Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

390results about "Tubes with electrostatic controls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

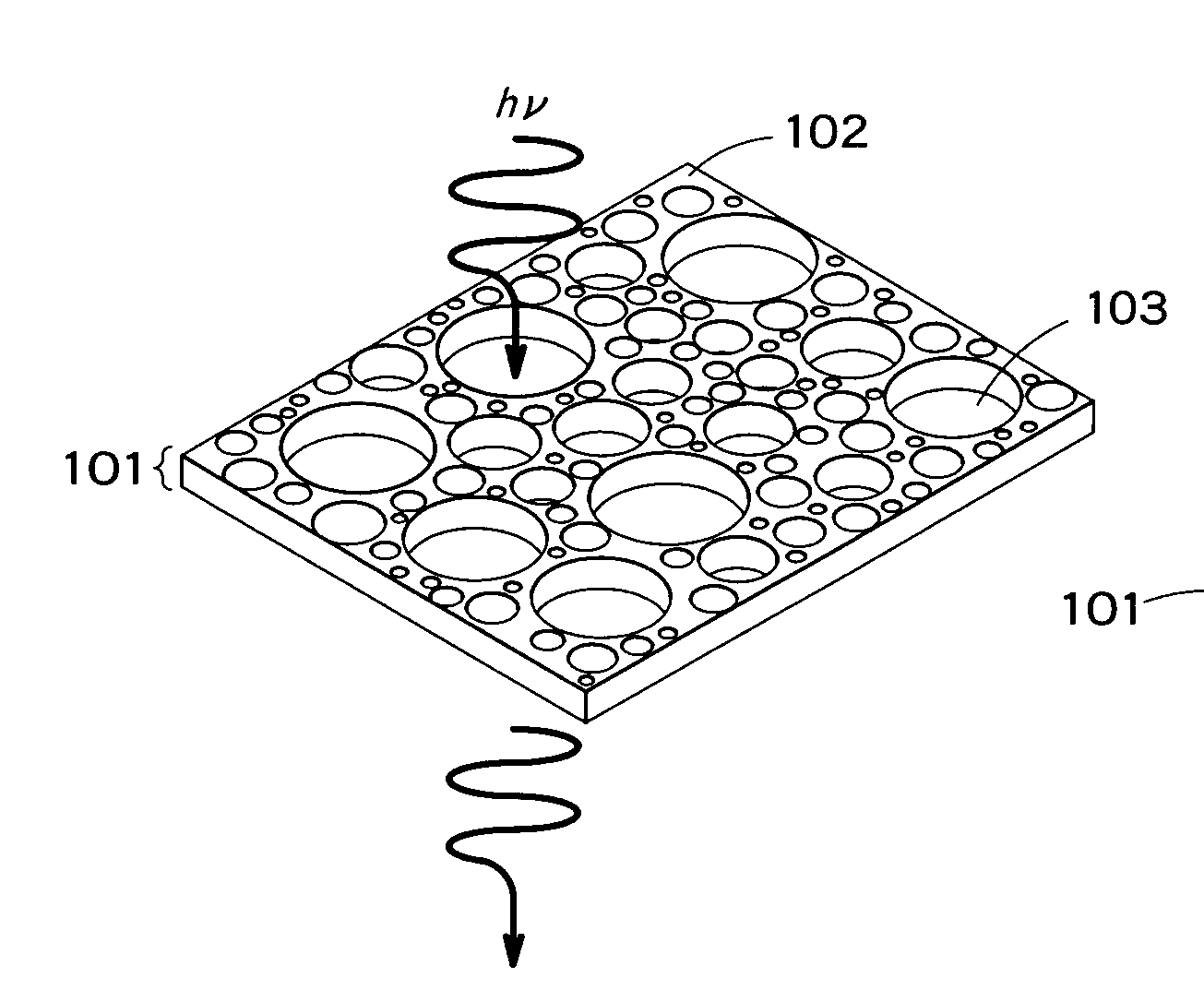

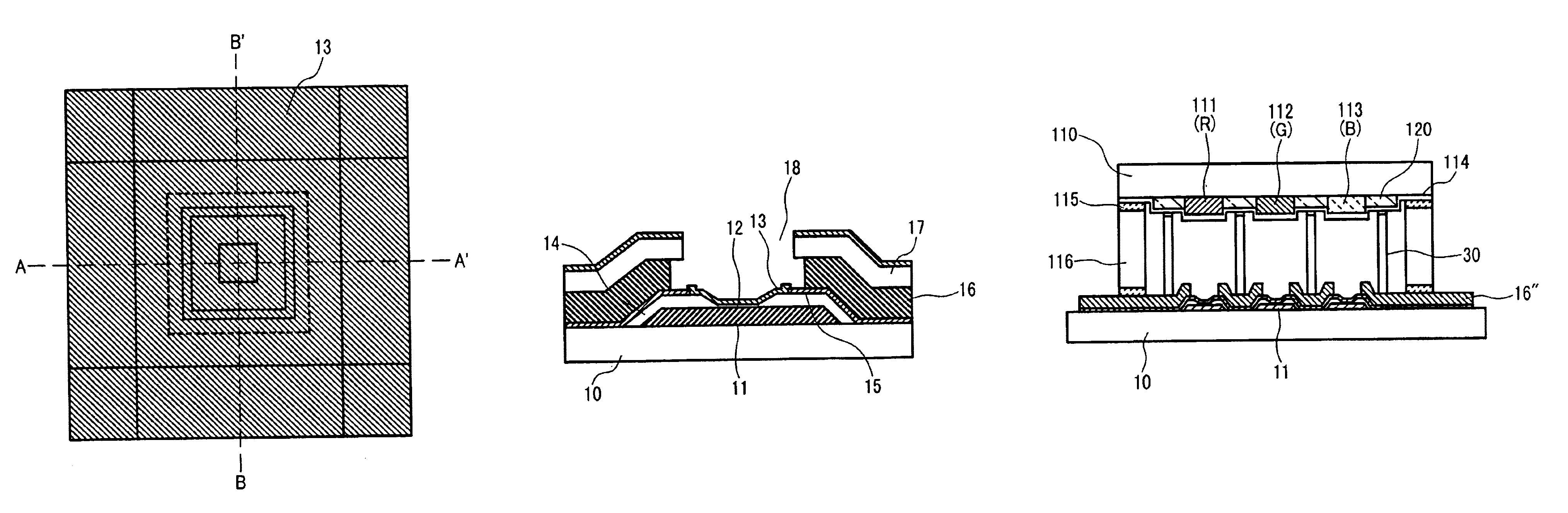

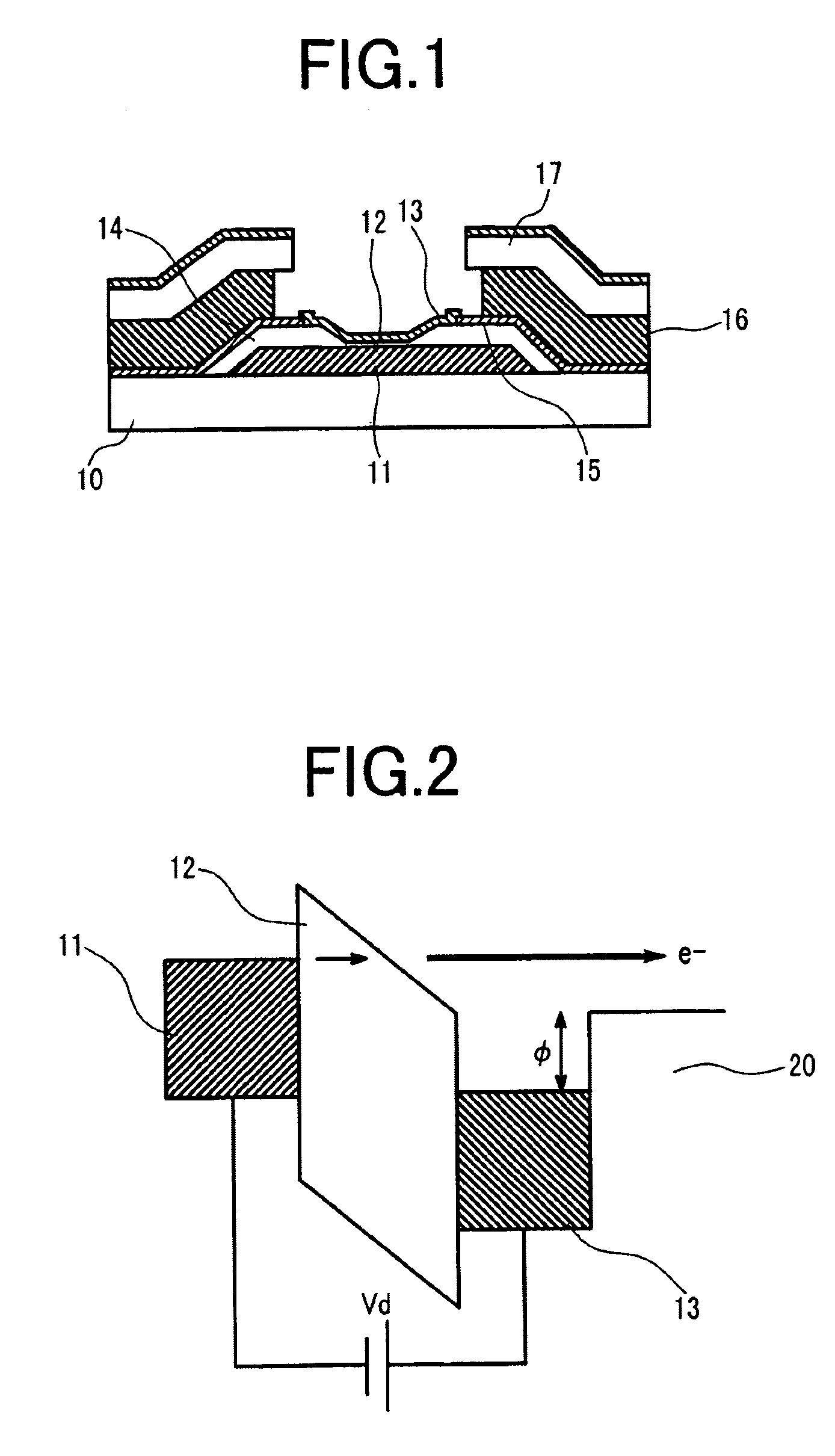

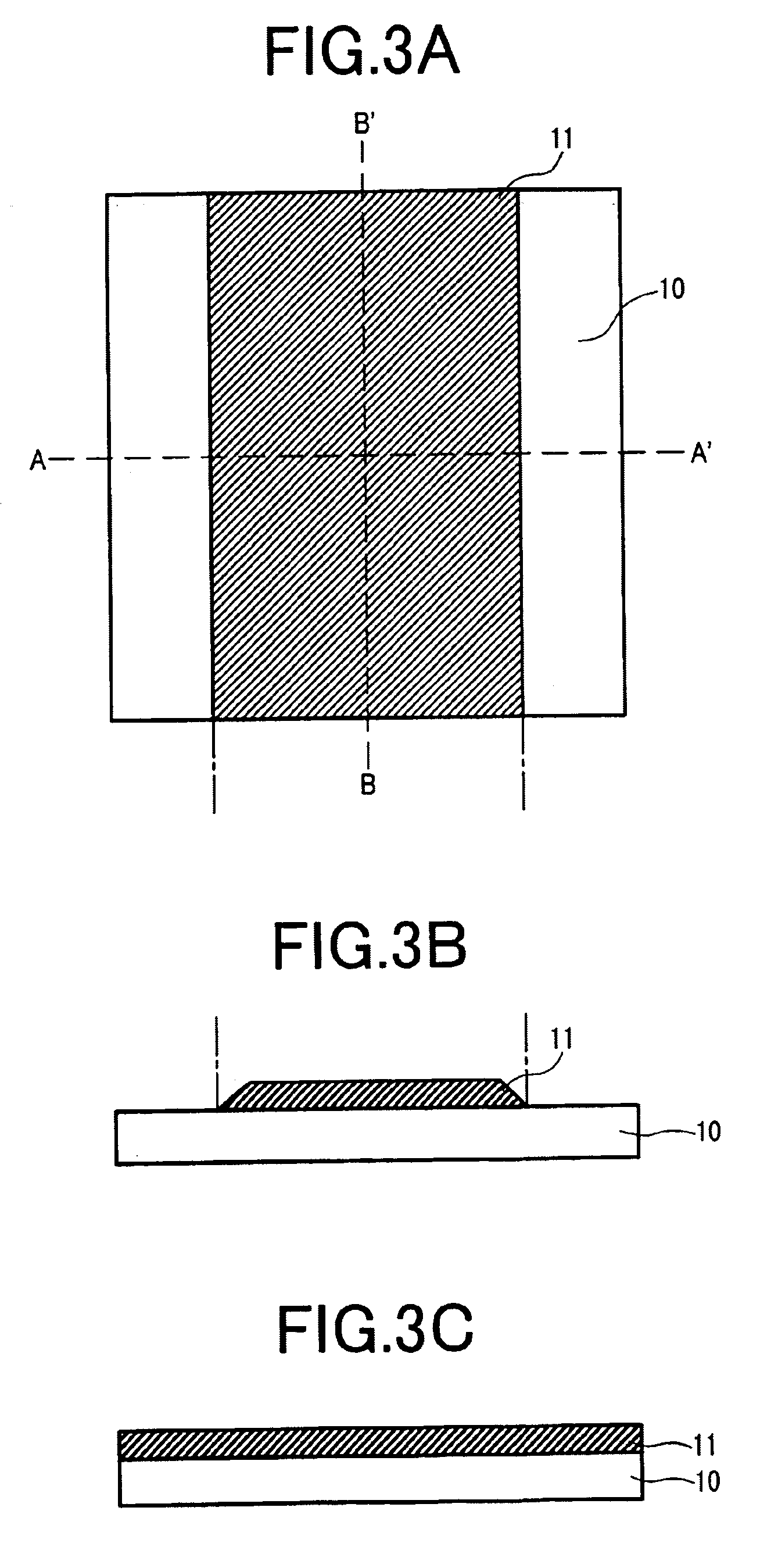

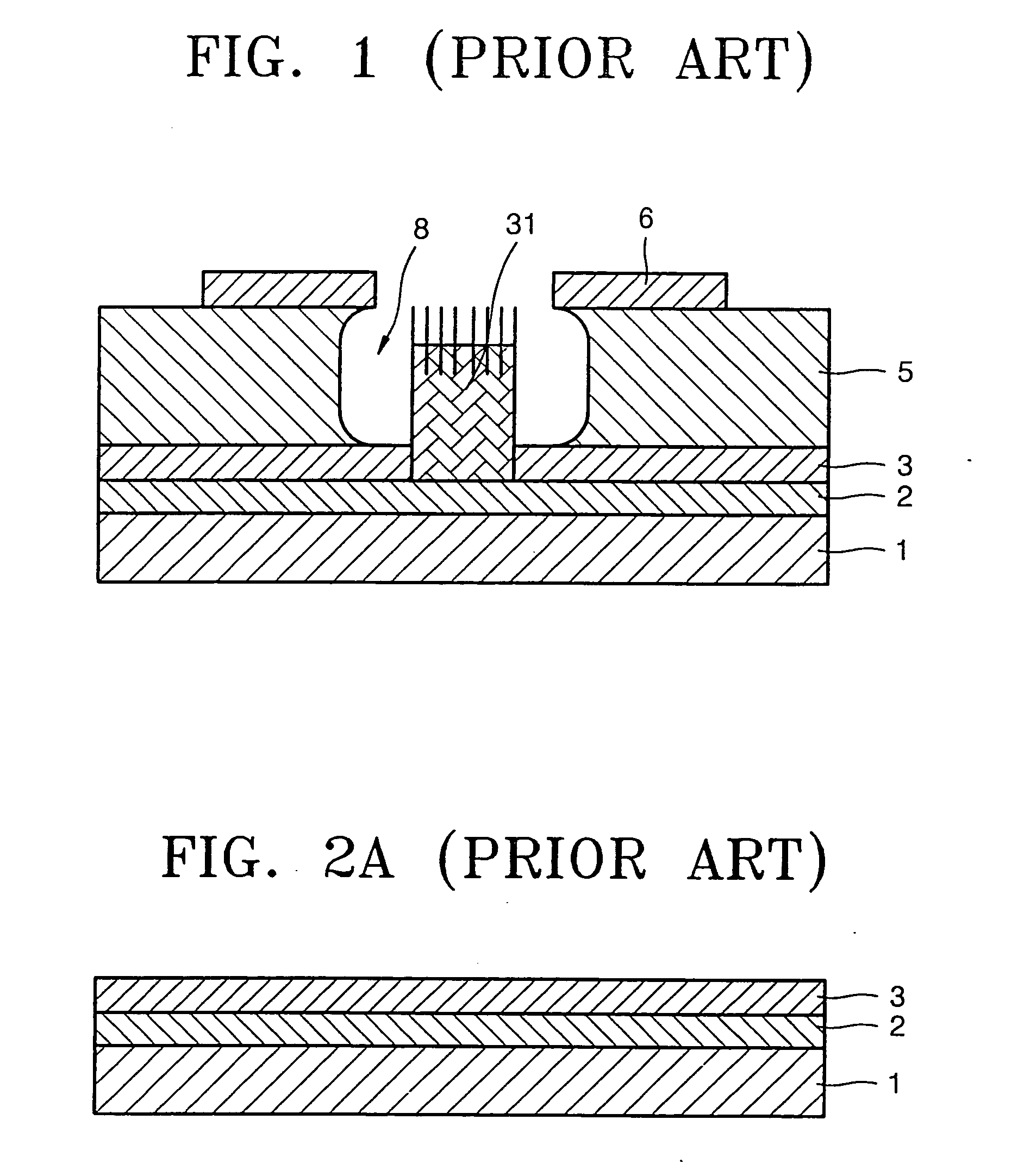

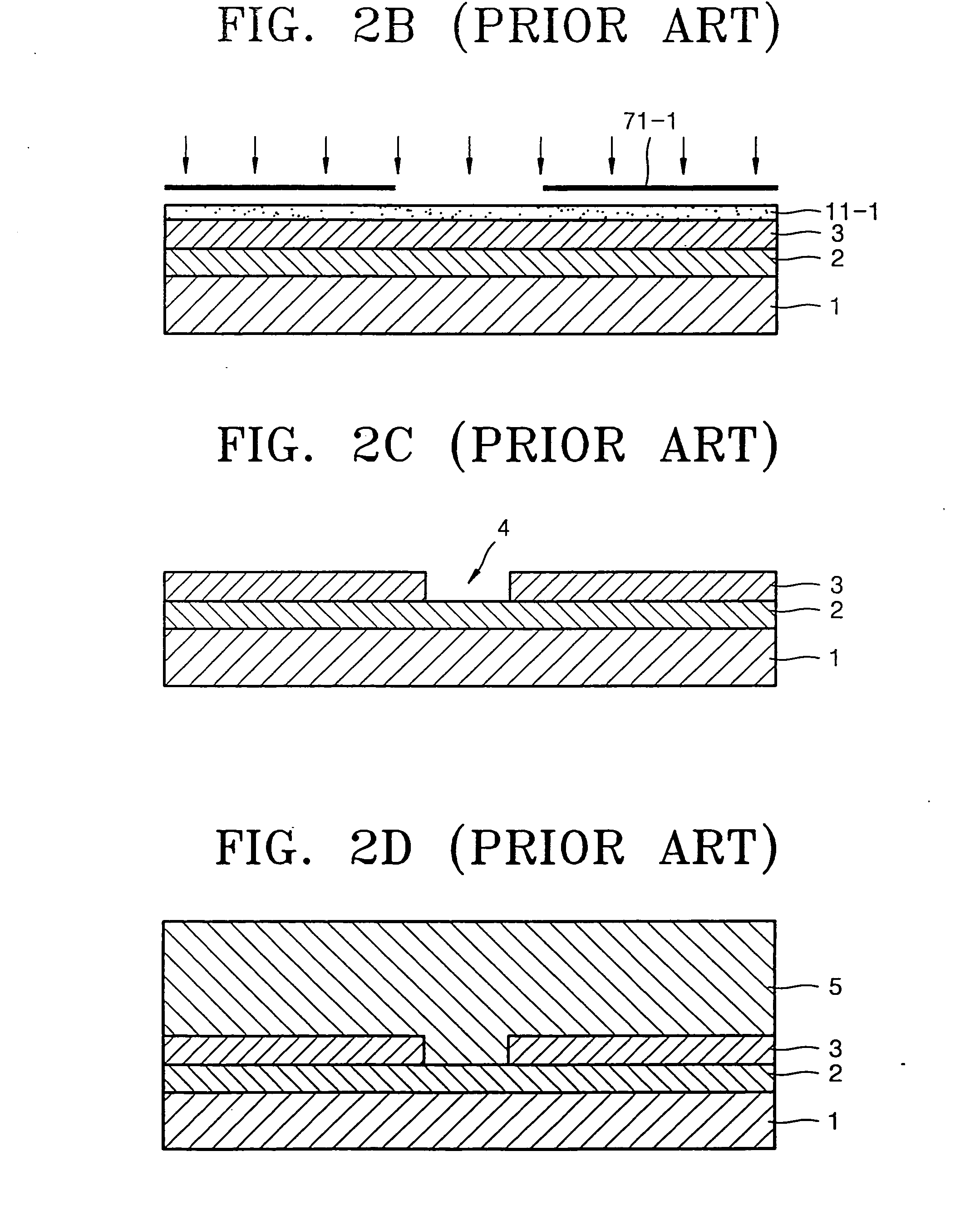

Electron-emitting device provided with pores that have carbon deposited therein

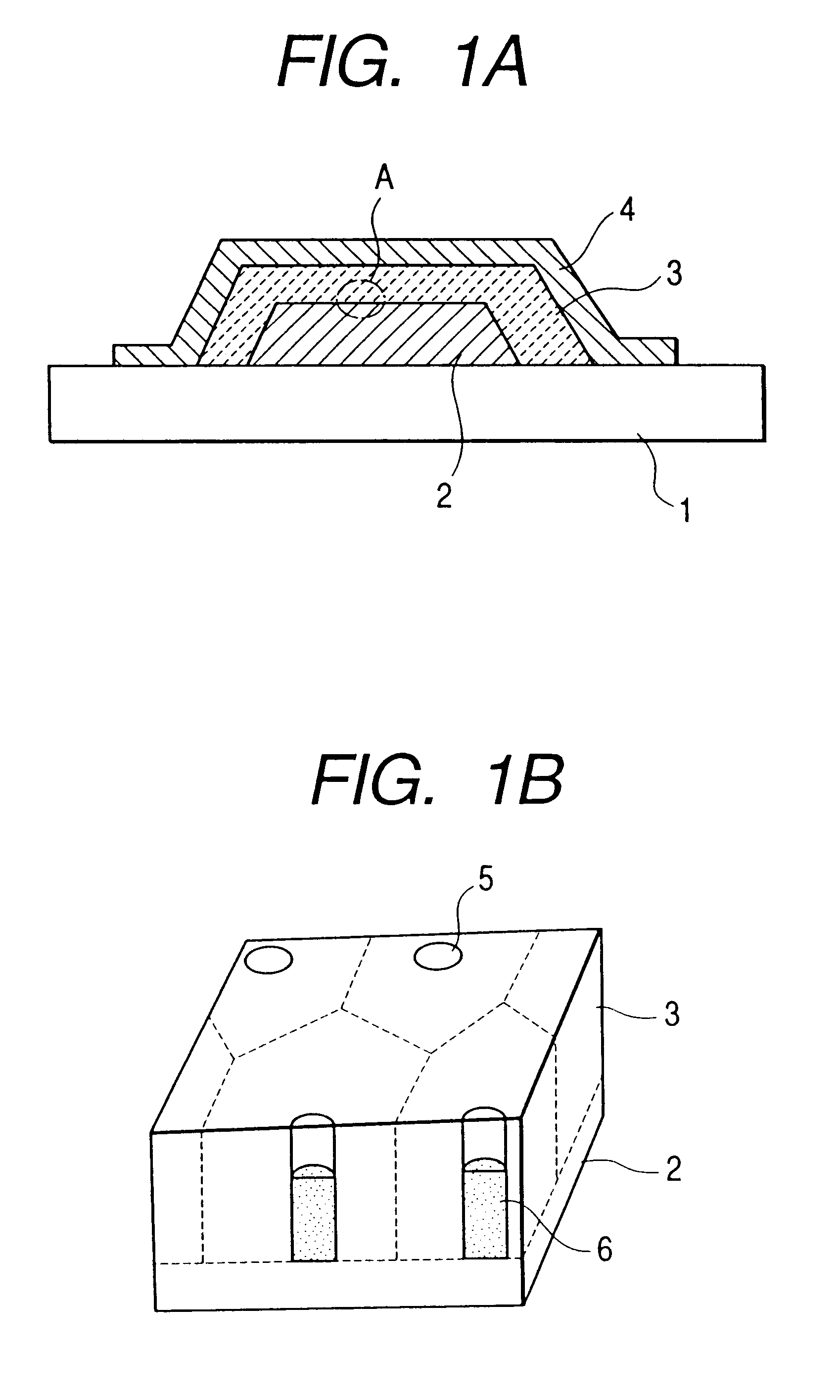

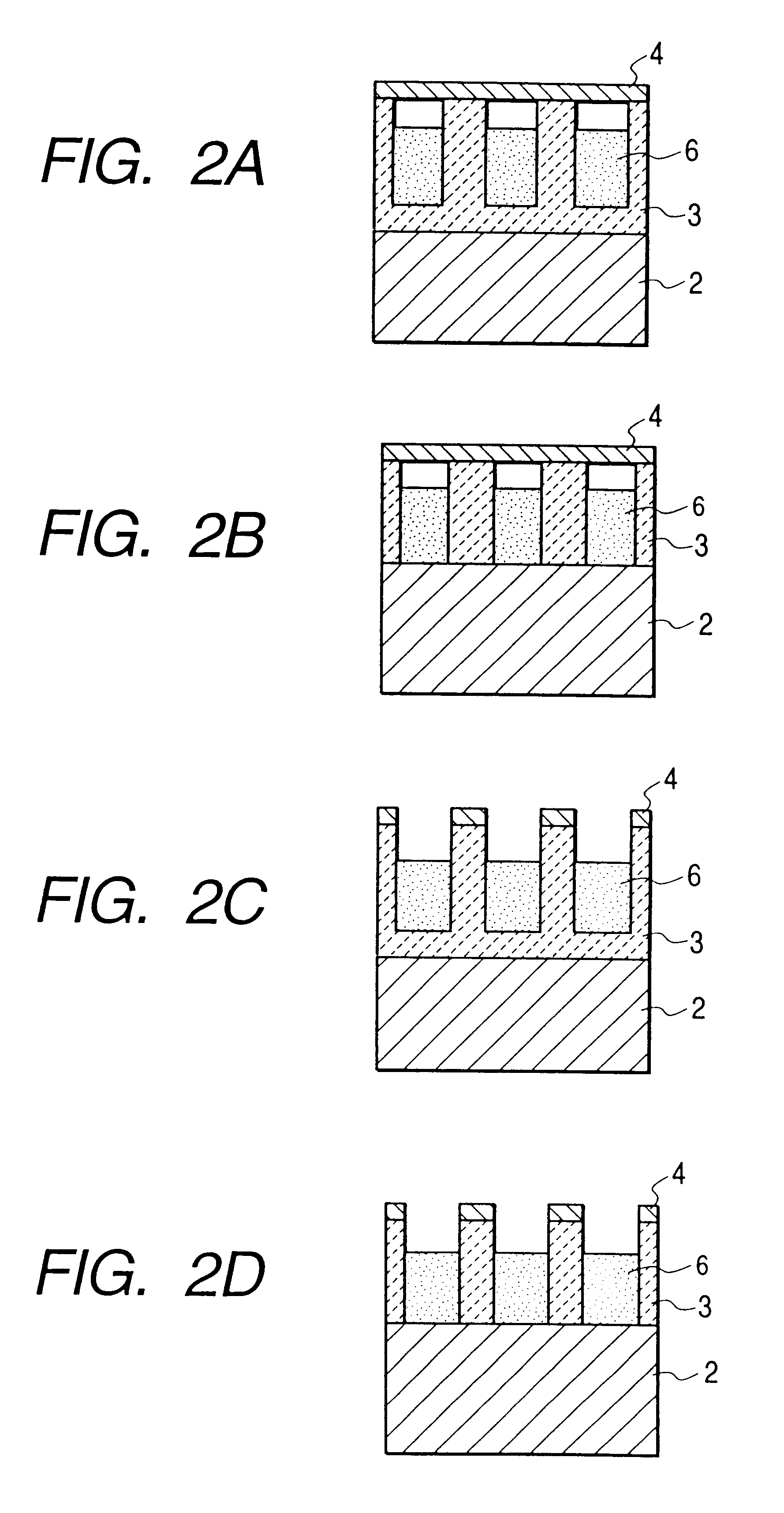

An electron-emitting device disclosed has stable electron emission characteristics with little variation, in high electron emission efficiency, in high definition, and at low driving voltage. The electron-emitting device disclosed is constructed in such structure that on a substrate there are a lower electrode, an insulating layer having pores, and an upper electrode stacked in this order, the insulating layer is an anodic oxide layer, and a carbon deposit is formed in the pores.

Owner:CANON KK

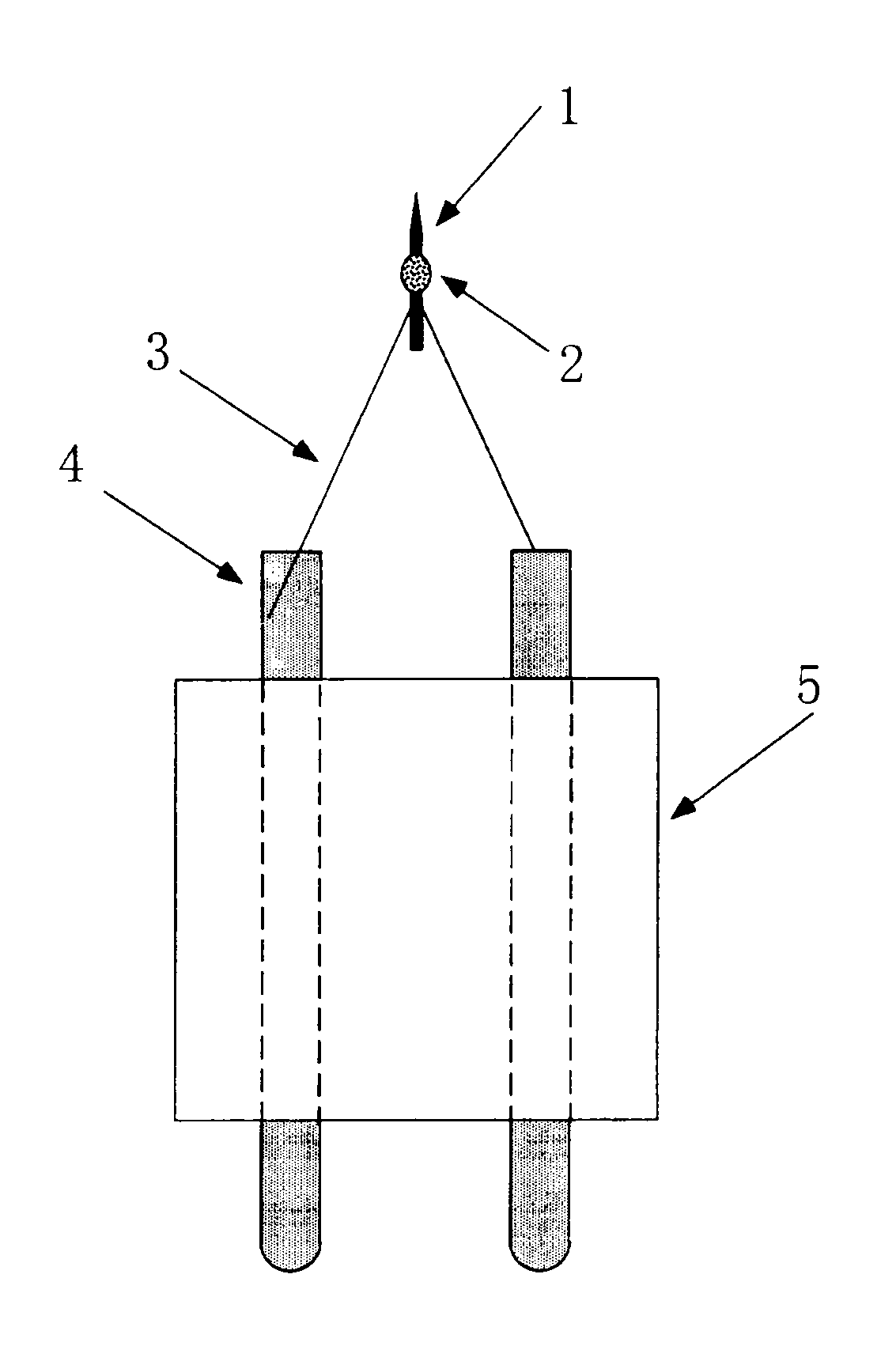

Thermionic emission device

ActiveUS20090167136A1Reduce consumptionLimited applicationControl electrodesElectrode and associated part arrangementsThermionic emissionAtomic physics

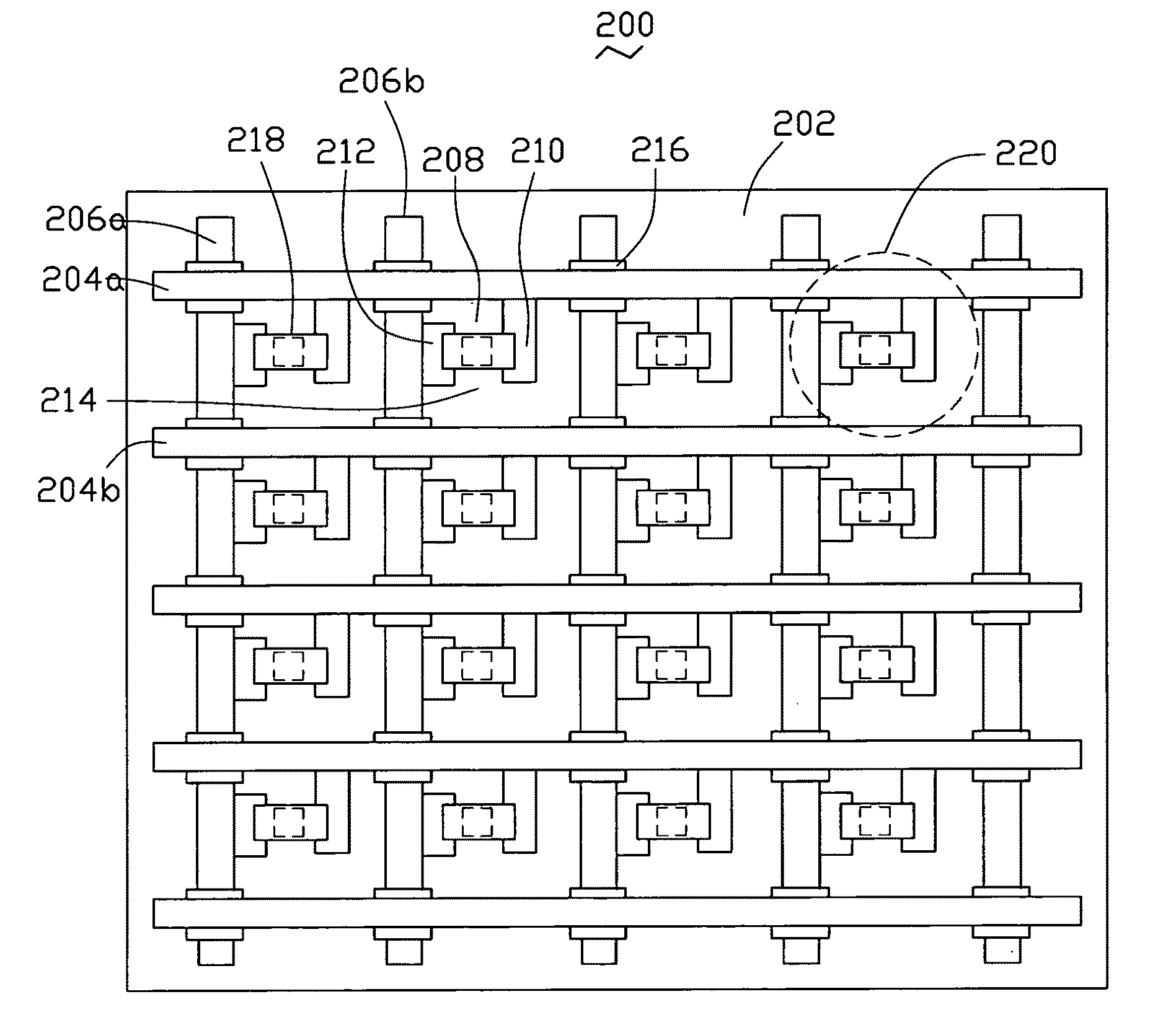

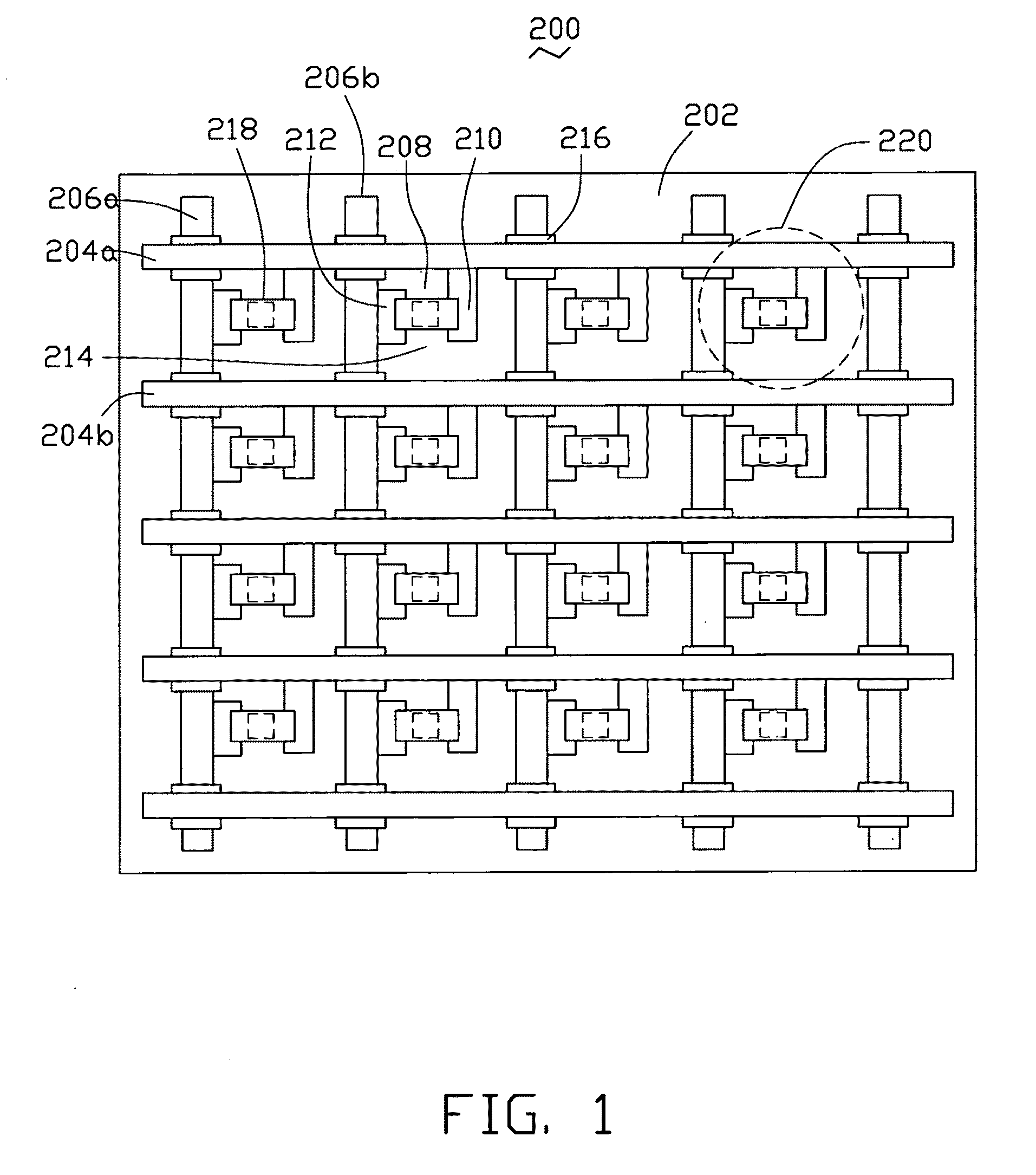

A thermionic emission device includes an insulating substrate, and one or more grids located thereon. Each grid includes a first, second, third and fourth electrode down-leads located on the periphery thereof, and a thermionic electron emission unit therein. The first and second electrode down-leads are parallel to each other. The third and fourth electrode down-leads are parallel to each other. The first and second electrode down-leads are insulated from the third and fourth electrode down-leads. The thermionic electron emission unit includes a first electrode, a second electrode, and a thermionic electron emitter. The first electrode and the second electrode are separately located and electrically connected to the first electrode down-lead and the third electrode down-lead respectively. The insulating substrate comprises one or more recesses that further insulate the thermionic electron emitters from the substrate.

