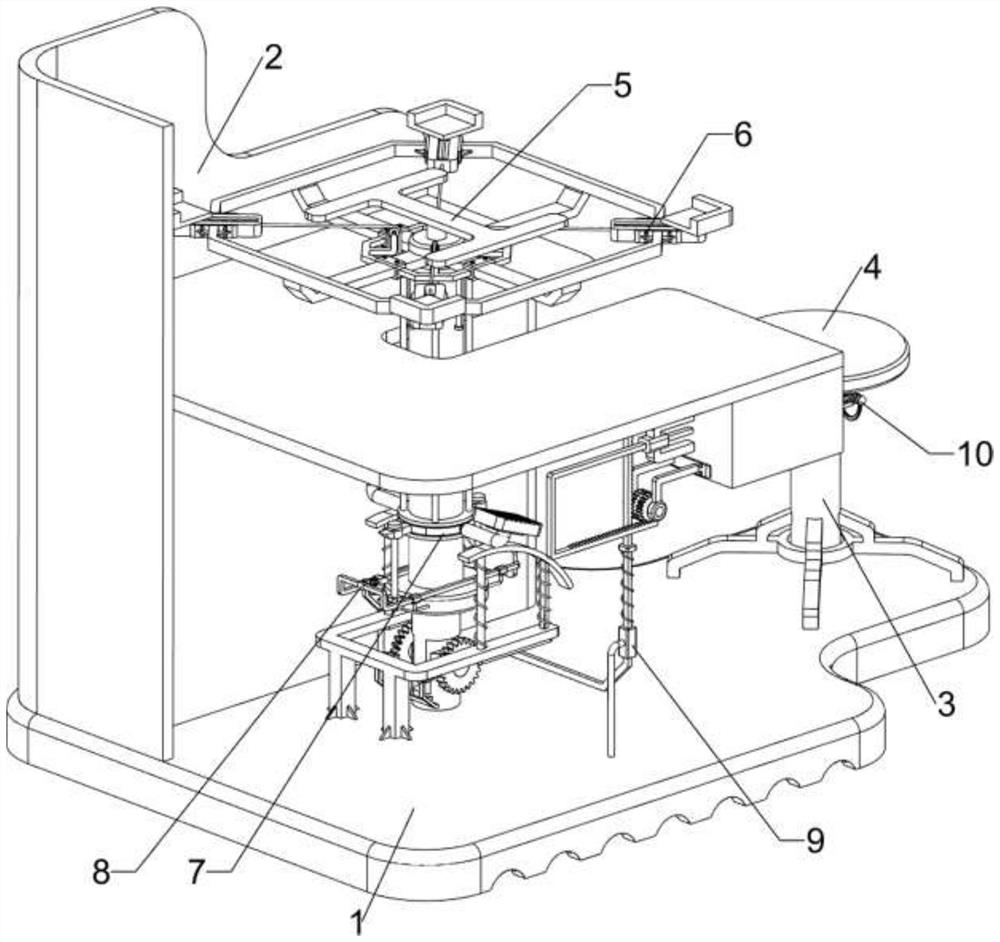

Printed board crystal supplementing and repairing device

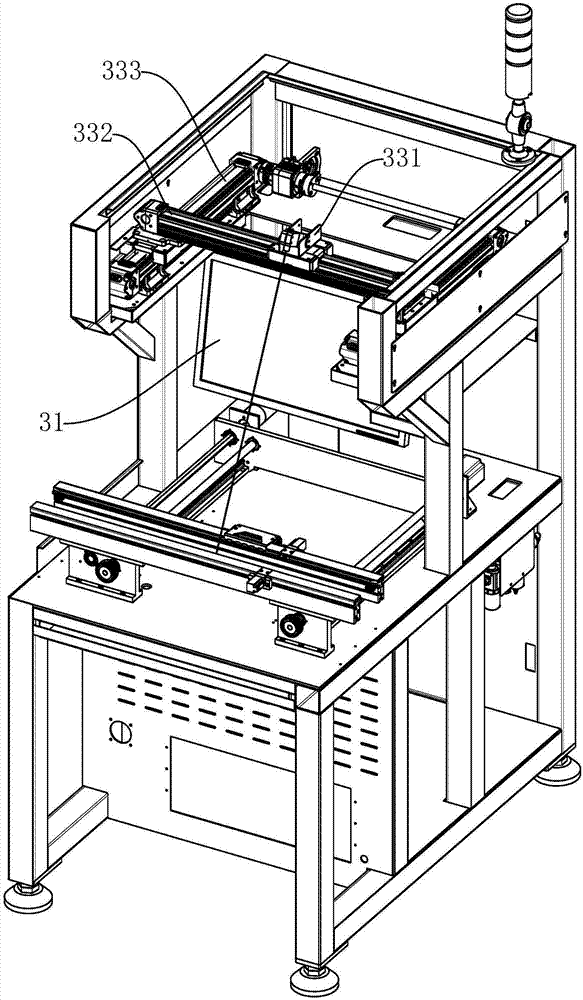

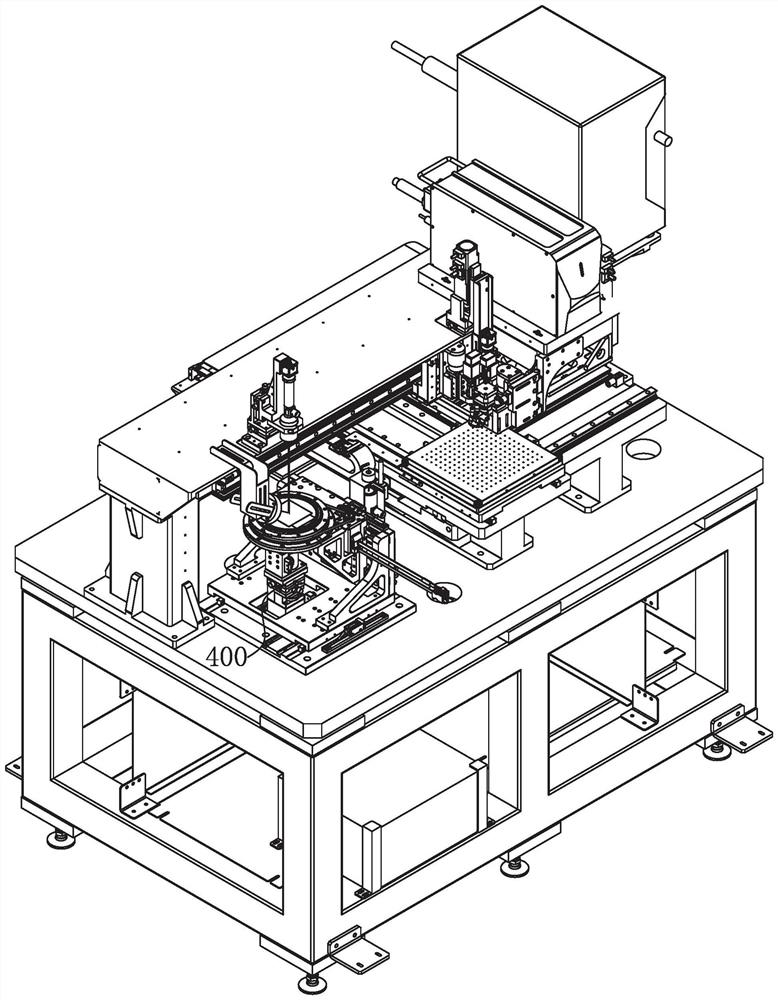

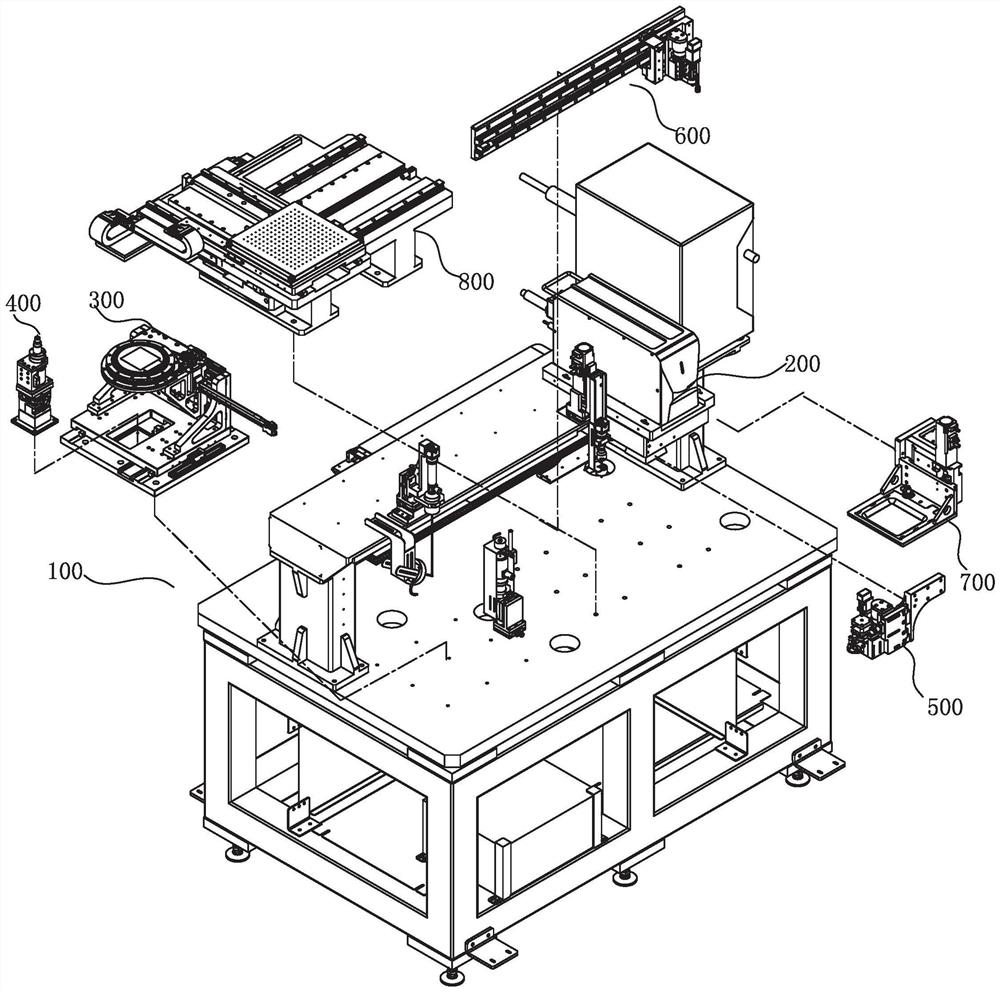

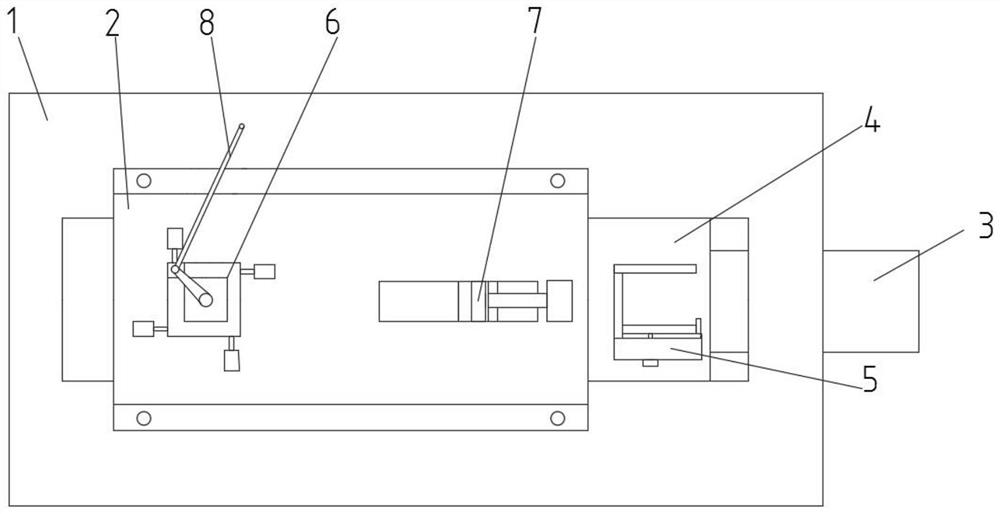

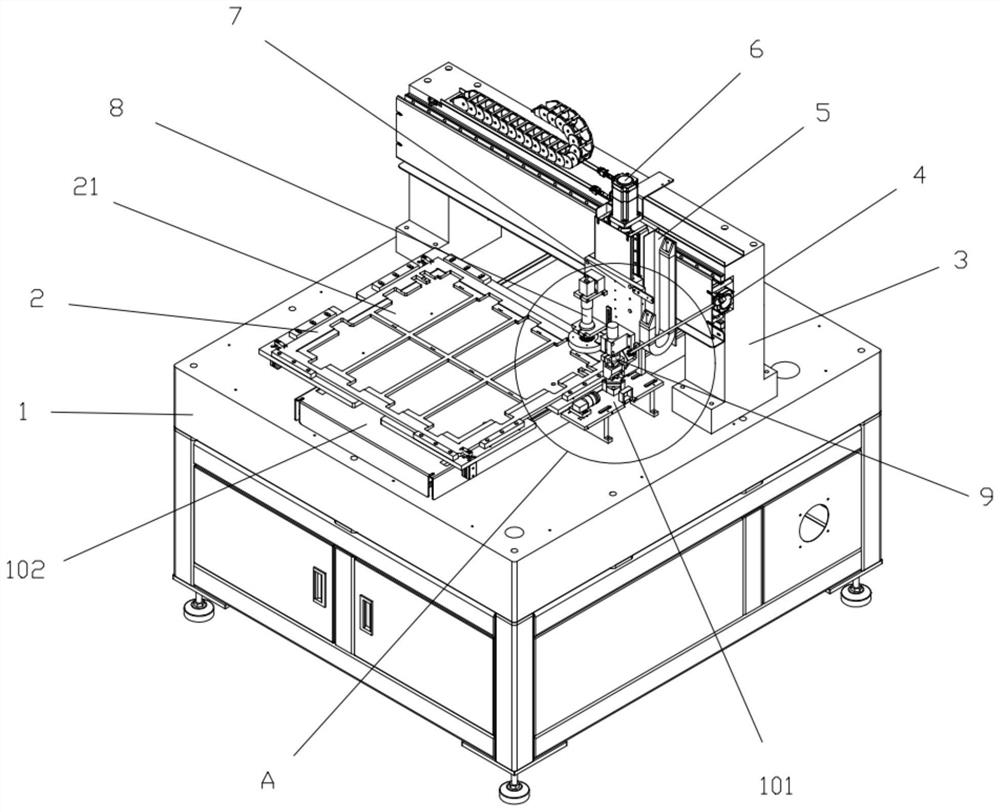

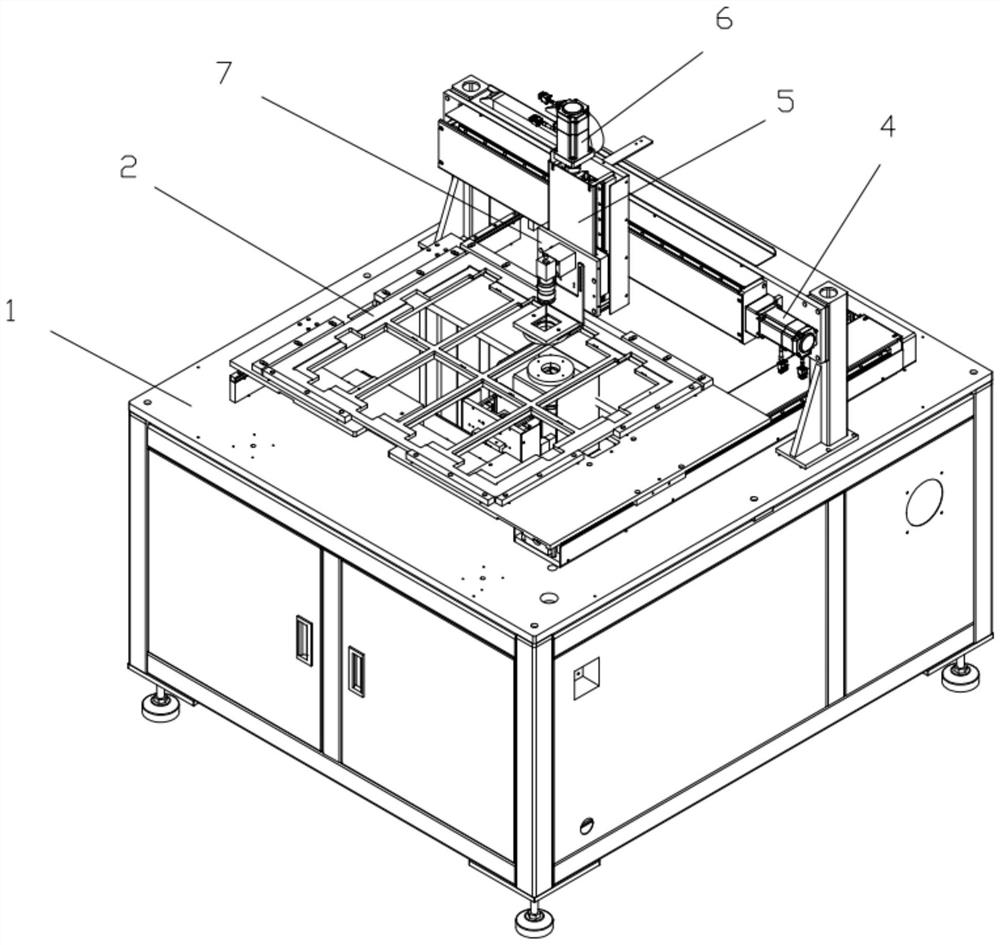

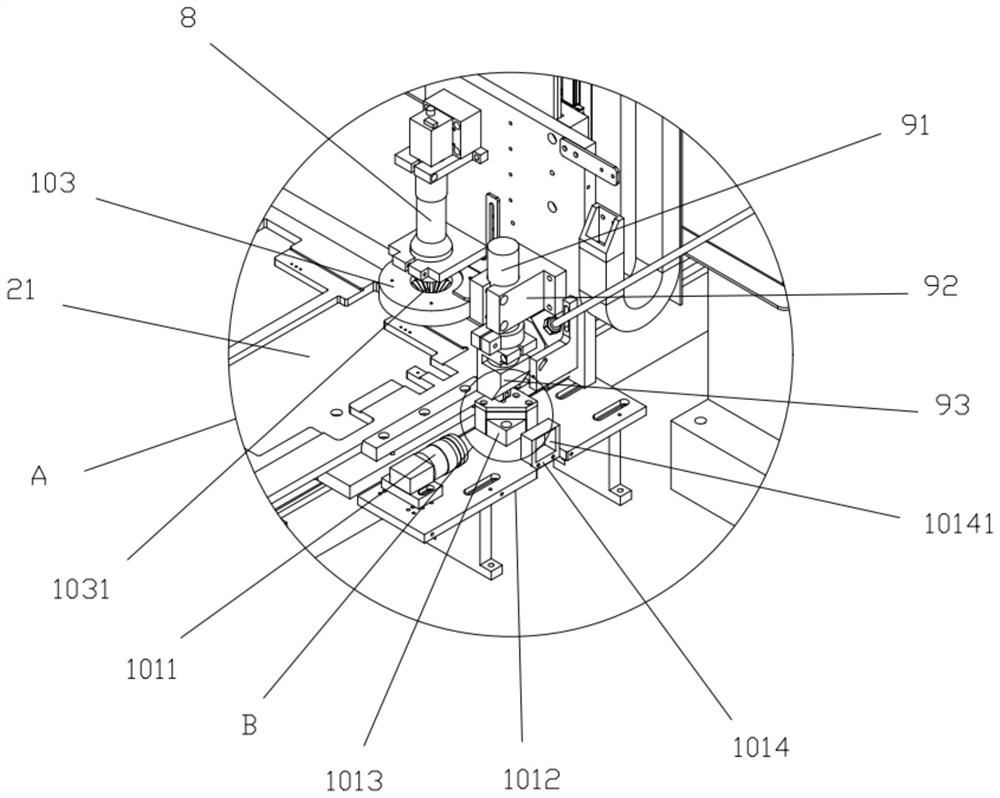

PendingCN114698258AShort production processSmall footprintPrinted circuit assemblingPost-manufacturing circuit processesSolder pasteMechanical engineering

The invention belongs to the technical field of semiconductor processing equipment, and particularly relates to a printed board crystal supplementing and repairing device which comprises a rack and further comprises a laser module arranged on the rack. The film module is used for moving a blue film chip disc which is arranged on the film module and is used for placing chips; the needle module is located below the blue film chip disc and used for impacting the chips placed on the blue film chip disc; the dispensing module is used for smearing solder paste on the position, where the chip needs to be complemented, of the printed board; the suction nozzle module is used for sucking the chips on the blue film chip disc and placing the chips on the solder paste-coated bonding pad on the printed board; the pressing module is used for fixing the to-be-welded chip placed on the printed board; and the transfer module is used for moving the printed board to the stations where the dispensing module, the suction nozzle module, the pressing module and the laser module are located. Compared with the prior art, the chip repairing and repairing device integrates chip repairing and welding processes on one device, so that the production process is effectively reduced, the operation efficiency and the product yield are improved, and the occupied area is reduced.

