Flexible circuit board processing method and device and apparatus

A flexible circuit board and processing method technology, applied in circuit devices, printed circuit grounding devices, printed circuits, etc., can solve problems such as reducing production costs, improving product yield, and dead conductive glue, so as to reduce production costs and improve Product yield, the effect of reducing the grounding resistance of the steel sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

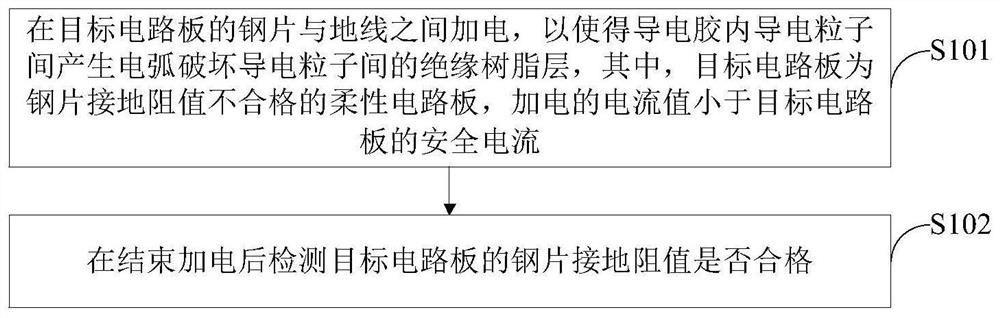

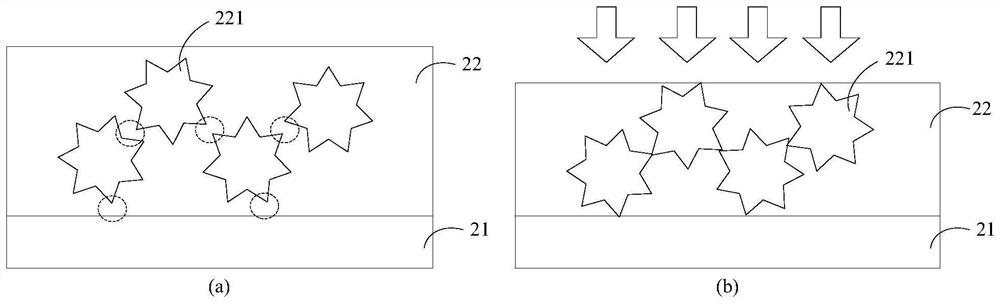

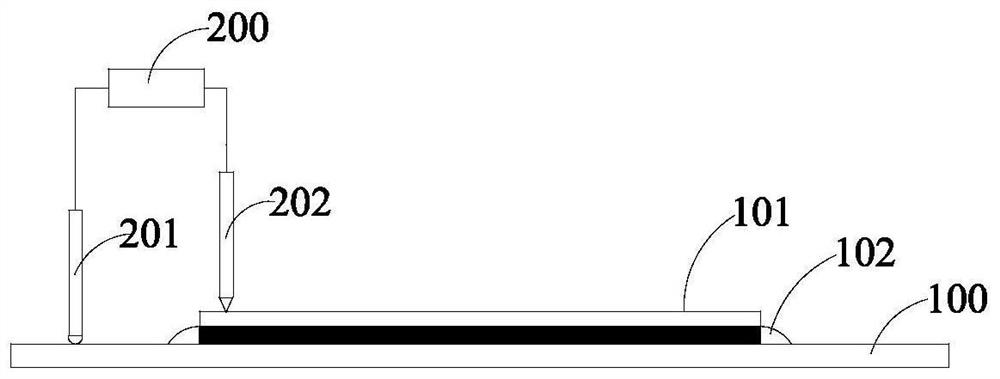

[0025] The embodiment of this specification provides a flexible circuit board processing method, by applying electricity between the steel sheet surface and the ground wire of the FPC whose steel sheet grounding resistance is unqualified, so that an arc is generated between the conductive particles in the conductive adhesive to destroy the insulating resin layer , so that the resistance value of the conductive adhesive is reduced and good conductivity is obtained, and the grounding resistance of the steel sheet is effectively reduced. When it is reduced to meet the qualified requirements, the defective product can be transformed into a good product and continue to be put into production, which is conducive to reducing the production scrap of FPC Quantity, improve product yield, reduce production costs.

[0026] In order to better understand the technical solutions provided by the embodiments of this specification, the technical solutions of the embodiments of this specification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com