Owner:TSINGHUA UNIV +1

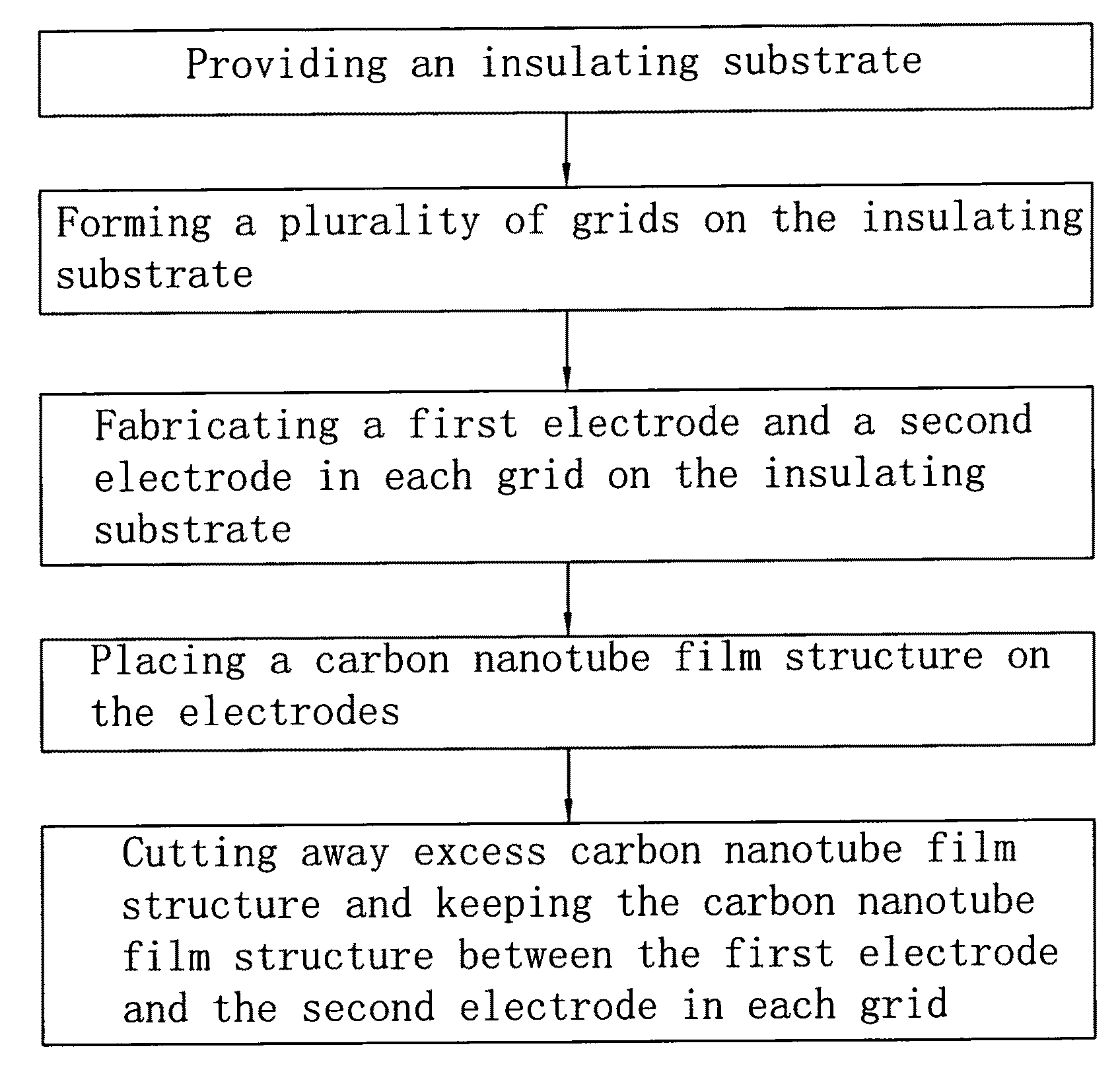

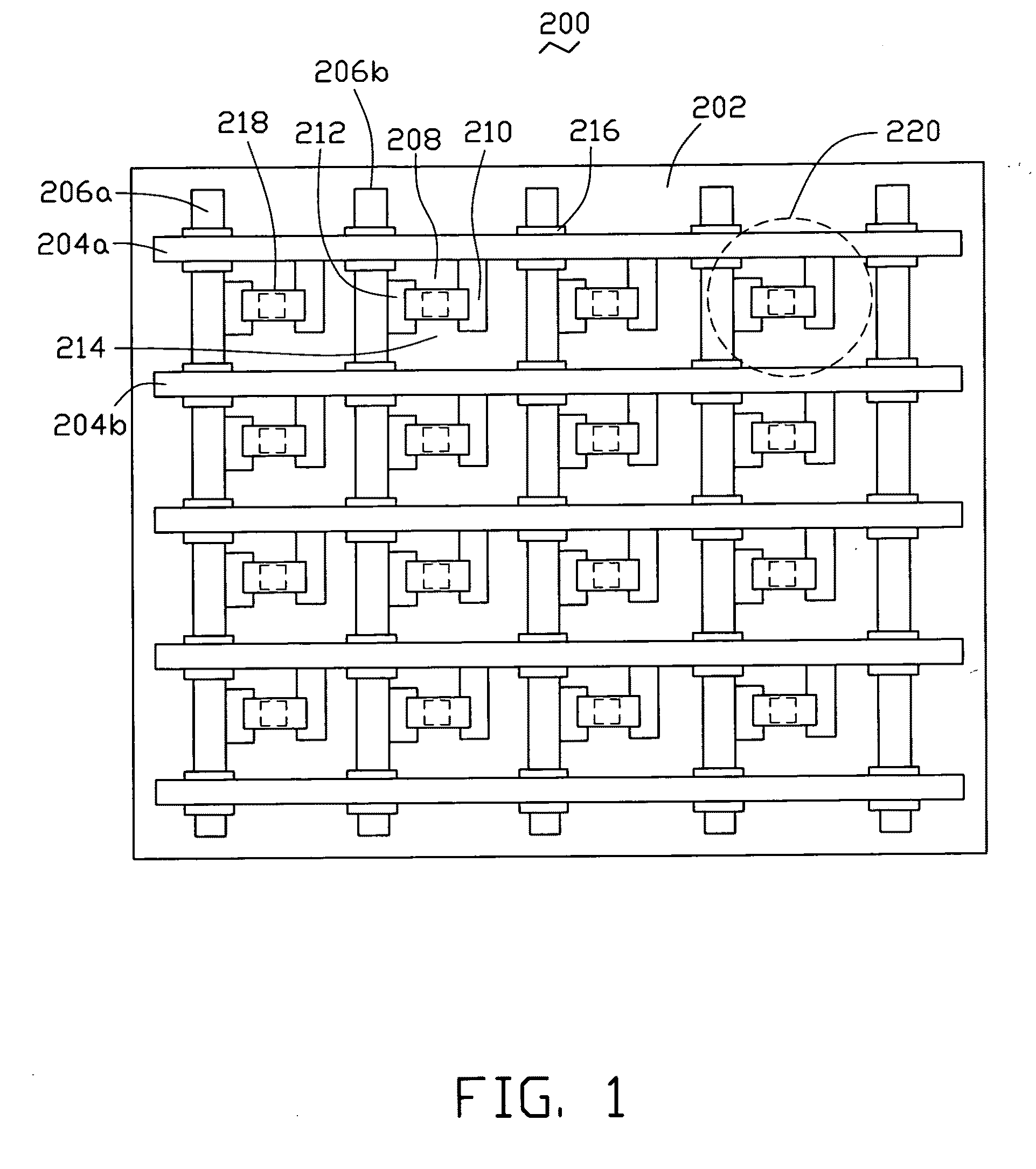

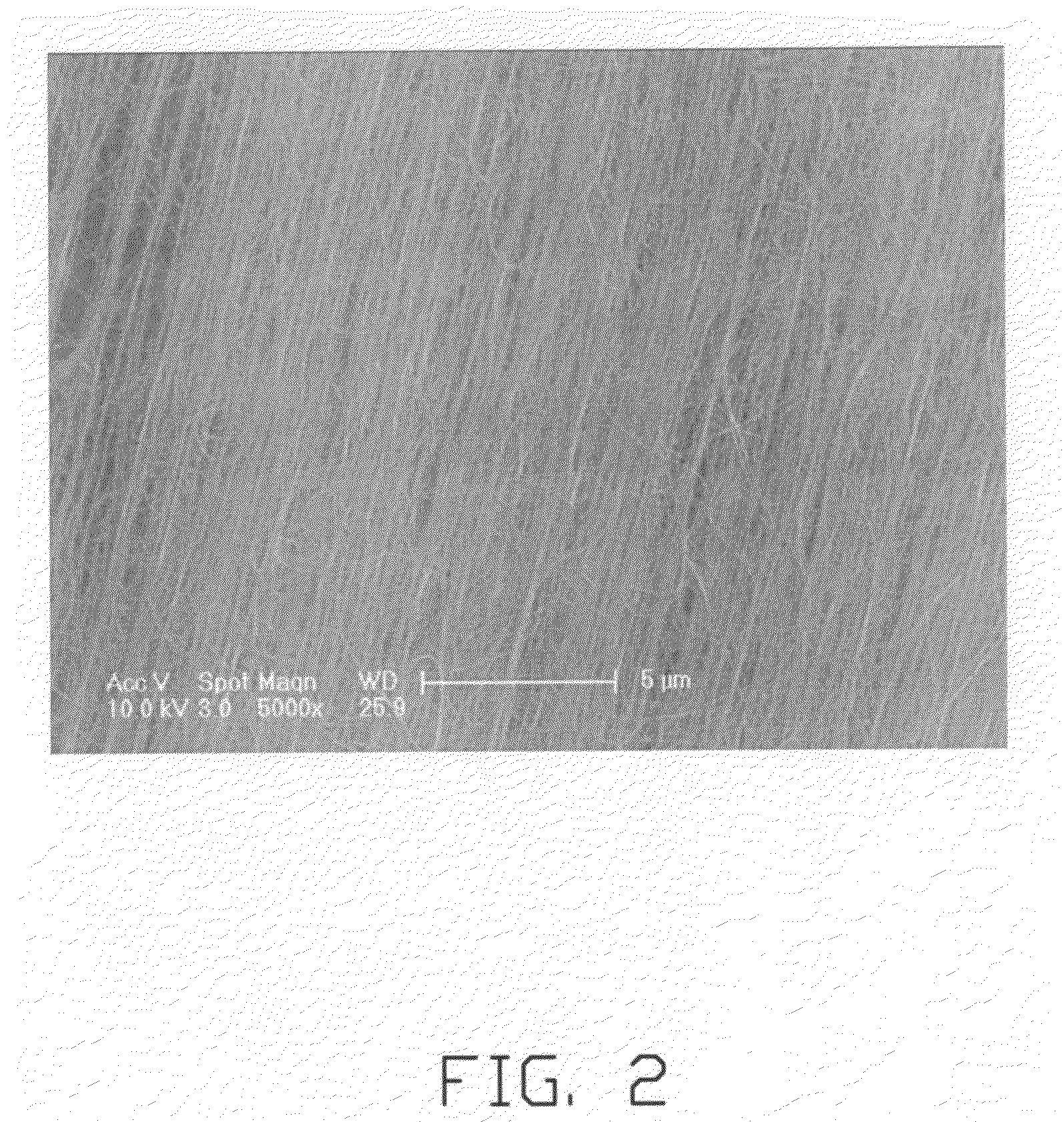

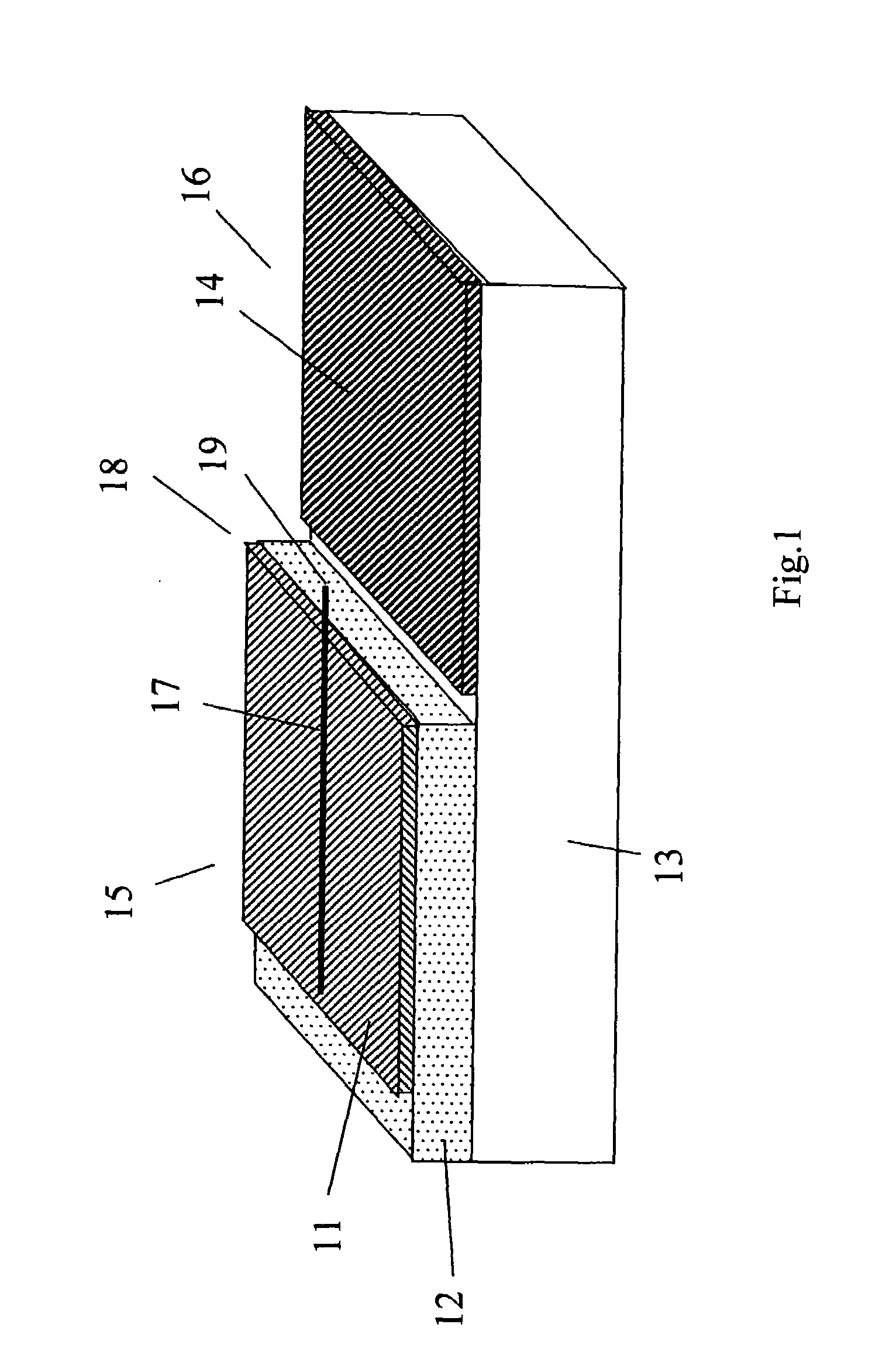

Thermionic electron emission device and method for making the same

ActiveUS20090167137A1Excellent thermal electron emitting propertyIncrease brightnessTube/lamp screens manufactureControl electrodesCarbon nanotubeElectron

A thermionic electron emission device includes an insulating substrate, and one or more grids located thereon. The one or more grids include(s) a first, second, third and fourth electrode down-leads located on the periphery thereof, and a thermionic electron emission unit therein. The first and second electrode down-leads are parallel to each other. The third and fourth electrode down-leads are parallel to each other. The first and second electrode down-leads are insulated from the third and fourth electrode down-leads. The thermionic electron emission unit includes a first electrode, a second electrode, and a thermionic electron emitter. The first electrode and the second electrode are separately located and electrically connected to the first electrode down-lead and the third electrode down-lead respectively. Wherein the thermionic electron emitter includes a carbon nanotube film structure.

Owner:TSINGHUA UNIV +1

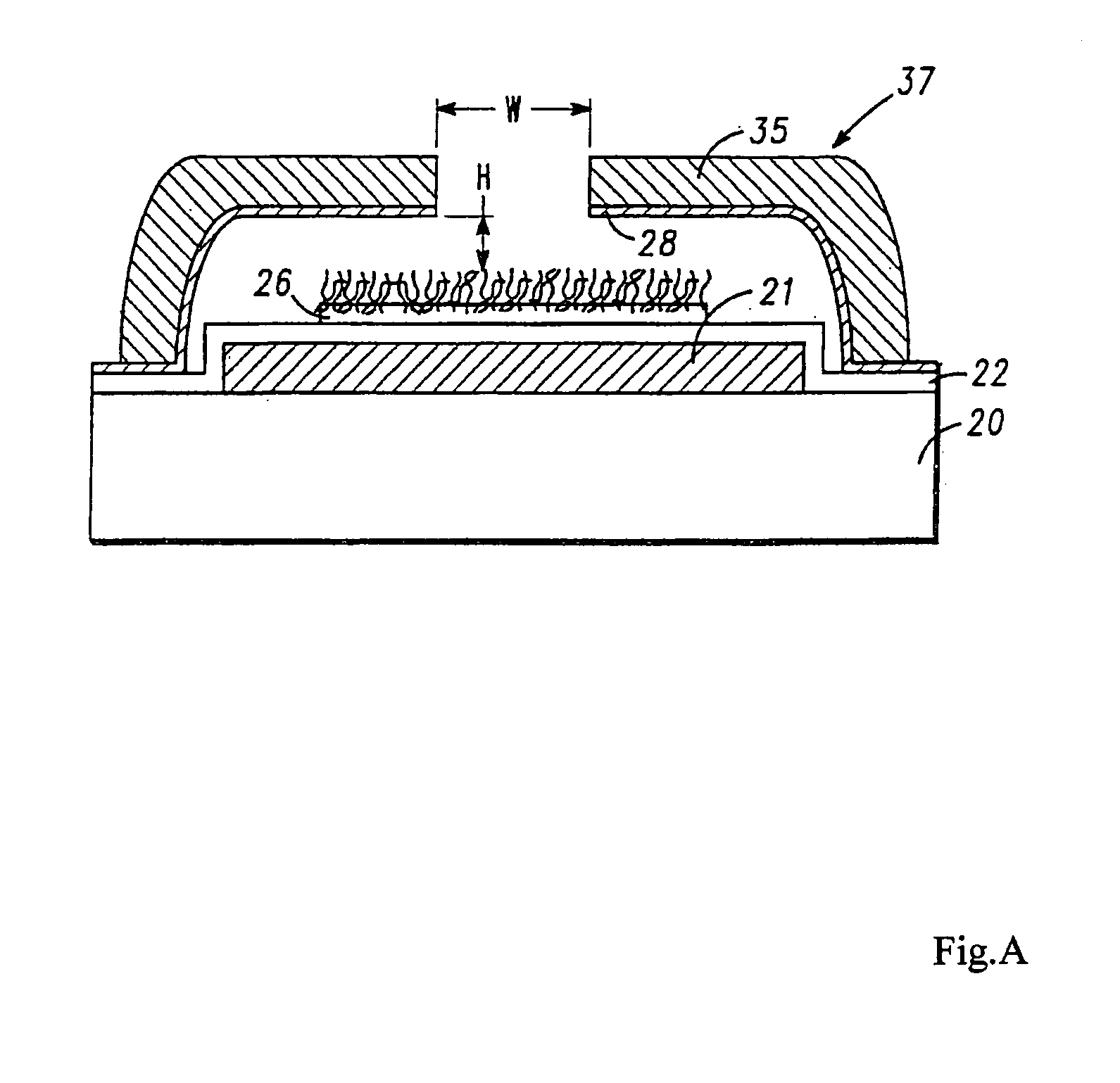

Thermionic electron source

ActiveUS20090153012A1Increase kinetic energyControl electrodesDischarge tube luminescnet screensElectron sourceAtomic physics

A thermionic electron source includes a substrate, at least two electrodes, and a thermionic emitter. The electrodes are electrically connected to the thermionic emitter. The thermionic emitter has a film structure. Wherein there a space is defined between the thermionic emitter and the substrate.

Owner:TSINGHUA UNIV +1

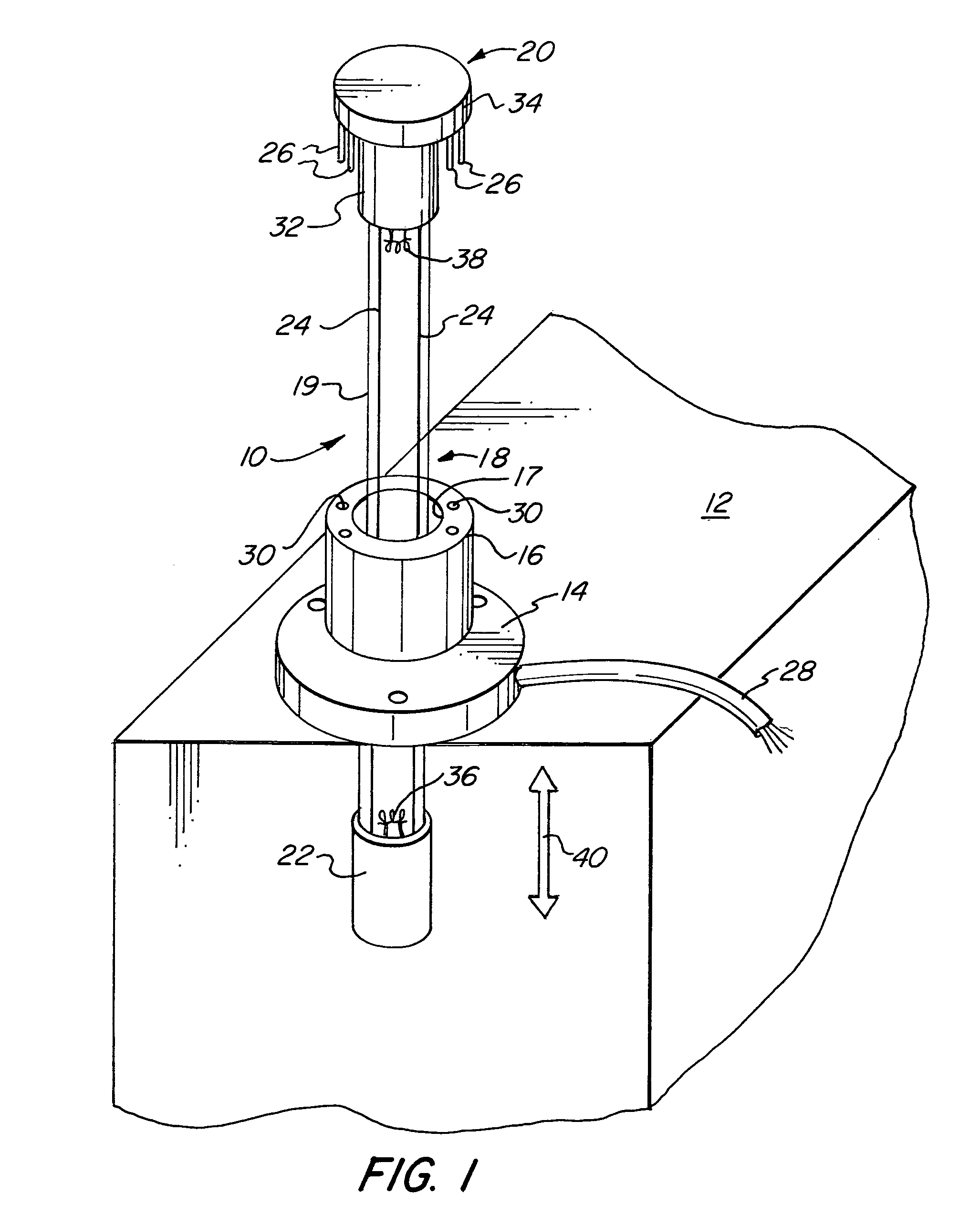

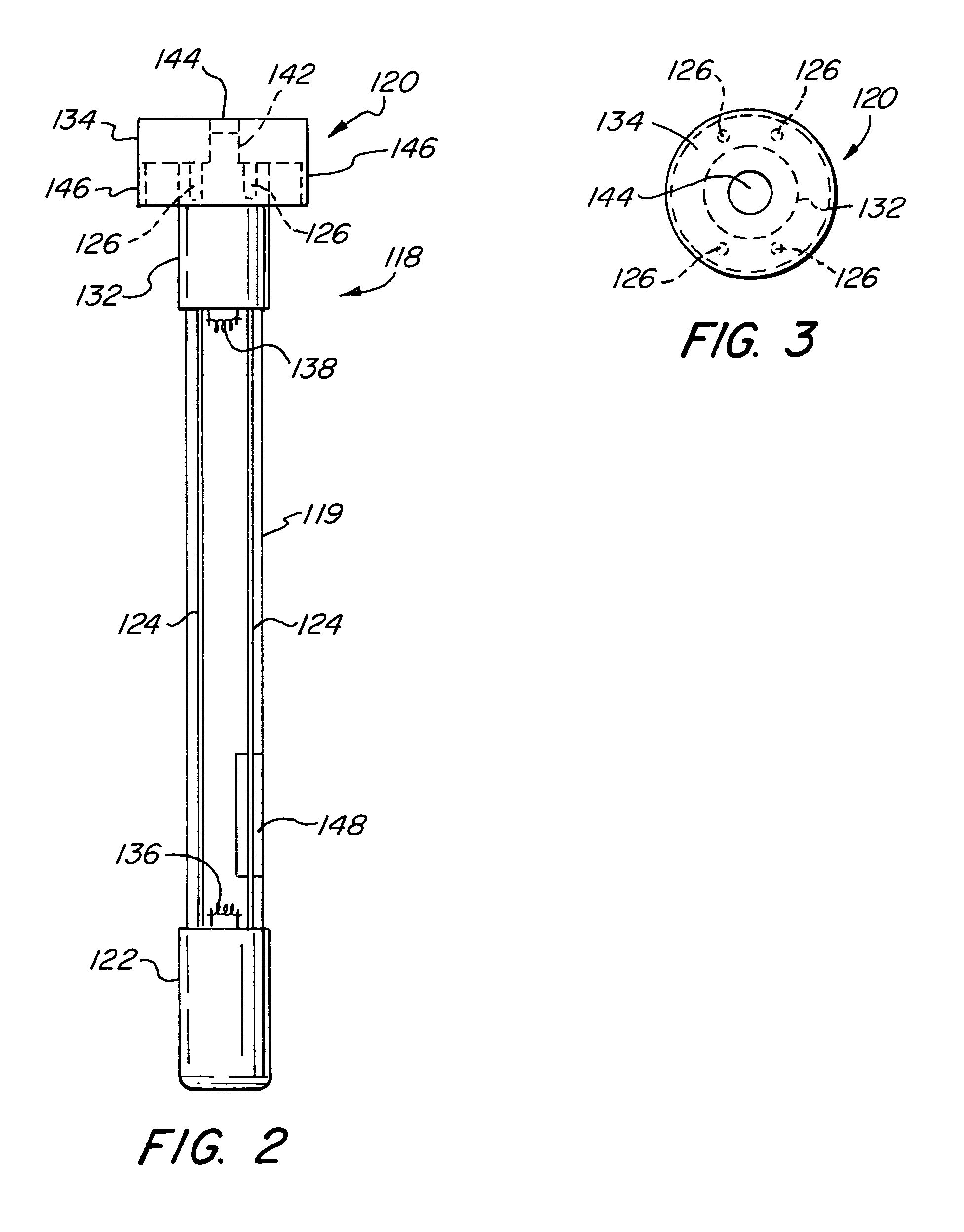

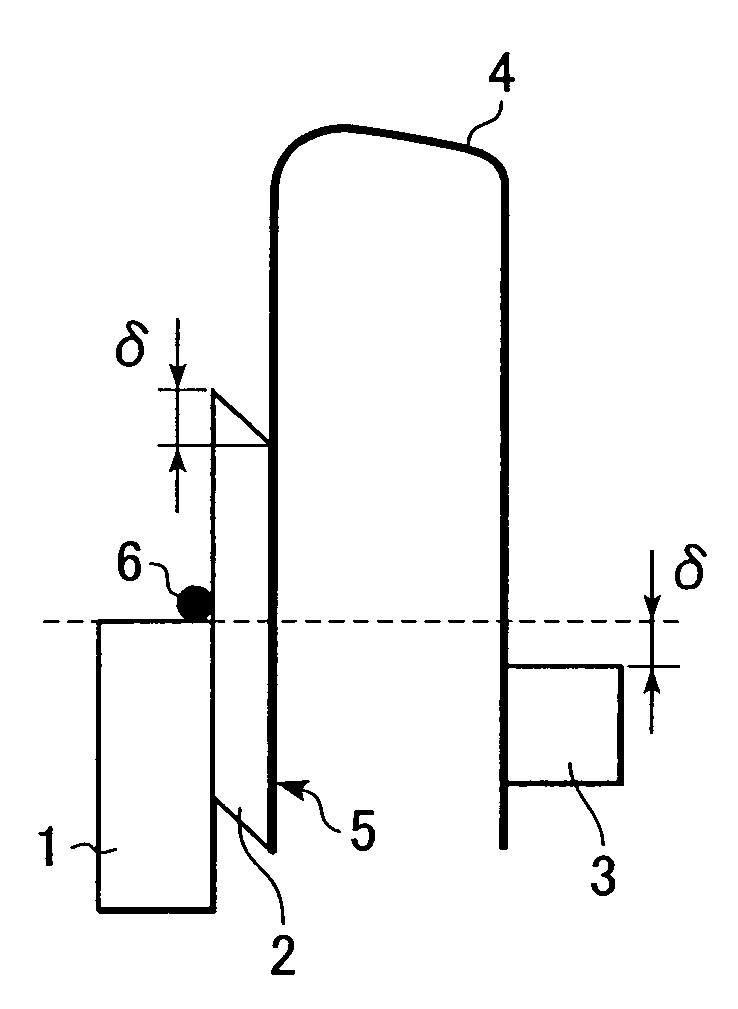

Ultraviolet germicidal lamp base and socket

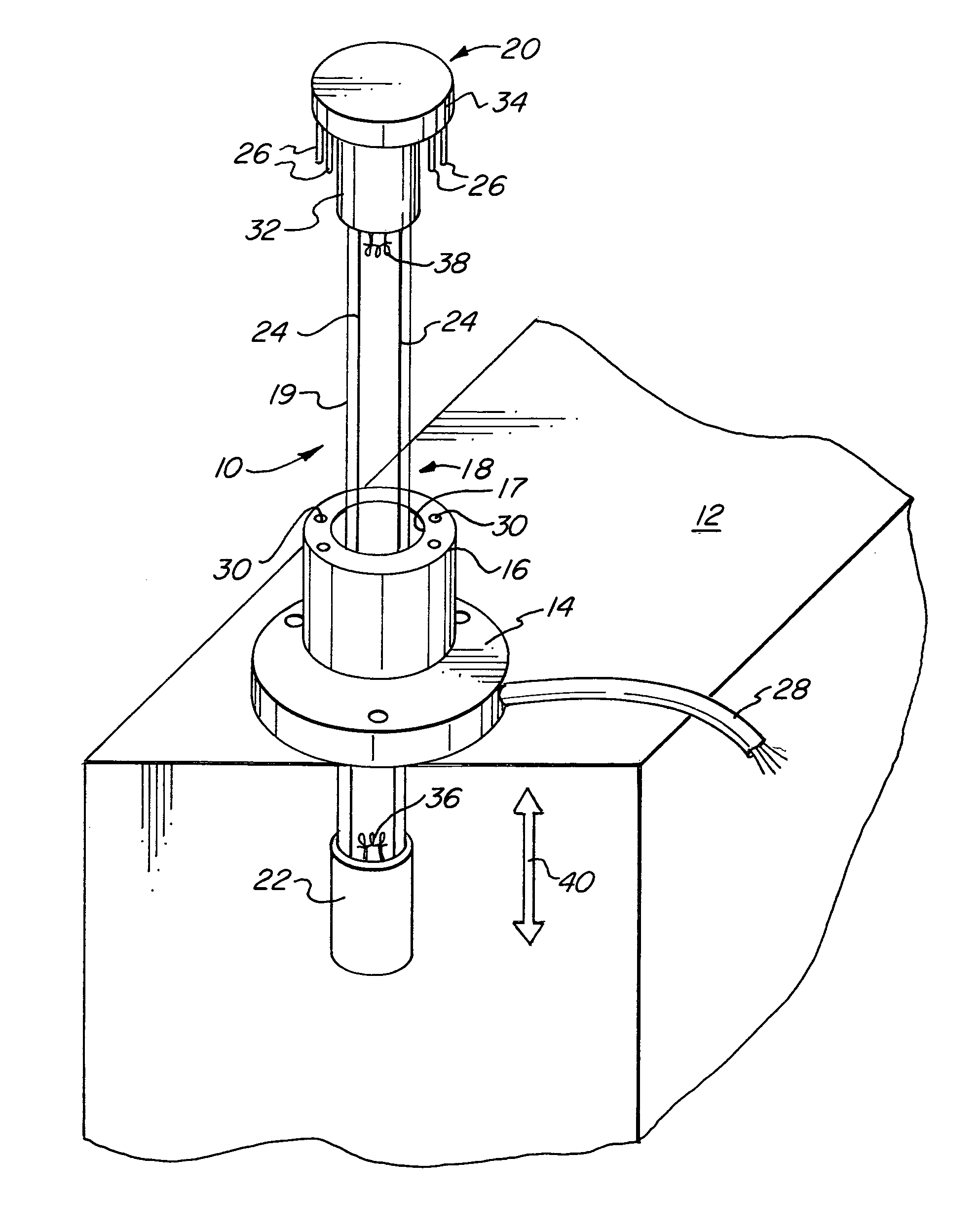

ActiveUS7569981B1Avoid possibilityControl electrodesIncorrect coupling preventionGas-discharge lampWater flow

An ultraviolet gas discharge lamp having contact pins extending downward from a base cap toward an opposing end. The lamp is placed within a conduit or duct for disinfecting air or water flowing within the conduit. The reverse contact pins that extend toward the opposing end mate with contact holes in a socket attached to the conduit through which the lamp is inserted. The lamp is only energized when the lamp is fully inserted into the duct and is de-energized upon removing the lamp from the duct. A shield protects the pins. A window may be place in the base cap so as to visually confirm that the lamp is energized and radiating. A key and mating receiver may be used on the base cap and the socket so as to prevent accidental insertion of an inappropriate lamp.

Owner:LIGHT SOURCES INC

Integrated circuit devices and methods employing amorphous silicon carbide resistor materials

InactiveUS6031250AReduce the temperatureLow implementation costSolid-state devicesSemiconductor/solid-state device manufacturingField emission deviceOxygen

Integrated circuits, including field emission devices, have a resistor element of amorphous SixC1-x wherein 0<x<1, and wherein the SixC1-x incorporates at least one impurity selected from the group consisting of hydrogen, halogens, nitrogen, oxygen, sulphur, selenium, transition metals, boron, aluminum, phosphorus, gallium, arsenic, lithium, beryllium, sodium and magnesium.

