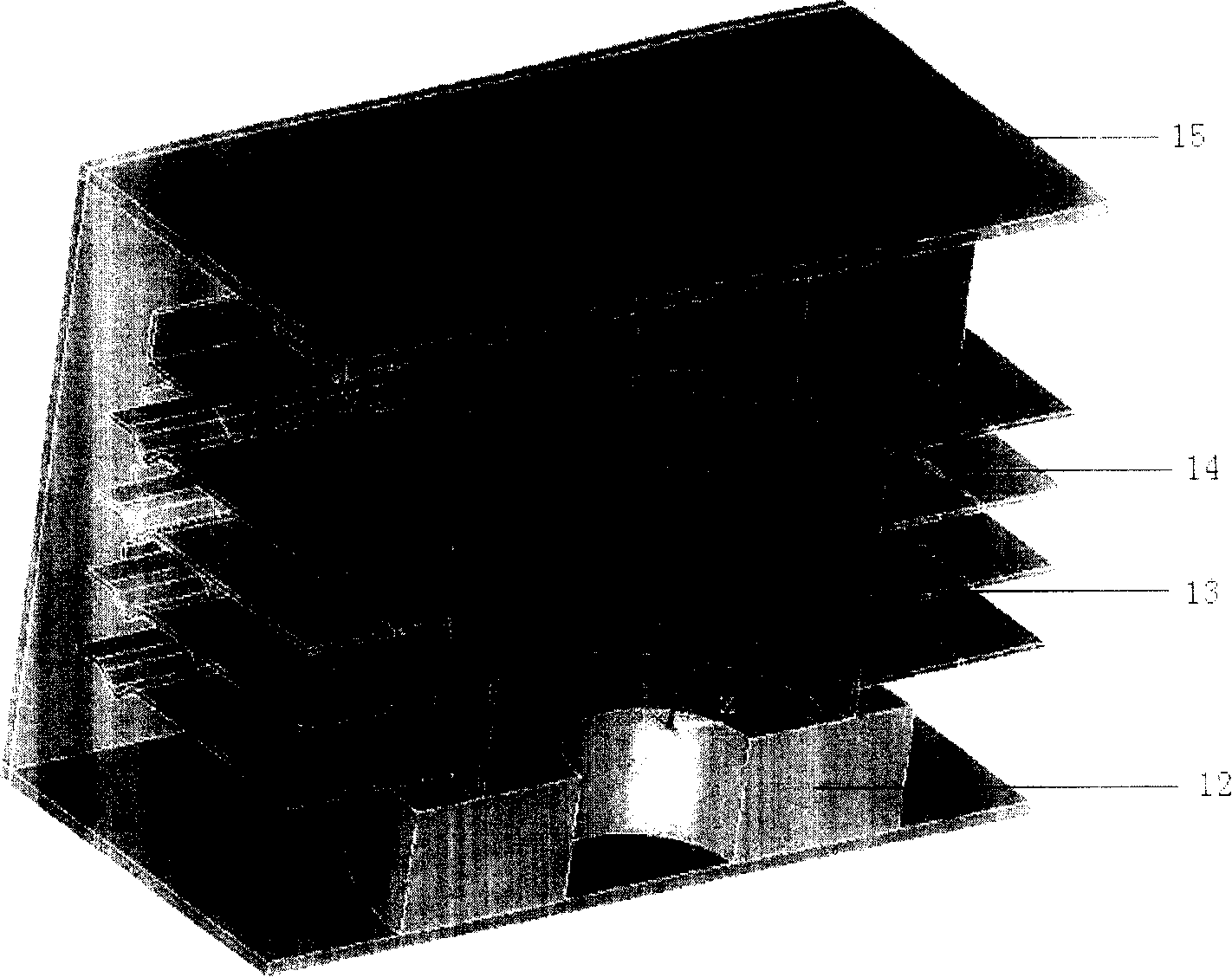

Forced-convection asymmetrical radiator

A forced convection, asymmetric technology, applied in non-electron emitting anodes, non-electron emitting electrodes, magnetrons, etc., can solve the problems of lack of heat dissipation, rising product costs, increasing material usage, etc., to achieve savings The amount of use, the production process is simple, and the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