Owner:深圳市易天半导体设备有限公司

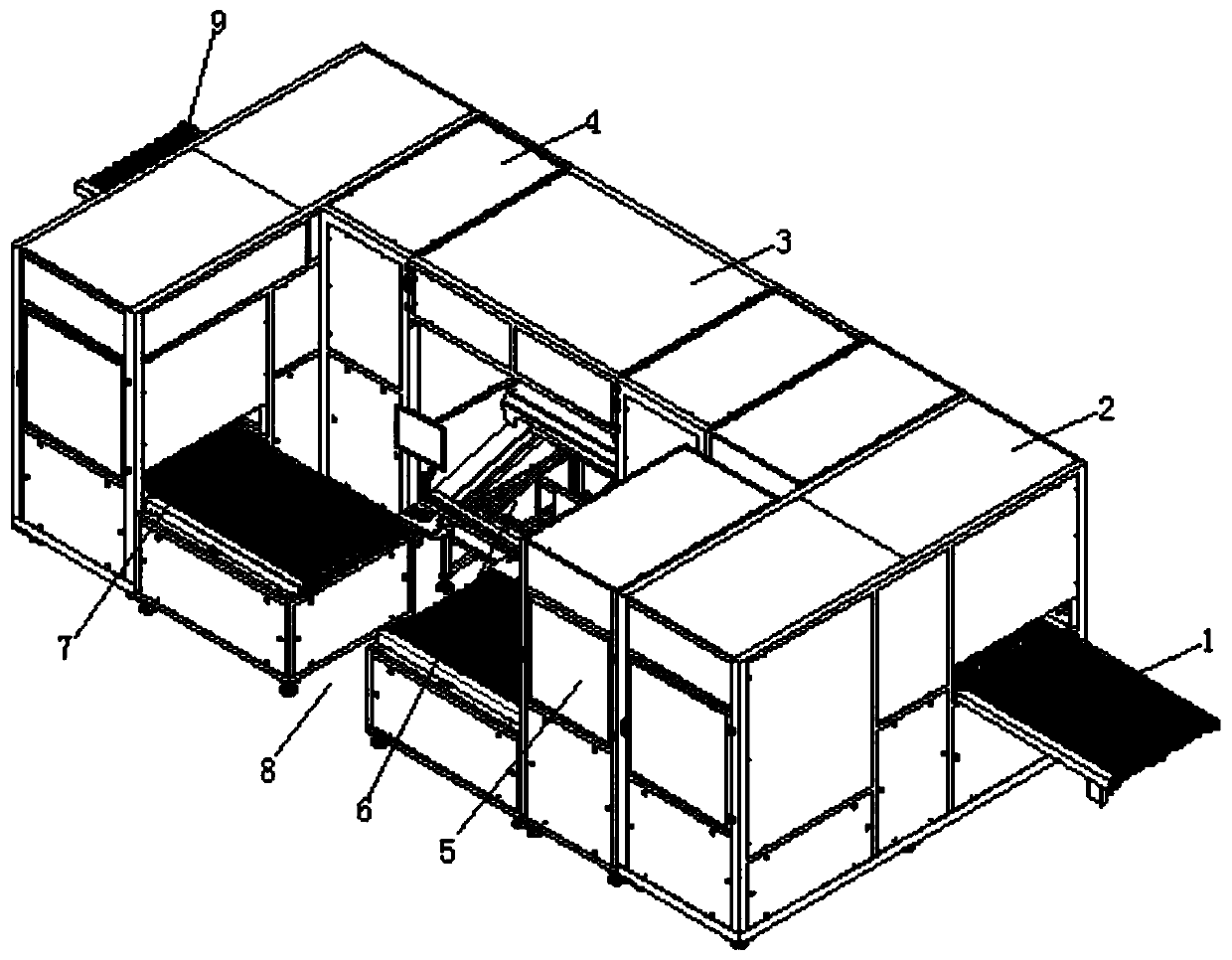

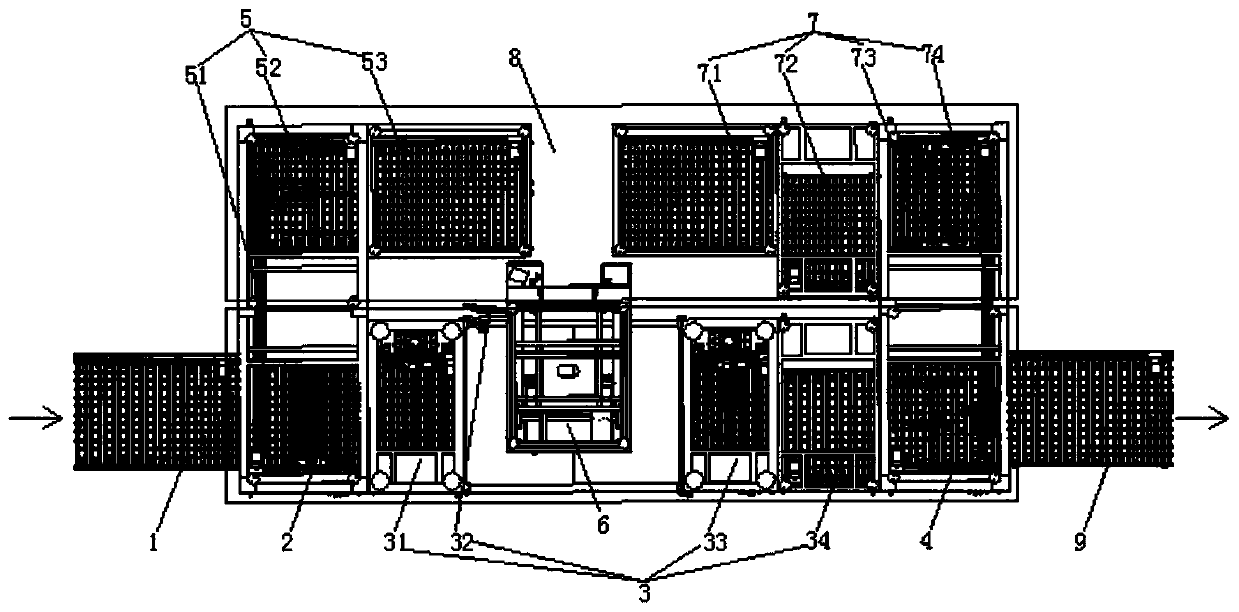

Maintenance equipment and maintenance method for online maintenance of PCB

PendingCN111586976AReduce scrap rateAvoid overlappingPost-manufacturing circuit processesOptically investigating flaws/contaminationProcess engineeringAssembly line

The invention relates to maintenance equipment for online maintenance of a PCB, which is connected with an AOI maintenance system through a board feeding conveying section and comprises a board separation conveying section and the board feeding conveying section. An induction device is arranged on the board separation conveying section; a first OK board conveying device is connected with the boardseparation conveying section; a board collection conveying section is connected with an NG board conveying device; the NG board conveying device is connected with the board separation conveying section, is positioned at the rear end of the board separation conveying section and is used for conveying NG boards; a rechecking machine is positioned at the right end of the NG board conveying device; and a second OK board conveying device is positioned between the rechecking machine and the board collection conveying section. According to the maintenance equipment for online maintenance of a PCB, assembly line production is achieved, the situation that the OK board is scratched due to the fact that the OK board and the NG board are overlapped together is avoided, the rejection rate of the PCB is reduced, meanwhile, the production efficiency is improved, and automatic production is achieved; the invention also provides a maintenance method for the maintenance equipment for online maintenanceof a PCB by using the maintenance equipment for online maintenance of a PCB.