Owner:ENTEGRIS INC +1

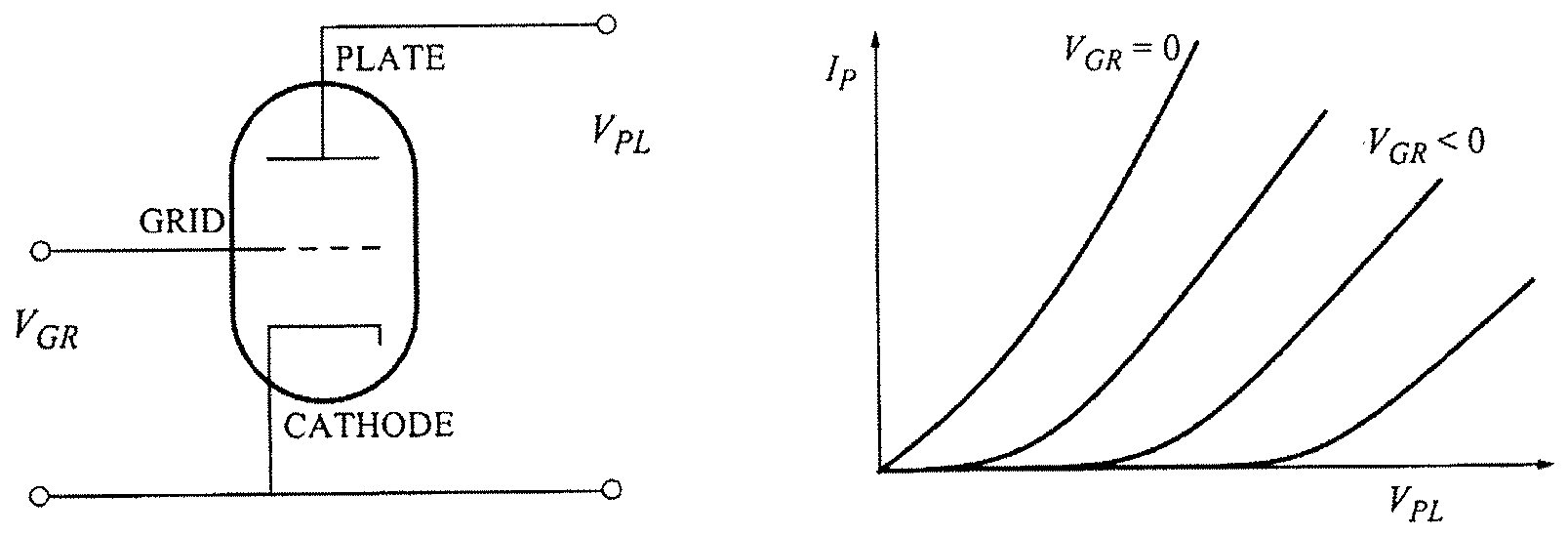

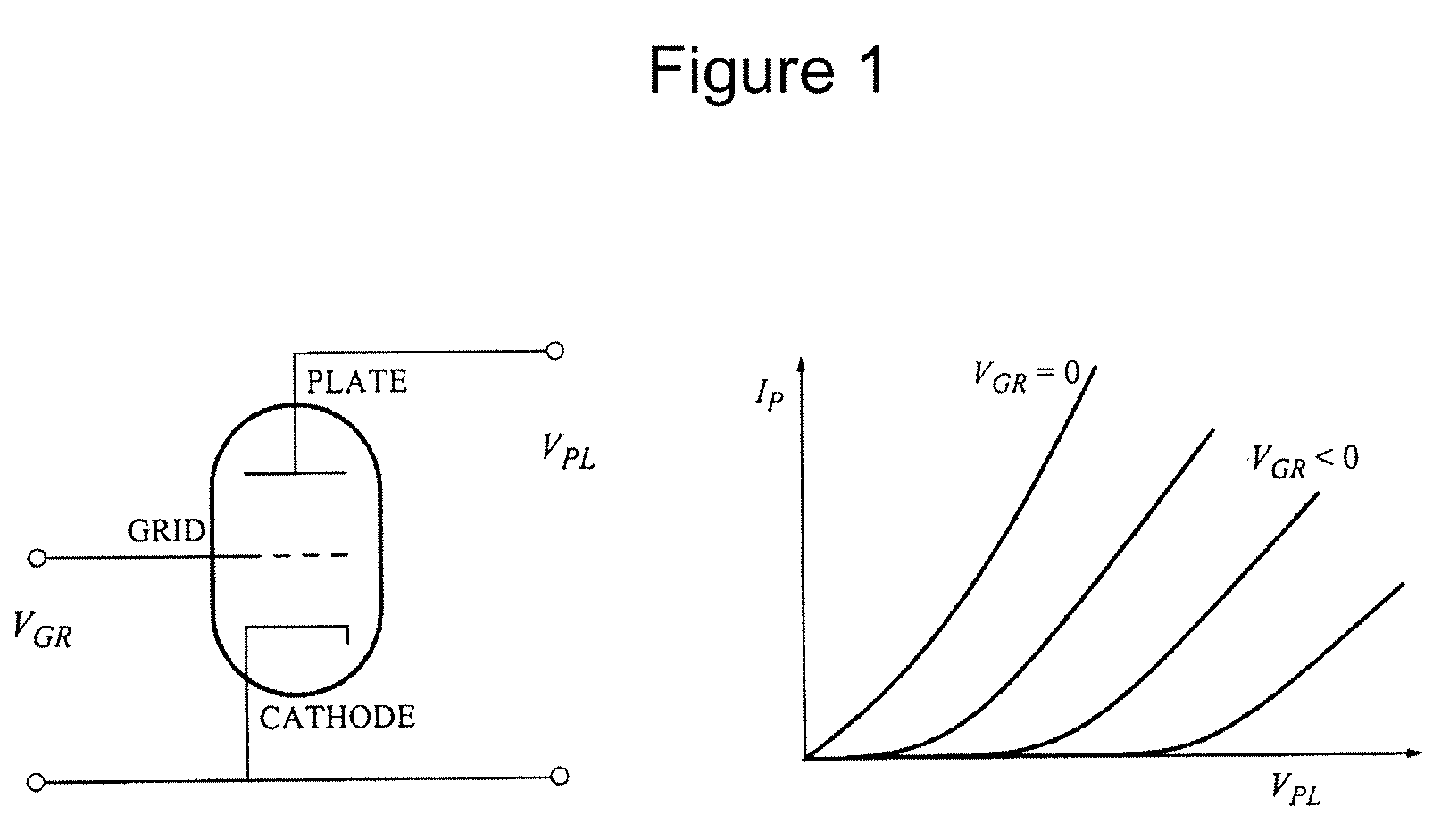

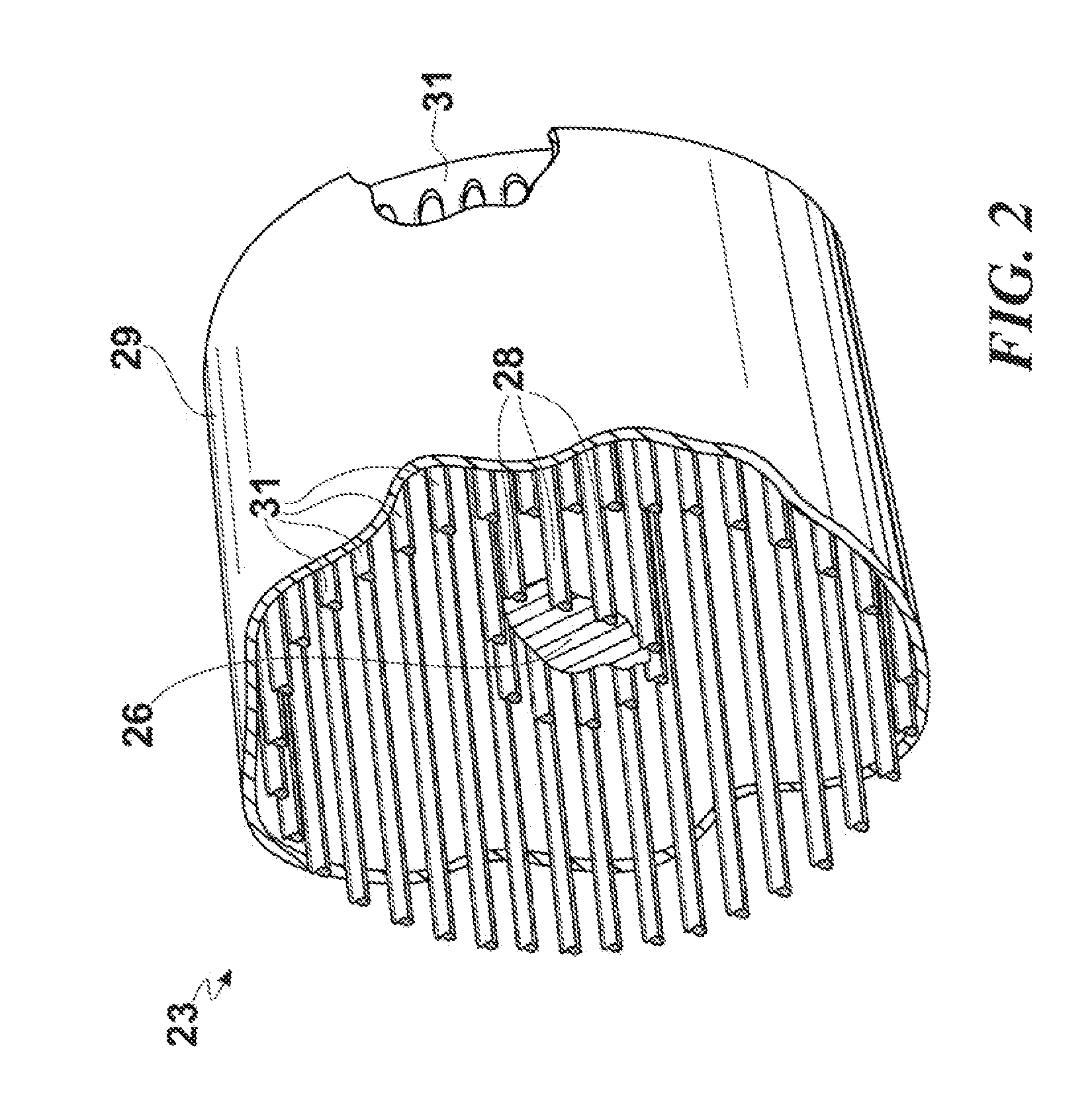

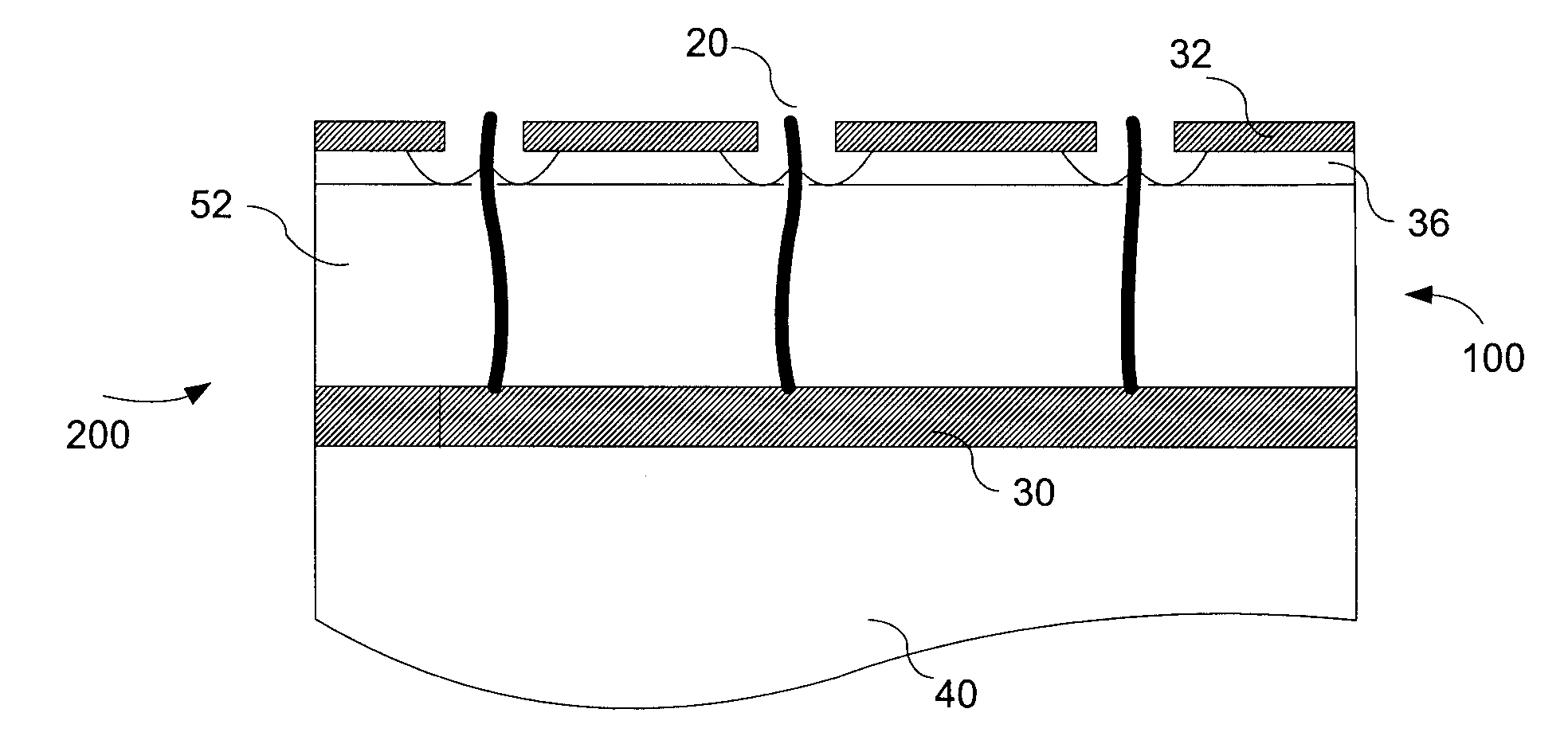

Triodes using nanofabric articles and methods of making the same

Vacuum microelectronic devices with carbon nanotube films, layers, ribbons and fabrics are provided. The present invention discloses microelectronic vacuum devices including triode structures that include three-terminals (an emitter, a grid and an anode), and also higher-order devices such as tetrodes and pentodes, all of which use carbon nanotubes to form various components of the devices. In certain embodiments, patterned portions of nanotube fabric may be used as grid / gate components, conductive traces, etc. Nanotube fabrics may be suspended or conformally disposed. In certain embodiments, methods for stiffening a nanotube fabric layer are used. Various methods for applying, selectively removing (e.g. etching), suspending, and stiffening vertically- and horizontally-disposed nanotube fabrics are disclosed, as are CMOS-compatible fabrication methods. In certain embodiments, nanotube fabric triodes provide high-speed, small-scale, low-power devices that can be employed in radiation-intensive applications.

Owner:NANTERO

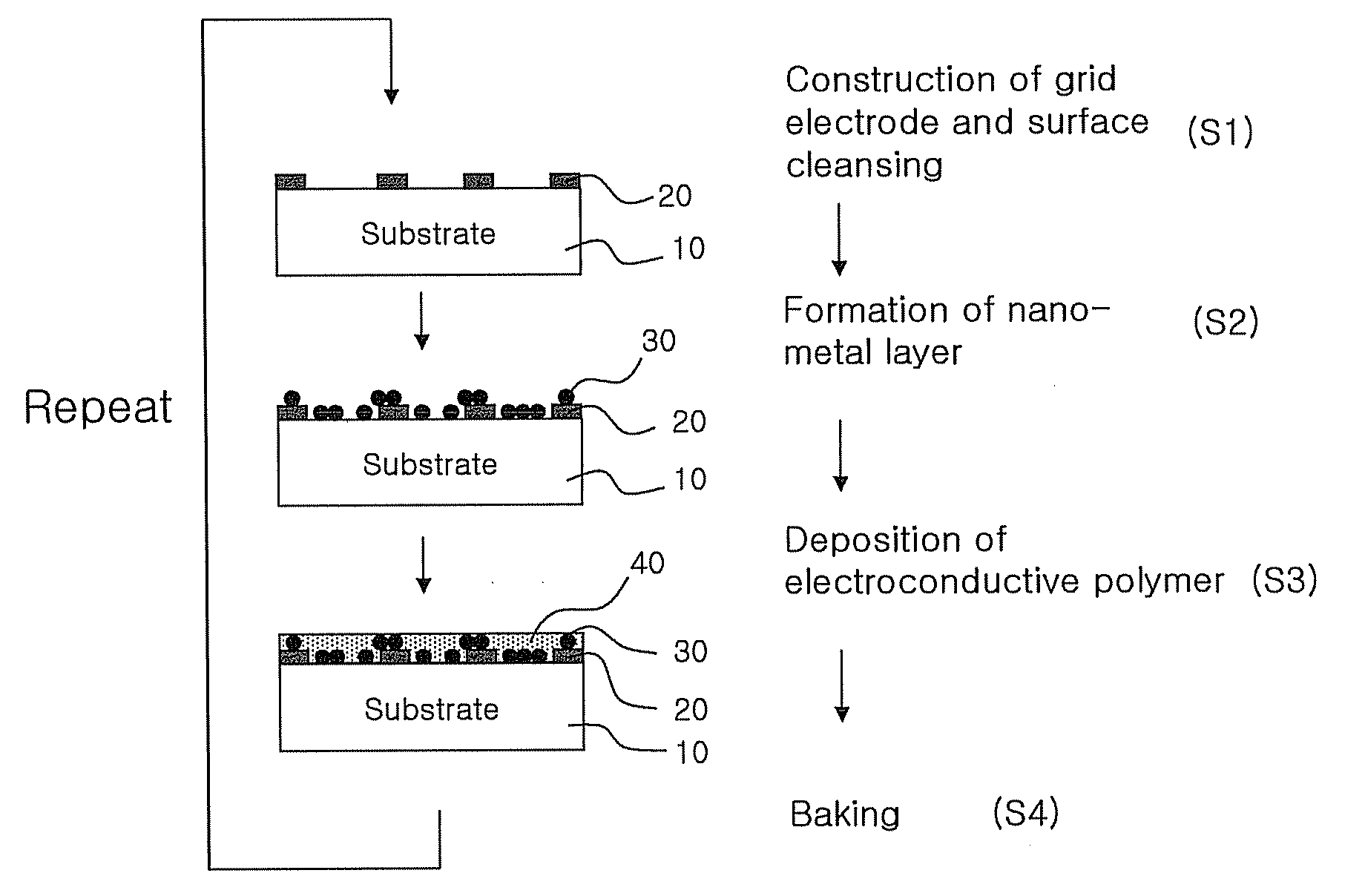

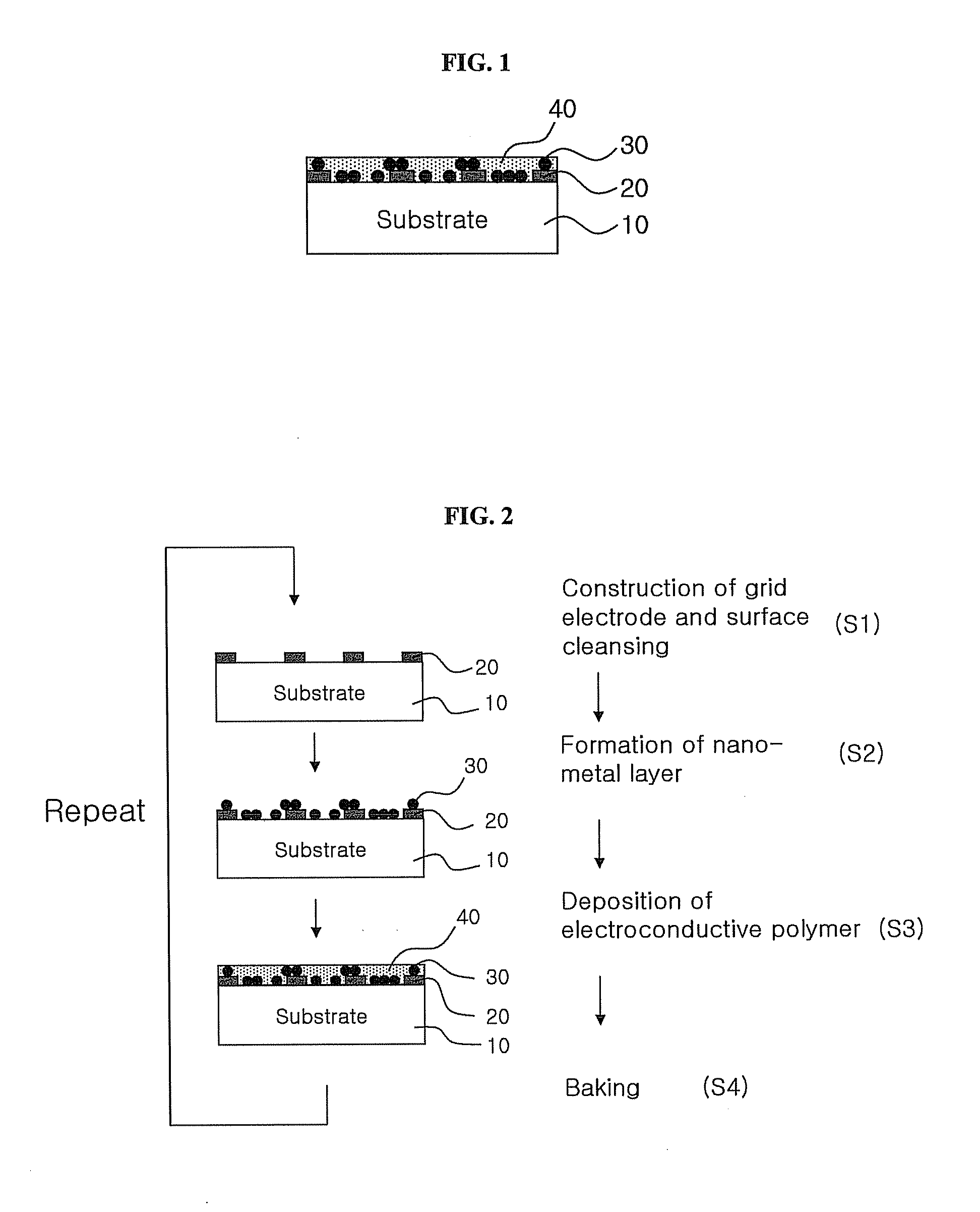

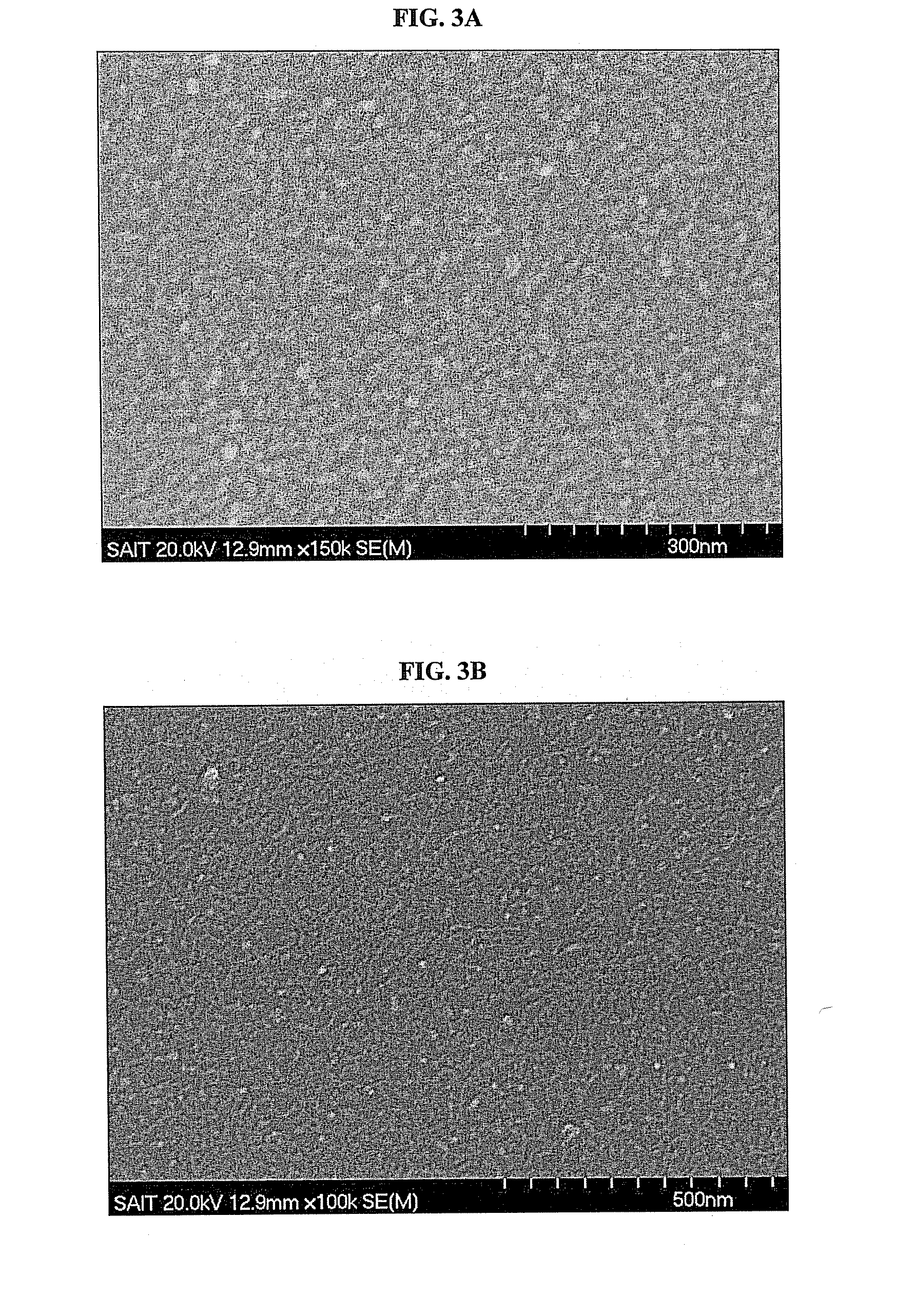

Transparent electrode and preparation method thereof

ActiveUS20070181878A1High light transmittanceLower resistanceControl electrodesGas discharge electrodesProduction rateConductive polymer

Disclosed herein is a transparent electrode featuring the interposition of a nano-metal layer between a grid electrode on a transparent substrate and an electroconductive polymer layer, and a preparation method thereof. The transparent electrode can be produced in a continuous process at high productivity and low cost and can be applied to various display devices.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

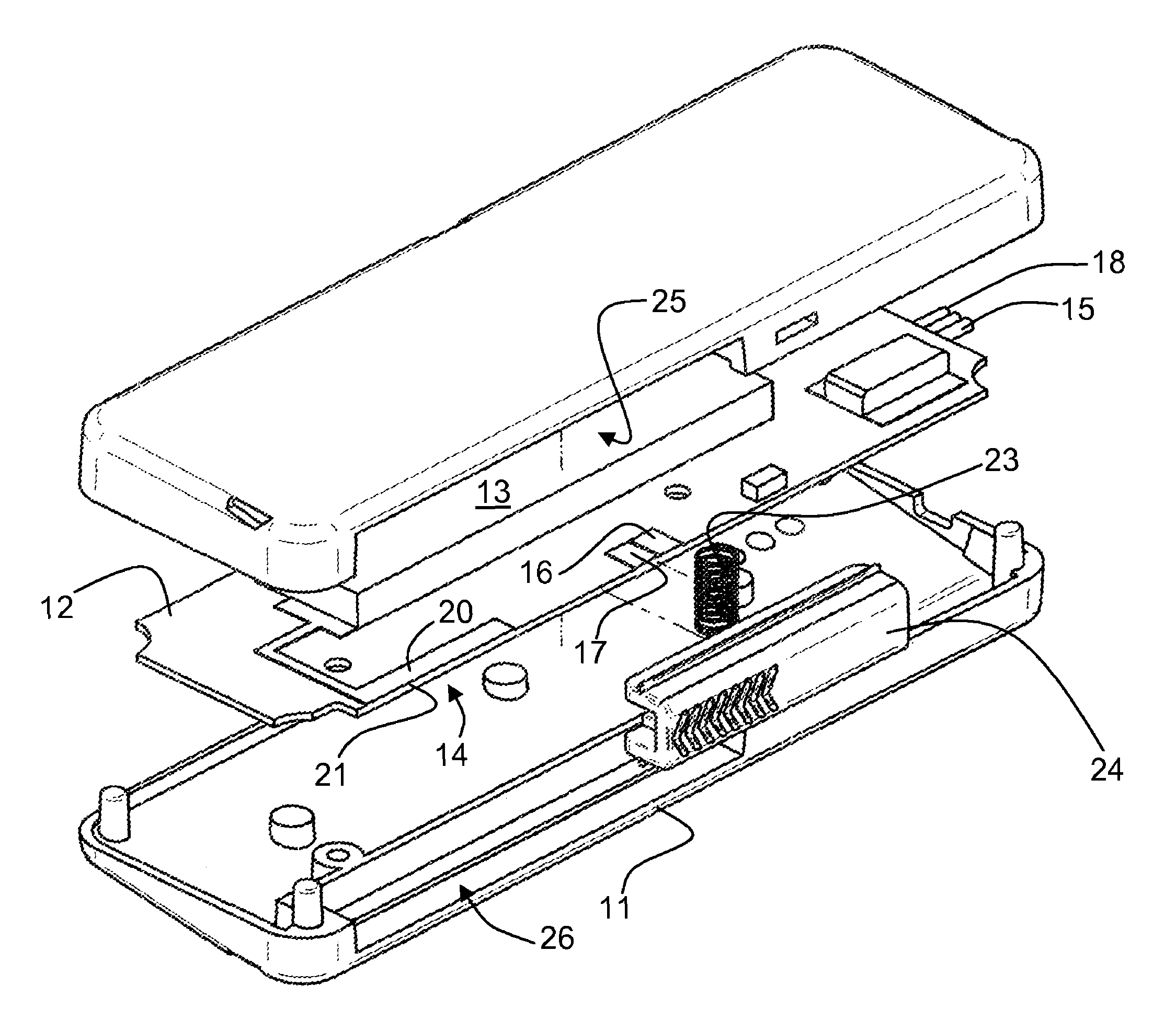

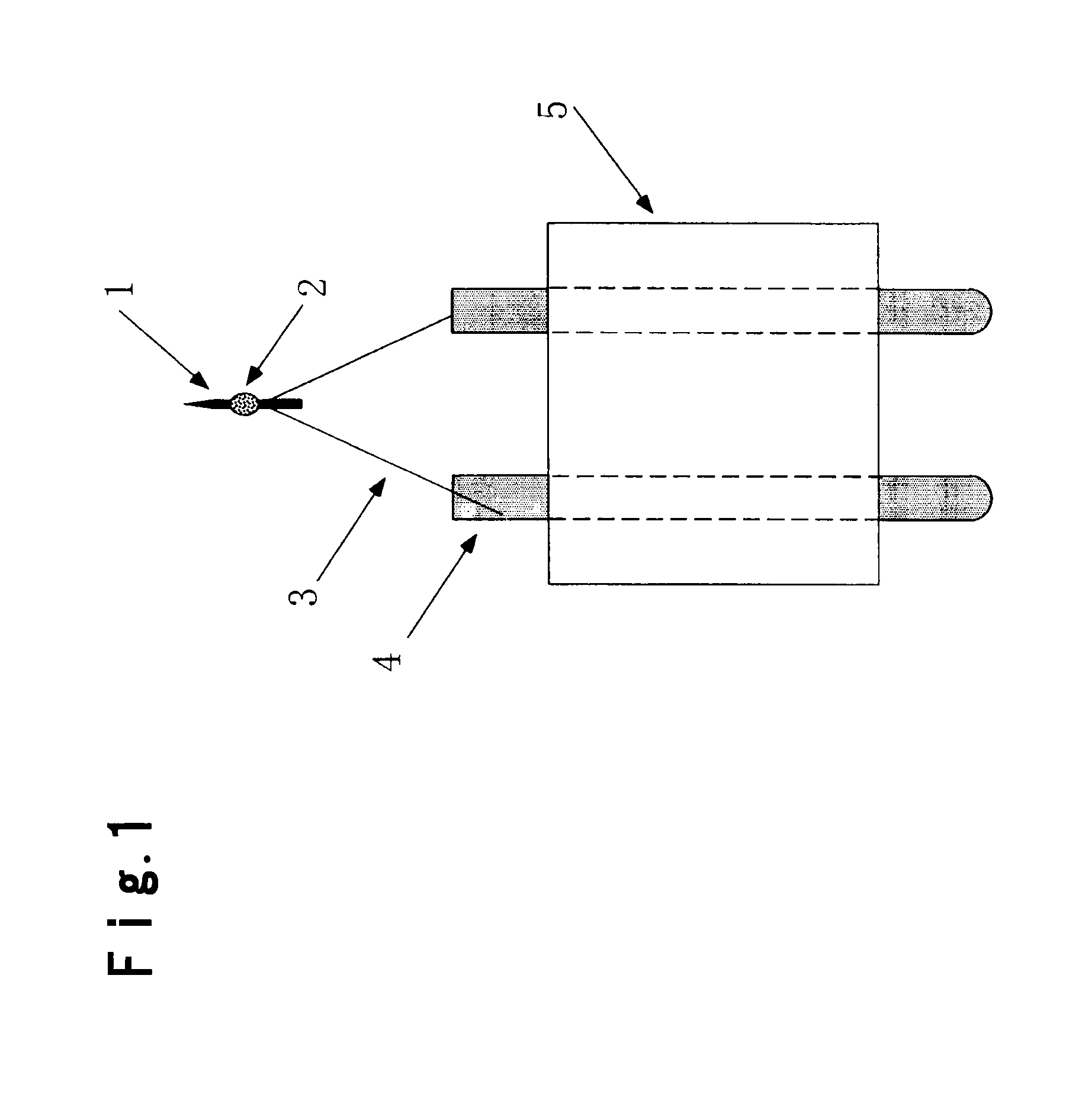

Method and ionizer for bipolar ion generation

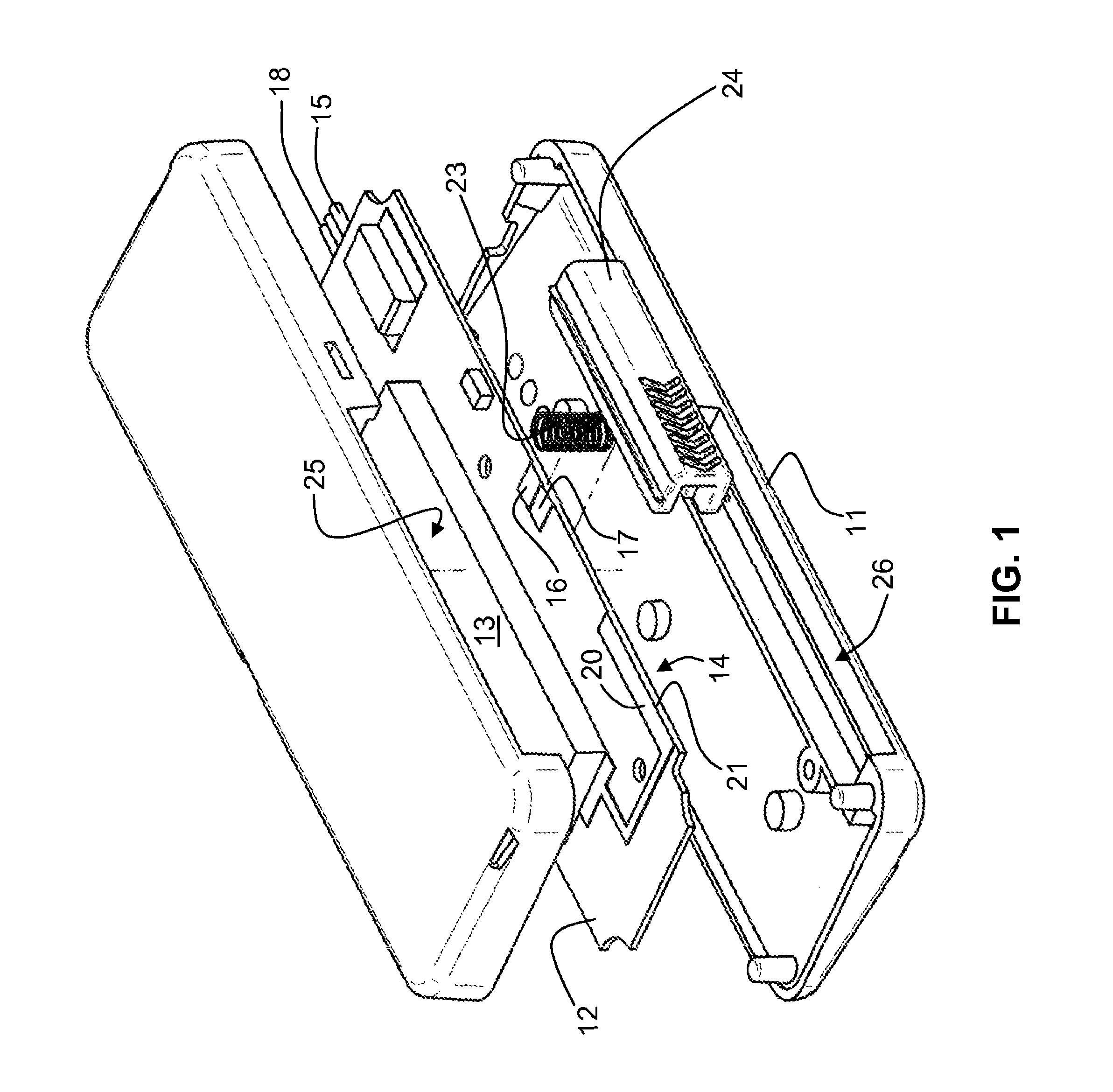

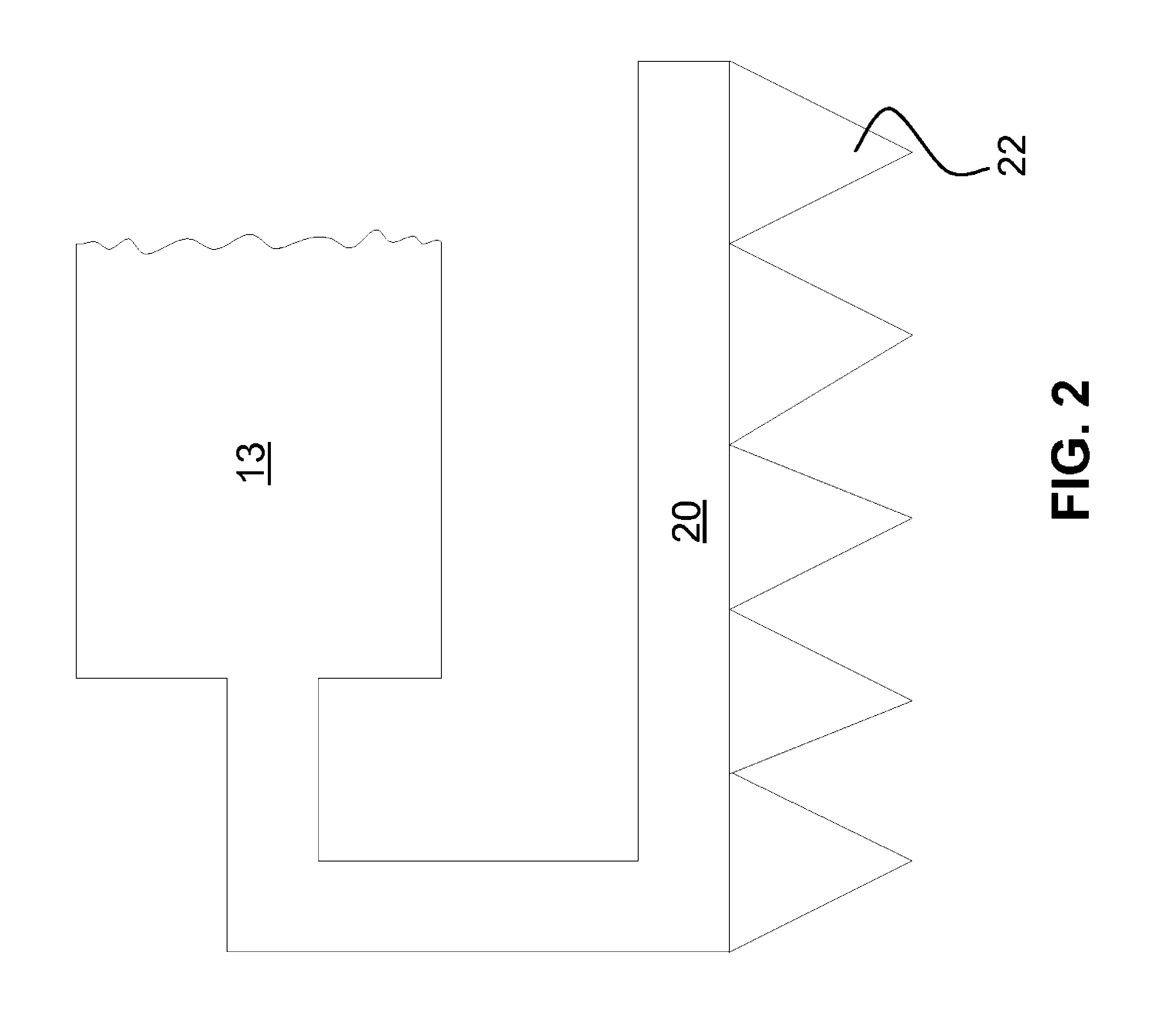

ActiveUS8106367B2Small sizeReduce impactControl electrodesMaterial analysis by optical meansCoil springHigh pressure

An ionizer includes a high voltage AC generator, and a planar ion emitter mounted on an insulating substrate and having an array of planar needles that protrude from an edge of the substrate. The high voltage AC generator may be actuated by a switch having a pair of mutually insulated planar contacts located near an edge of the insulating substrate and configured to be contacted by an electrically conductive coil spring. The coil spring is supported by a slider that is moveable toward the ion emitter from an initial position wherein the planar contacts are shorted by the spring so as to actuate the high voltage AC generator. Continued movement of the spring collects dust in its coils while breaking the switch contacts and de-energizing the high voltage AC generator.

Owner:FILT AIR

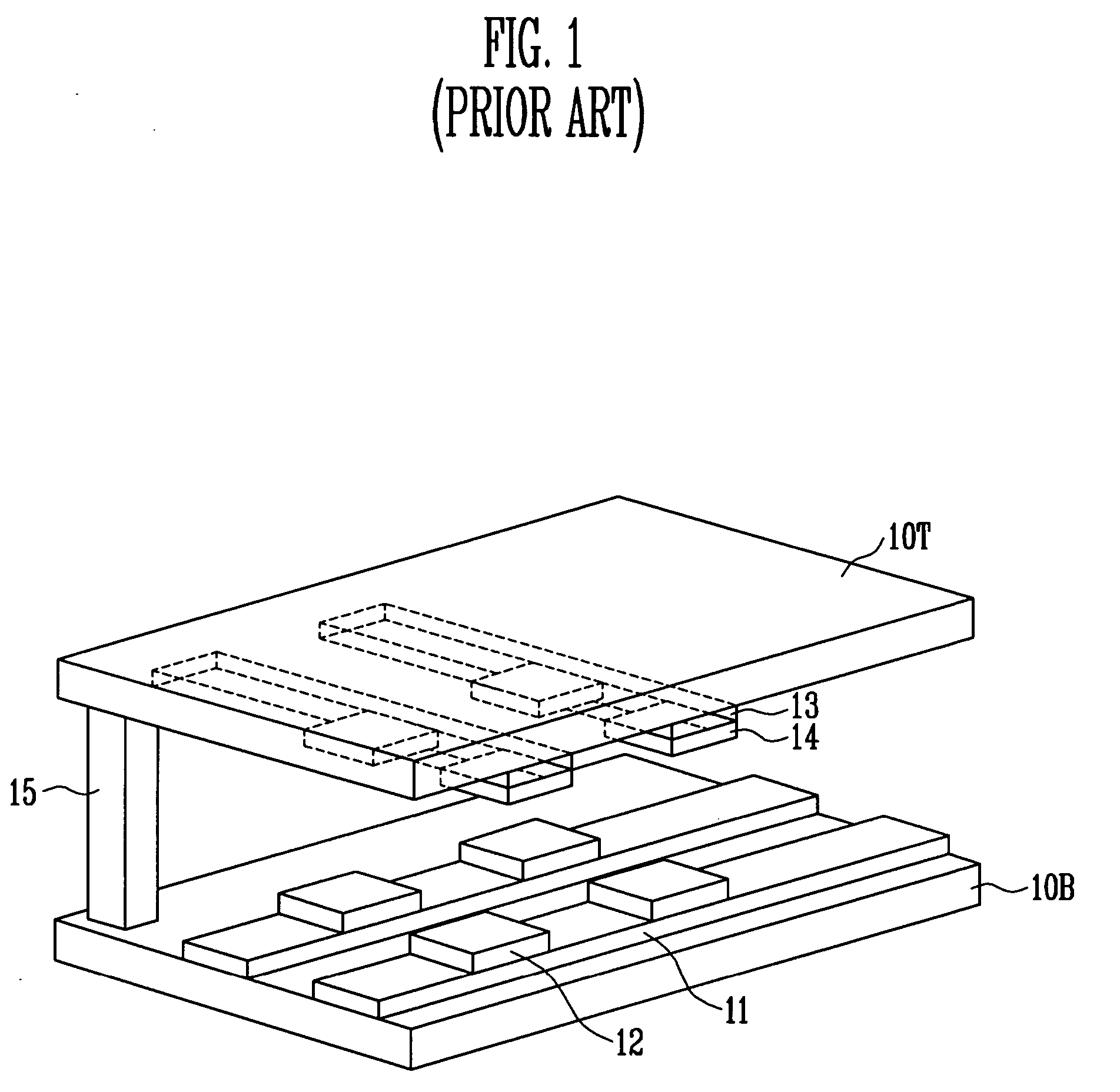

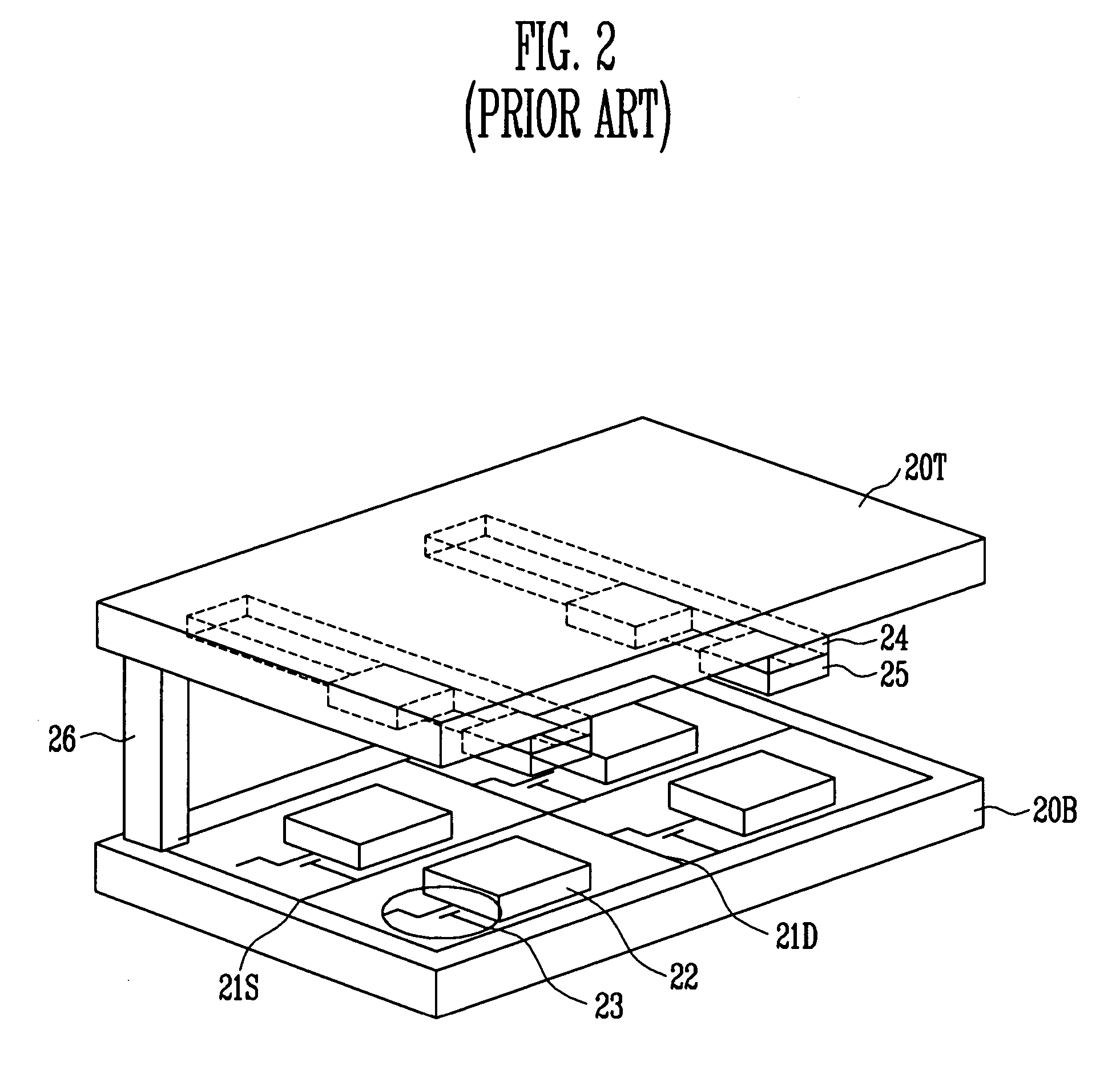

Field emission display

ActiveUS20050248256A1High voltageIncrease brightnessControl electrodesDischarge tube luminescnet screensPhosphorField emission display

Provided is a field emission display, which includes: a cathode portion including row signal lines and column signal lines in a stripe form allowing matrix addressing to be carried out on a substrate, and pixels defined by the row signal lines and the column signal lines, each pixel having a field emitter and a control device which controls the field emitter with two terminals connected to at least the row signal line and the column signal line and one terminal connected to the field emitter; an anode portion having an anode electrode, and a phosphor connected to the anode electrode; and a gate portion having a metal mesh with a plurality of penetrating holes, and a dielectric layer formed on at least one region of the metal mesh, wherein the gate portion is disposed between the cathode portion and the anode portion to allow the surface where the dielectric layer is formed to be faced to the cathode portion and to allow electrons emitted from the field emitter to collide with the phosphor via the penetrating holes.