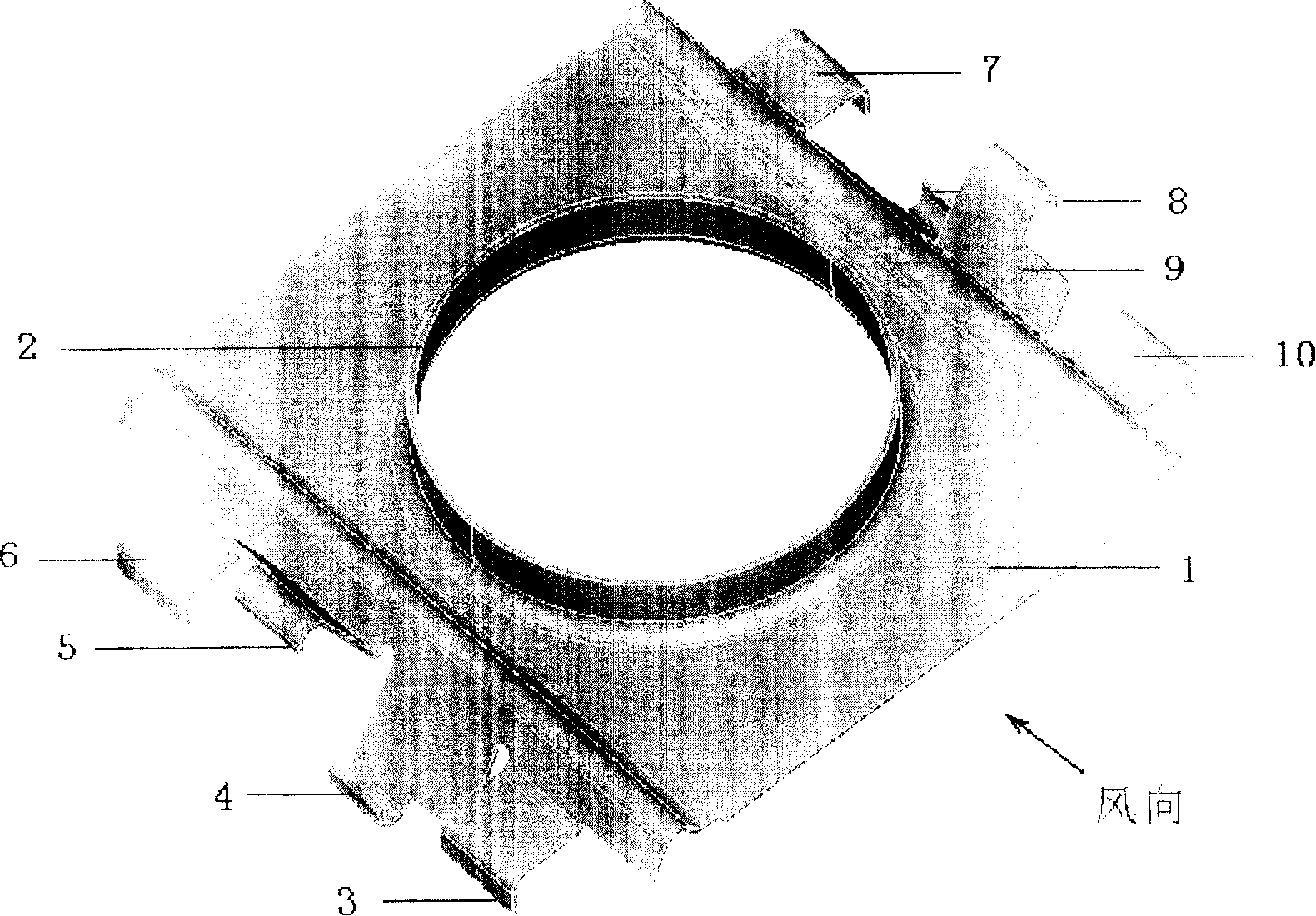

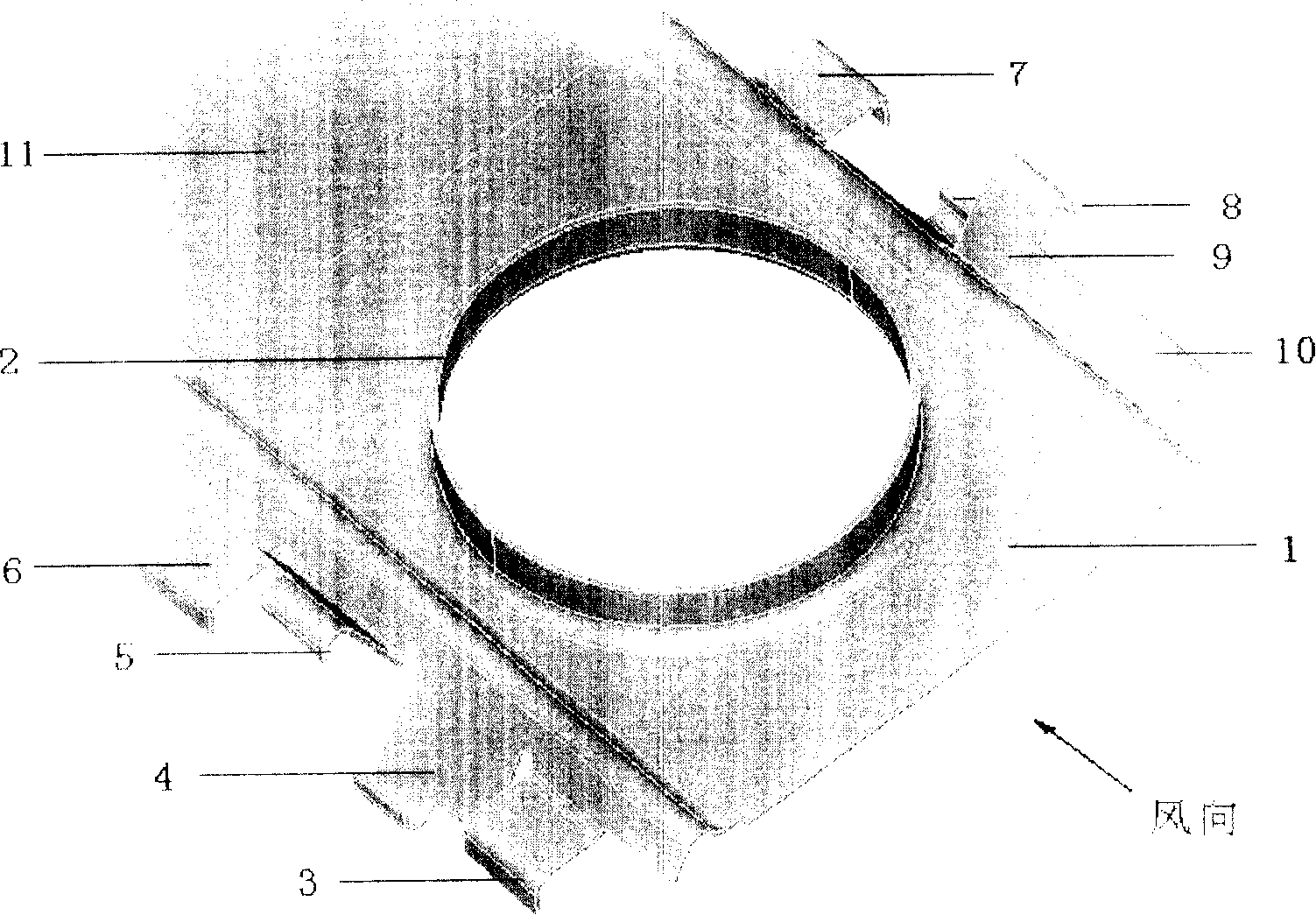

[0030] The present invention will be described more clearly below through detailed embodiments and with reference to the accompanying drawings.

[0031] The numerical simulation calculation of the temperature field distribution of the 2M217 magnetron under forced convection shows that the maximum temperature of the central anode is 123°C ( Figure 5 The dotted line range in the middle), cut off the heat sink at the air inlet by 9mm and then calculate, the maximum temperature of the central anode after cutting off is 116°C ( Figure 5 The dashed range in ). It can be seen from this example that the present invention is simple and easy to implement, saves materials and reduces costs while ensuring the same heat dissipation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com