Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about "Non-electron-emitting anodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Information storage

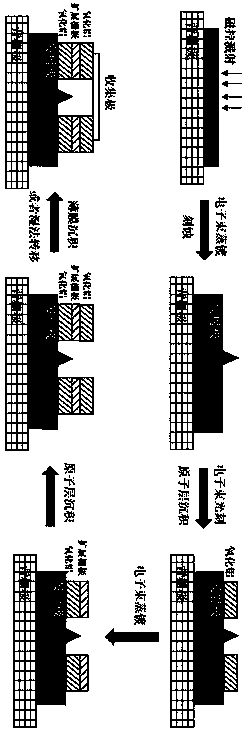

InactiveUS20060072427A1Increase speedImprove accuracyRead-only memoriesRecord information storageHigh energyPotential difference

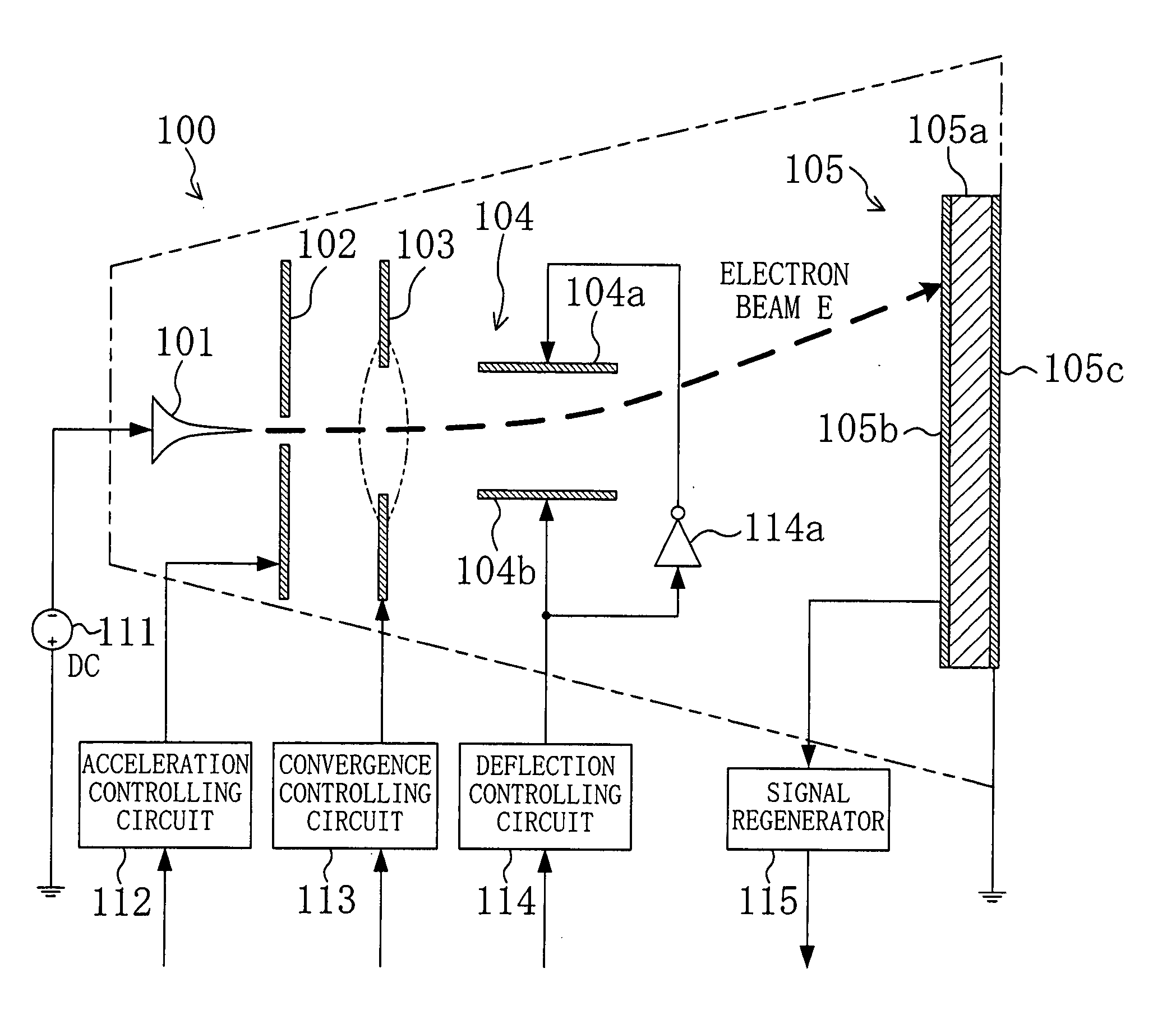

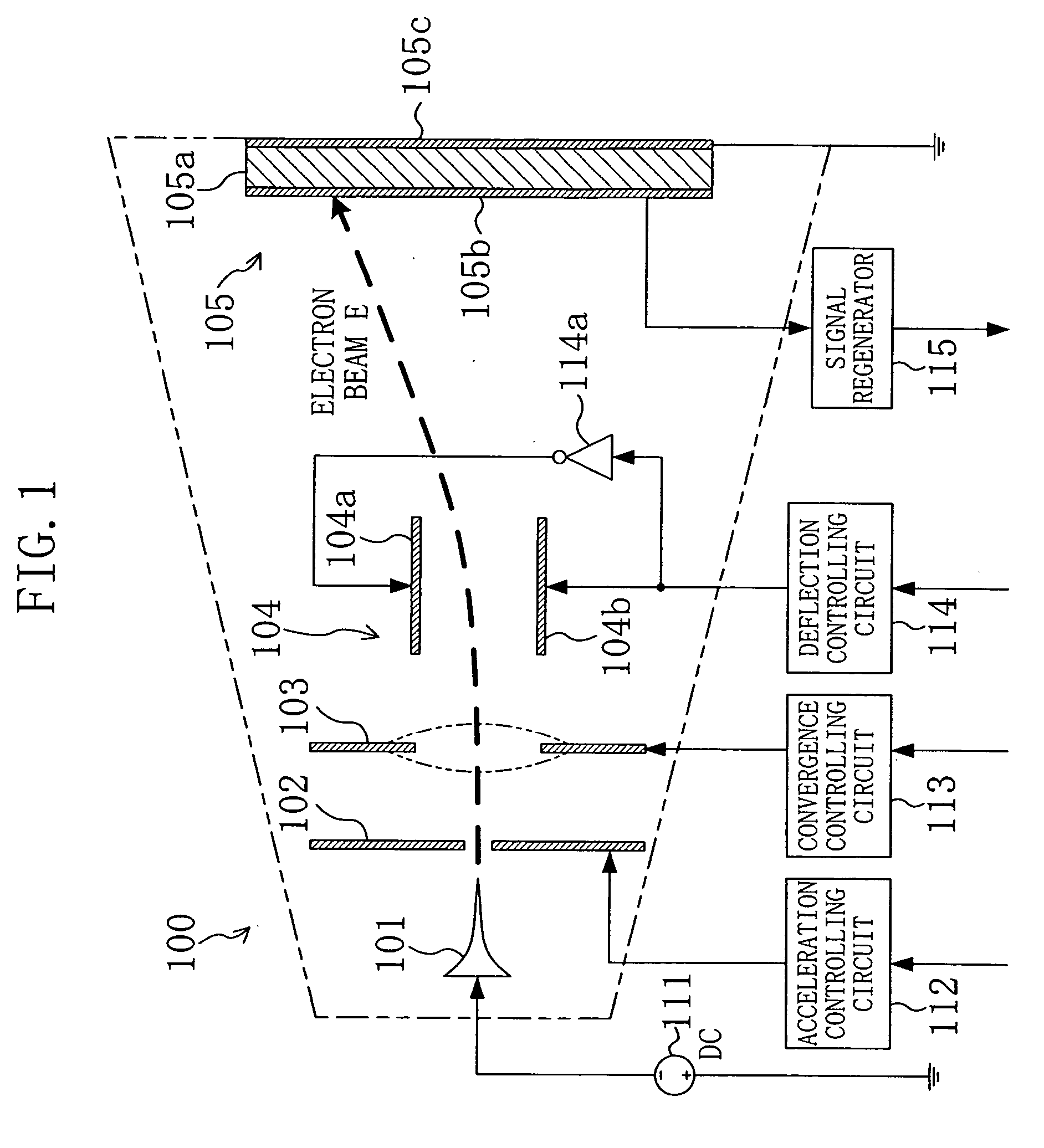

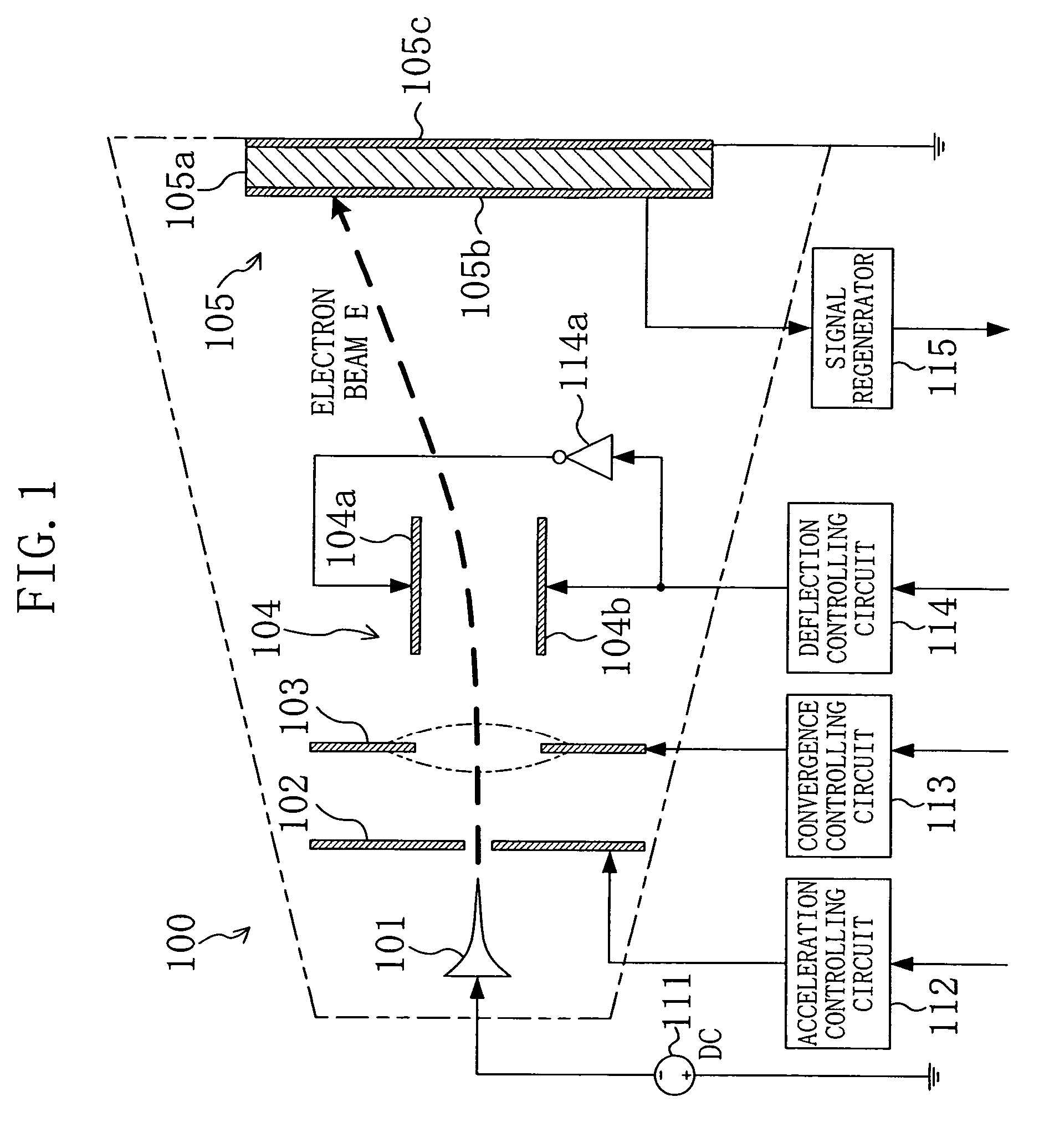

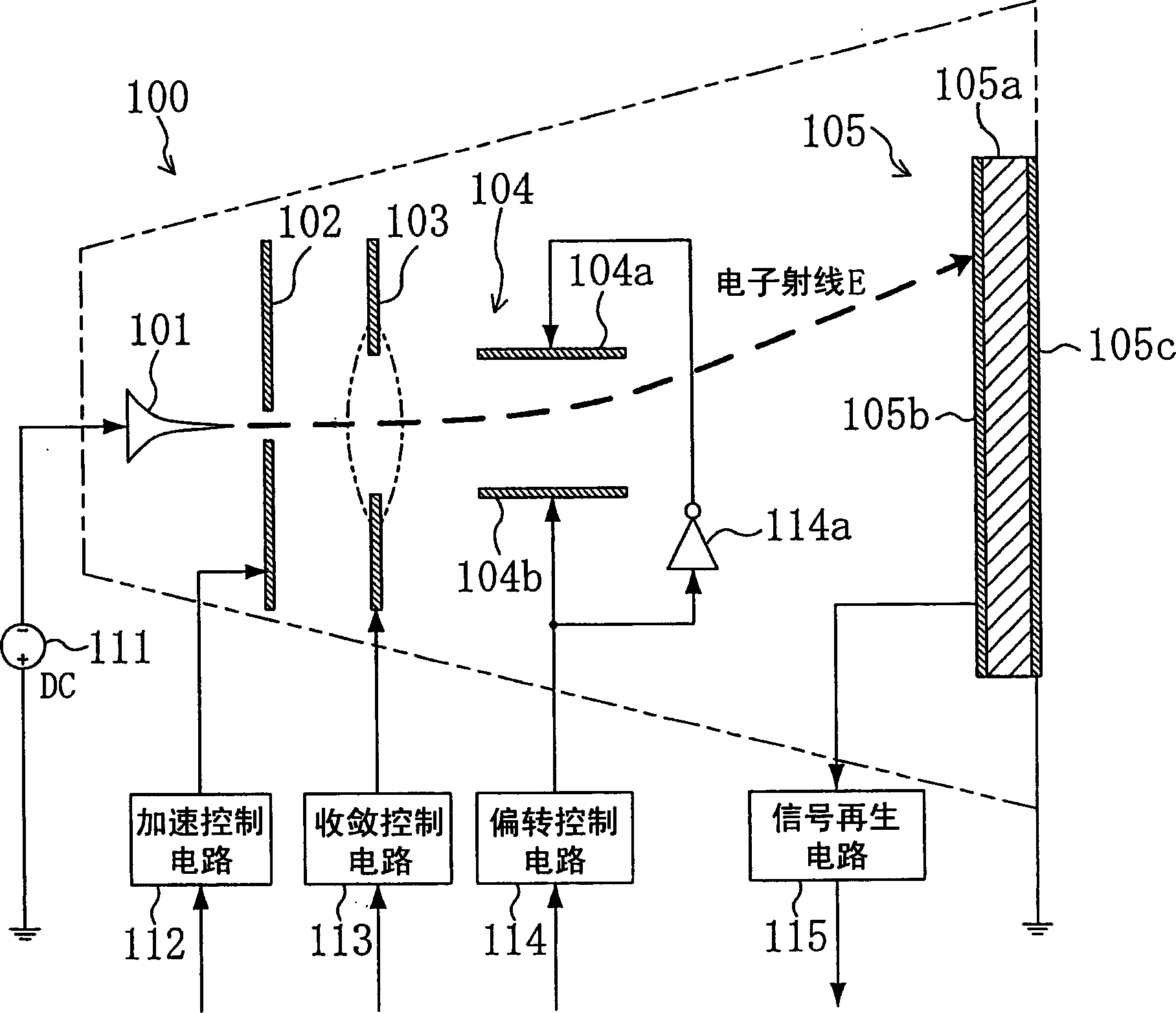

To greatly increase the storage density of a storage apparatus, an electron beam E emitted from a cold cathode 101 is accelerated by an accelerating electrode 102, caused to converge by a convergence electrode 103, deflected by a deflection electrode 104 and applied to a minute region of a storage film 105. The storage film 105 includes, for example, a phase change film 105a. The film is rapidly heated and cooled to change into an amorphous state upon irradiation with an electron beam E with high energy, while being gradually cooled to change into a crystallized state upon irradiation with an electron beam E with approximately intermediate energy, thereby storing data. Upon irradiation with an electron beam E with low energy, the potential difference between a detection electrode 105b and an anode 105c is detected depending on the state, i.e., the amorphous or crystallized state, thereby reading stored data.

Owner:PANASONIC CORP

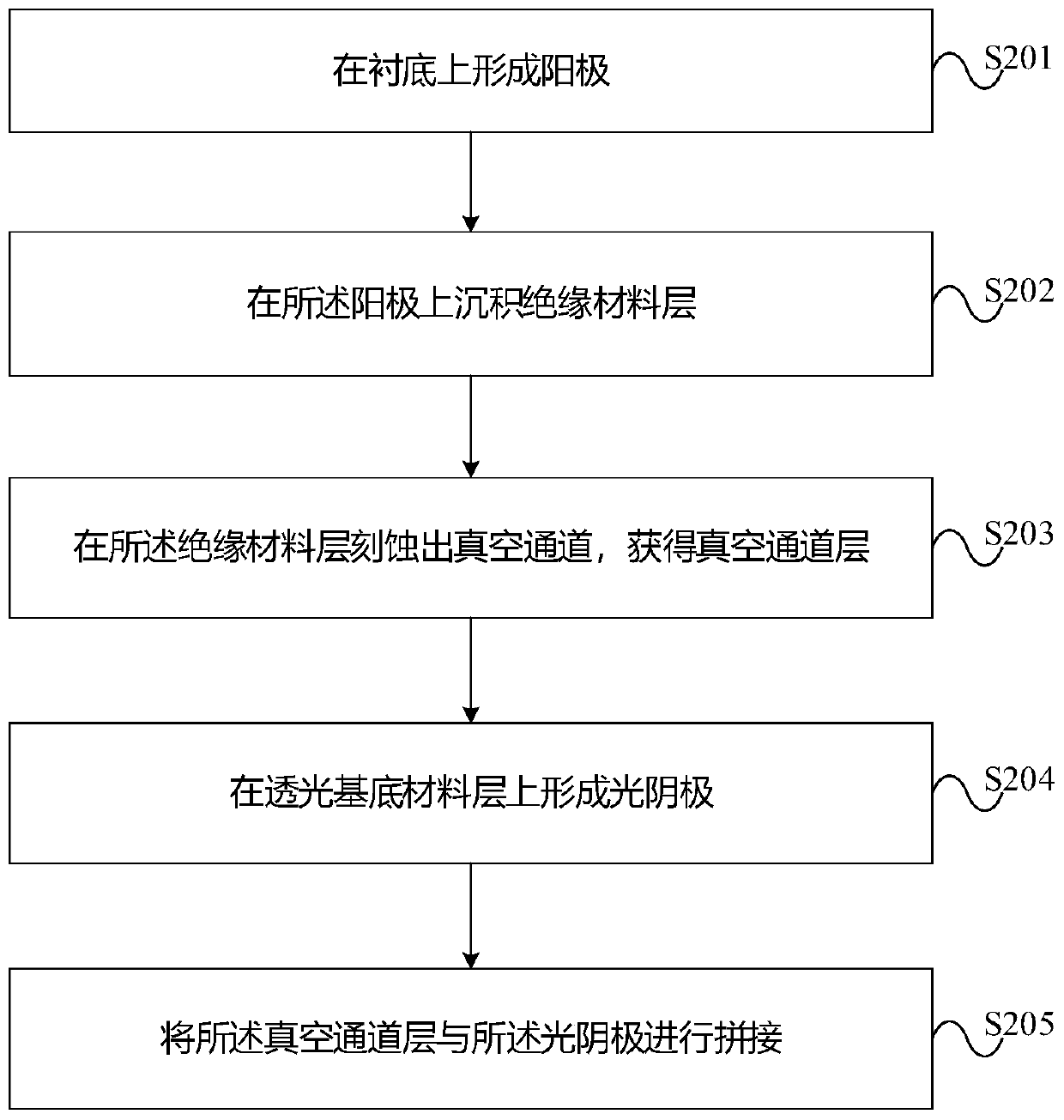

Nanometer vacuum triode structure with flip-chip-type anode, and preparation method

ActiveCN105118762AEasy to integrateReduce manufacturing difficultyNon-electron-emitting anodesTubes with electrostatic controlsMetal electrodesElectron

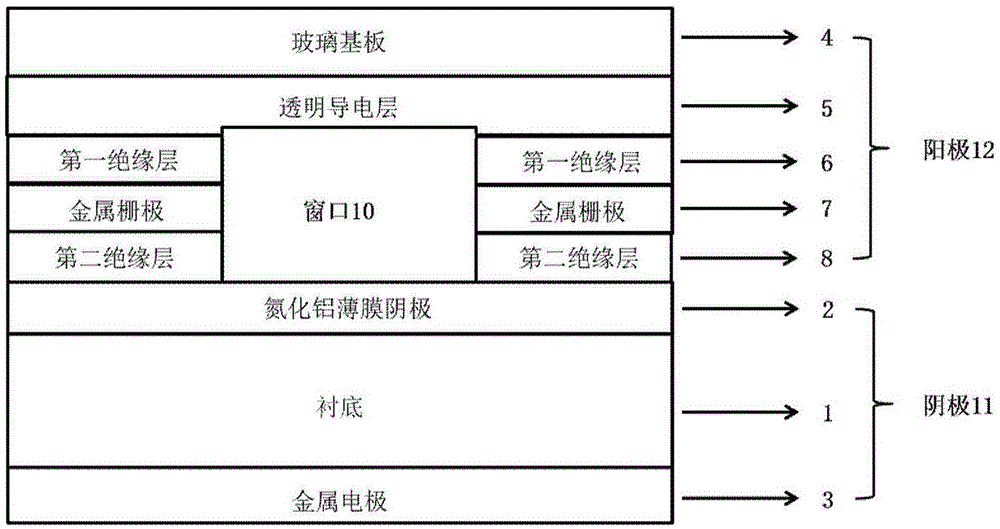

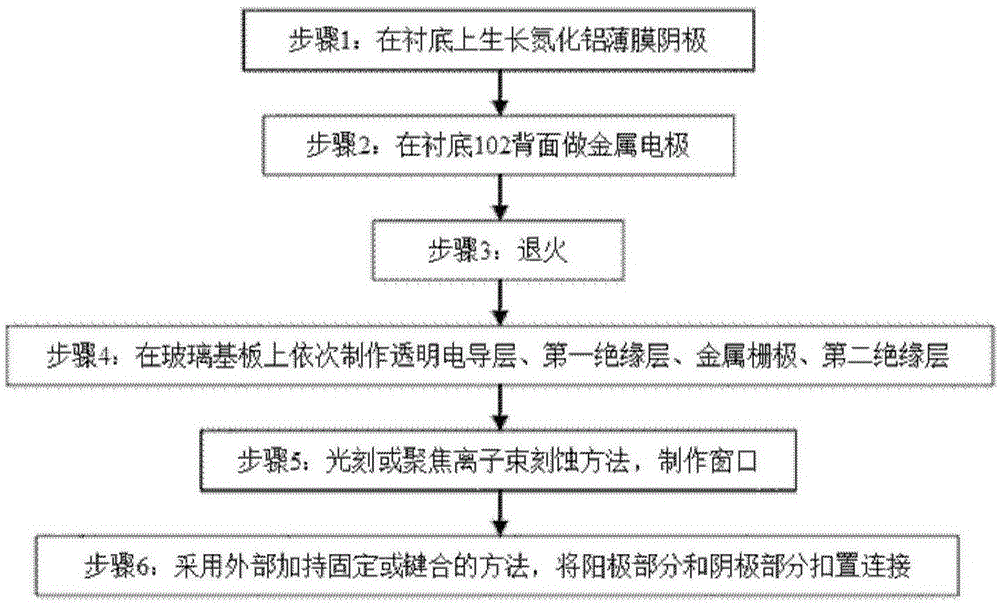

Provided is a nanometer vacuum triode structure with a flip-chip-type anode, comprising a substrate; an aluminum nitride film cathode growing on the front side of the substrate; a metal electrode manufactured on the back of the substrate, wherein the substrate, the aluminum nitride film cathode and the metal electrode form a cathode; a glass substrate; a transparent conducting layer manufactured on the glass substrate; a first insulating layer manufactured on the transparent conducting layer, wherein the intermediate part is a window; a metal gate manufactured on the first insulating layer, wherein the intermediate part is a window; and a second insulating layer manufactured on the metal gate, wherein the intermediate part is a window, and the glass substrate, the transparent conducting layer, the first insulating layer, the metal gate and the second insulating layer form an anode. The second insulating layer of the cathode and the aluminum nitride film cathode of the cathode are in buckled connection to form a nanometer vacuum triode structure with a flip-chip-type anode. The nanometer vacuum triode structure with a flip-chip-type anode overcomes deficiencies of a present nanometer vacuum triode structure, and can avoid cathode oxidation, improve the electronic collection capability of the anode, and facilitate flip-chip integration.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

High dose output, through transmission target X-ray system and methods of use

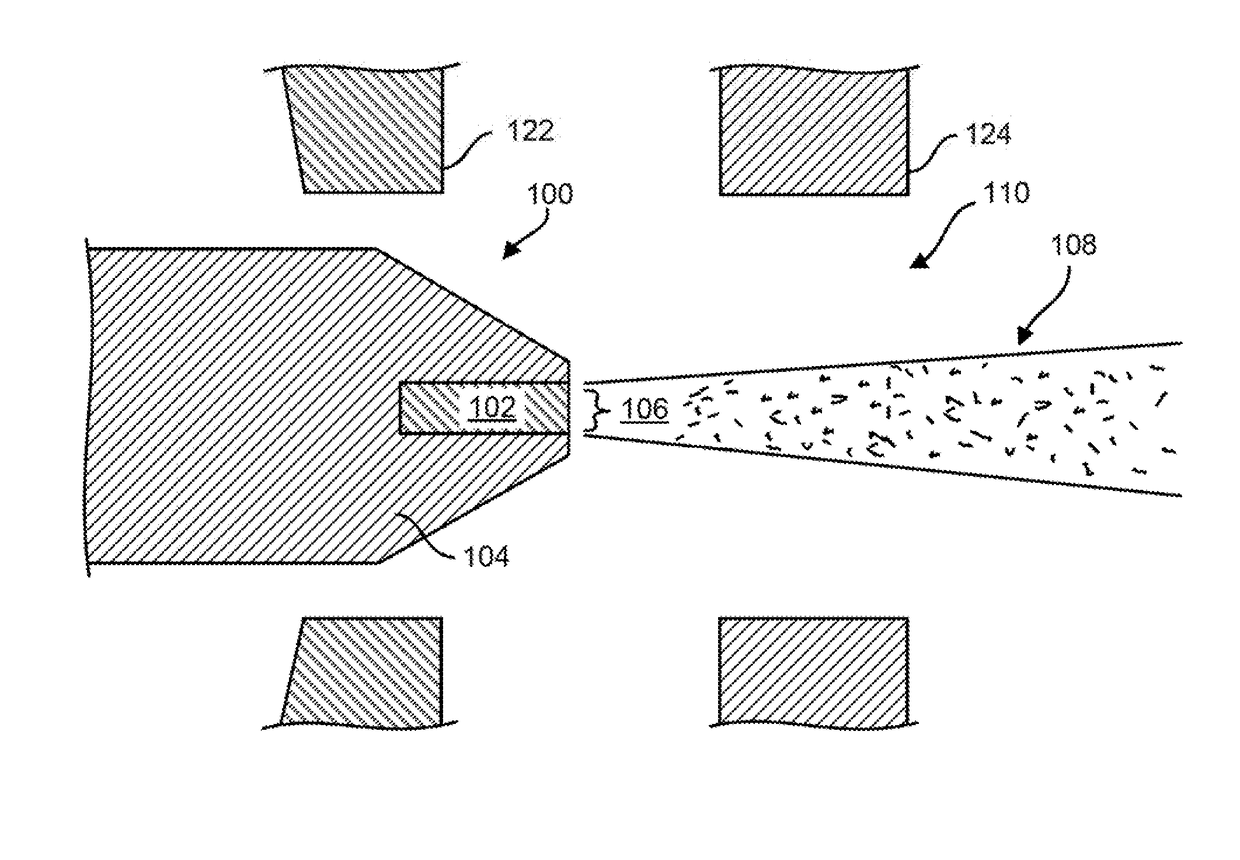

ActiveUS9818569B2Increase surface areaHigh outputX-ray tube electrodesVacuum tube vessels/containers/shieldsX-rayThrough transmission