Owner:ELECTRONICS & TELECOMM RES INST

Displaying device and lighting device employing organic electroluminescence element

InactiveUS20090236962A1Shape is not particularly restrictedInhibition is effectiveControl electrodesSolid-state devicesDisplay deviceEffect light

Owner:KK TOSHIBA

Printed active device

ActiveUS20150270089A1Reduce manufacturing costLow costAdditive manufacturing apparatusControl electrodesElement spaceElectrical connection

Owner:BRITISH TELECOMM PLC

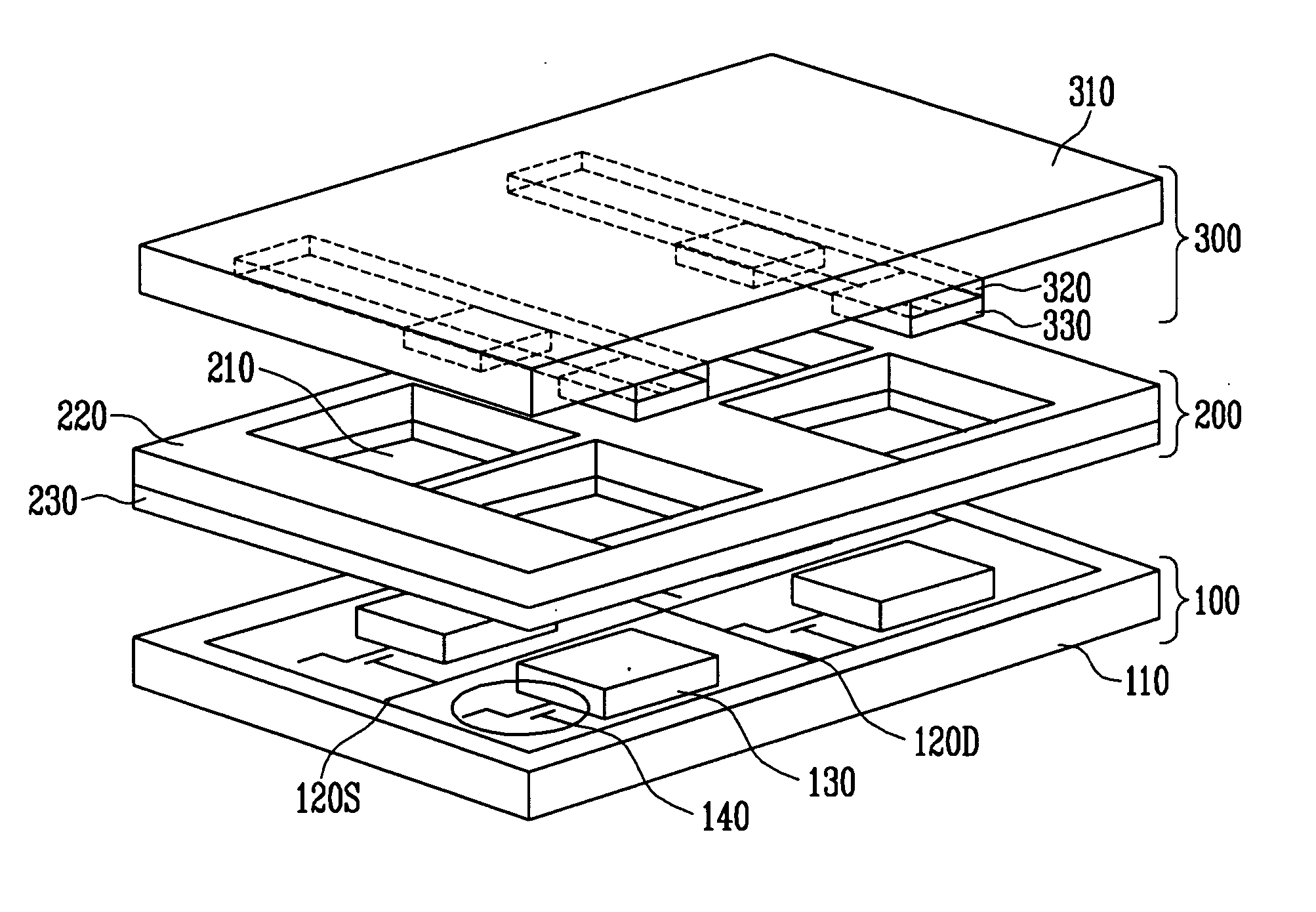

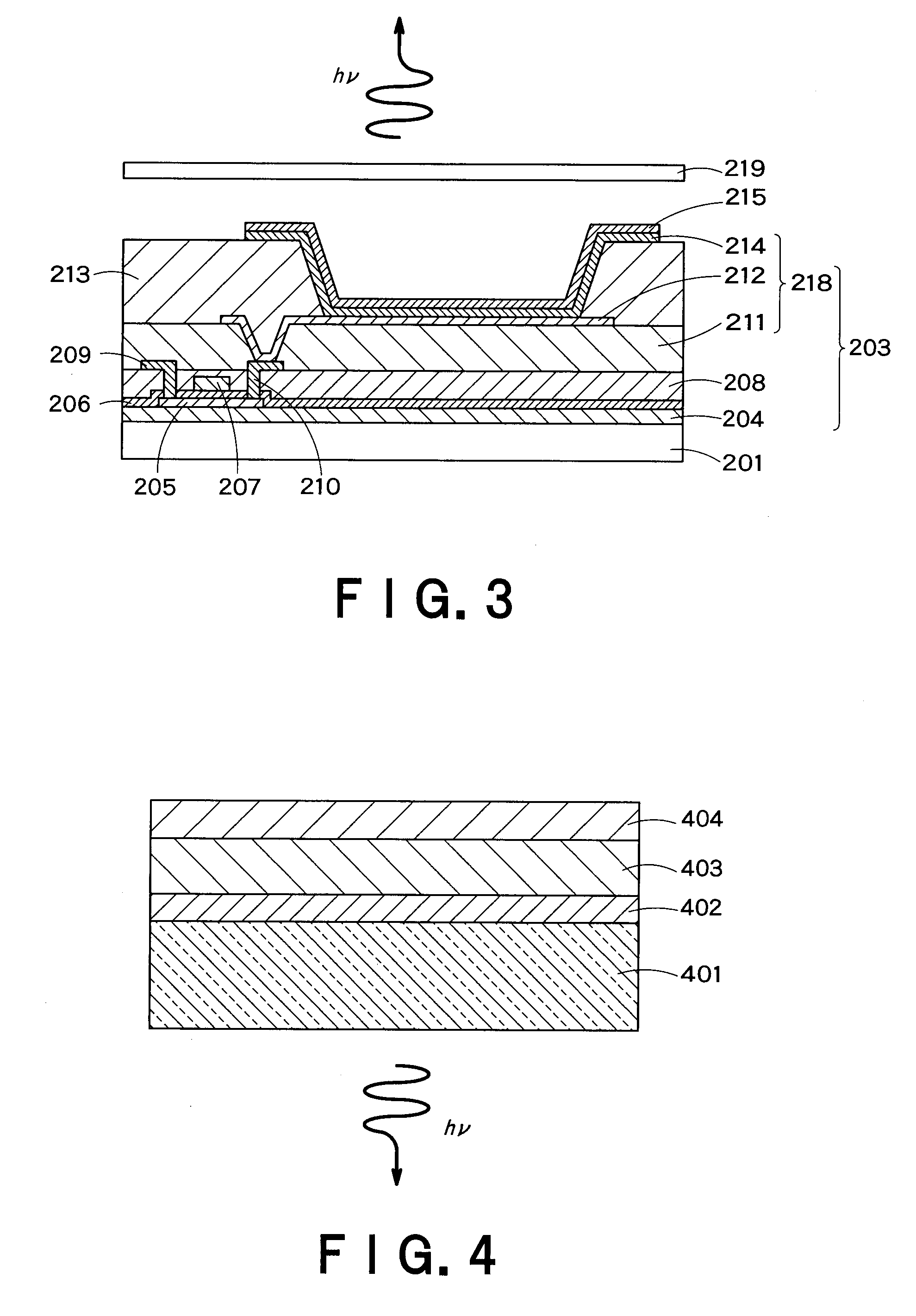

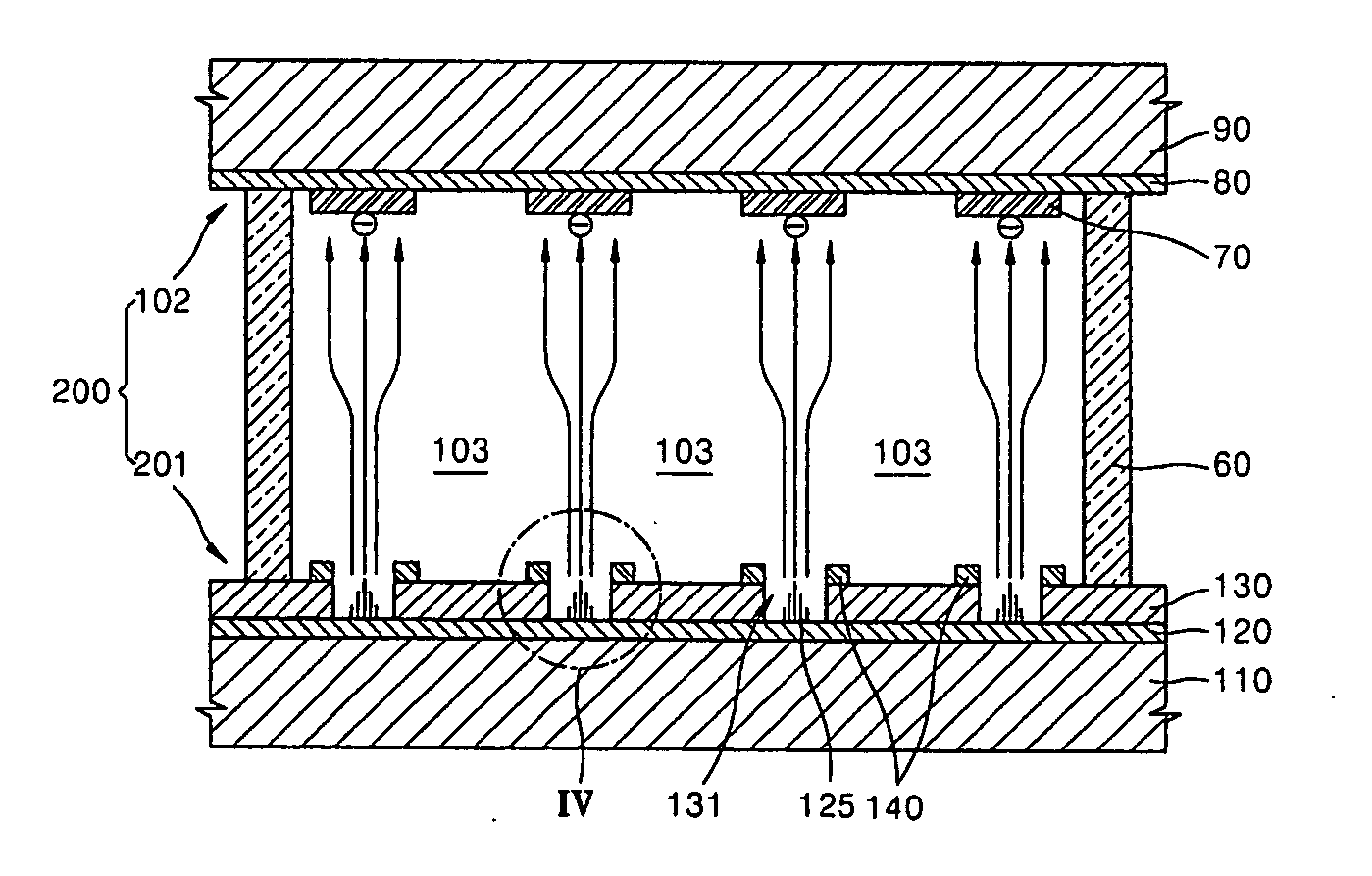

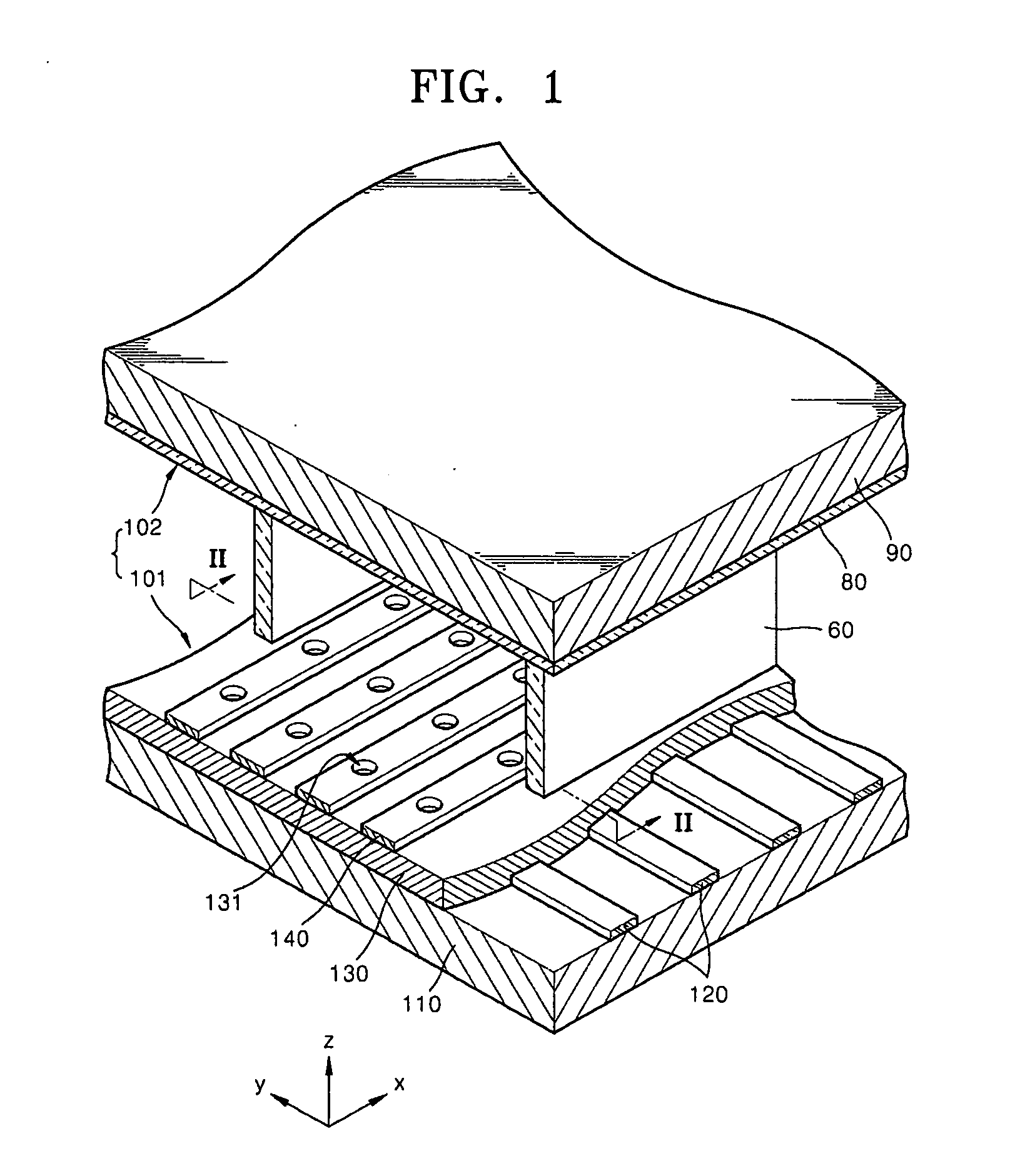

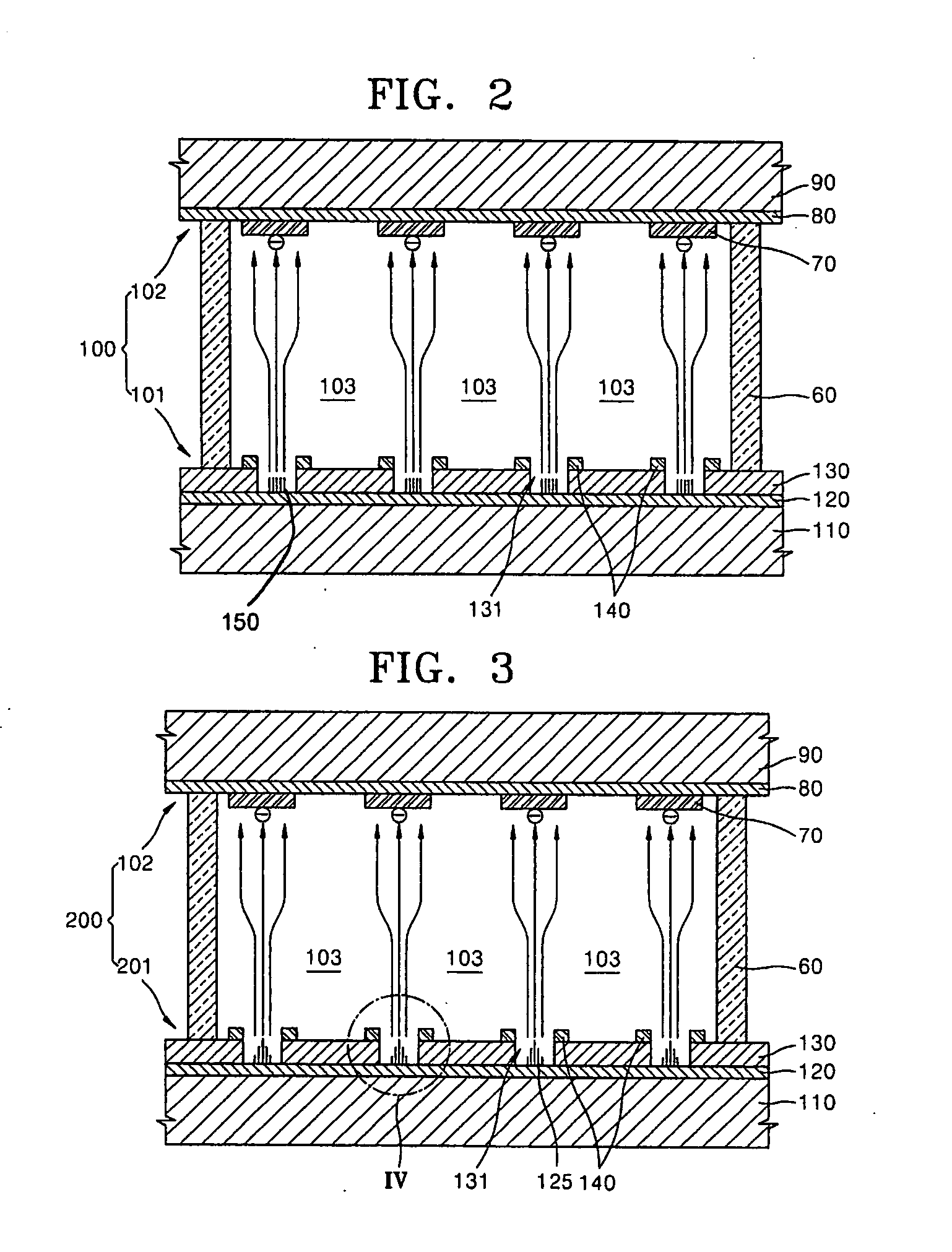

Electronic emission device, electron emission display device having the same, and method of manufacturing the electron emission device

InactiveUS7652418B2Low costImprove uniform brightnessControl electrodesDischarge tube luminescnet screensCarbon nanotubeDisplay device

An electron emission device which can uniformly emit electrons and can be simply manufactured at a reduced cost, and a display apparatus having improved uniform brightness of pixels by using the electron emission device. In addition, a simple method of manufacturing the electron emission device. The electron emission device includes: a first substrate; a cathode electrode and an electron emission unit disposed on the first substrate; a gate electrode electrically insulated from the cathode electrode; an insulating layer disposed between the cathode electrode and the gate electrode to insulate the cathode electrode from the gate electrode; and an electron emission source including carbon nanotubes (CNTs) that contact the cathode electrode, wherein distances between the gate electrode and the tips of the CNTs are uniform.

Owner:SAMSUNG SDI CO LTD

Display and display panel thereof

ActiveUS20110241526A1Prevent capacitanceInhibit productionControl electrodesStatic indicating devicesScan lineComputer science

A display panel including a plurality of scan lines, a plurality of data lines, and a plurality of pixels is provided. The data lines are disposed substantially perpendicular to the scan lines Each of the pixels is electrically connected with the corresponding data line and the corresponding scan line and the pixels are arranged as an array. The data lines are grouped into a plurality of groups and each of the groups is disposed between two adjacent pixel columns and has N data lines, where N is a positive integer greater than or equal to 3. A portion of the data lines of at least a first group among the groups cross over a portion of the scan lines. The rest data lines of the first group cross over all the scan lines.