Owner:黄石广合精密电路有限公司

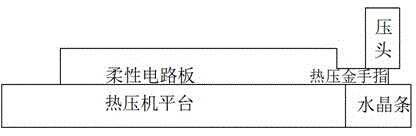

Modifying method for hot pressed golden finger warping of repaired flexible printed circuit board

InactiveCN104470238AReduce wasteLow costPost-manufacturing circuit processesPrinted circuits repair/correctingHead pressingAnisotropic conductive adhesive

The invention relates to a modifying method for hot pressed golden finger warping of a repaired flexible printed circuit board. The modifying method comprises the following steps that firstly, static electric hand rings and antistatic gloves are put on, and the analyzed defective product reasons are marked on the back faces of products through an oil pen in details; secondly, under the condition with the high temperature of 250+ / - 10 DEG C, the flexible printed circuit board is torn down from a base material slightly, and the high-temperature ironing time is determined according to the size of the flexible circuit board; thirdly, a cotton bar is used for dipping a small amount of removing liquid of anisotropic conductive adhesive to wipe the anisotropic conductive adhesive on a hot pressed golden finger of the flexible printed circuit board away, and then ethyl alcohol is used for cleaning the flexible circuit board; fourthly, the flexible circuit board with the hot pressed golden finger facing upward is placed in a clamp of a crystal strip of a hot press platform, and the crystal strip is adjusted so that the hot pressed golden finger can be located at the pressing position of a pressing head; fifthly, the hot pressing time, temperature and pressure parameter are set according to the area of the flexible circuit board, a hot press is started, and the pressing head presses the hot pressed golden finger of the flexible circuit board; sixthly, the flexible circuit board is taken out. The modifying method has the technical advantages that material waste is reduced and cost is saved.

Owner:中环高科(天津)股份有限公司

Method for treating and maintaining equipment damaged by water

PendingCN111985657ALow costMeasurement devicesPost-manufacturing circuit processesWater leakageElectric control

The invention relates to a method for treating and maintaining equipment damaged by water, which comprises the following steps of: 1, pretreatment: detaching a product polluted by water pollution, andcleaning the product; 2, detection before electrification of the equipment polluted by water, and detecting whether each electric control part of the cleaned equipment is short-circuited or not, whether an equipment cable is poor in insulation or not, and whether air leakage, oil leakage and water leakage phenomena exist in an air path and an oil-water path or not; 3, detection after electrification of the equipment: based on the result detected in the step 2, performing energy supply and detecting the on-off state on the premise of meeting the basic energy supply of the equipment; and step 4, equipment maintenance: maintaining or replacing the damaged device after the detection in the step 3. The purpose of reducing the cost can be achieved.

Owner:苏州英睿派机电科技有限公司

Circuit board cleaning equipment

InactiveCN112845247AEasy to cleanGuaranteed uptimePost-manufacturing circuit processesDrying gas arrangementsEngineeringStructural engineering

Owner:杭州展虹科技有限公司

Method for repairing circuit of electronic display screen by using ITO (Indium Tin Oxide) electrode

PendingCN113194612AQuick fixImprove conductivityPost-manufacturing circuit processesTransparent dielectricsIndiumIndium tin oxide

The invention discloses a method for repairing a circuit of an electronic display screen by using an IT0 electrode, which comprises the following steps of: firstly, cutting a protective layer and an isolating layer on a display screen by using a blade, exposing the damaged display screen circuit, grinding, polishing and cleaning residues adhered to glass, putting an IT0 wire at a scraped part, forming a groove in a display screen according to a line repair trend line by using a scraper, attaching the scraper to the IT0 wire to rub back and forth at the damaged line, so that the nanometer indium tin oxide wire generates heat by friction, the IT0 wire is changed into a molten IT0 indium tin oxide film by using the friction heat; and meanwhile, filling the molten IT0 film in the groove by using the scraper, and forming a continuous IT0 electrode to repair the circuit of the electronic display screen. According to the method for repairing the circuit of the electronic display screen through the IT0 electrode, the repairing process is simple, the repairing time is short, the repairing efficiency is high, and the repairing effect is good.

Owner:黄冬云

Integrated circuit processing cleaning equipment with good cleaning effect

InactiveCN111940412AEasy to fixEasy to cleanPost-manufacturing circuit processesCleaning using gasesDrive shaftElectric machinery

The invention discloses integrated circuit processing cleaning equipment with a good cleaning effect. The integrated circuit processing cleaning equipment comprises a supporting plate, a bearing beam,a positioning mechanism and a cleaning mechanism, wherein the bearing beam, the positioning mechanism and the cleaning mechanism are welded and fixed to the two sides of the top wall of the supporting plate respectively. A conveying plate is arranged on the top wall of the supporting plate, and an adjusting groove is formed in the center of the top wall of the supporting plate. The cleaning mechanism is composed of a mounting frame, two sets of parallel stretching rods and two sets of direct-current air blowers. The two ends of each set of stretching rods are welded and fixed to the top wallof the inner side of the bearing beam and the top wall of the mounting frame respectively. A first stepping motor is mounted in the supporting plate. According to the integrated circuit processing cleaning equipment with the good cleaning effect, by arranging a motor, a transmission shaft, a telescopic rod, an angle block, a driven shaft and clamping seats, the motor works to drive the two sets ofclamping seats to rotate, then an integrated circuit board can be driven to rotate, and therefore the cleaning mechanism can clean the two faces of the integrated circuit board, and the same face ofthe integrated circuit board can be cleaned from different angles.

Owner:杨志华

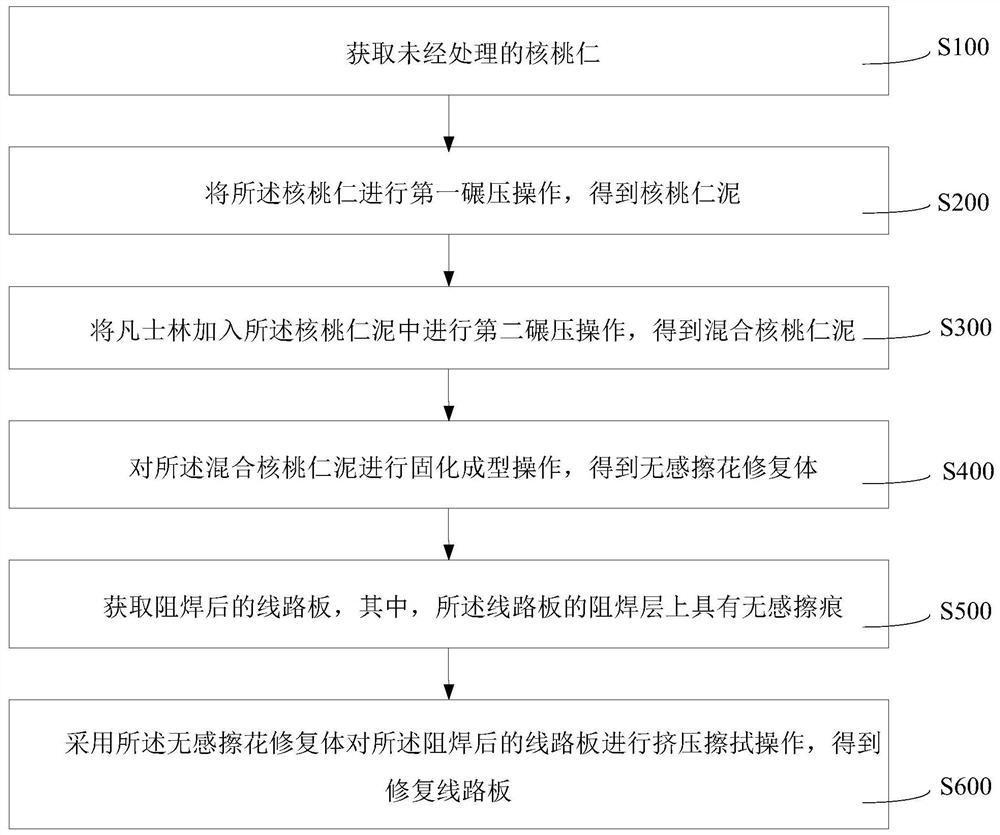

Circuit board and its non-inductive scratch repair process

ActiveCN112739023BGood lookingImprove repair effectPost-manufacturing circuit processesSpecific circuit substancesSolder maskProcess engineering

The present application provides a non-inductive scratch repair process for circuit boards. The above-mentioned non-inductive rubbing repair process for circuit boards includes the following steps: obtaining untreated walnut kernels; performing a first rolling operation on the walnut kernels to obtain walnut kernel mud; adding Vaseline to the walnut kernel mud for a second rolling operation , to obtain mixed walnut kernel paste; solidify and form the mixed walnut kernel paste to obtain a non-inductive scratch restoration; obtain a circuit board after solder masking, wherein there are non-inductive scratches on the solder mask layer of the circuit board; Squeeze and wipe the circuit board after the solder resistance with the scratch-scratch restoration body to obtain the repaired circuit board. The above-mentioned non-inductive scratch repair process for circuit boards can better repair the non-inductive scratches and improve the appearance of the circuit board.

Owner:CAMELOT QINGYUAN HYTEC TECH INVESTMENT

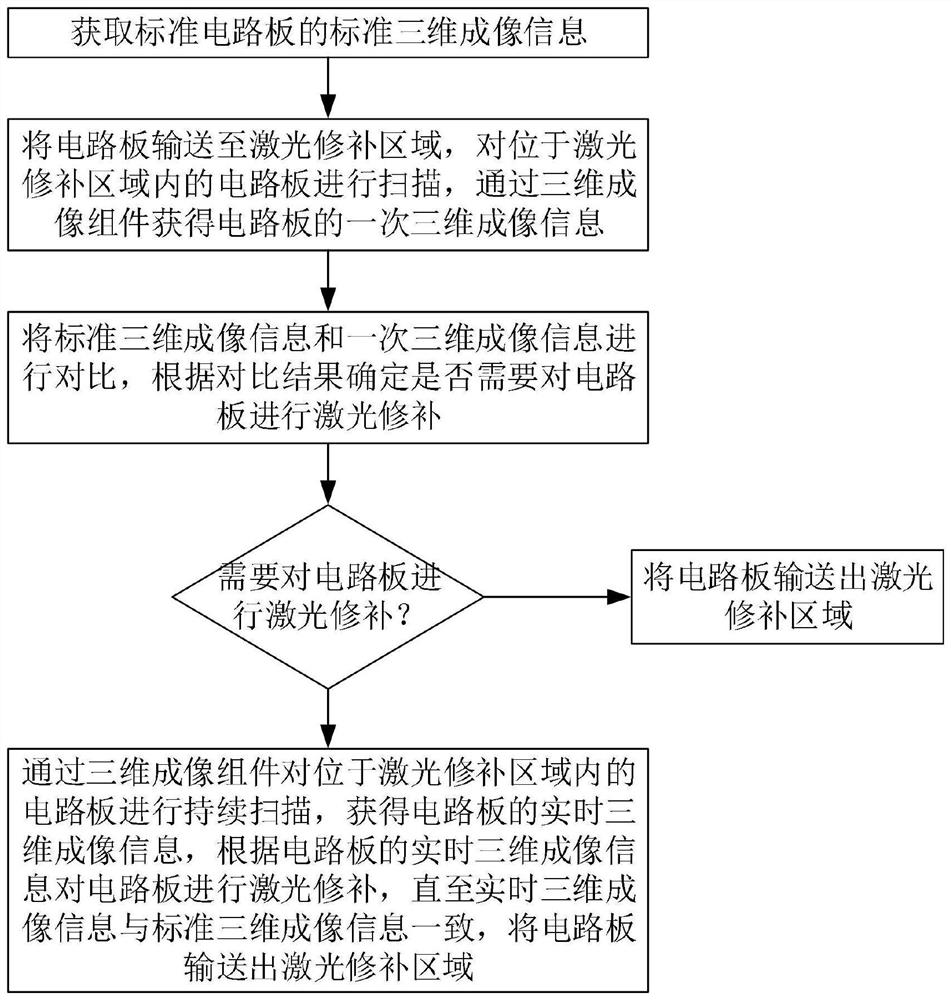

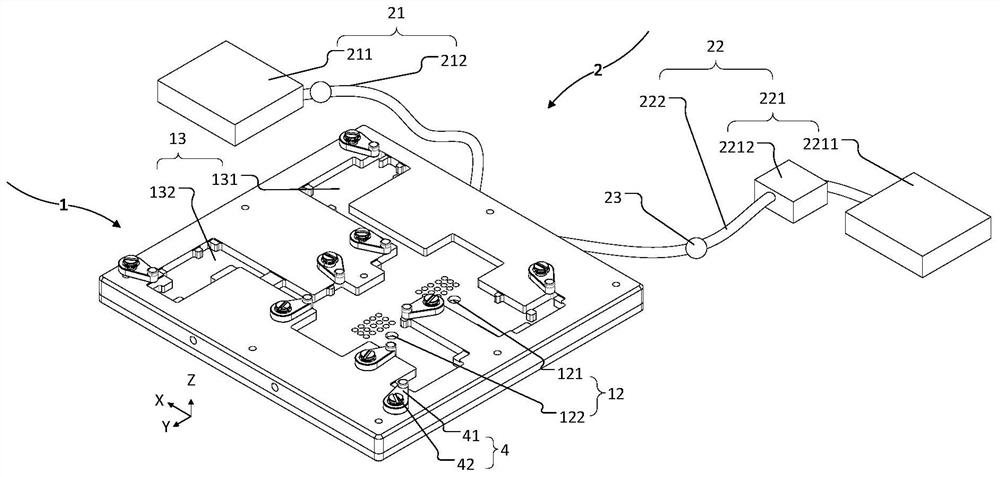

A method and system for real-time repairing of PCB circuit boards based on 3D vision