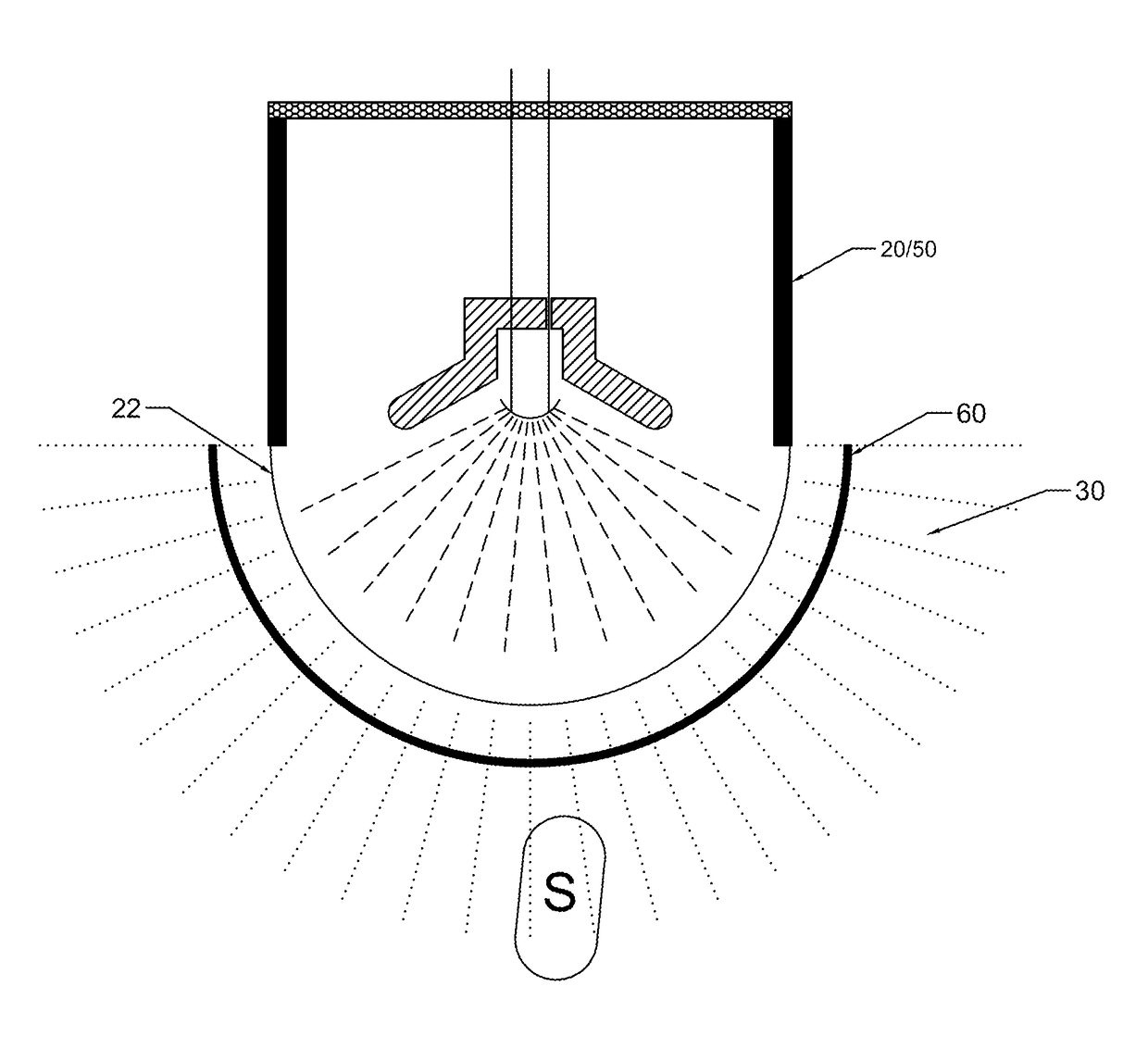

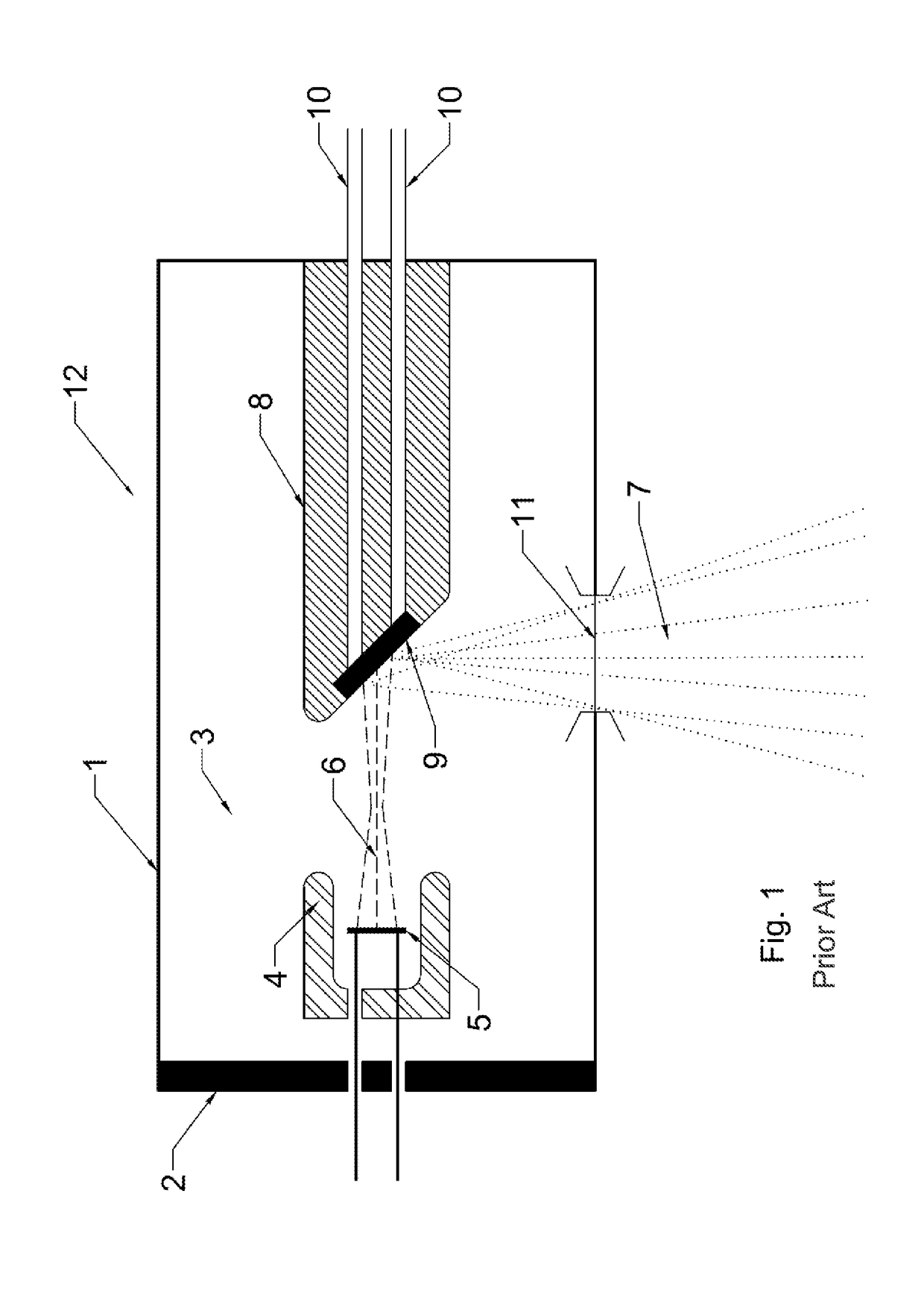

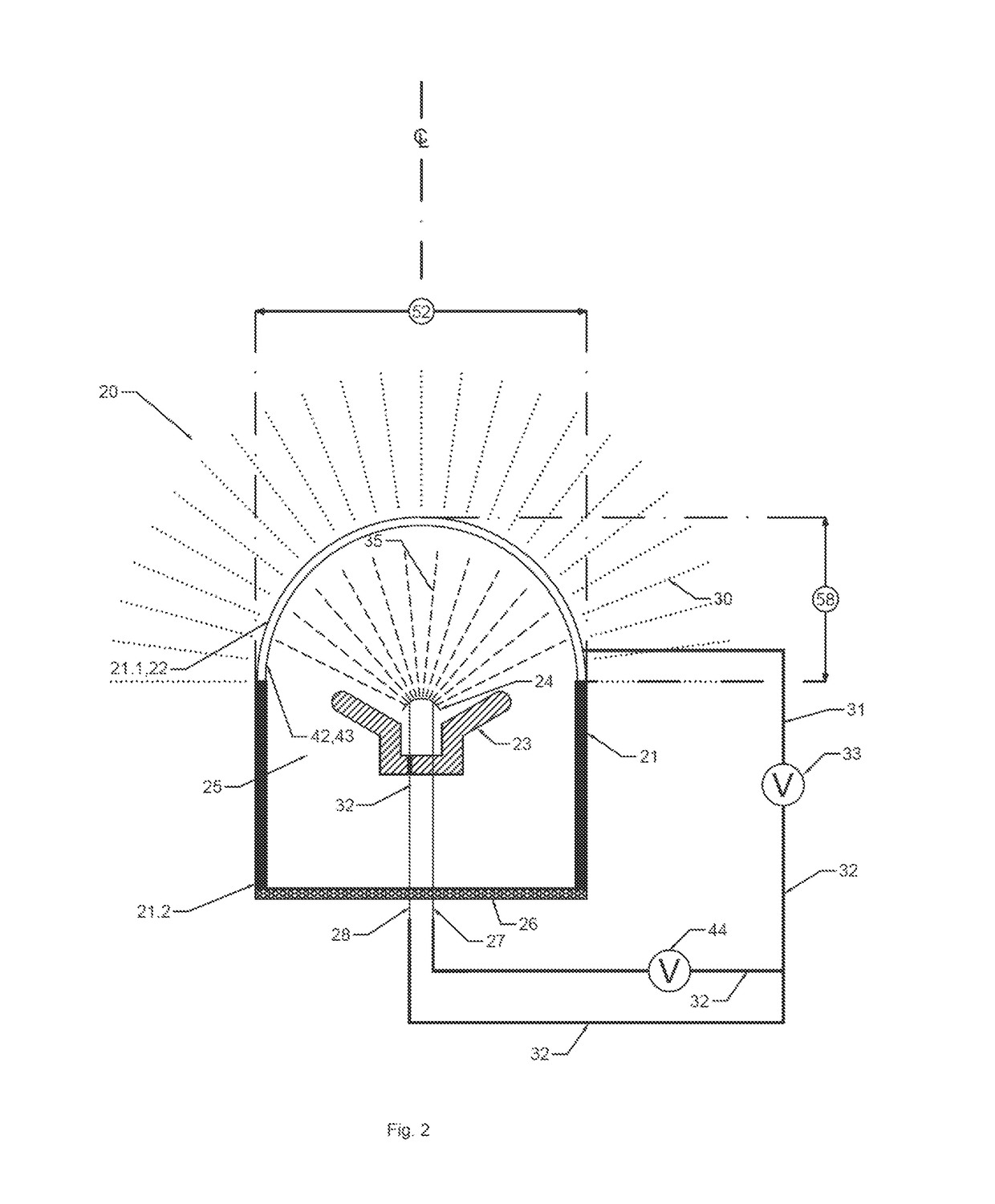

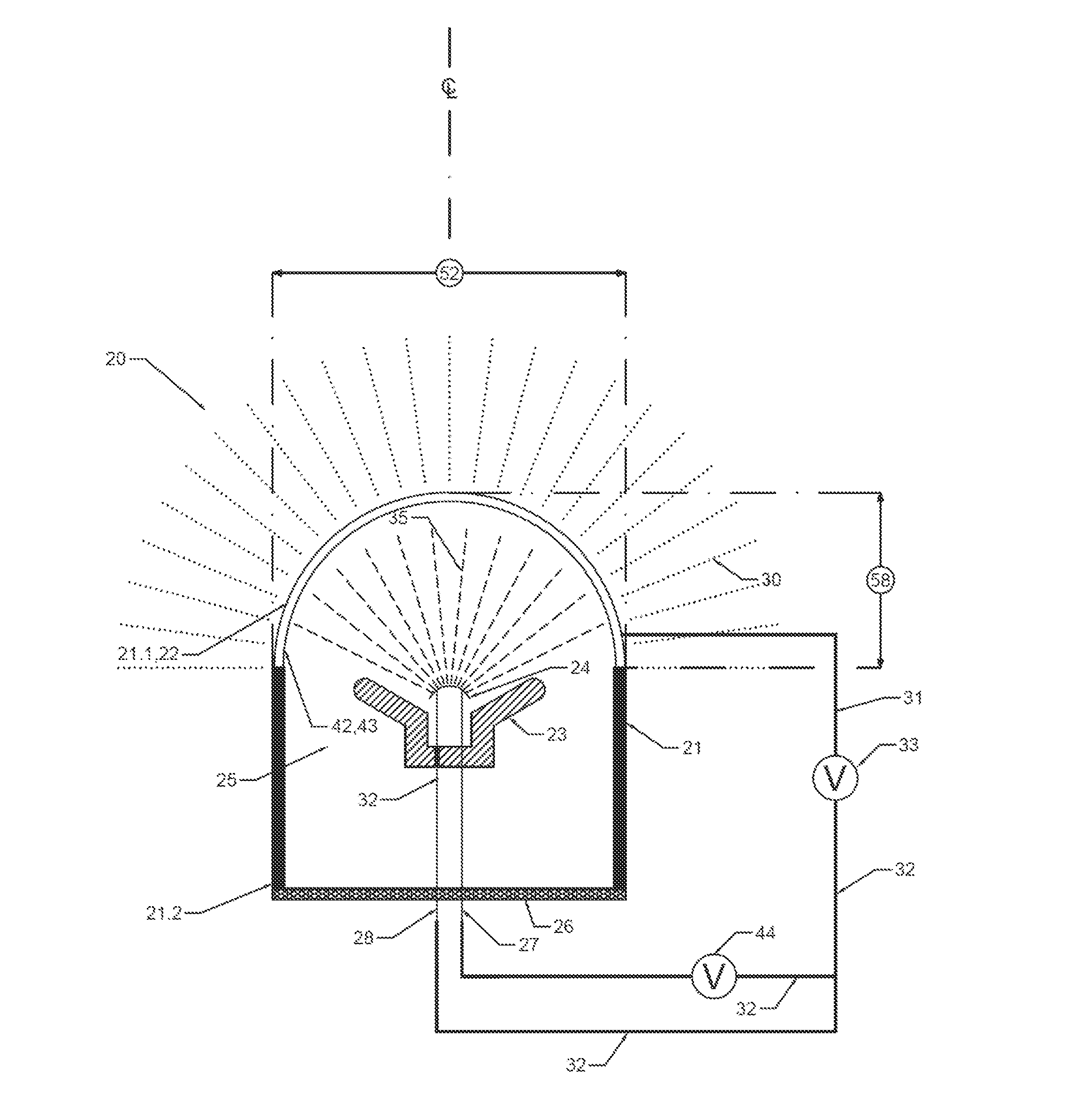

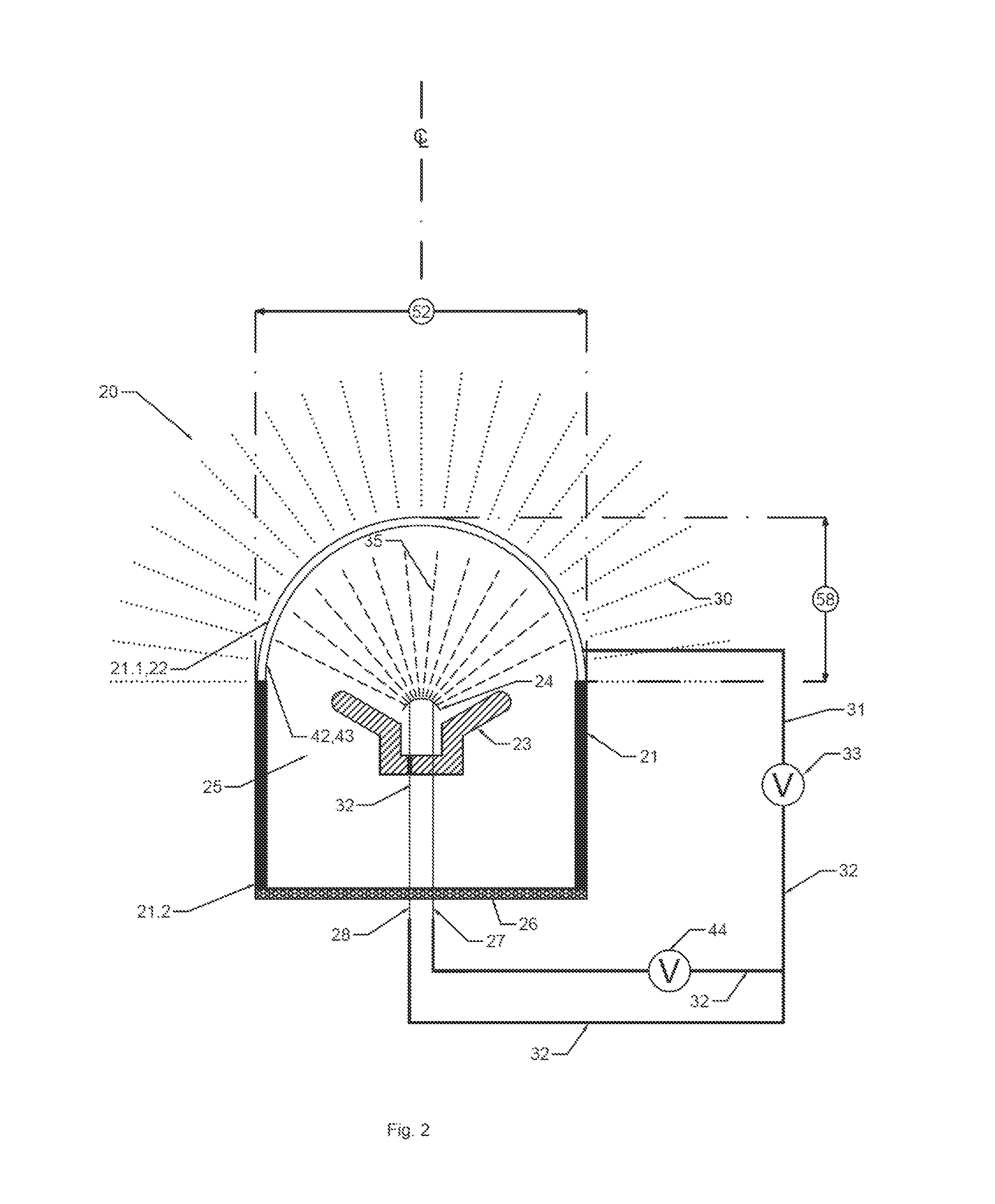

A high dose output, through transmission target X-ray tube and methods of use includes, in general an X-ray tube for accelerating electrons under a high voltage potential having an evacuated high voltage housing, a hemispherical shaped through transmission target anode disposed in said housing, a cathode structure to deflect the electrons toward the hemispherical anode disposed in said housing, a filament located in the geometric center of the anode hemisphere disposed in said housing, a power supply connected to said cathode to provide accelerating voltage to the electrons.

Owner:RAD SOURCE TECH

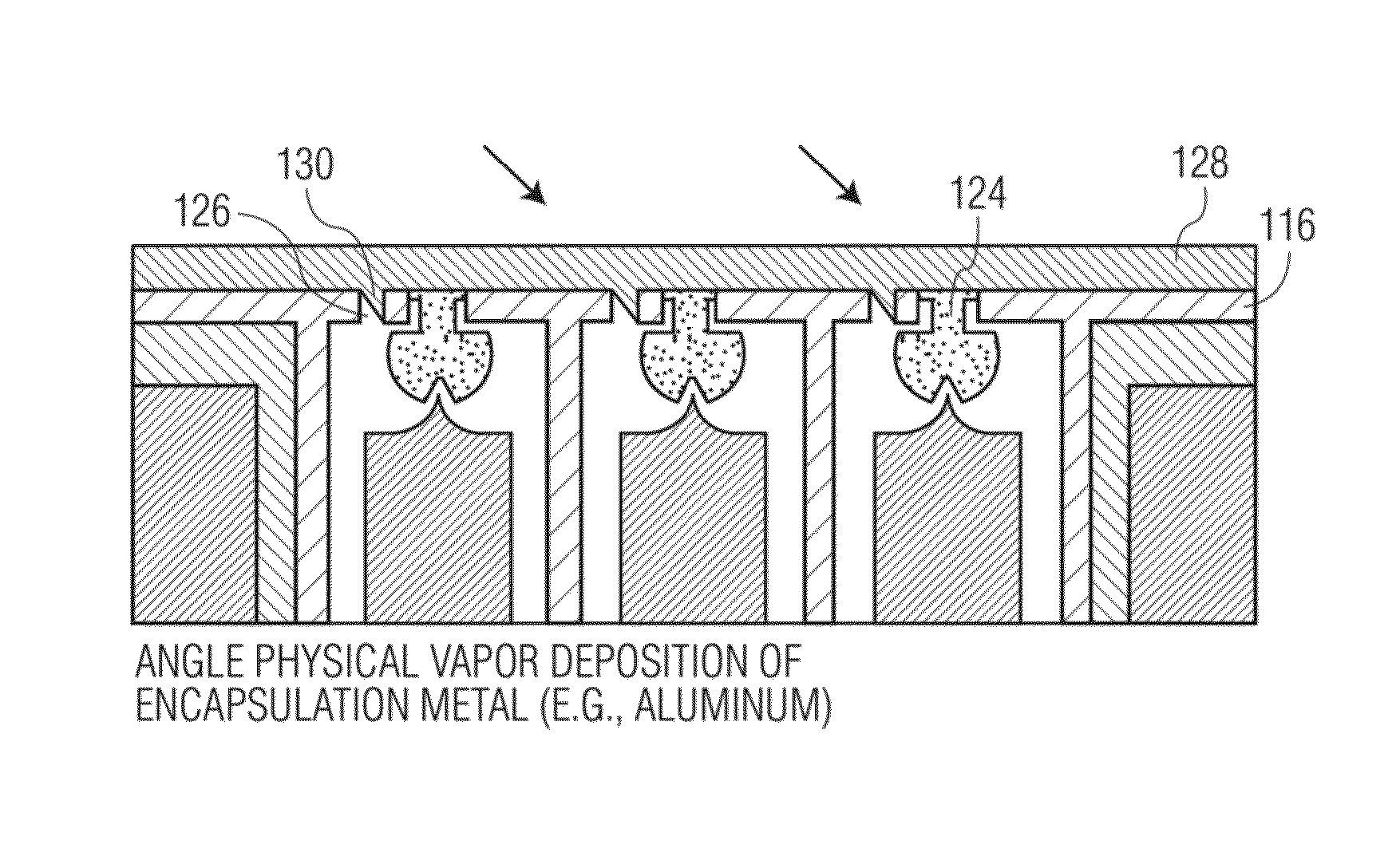

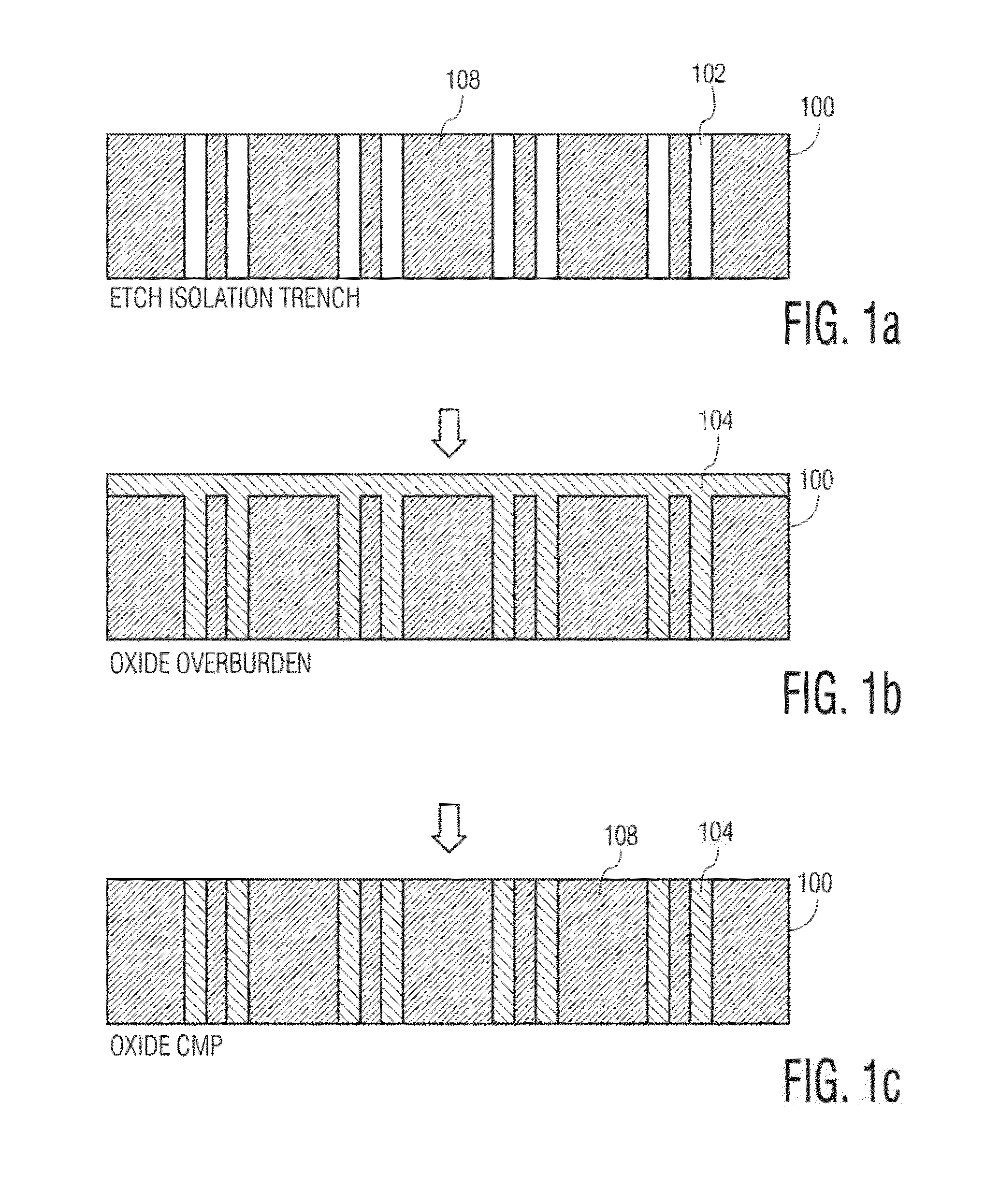

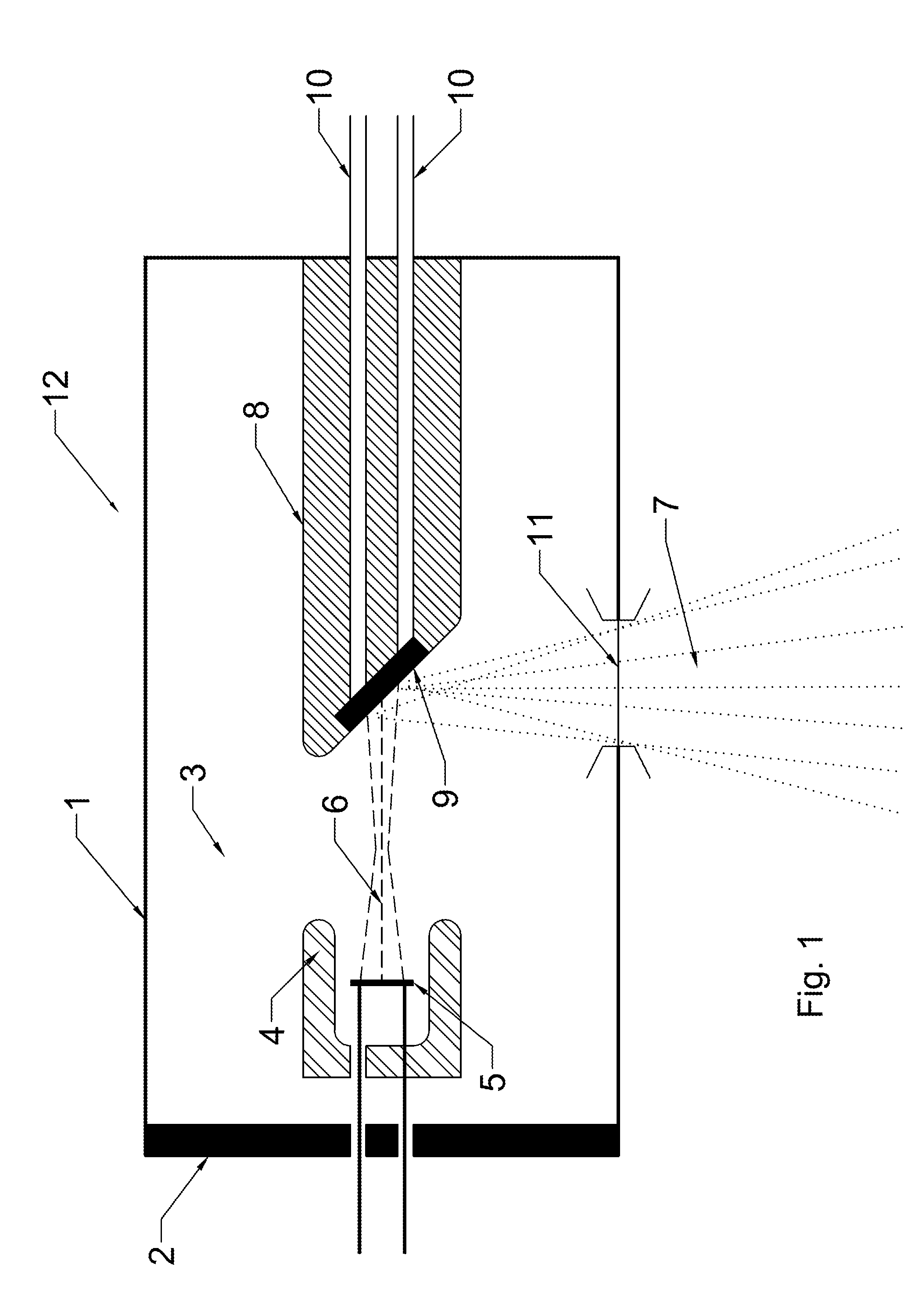

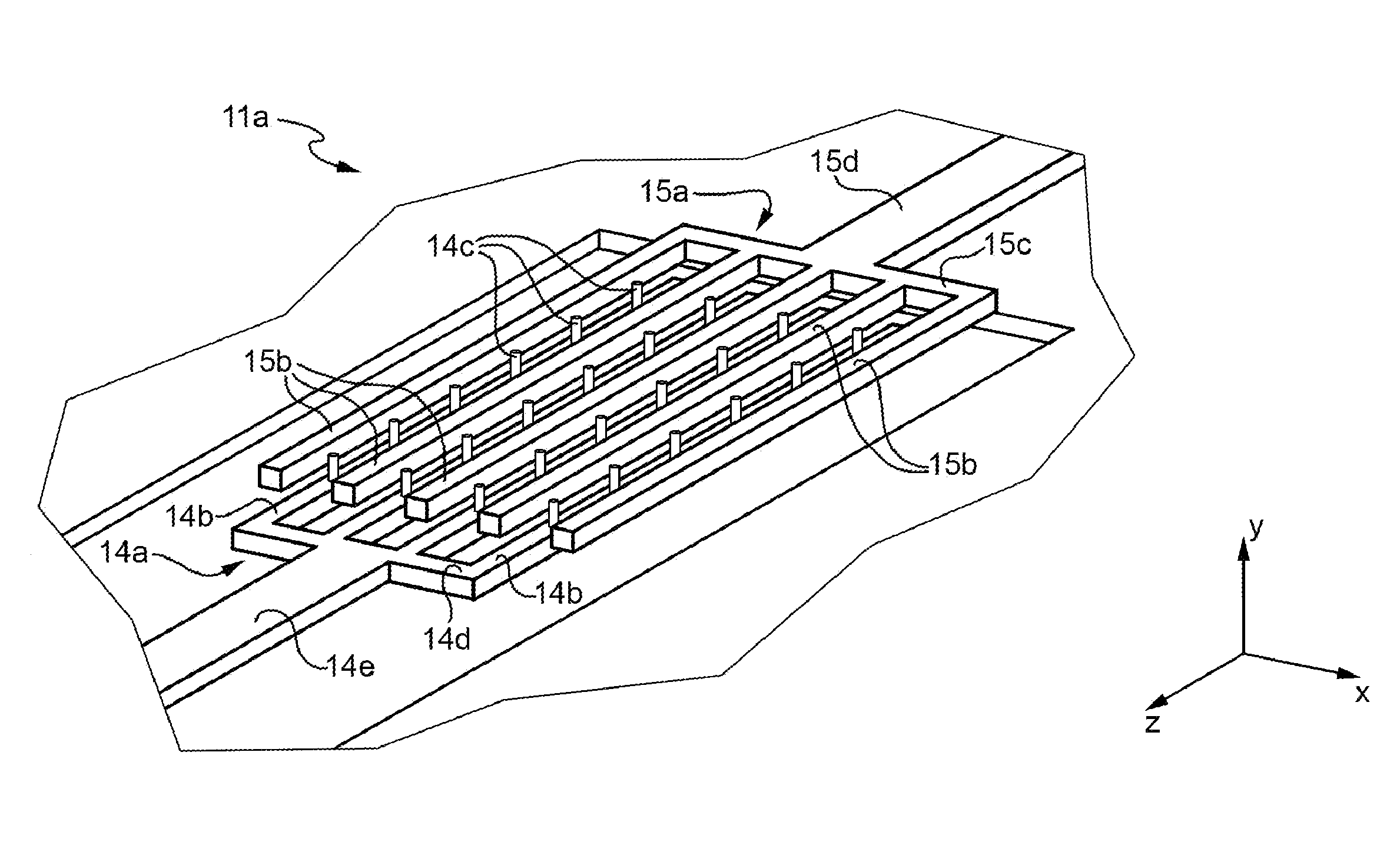

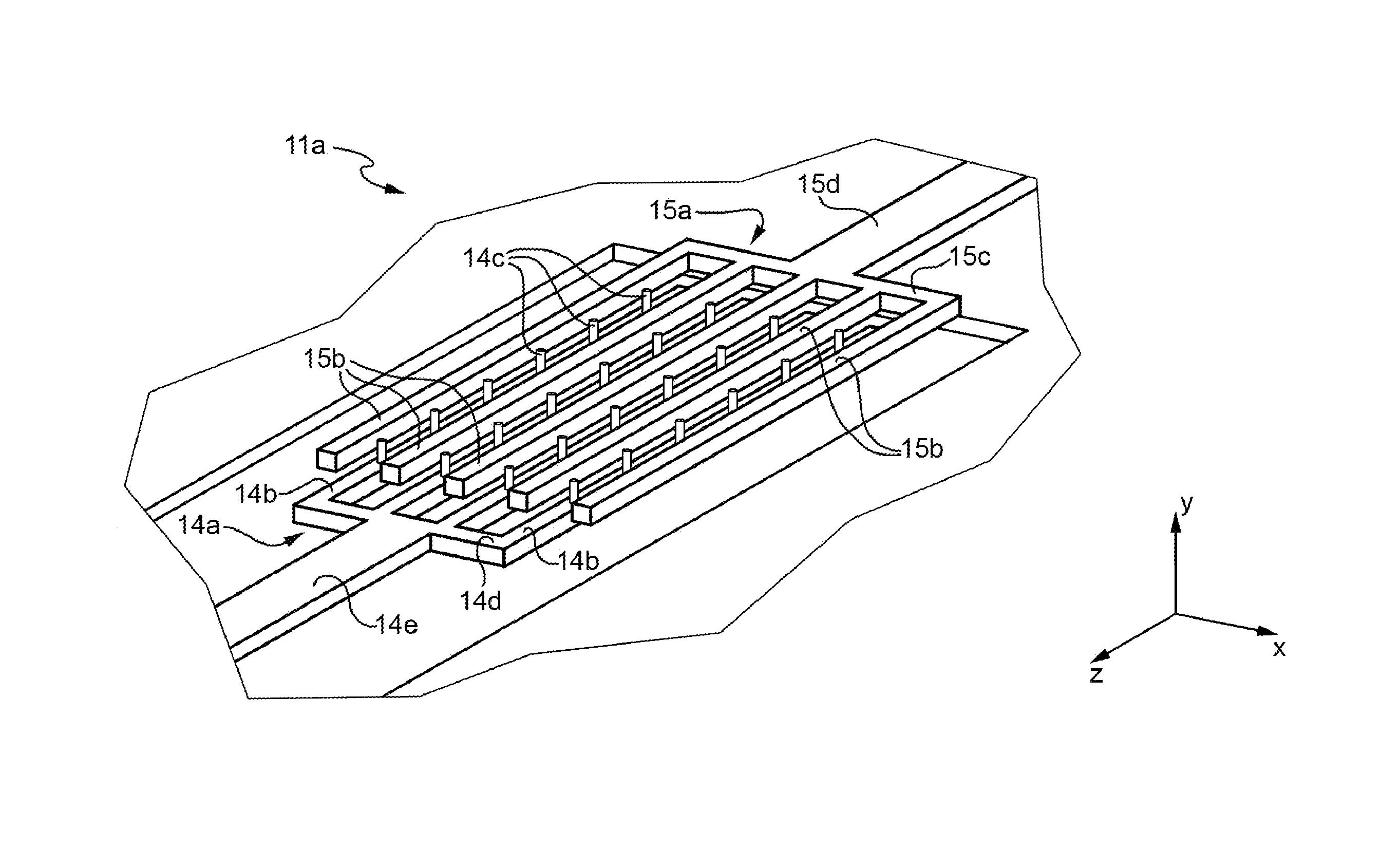

Method of manufacturing a fully integrated and encapsulated micro-fabricated vacuum diode

ActiveUS8814622B1Vacuum tube vessels/containers/shieldsThermionic cathodesConductive materialsEngineering

Disclosed is an encapsulated micro-diode and a method for producing same. The method comprises forming a plurality columns in the substrate with a respective tip disposed at a first end of the column, the tip defining a cathode of the diode; disposing a sacrificial oxide layer on the substrate, plurality of columns and respective tips; forming respective trenches in the sacrificial oxide layer around the columns; forming an opening in the sacrificial oxide layer to expose a portion of the tips; depositing a conductive material in of the opening and on a surface of the substrate to form an anode of the diode; and removing the sacrificial oxide layer.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Vertical type nano gap vacuum transistor with extended gate structure and preparation method thereof

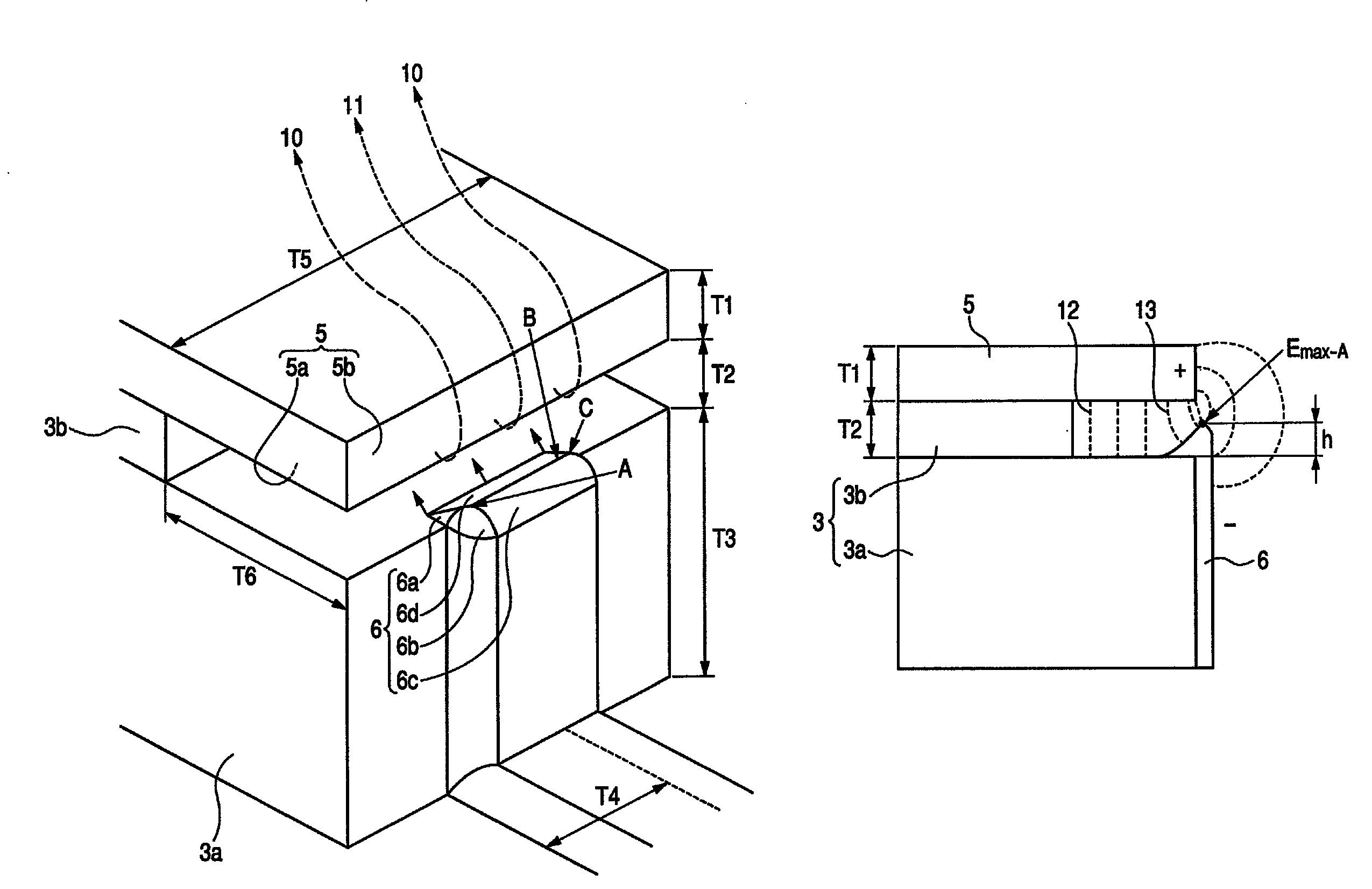

InactiveCN110310873AEnhanced surface electric field strengthImprove emission efficiencyNon-electron-emitting anodesNon-emitting electrodes manufactureElectricityElectronic systems

The invention discloses a vertical type nano gap vacuum transistor with an extended gate structure and a preparation method thereof. The vertical type nano gap vacuum transistor includes an emitter, acollector, a gate and an oxide insulating layer, and the nano gap refers to distances between the collector and the emitter and between the gate and the emitter in a sub-100 nm scale. The vertical type nano gap vacuum transistor is advantaged in that dimensions of vacuum devices are compressed to the sub-100 nm scale, device processing requirements are similar to traditional semiconductor processes, a problem that traditional electric vacuum devices require complex machining and assembling is ameliorated, more importantly, and the possibility of realizing miniaturization and integration of vacuum components, integrated circuits and vacuum electronic systems in the future is provided.

