Printed board crystal supplementing and repairing device

A printed circuit board and rework technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit secondary treatment, etc., can solve the problems of increased production process, many processes, increased cost, etc., to reduce product yield and reduce production process , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make those skilled in the art better understand the solution of the present invention, the present invention is further described in detail below with reference to the accompanying drawings and embodiments.

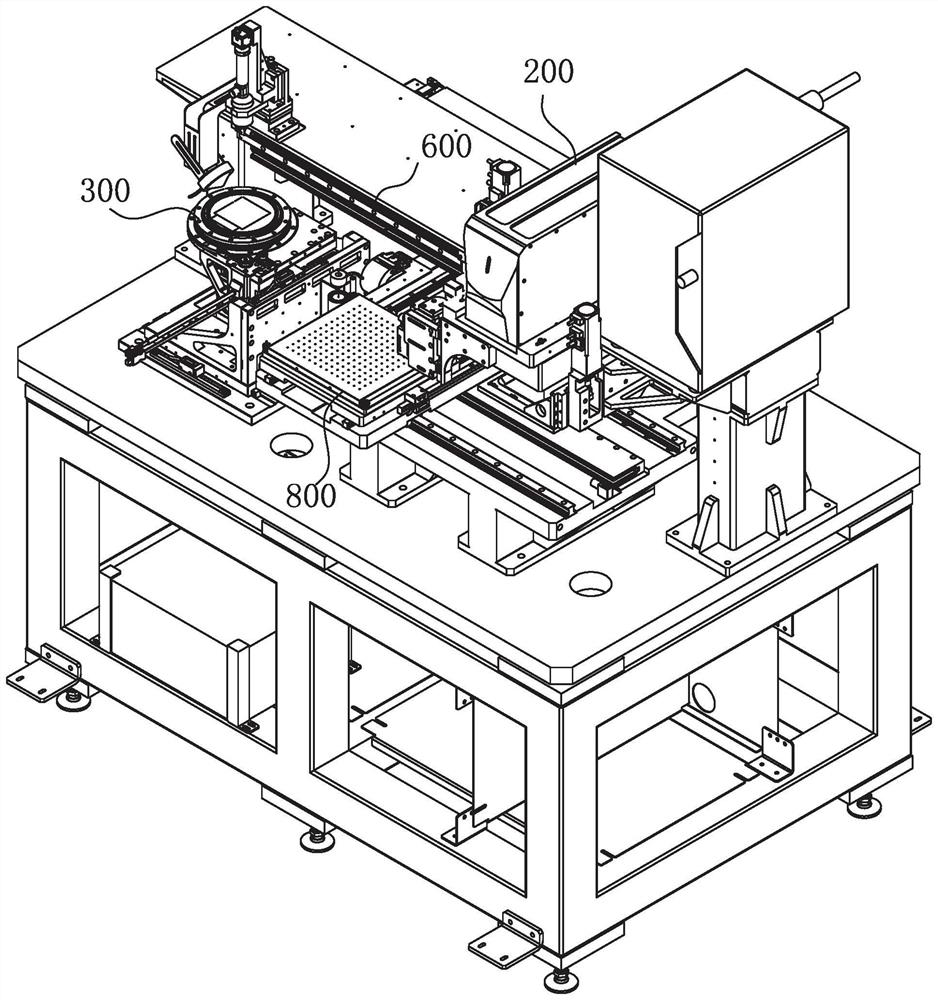

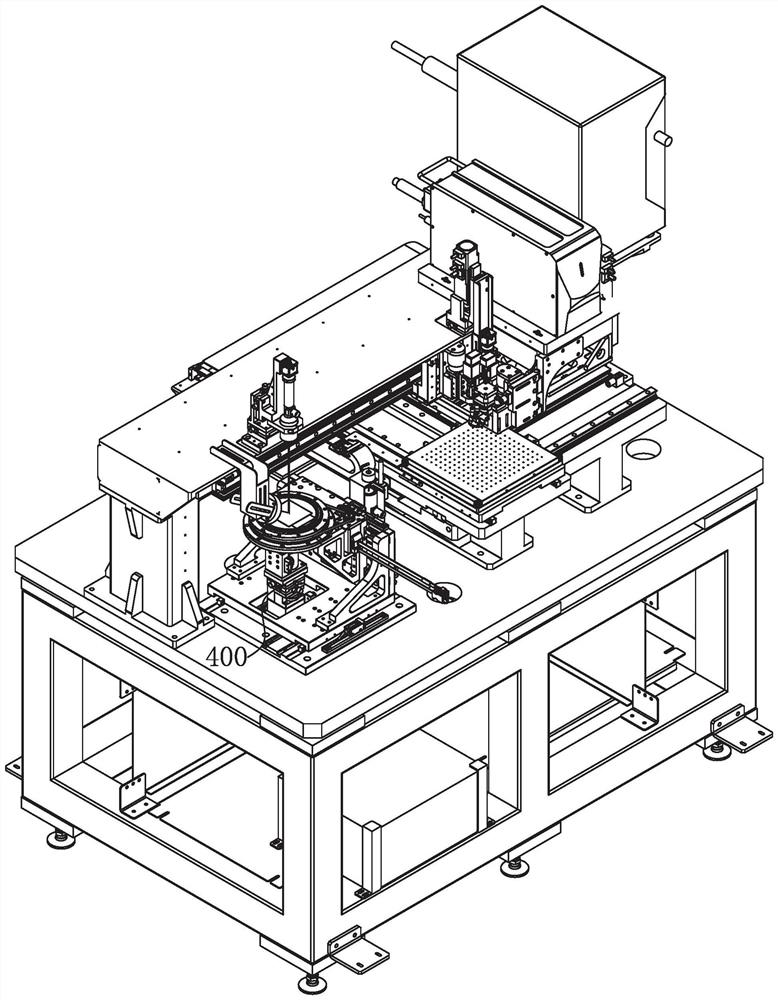

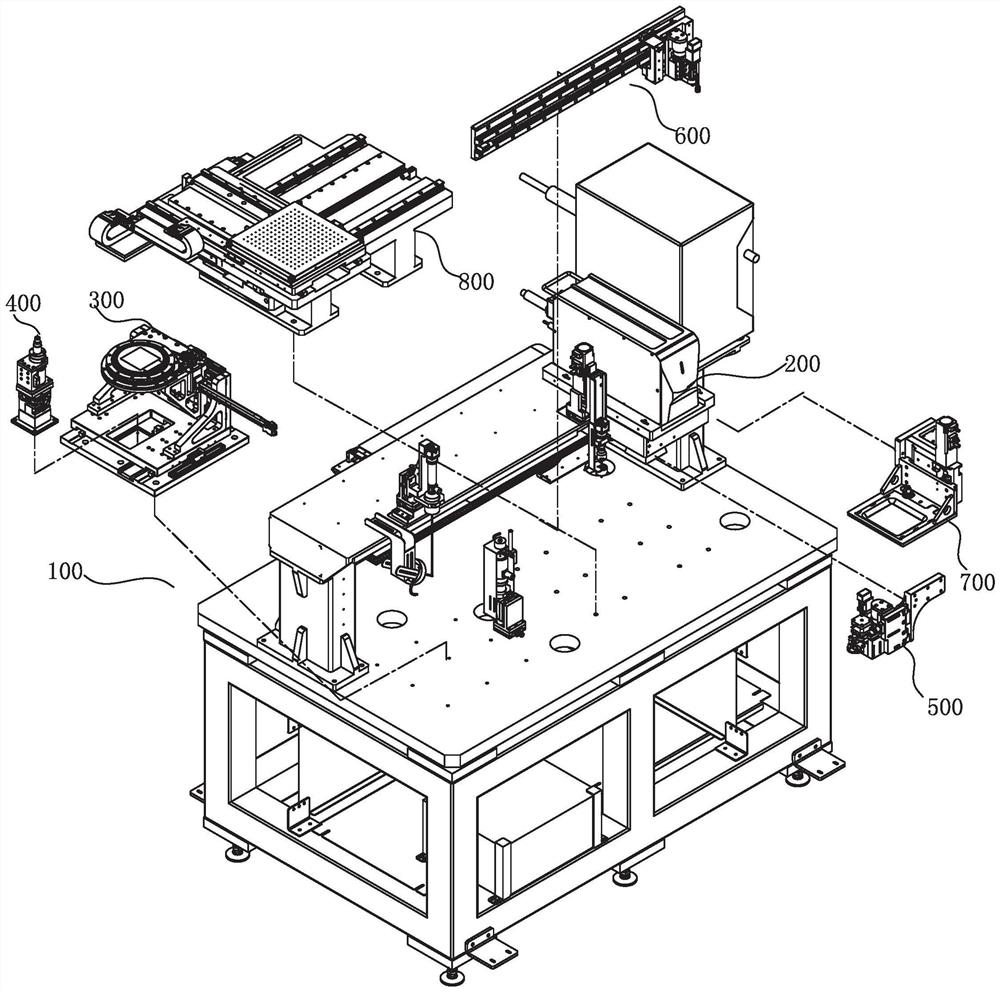

[0050] like Figure 1-3 As shown, an embodiment of the present invention provides a device for patching and repairing printed circuit boards, including a frame 100, and further comprising: a laser module 200 disposed on the frame; the laser module here is a commercially available standard part, namely Laser; film module 300, which is installed on the rack 100 for moving the blue film chip tray on which the chip is placed; needle module 400, which is installed on the rack 100 and is located below the blue film chip disk , used to impact the chip placed on the blue film chip tray; the dispensing module 500, which is arranged on the rack 100, is used to apply solder paste on the printed board where the chip needs to be filled; the nozzle module 600 , whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com