Owner:AU OPTRONICS CORP

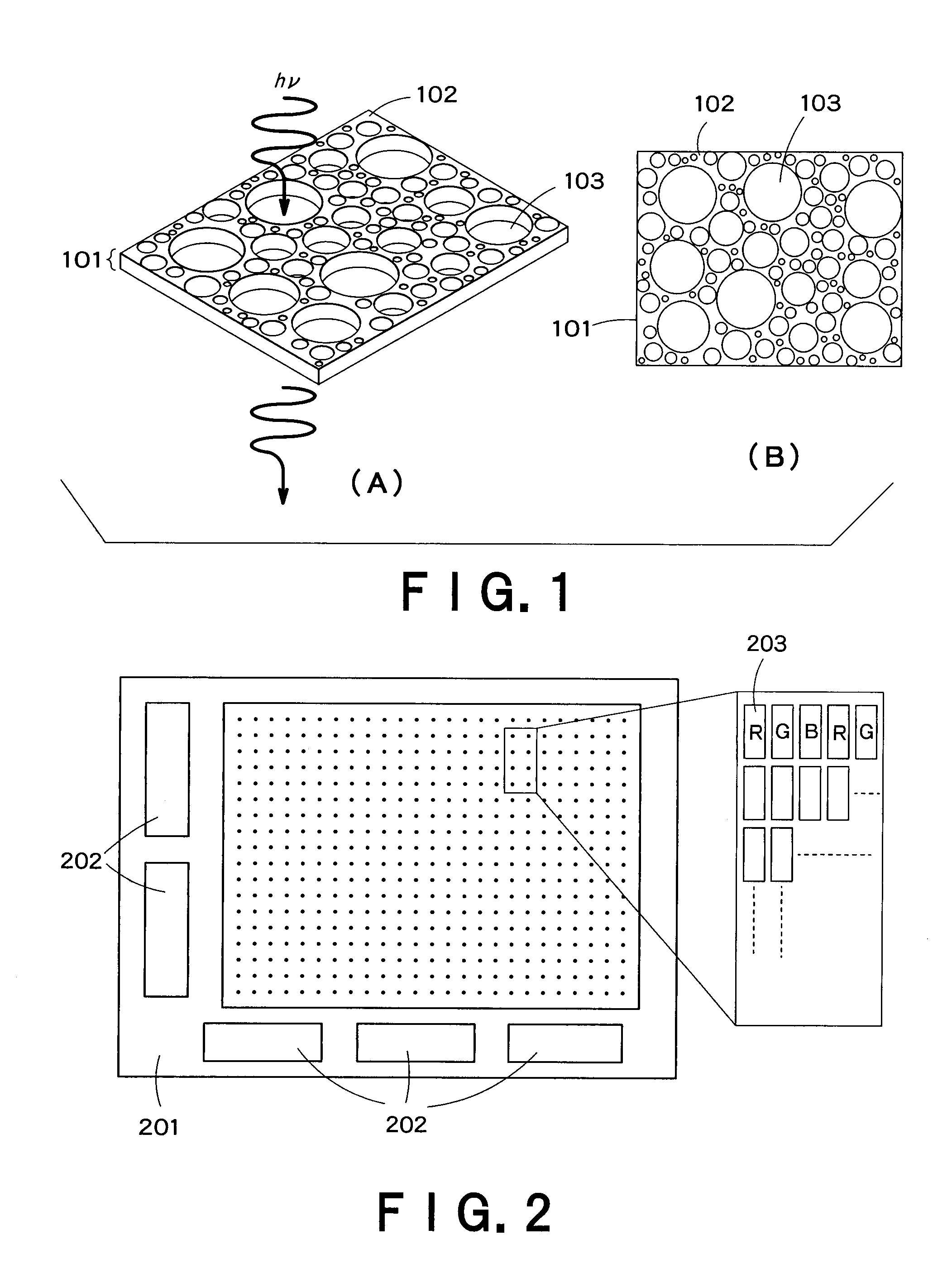

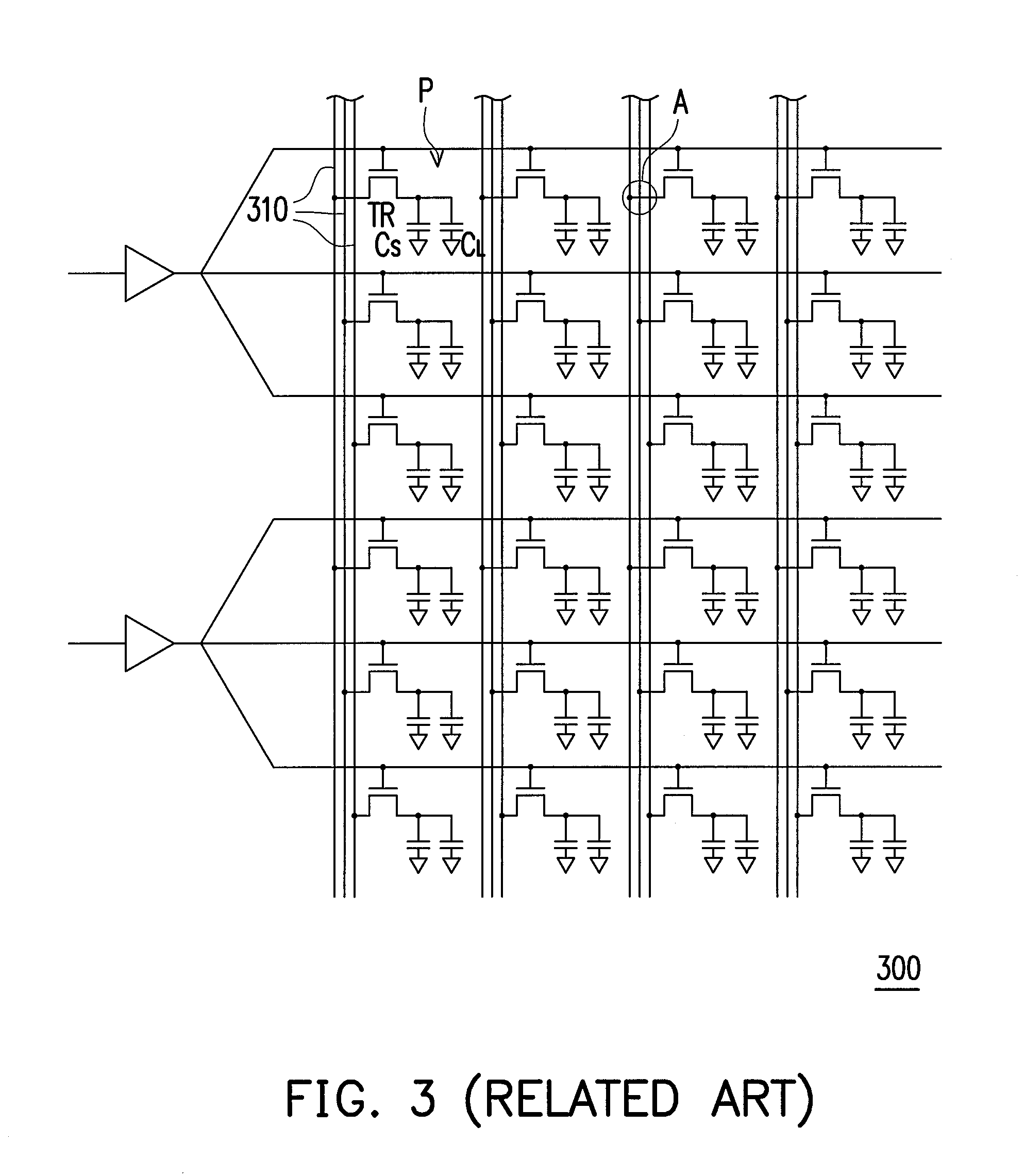

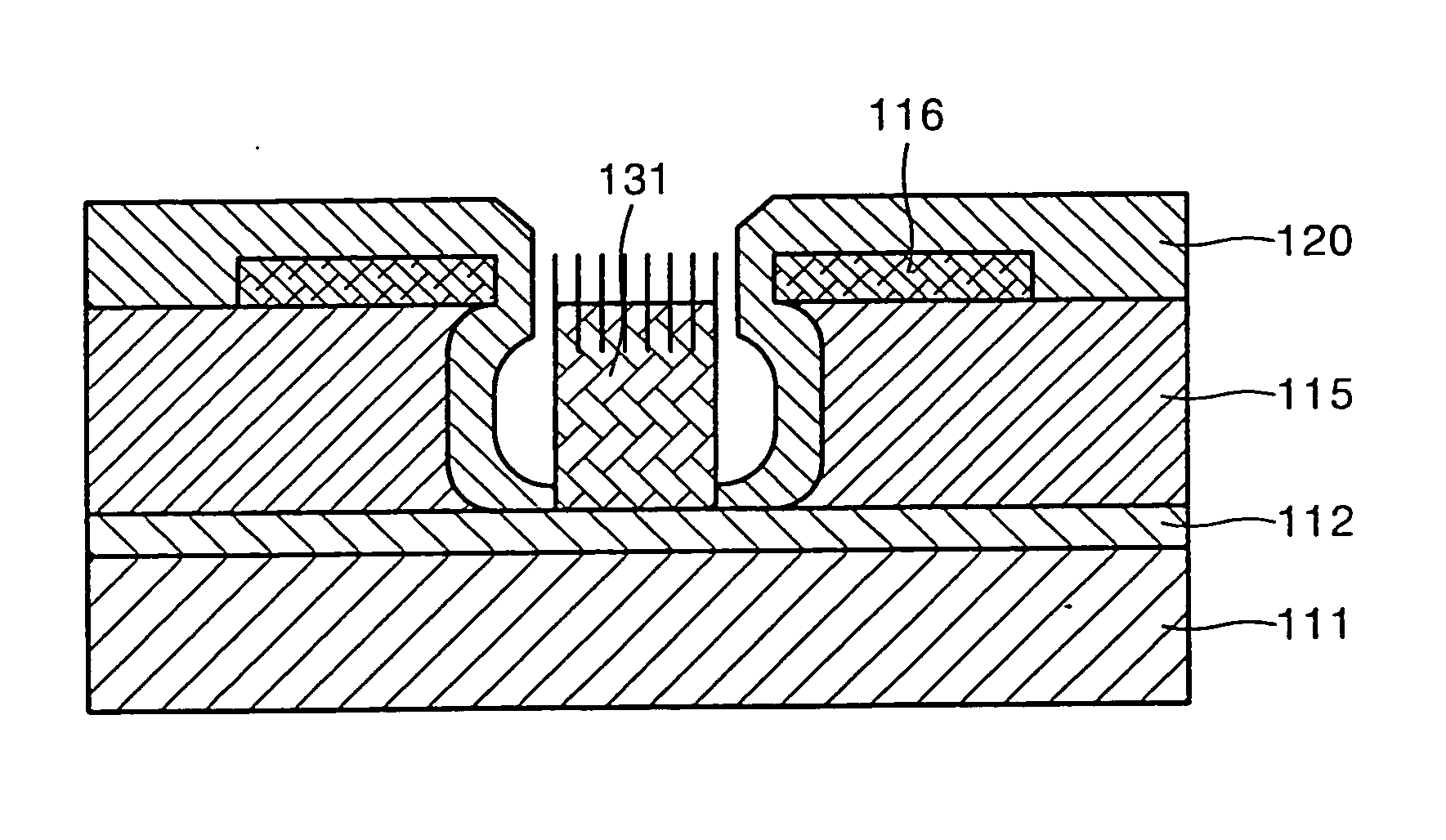

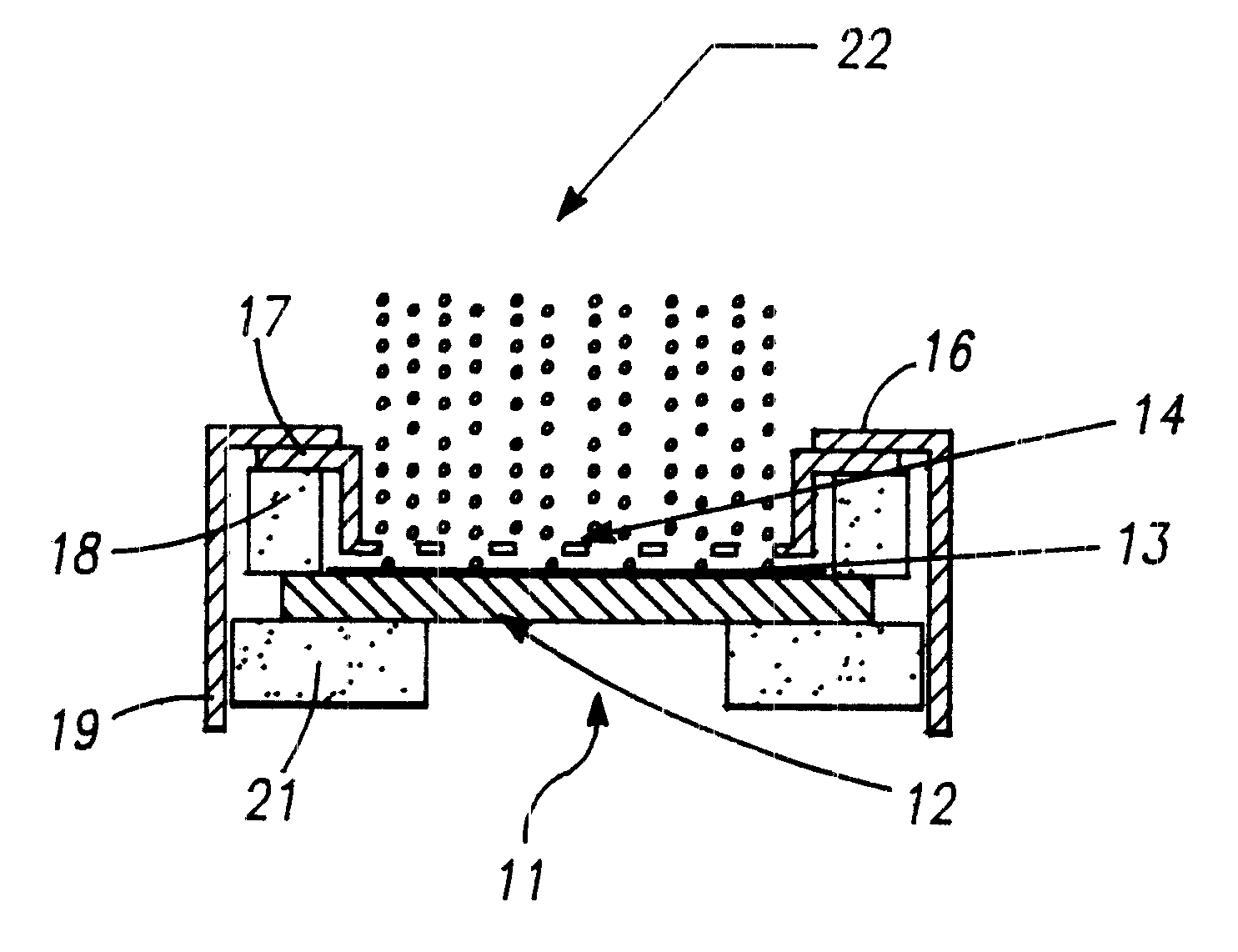

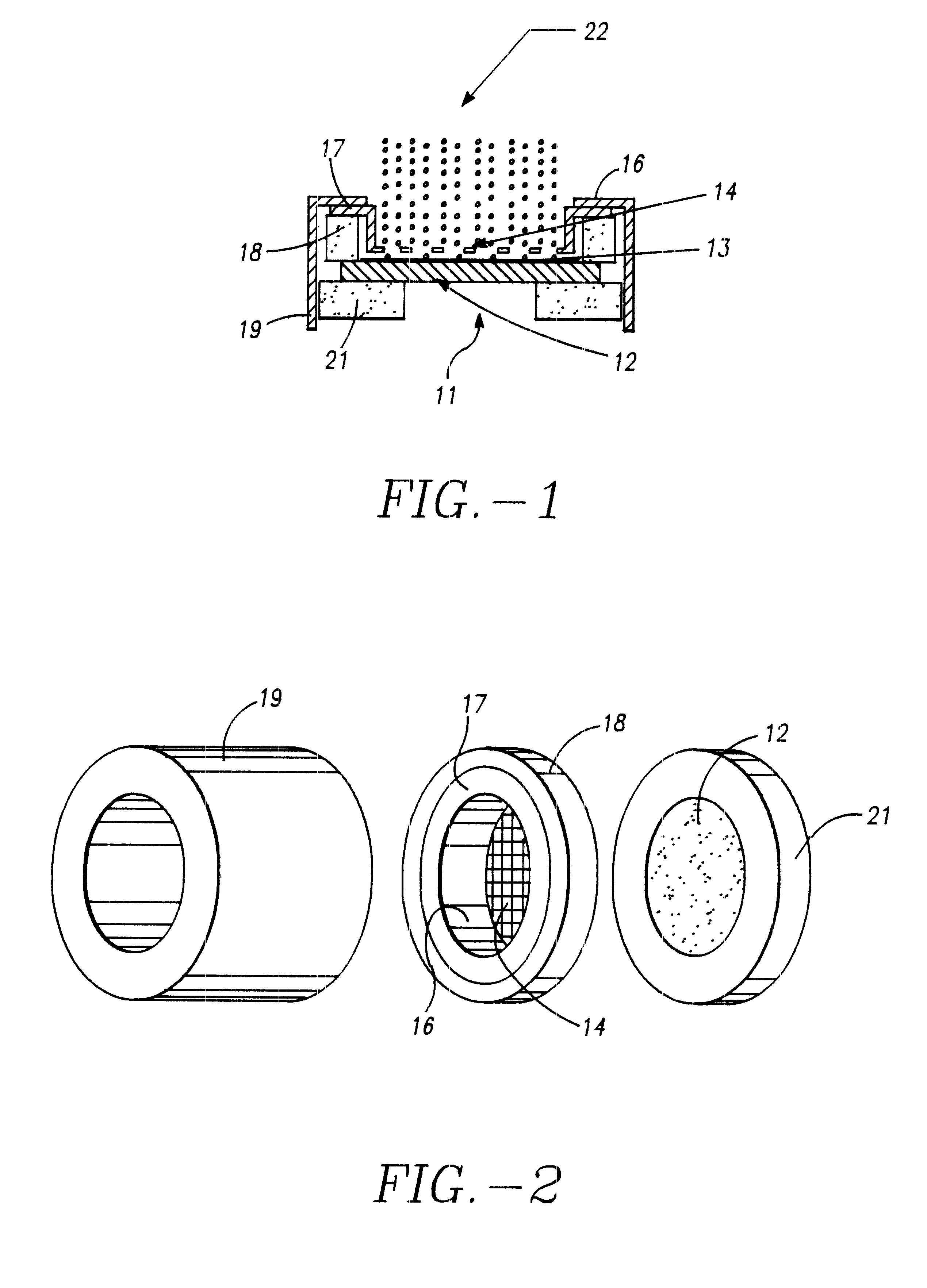

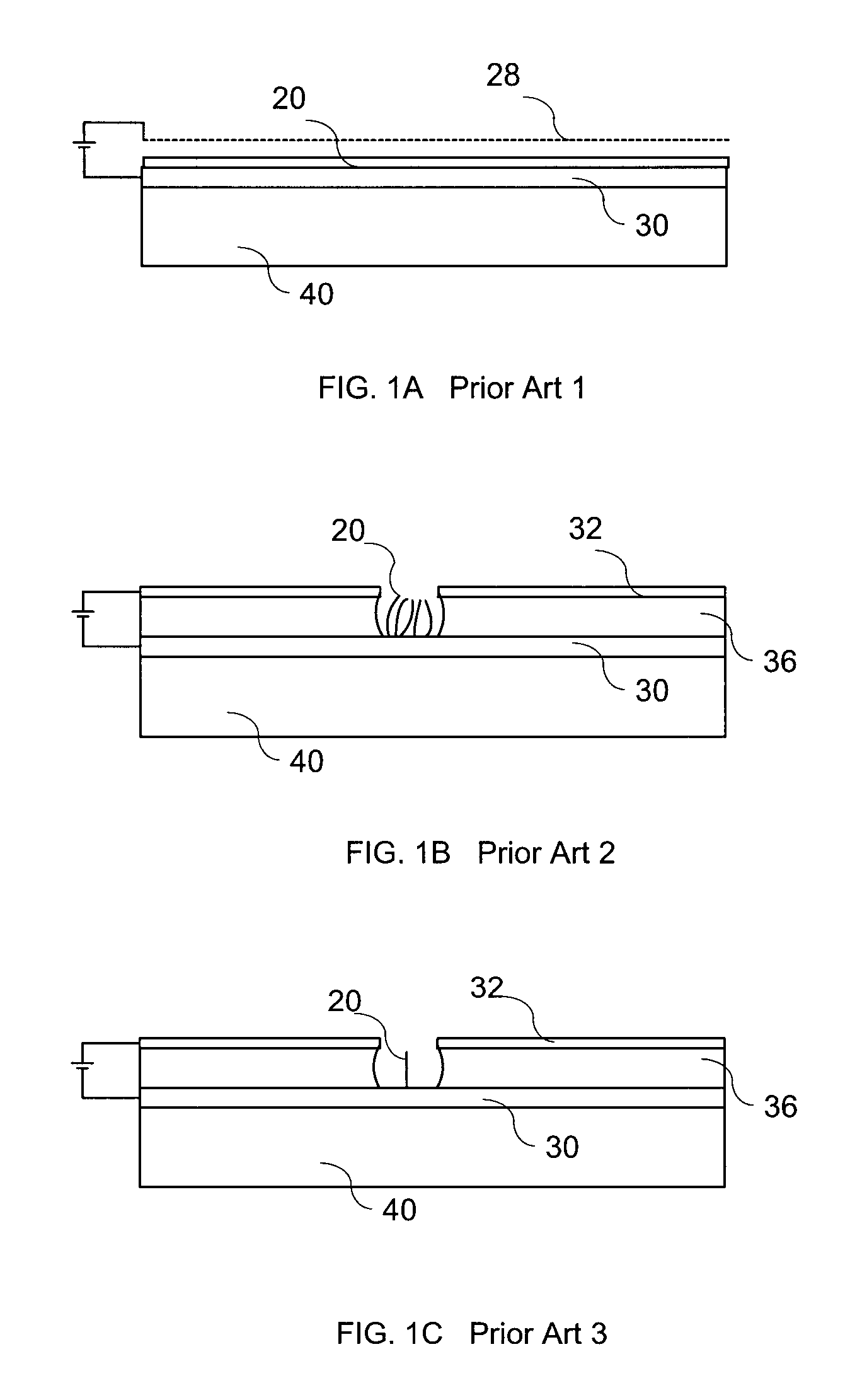

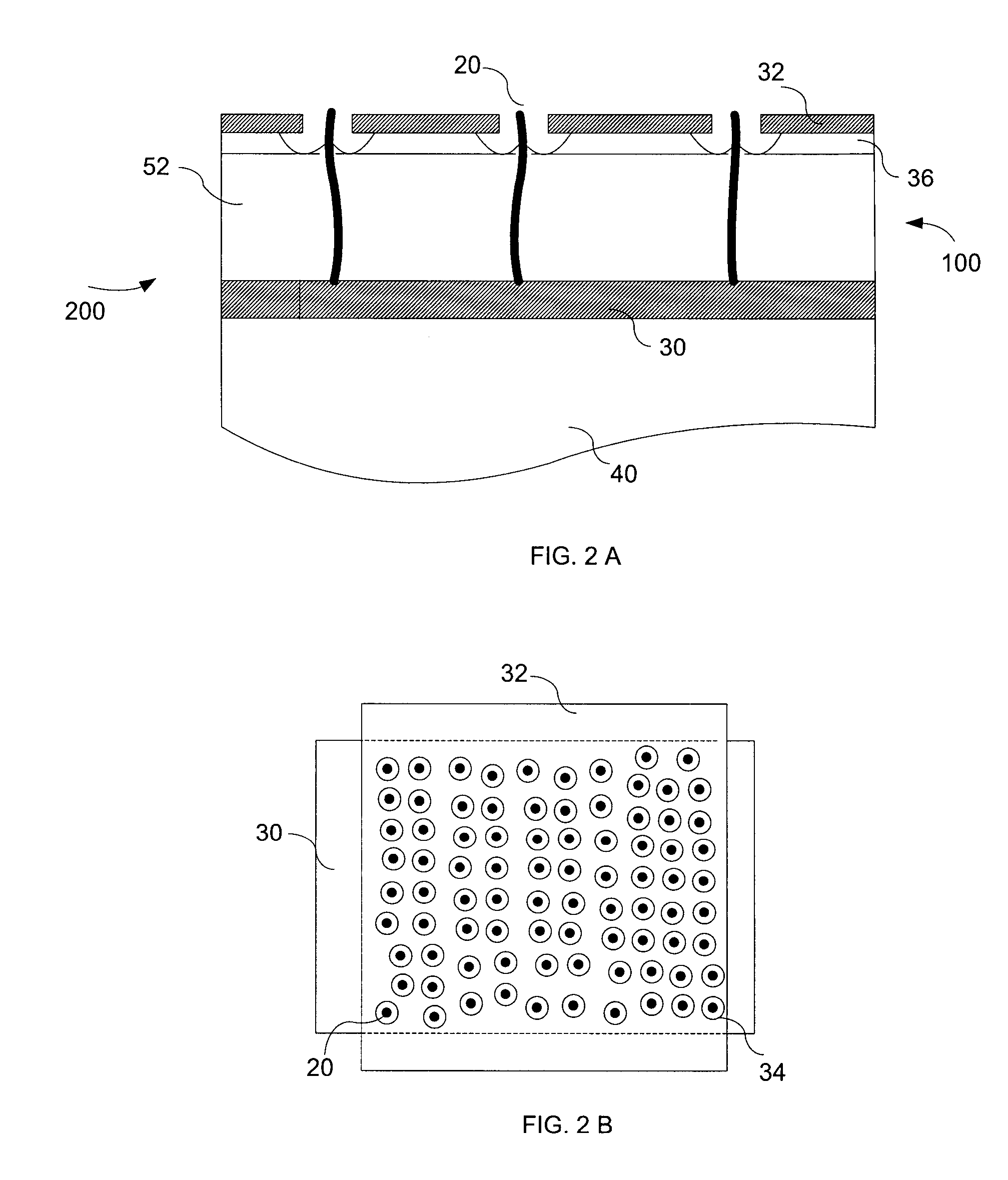

Field emission display

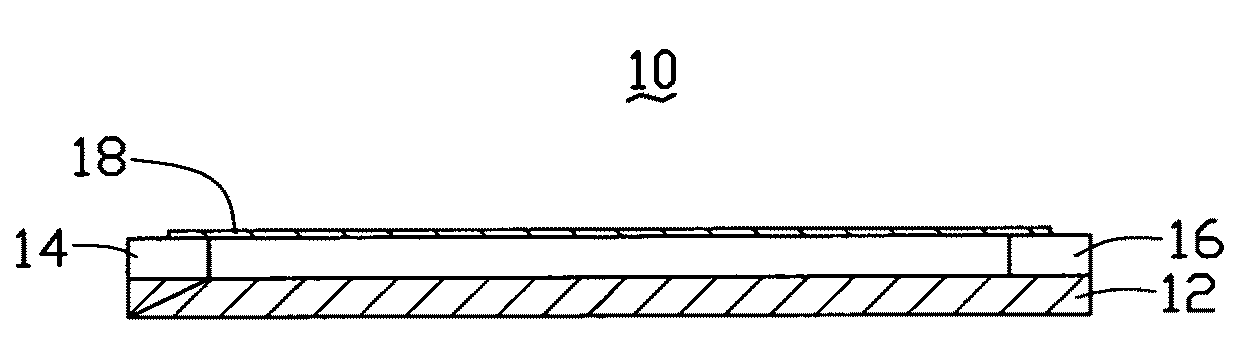

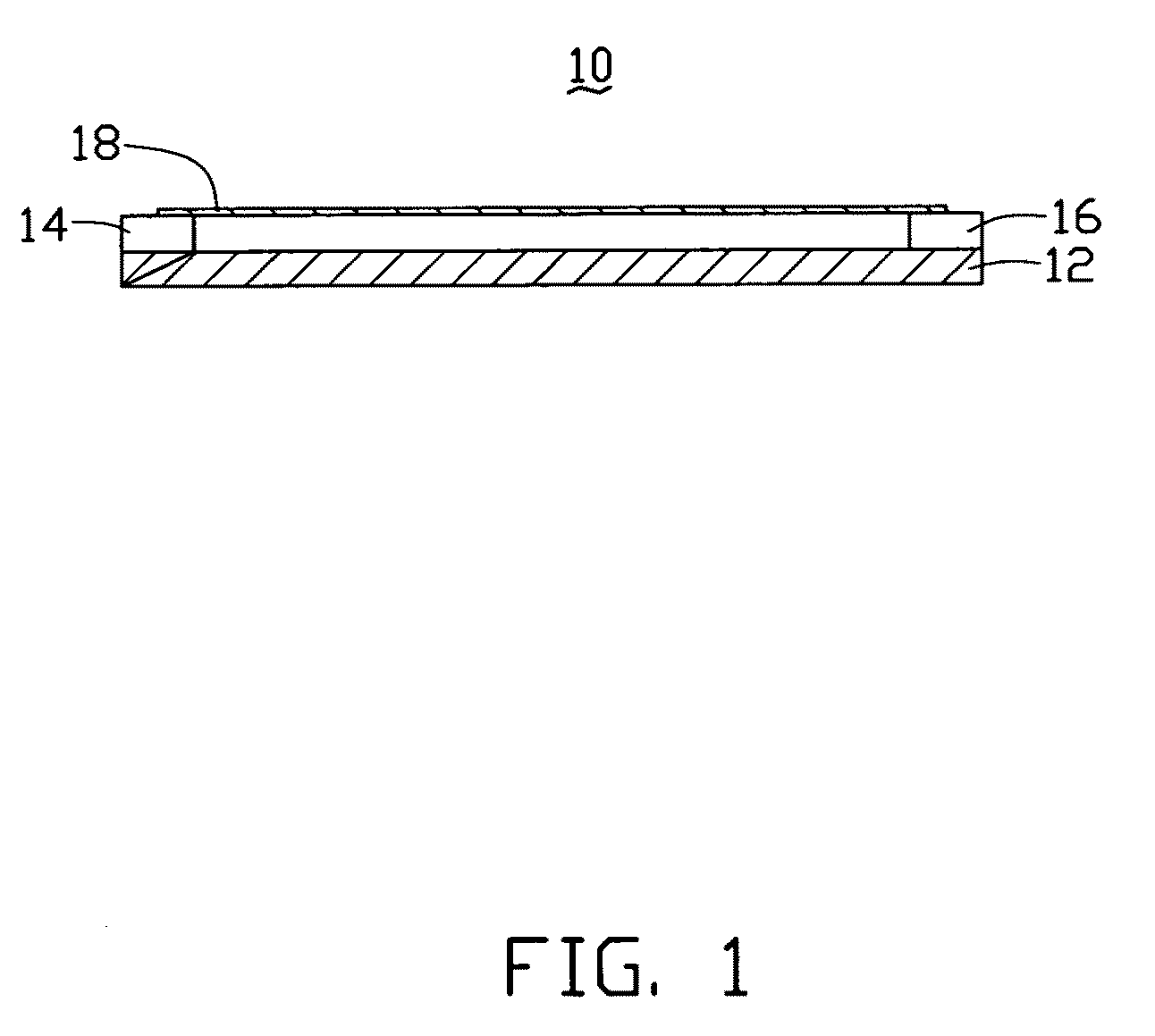

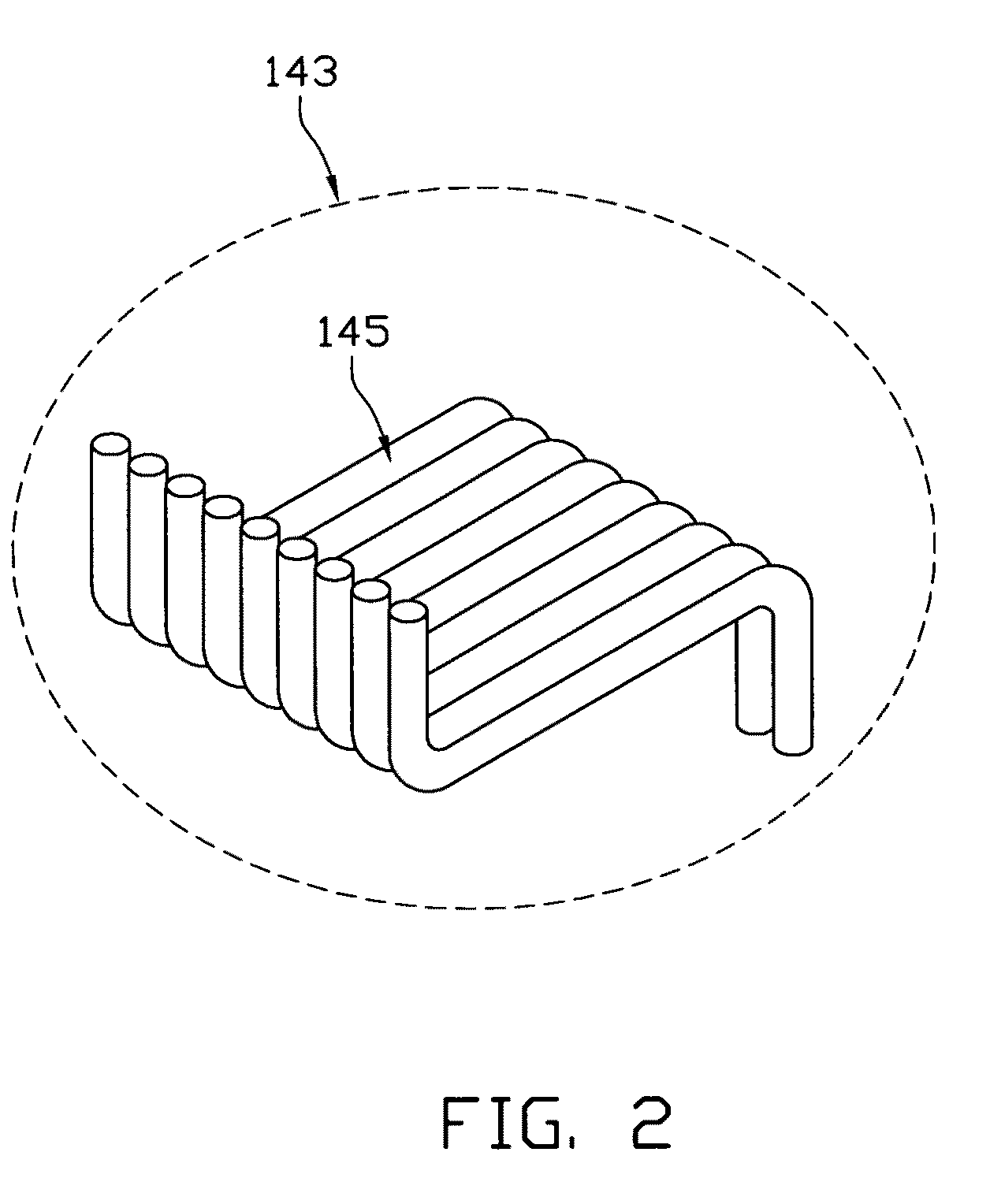

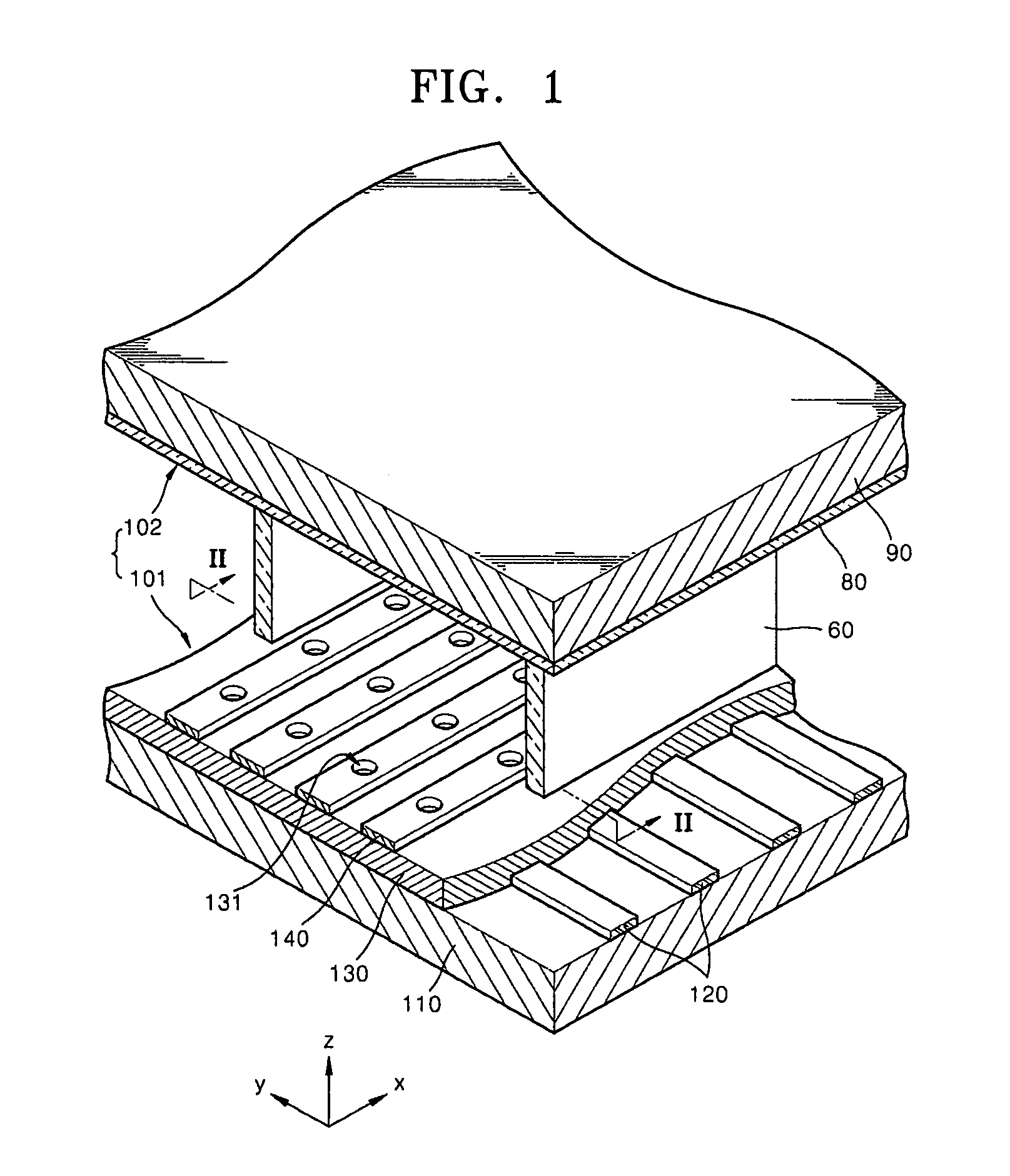

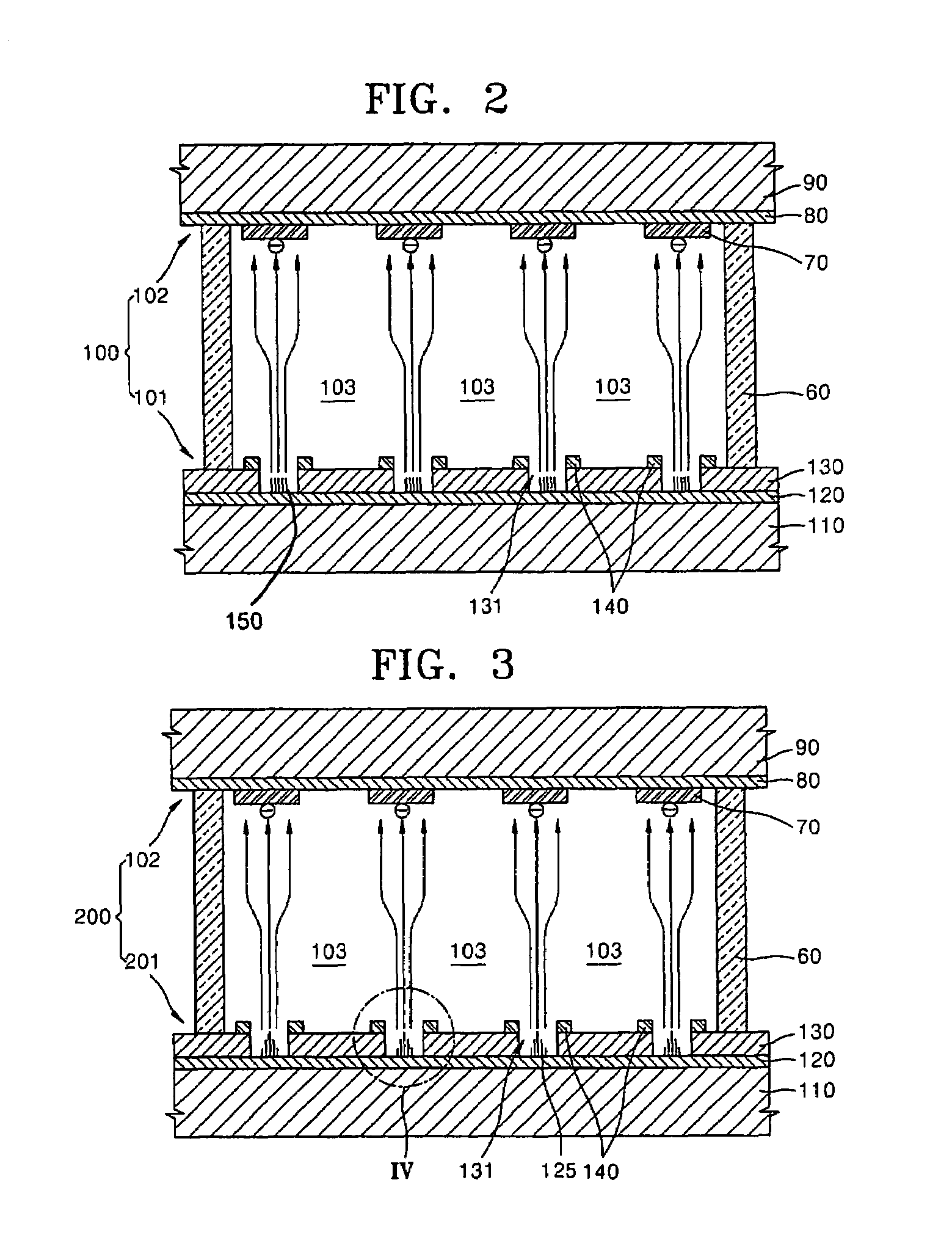

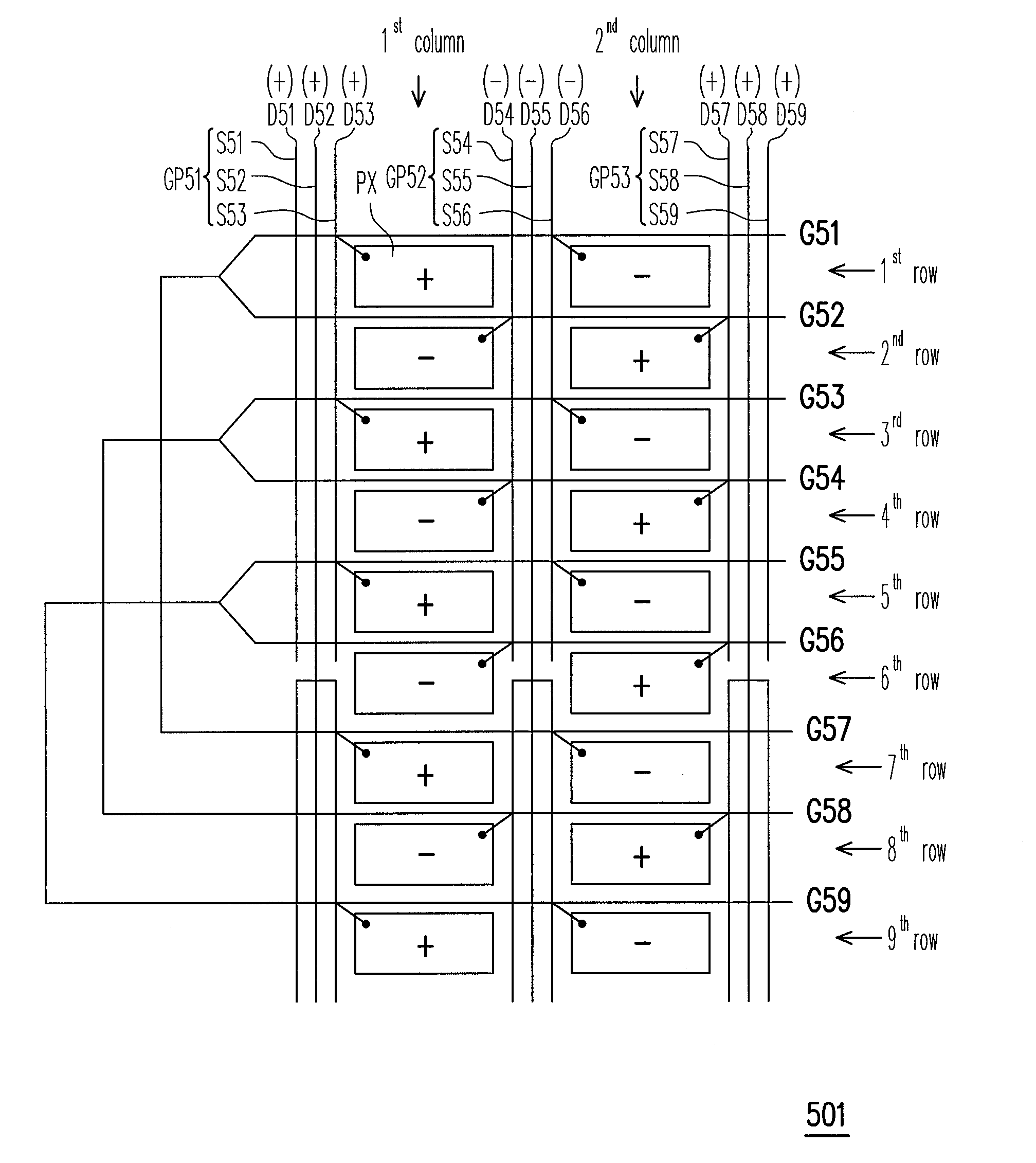

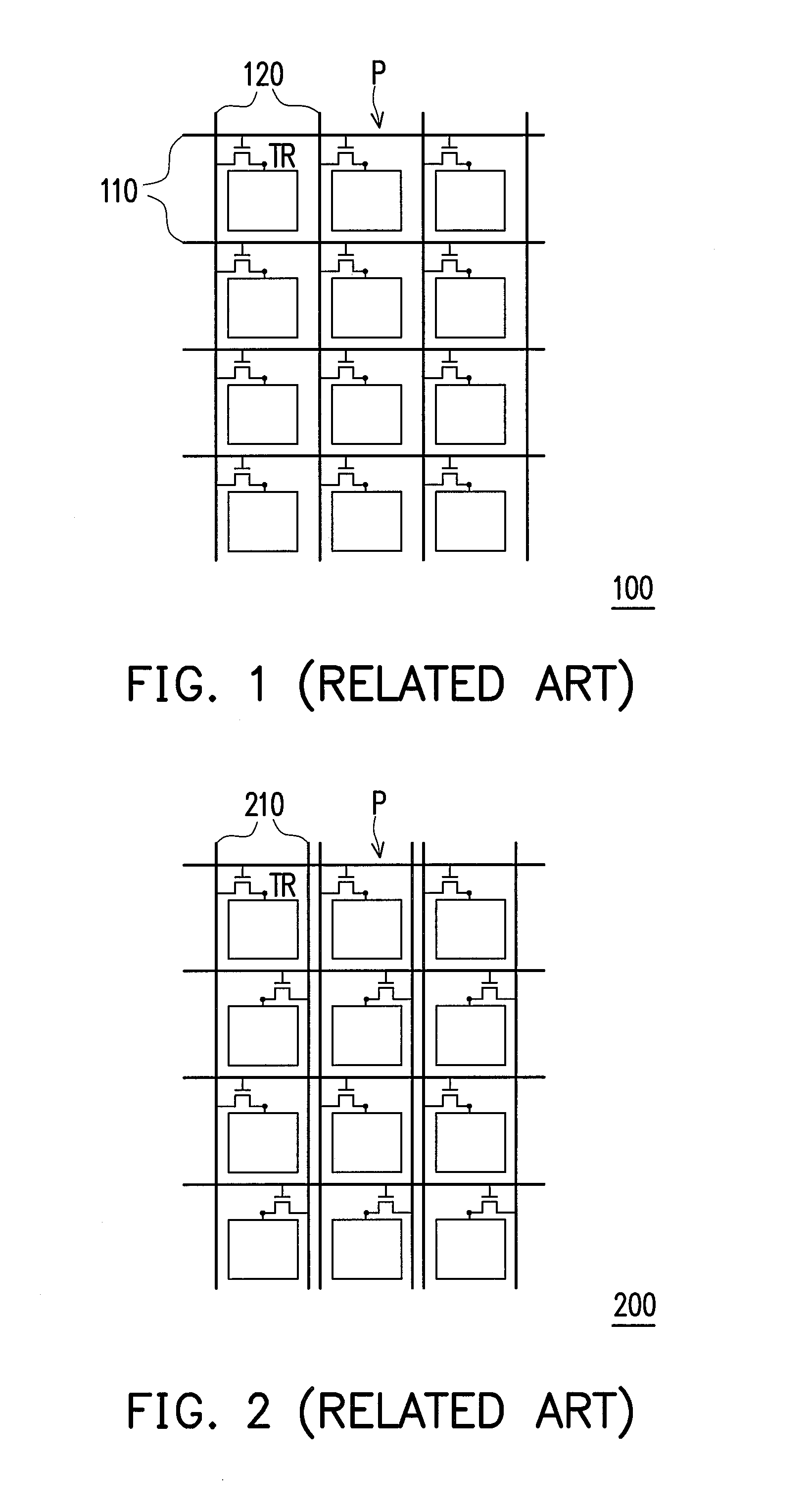

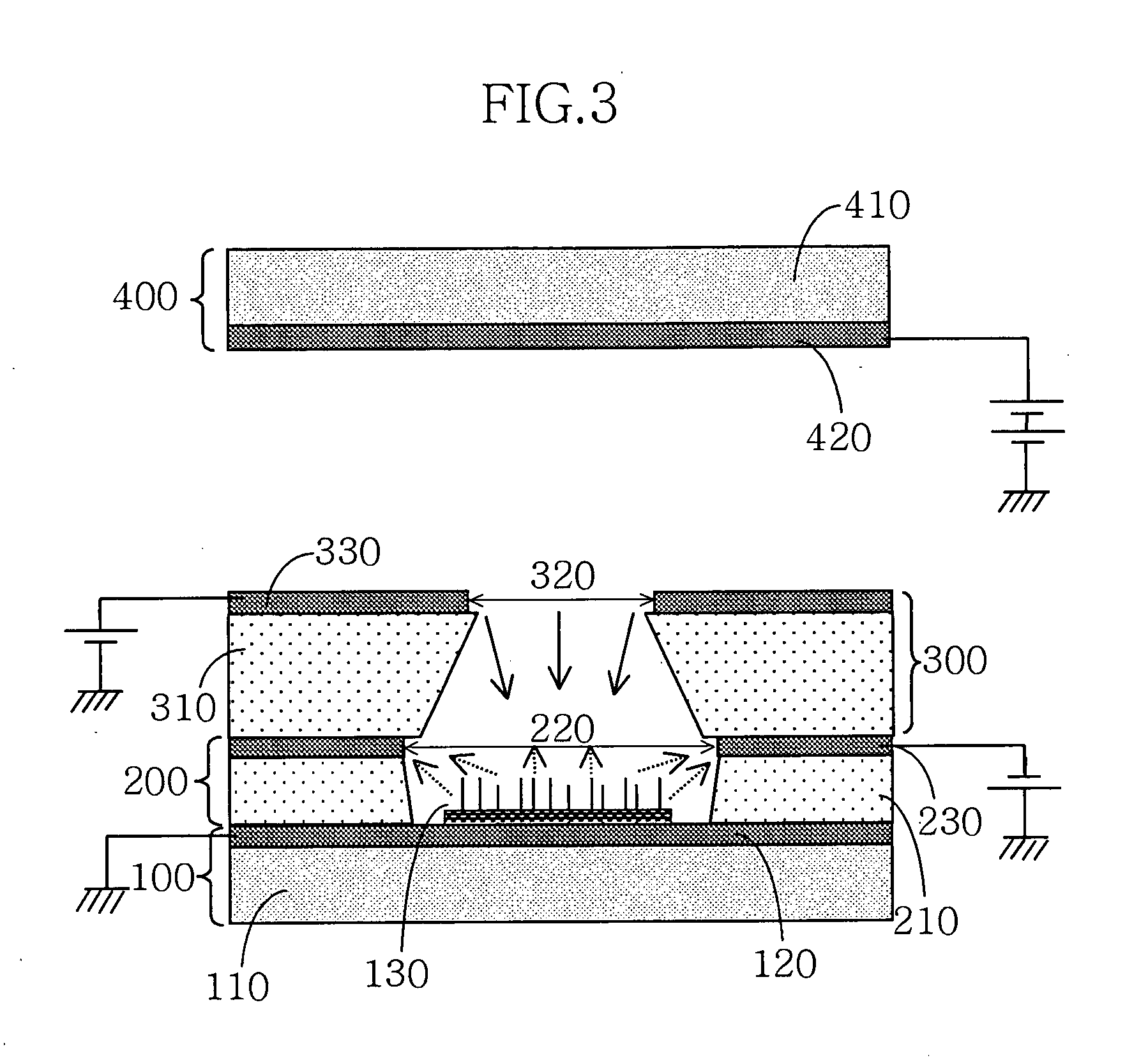

InactiveUS6873115B2Reduce sheet resistanceLarge film thicknessControl electrodesDischarge tube luminescnet screensElectron sourceScan line

A display having hot electron type electron sources displaying an image by a line sequential scanning scheme is provided to prevent poor brightness uniformity along scan lines. The hot electron type electron source is provided with a top electrode bus line serving as a scan line and a bottom electrode bus line serving as a data line. The top electrode bus line has a sheet resistance lower than that of the bottom electrode. The wire sheet resistance of the scam line can be reduced to several m / square. When forming a 40 inch large screen FED using the hot electron type electron sources, a voltage drop amount produced in the scan line can be suppressed below an allowable range. As a result, high quality image without poor brightness uniformity can be obtained.