ActiveCN113453440BReduce repair efficiencySimple methodPost-manufacturing circuit processesPrinted circuits repair/correctingVisual perception3d vision

The invention discloses a method and system for real-time repairing of PCB circuit boards based on 3D vision, wherein the method for real-time repairing of PCB circuit boards includes: A. obtaining standard three-dimensional imaging information of standard circuit boards; B. obtaining circuit boards through three-dimensional imaging components C. Compare the standard 3D imaging information with the primary 3D imaging information, and determine whether laser repair is required for the circuit board according to the comparison result. A real-time PCB circuit board repair method based on 3D vision proposed in this technical solution can realize synchronous processing of 3D imaging and laser repair, greatly improving the repair efficiency of circuit lines, and then proposes a PCB circuit board based on 3D vision The board real-time repair system has high precision, which is beneficial to realize the synchronous processing of 3D imaging and laser repair, short circuit repair and open circuit repair, as well as realize the synchronous repair of circuit board open circuit and short circuit. It has simple structure, reliable performance and easy operation.

Owner:广东炬森智能装备有限公司

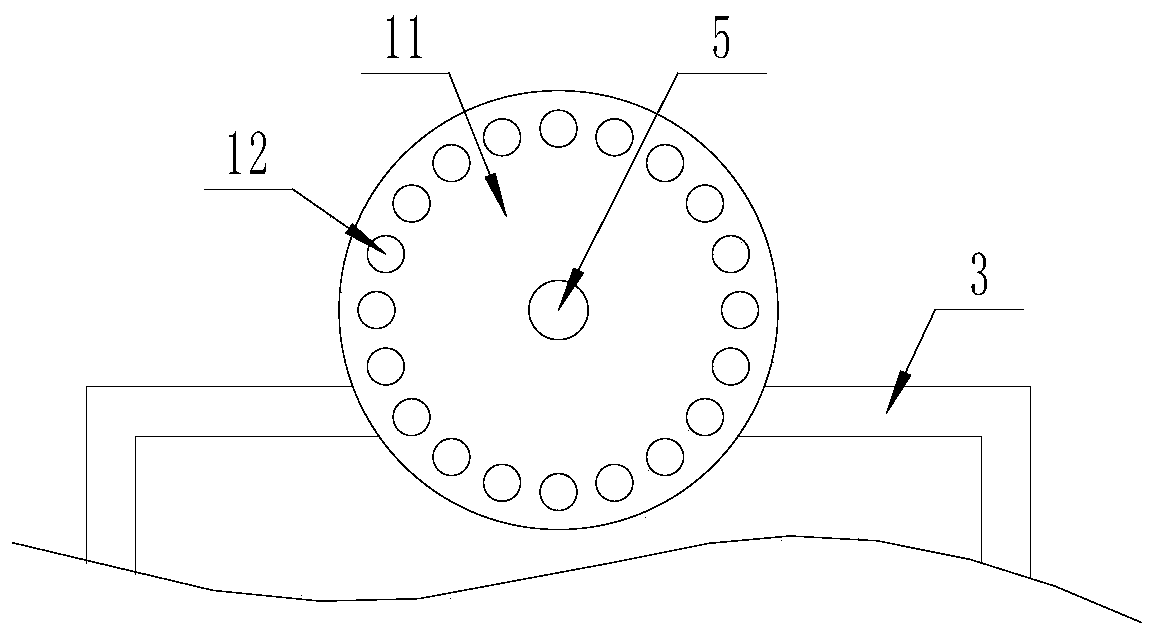

Circuit board maintenance jig

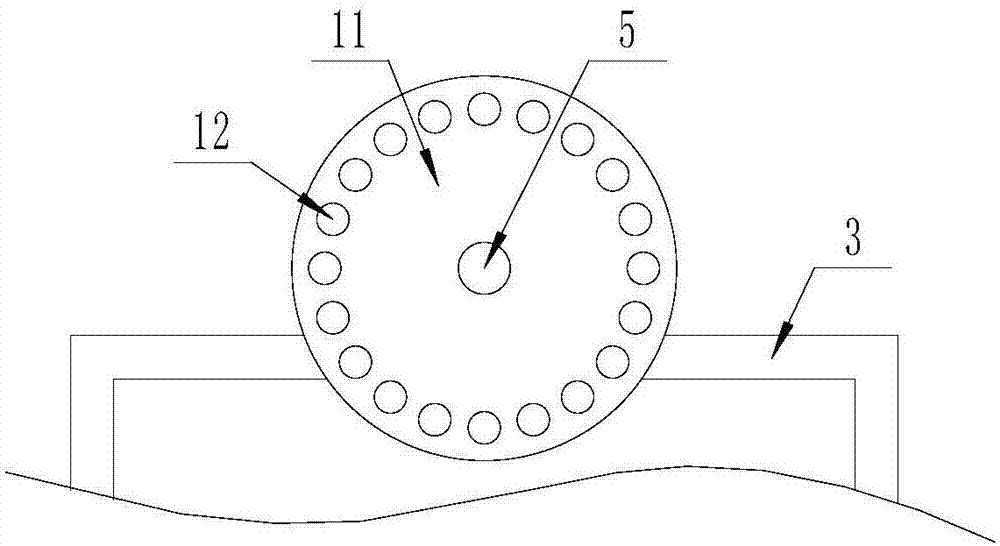

PendingCN113099614AReduce surface temperaturePost-manufacturing circuit processesMechanical engineeringElectrical and Electronics engineering

The invention relates to a circuit board maintenance jig which comprises a jig body used for installing a circuit board, the jig body is connected with an airflow driving mechanism, and the airflow driving mechanism drives airflow in the jig body to flow; the maintenance jig for the circuit board further comprises an airflow channel formed in the jig body and vent holes formed in the jig body, the vent holes are communicated with the airflow channel, and the jig body is communicated with the airflow driving mechanism through the airflow channel. In a mounting state, the vent holes correspond to the circuit board. The vent holes are communicated with the airflow channel, the jig body is communicated with the airflow driving mechanism through the airflow channel, when the airflow driving mechanism drives airflow in the airflow channel to pass through the vent holes, heat on the surface of the circuit board is taken away, and thus the surface temperature of the circuit board is effectively reduced.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

