Rear-mounted axis clamping sealing sleeve of fan

A rear-mounted, sealed-sleeve technology, applied in non-variable volume pumps, components of pumping devices for elastic fluids, machines/engines, etc. Achieve the effect of preventing less or missing assembly, high product stability, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

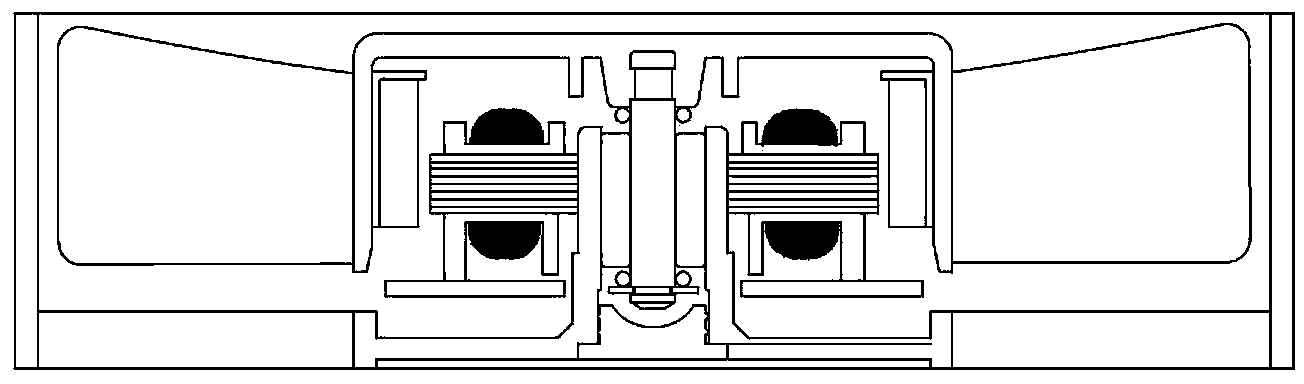

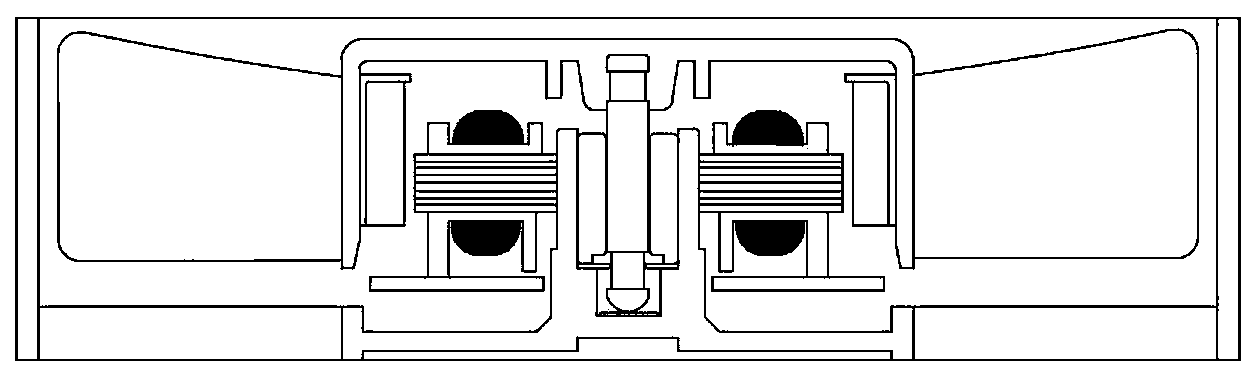

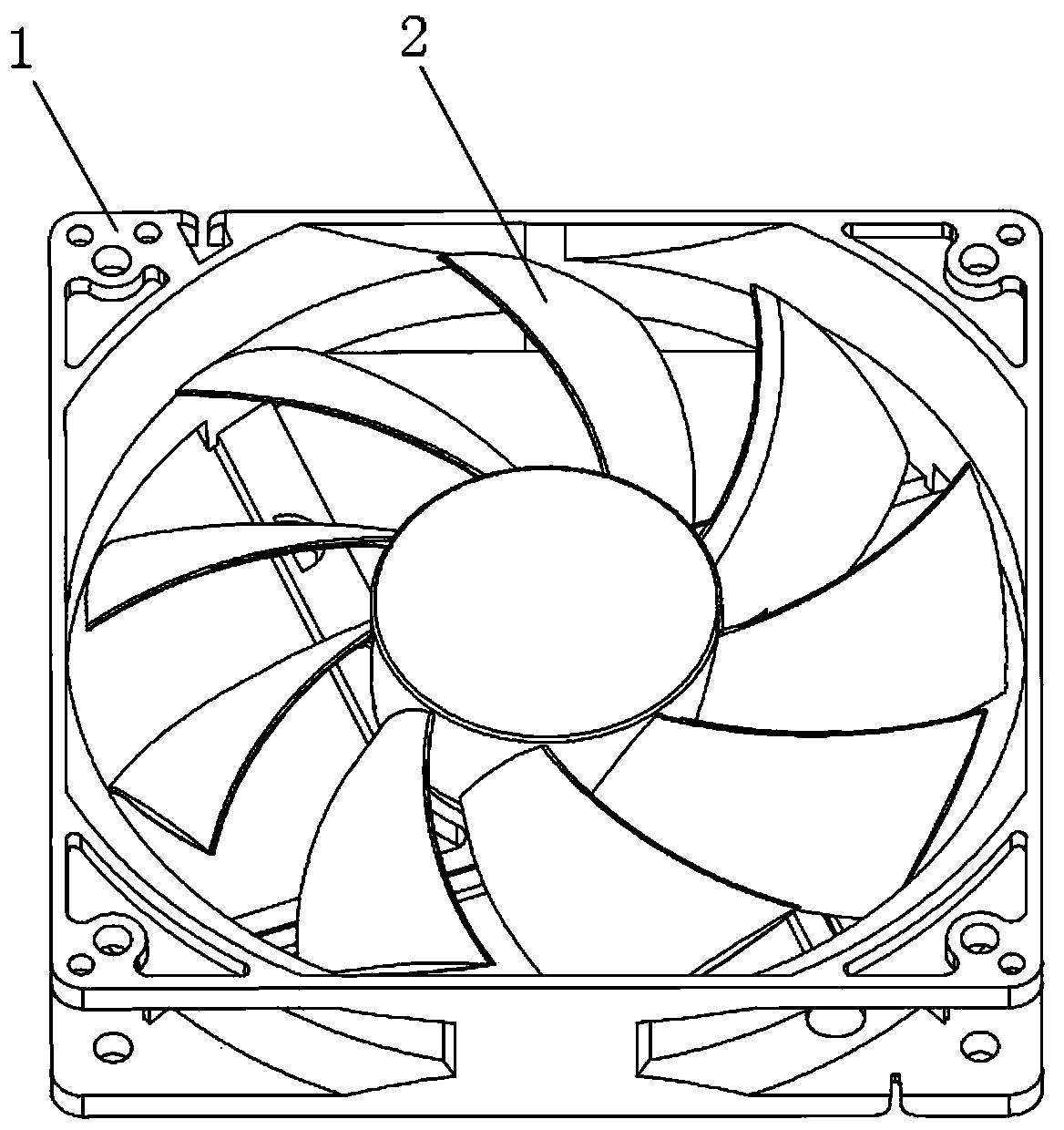

[0020] Such as Figure 3-5 As shown, a fan rear-mounted axial buckle sealing sleeve includes a fan frame 1, a fan blade 2 rotatably installed in the fan frame 1, and a drive device 3 installed in the fan blade 2. The fan blade 2 is provided with a drive The device 3 contains a cavity 4, the center of the cavity 4 is provided with a rotation axis 5, and the axis 5 is set with a bearing 6, the driving device 3 is coaxially installed in the cavity 4 on the rotation axis 5, and the drive shaft The rotation of the core 5 drives the fan blade 2 to rotate. The fan frame 1 is equipped with a rear-mounted shaft buckle sealing sleeve 15. The rear-mounted shaft buckle sealing sleeve 15 is integrally provided with a wear-resistant plate 7. The rear-mounted shaft buckle is sealed. The sleeve 15 is provided with a shaft center buckle 8 and a three-point fixed buckle 9. The shaft center buckle 8 is fastened to the shaft center 5 on the fan blade 2, so that the fan blade 2 is rotatably instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com