Owner:HITACHI LTD

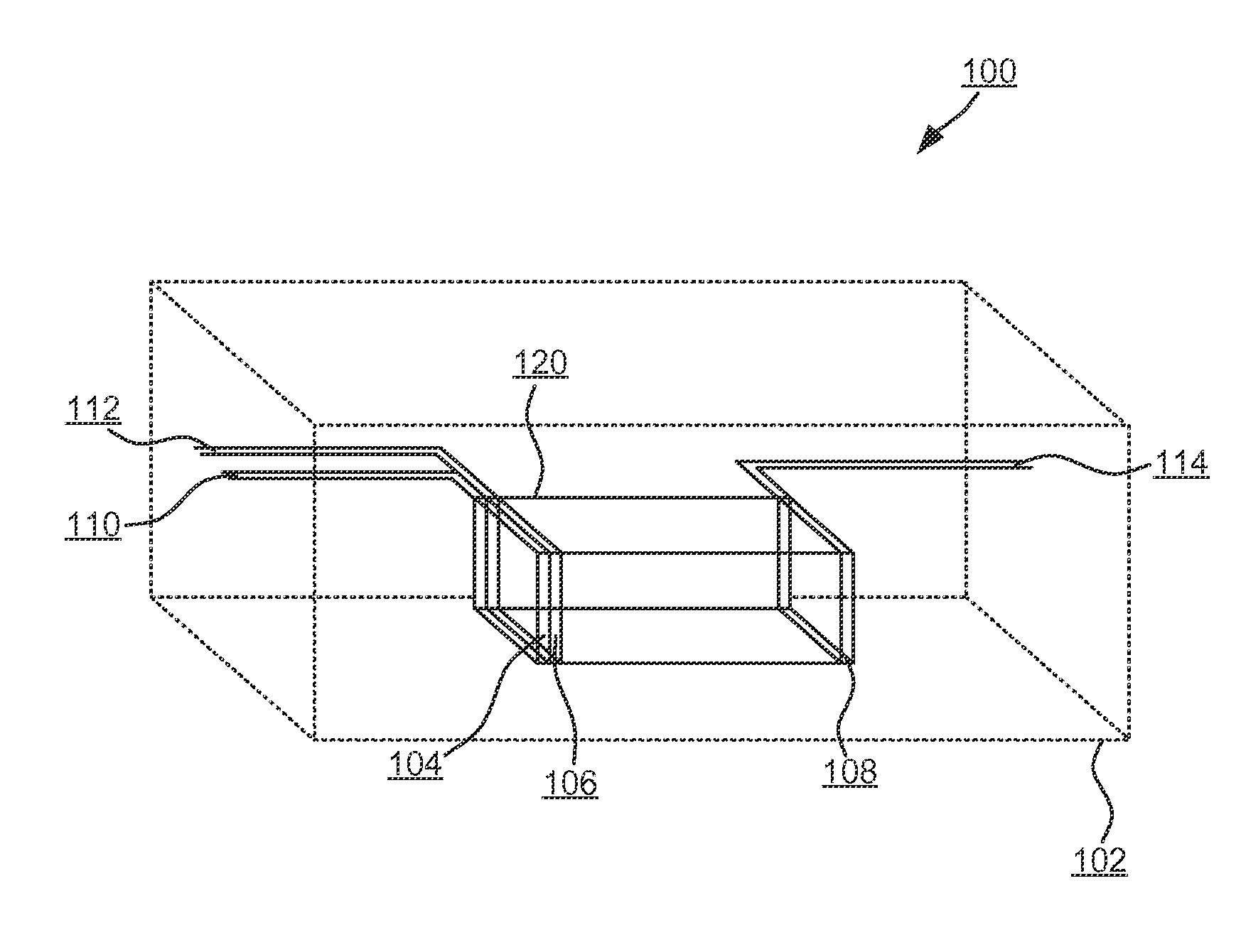

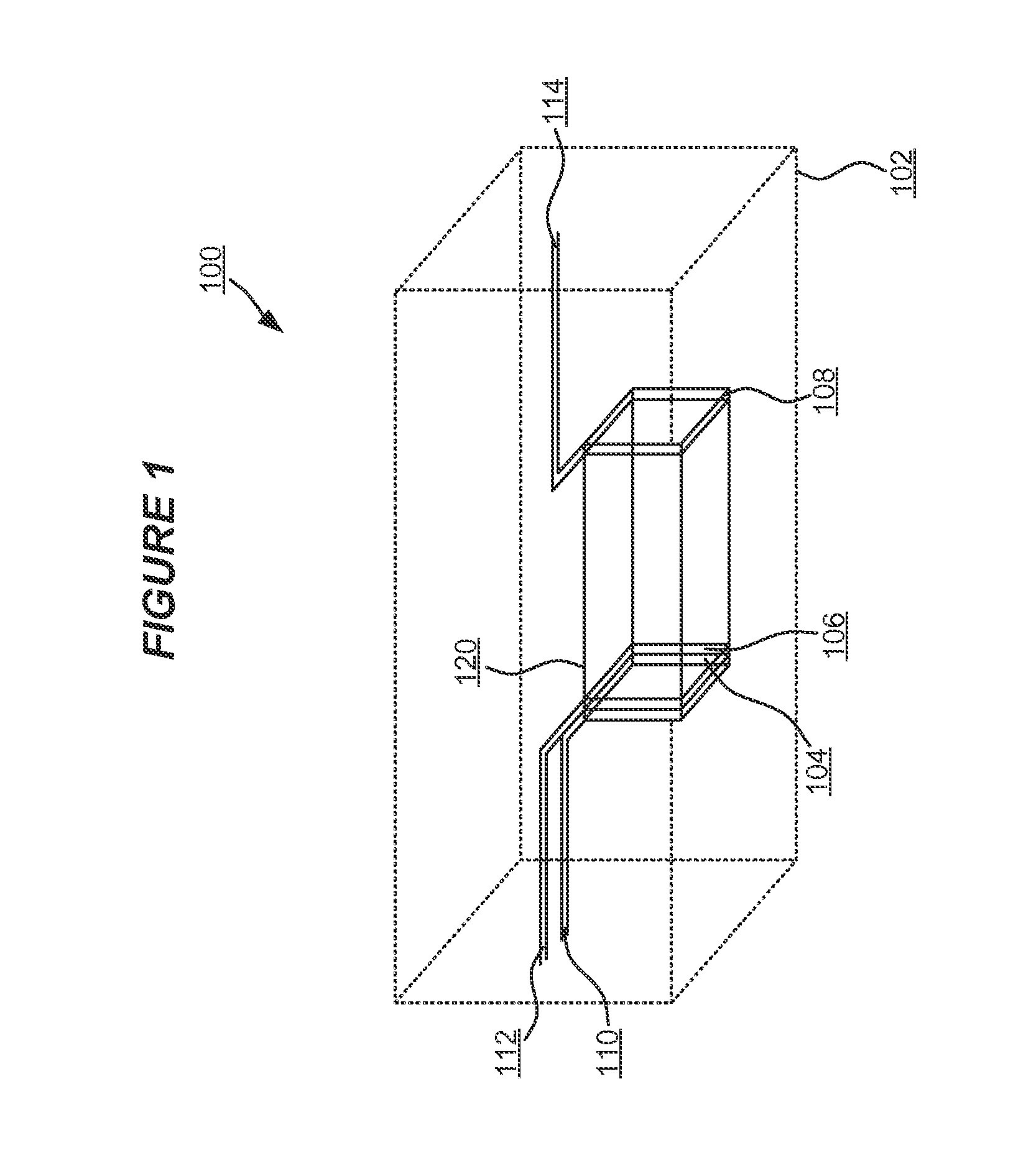

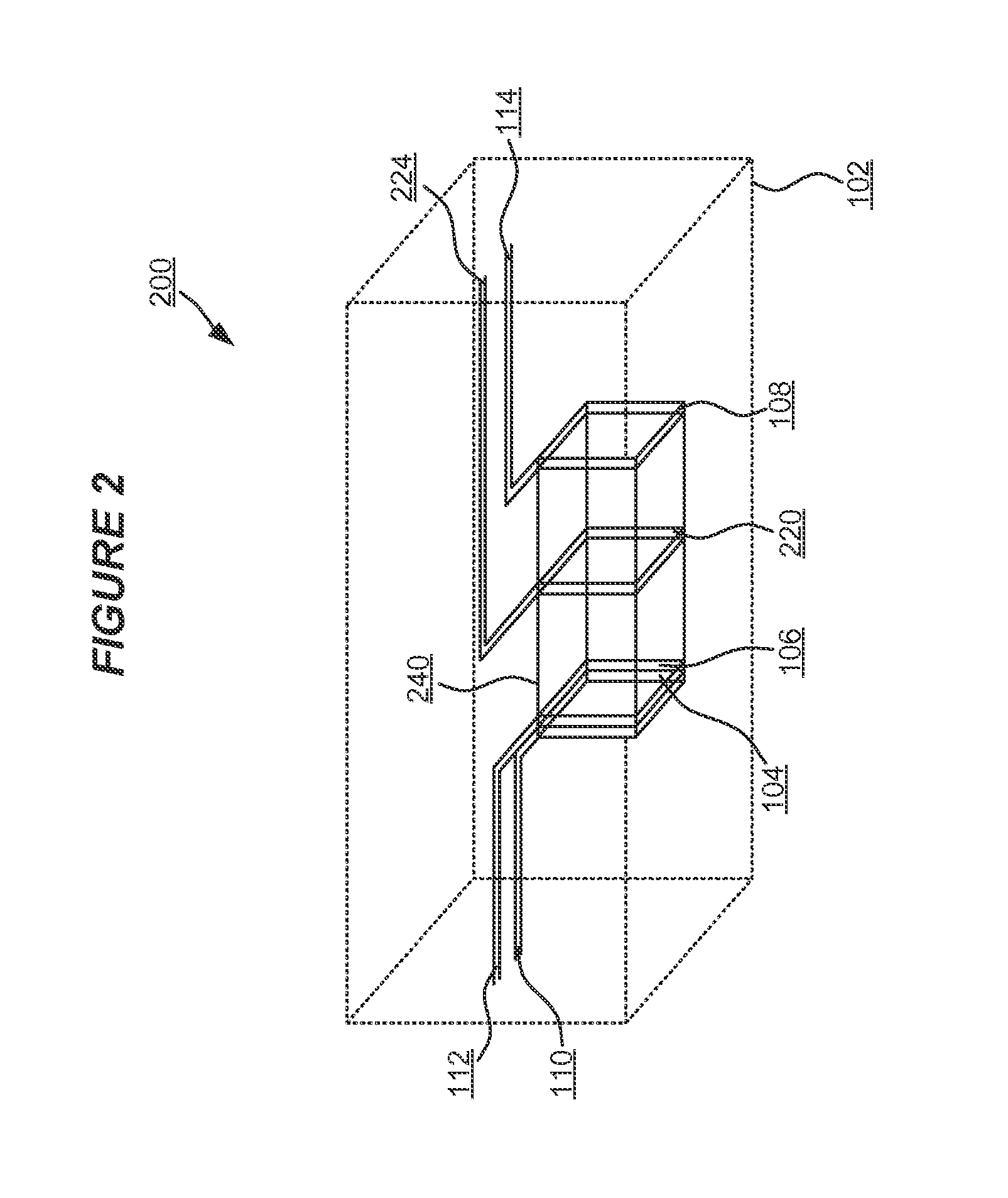

Nanotube-based vacuum devices

InactiveUS7102157B2Minimize threshold voltageLow inputNanoinformaticsSolid-state devicesCapacitanceTerminal equipment

New, hybrid vacuum electronic devices are proposed, in which the electrons are extracted from the nanotube into vacuum. Each nanotube is either placed on the cathode electrode individually or grown normally to the cathode plane. Arrays of the nanotubes are also considered to multiply the output current. Two- and three-terminal device configurations are discussed. In all the cases considered, the device designs are such that both input and output capacitances are extremely low, while the efficiency of the electron extraction into vacuum is very high, so that the estimated operational frequencies are expected to be in a tera-hertz range. New vacuum triode structure with ballistic electron propagation along the nanotube is also considered.

Owner:ITUS

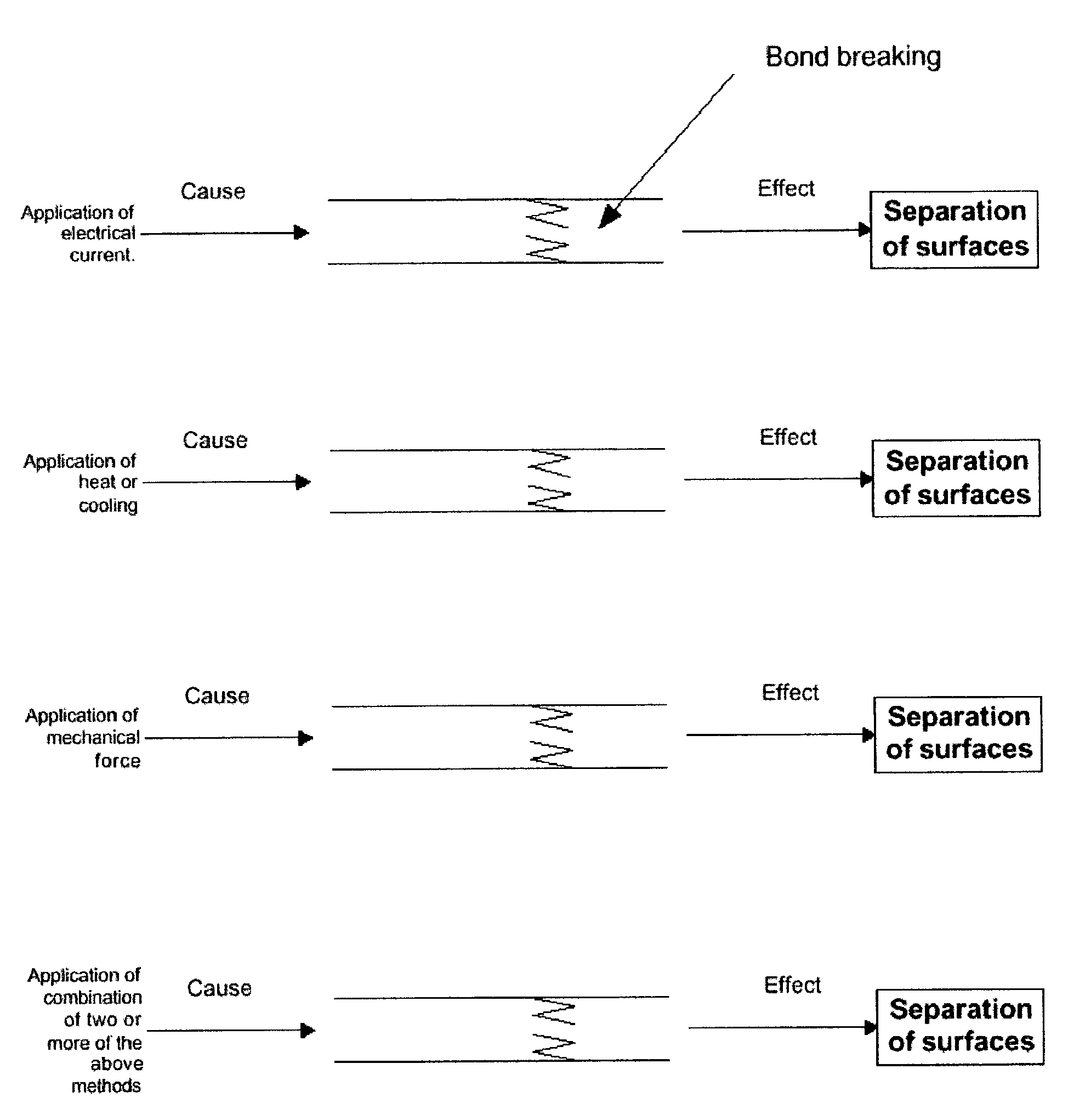

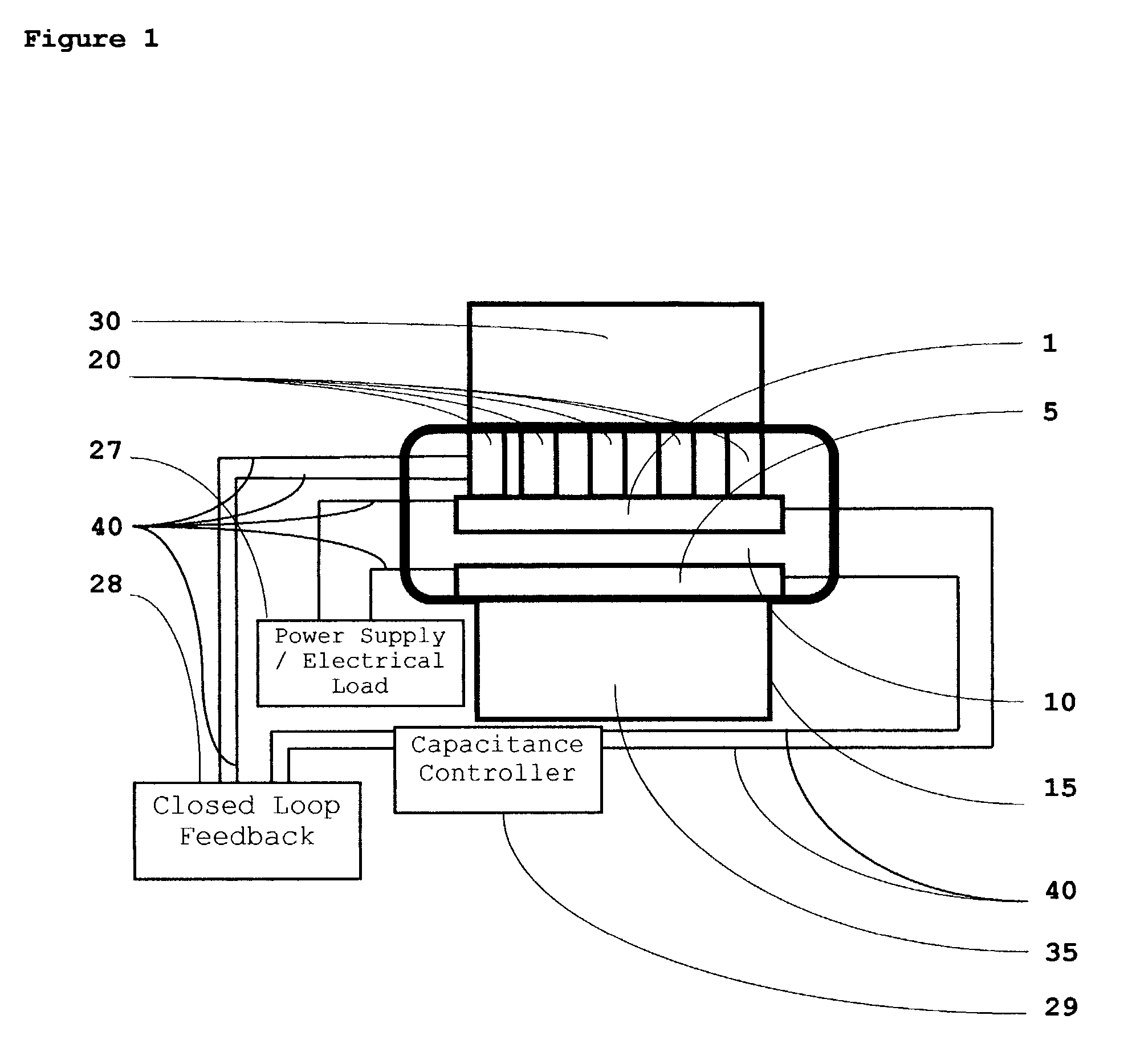

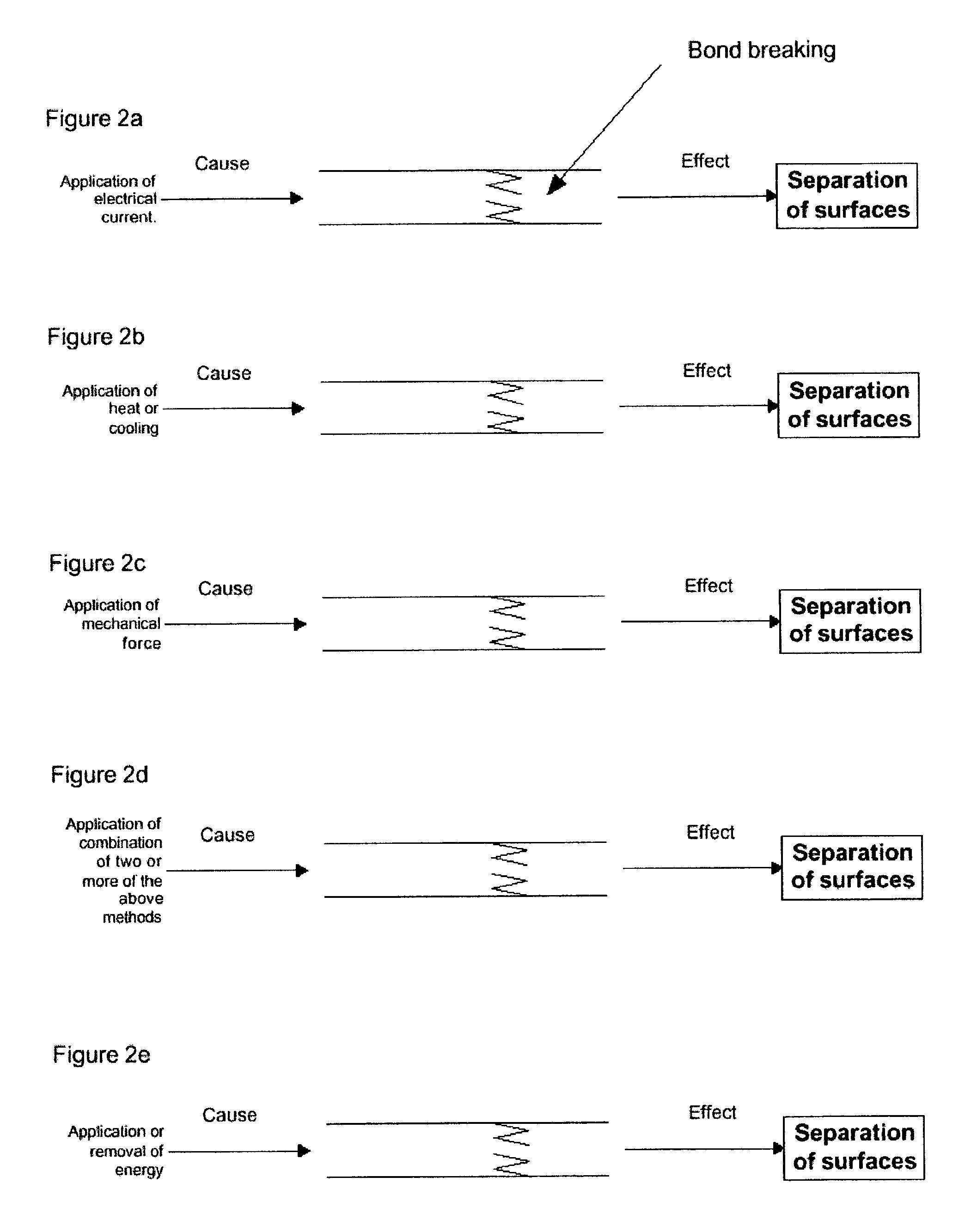

Electrode sandwich separation

InactiveUS7140102B2Easy to separateElectrically conductive connectionsSemiconductor/solid-state device manufacturingBiomedical engineeringElectrical current

Materials bonded together are separated using electrical current, thermal stresses, mechanical force, any combination of the above methods, or any other application or removal of energy until the bonds disappear and the materials are separated. In one embodiment the original bonding was composed of two layers of material. In another embodiment, the sandwich was composed of three layers. In a further embodiment, the parts of the sandwich are firmly maintained in their respective positions during the application of current so as to be able to subsequently align the materials relative to one another.

Owner:BOREALIS TECH LTD

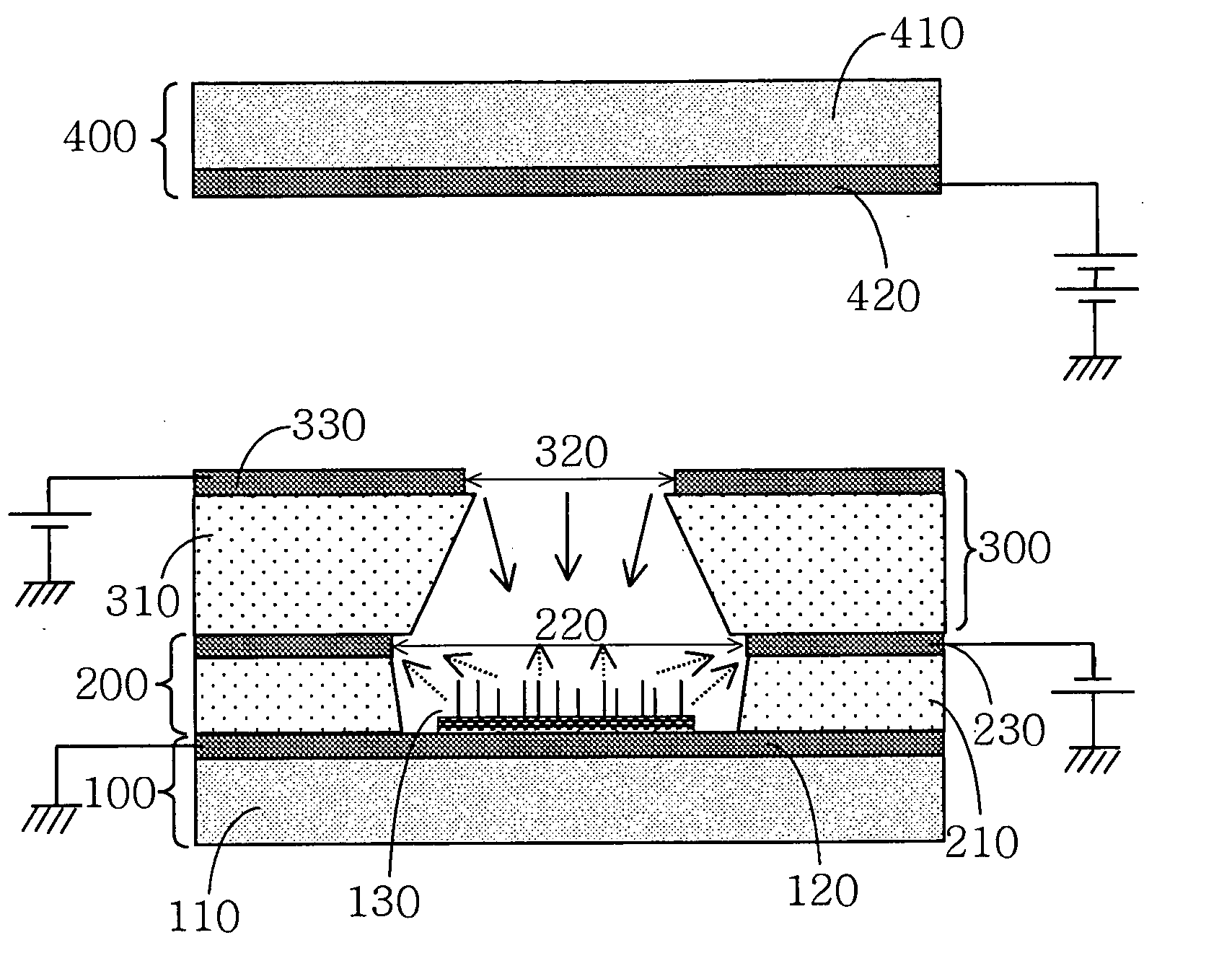

Field emission device

ActiveUS20050057168A1Reduce leakage currentEasy to controlControl electrodesDischarge tube luminescnet screensField emission deviceGate leakage current

A field emission device including a cathode having an electric field emitter for emitting electrons, a field emission inducing gate for inducing electron emission, and an anode for receiving the emitted electrons. A field emission suppressing gate is interposed between the cathode and the field emission inducing gate for suppressing electron emission, so that problems such as gate leakage current, electron emission due to anode voltage, and electron beam spreading of the conventional field emission device are significantly overcome.

Owner:ELECTRONICS & TELECOMM RES INST

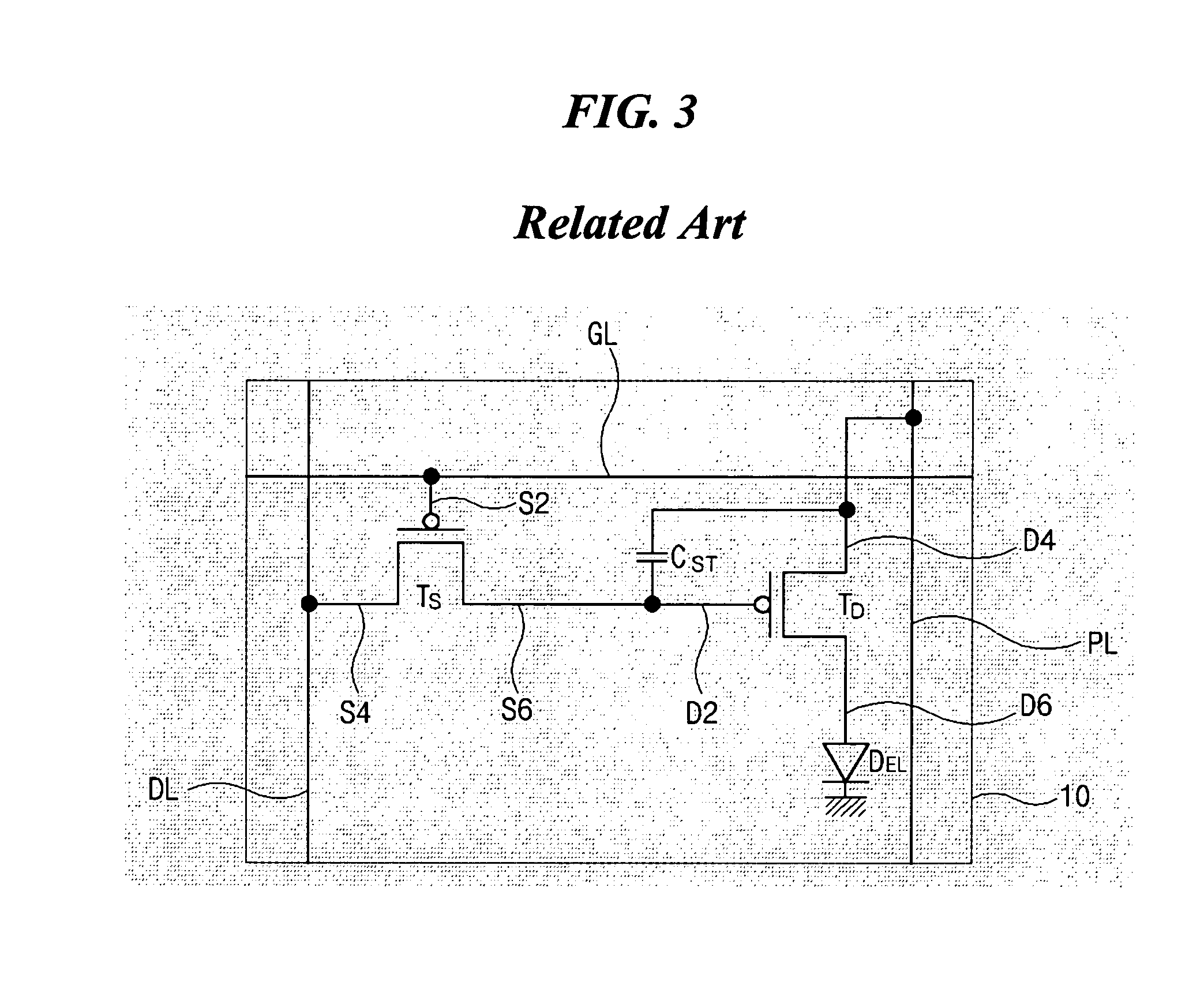

Image display device and driving method thereof

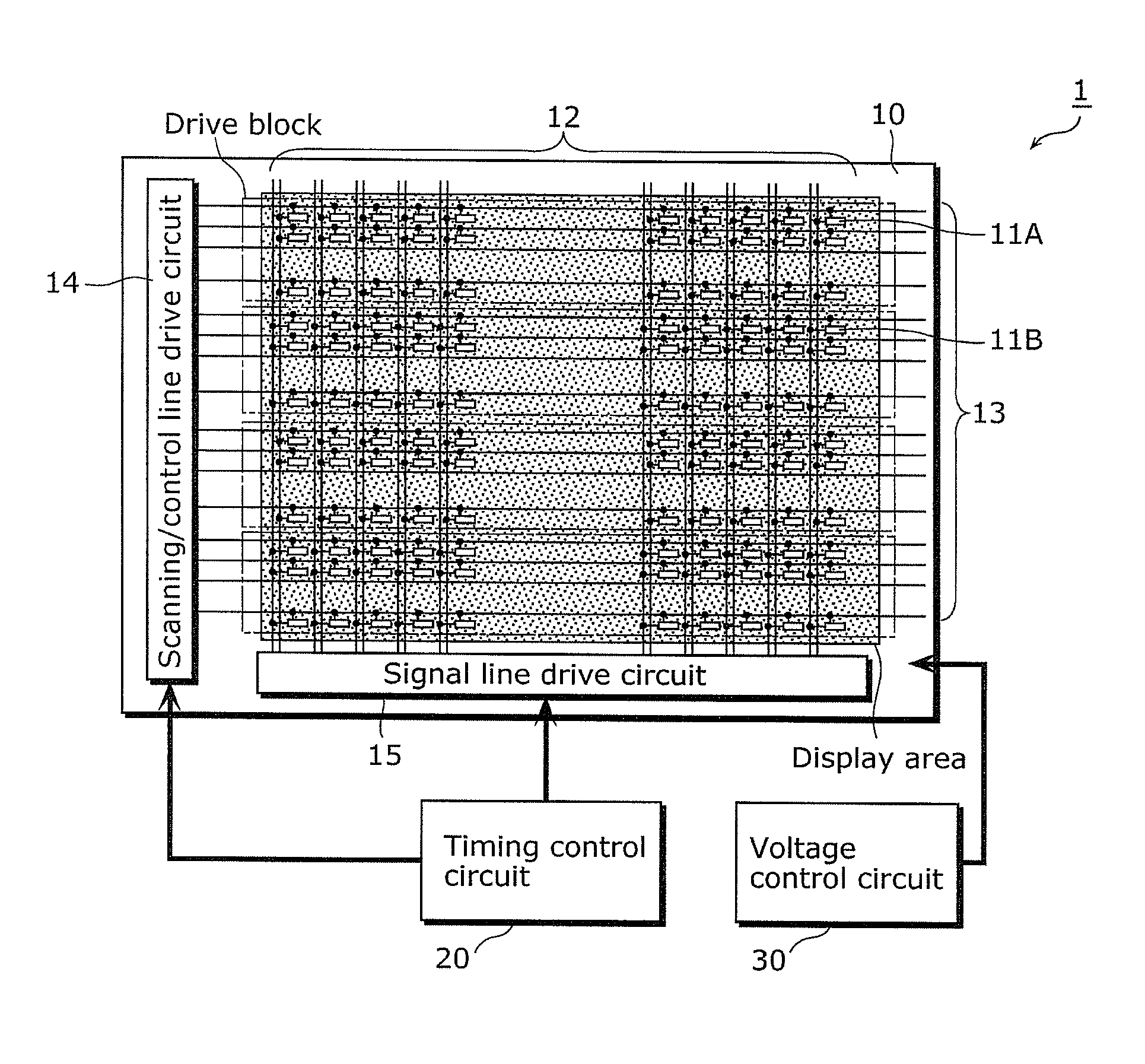

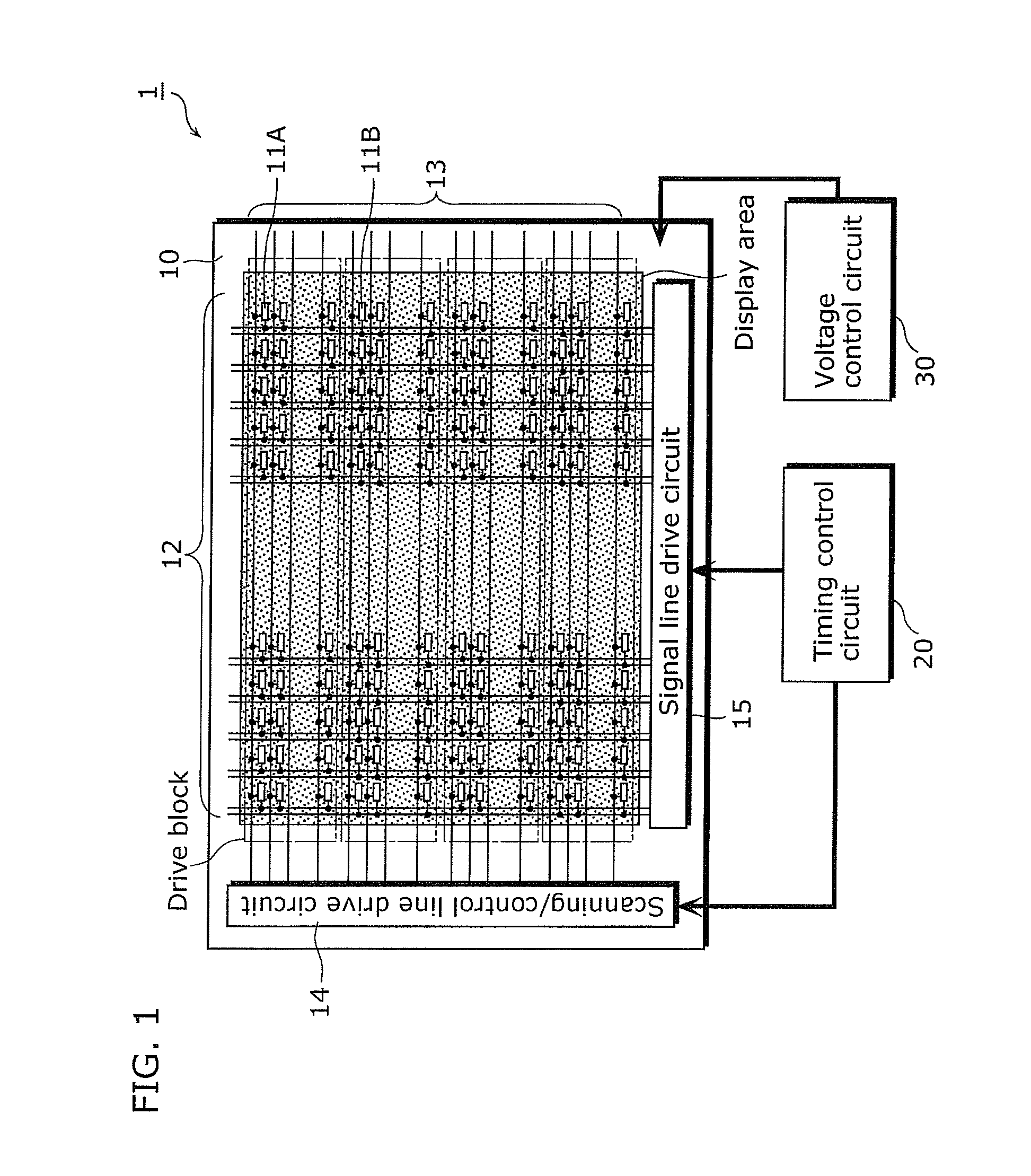

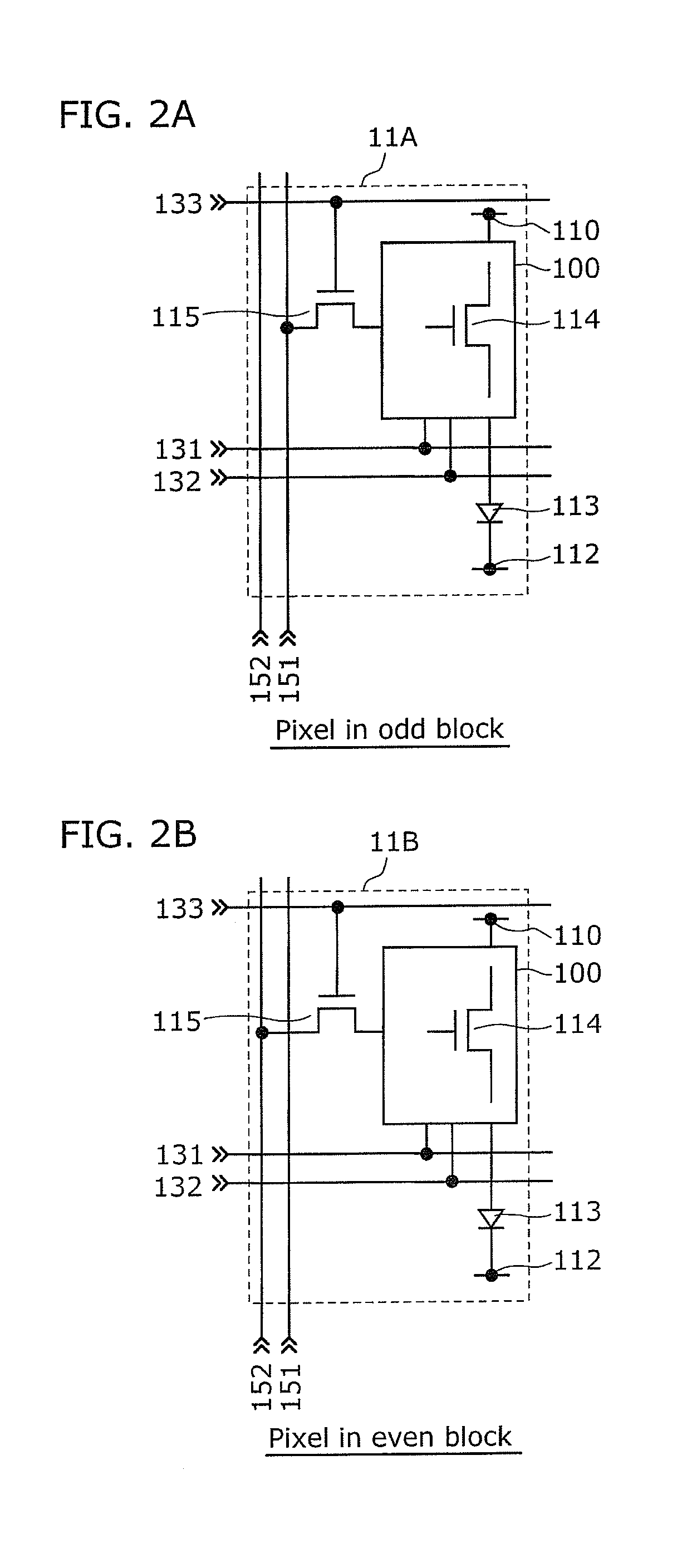

ActiveUS20110181192A1Reduce loadHighly precise drive current flowControl electrodesCathode-ray tube indicatorsControl lineComputer science

An image display device includes luminescence pixels arranged in rows and columns. The image display device includes a first signal line and a second signal line, first control lines, and at least two drive blocks. Each drive block is composed of luminescence pixels in at least two of the rows. Each luminescence pixel includes a luminescence element and a current controller. Each of the luminescence pixels that belong to a kth drive block further includes a first switch provided between the first signal line and the current controller. Each of the luminescence pixels that belong to a (k+1)th drive block further includes a second switch provided between the second signal line and the current controller. Each of the first control lines is connected to all of the luminescence pixels in one of the drive blocks and not connected to the luminescence pixels in a different drive block.

