Vacuum field effect transistor

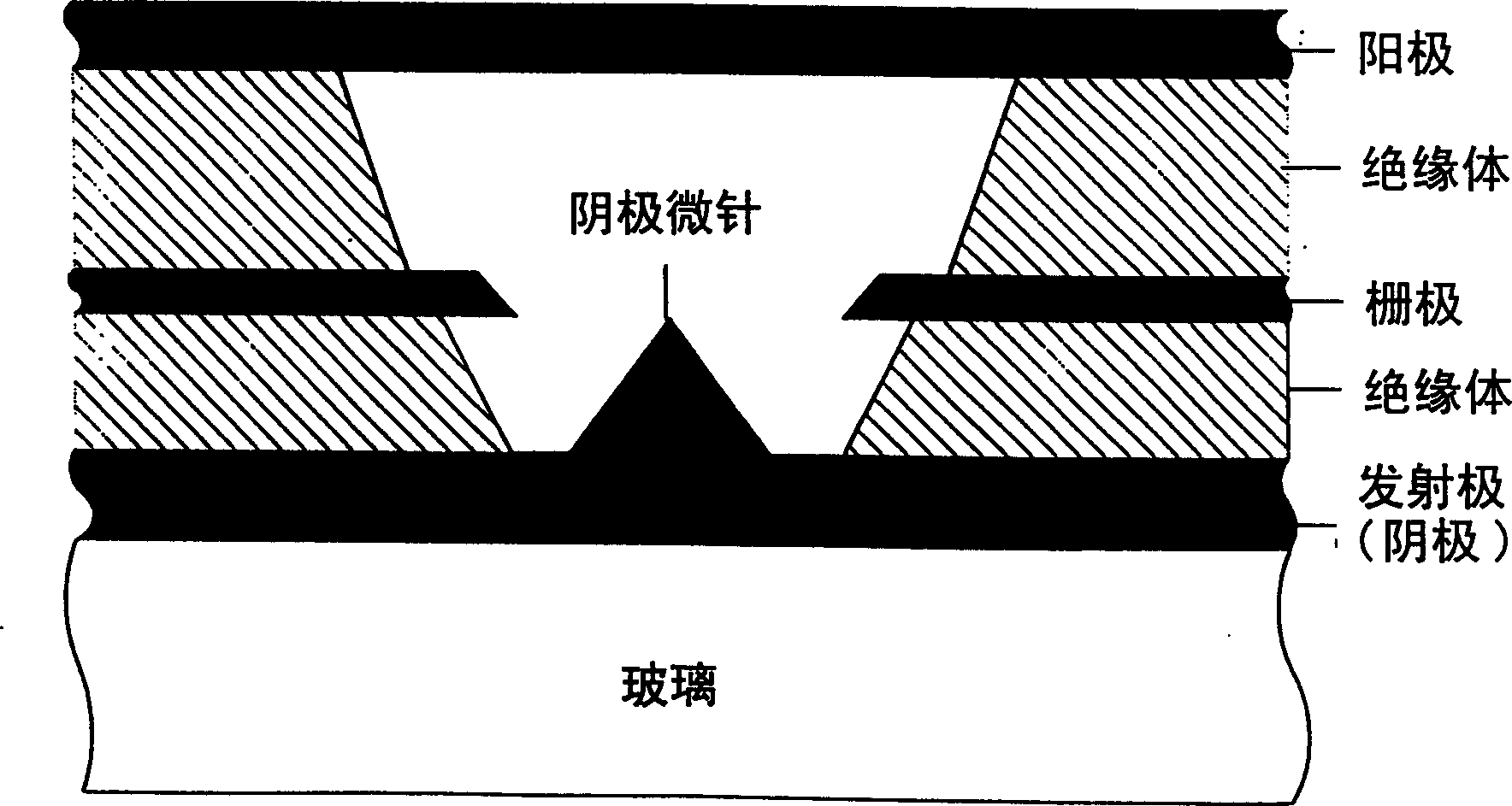

A vacuum field effect, transistor technology, used in vacuum tubes, transistors, discharge tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the invention will be best understood by referring to the accompanying drawings, wherein like reference numerals are used for corresponding parts.