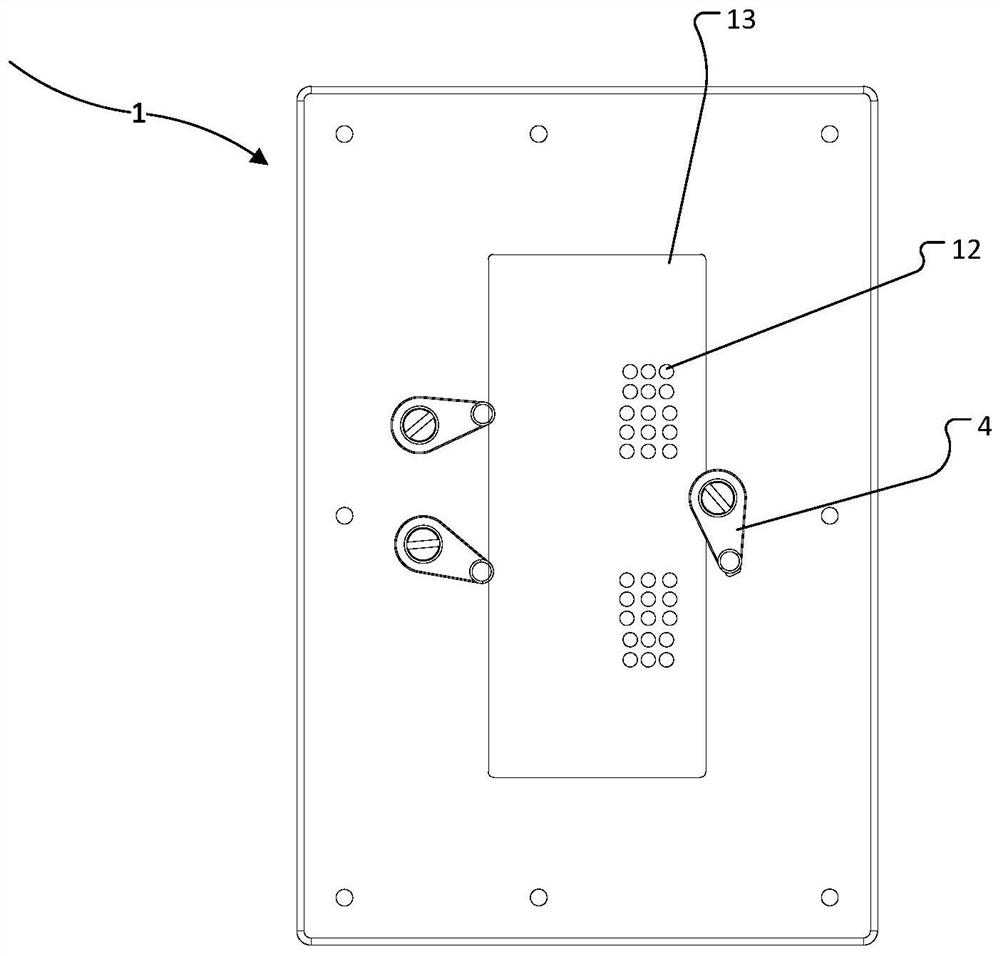

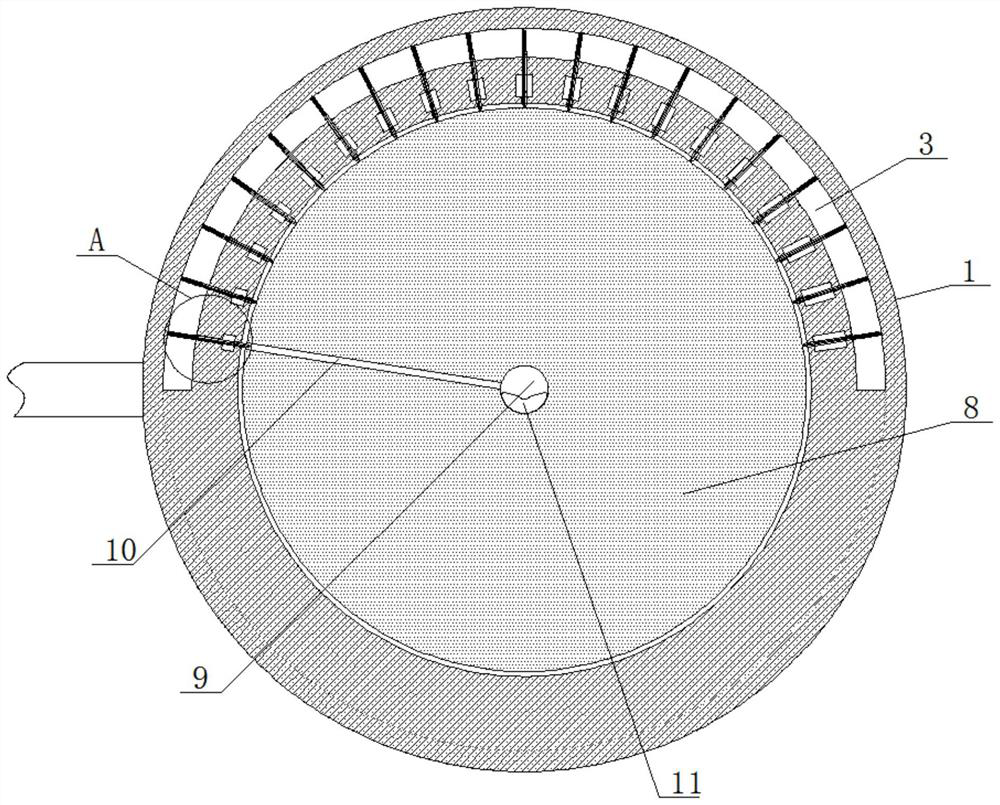

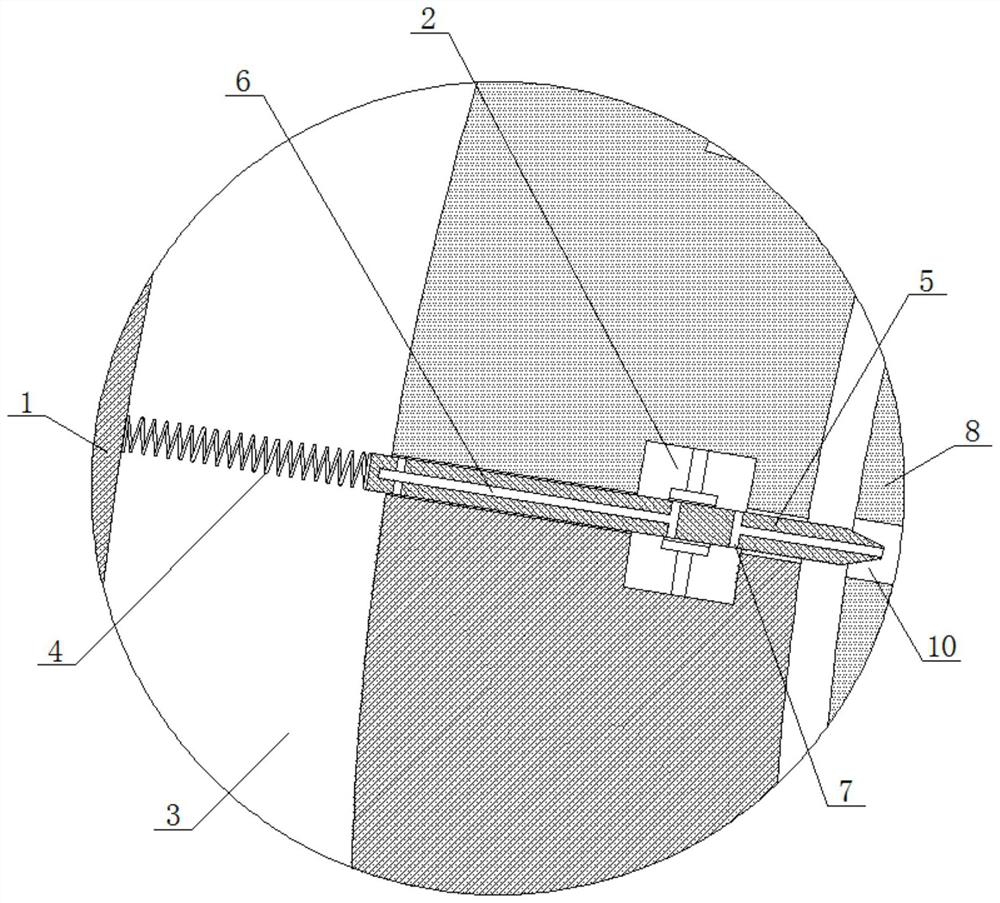

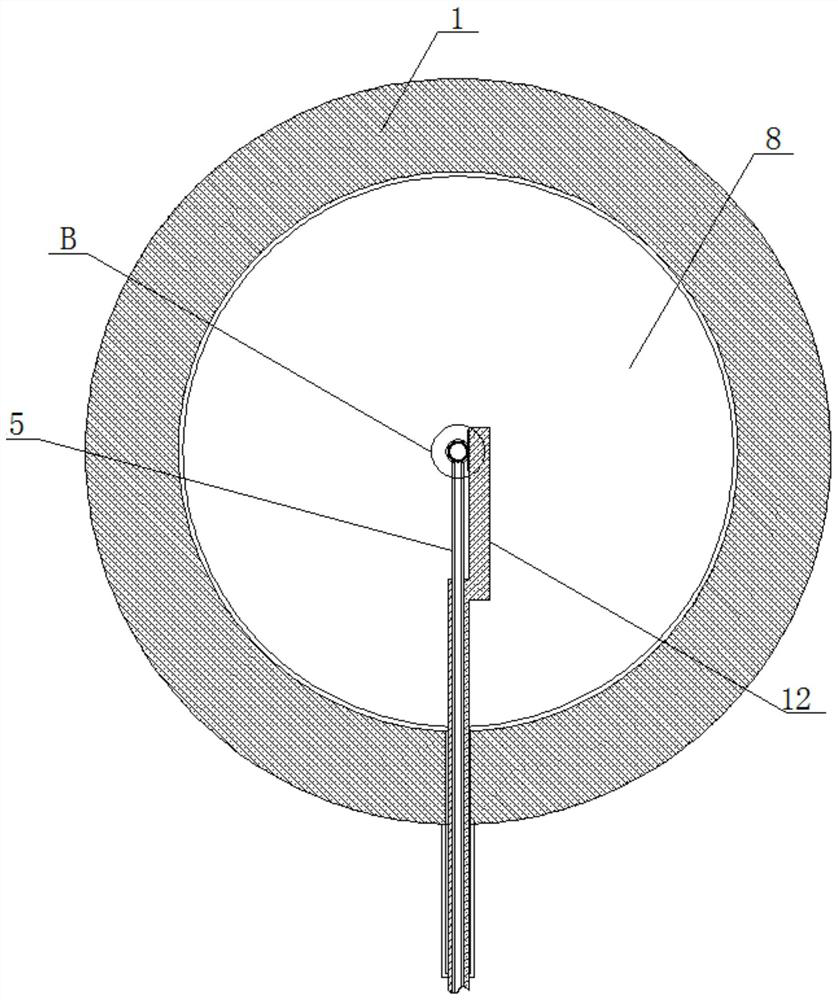

Polymer resin control panel repairing mechanism for base station wireless signal transmission equipment

InactiveCN112333923AAccurate and fast repairDielectric materialsPost-manufacturing circuit processesMaterials preparationPolymer resin

The invention discloses a polymer resin control panel repair repairing mechanism for base station wireless signal transmission equipment. The polymer resin control panel repairing mechanism for the base station wireless signal transmission equipment comprises a shell, a material preparation cavity and a material storage cavity are formed in the wall of the shell, a pushing spring is fixedly connected to the outer side of the inner wall of the material storage cavity, and a communicating rod is fixedly connected to the end, close to the material preparation cavity, of the pushing spring; and acommunicating hole is formed in the communicating rod, a side hole communicating with the communicating hole is formed in the outer side of the communicating rod, a rotating wheel is rotatably connected to the interior of the shell, a center hole is formed in the rotating wheel, and a material passing hole communicating with the center hole is formed in the outer side of the rotating wheel. According to the polymer resin control panel repairing mechanism for the base station wireless signal transmission equipment, the sunken degree of the polymer resin control panel repairing mechanism is judged according to the displacement distance of a movable rod in an area to be repaired, then repairing resin in the corresponding material preparation cavity is discharged, the area is repaired, the purpose of accurate and rapid repairing is achieved, and the labor cost and the material cost are saved.

Owner:南京傲战商贸有限公司

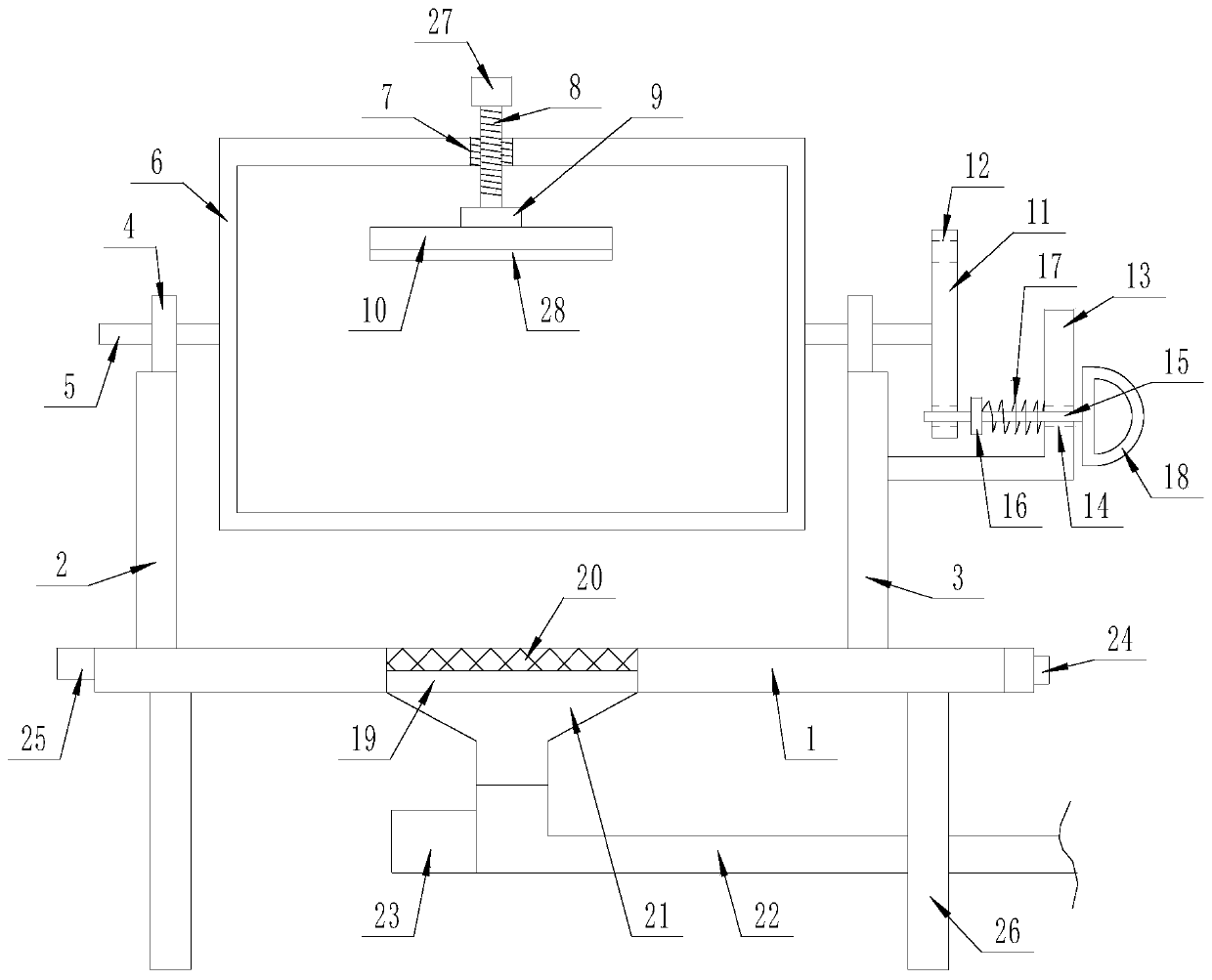

Adjustable positioning device for internal welding of small tin furnace

PendingCN114501802AEasy to pushGuaranteed stabilityPrinted circuit assemblingPost-manufacturing circuit processesEngineeringStructural engineering

The invention discloses an adjustable positioning device for internal welding of a small tin furnace, which comprises a furnace body, hinge seats are arranged on both sides of the surface of one end of the furnace body, a U-shaped frame is hinged to the surfaces of the hinge seats, sliding grooves are formed in both side surfaces of the U-shaped frame, rollers are mounted on both side surfaces of both ends of the sliding grooves in a rolling manner, and the rollers are movably connected with the furnace body. A transverse rod is fixedly connected to the surface of one side of the rolling wheel, connecting rods are fixedly connected to the surfaces of the two ends of the transverse rod, a connecting plate is fixedly installed on the surface of one end of each connecting rod, a transverse adjusting groove is formed in the surface of one end of each connecting plate, and a fixing sleeve is fixedly installed on the surface of the other end of each connecting plate; and a sliding sleeve is slidably mounted on the side face of the transverse adjusting groove, sliding rods are slidably mounted on the side faces of the fixed sleeve and the sliding sleeve correspondingly, and a clamping block is fixedly connected to the surface of one end of each sliding rod, so that the use convenience and stability can be greatly improved, and the welding positioning safety is guaranteed.

Owner:李秀微

A fixed frame for easy maintenance of circuit board

InactiveCN108012440BEasy maintenanceAvoid damagePost-manufacturing circuit processesPrinted circuits repair/correctingFixed bearingFixed frame

The invention discloses a fixing frame capable of facilitating maintenance of a circuit board. The fixing frame comprises a rectangular base, wherein a first portal bracket and a second portal bracketare arranged at two sides of the upper surface of the rectangular base separately; fixed bearings are arranged on the upper surfaces of the first portal bracket and the second portal bracket; a horizontal rotating shaft is arranged in each fixed bearing; a rectangular fixing frame fixedly connected with the horizontal rotating shafts is arranged between the first portal bracket and the second portal bracket; a threaded through hole is processed in the upper surface of the rectangular fixing frame; a threaded rod is embedded into the threaded through hole; and a rotating bearing sleeves one end, at the inner side of the rectangular fixing frame, of the threaded rod. The fixing frame has the beneficial effects that the circuit board is fixed by adopting a method of extruding and fixing theside of the circuit board, so that the damage of a fixing clamp to the surface of the circuit board is avoided; and the fixing angle of the circuit board can be adjusted and the circuit board can be turned over at any time, so that maintenance of the circuit board is facilitated.

