Modifying method for hot pressed golden finger warping of repaired flexible printed circuit board

A flexible circuit board and gold finger technology, which is applied in printed circuit maintenance/correction, printed circuit secondary treatment, post-manufacturing process, etc., can solve problems affecting product hot pressing yield, and achieve cost saving and material waste reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

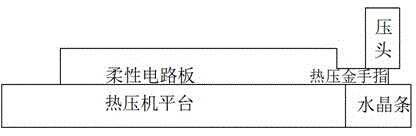

[0011] Describe the operation steps in detail with examples, such as figure 1 As shown, the tools used include dust-free cloth, alcohol, ACF remover, electrostatic wrist strap, and anti-static gloves; the steps are as follows,

[0012] Wear an electrostatic bracelet and anti-static gloves, and use an oil-based pen to indicate the cause of the defective product in detail on the back of the product after analysis;

[0013] 1. Gently tear off the flexible circuit board from the base material at a high temperature of 250±10°C, and determine the high-temperature scalding time according to the size of the flexible circuit board.

[0014] 1. Use a cotton swab to stick a small amount of anisotropic conductive adhesive remover to wipe off the anisotropic conductive adhesive on the hot-pressed gold finger of the flexible circuit board, and then clean the flexible circuit board with alcohol.

[0015] 1. Place the flexible circuit board with the hot-pressed gold finger faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com