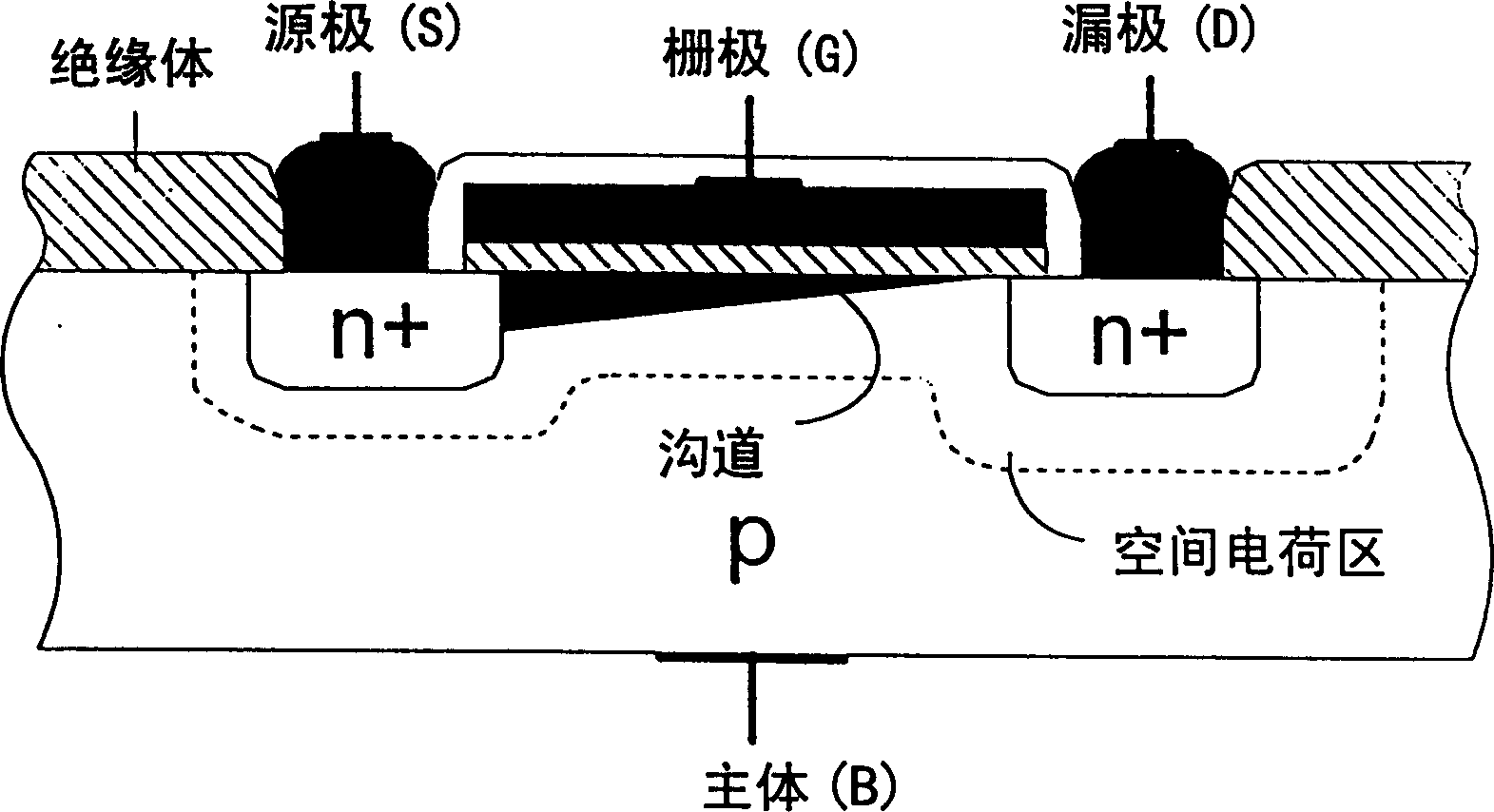

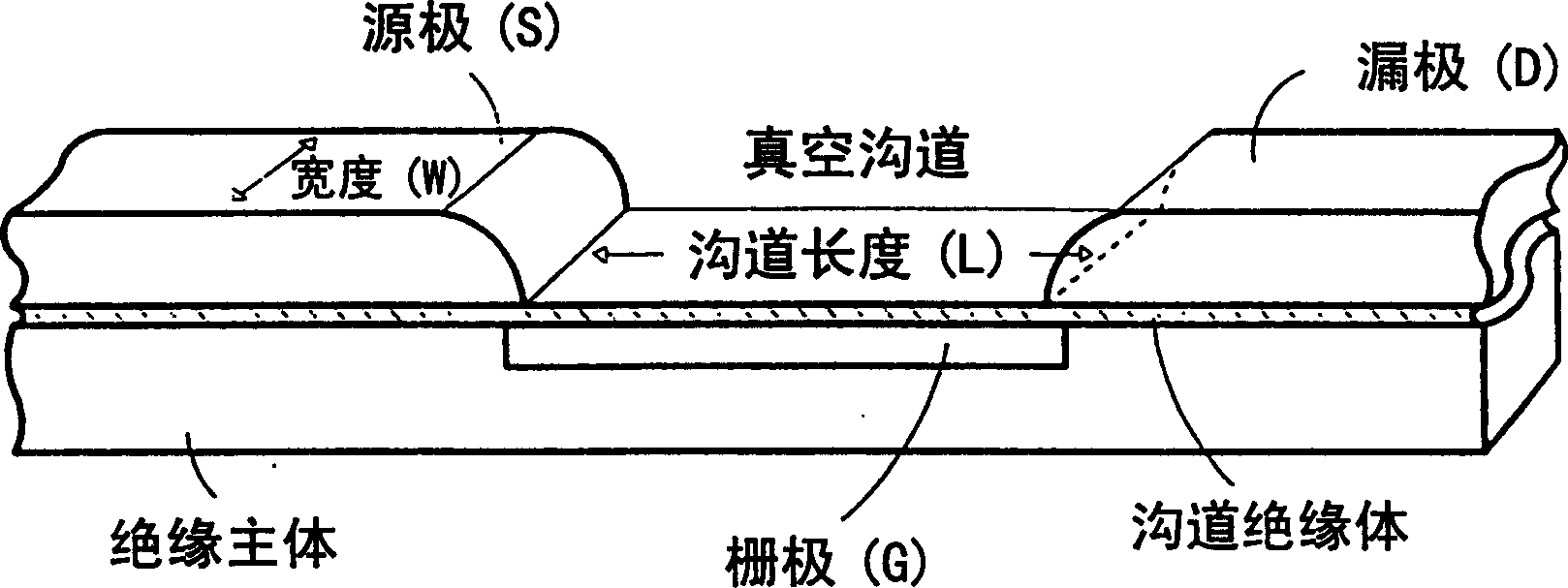

[0041] refer to Figure 3a with 3b, a structure is given, showing the basic concept of the VFT of the present invention in the form of a perspective view and a sectional view, respectively. This VFT structure seems to be a MOSFET structure, but the difference is that the channel is blanked and the gate is discharged in place. This VFT structure is divided into an upper structure consisting of a source S, a drain D and a vacuum channel therebetween, and a lower structure consisting of a gate G and a body. Each of the source S, the drain D and the gate G is a conductor, and an insulator with a vacuum channel between the upper structure and the lower structure. This vacuum channel is above the gate G, which is in an insulating body supporting the whole therebetween.

[0042] If a voltage is app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com