Owner:信丰明新电子科技有限公司

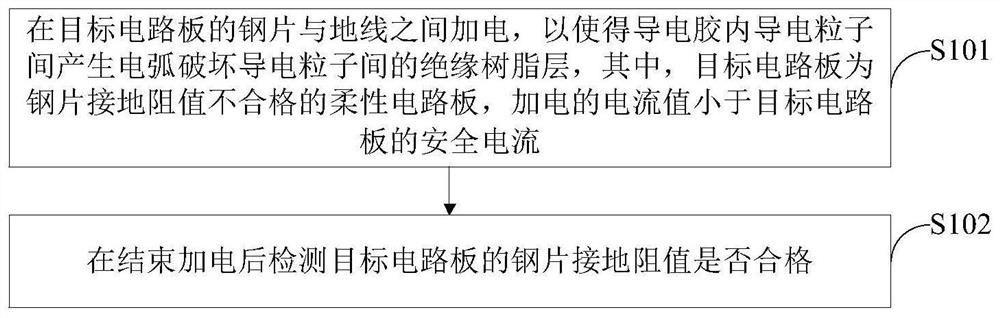

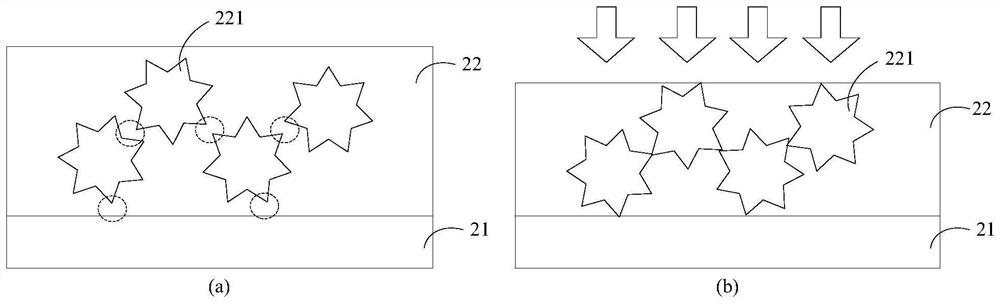

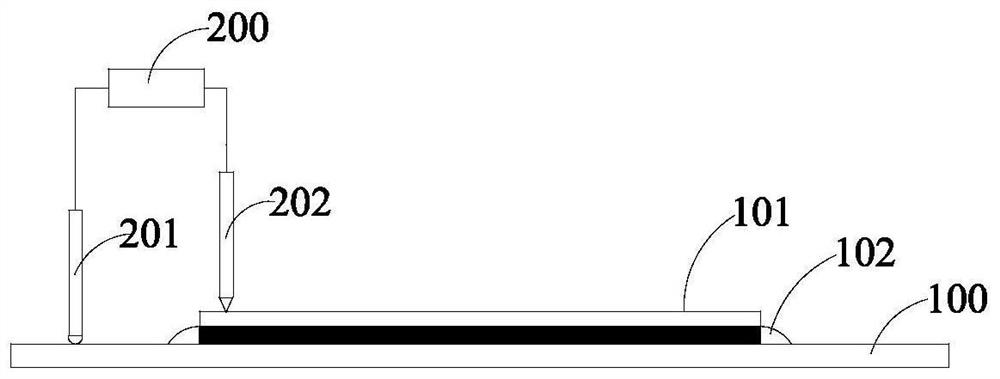

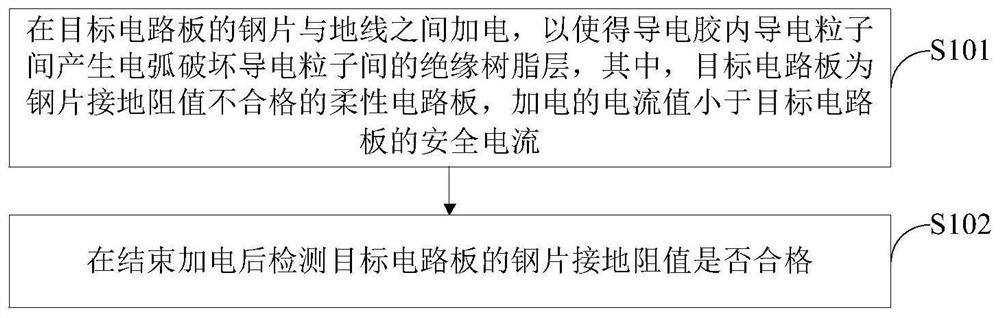

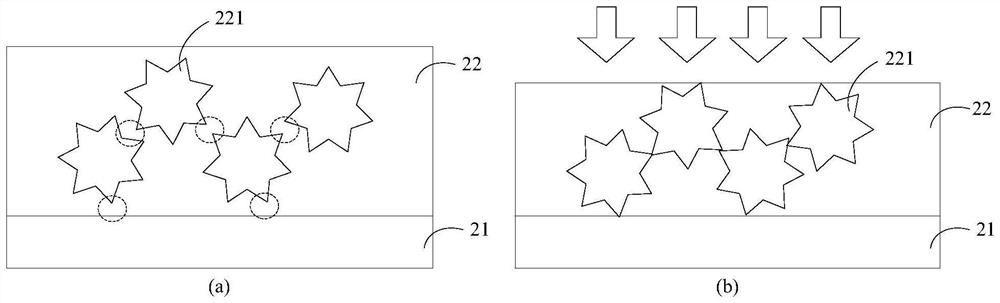

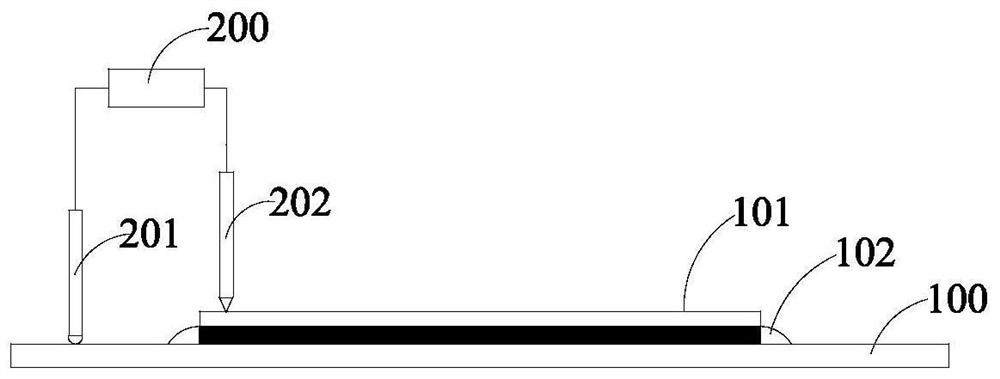

Flexible circuit board processing method and device and apparatus

ActiveCN113271719AReduce production scrapReduce ground resistancePrinted circuit groundingCross-talk/noise/interference reductionElectrical resistance and conductanceFlexible circuits

The invention discloses a flexible circuit board processing method and device and an apparatus. By adding electricity between the surface of a steel sheet of a target circuit board, namely a flexible circuit board with an unqualified steel sheet grounding resistance value and a ground wire so as to generate electric arcs among the conductive particles in a conductive adhesive to thereby damage an insulating resin layer among the conductive particles, the resistance value of the conductive adhesive is reduced, the good conductivity is obtained, and whether the grounding resistance value of the steel sheet of the target circuit board is qualified or not is detected again after power-on is finished, so that the steel sheet grounding resistance of the target circuit board can be effectively reduced, and products with defective steel sheet grounding resistance values can be converted into good products, the product yield is improved, and the production cost is reduced.

Owner:昆山丘钛生物识别科技有限公司

Flexible circuit board processing method, device and equipment

ActiveCN113271719BReduce production scrapReduce ground resistancePrinted circuit groundingCross-talk/noise/interference reductionElectrical resistance and conductanceFlexible circuits

The invention discloses a flexible circuit board processing method, device and equipment. By applying electricity between the surface of the steel sheet of the target circuit board, that is, the flexible circuit board with unqualified grounding resistance value of the steel sheet, and the ground wire, the conductive adhesive is internally The arc generated between the conductive particles destroys the insulating resin layer between the conductive particles, so that the resistance value of the conductive adhesive is reduced and good conductivity is obtained. In this way, the grounding resistance of the steel sheet of the target circuit board can be effectively reduced, which is conducive to transforming a product with a poor grounding resistance value of the steel sheet into a good product, thereby improving the product yield and reducing the production cost.

Owner:昆山丘钛生物识别科技有限公司

PCB welding device

PendingCN114745852AEasy to collectEasy to fixPrinted circuit assemblingPost-manufacturing circuit processesEngineeringCopper foil

The invention discloses a PCB welding device which comprises a fixing mechanism, a mounting mechanism, a guide plate and a belt conveyor, the belt conveyor is an existing device, excessive details are not needed, the belt conveyor is mounted in a groove formed in the upper surface of the fixing mechanism, the mounting mechanism is connected to the upper end of the fixing mechanism in a threaded mode, and the guide plate is connected to the fixing mechanism in a threaded mode. The material guide plate is located on one side of the fixing mechanism, one end of the material guide plate extends into the groove, the other end of the material guide plate is located below the belt conveyor, a plurality of clamping mechanisms arranged at equal intervals are installed on the outer surface of the belt conveyor, and the belt conveyor is used for conveying the clamping mechanisms; the device is used for conducting pre-welding treatment on the PCB, and the problems that due to the fact that the surface is not treated thoroughly, an obvious black boundary exists between soldering tin and a component lead or between the soldering tin and a copper foil, the soldering tin sinks towards the boundary, normal work cannot be conducted, and the problems that welding flux is wasted and welding quality is reduced due to the fact that too much solution is sprayed are solved.

Owner:安徽宏鑫电子科技有限公司

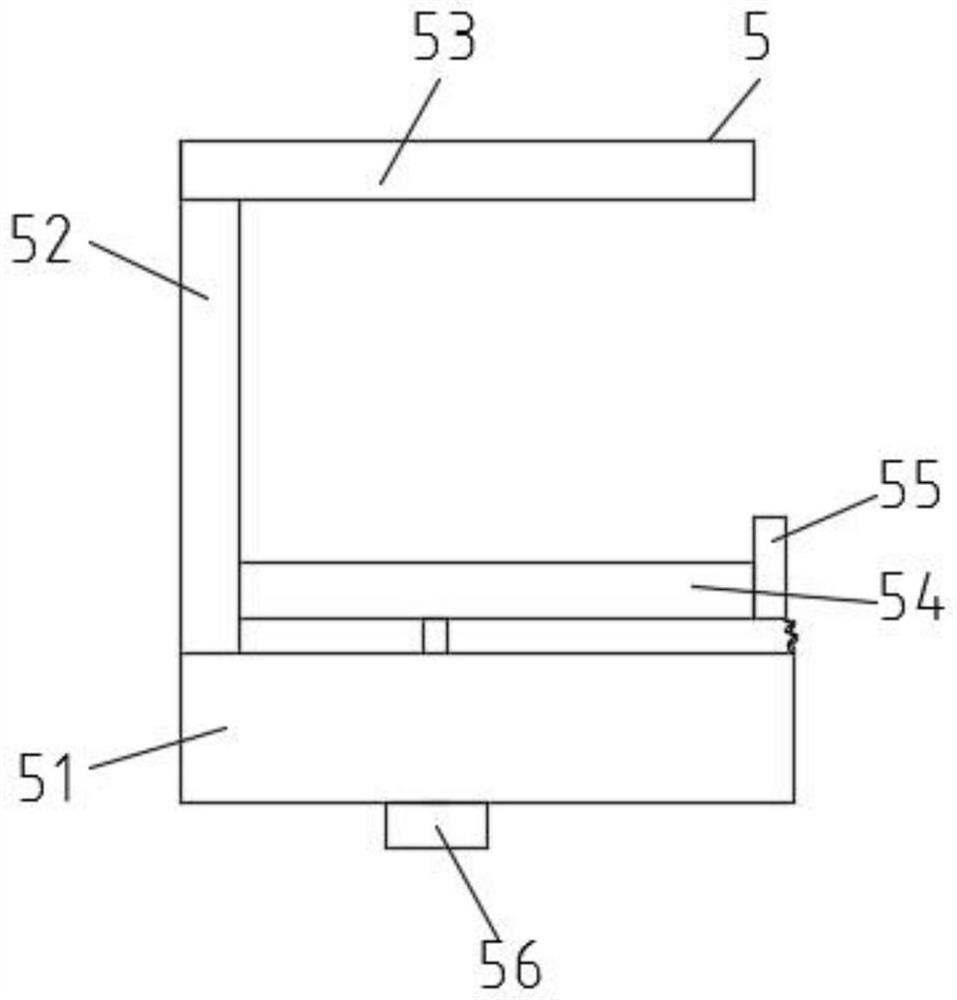

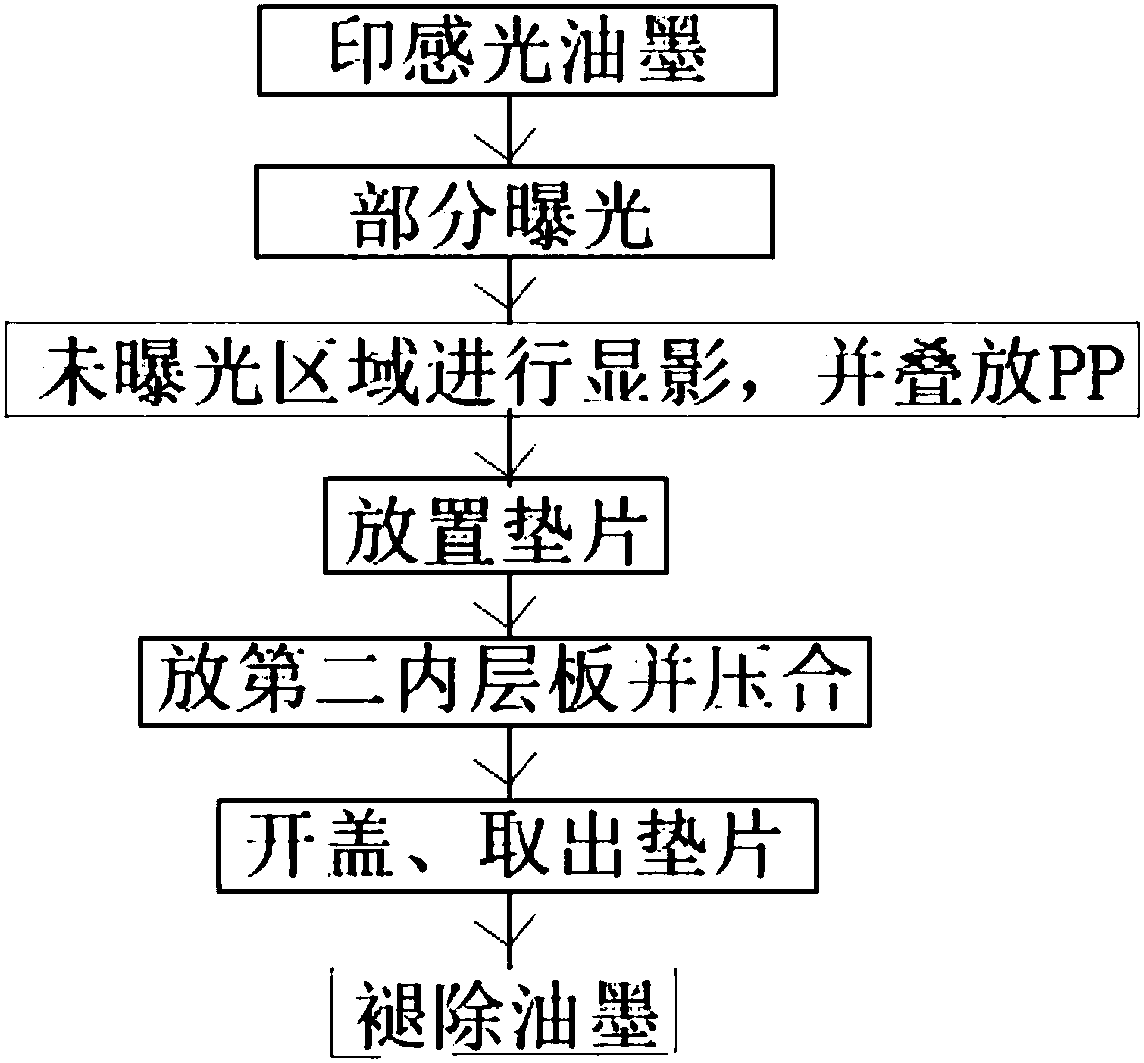

Method for processing excess tape of communication IC metal-based carrier board

InactiveCN108207086ASolve cleaning problemsReduce scrap rateLithography/patterningPost-manufacturing circuit processesEngineeringMetal