Owner:SOUTHEAST UNIV

Information storage apparatus storing and reading information by irradiating a storage medium with electron beam

InactiveUS7471542B2Inhibition of attachmentReduced stabilityRead-only memoriesRecord information storageHigh energyPotential difference

To greatly increase the storage density of a storage apparatus, an electron beam E emitted from a cold cathode 101 is accelerated by an accelerating electrode 102, caused to converge by a convergence electrode 103, deflected by a deflection electrode 104 and applied to a minute region of a storage film 105. The storage film 105 includes, for example, a phase change film 105a. The film is rapidly heated and cooled to change into an amorphous state upon irradiation with an electron beam E with high energy, while being gradually cooled to change into a crystallized state upon irradiation with an electron beam E with approximately intermediate energy, thereby storing data. Upon irradiation with an electron beam E with low energy, the potential difference between a detection electrode 105b and an anode 105c is detected depending on the state, i.e., the amorphous or crystallized state, thereby reading stored data.

Owner:PANASONIC CORP

Electron emitter source

An electron emitter that consists of: a low work function material including Lanthanum hexaboride or Iridium Cerium that acts as an emitter, a cylinder base made of high work function material that has a cone shape where the low work function material is embedded in the high work function material but is exposed at end of the cone and the combined structure is heated and biased to a negative voltage relative to an anode, an anode electrode that has positive bias relative to the emitter, and a wehnelt electrode with an aperture where the cylindrical base protrudes through the wehnelt aperture so the end of the cone containing the emissive area is placed between the wehnelt and the anode.

Owner:OREGON PHYSICS +1

High dose output, through transmission target x-ray system and methods of use

ActiveUS20160189911A1Increase surface areaIncreased radiation outputX-ray tube laminated targetsX-ray tube anode coolingX-rayHigh doses

A high dose output, through transmission target X-ray tube and methods of use includes, in general an X-ray tube for accelerating electrons under a high voltage potential having an evacuated high voltage housing, a hemispherical shaped through transmission target anode disposed in said housing, a cathode structure to deflect the electrons toward the hemispherical anode disposed in said housing, a filament located in the geometric center of the anode hemisphere disposed in said housing, a power supply connected to said cathode to provide accelerating voltage to the electrons.

Owner:RAD SOURCE TECH

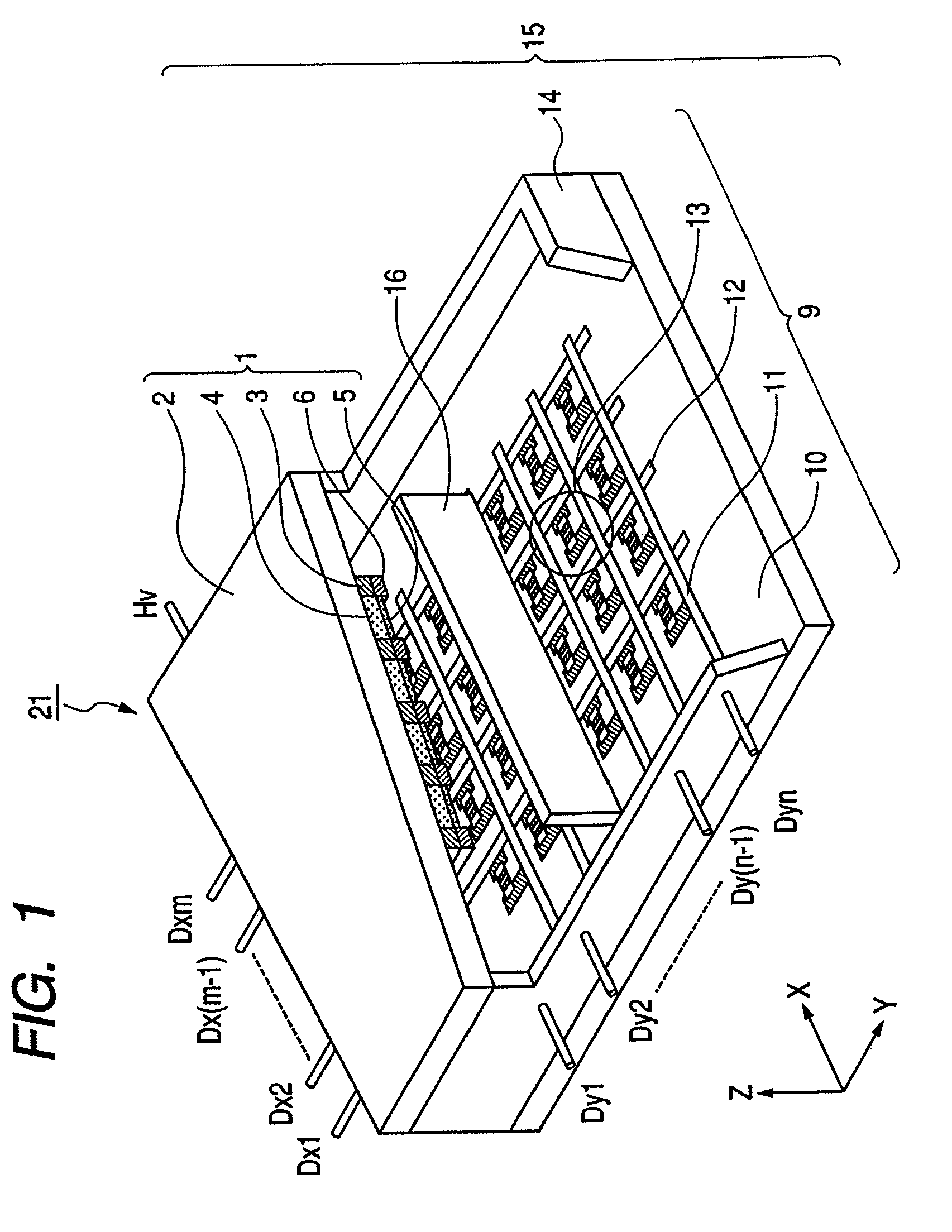

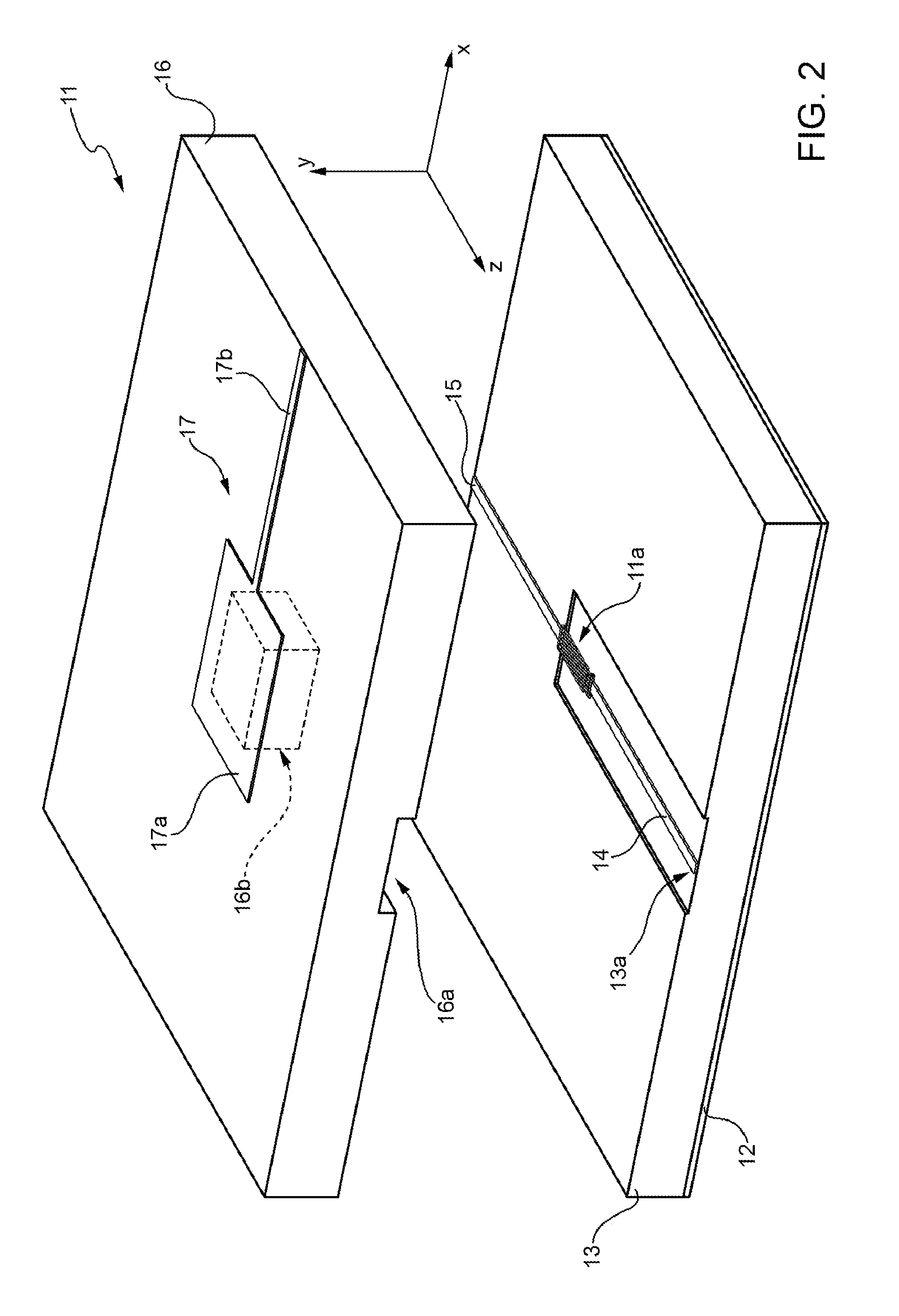

Electron beam apparatus and image display apparatus using the same

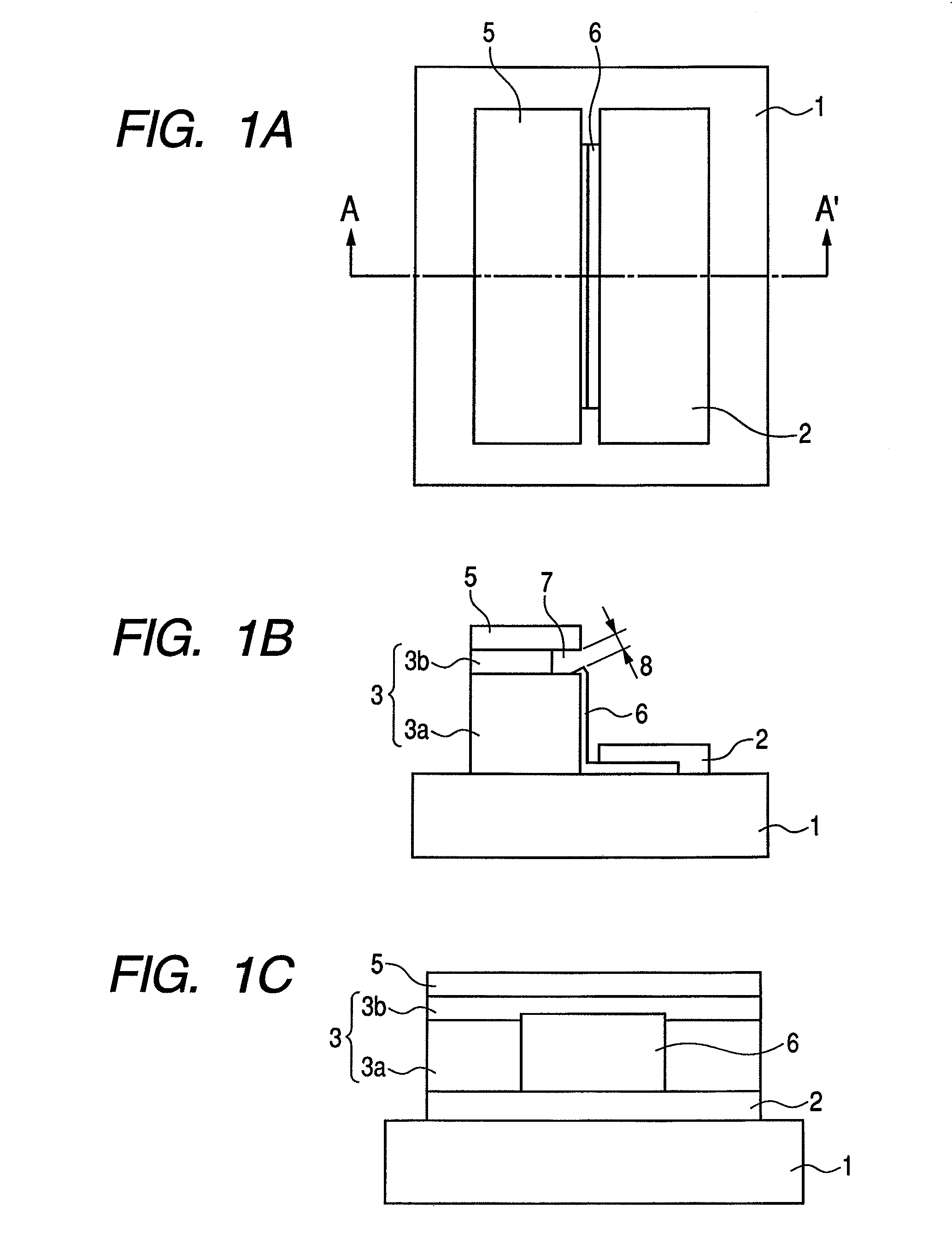

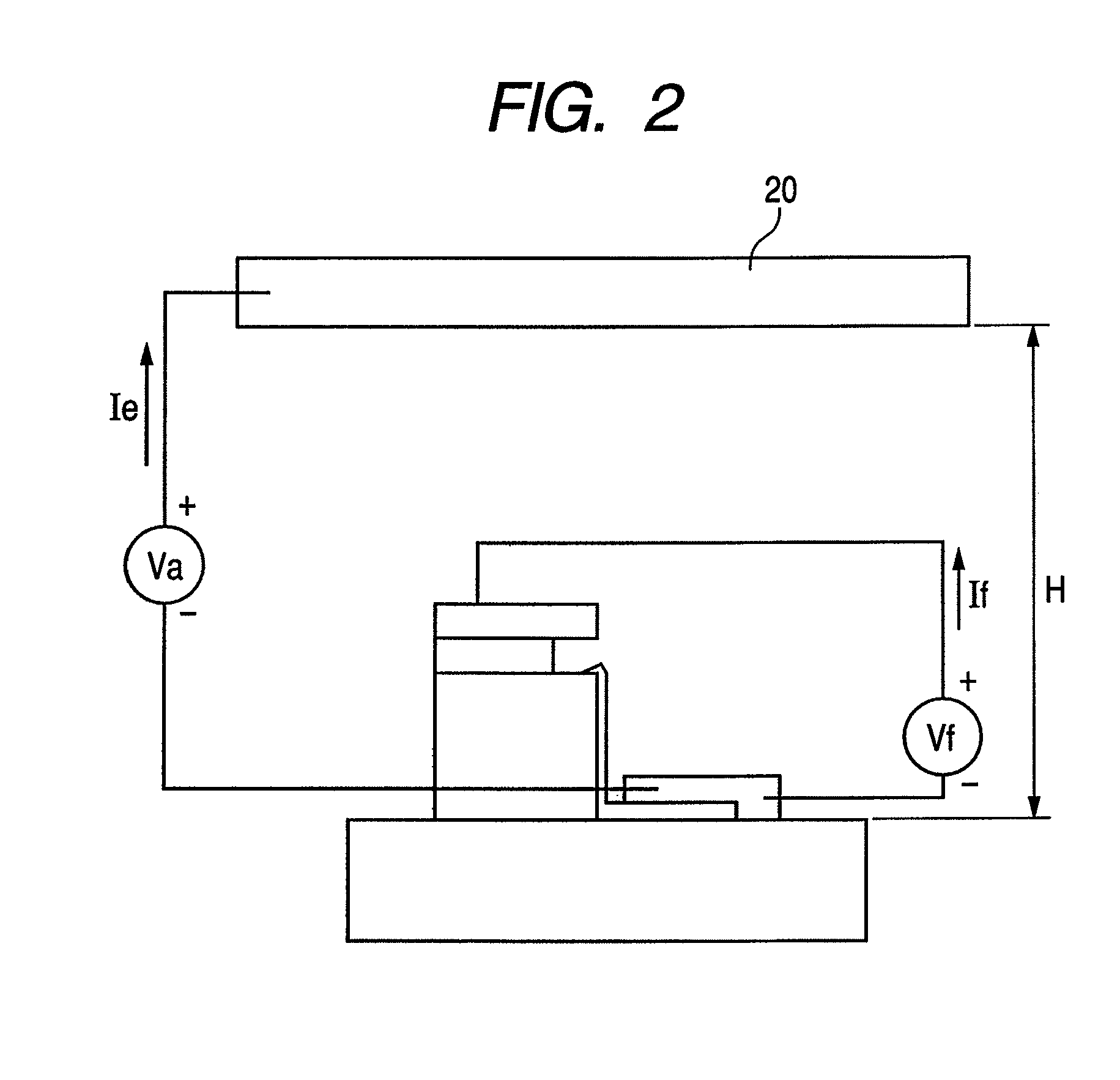

InactiveUS7884533B2Simple structureHigh electron-emitting efficiencyDischarge tube luminescnet screensCathode ray tubes/electron beam tubesHigh electronElectron

The present invention provides an electron beam apparatus provided with an electron-emitting device which has a simple structure, shows high electron-emitting efficiency and stably works. This electron beam apparatus has an insulating member and a gate formed on a substrate, a recess portion formed in the insulating member, a protruding portion that protrudes from an edge of the recess portion toward the gate and is provided on an end part of a cathode opposing to the gate, which is arranged on the side face of the insulating member; and makes an electric field converge on an end part in the width direction of the protruding portion to make an electron emitted therefrom.

Owner:CANON KK

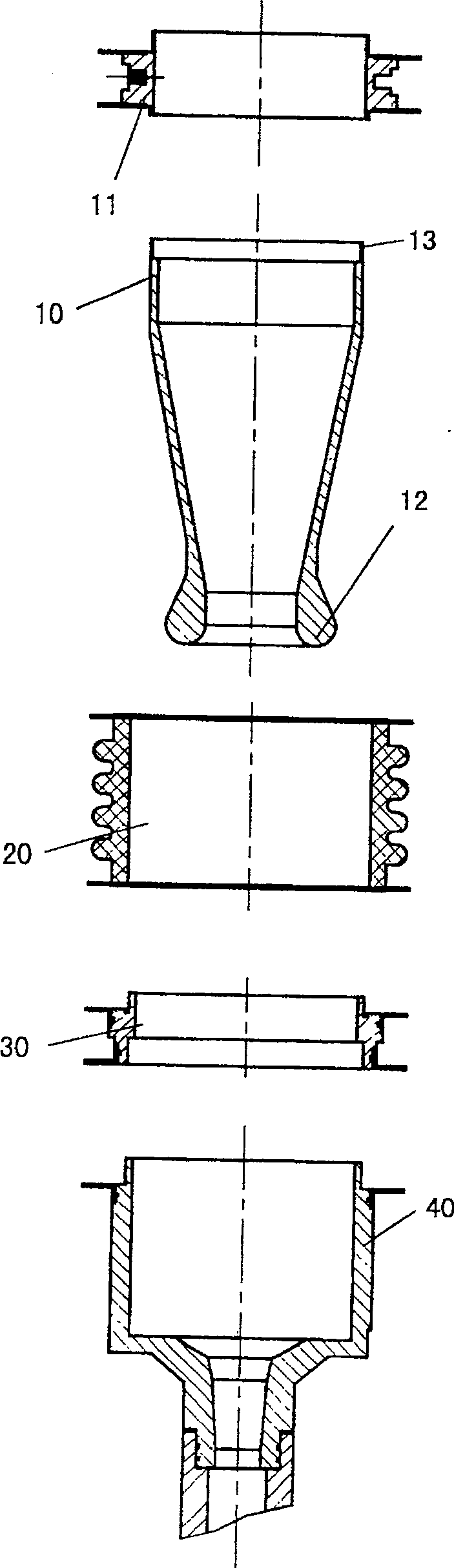

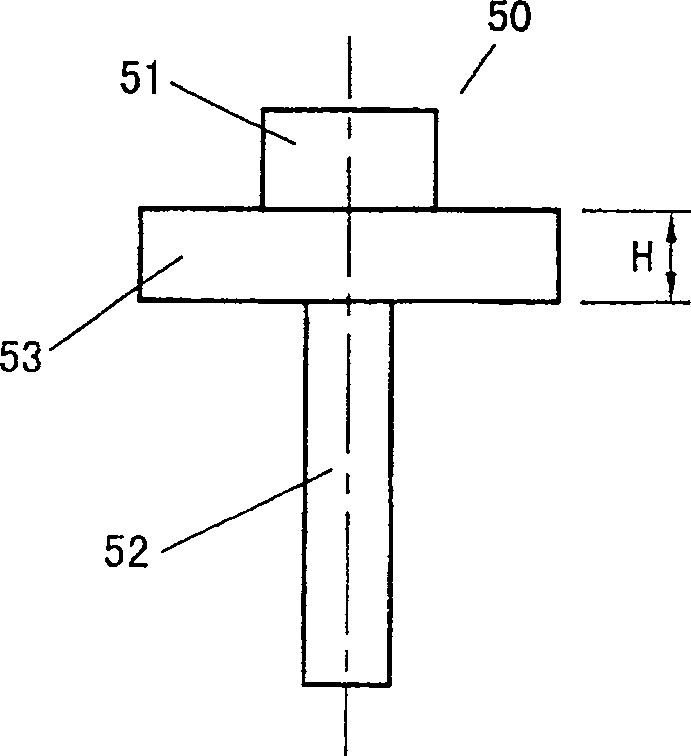

Electrovacuum tube with dual anodes, and assembling method

InactiveCN1917128AEliminate spacing effectsReduce the impact on the centerNon-electron-emitting anodesCold cathode manufactureEngineeringMechanical engineering

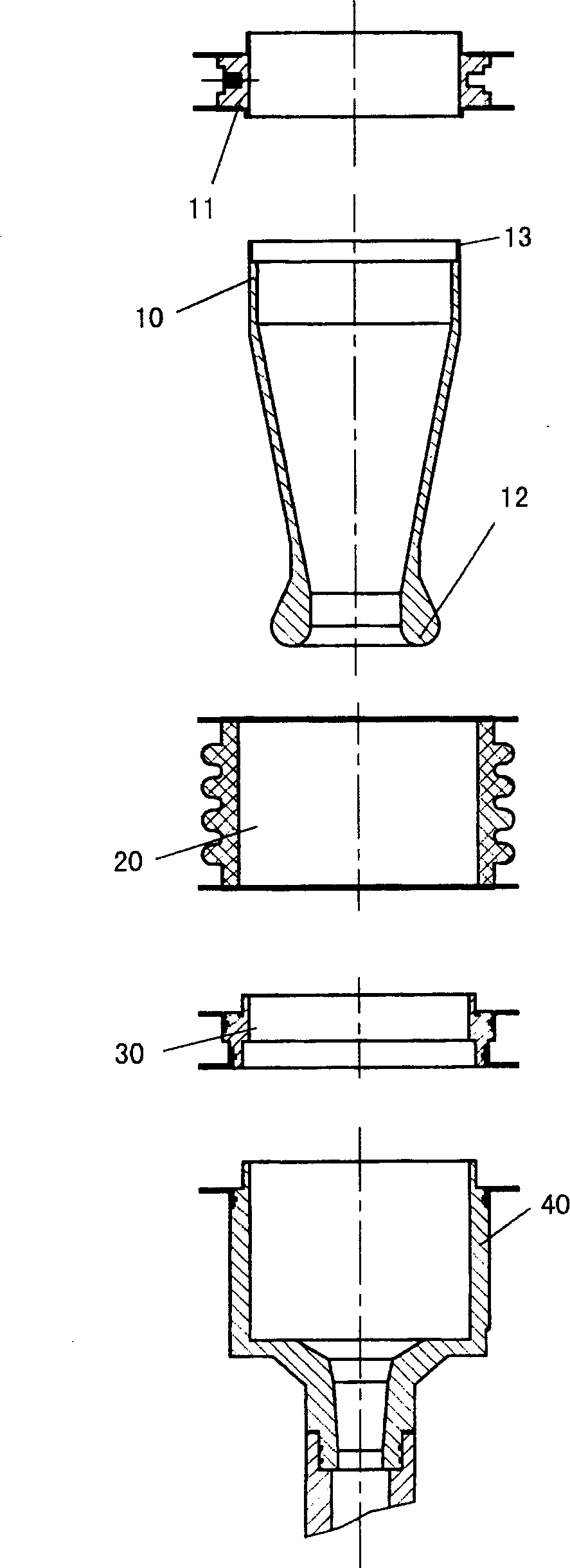

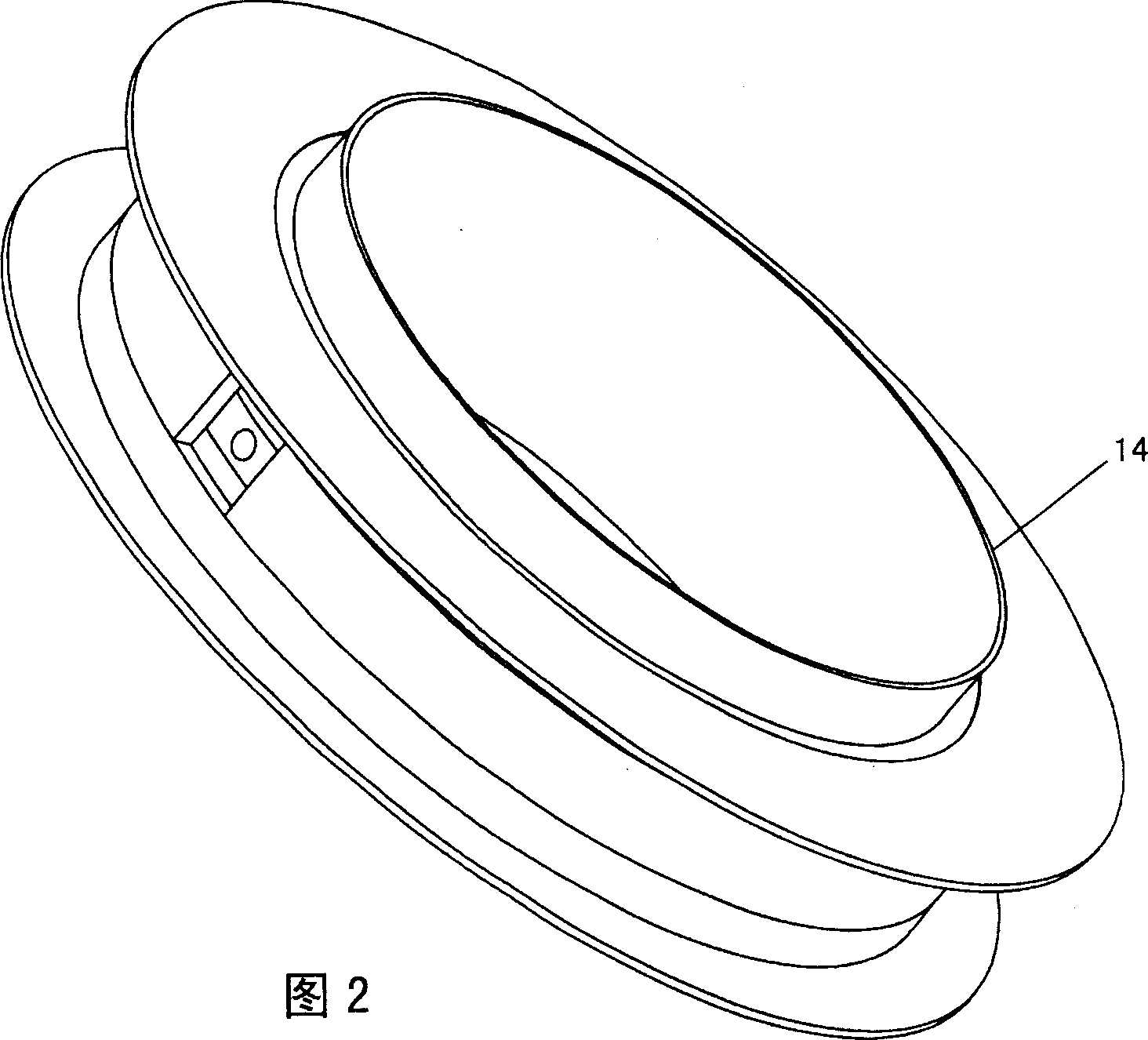

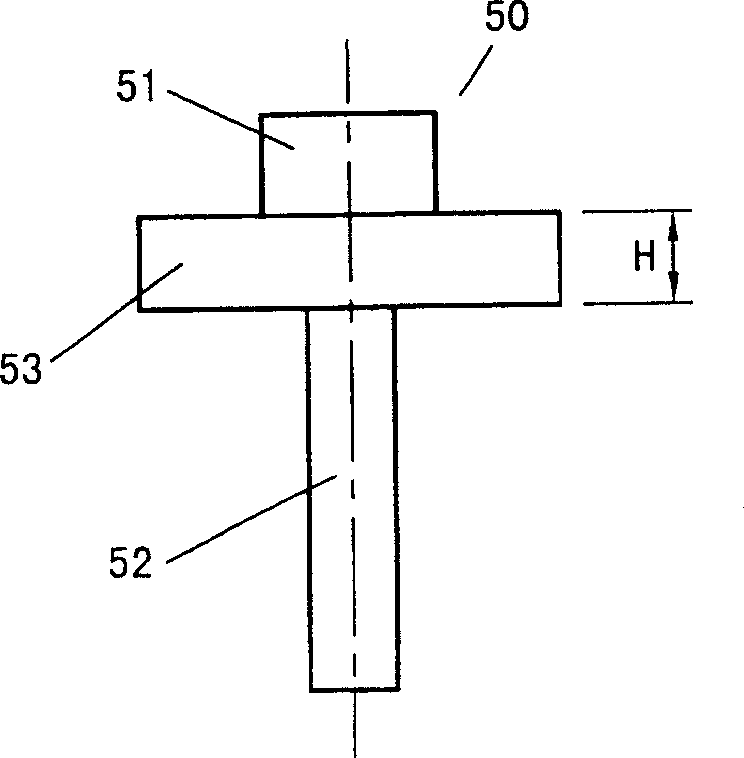

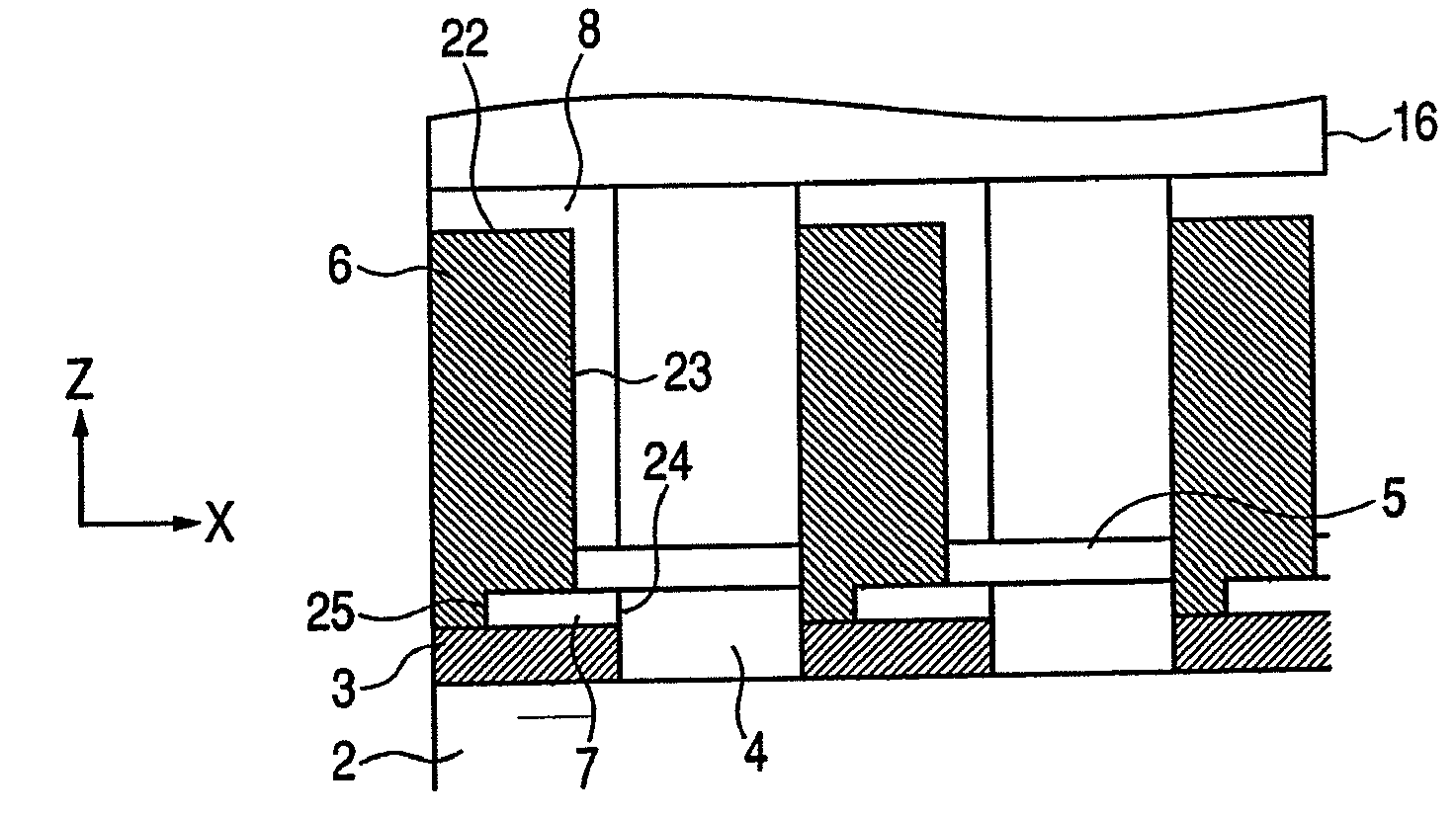

First anode is connected to one end of ceramic insulation sect module. The other end of the ceramic insulation sect module is connected to a terminal port of a transition sect module, which is connected to second anode. First anode seat is installed on the first anode, and a featheredge area as a soldering edge is setup at tail part of the first anode. There is a lamellar soldering edge between same terminal ports of first anode seat and the tail part of the first anode. Assembling procedure includes steps: inserting die in to second anode; placing the transition sect module, the ceramic insulation sect module, first anode, and first anode seat; inner diameter of first anode head sheathed on up end of the die; being placed to first anode, tool bar impresses force downward; then, soldering two modules, first anode, and first anode seat as integrated module; taking die out and replacing second anode back to original position; soldering second anode and transition sect module.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Image displaying apparatus

InactiveUS7939997B2Easy to implementSimplified suppressionDischarge tube luminescnet screensCathode ray tubes/electron beam tubesEngineeringElectron

To simultaneously suppress halation and discharging current flowing in the unlikely event of discharge, and easily perform potential regulating for a spacer, an image displaying apparatus comprises: a rear plate having electron-emitting devices arranged in matrix; a face plate having a substrate, light-emitting members arranged in matrix on the substrate, metal backs each covering at least one member and mutually arranged in matrix at gaps, ribs having first striped portions respectively positioned among the members and protruding toward the rear plate, and a resistive wiring including a resistor between the substrate and the ribs and electrically connecting the metal backs, and positioned oppositely to the rear plate; and a spacer positioned between the rear plate and the ribs to mutually support the rear and face plates, wherein the rib has a spacer connection wiring abutting against the spacer, and the spacer connection wiring is electrically connected to the resistive wiring.

