Combined circuit board maintenance platform

A maintenance platform and circuit board technology, which is applied in printed circuit maintenance/calibration, printed circuit, printed circuit manufacturing, etc., can solve problems such as low work efficiency, large equipment volume, time-consuming and laborious, etc., to avoid circuit board damage and equipment structure Simple, effective cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

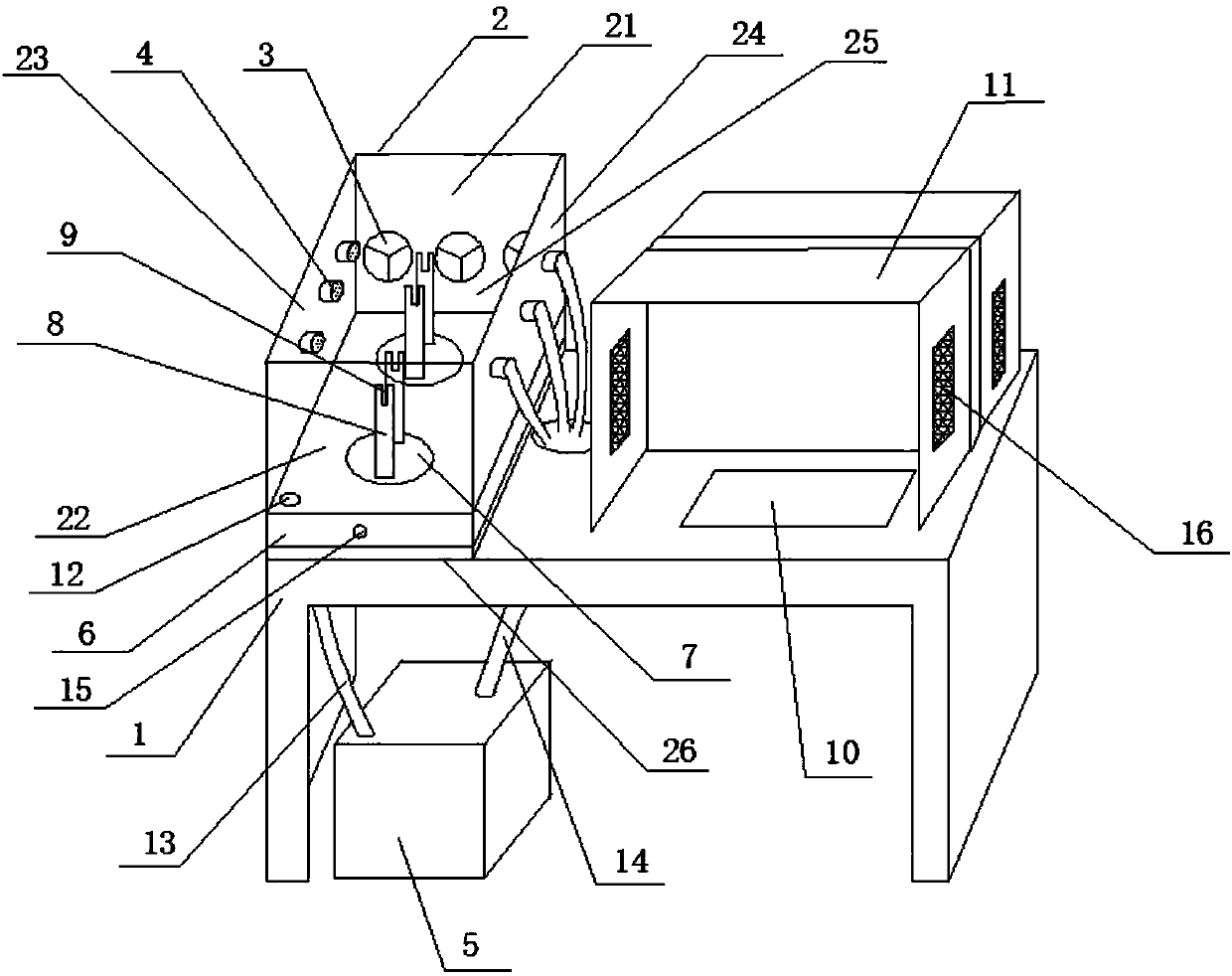

[0017] Such as figure 1 As shown, a combined circuit board maintenance platform includes a workbench 1, on which a cleaning device and a maintenance device are sequentially arranged from left to right, and the cleaning device includes a cleaning box 2, a fan 3, and a nozzle 4 And the water tank 5, the cleaning box 2 is a cube structure, the fan 3 and the nozzle 4 are arranged inside the cleaning box 2, the fan 3 is arranged on the rear surface 21 of the cleaning box 2, the nozzle 4 It is arranged on the left surface 23 and the right surface 24 of the cleaning box 2, and a drawing plate 6 is movably arranged on the lower surface 26 of the cleaning box 2, and a turntable 7 is arranged on the drawing plate 6. Two support columns 8 are oppositely arranged on the turntable 7, and the two support columns 8 are perpendicular to the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com