The invention discloses a method for processing the excess tape of a communication IC metal-based carrier board. The method comprises steps that firstly, the first inner board is entirely printed withphotosensitive ink; secondly, the ink of a grooving area of the first inner plate is exposed; thirdly, the ink of an unexposed area of the first inner plate is developed to remove the ink; fourthly,the PP is stacked at the area after development, and a gasket is arranged at the area without the PP; fifthly, a second inner plate is arranged at an upper surface of the PP and the gasket, and high temperature stitching is carried out; the second inner plate after stitching is opened, and the gasket is taken out; after the gasket is taken out, the ink is removed. The method is advantaged in thatthe first inner plate is printed with the ink for protection, both the PP powder and the PP residual tape drop on the ink in the whole stacking and stitching process, only through removing the ink, the PP powder and the PP excess tape disappear naturally, and manual grinding is not needed.

Owner:WUXI SHENNAN CIRCUITS CO LTD

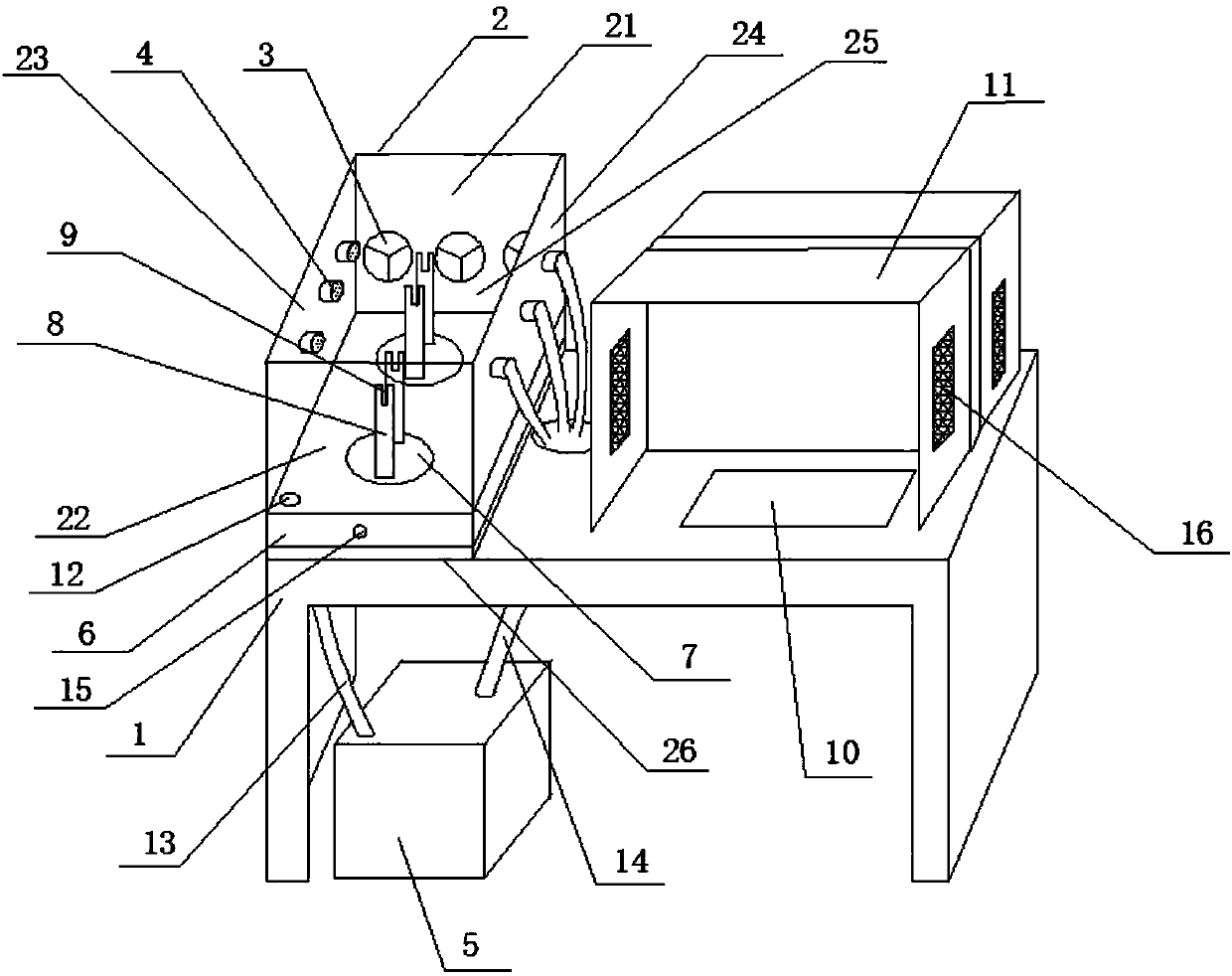

Combined circuit board maintenance platform

InactiveCN107931202AEasy to cleanImprove cleaning efficiencyPost-manufacturing circuit processesDrying gas arrangementsSmall footprintEngineering

The invention provides a combined circuit board maintenance platform, which includes a workbench, on which a cleaning device and a maintenance device are sequentially arranged from left to right. The cleaning device includes a cleaning box, a fan, a nozzle and a water tank. The cleaning box is a cube structure. The fan and the nozzle are arranged inside the cleaning box, the fan is arranged on the back surface of the cleaning box, the nozzles are arranged on the left surface and the right surface of the cleaning box, and a drawing plate is movable on the lower surface of the cleaning box. A turntable is provided, and two support columns are arranged opposite to the turntable, the two support columns are perpendicular to the turntable, the top of the support column is provided with a groove, the groove is perpendicular to the drawing plate, the maintenance device includes a maintenance slot and a rectangular baffle, The maintenance tank is arranged on the lower surface of the workbench, and the rectangular baffle is arranged on the upper surface of the workbench. The invention has the advantages of simple structure, good cleaning effect, and small occupied area.