Owner:CANON KK

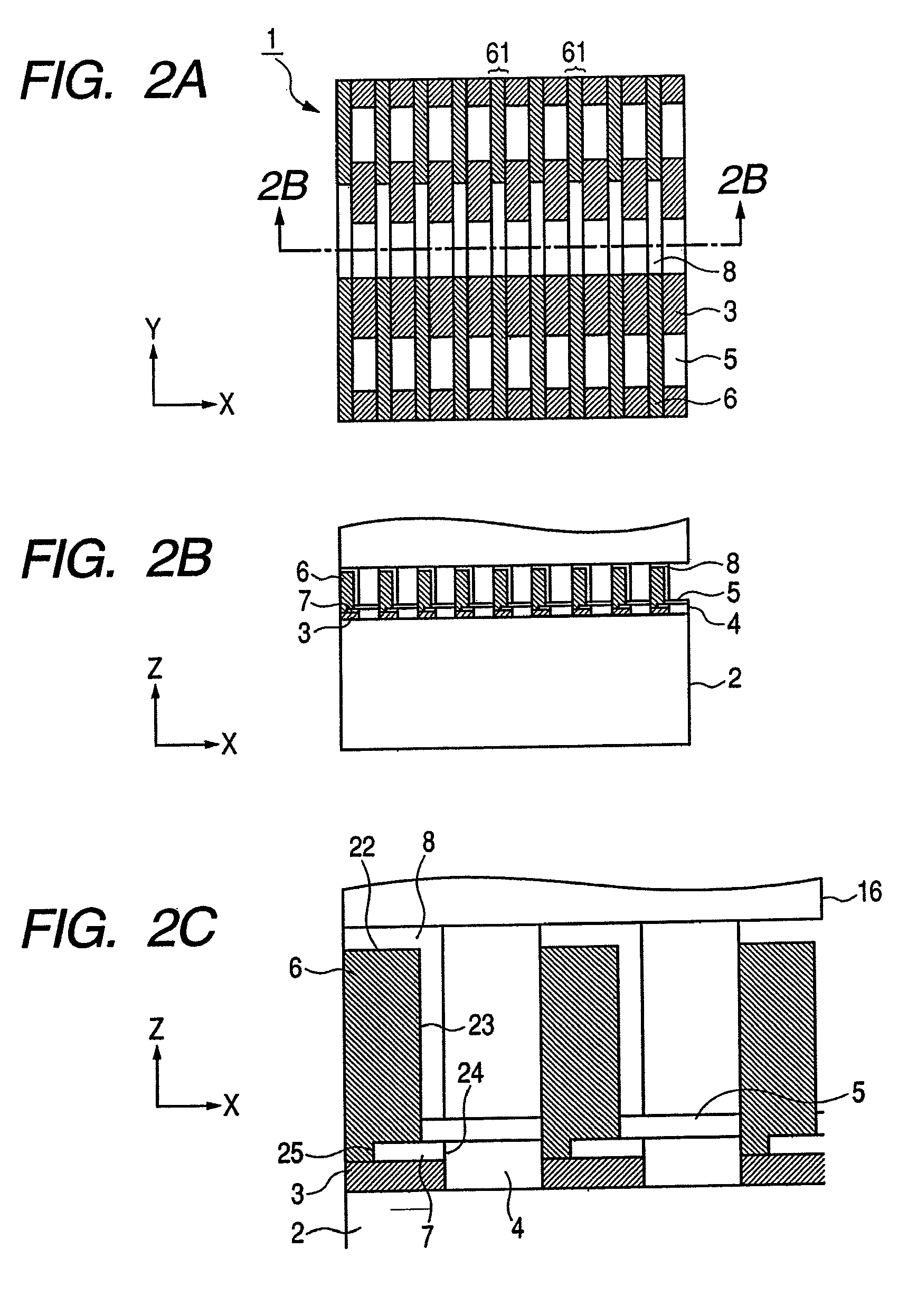

Electron-emitting cold cathode device

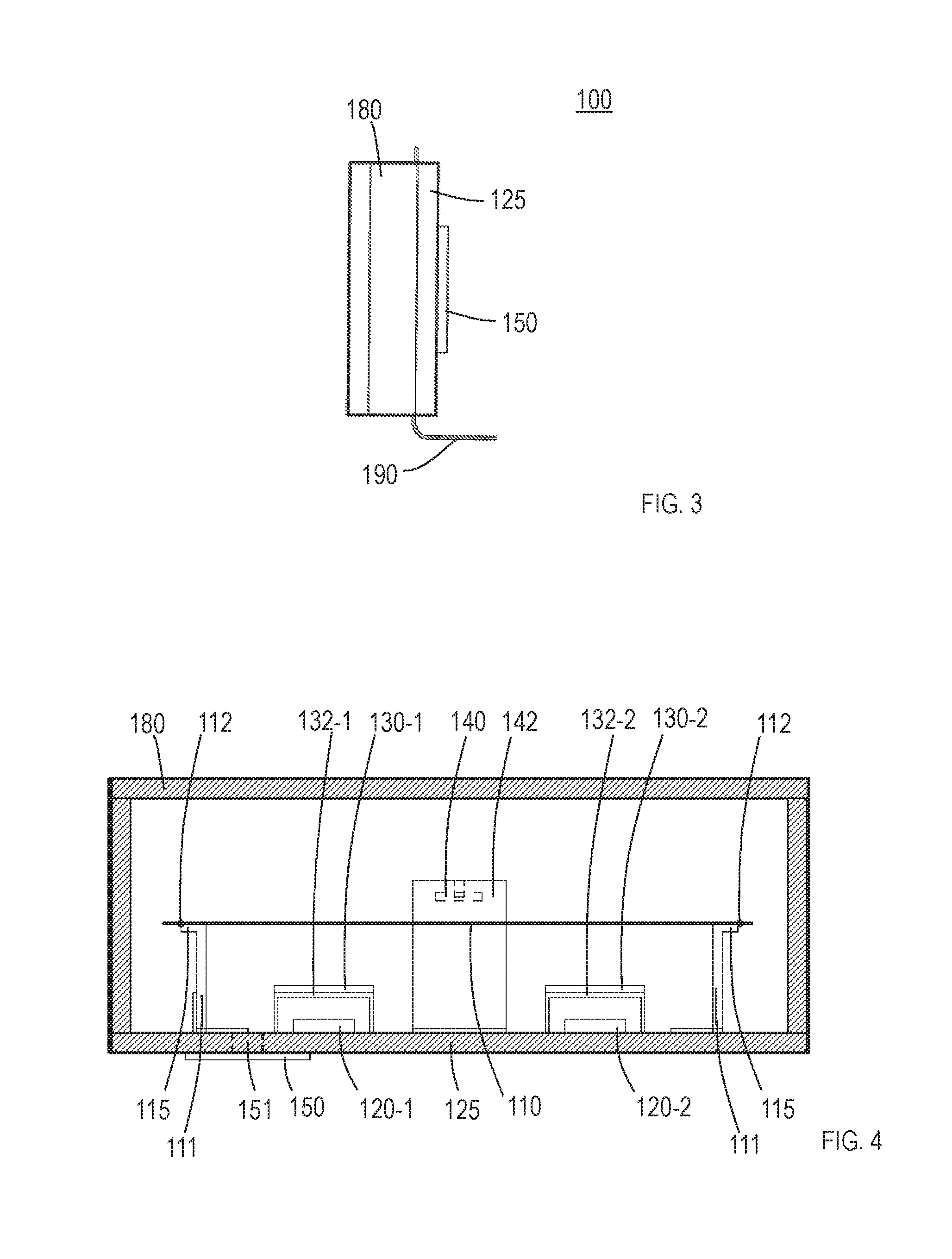

InactiveUS20150022076A1Increase working frequencyMitigate such drawbackControl electrodesCold cathodesOhmic contactCold cathode

One or more embodiments of the invention concern a device comprising: a cathode that lies on a cathode plane and includes, in an active region one or more cathode straight-finger-shaped terminals with a main extension direction parallel to a first reference direction; for each cathode terminal, one or more electron emitters formed on, and in ohmic contact with, said cathode terminal; and a gate electrode that lies on a gate plane parallel to, and spaced apart from, said cathode plane, does not overlap the cathode and includes, in the active region, two or more gate straight-finger-shaped terminals with a main extension direction parallel to the first reference direction; wherein the gate terminals are interlaced with said cathode terminal(s).

Owner:SELEX ES

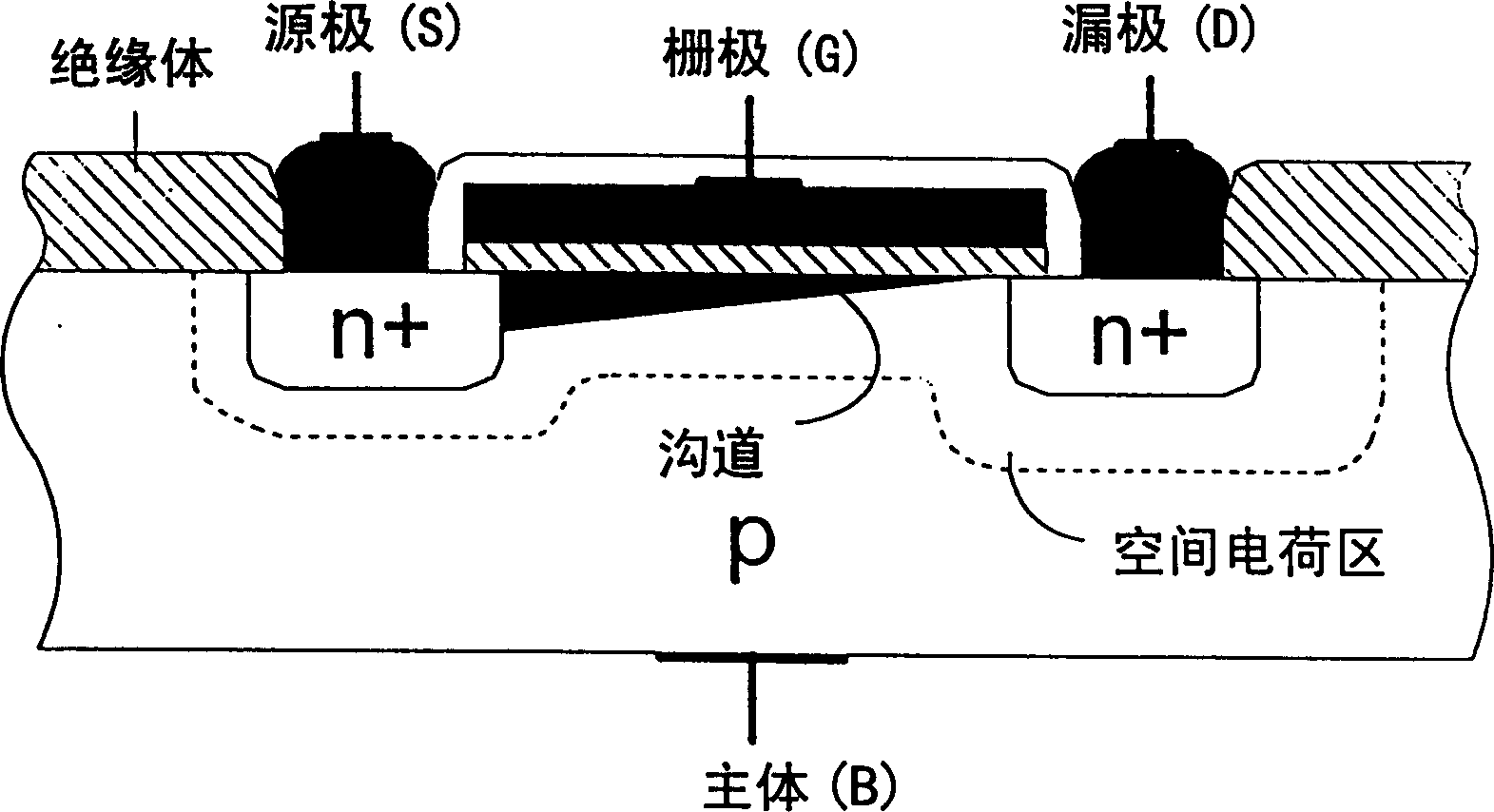

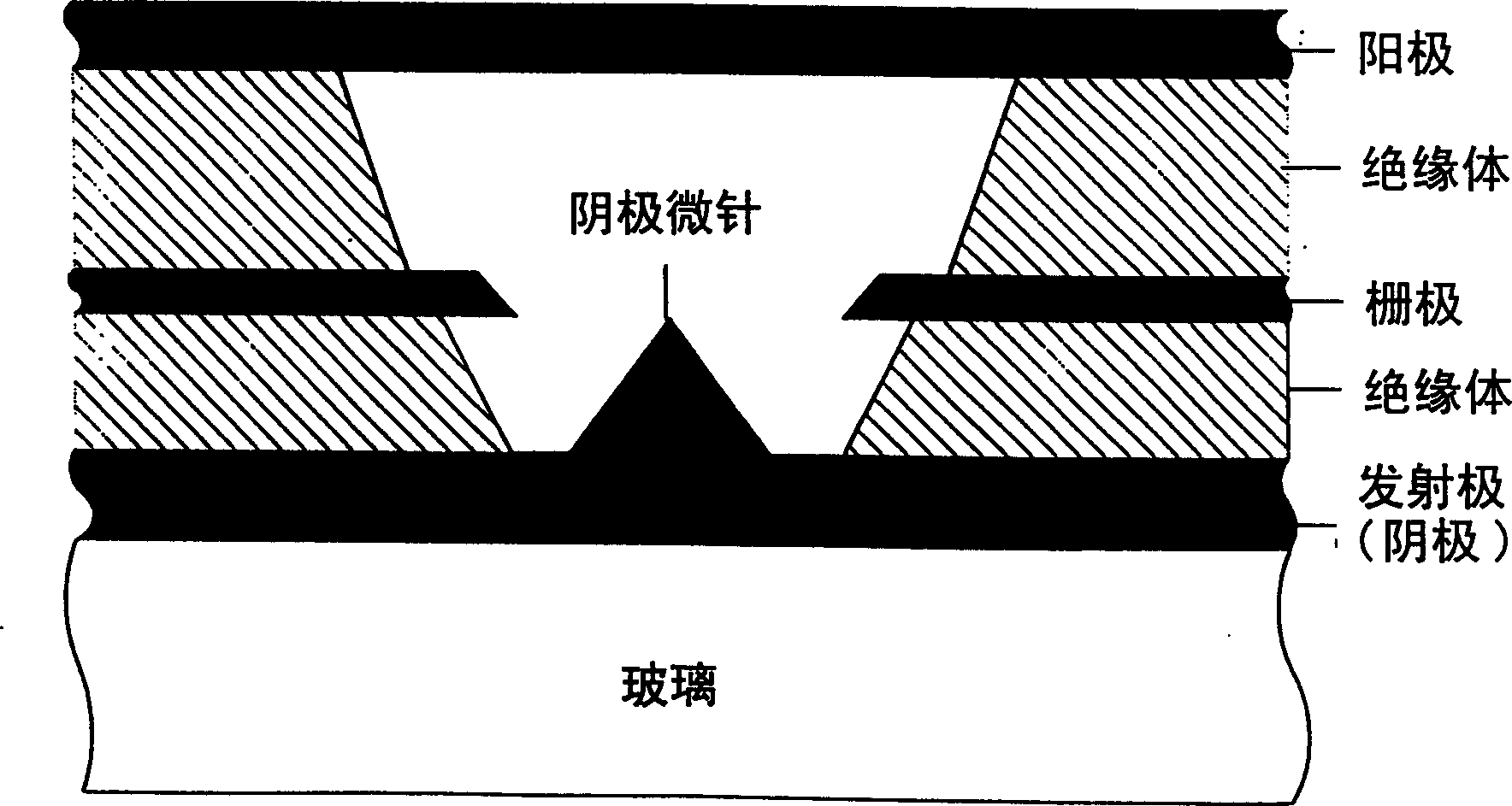

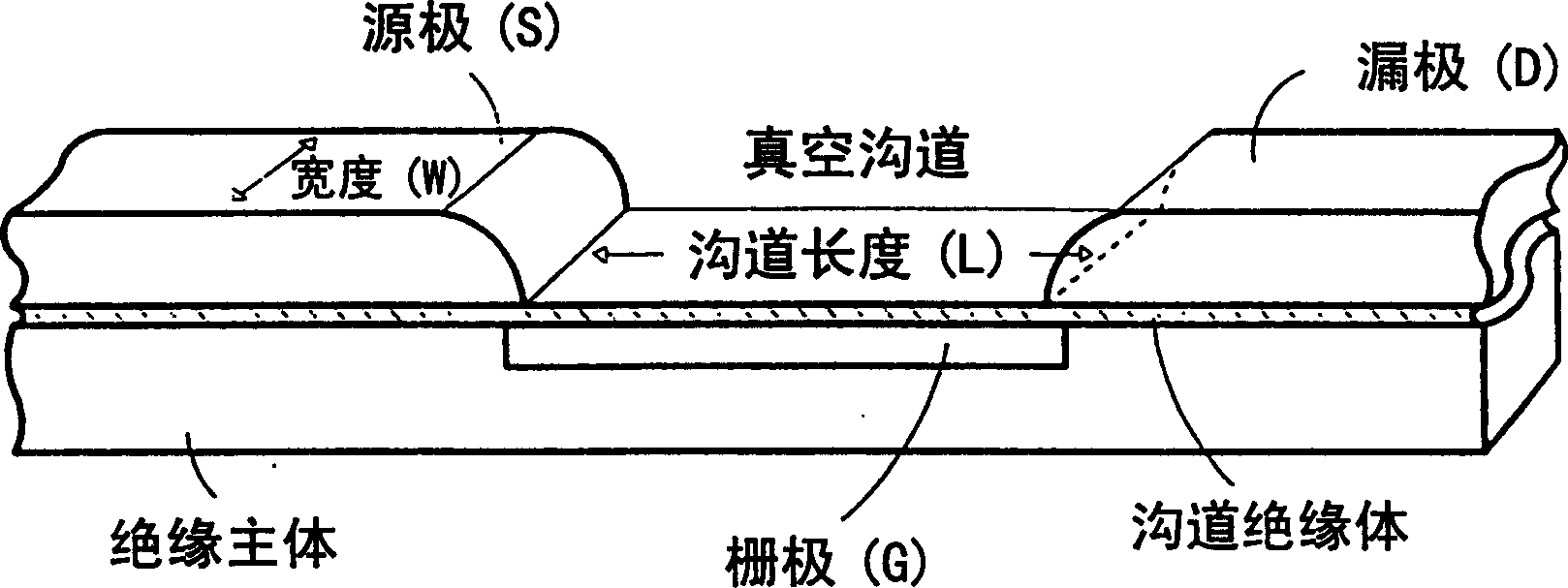

Vacuum field effect transistor

InactiveCN1202576CHighly integratedRun at high speedTransistorCold cathodesMOSFETElectrical conductor

The invention discloses a planar / vertical vacuum field effect transistor (VFT) structure, which adopts a planar or vertical structure similar to a MOSFET to improve integration and can operate at a lower operating voltage at high speed. This planar type VFT includes source and drain electrodes made of conductors, which are kept on a thin channel insulator with a predetermined distance apart, with a vacuum channel in between; gate electrodes made of conductors, which have a certain The width is formed under the source and the drain, and the function of the channel insulator is to insulate the gate from the source and the drain; the insulating body is used as a substrate for supporting the channel insulator and the gate. A vertical vacuum field effect transistor comprising: a conductive continuous circular source having a vacant center formed on a trench insulator; a conductive continuous source formed under said trench insulator and extending across said source a gate; an insulating body serving as a substrate supporting the gate and a channel insulator; an insulating wall mounted above the source to form a closed vacuum channel; a drain formed above the vacuum channel . In both types an appropriate bias is applied between the gate, source and drain to enable electrons to be field emitted from the source to the drain through the vacuum channel.

Owner:IKAIST CO LTD

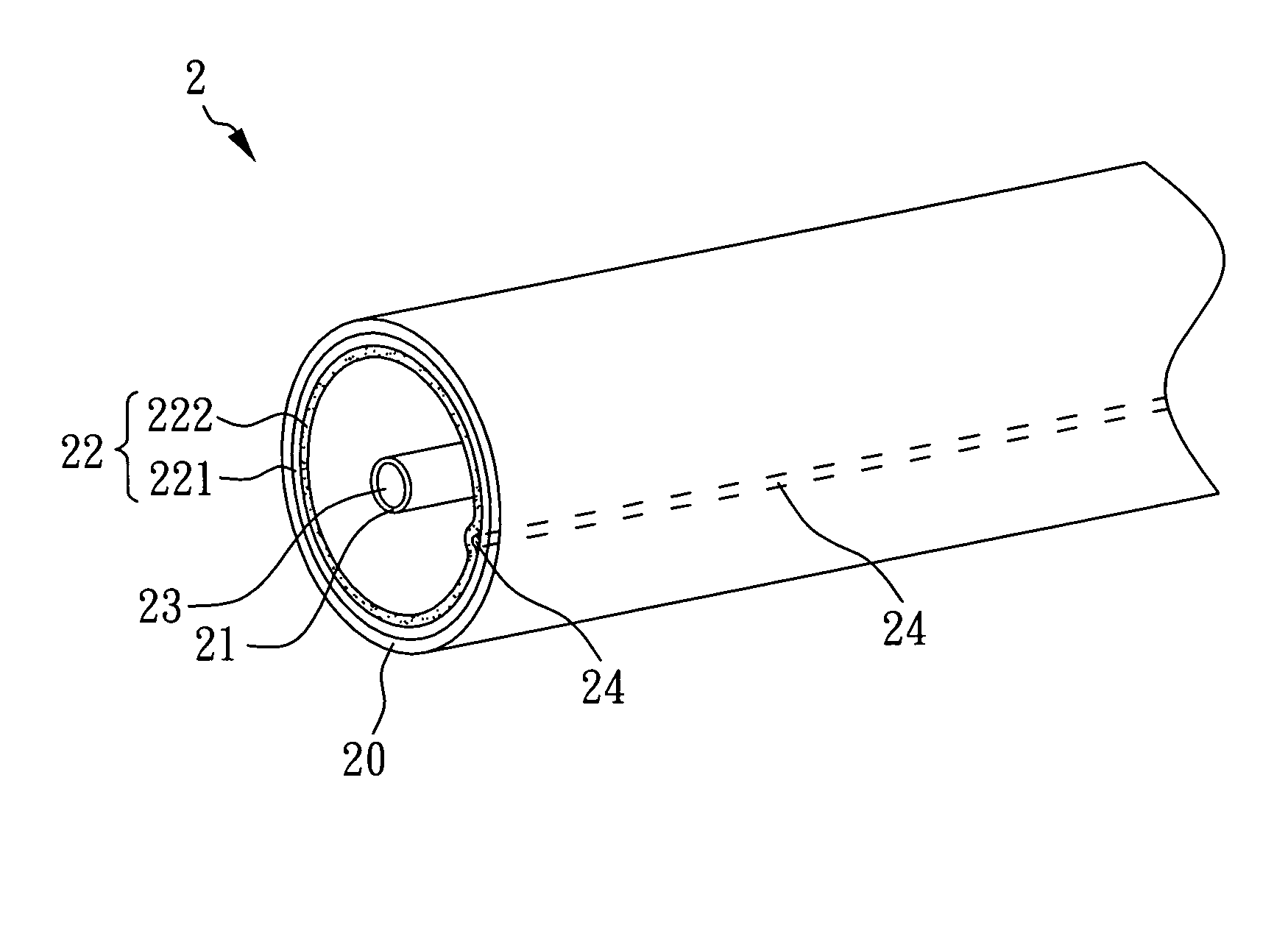

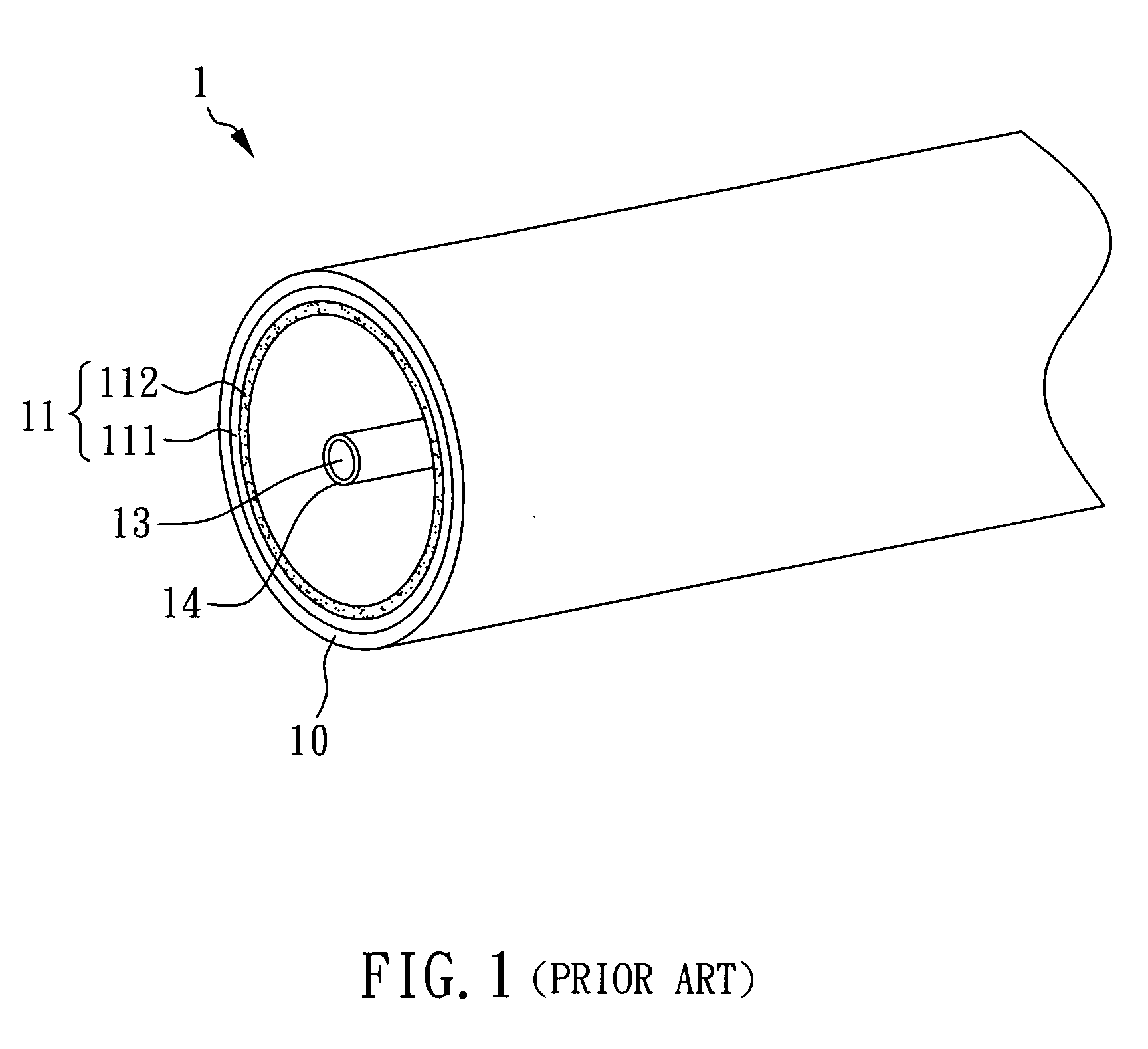

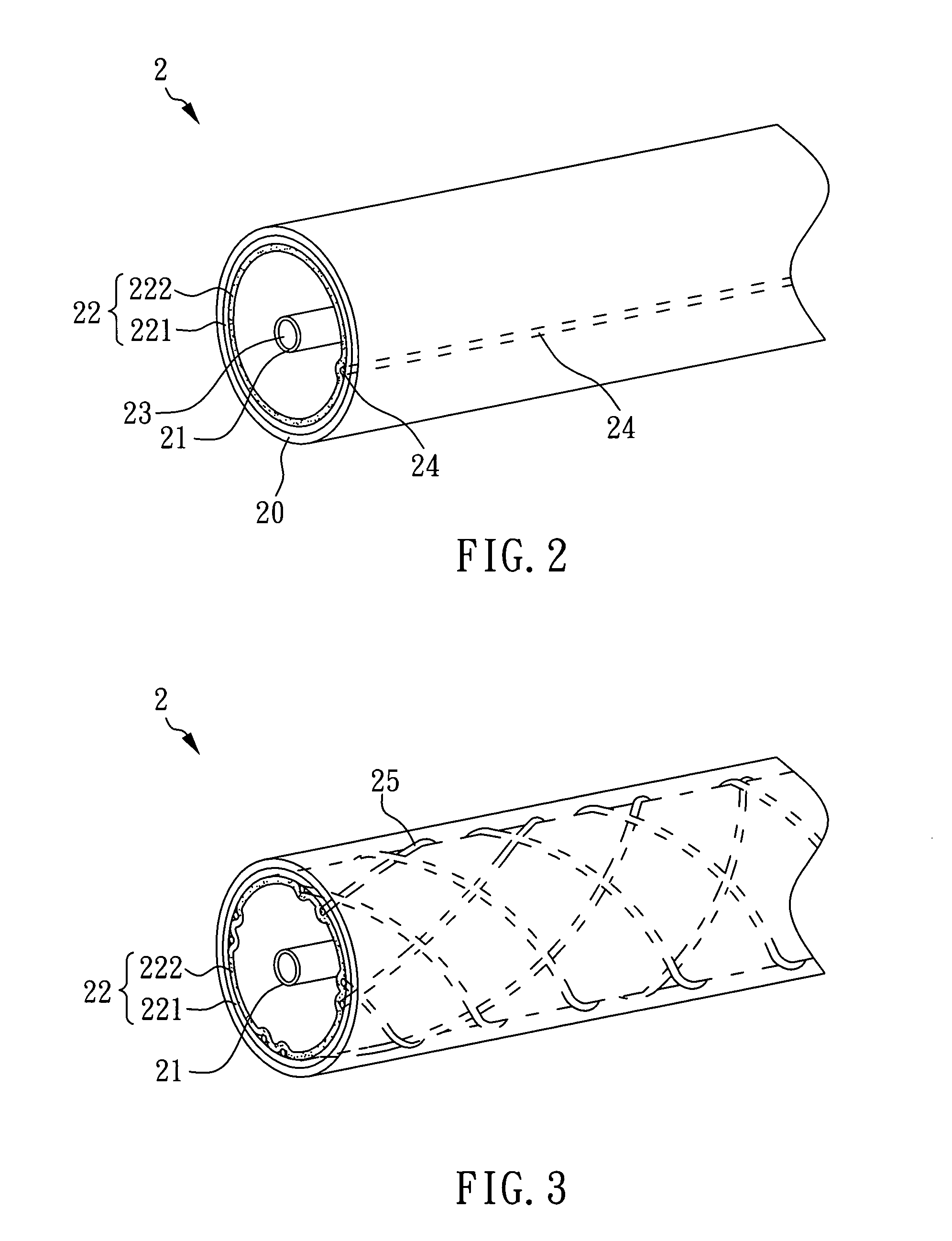

Field emission lamp and method for making the same

InactiveUS20110025188A1High light transmittanceShortening electron transportation path lengthDischarge tube luminescnet screensLamp detailsAuxiliary electrodeHigh electron

A field emission lamp and method of fabricating the same are disclosed, the field emission lamp of the present invention comprising a lamp tube, an anode, at least one auxiliary electrode, a cathode, and an emitter layer. The anode comprises a transparent conductive layer and a phosphor layer, and the transparent conductive layer is made of ITO, IZO, AZO, GZO, zinc oxide, or the combination thereof. The auxiliary electrode of the field emission lamp of the present invention can shorten the electron transportation path length, increase the electron transportation efficiency, reduce the phenomenon of micro-discharges caused by electron charging, reduce the voltage loss, reduce the temperature increase of the phosphor layer and elongate the lifetime of the field emission lamp.