Owner:JOLED INC

Electronic emission device, electron emission display device having the same, and method of manufacturing the electron emission device

InactiveUS20080018228A1Low costImprove uniform brightnessControl electrodesDischarge tube luminescnet screensExoelectron emissionDisplay device

An electron emission device which can uniformly emit electrons and can be simply manufactured at a reduced cost, and a display apparatus having improved uniform brightness of pixels by using the electron emission device. In addition, a simple method of manufacturing the electron emission device. The electron emission device includes: a first substrate; a cathode electrode and an electron emission unit disposed on the first substrate; a gate electrode electrically insulated from the cathode electrode; an insulating layer disposed between the cathode electrode and the gate electrode to insulate the cathode electrode from the gate electrode; and an electron emission source including carbon nanotubes (CNTs) that contact the cathode electrode, wherein distances between the gate electrode and the tips of the CNTs are uniform.

Owner:SAMSUNG SDI CO LTD

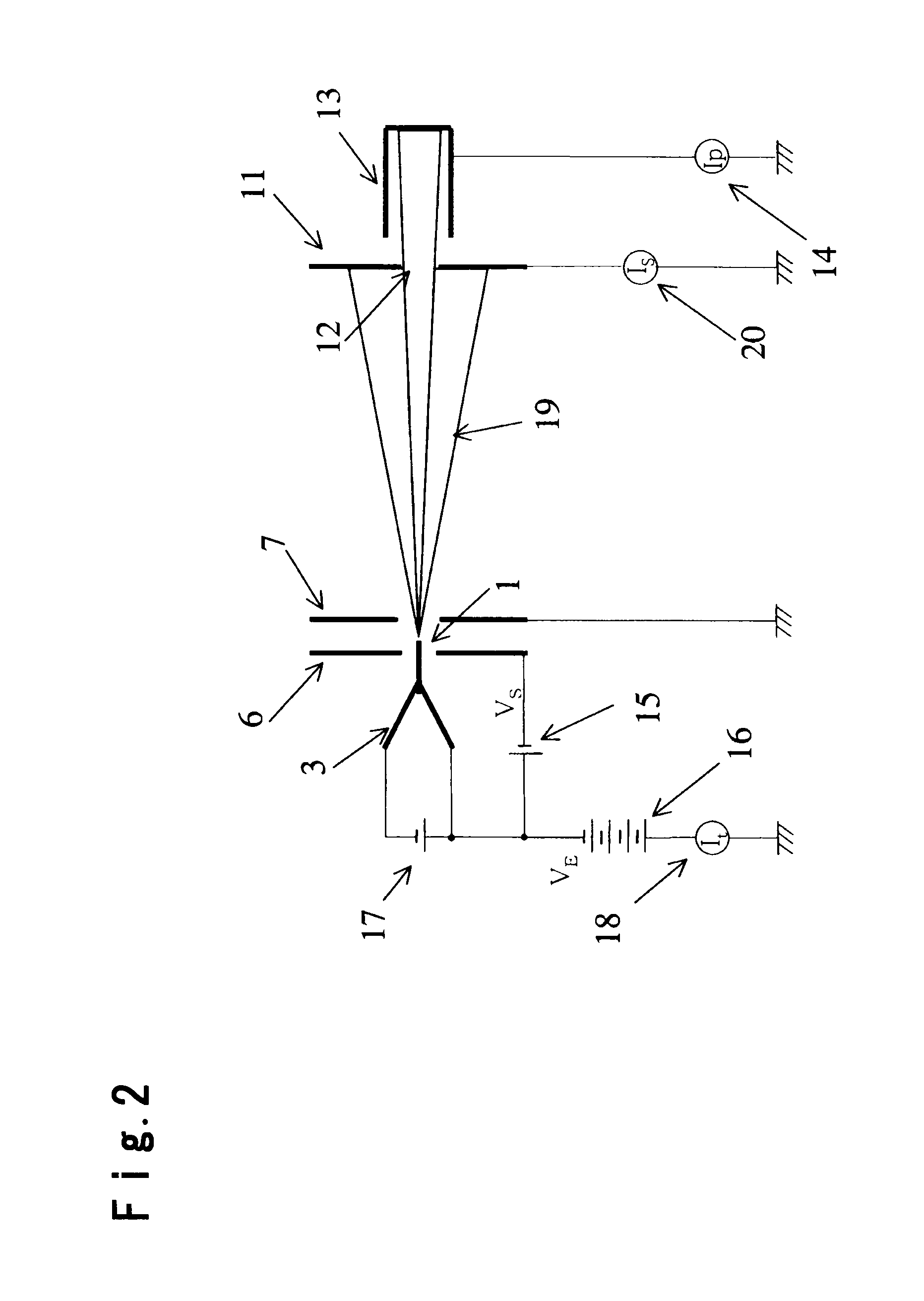

Electron source

InactiveUS20100026160A1Suppress surplus currentHigh currentControl electrodesNanoinformaticsLeading edgeElectron source

An electron source showing little surplus current even at a time of high angular intensity operation is provided. An electron source comprising an electron emitting portion, a suppressor electrode and an extractor electrode, wherein the electron emitting portion is present at a leading edge of an end of a single crystal rod having a shape comprising a first truncated cone portion or a cone portion, and a second truncated cone portion continuing therefrom. It is preferably the electron source, wherein the single crystal rod has an oxide of a metal element selected from the group consisting of Ca, Sr, Ba, Sc, Y, La, Ti, Zr, Hf and lanthanoide elements as a diffusion source, and the single crystal rod is made of tungsten or molybden of <100> orientation.

Owner:DENKA CO LTD

Organic electroluminescent device and fabricating method thereof

ActiveUS7354328B2Simple manufacturing processControl electrodesElectroluminescent light sourcesOrganic electroluminescenceMetal

Owner:LG DISPLAY CO LTD

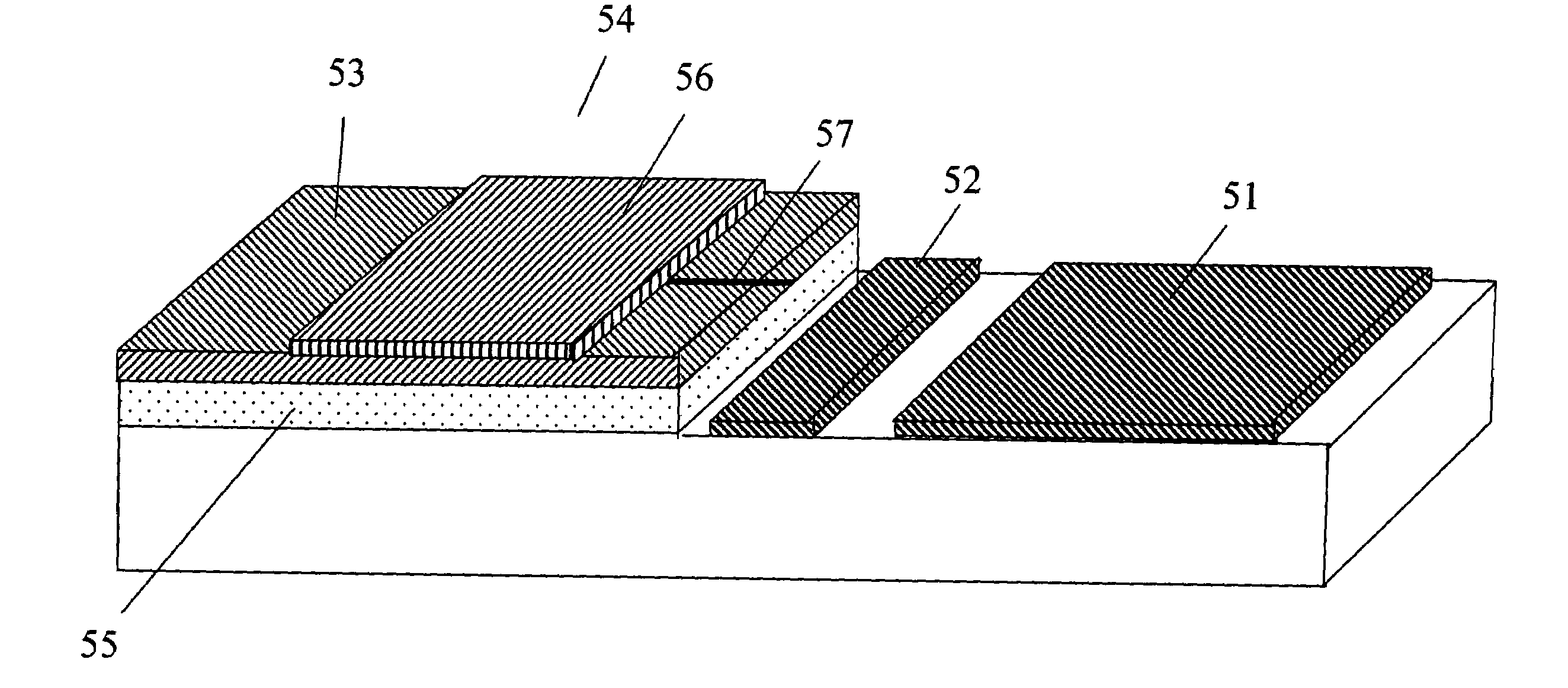

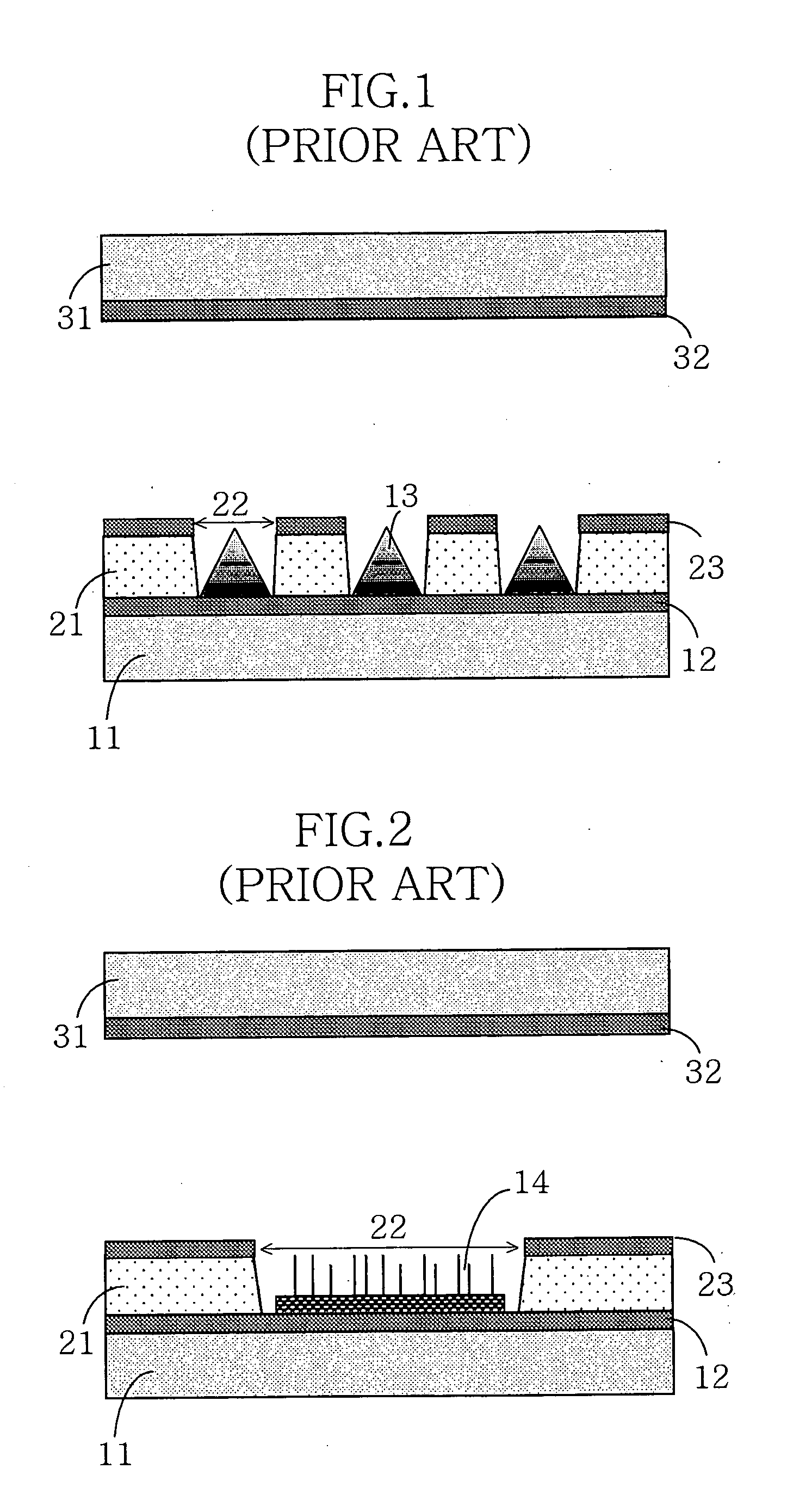

Triode structure field emission display device using carbon nanotubes and method of fabricating the same

InactiveUS20050040752A1Short circuit can be preventedBlocking may occurControl electrodesNanoinformaticsInsulation layerField emission display

A field emission display device and a method of fabricating the same are provided. The field emission display device includes a substrate, a transparent cathode layer, an insulation layer, a gate electrode, a resistance layer, and carbon nanotubes. The transparent cathode layer is deposited on the substrate. The insulation layer is formed on the cathode layer and has a well exposing the cathode layer. The gate electrode is formed on the insulation layer and has an opening corresponding to the well. The resistance layer is formed to surround the surface of the gate electrode and the inner walls of the opening and the well so as to block ultraviolet rays. The carbon nanotube field emitting source is positioned on the exposed cathode layer. An alignment error between the gate electrode and the cathode is removed, and carbon nanotube paste is prevented from remaining during development, thereby preventing current leakage and short circuit between the electrodes and diode emission. Accordingly, the performance of the field emission display device can be improved.

Owner:SAMSUNG SDI CO LTD

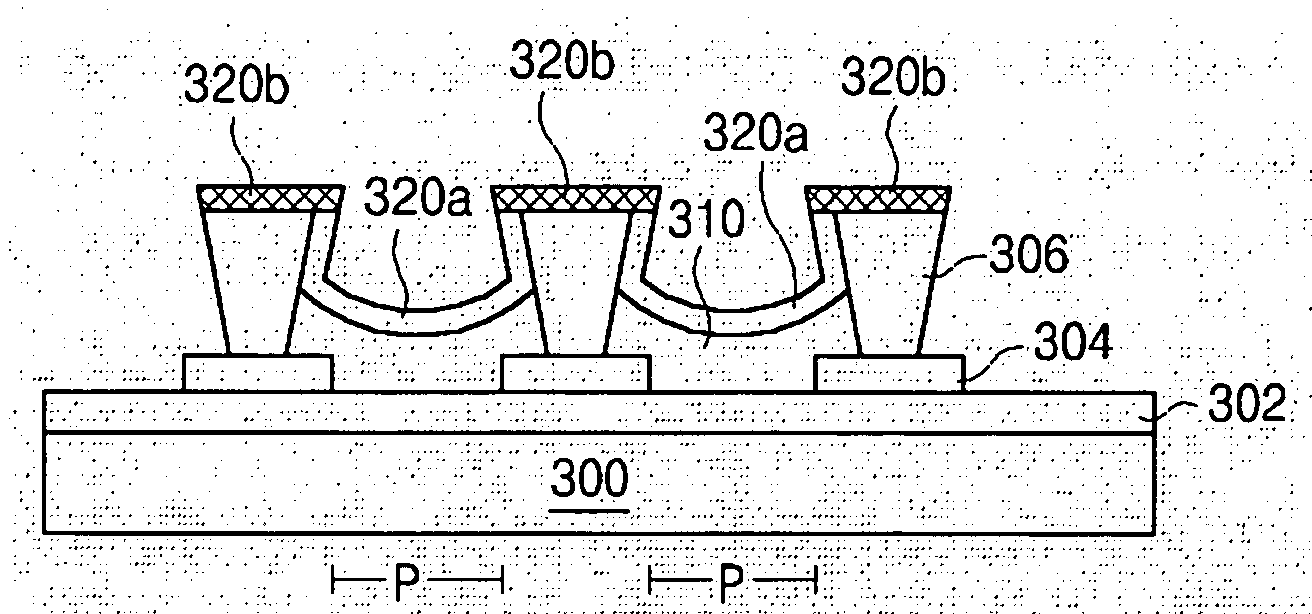

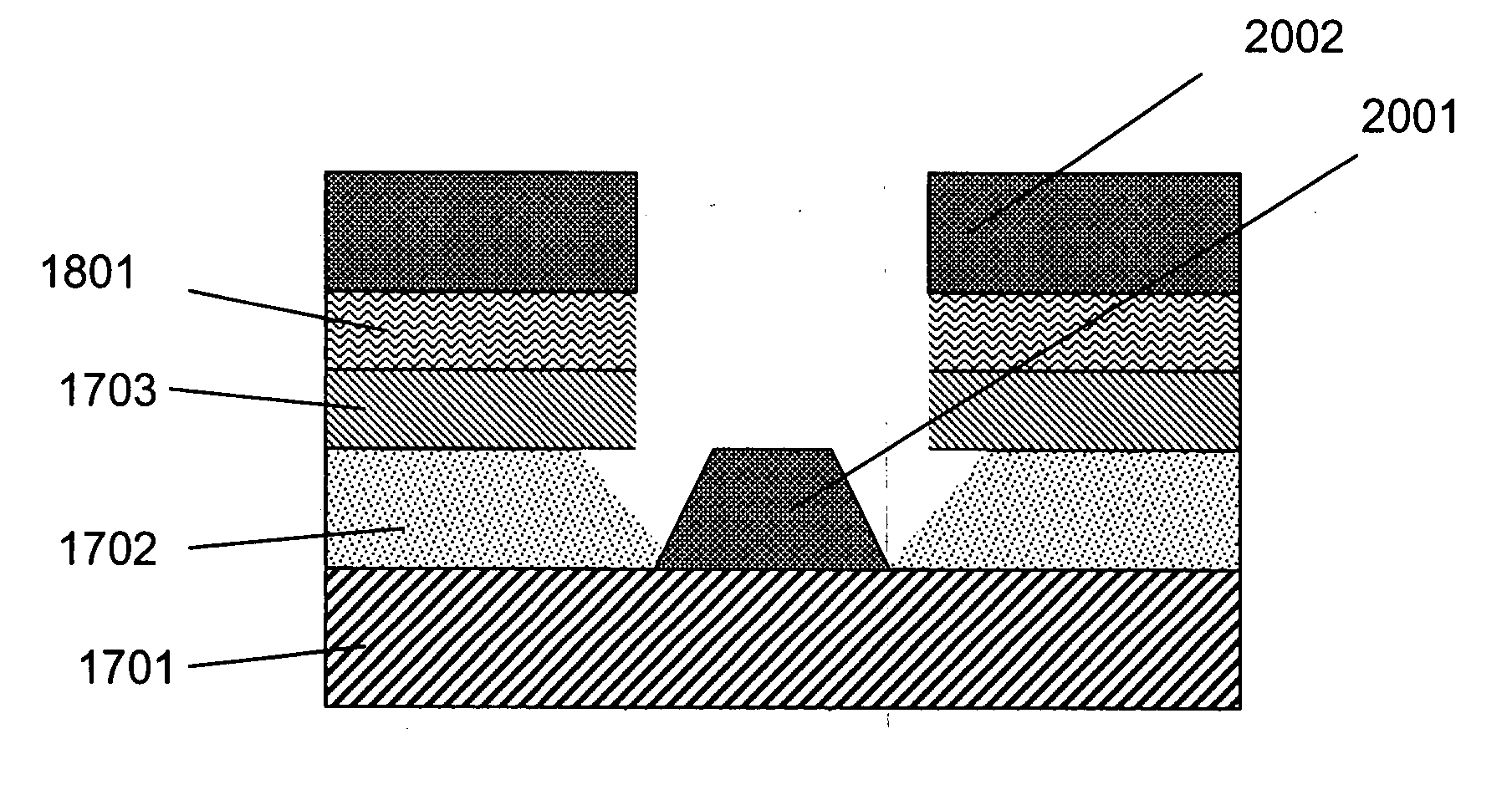

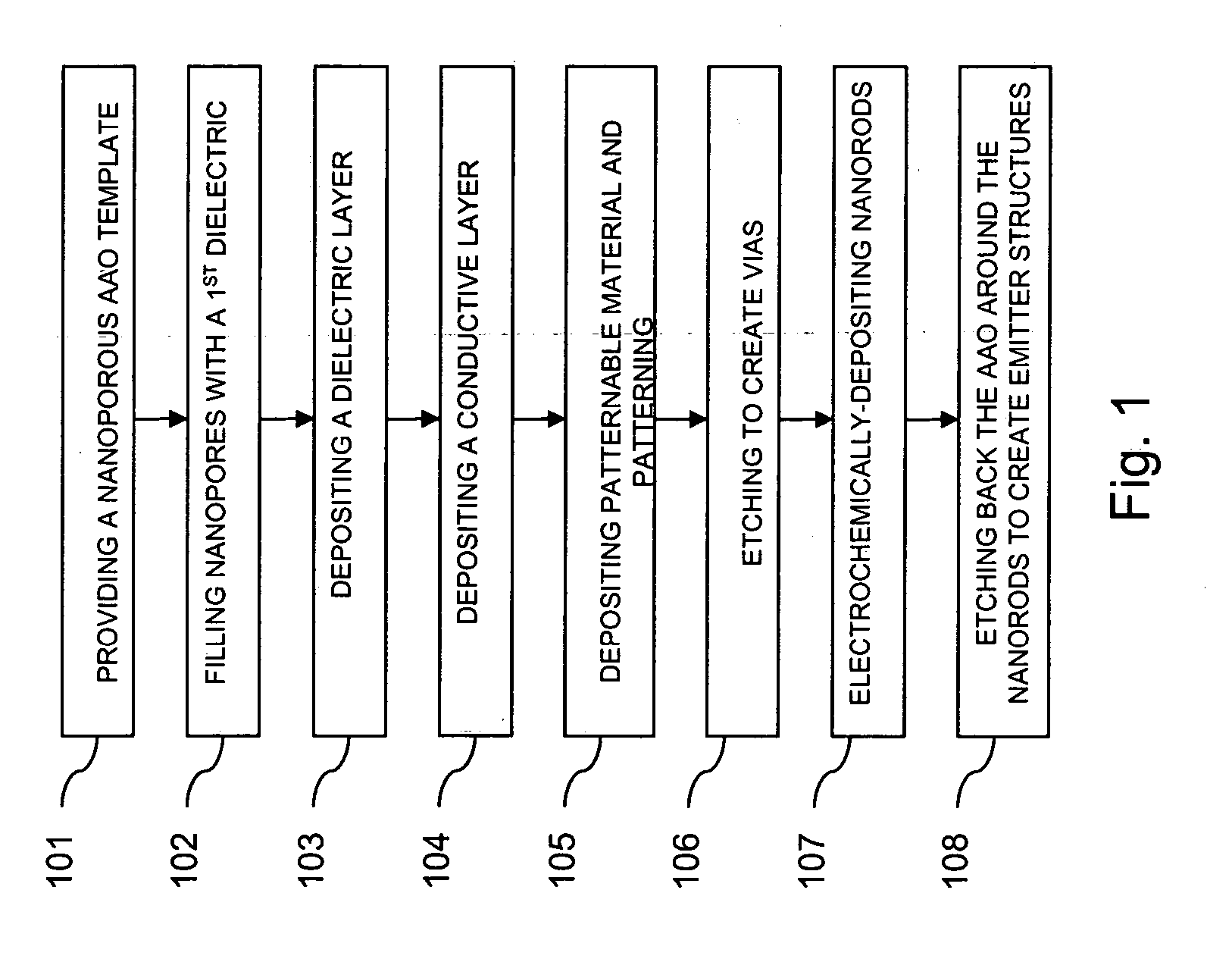

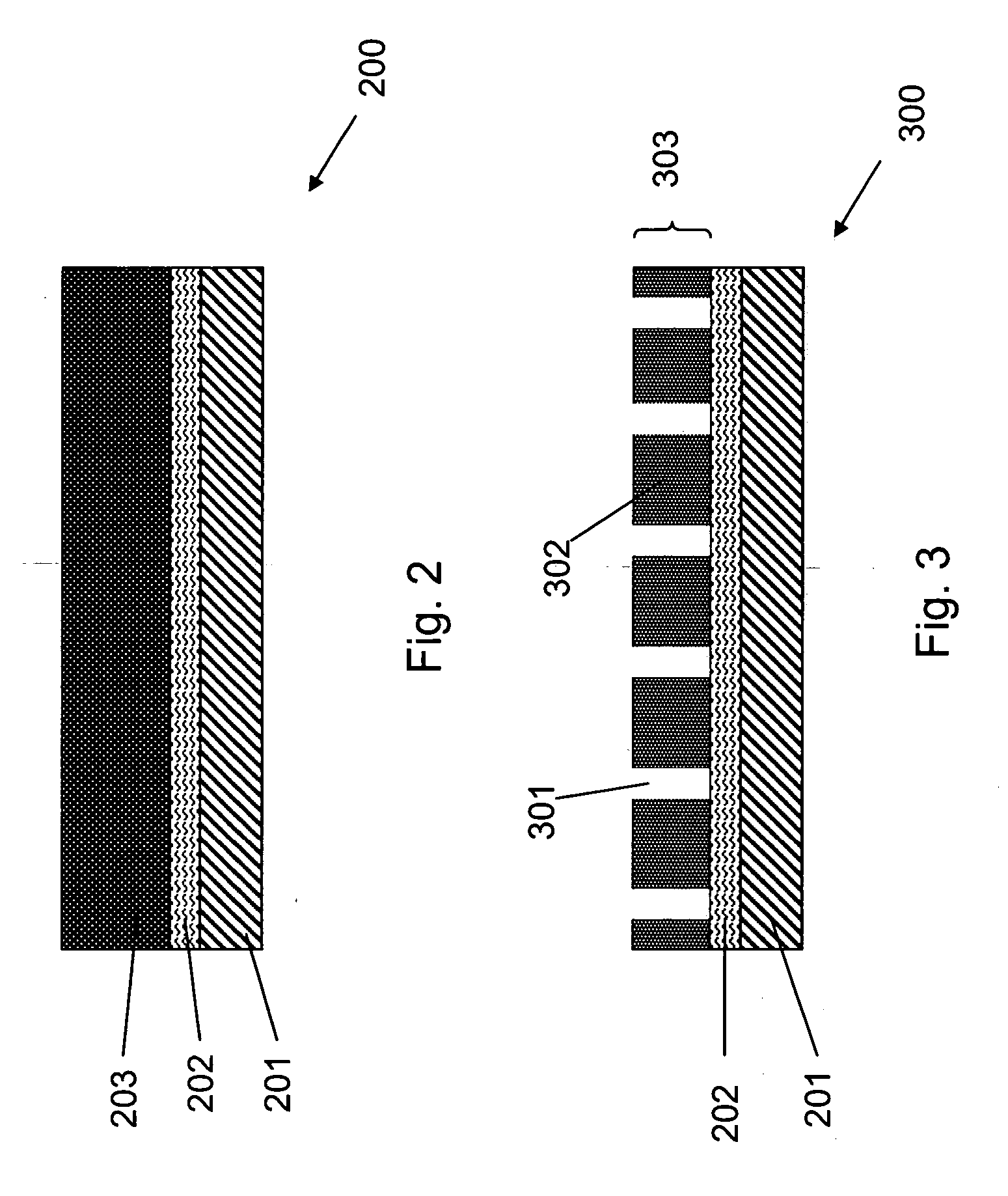

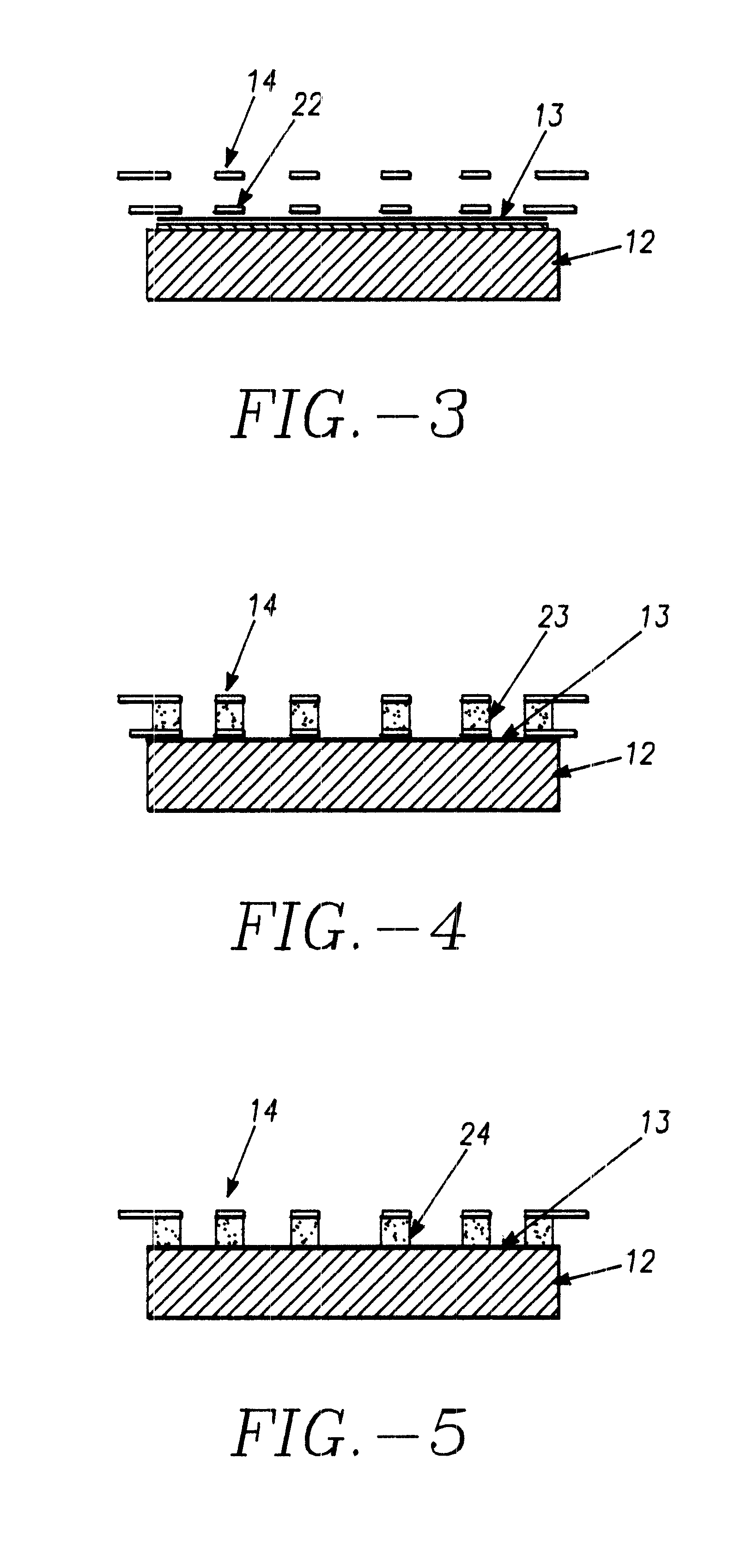

Gated nanorod field emitter structures and associated methods of fabrication

ActiveUS20070029911A1High densitySimple and cost-effective and efficientControl electrodesDischarge tube main electrodesField emission deviceEtching

The present invention relates to gated nanorod field emission devices, wherein such devices have relatively small emitter tip-to-gate distances, thereby providing a relatively high emitter tip density and low turn on voltage. Such methods employ a combination of traditional device processing techniques (lithography, etching, etc.) with electrochemical deposition of nanorods. These methods are relatively simple, cost-effective, and efficient; and they provide field emission devices that are suitable for use in x-ray imaging applications, lighting applications, flat panel field emission display (FED) applications, etc.

Owner:GENERAL ELECTRIC CO

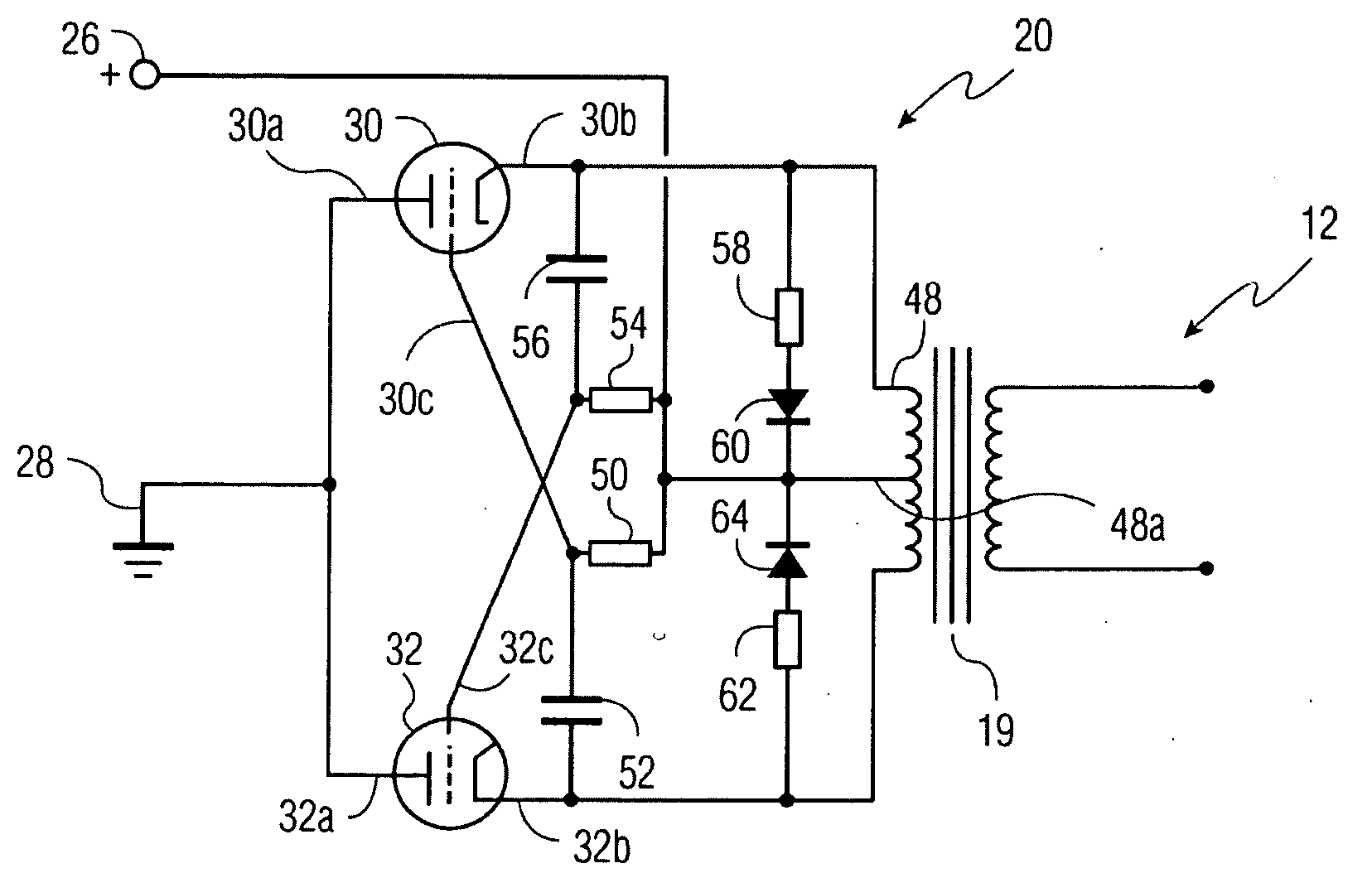

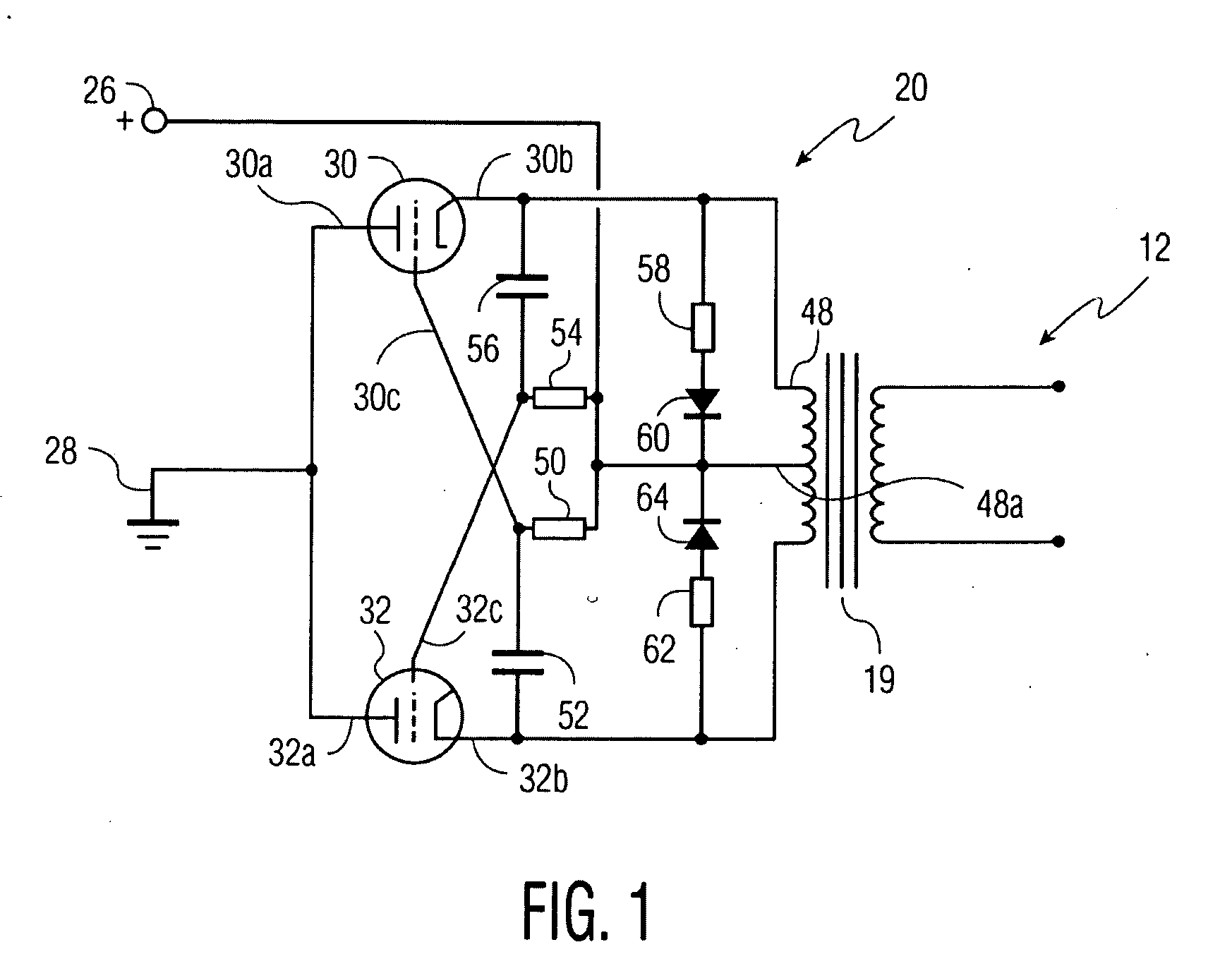

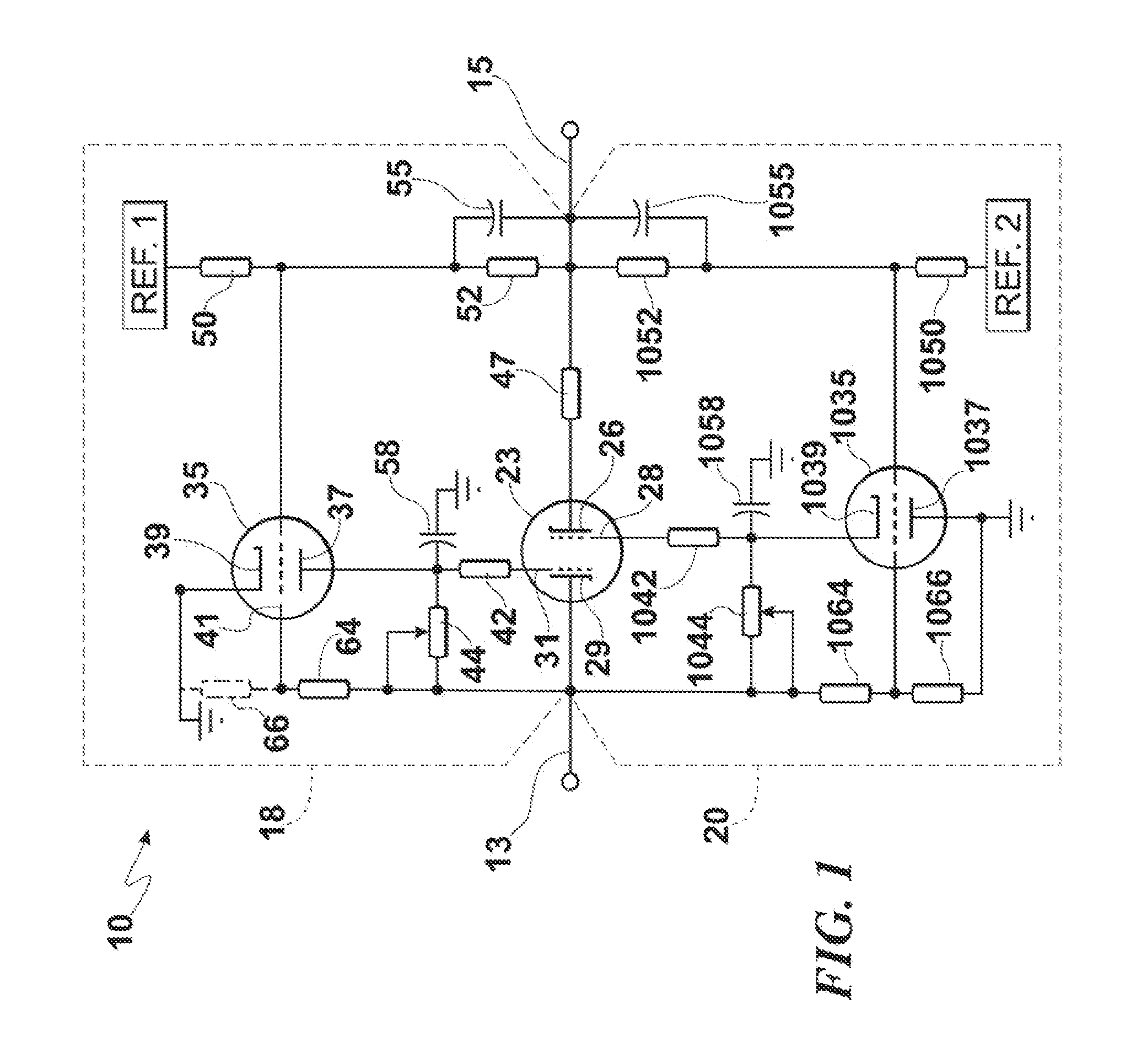

High Voltage Inverter

ActiveUS20090190383A1Improve reliabilityReduce the numberConversion with intermediate conversion to dcLighting elementsEngineeringHigh pressure

Disclosed is a high voltage inverter for converting DC power to AC power with one or more AC output phases. The inverter has for each AC output phase an AC input phase circuit comprising first and second cold cathode field emission controllable electron tubes of triode, tetrode or pentode structure. Each electron tube has a first input node for connection to a high voltage DC potential in excess of 20 KV and a second input node for connection to ground. First electron tube is serially connected between a first end of a primary winding and ground, and second electron tube is serially connected between a second end of the primary winding and ground. Control circuitry controls the electron tubes so that the first and second electron tubes alternatively conduct so as to alternately bring the first and then second end of the primary winding approximately to the potential of ground.