Owner:TIANJIN HUAMAI TECH

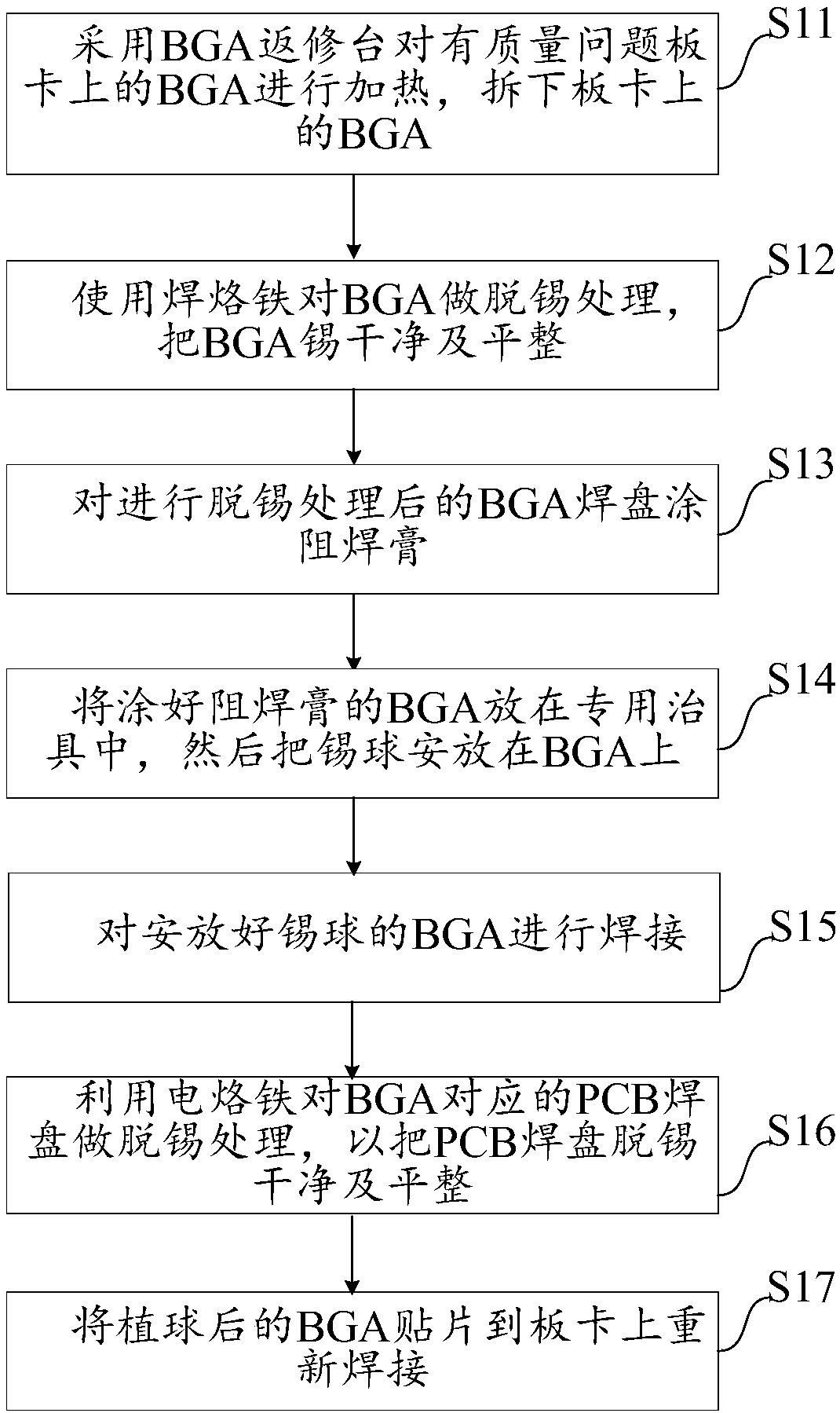

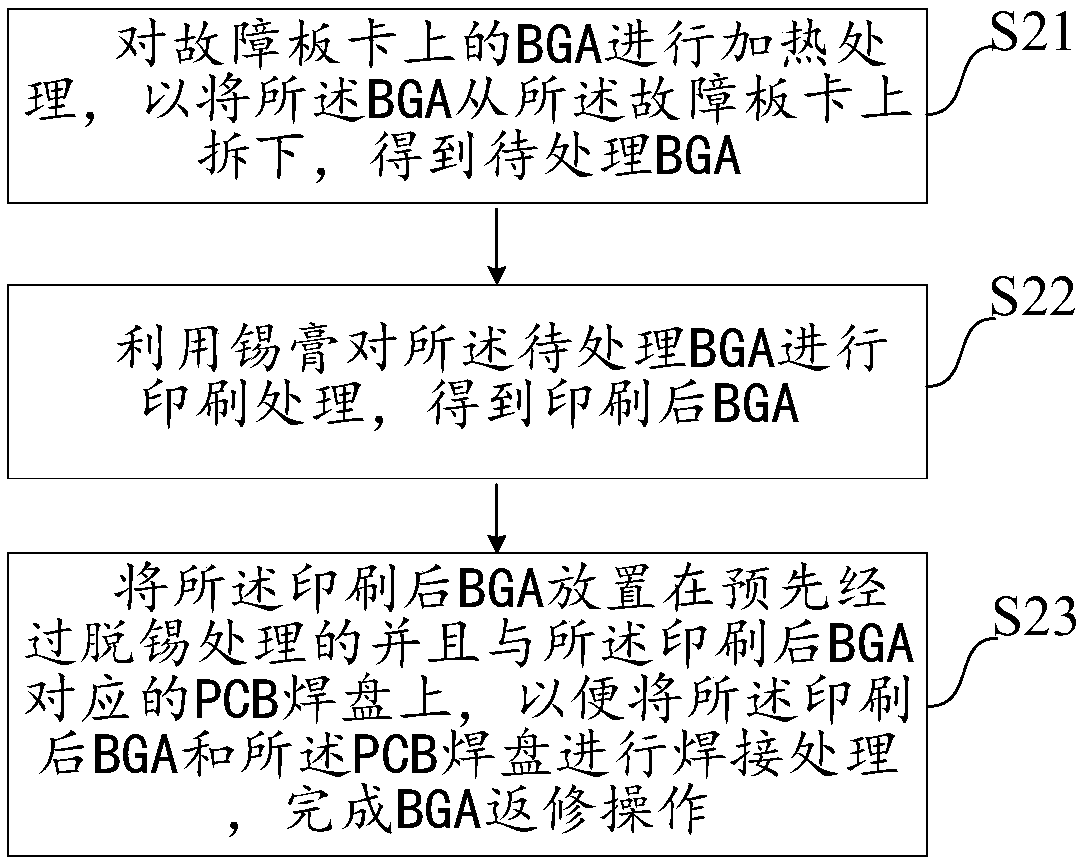

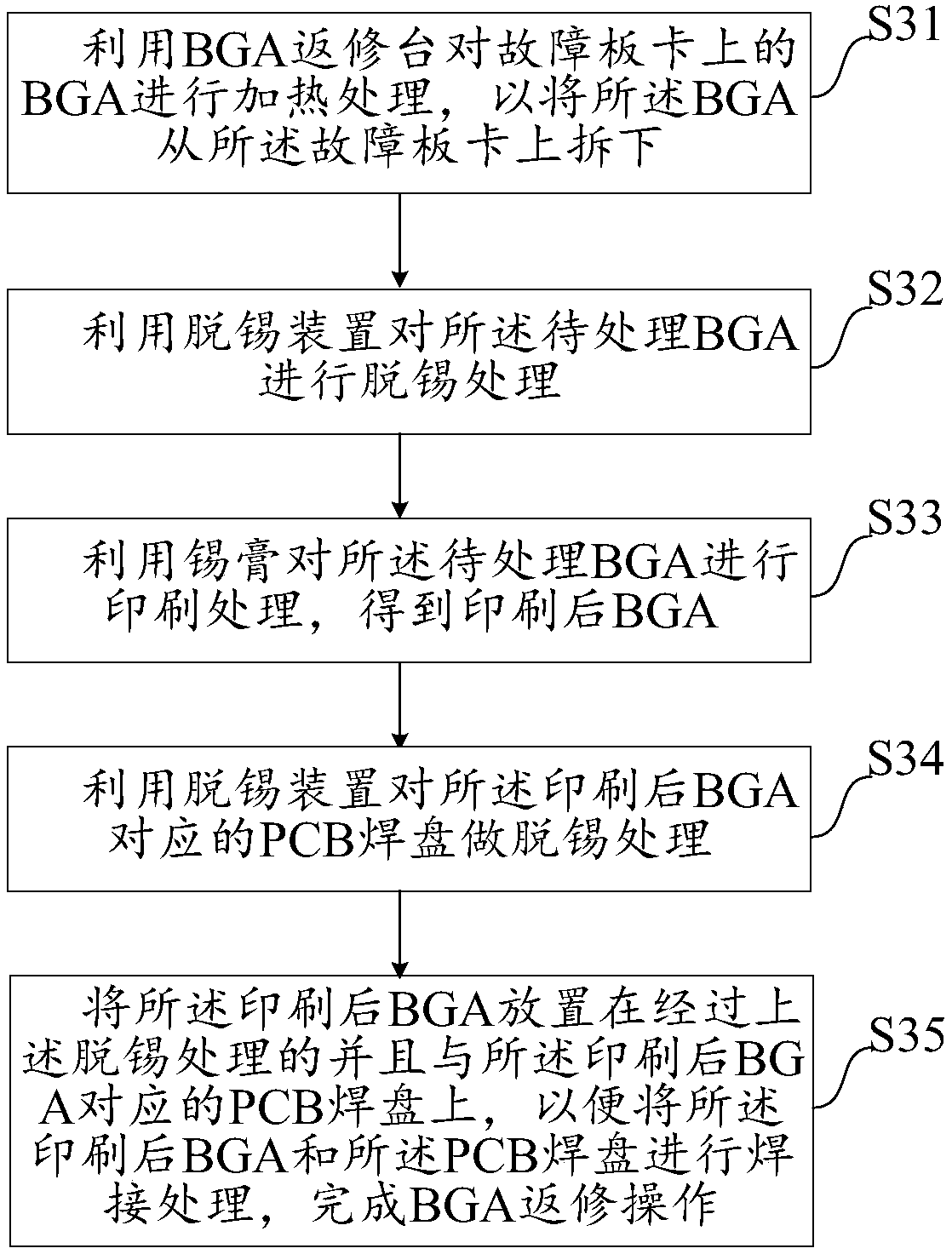

BGA repair method, apparatus and system

InactiveCN107864567AReduce the number of heat treatmentsShort processPost-manufacturing circuit processesPrinted circuits repair/correctingRepair methodTin

The invention discloses a BGA repair method, apparatus and system. The repair method comprises the steps of performing heating treatment on a BGA on a fault board card to detach the BGA from the faultboard card to obtain a to-be-processed BGA; performing printing treatment on the to-be-processed BGA by tin paste to obtain a printed BGA; and putting the printed BGA on a PCB bonding pad which is subjected to de-tinning treatment in advance and corresponding to the printed BGA, so as to perform welding treatment on the printed BGA and the PCB bonding pad to complete BGA repair operation. By virtue of the BGA repair method disclosed in the invention, number of times of high-temperature treatment on the BGA chip can be reduced, thereby lowering influence of a high temperature to the BGA chip,and dramatically prolonging the service life and improving reliability of the BGA chip.

Owner:GUANGDONG VTRON TECH CO LTD

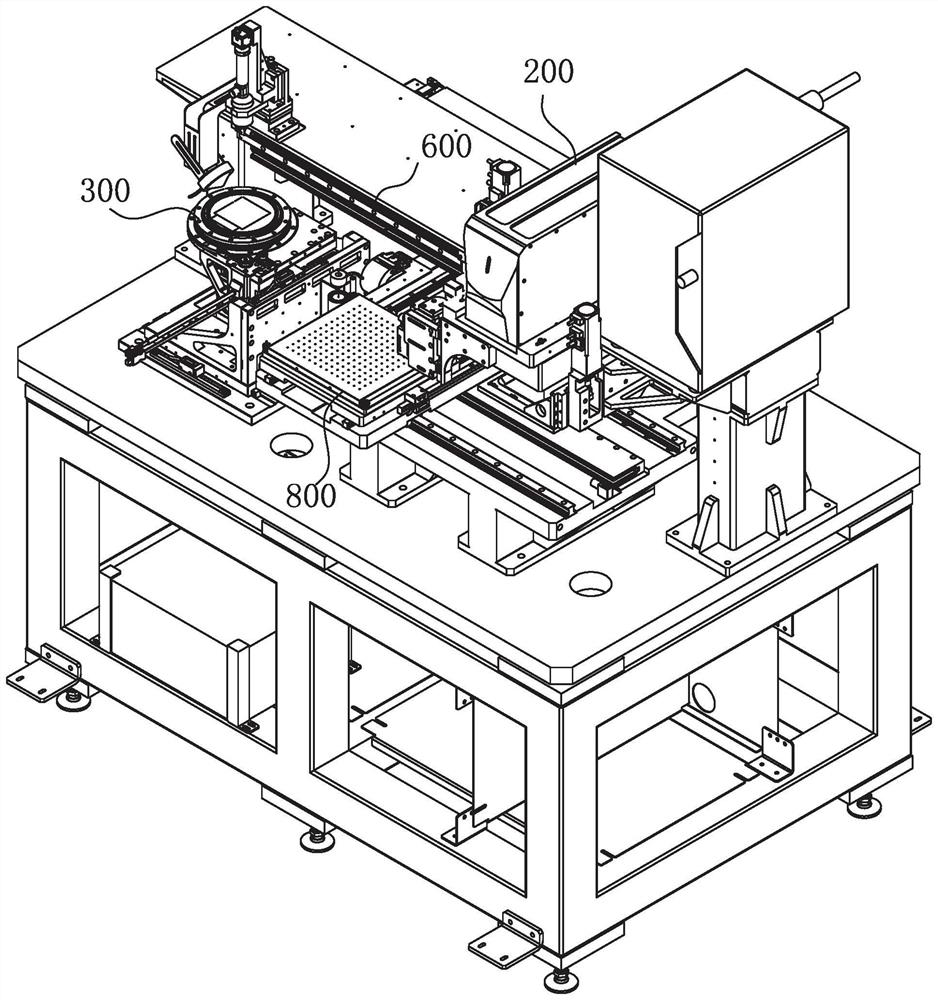

Micro-carving repairing machine for detecting and repairing short circuit of PCB

PendingCN112432959ASolve the problem that the surface short circuit is difficult to repairLow costPost-manufacturing circuit processesMaterial analysis by optical meansMetal impuritiesEngineering

The invention provides a micro-carving repairing machine for detecting and repairing a short circuit of a PCB, which comprises a main control machine table, a processing table, a support frame, a first driving device, a first sliding platform, a second driving device, a second sliding platform, a first camera device, a processing device, a tool setting device and a third driving device. The firstcamera device and the machining device both face the machining table. The main control machine table is electrically connected with the first driving device, the second driving device, the first camera shooting device, the machining device, the tool setting device and the third driving device. The micro-carving repairing machine for detecting and repairing the short circuit of the PCB can effectively solve the problem that the short circuit of the surface layer is difficult to repair due to large residual copper, metal impurities or contact between adjacent metals during printing in the conventional PCB, so that the material cost of an enterprise is effectively saved.

Owner:深圳市中源创科技有限公司

Circuit board repair welding device enabling convenience in observing circuit board

InactiveCN107949181AAdjustable angleEasy to observePrinted circuit assemblingPost-manufacturing circuit processesMotor driveElectric machine

The invention provides a circuit board repair welding device for convenient observation of boards, which includes a base and a vertical box fixed on the base. The back of the vertical box is fixed with a lifting cylinder, and the lifting cylinder drives a lifting device. The lifting device is fixed with a first motor, and the first motor drives a first lead screw, and the vertical box is also provided with a second motor, and the second motor drives a second lead screw, and the first lead screw is driven by the first motor. The end of the lead screw is provided with a first rotating motor, and the end of the second lead screw is provided with a second rotating motor, and the first rotating motor and the second rotating motor are respectively connected with a matching first clamping block and a second rotating motor. Two clamping blocks. The invention enables the angle of the circuit board to be repaired to be adjusted, and allows repair workers to observe the front and back sides of the circuit board very conveniently.

Owner:TIANJIN HUAMAI TECH

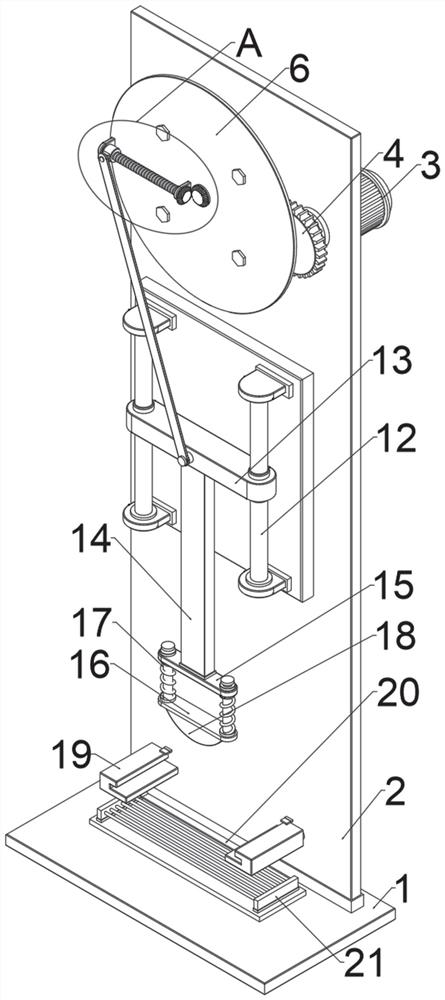

Stabilizing equipment for inspection and maintenance of industrial intelligent internet circuit board

ActiveCN113141725AEasy to operatePost-manufacturing circuit processesPrinted circuits repair/correctingSmart internetIndustrial engineering

The invention relates to stabilizing equipment, in particular to stabilizing equipment for inspection and maintenance of an industrial intelligent internet circuit board. The technical problem of the invention is to provide the stabilizing equipment for inspection and maintenance of the industrial intelligent internet circuit board, which is convenient to inspect and easy to operate. According to the technical scheme, the stabilizing equipment for inspection and maintenance of the industrial intelligent internet circuit board comprises a base; a shell arranged in the middle of the base; a first supporting frame arranged on one side of the base; a seat cushion arranged on the first support frame in a sliding manner; a placing assembly arranged at the upper middle part of the base; a fixing assembly arranged on the upper side of the placing assembly; and a pedal assembly arranged in the middle of the placing assembly. The maintenance tool storage device has the beneficial effects that maintenance tools can be placed in the storage frame by people, and when a pedal moves downwards to make contact with a lower pressing rod, a second rack can drive the storage frame to move forwards, so that people can operate the maintenance tool storage device more conveniently.

Owner:江西威尔高电子股份有限公司

Circuit board bonding pad correction device

ActiveCN113709998AAvoid damageReduce forcePost-manufacturing circuit processesPrinted circuits repair/correctingEngineeringStructural engineering

The invention relates to a circuit board bonding pad correction device, and the device comprises a frame structure which is movably provided with a liftable elastic plate, and the elastic plate being used for correcting a bent circuit board bonding pad; a fixing assembly, arranged on the frame body structure and used for carrying a circuit board bonding pad; a tending mechanism, arranged on the frame body structure, and the tending mechanism being used for driving the elastic plate to do lifting motion in the space vertical direction so as to correct a circuit board bonding pad arranged on the fixing assembly, and in the continuous action process of the tending mechanism, the amplitude of driving the elastic plate to do lifting motion being smaller and smaller; a guiding assembly, arranged on the frame body structure and connected with the trend mechanism and the elastic plate, and when the trend mechanism acts, the guiding assembly driving the elastic plate to do lifting motion, so that the bonding pad of the circuit board is corrected.

Owner:怀化海红盛电子科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com