Owner:TATUNG COMPANY

Information storage

In order to significantly increase a recording density of a storage, an electron beam (E) emitted from a cold cathode (101) is accelerated by an acceleration electrode (102), converged by a convergence electrode (103), deflected by a deflection electrode (104), and made to impinge on a micro region of a memory film (105). The memory film (105) has, for example, a phase change film (105a). When the memory film (105) is irradiated with a high-energy electron beam (E), it is rapidly heated and cooled and becomes an amorphous state. When the memory film (105) is irradiated with a middle-energy electron beam (E), it is slowly cooled and crystallized thereby to store data. When the memory film (105) is irradiated with a low-energy electron beam (E), depending on the state of amorphous development or crystallization, a different potential difference between a detection electrode (105b) and an anode (105c) is detected and the stored data is read out.

Owner:PANASONIC CORP

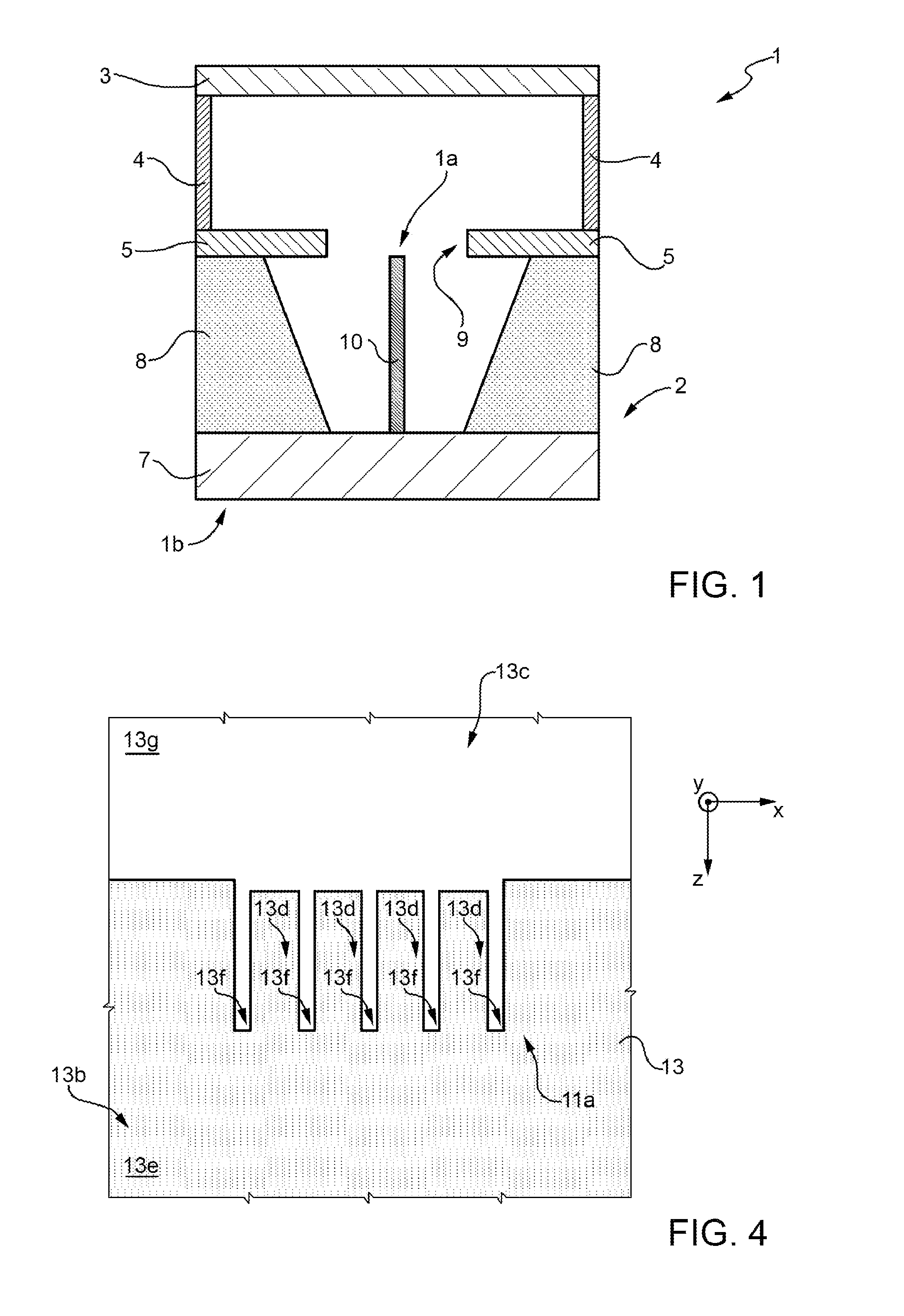

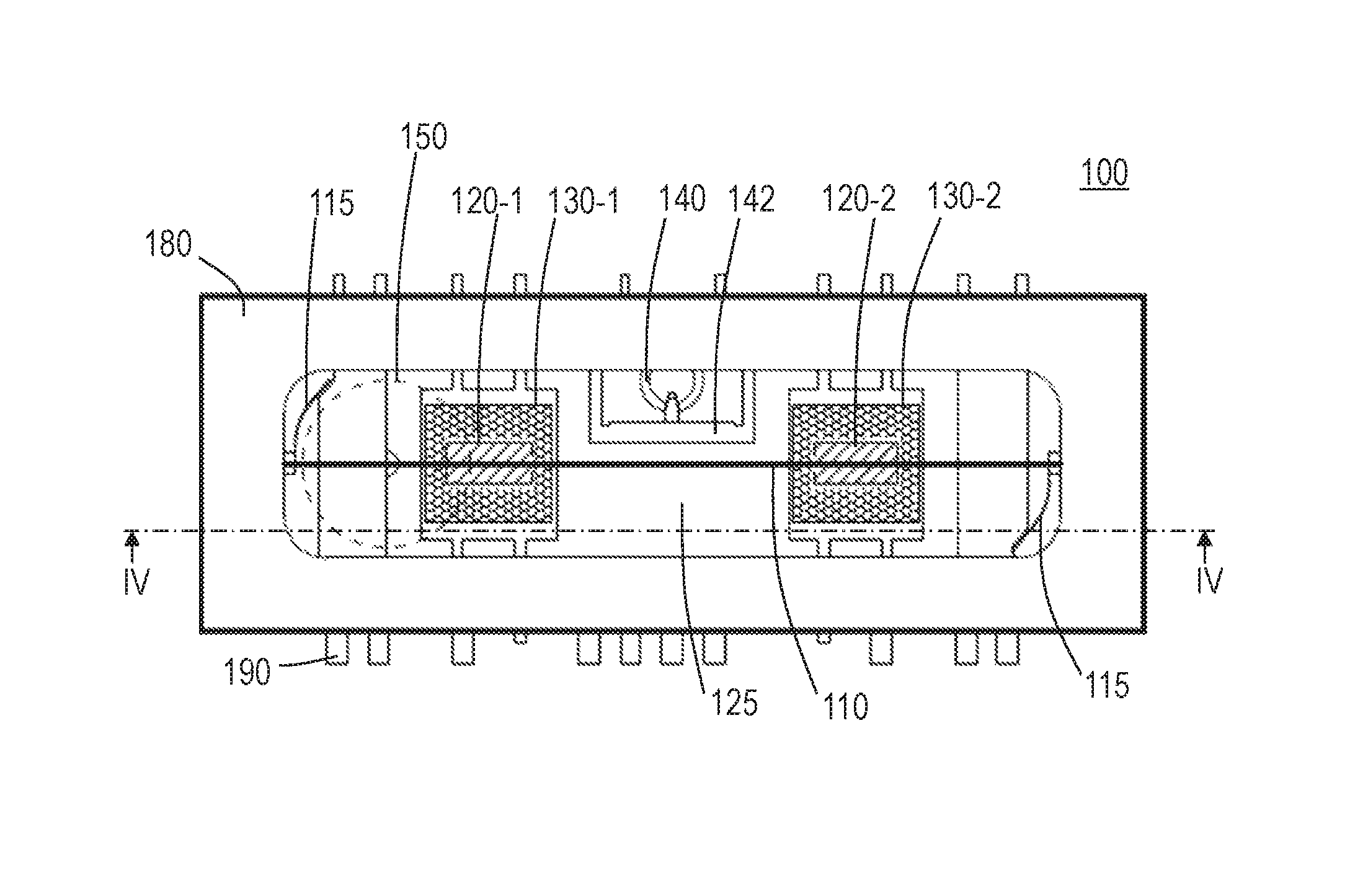

Vacuum tube

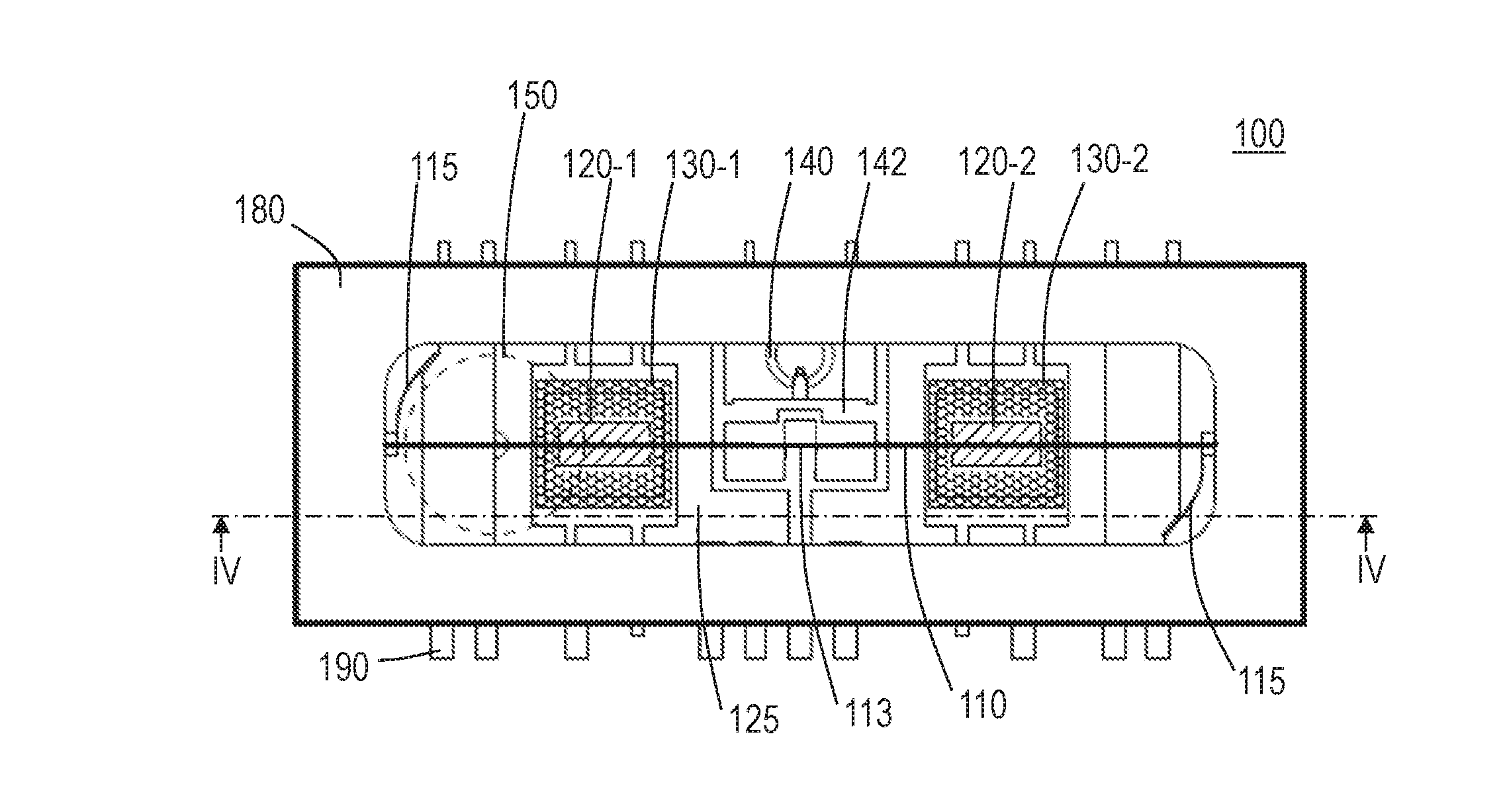

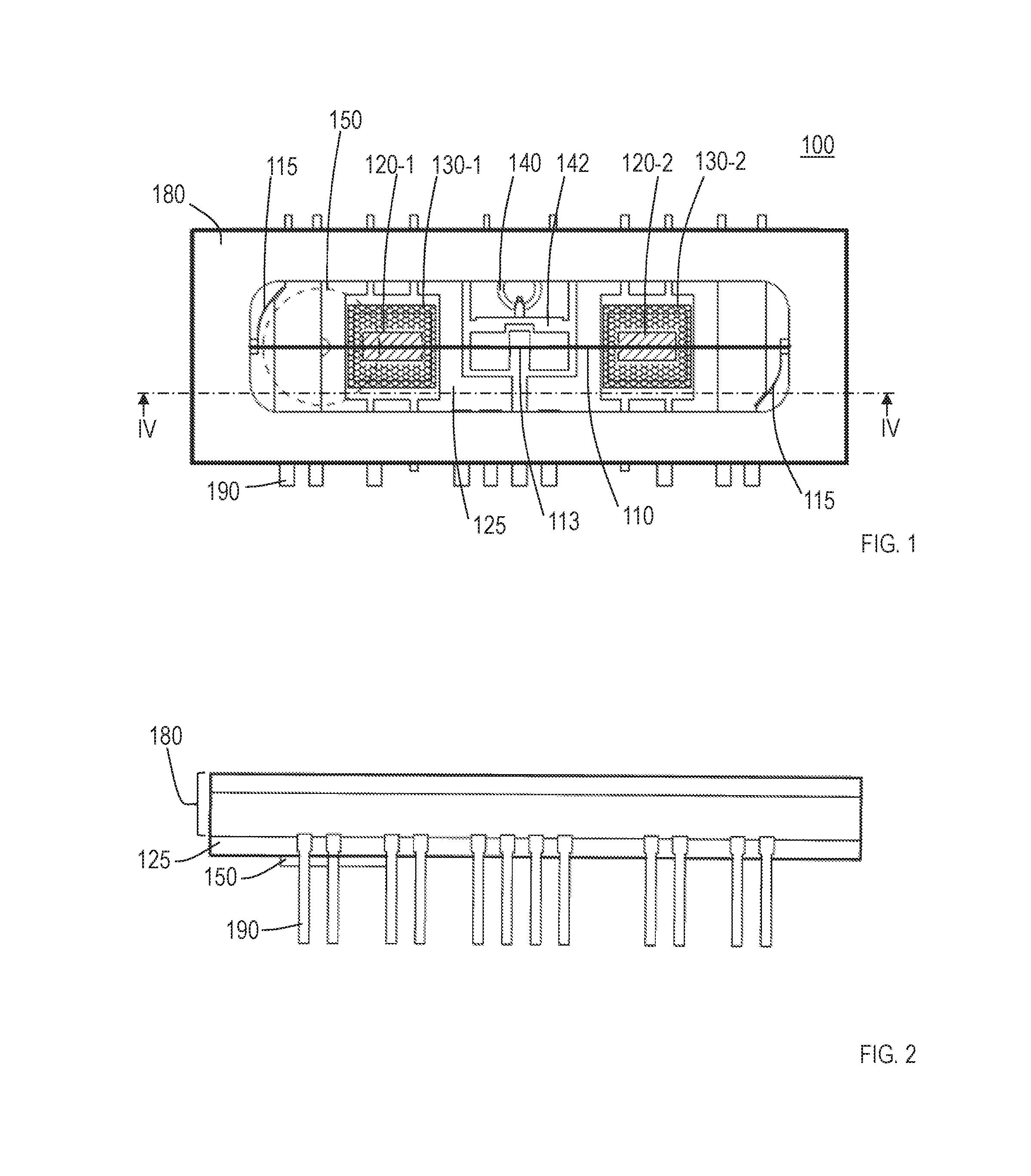

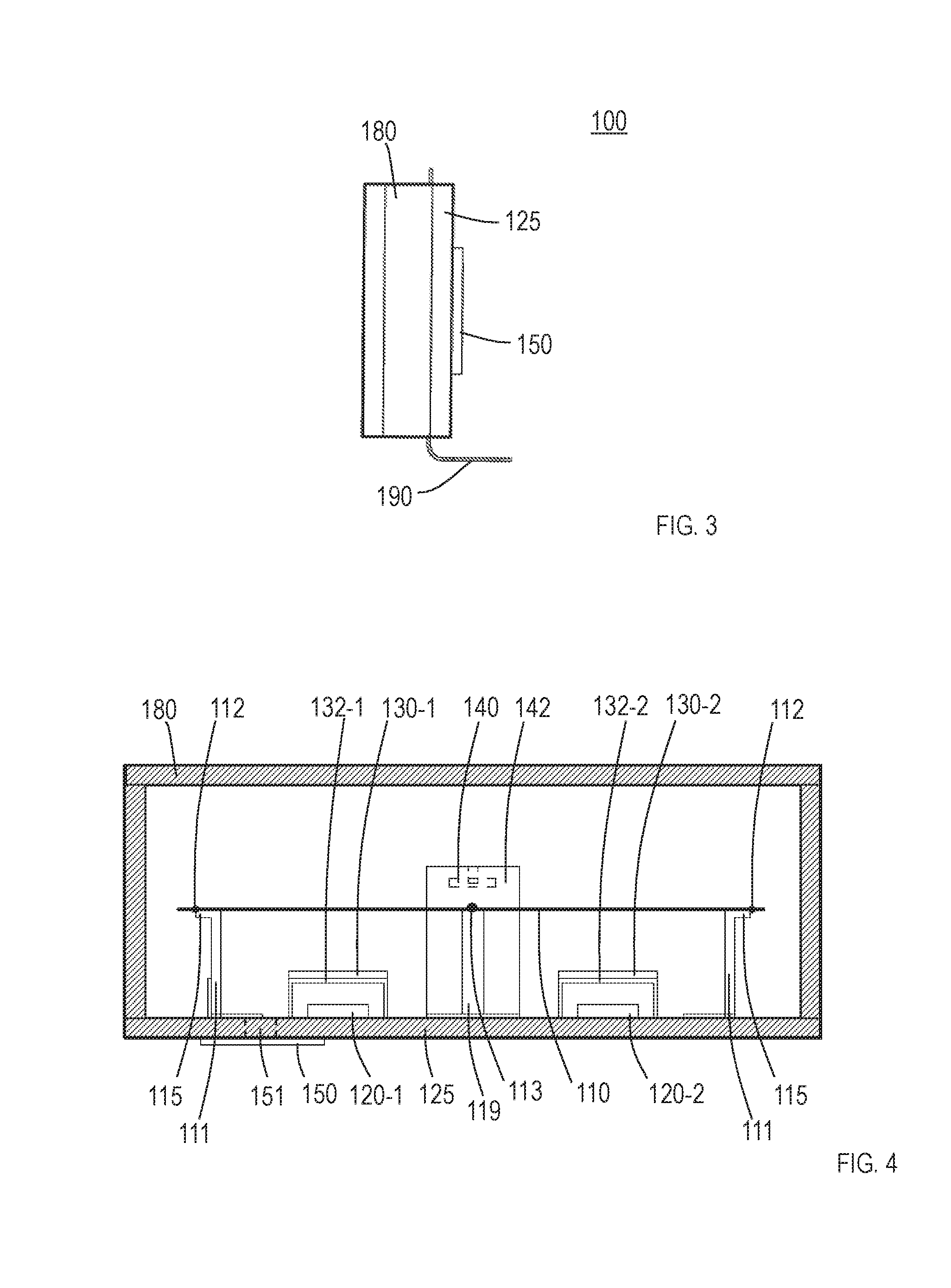

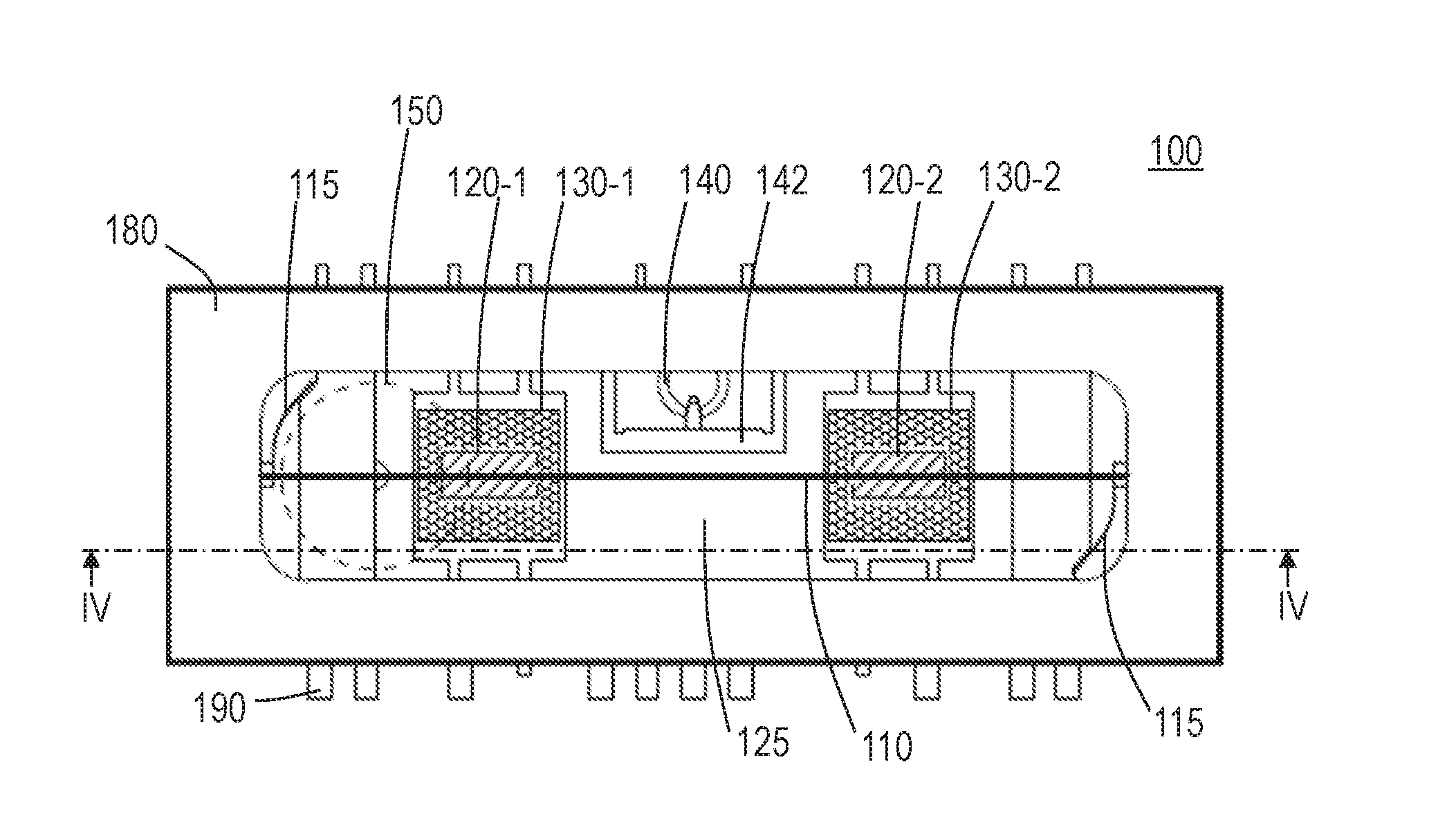

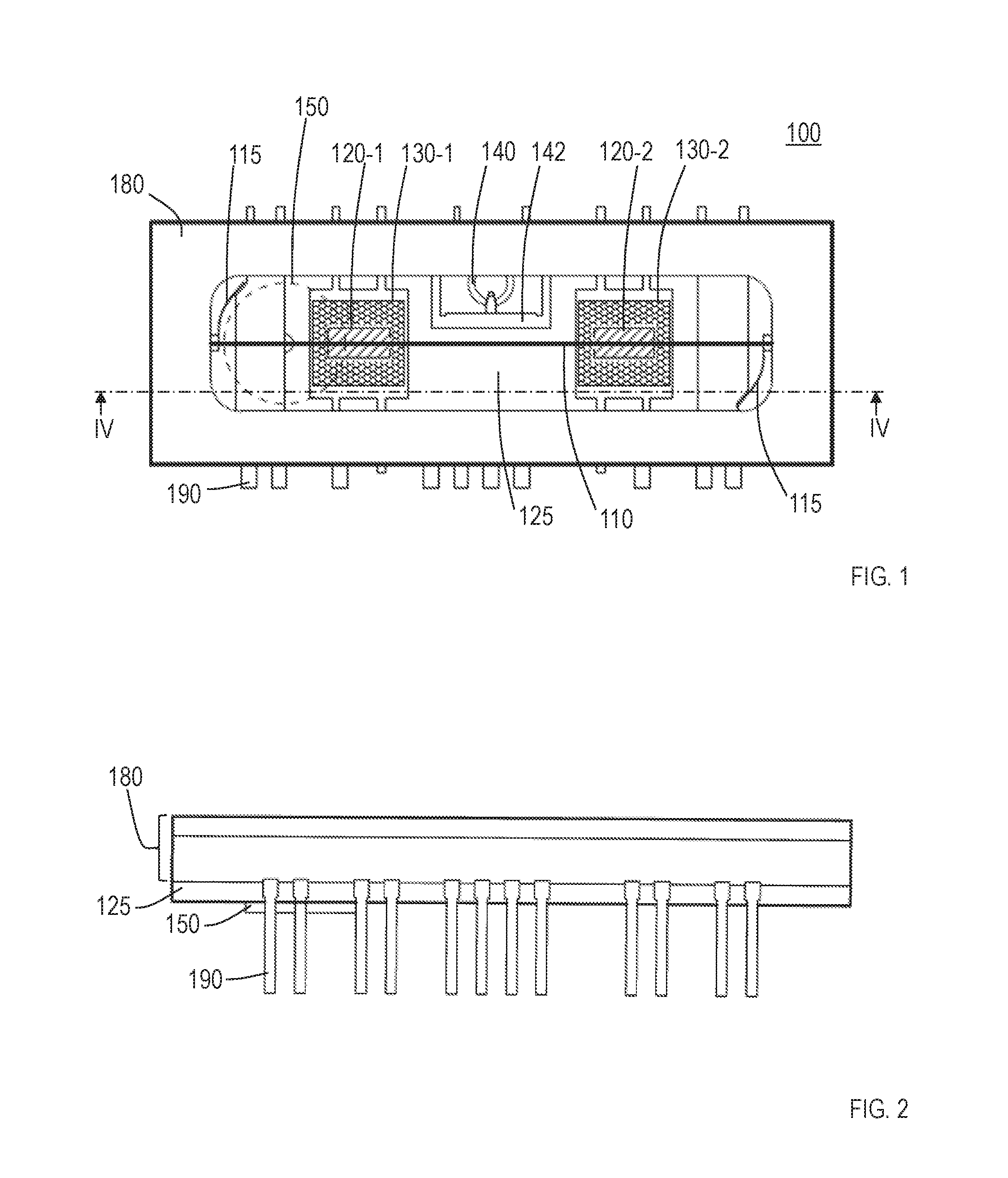

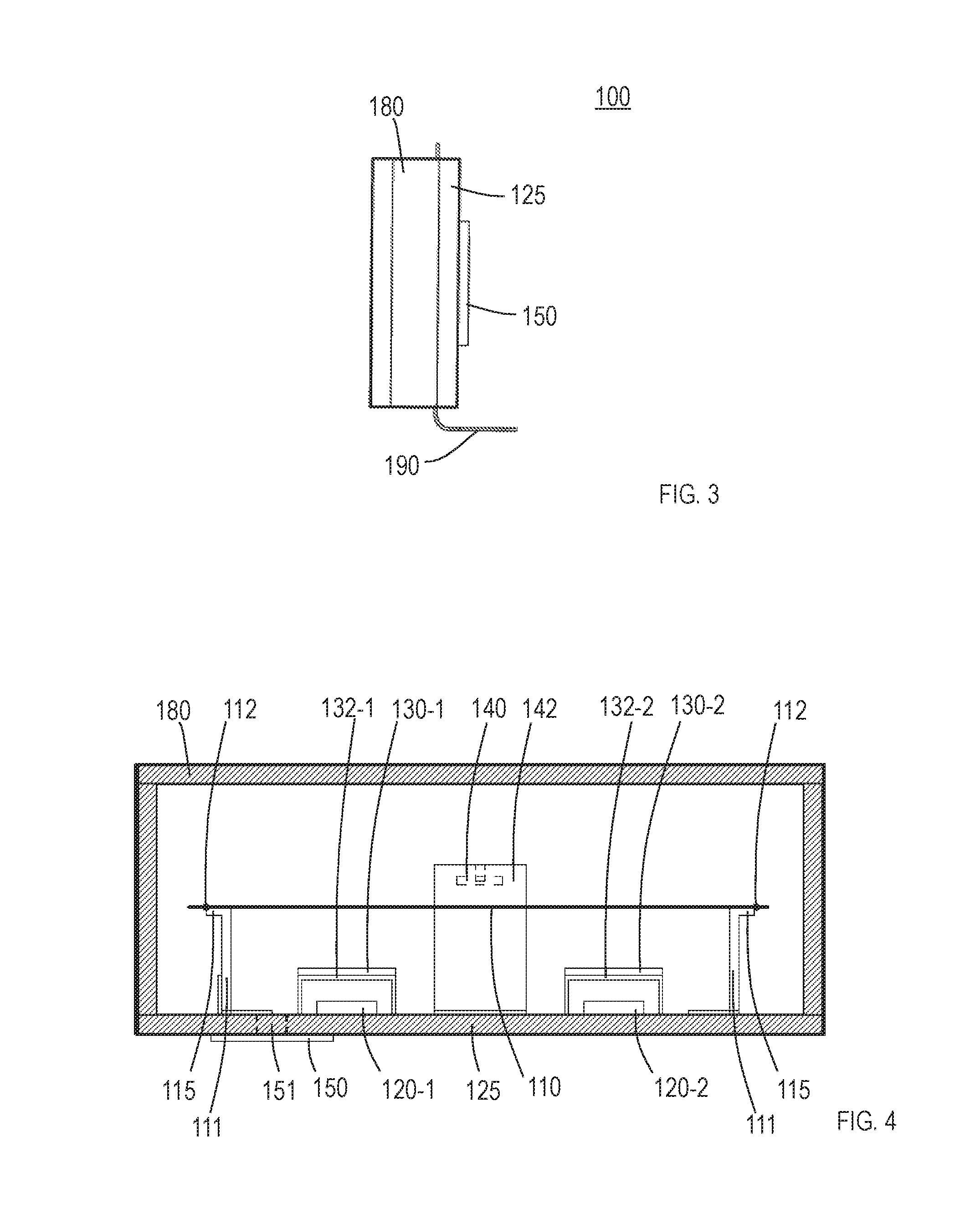

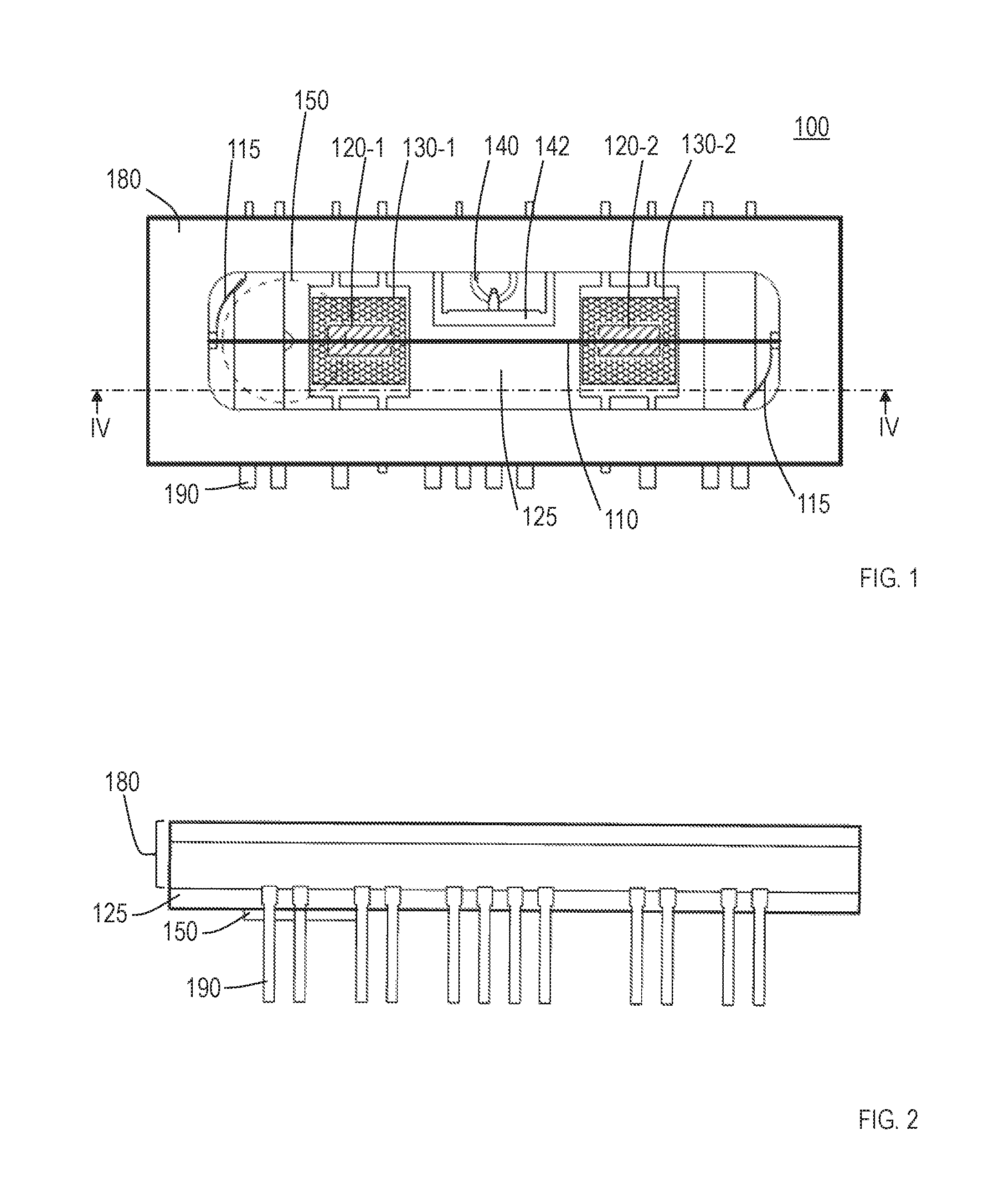

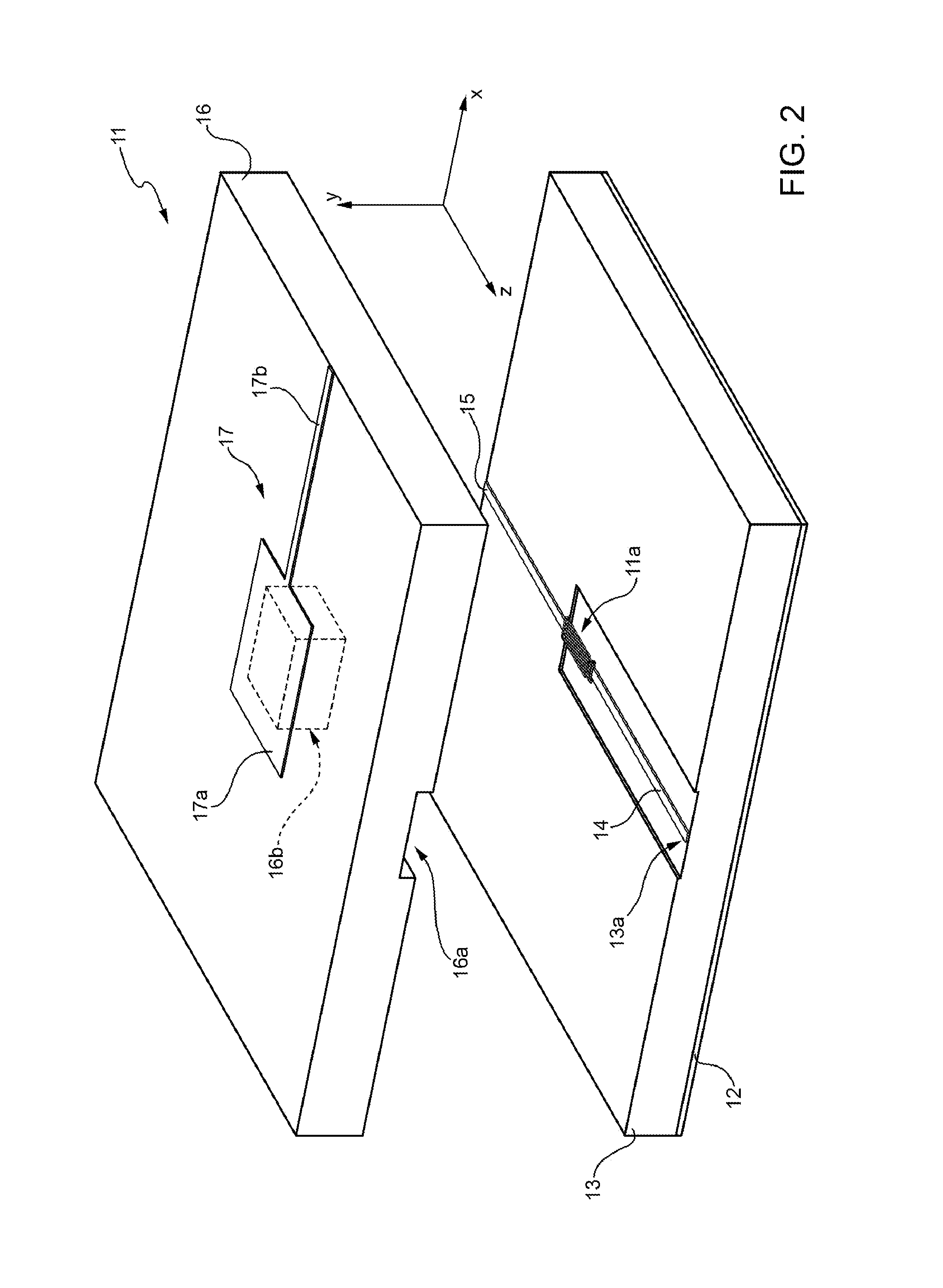

ActiveUS20160211106A1High vibration frequencyEasy to useControl electrodesLow frequency amplifiersPlanar substrateIntermediate filament