Owner:ADVANCED FUSION SYST LLC

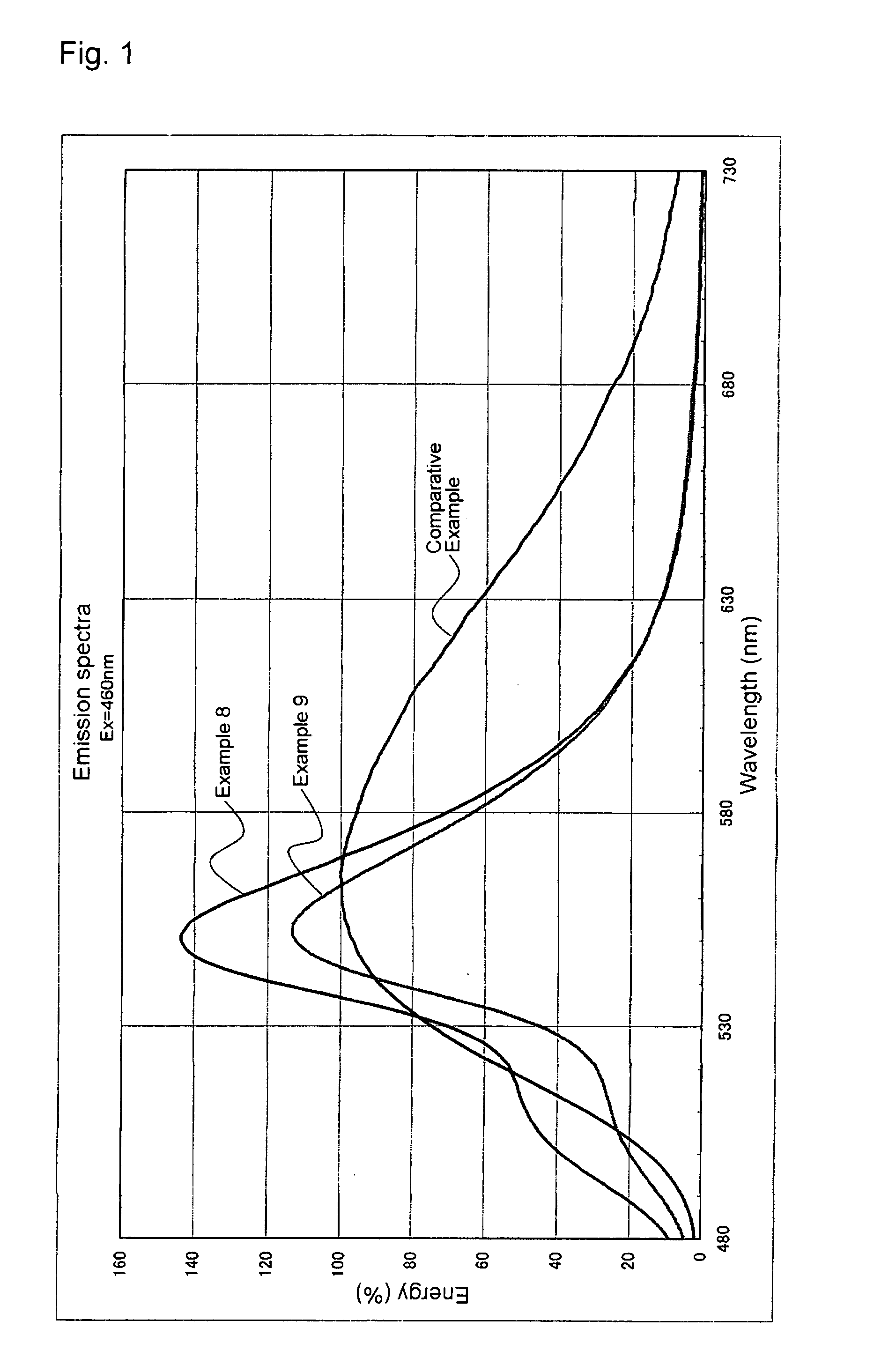

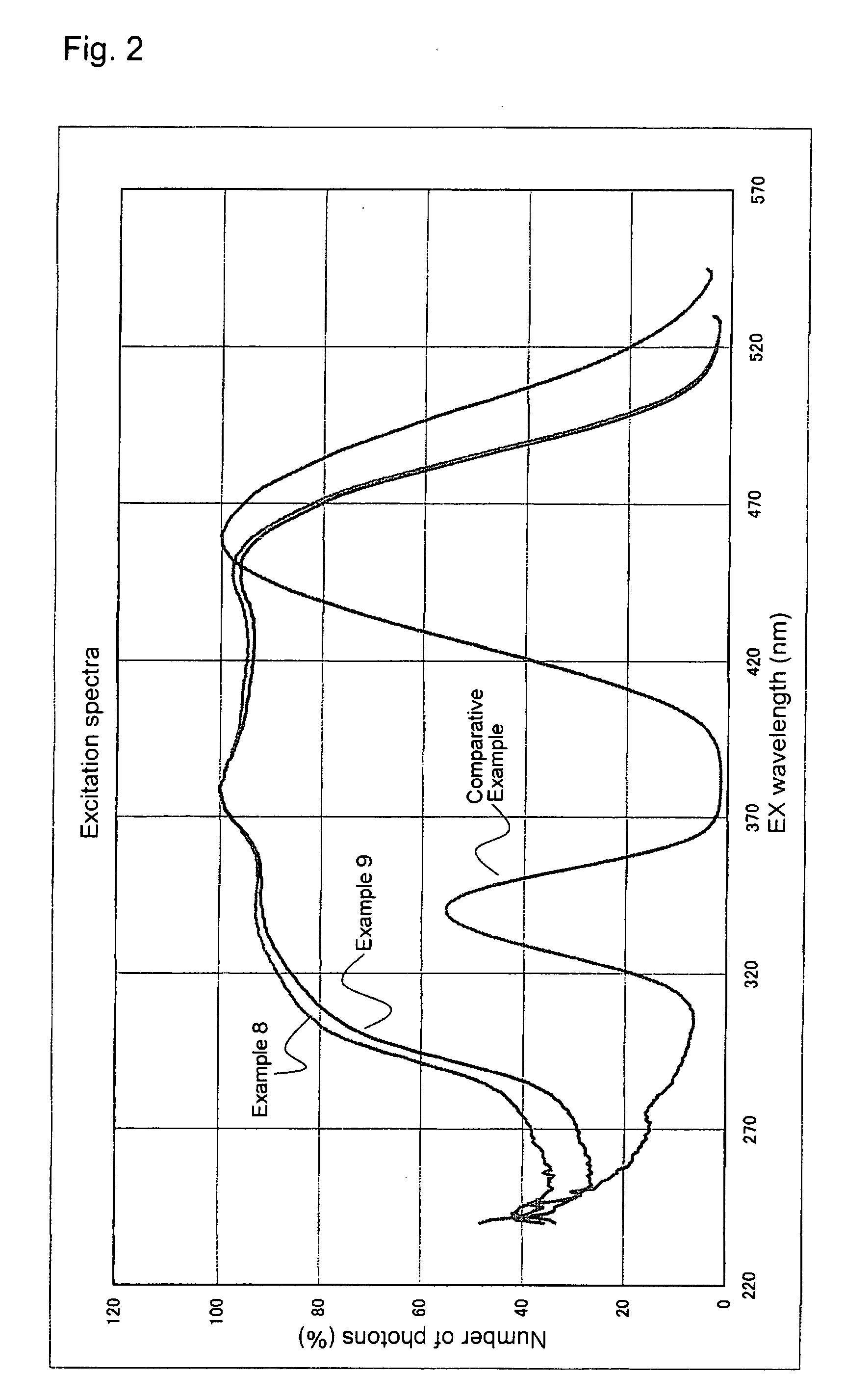

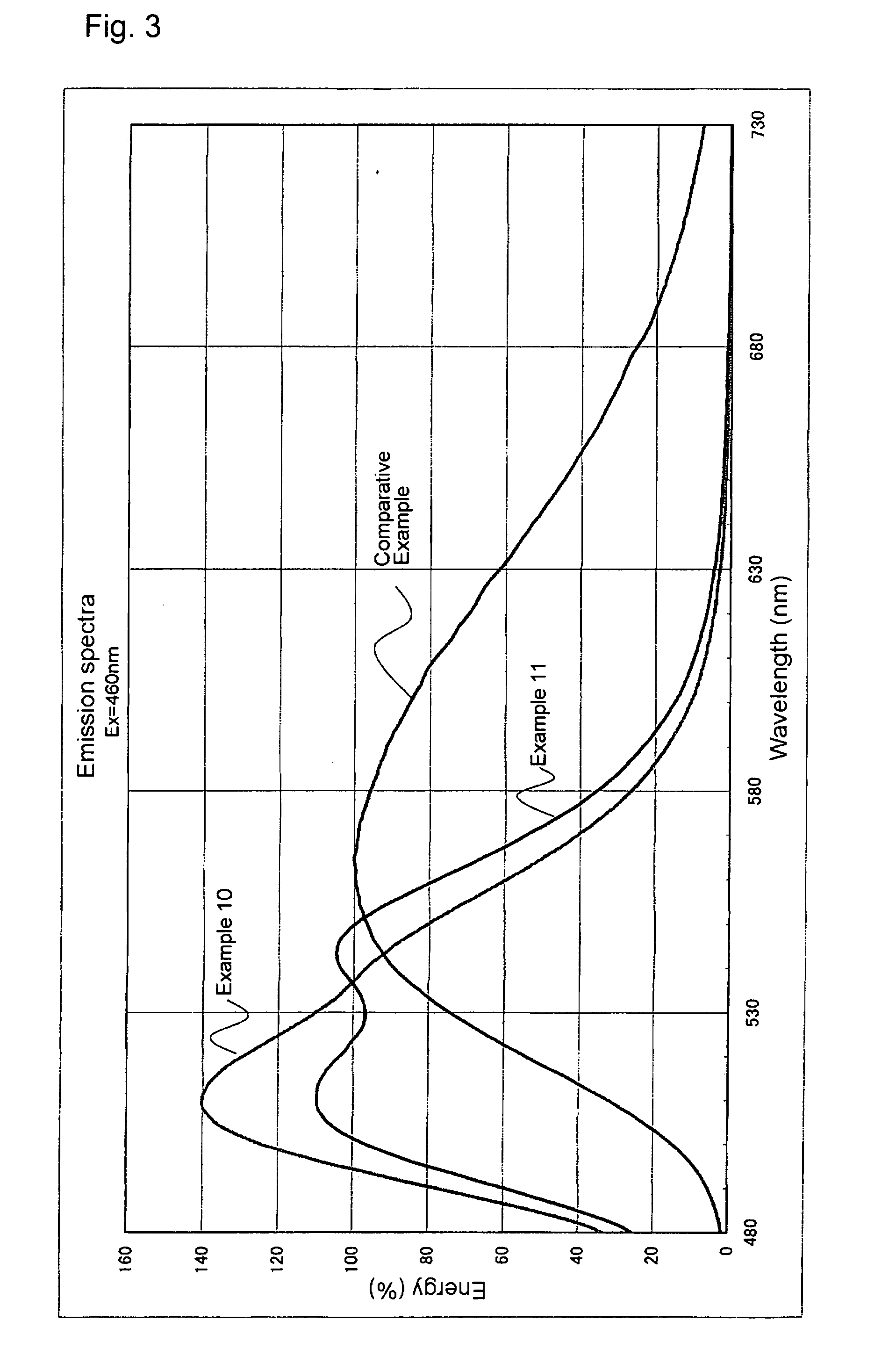

Phosphor and light emitting device using the same

ActiveUS20070200095A1Increase brightnessGood weather resistanceControl electrodesLuminescent compositionsRare-earth elementPhosphor

There is provided a phosphor emitting light of high brightness and having high weatherability, which has a composition represented by the following general formula:(M11−yRy)aMgM2bM3cOa+2b+(3 / 2)cX2wherein M1 is at least one element selected from the group consisting of Ca, Sr, Ba, Zn and Mn, M2 is at least one element selected from the group consisting of Si, Ge and Sn, M3 is at least one element selected from the group consisting of B, Al, Ga and In, X is at least one element selected from the group consisting of F, Cl, Br and I, R is at least one element selected from the group consisting of rare earth elements with Eu being an inevitable element, and y, a, b and c satisfy the following relationships of 0.0001≦y≦0.3, 7.0≦a<10.0, 3.0≦b<5.0 and 0≦c<1.0.

Owner:NICHIA CORP

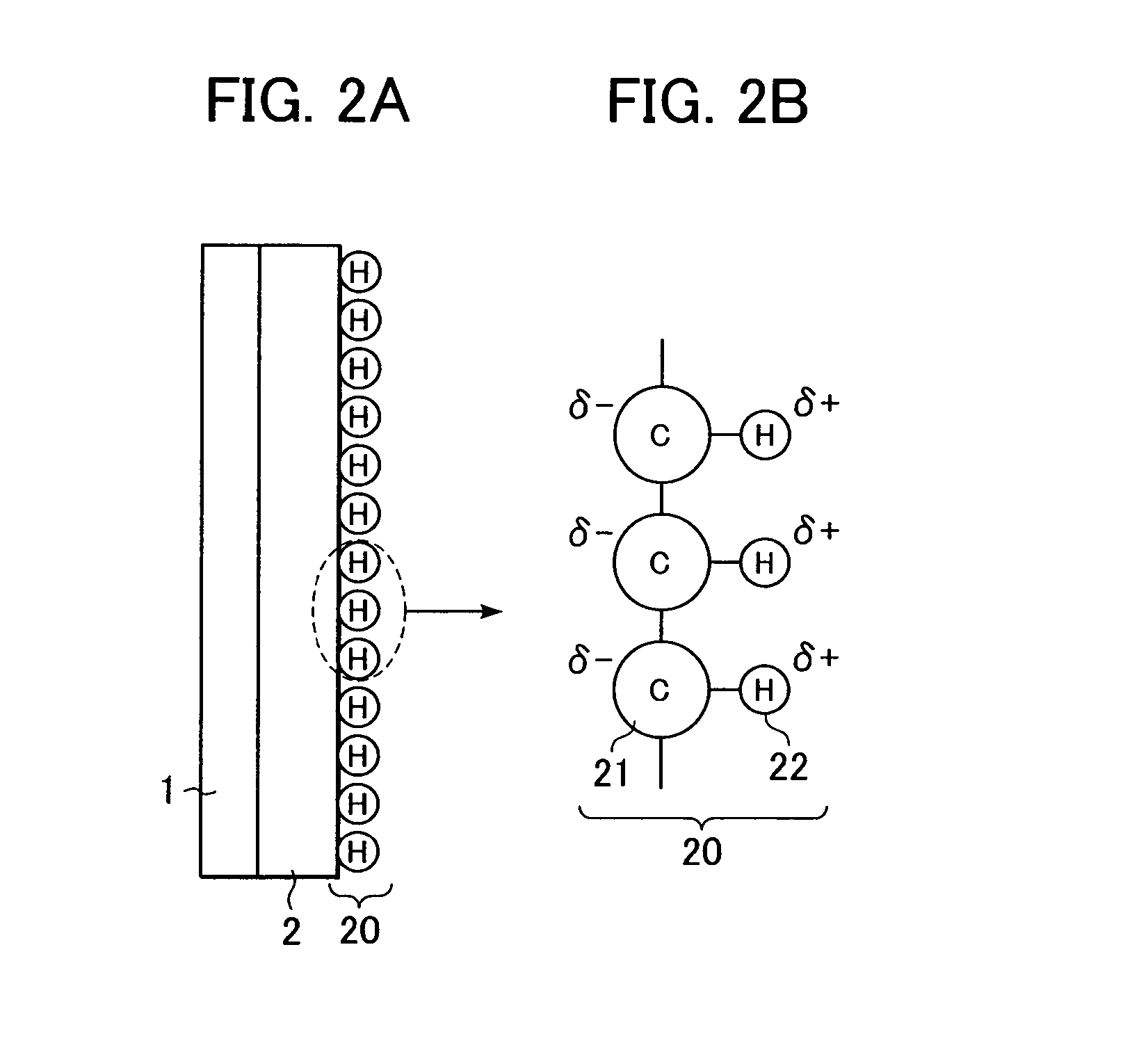

Electron emission device, electron source, and image display having dipole layer

InactiveUS7109663B2Efficient emissionsIncrease contrastDischarge tube luminescnet screensStatic indicating devicesInsulation layerElectron source

An electron emission device is provided which has sufficient on / off characteristics and is capable of efficiently emitting electrons with a low voltage. An electron emission device includes a substrate, a cathode electrode, a gate electrode, which are arranged on the substrate, an insulation layer covering the surface of the cathode electrode, and a dipole layer formed by terminating the surface of the insulation layer with hydrogen.

Owner:CANON KK

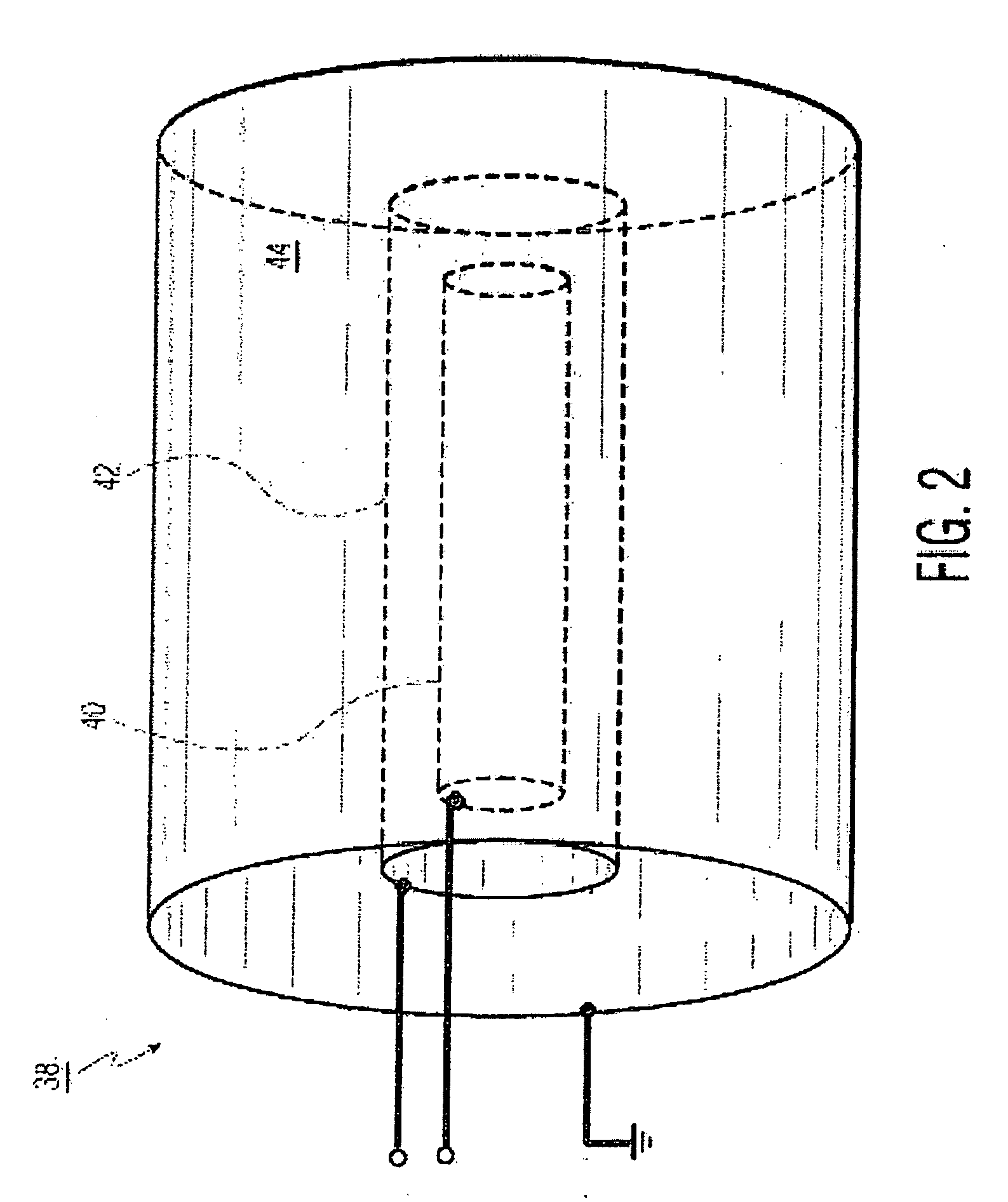

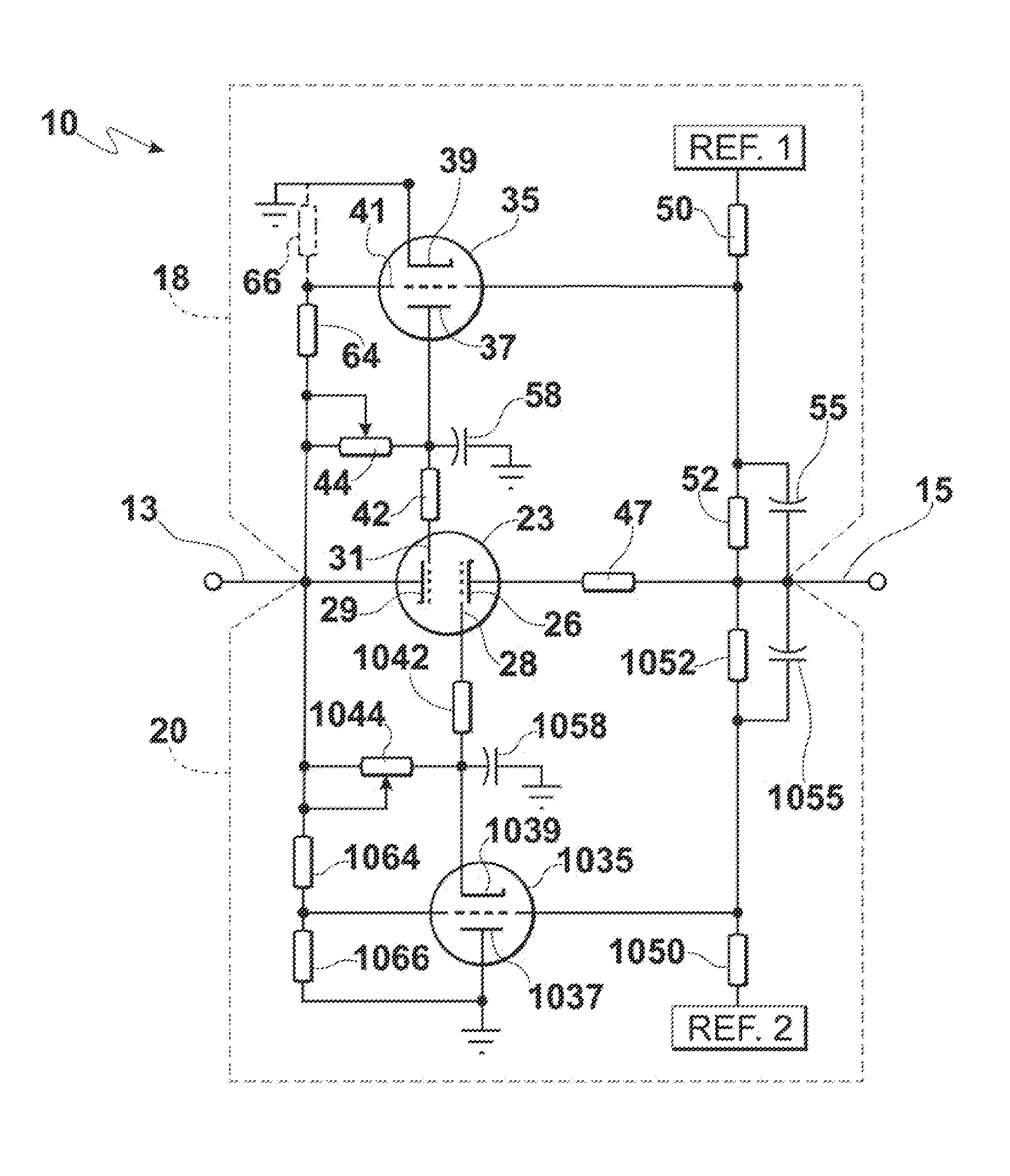

High Voltage High Current Regulator

ActiveUS20120081097A1Minimized size requirementPreventing internal electrical short circuitAnti-noise capacitorsElectrode assembly support/mounting/spacing/insulationHigh voltage igbtControl signal

High voltage high current regulator circuit for regulating current is interposed between first and second terminals connected to an external circuit and comprises at least one main-current carrying cold-cathode field emission electron tube conducting current between the first and second terminals. First and second grid-control cold-cathode field emission electron tubes provide control signals for first and second grids of the at least one main-current carrying cold-cathode field emission electron tube for positive and negative excursions of voltage on the first and second terminals, respectively. The current regulator circuit may be accompanied by a voltage-clamping circuit that includes at least one cold-cathode field emission electron tube. At least two cold-cathode field emission electron tubes, configured to operate at high voltage and high current, are preferably contained within a single vacuum enclosure and are interconnected to provide a circuit function, so as to form a high voltage high current vacuum integrated circuit.

Owner:ADVANCED FUSION SYST LLC

Electron source

InactiveUS6534923B2Inexpensive and simple and efficientControl electrodesNanoinformaticsElectron sourceNanostructured carbon

An electron source including a nanostructured carbon electron-emitting film and an electron extraction grid spaced closely adjacent the surface of said film.

Owner:MICROWAVE POWER TECH

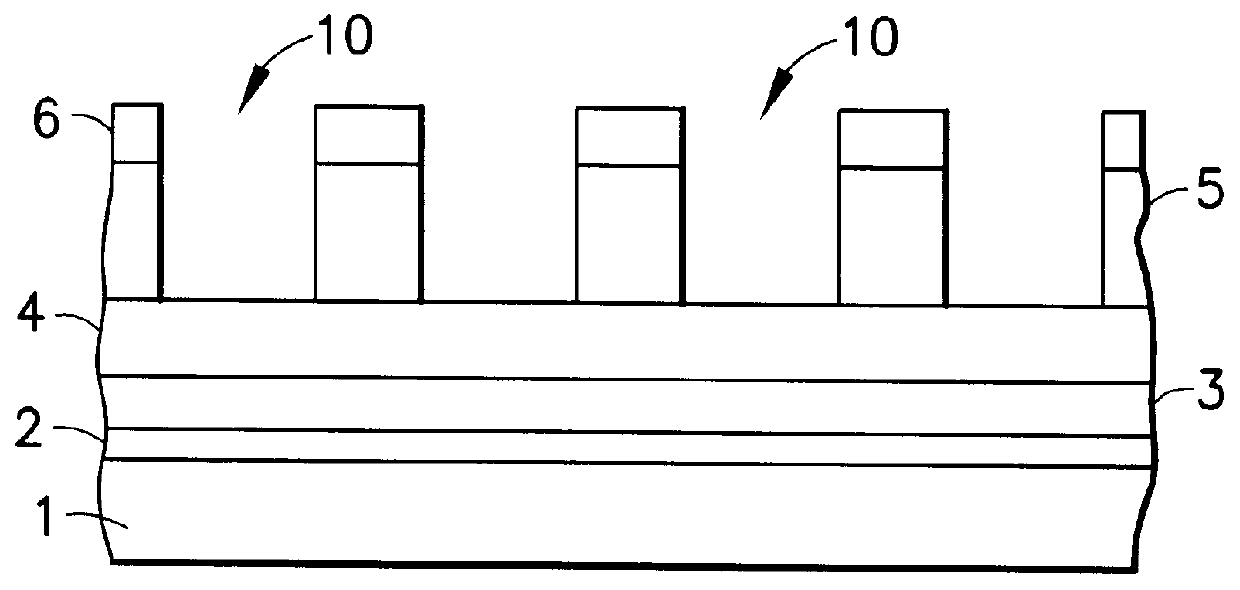

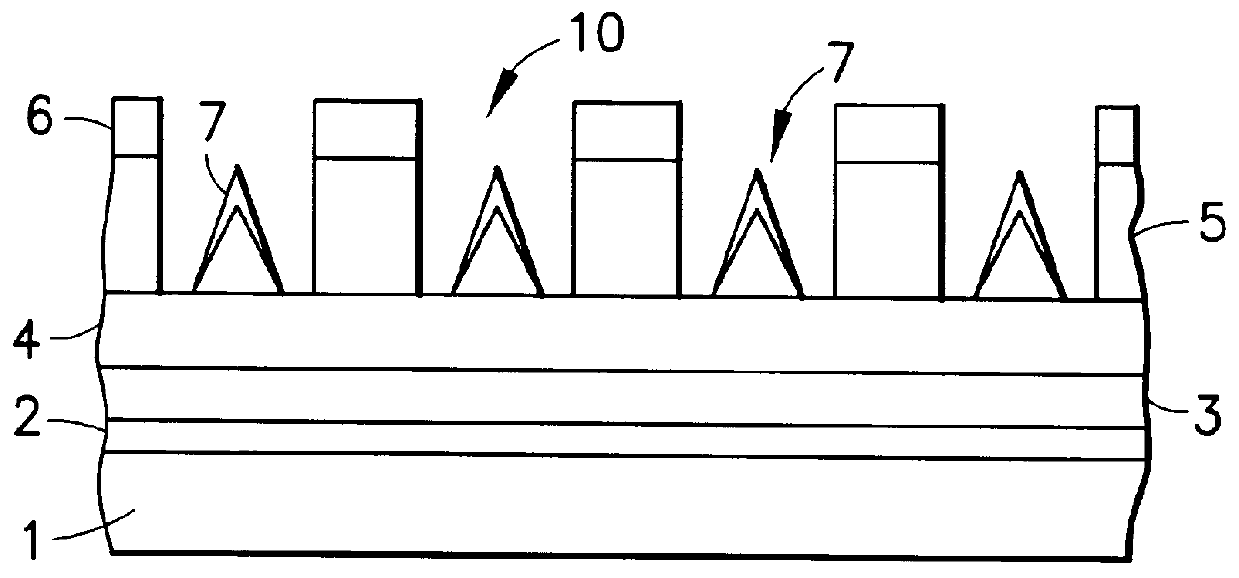

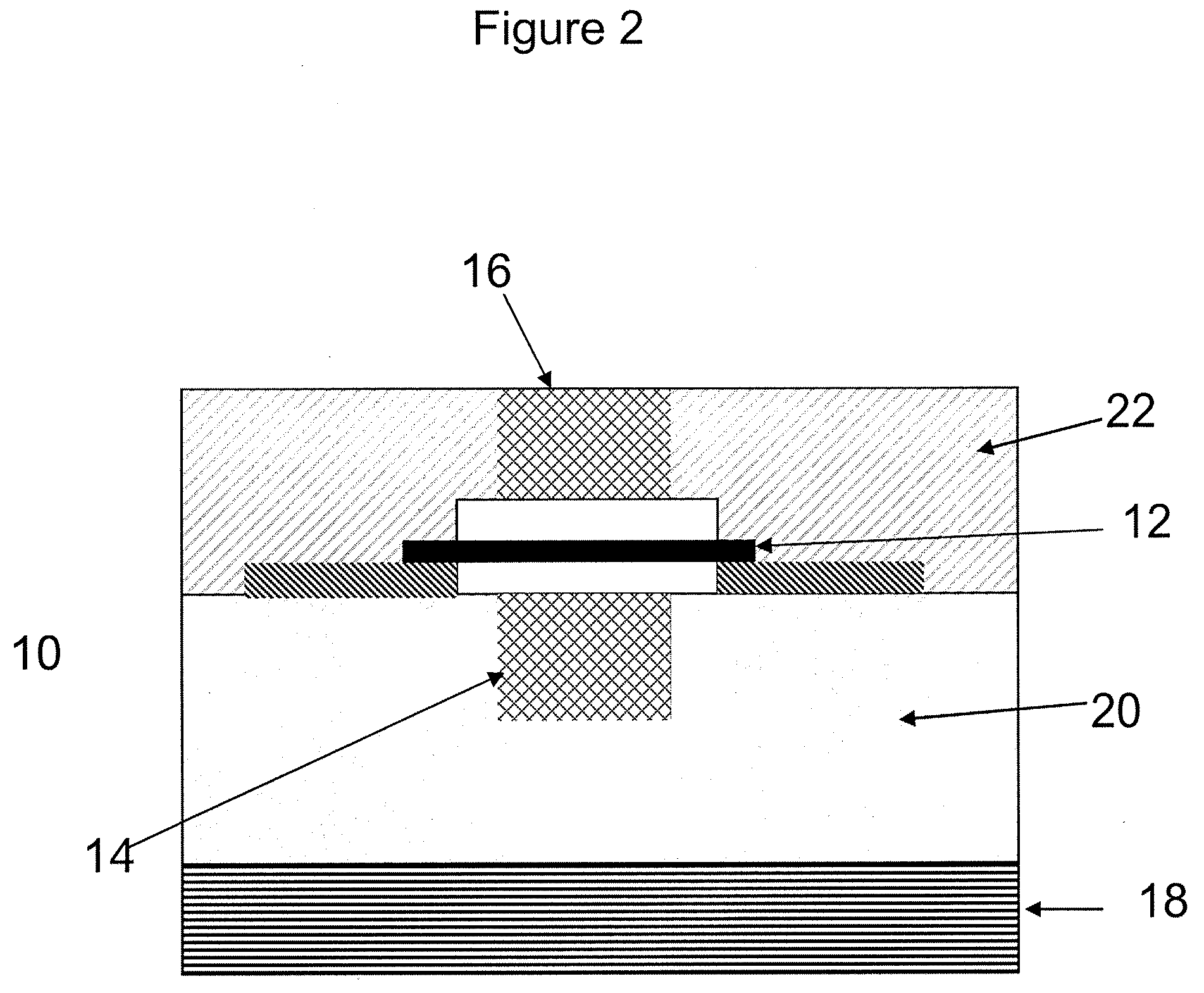

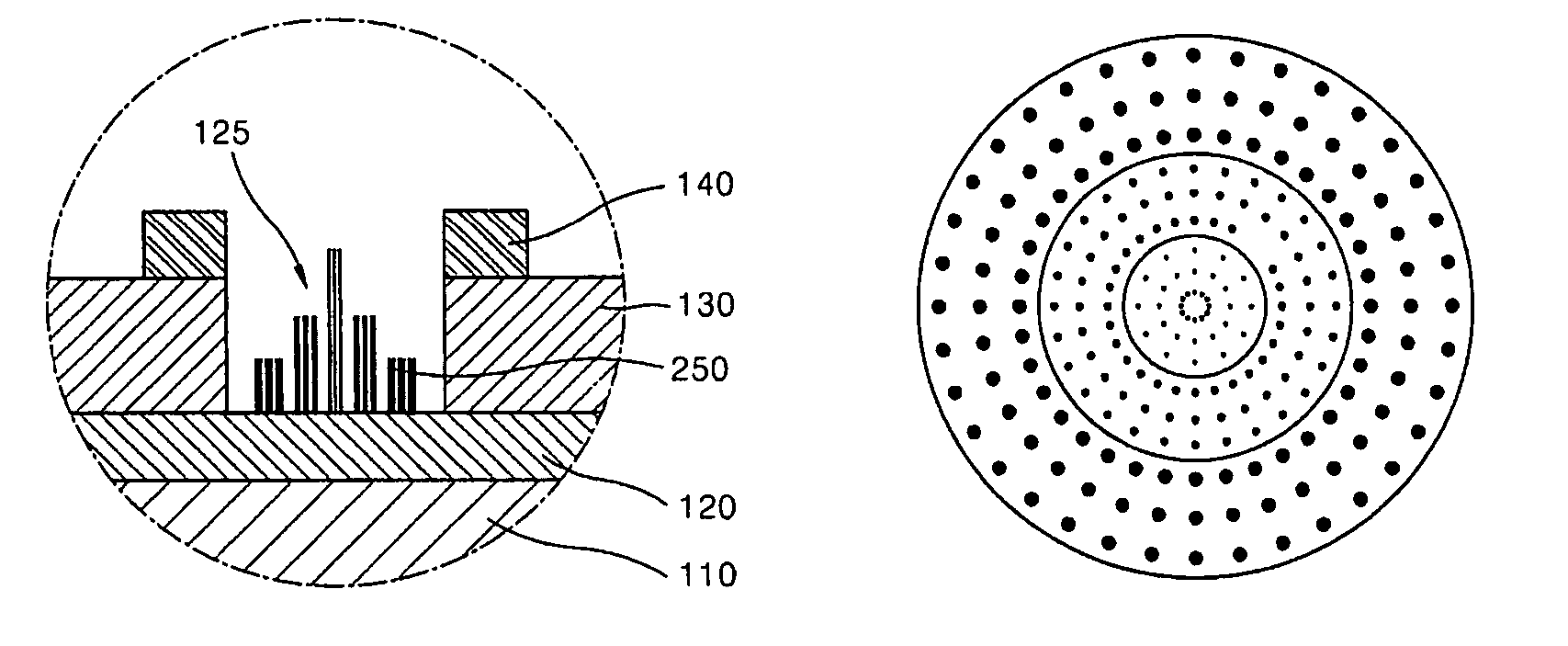

Low voltage electron source with self aligned gate apertures, fabrication method thereof, and devices using the electron source

InactiveUS20090039754A1Narrow distributionHigh densityControl electrodesDischarge tube luminescnet screensNano structuringElectron source

A method of fabricating an electron source having a self-aligned gate aperture is disclosed. A substrate is deposited on a first conductive layer. Over the first conductive layer an emitter layer is deposited. The emitter layer includes one or a plurality of spaced-apart nano-structures and a solid surface with nano-structures protruding above the surface. An insulator is conformally deposited over the emitter layer surface and forms a post from each protruding nano-structure. A second conductive layer is deposited over the insulator and the second conductive layer and the insulator are removed from the nano-structures such that apertures are formed in the second conductive layer and at least the ends of the nano-structures are exposed at the centers of said apertures.

Owner:TOLT ZHIDAN L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com