The vacuum tube subject to the present invention comprises a filament and two pairs of a grid and an anode. The filament is tensioned linearly and emitting thermoelectrons. Both of the anodes are formed on the same face on a planar substrate. The filament is arranged parallel to the planar substrate at a position facing both of the anodes. Each of the grids is arranged, such that the grid faces the anode in the same pair at a first predetermined distance from the anode and has a second predetermined distance from the filament, between the anode and the filament. The vacuum tube comprises an intermediate filament fixing part fixing the filament at a position corresponding to an intermediate point between the anodes of the two pairs.

Owner:NORITAKE ITRON CORP +2

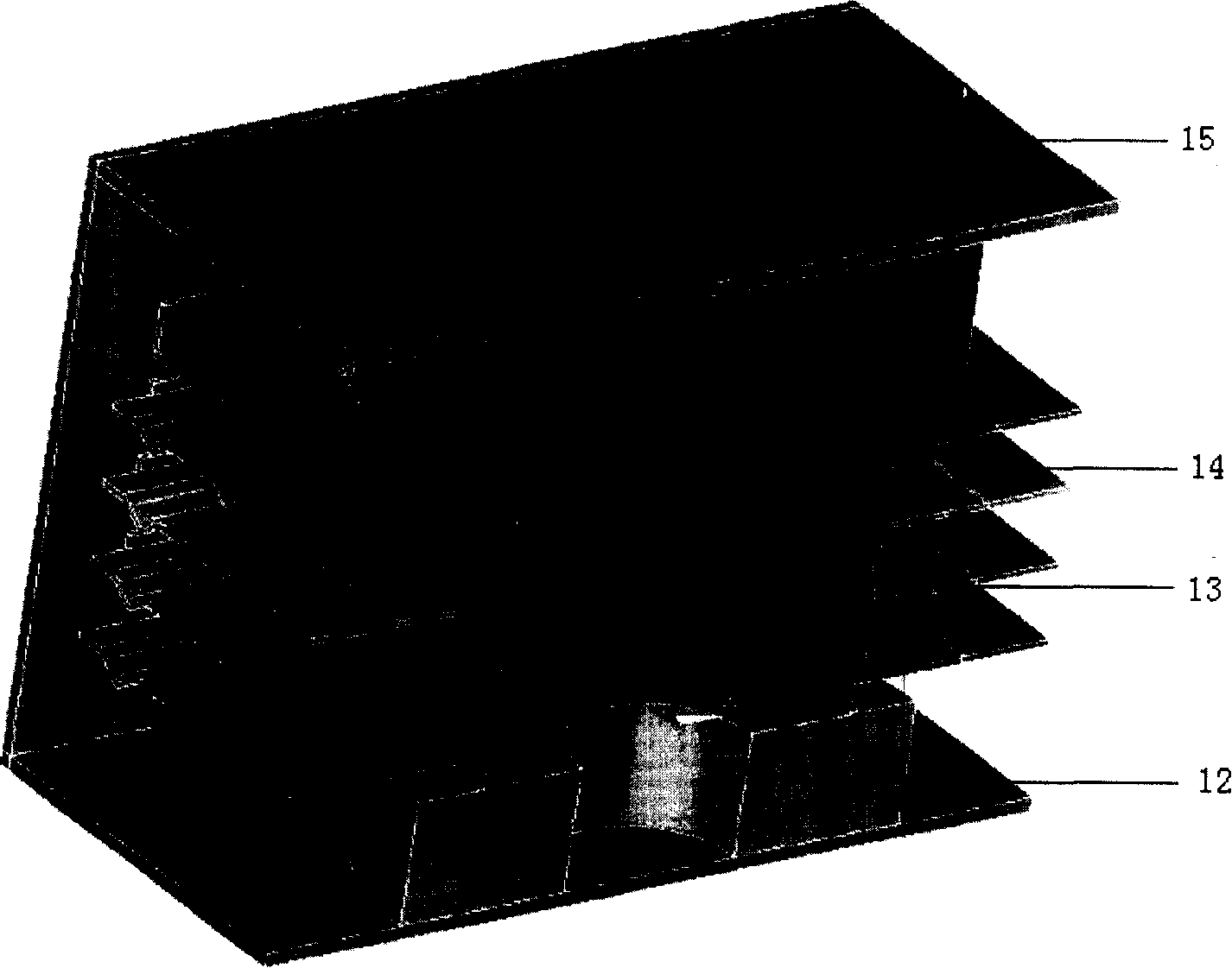

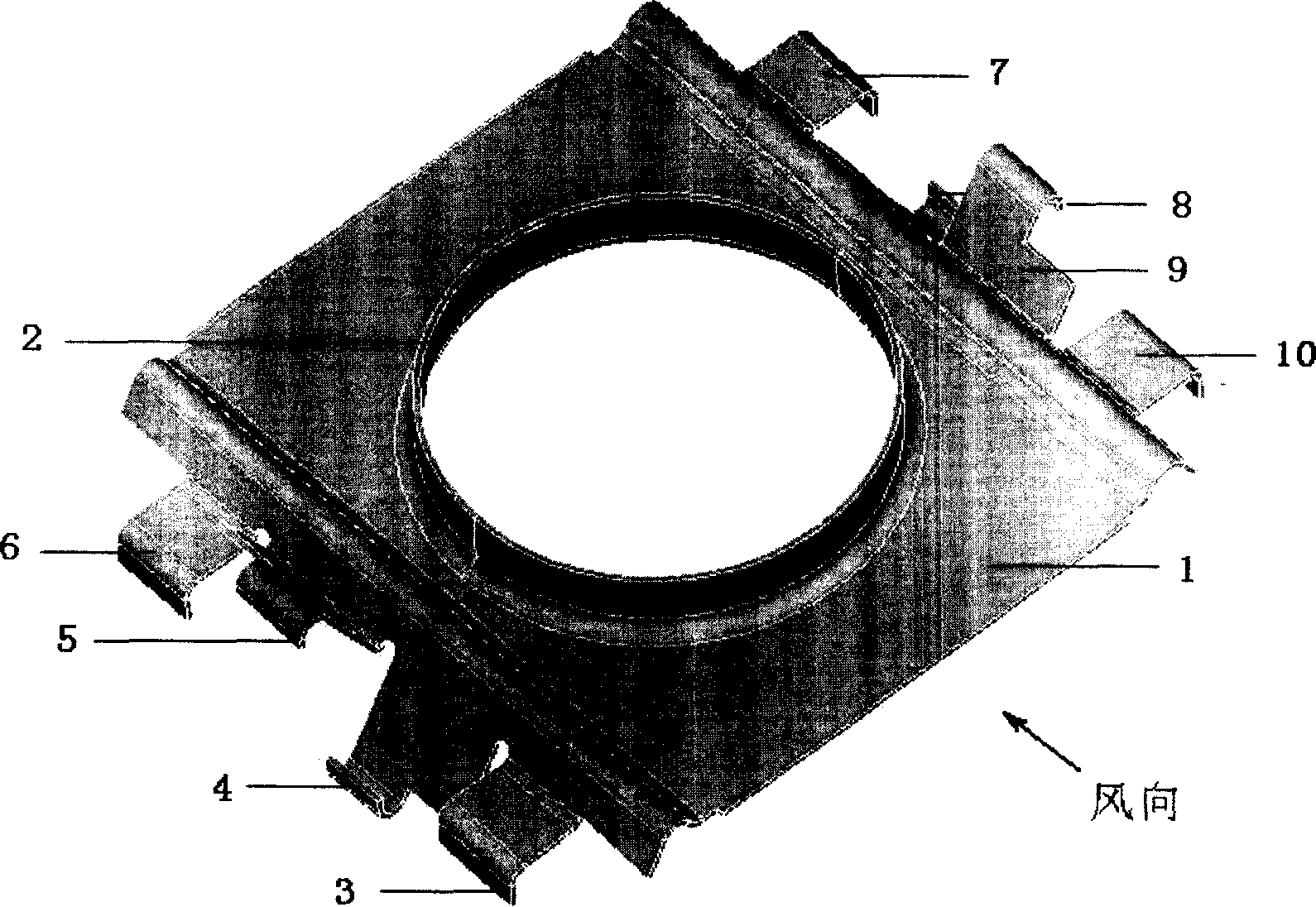

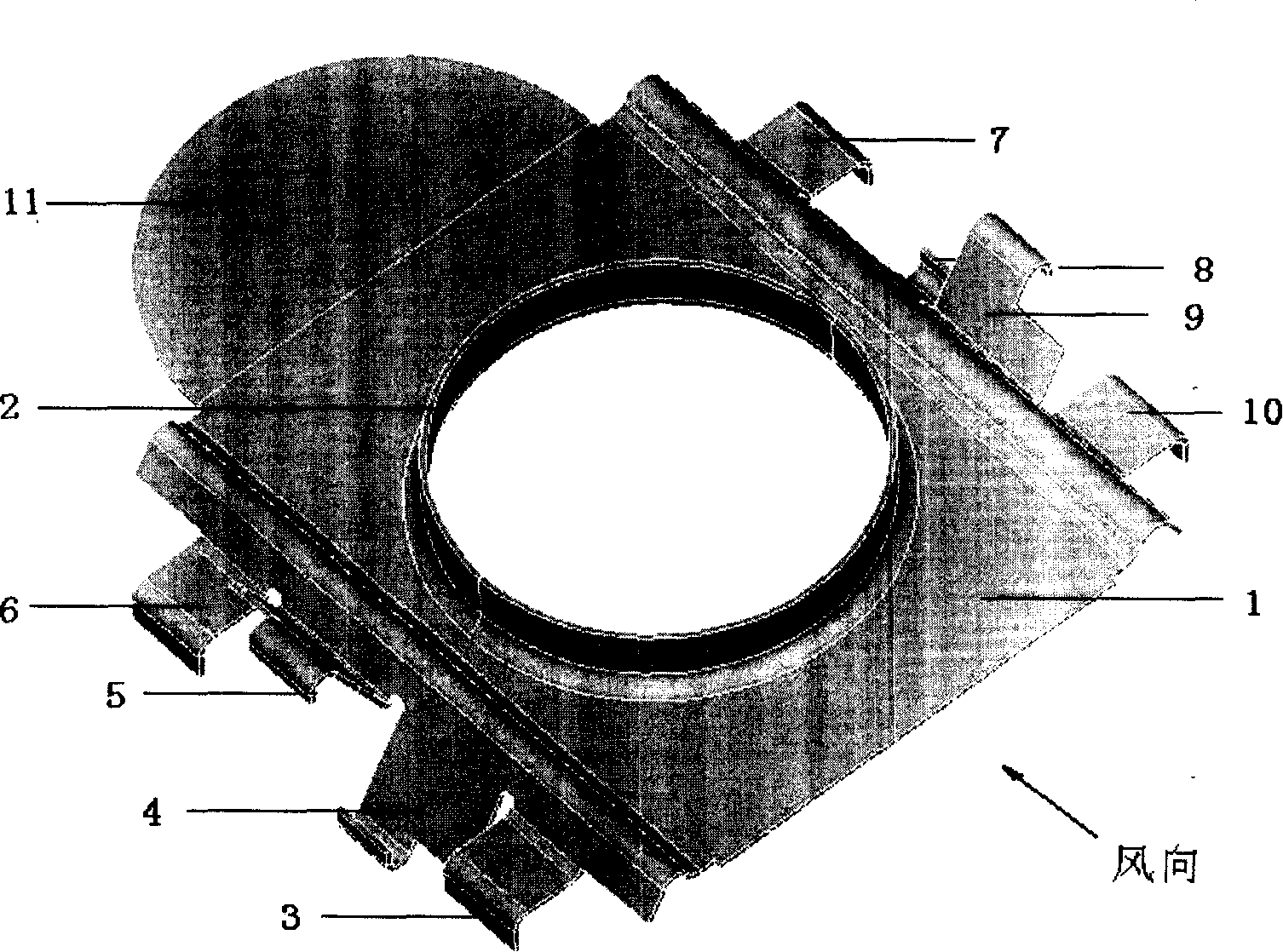

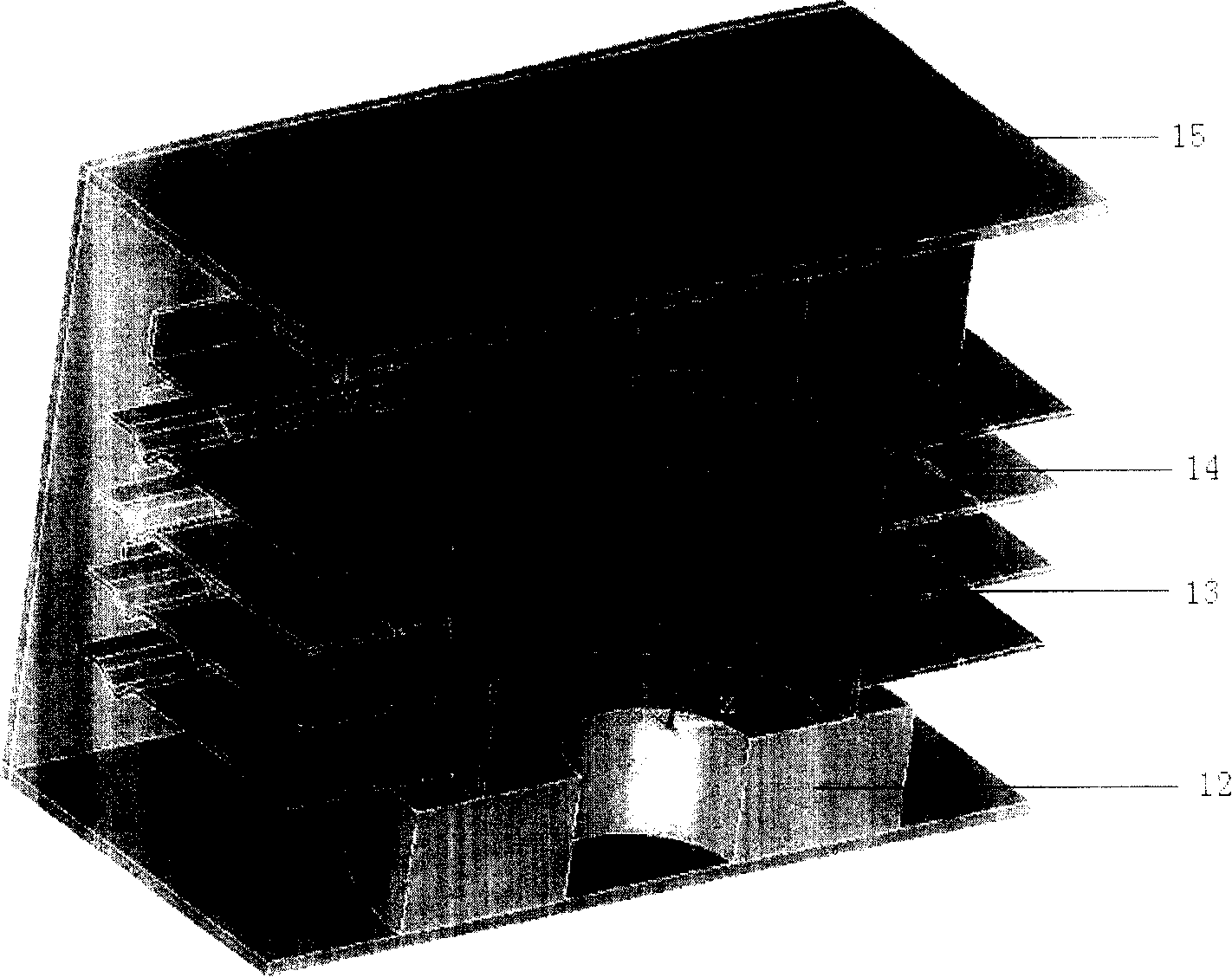

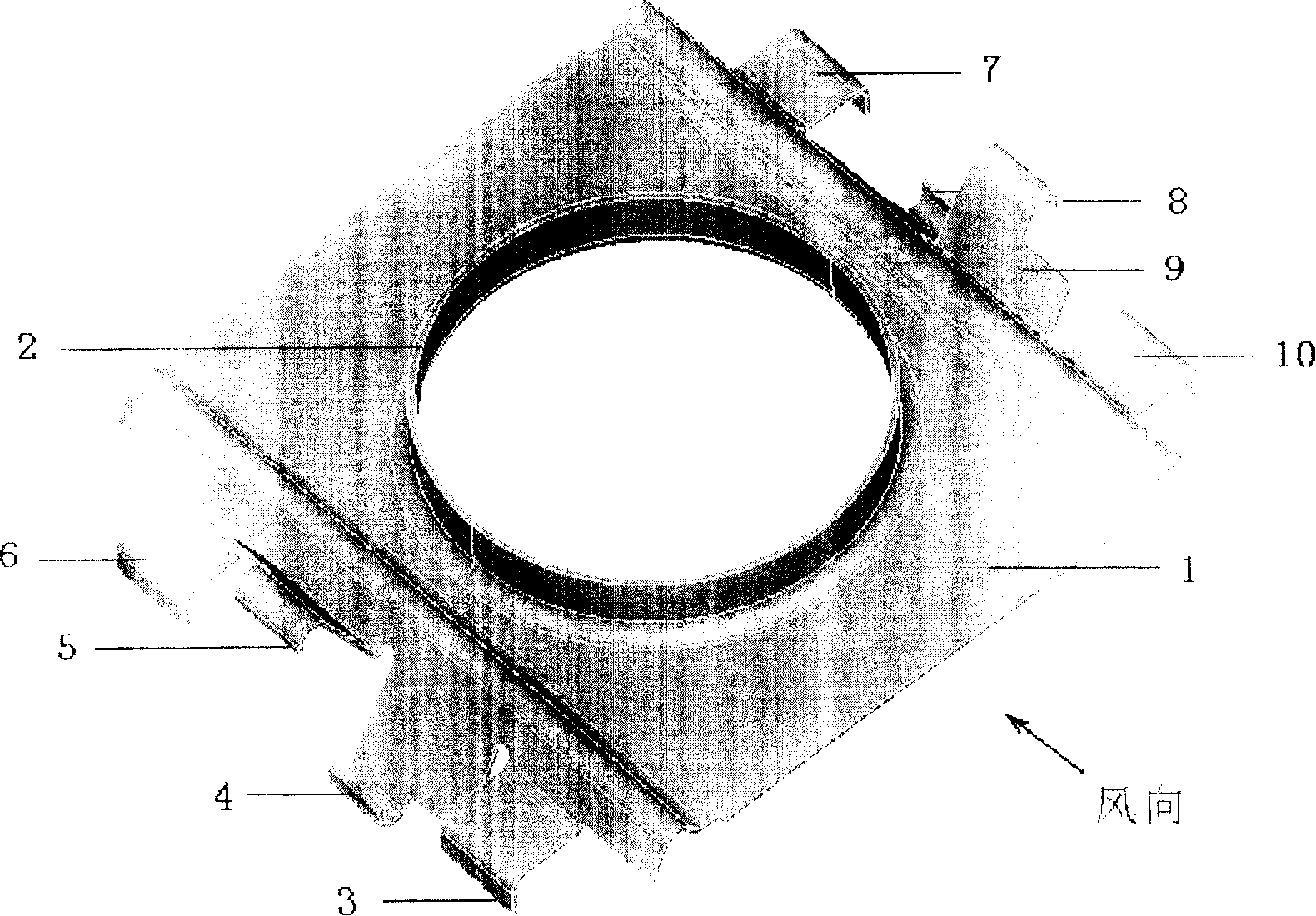

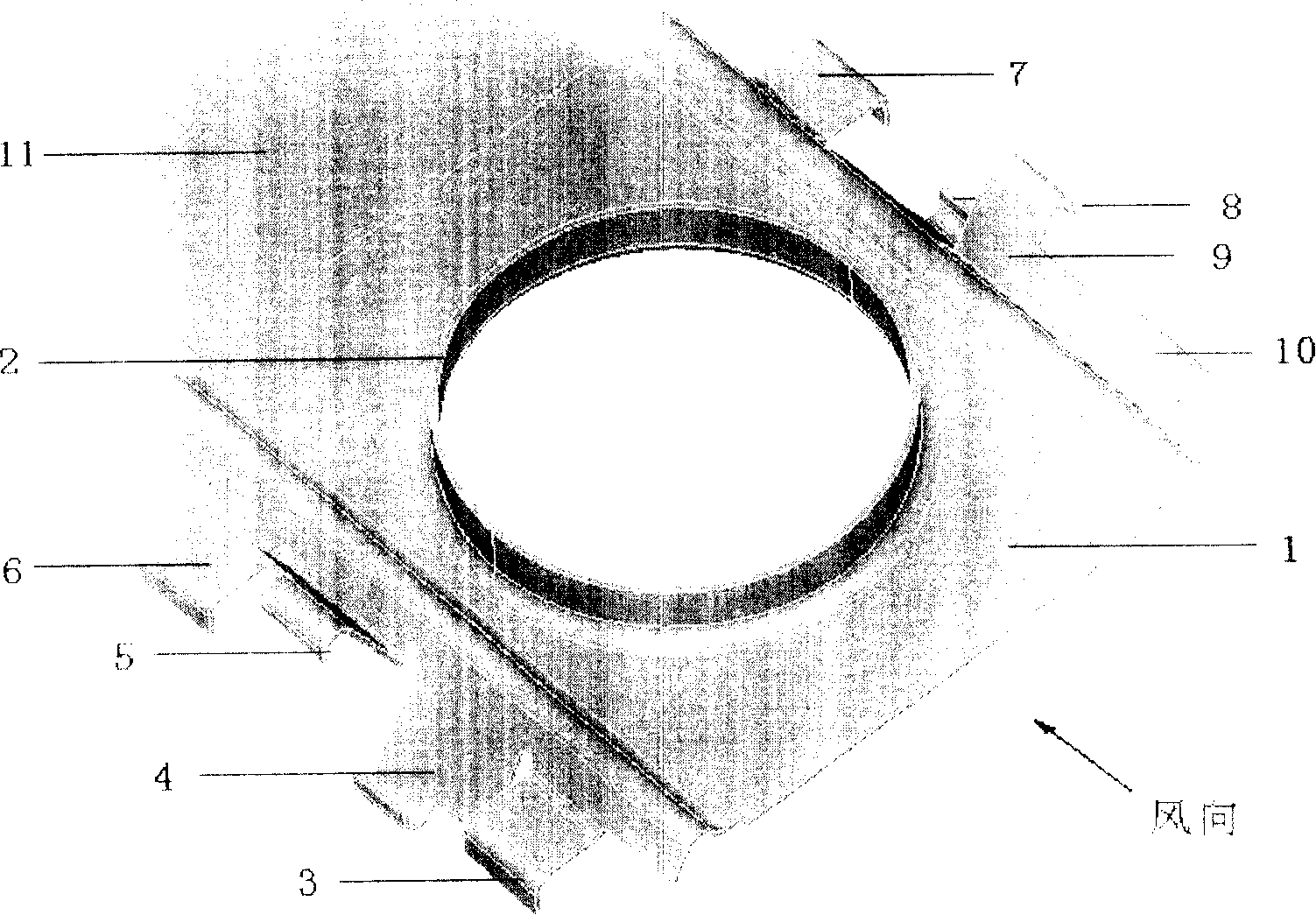

Forced-convection asymmetrical radiator

InactiveCN1641825ADoes not affect heat dissipationReduce usageMagnetronsNon-electron-emitting anodesProduction lineHigh volume manufacturing

The invention discloses a dissymmetrical radiator under compelling convection. It uses the feature that the temperature field is dissymmetrical while compelling convection. Cutting off a certain wideness of the main fan in existence at the wind entrance, and keep the original size at the wind exit. Thus, the magnetron anode is in the dissymmetrical location relative to the main fan. It is easy to produce and need not to change the product line and process. The invention can not only used for magnetron heat emission, but also used as the other radiator under compelling convection.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Microwave driven electrodeless lamp comprising magnetron without forced convective cooling

InactiveUS9159520B2Lighting heating/cooling arrangementsDischarge tube main electrodesMicrowaveForced convection

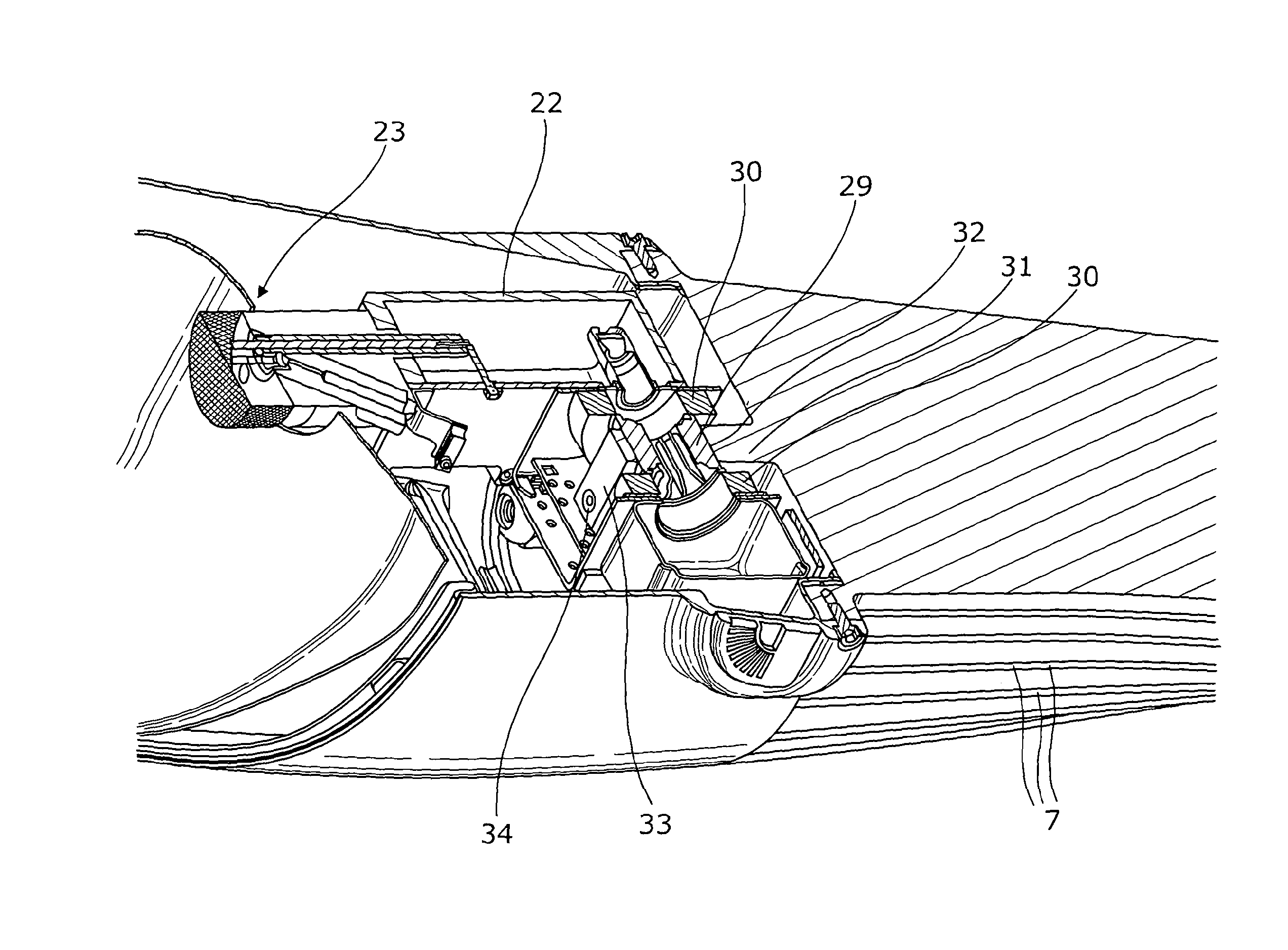

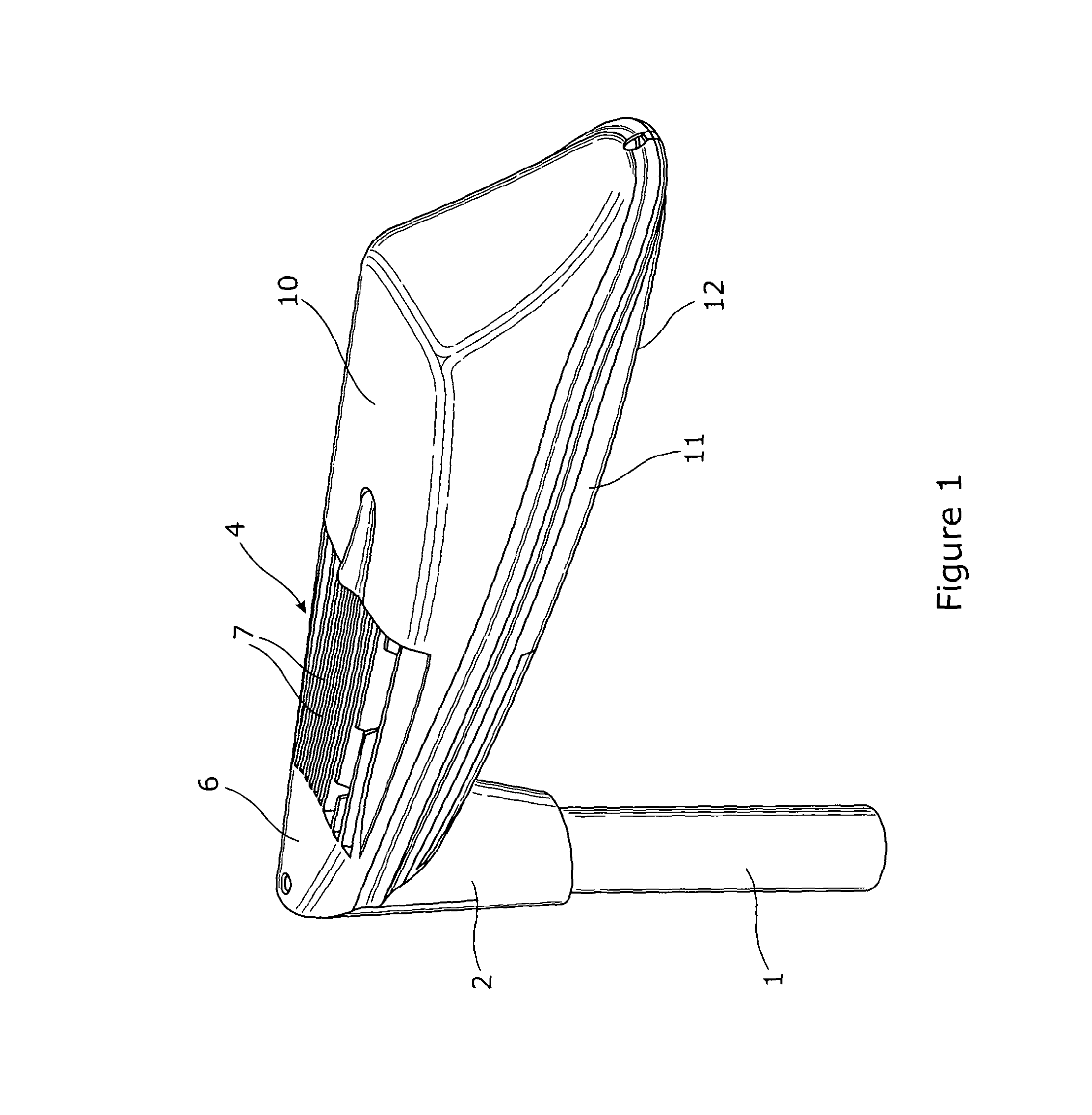

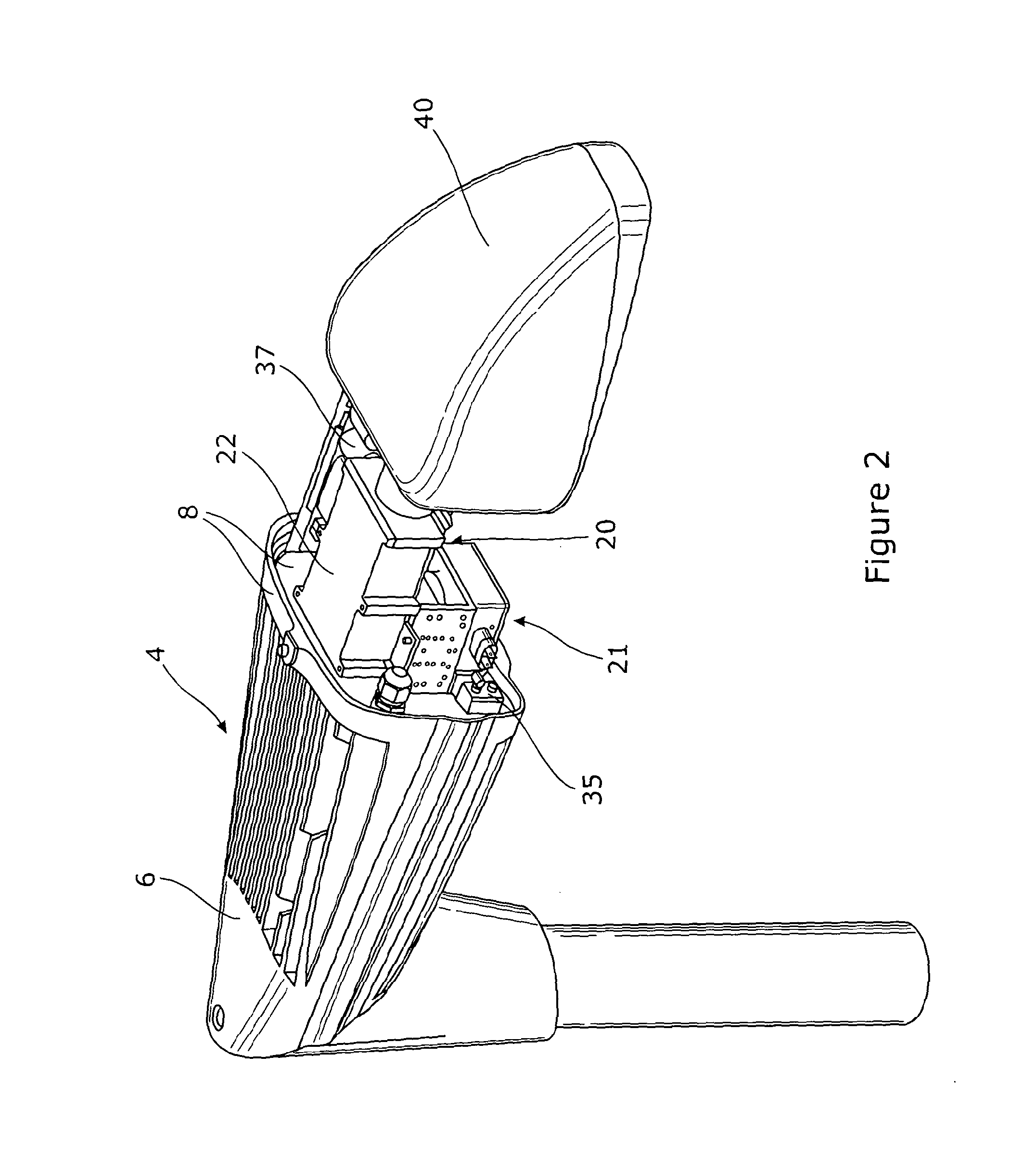

A LUWPL luminaire has a housing with a lower transparent closure and a heat dissipating top of cast aluminum. This has a suspension eye. The housing has an upper flange via which it is bolted with the interposition of a seal to a underside rim of the top. Within the rim, the underside is substantially flat, with a magnetron attachment boss and other attachment points. A magnetron is supported by being clamped by a saddle to the attachment boss at the magnetron's anode. The magnetron is fast with a transition box and a crucible support block. A bracket fixed to certain of the attachment points extends down from the top is screwed to the transition box. Thus the LUWPL parts are securely supported below the top.

Owner:CERAVISION LTD

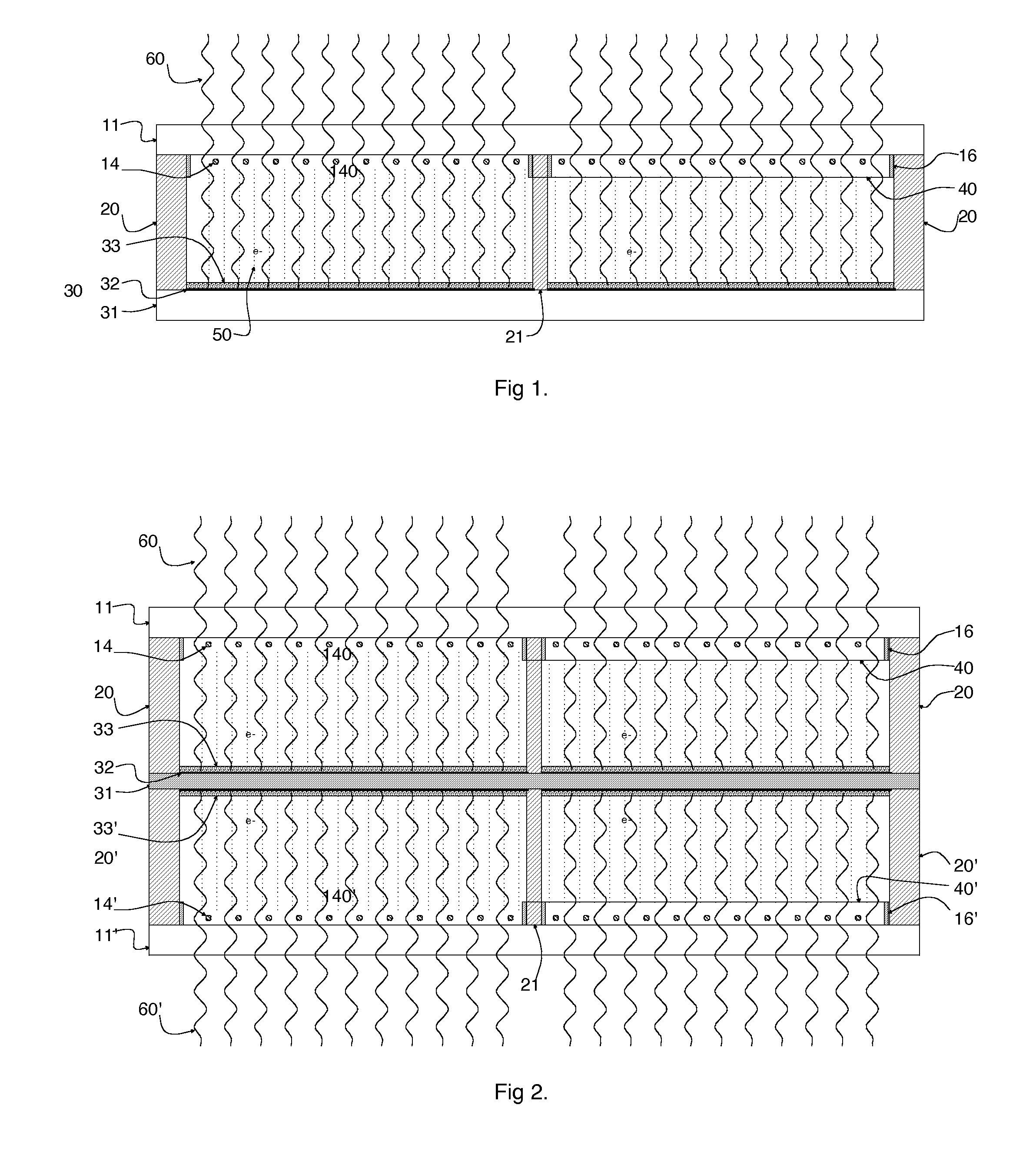

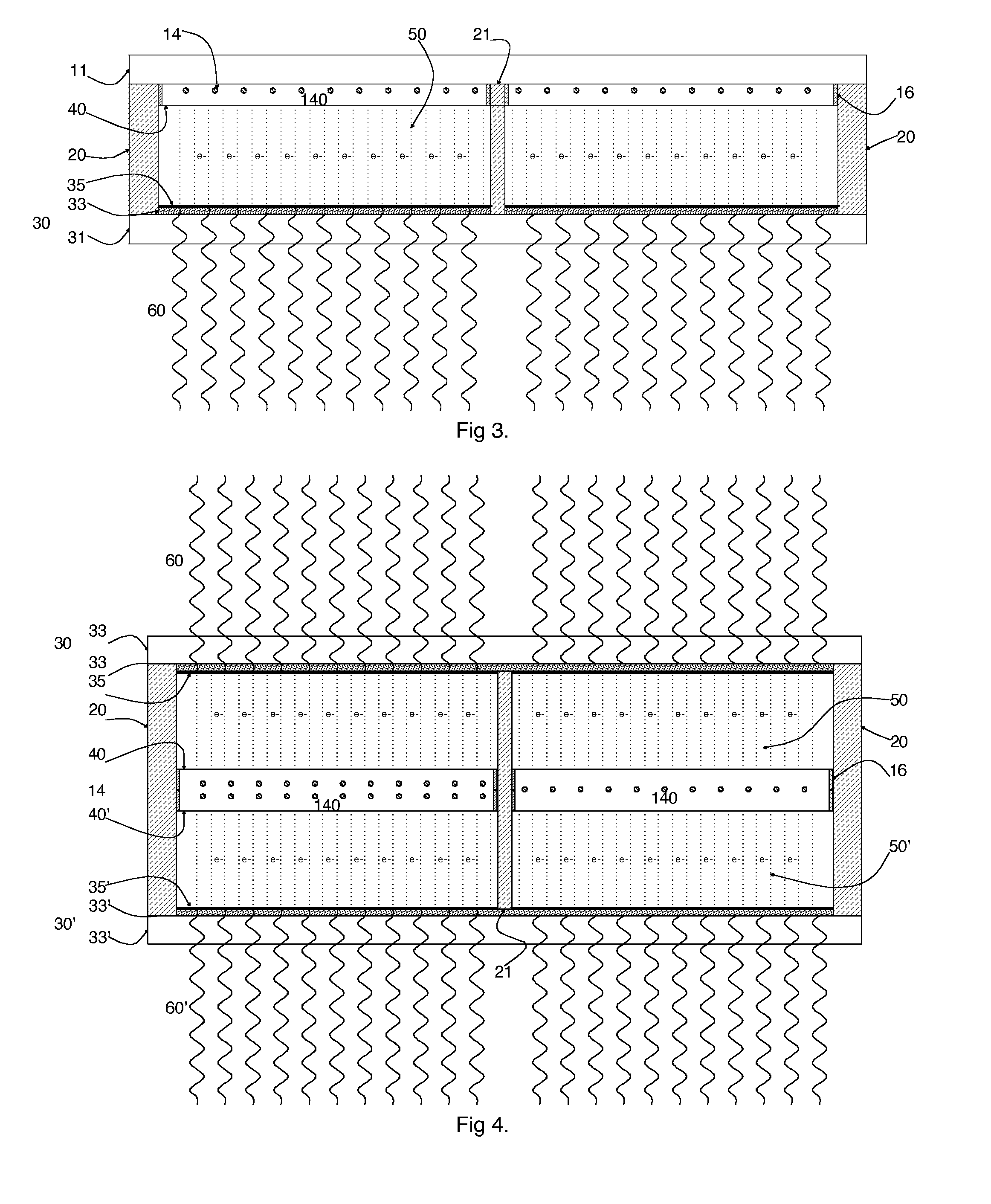

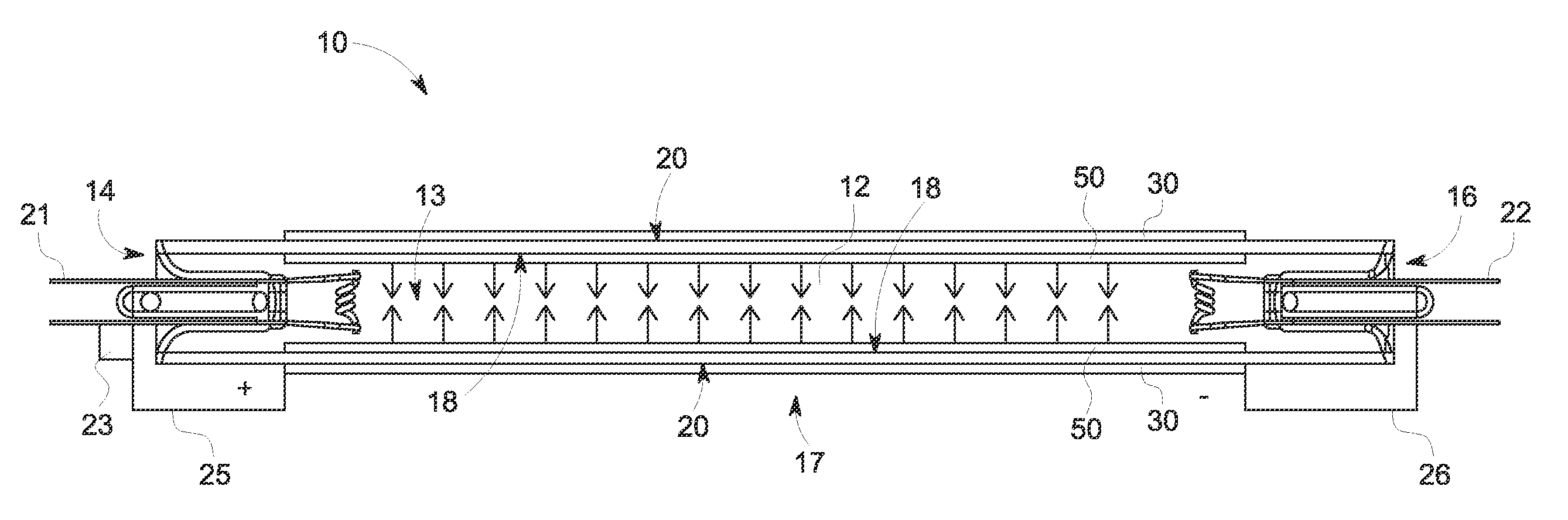

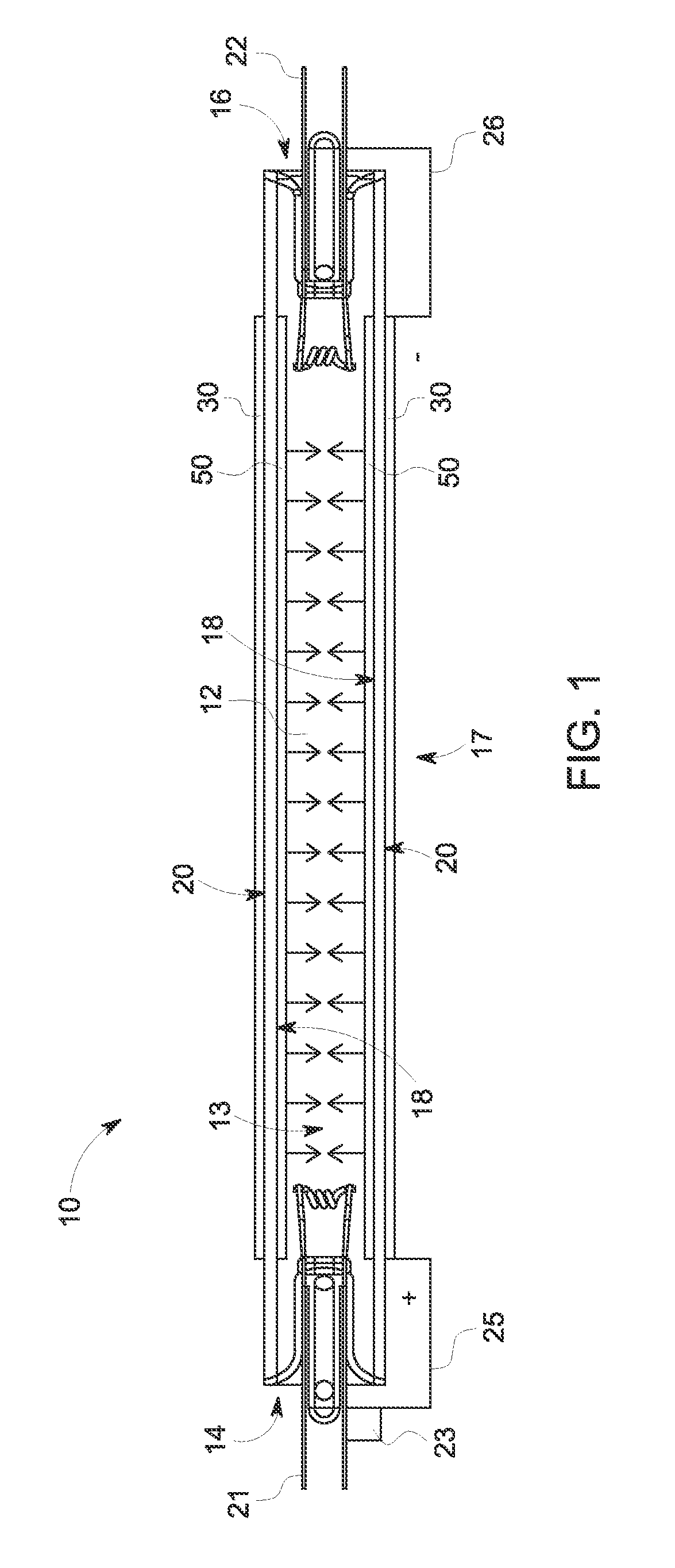

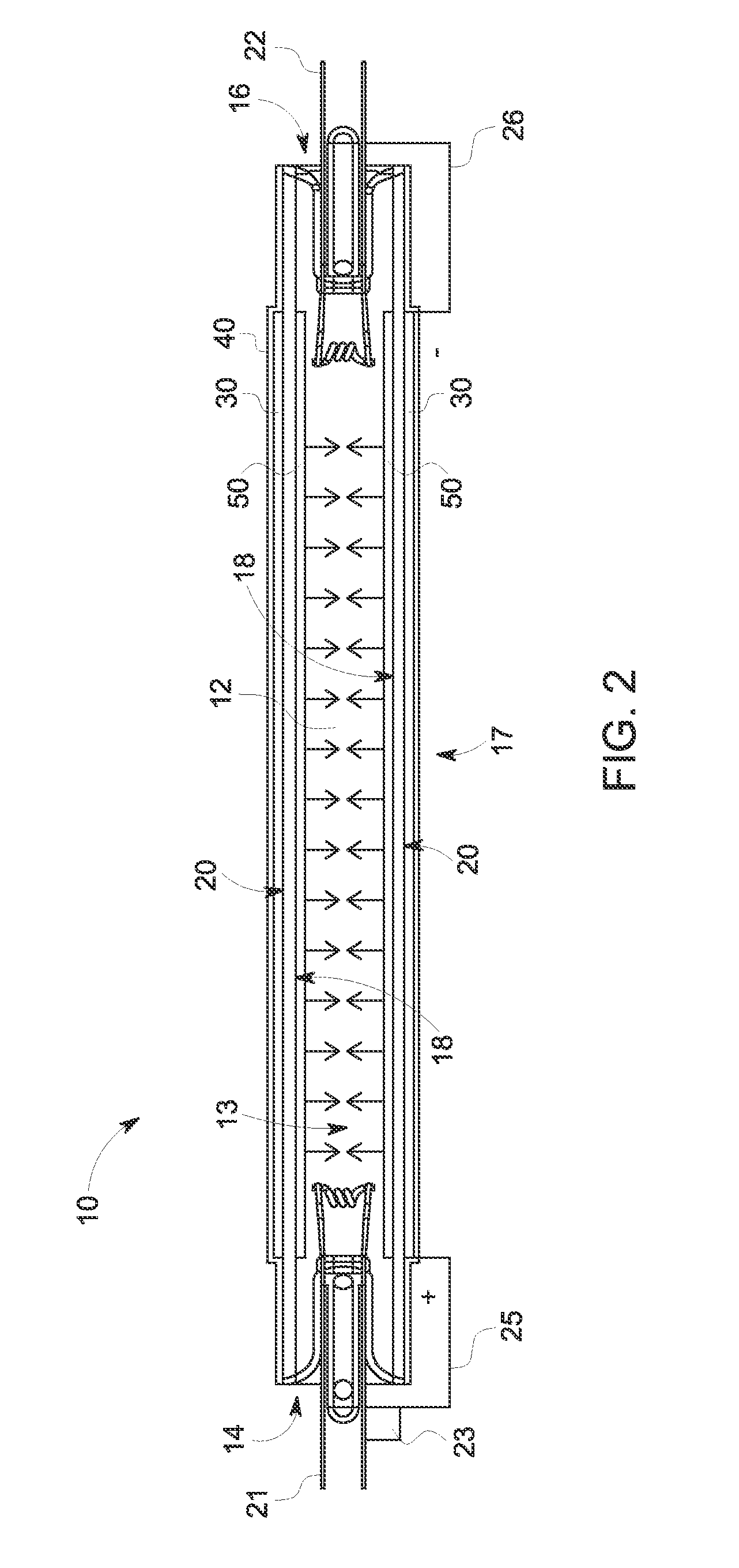

Cathodoluminescent UV Panel

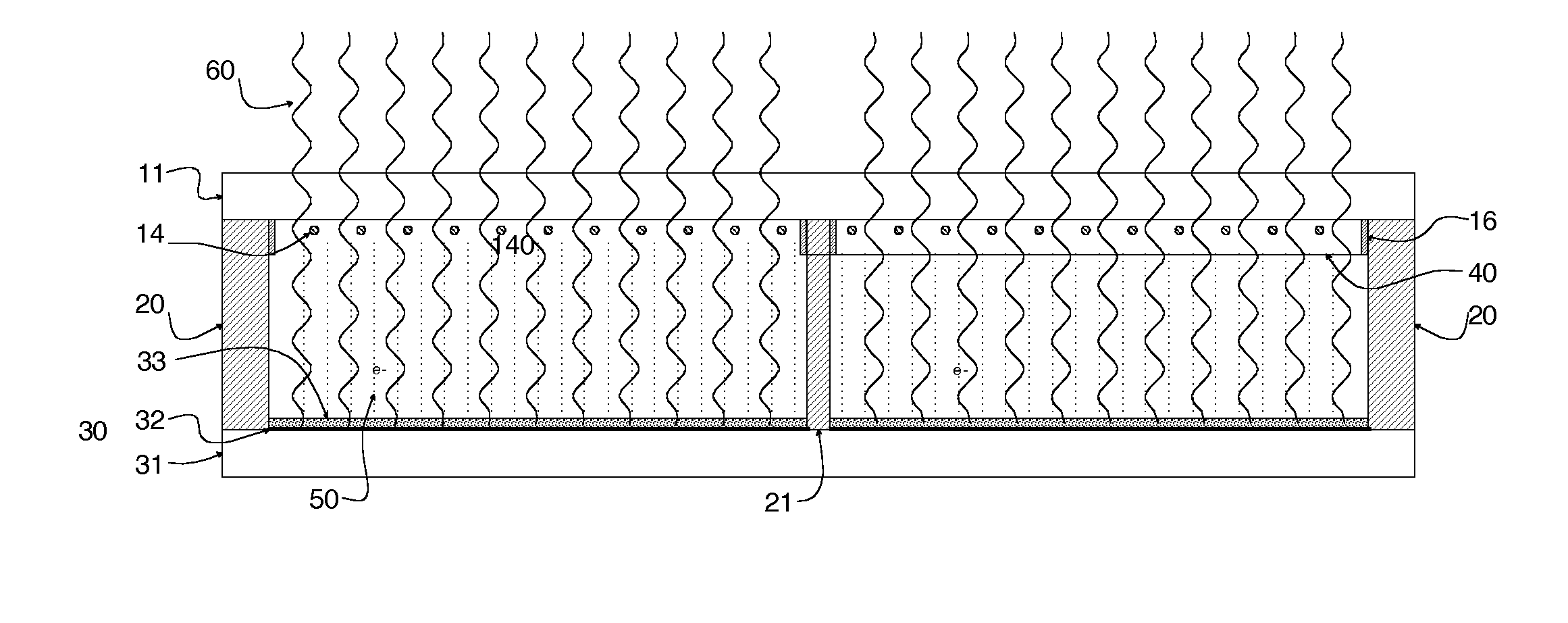

InactiveUS20150262779A1Inexpensive and power-efficient sourceEasy to scaleDischarge tube luminescnet screensVacuum tube vessels/containers/shieldsPower flowCathode ray

A flat panel UV source emits UV flux from one or more phosphor materials disposed on an anode plate and excited by electron beam current accelerated in vacuum toward the anode from one or more arrays of thermionic filament cathodes. The filament cathode arrays may be constructed and held in one or more cathode frames attached to or near a cathode plate. Increasing the number of these frames allows scaling of the areal size of the source, since the frames are constructed so as to allow for sag of the filaments as they are heated and cooled during operation.

Owner:STELLARRAY

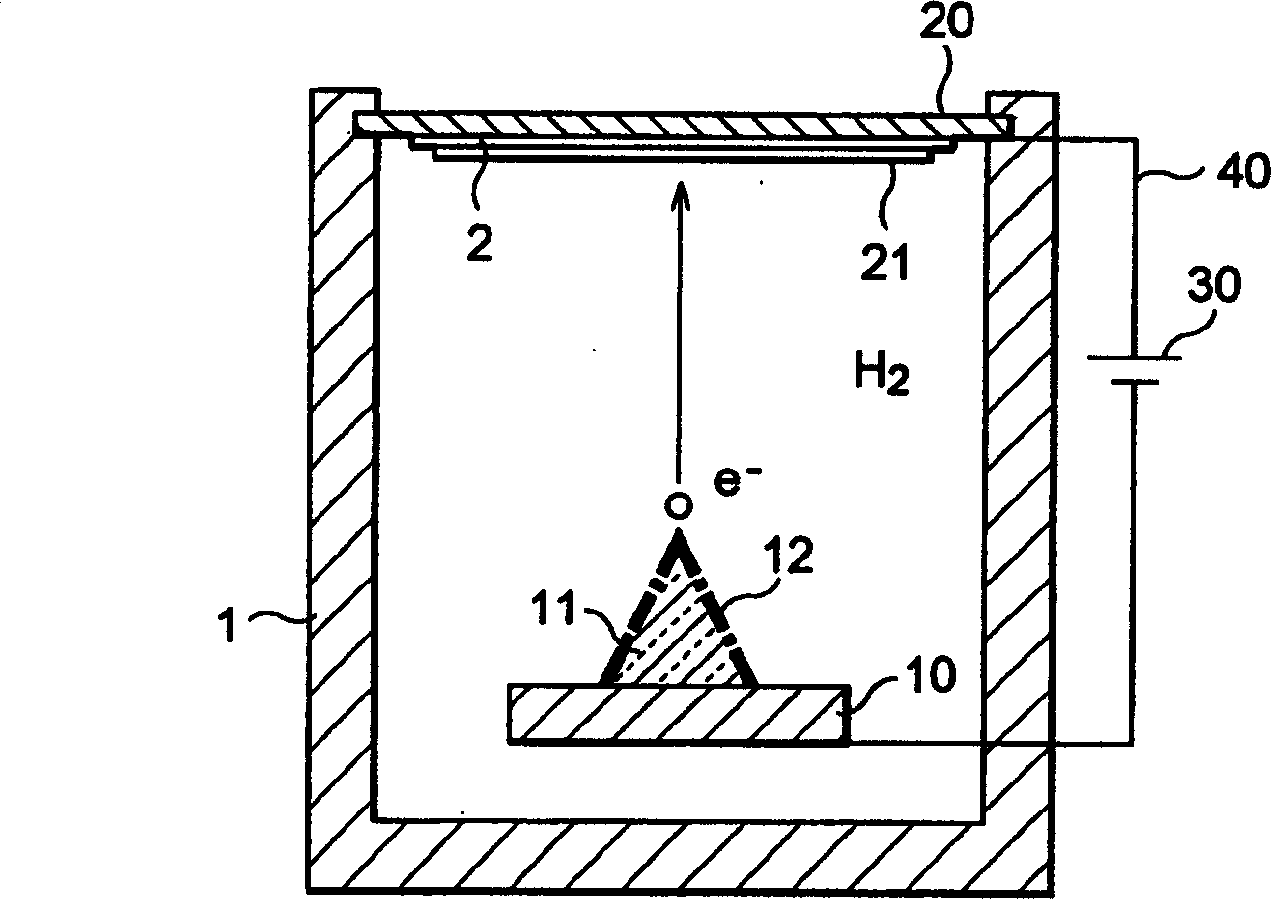

Electron tube

InactiveCN1482646AGas filling substance selectionImage/pattern display tubesHydrogenField electron emission

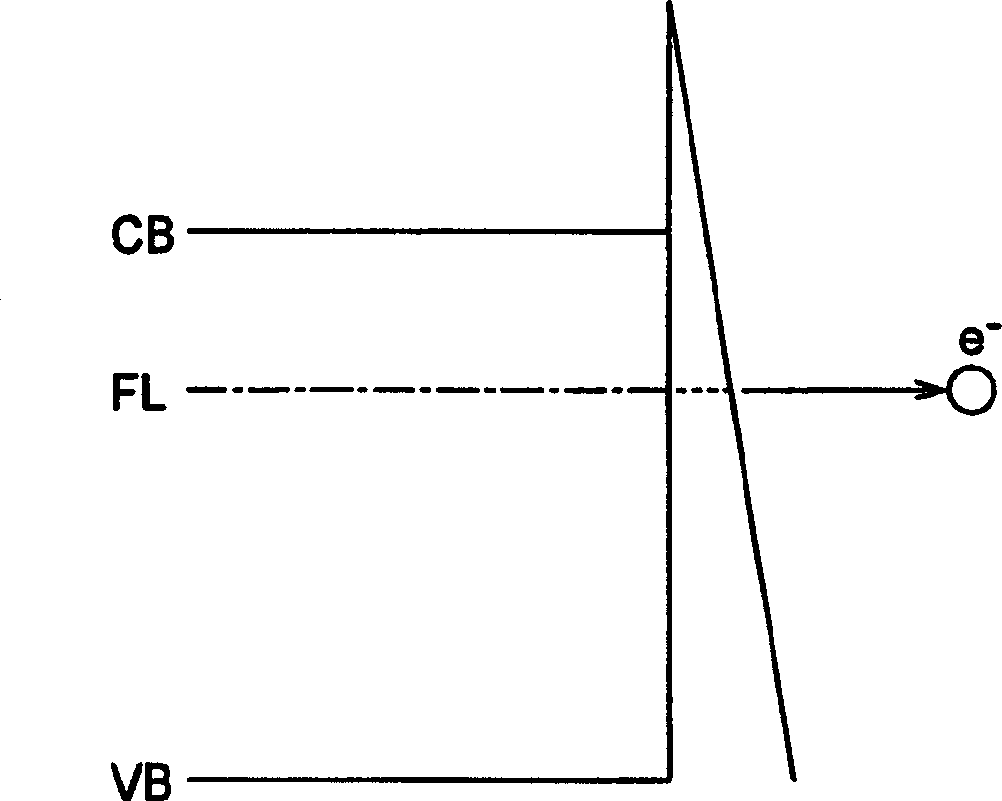

The present invention relates to an electron tube having a configuration which can maintain its operating stability for a long period of time. The electron tube comprises, at least, a field emitter which is made of diamond or a material mainly composed of diamond and has a surface terminated with hydrogen, and a sealed envelope for accommodating the diamond field emitter. Due to the hydrogen termination, the electron affinity of the diamond field emitter is set to a negative state. Also, hydrogen is enclosed within the sealed envelope. Due to this configuration, the hydrogen-terminated state of the diamond field emitter surface is stabilized, and the electron affinity of the diamond emitter is restrained from changing for a long period of time.

Owner:HAMAMATSU PHOTONICS KK

Vacuum tube

ActiveUS20160211107A1Easy to useEasy to operateControl electrodesThermionic cathodesAudio power amplifierDisplay device

An object of the present invention is to provide a vacuum tube with a structure close to that of an inexpensive and easily available vacuum fluorescent display which easily operates as an analog amplifier. A vacuum tube subject to the present invention comprises: a filament which is tensioned linearly and emits thermoelectrons, an anode arranged parallel to the filament, and a grid arranged between the filament and the anode such that the grid faces the anode. The present invention is characterized in that a distance between the filament and the grid is between 0.2 mm and 0.6 mm, including 0.2 mm and 0.6 mm.

Owner:NORITAKE ITRON CORP +1

Resistive thin layer heating of fluorescent lamp

InactiveUS9117649B2Tube/lamp screens manufactureNon-electron-emitting anodesThin layerFluorescent lamp

Fluorescent lamps, along with their methods of manufacture and use, are provided. The fluorescent lamp can include a discharge tube extending from a first end to a second end; a resistive transparent coating (e.g., a tin oxide thin film layer, such as a fluor-doped tin oxide thin film layer) on the outer surface of the discharge tube; and a pair of electric terminals positioned on the discharge tube such that a first terminal is on the first end and a second terminal is on the second end.

Owner:GENERAL ELECTRIC CO

Vacuum tube

ActiveUS9589758B2Easy to operateEasy to useThermionic cathodesNon-electron-emitting anodesAudio power amplifierDisplay device

An object of the present invention is to provide a vacuum tube with a structure close to that of an inexpensive and easily available vacuum fluorescent display which easily operates as an analog amplifier. A vacuum tube subject to the present invention comprises: a filament which is tensioned linearly and emits thermoelectrons, an anode arranged parallel to the filament, and a grid arranged between the filament and the anode such that the grid faces the anode. The present invention is characterized in that a distance between the filament and the grid is between 0.2 mm and 0.6 mm, including 0.2 mm and 0.6 mm.

Owner:NORITAKE ITRON CORP +1

Electron-emitting cold cathode device

InactiveUS9111711B2Increase working frequencyMitigate such drawbackCold cathodesNon-electron-emitting anodesElectricityOhmic contact

One or more embodiments of the invention concern a device comprising: a cathode that lies on a cathode plane and includes, in an active region, one or more cathode straight-finger-shaped terminals with a main extension direction parallel to a first reference direction; for each cathode terminal, one or more electron emitters formed on, and in ohmic contact with, said cathode terminal; and a gate electrode that lies on a gate plane parallel to, and spaced apart from, said cathode plane, does not overlap the cathode and includes, in the active region, two or more gate straight-finger-shaped terminals with a main extension direction parallel to the first reference direction; wherein the gate terminals are interlaced with said cathode terminal(s).

Owner:SELEX ES

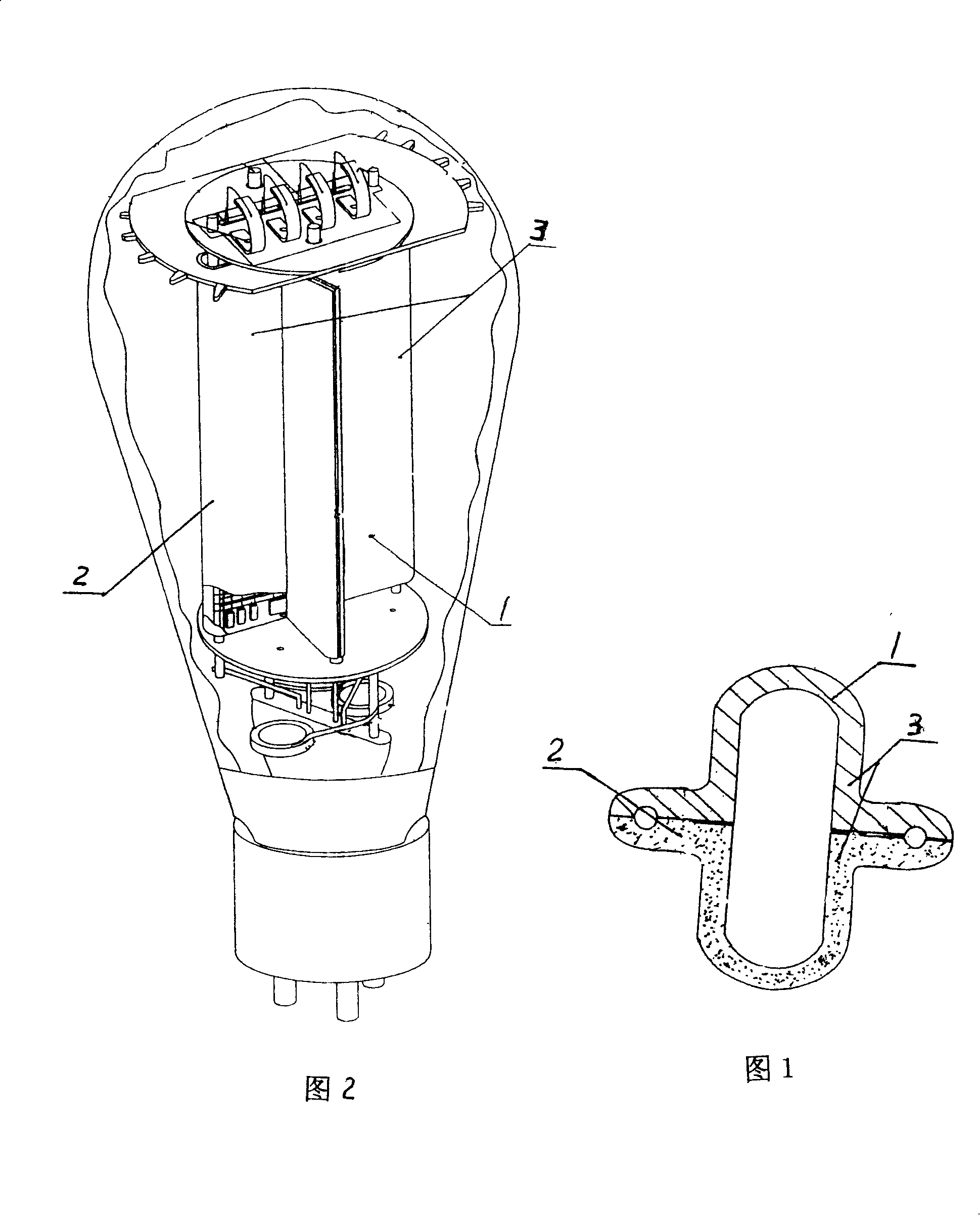

Anode of electronic tube for sound equipment

InactiveCN101221878AImprove sound qualityTransducer detailsPublic address systemsGraphiteAudio frequency

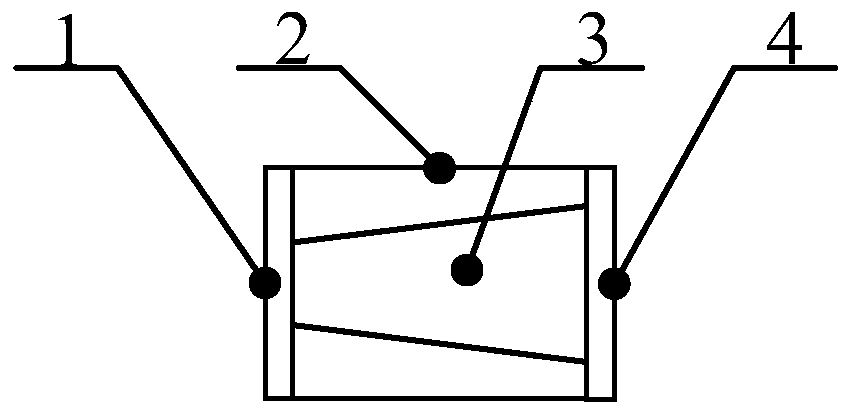

The invention relates to an audio electronic tube, in particular to an anode of an audio electronic tube. The anode is a hollow anode 3 compounded by two arch half anodes 1 and 2 made of two different materials, wherein the arch half anode 1 is an iron nickel alloy reticular arch half anode, and the arch half anode 2 is a graphite arch half anode. The utility model has the advantages that the anode of the utility model is adopted as the anode of the audio electronic tube, and thus the tones of the high, middle, and low audio frequencies of the audio electronic tube are better and more satisfactory than the tone of the prior audio electronic tube.

Owner:TIANJIN XINQUANZHEN TUBE TECH

Forced-convection asymmetrical radiator

InactiveCN100385601CDoes not affect heat dissipationReduce usageMagnetronsNon-electron-emitting anodesProduction lineHigh volume manufacturing

The invention discloses a dissymmetrical radiator under compelling convection. It uses the feature that the temperature field is dissymmetrical while compelling convection. Cutting off a certain wideness of the main fan in existence at the wind entrance, and keep the original size at the wind exit. Thus, the magnetron anode is in the dissymmetrical location relative to the main fan. It is easy to produce and need not to change the product line and process. The invention can not only used for magnetron heat emission, but also used as the other radiator under compelling convection.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

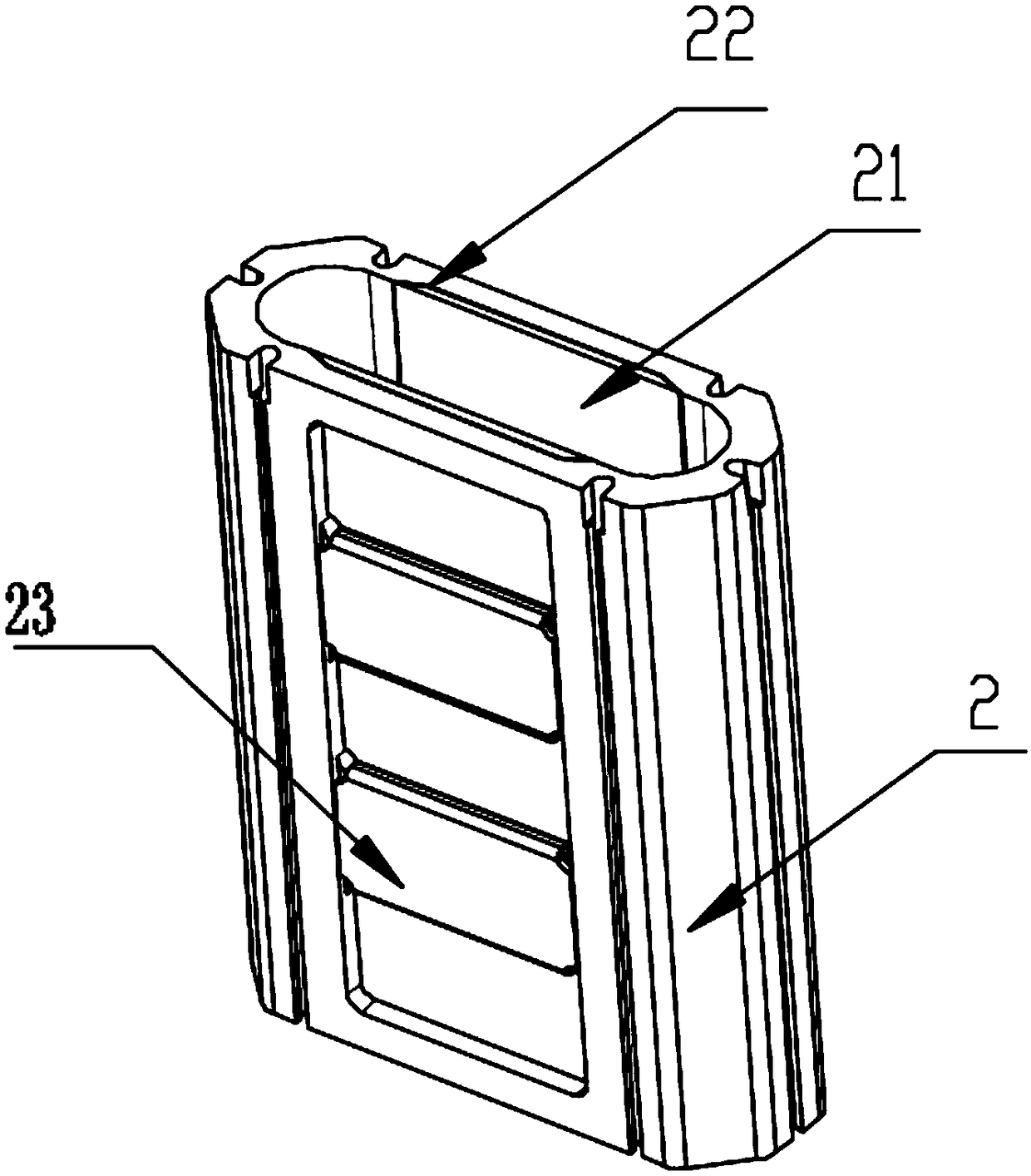

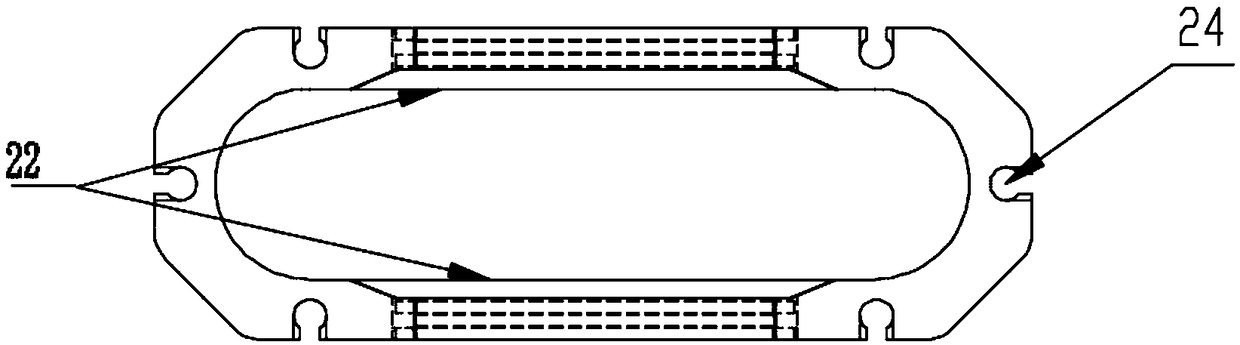

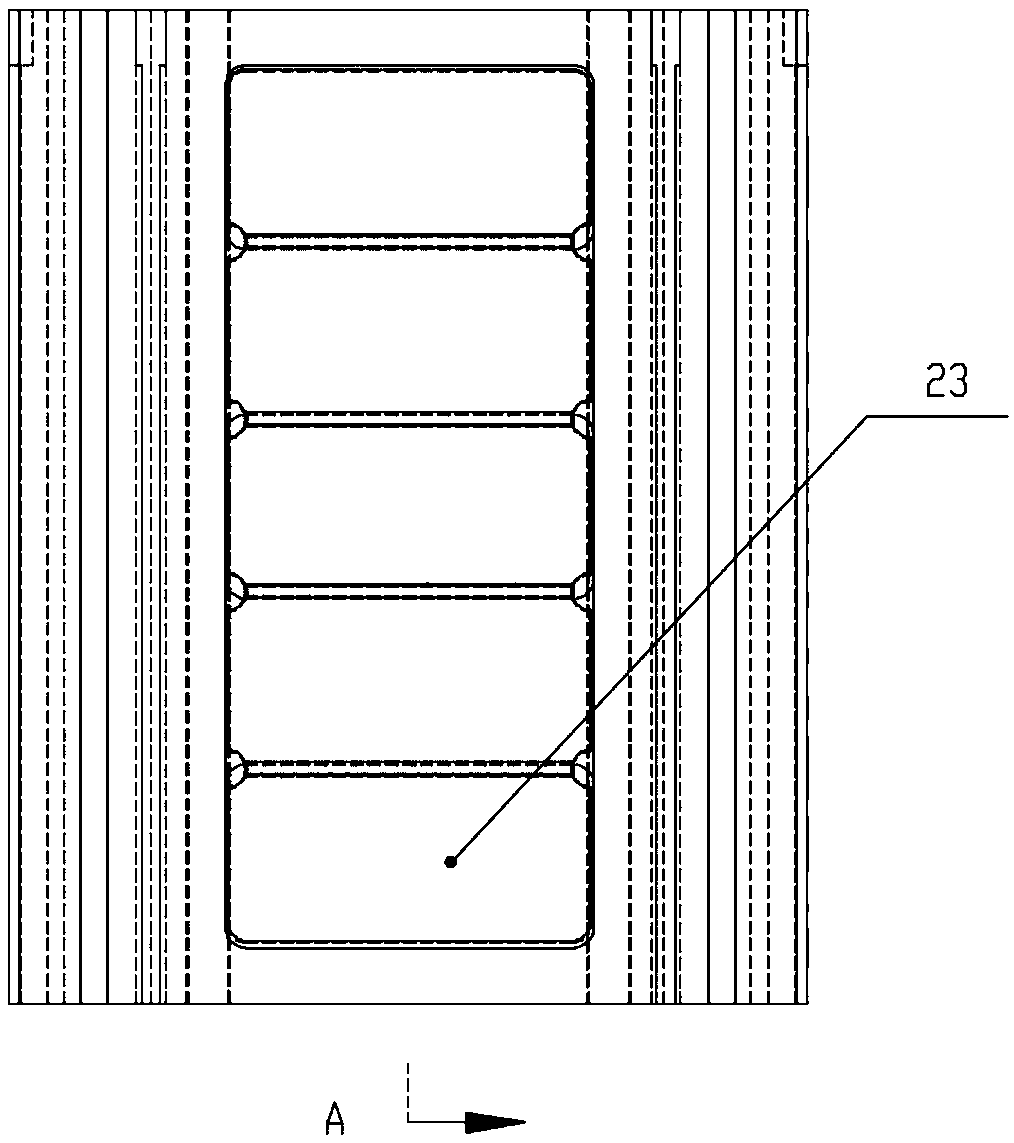

An audio tube with a composite anode

PendingCN109037011AReasonable structural designGood voice performanceNon-electron-emitting electrode materialsNon-electron-emitting anodesGraphiteMaterials science

The invention provides an audio electronic tube with a composite anode, comprising a glass tube shell, an anode, a cathode, a grid, a core column, an upper and lower spacer plates, a top sheet, a leadwire, a degassing agent ring, and a tube base of a lower part of the glass tube shell, wherein the anode molybdenum net and graphite are superposed to form a composite anode. The invention has simplestructure and good sound performance.

Owner:长沙恒扬电子有限公司

Method of driving a gas-discharge lamp

InactiveUS9161423B2Improve efficacyAvoid condensationElectric lighting sourcesNon-electron-emitting anodesGas-discharge lampCombustor

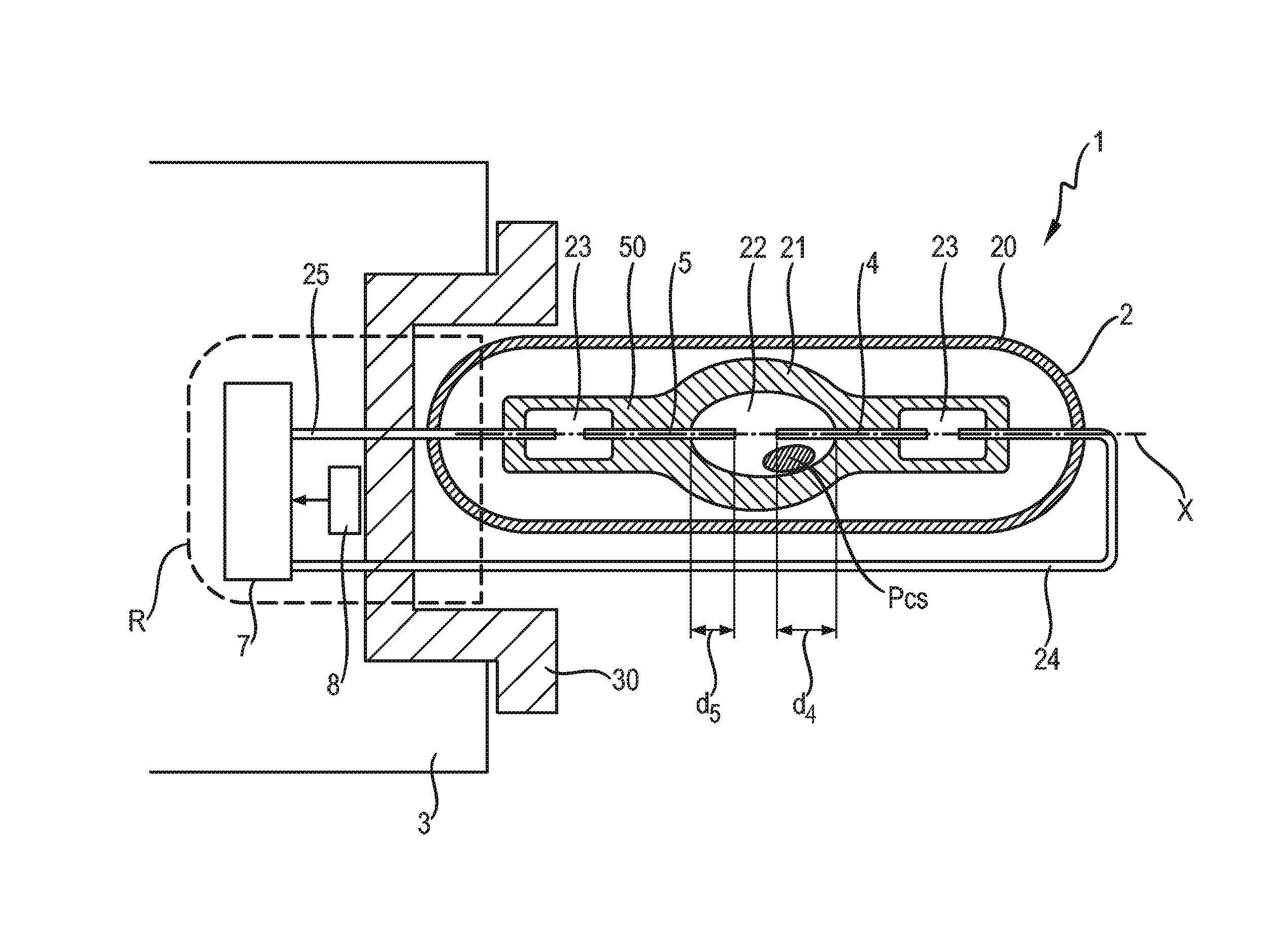

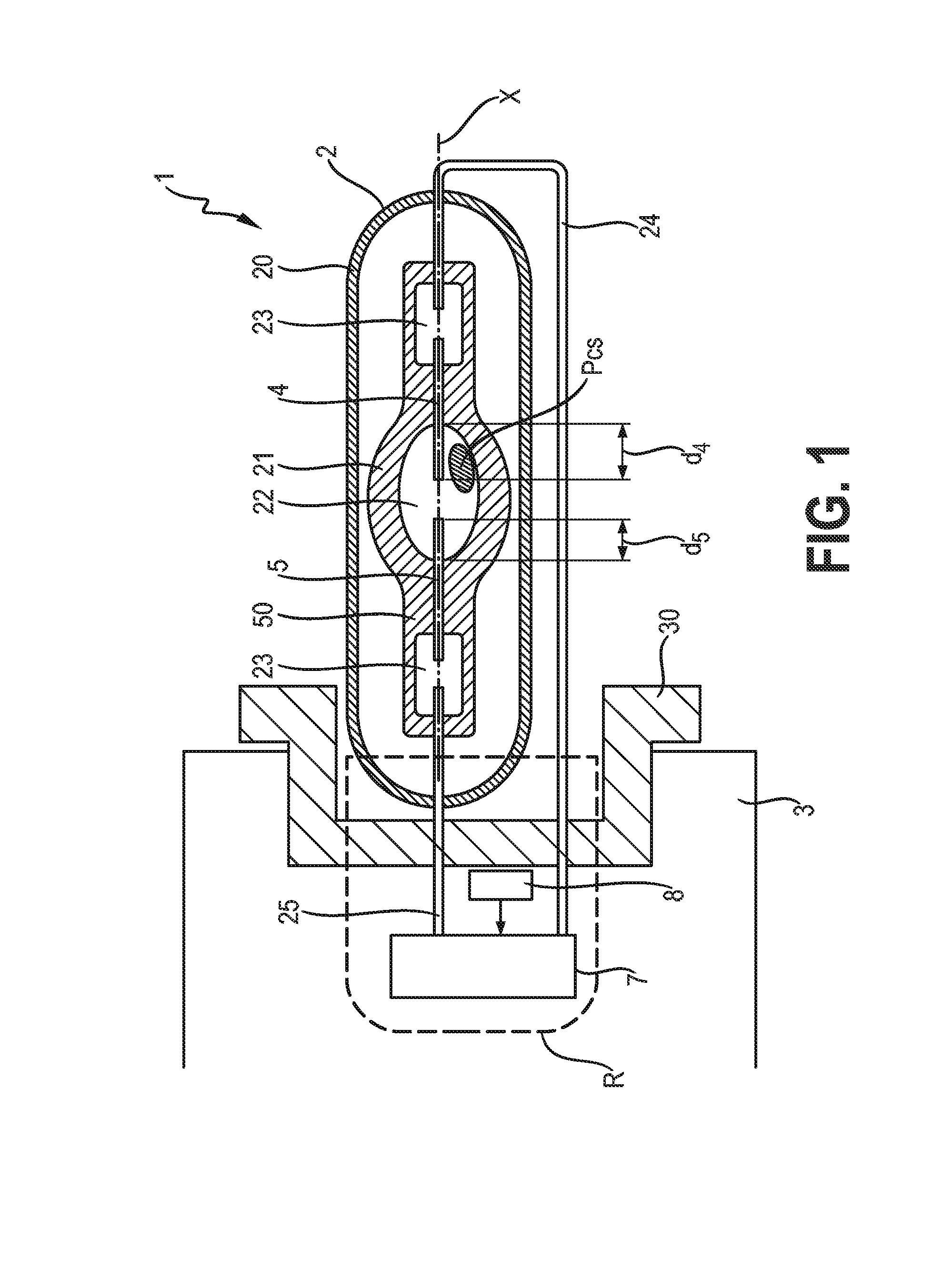

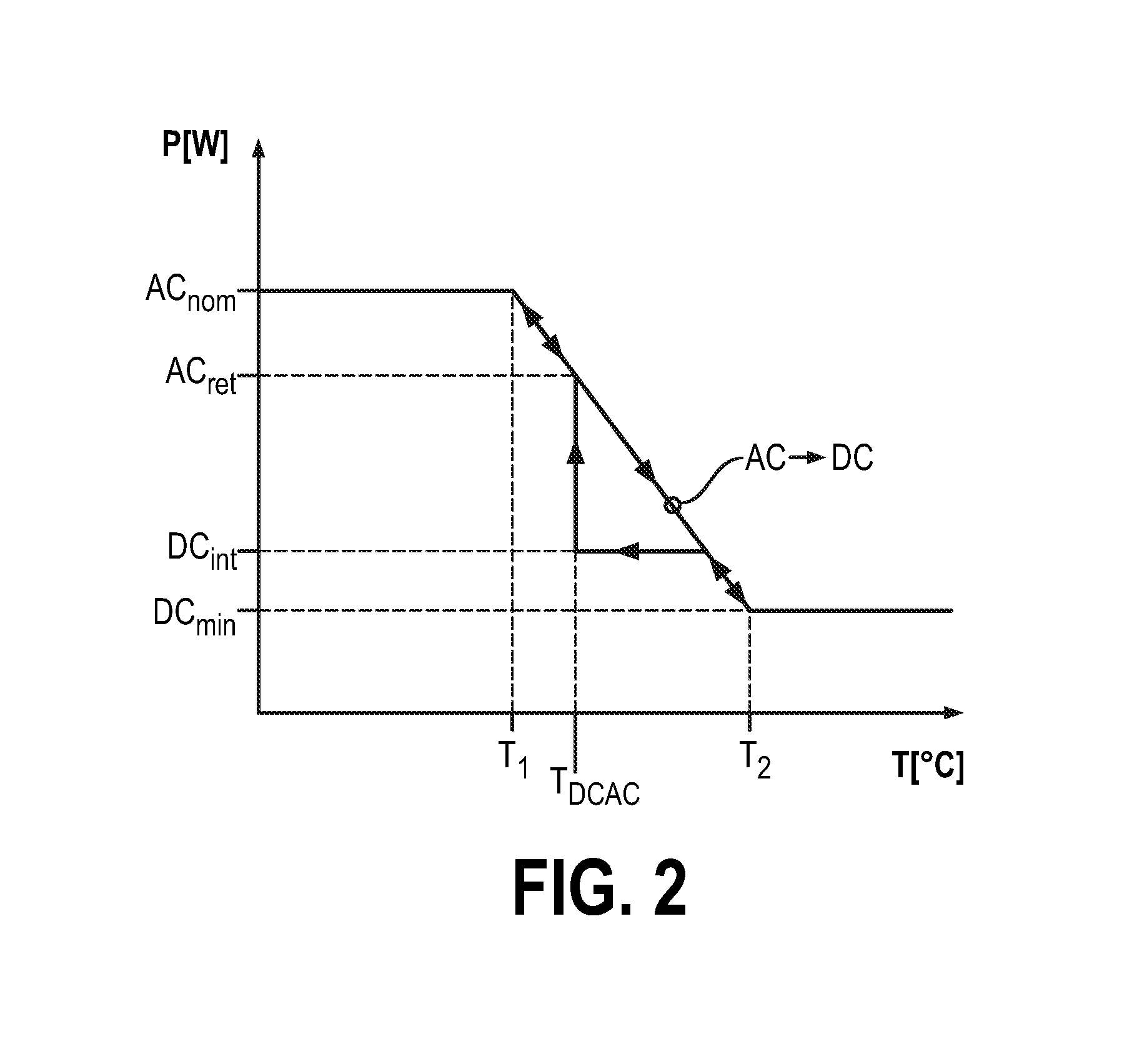

The invention describes a method of driving a gas-discharge lamp (1) according to conditions in a specific region (R) of the lamp (1), which gas-discharge lamp (1) comprises a burner (2) in which a first electrode (4) and a second electrode (5) are arranged on either side of a discharge gap, which lamp (1) is realised such that the position (PCs) of a coldest spot during an AC mode of operation is in the vicinity of the first electrode (4), which method comprises the steps of initially driving the lamp (1) in the AC mode of operation; monitoring an environment variable of the lamp (1), which environment variable is indicative of conditions in a specific region (R) of the lamp (1); switching to a temporary DC mode of operation at a DC power value on the basis of the monitored environment variable, whereby the first electrode (4) is allocated as the anode; and driving the lamp (1) in the DC mode of operation until the monitored environment variable has returned to an intermediate environment variable threshold value (TDCAC). The invention also describes a gas-discharge lamp and a driver for a gas-discharge lamp.

Owner:LUMILEDS

Terahertz vacuum diode and manufacturing method thereof

InactiveCN109860001AVacuum tube vessels/containers/shieldsNon-electron-emitting anodesPhotocathodeDiode

Embodiments of the invention disclose a terahertz vacuum diode and a manufacturing method thereof. The terahertz vacuum diode includes a photocathode, a vacuum channel layer and an anode; the vacuum channel layer is provided with a vacuum channel; the vacuum channel penetrates the vacuum channel layer; the photocathode and the anode are arranged on the two ends of the vacuum channel; sealing cavities are formed between the photocathode, the vacuum channel layer and the anode; the vacuum channel is in a circular truncated cone shape; and the contact area of the photocathode and the vacuum channel is less than that of the anode and the vacuum channel. A novel terahertz vacuum electronic device can be provided through the provided terahertz vacuum diode and the manufacturing method thereof.

Owner:BEIHANG UNIV +1

Electrovacuum tube with dual anodes, and assembling method

InactiveCN100505138CNon-electron-emitting anodesCold cathode manufactureMaterials scienceVacuum tube

A double-anode electric vacuum tube, the first anode is connected to one end of the ceramic insulation section assembly, the other end of the ceramic insulation section assembly is connected to a port of the transition section assembly, and the transition section assembly is connected to the second anode; the first anode is equipped with The first anode seat is provided with a thin edge area as a welding edge at the tail of the first anode, and there is a sheet-shaped welding edge at the same port of the first anode seat and the tail of the first anode seat. When assembling, insert the mold into the second anode, put the transition section assembly, the ceramic insulation section assembly, the first anode and the first anode seat in sequence, wherein the inner diameter of the first anode head is sleeved on the upper end of the mould, and then place a tool Put the rod into the first anode to exert a vertical downward force, and weld the transition section assembly, the ceramic insulation section assembly, the first anode and the first anode seat together in the following order, and weld the second anode and the above welding together The components are separated, the second anode is placed back in place after the mold is taken out, and the connection between the second anode and the transition section component is welded.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Popular searches

Non-electron-emitting control electrodes Non-electron-emitting shielding screens Optical recording/reproducing Discharge tube solid anodes X-ray tube vessels/container Discharge tube solid thermionic cathodes Mounting/support/spacing/insulation of electrode assemblies Individual electrode mounting Electric discharge lamps Radiation generation arrangements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com