Electrovacuum tube with dual anodes, and assembling method

A technology of electric vacuum tube and double anode, which is applied in the direction of vacuum tube, discharge tube, non-electron emitting anode, etc., and can solve the problems of increased anode spacing and concentricity error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

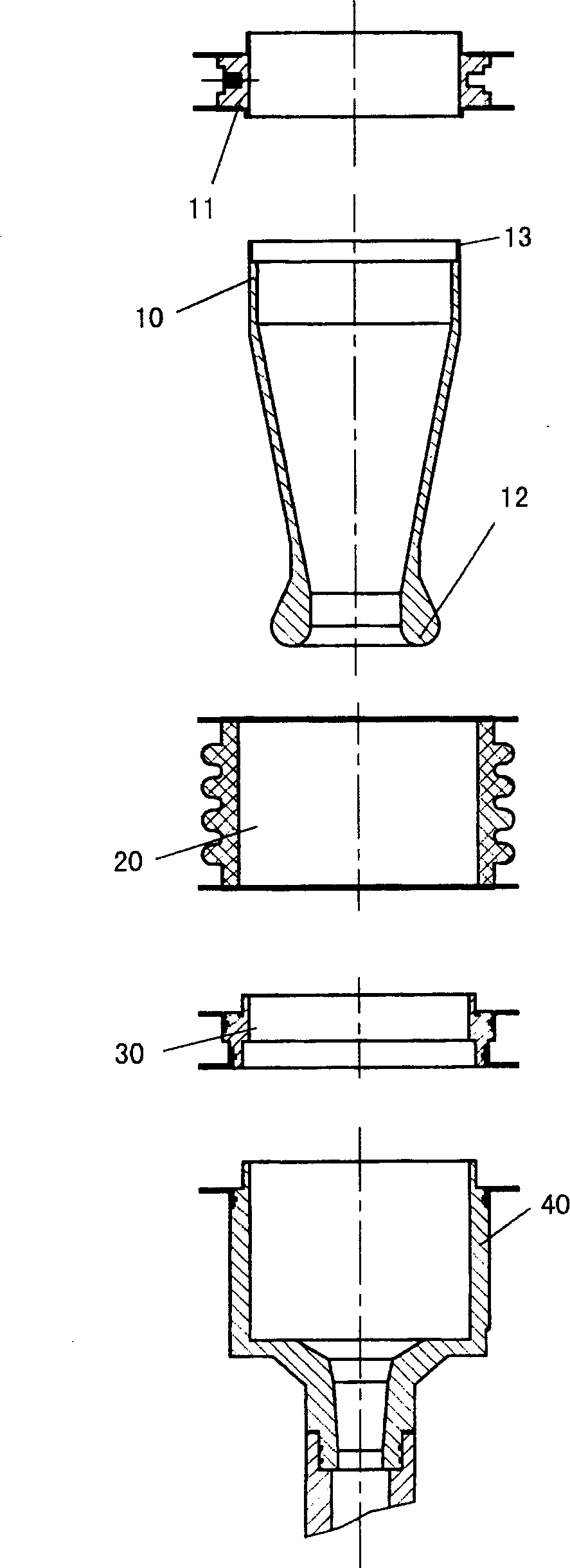

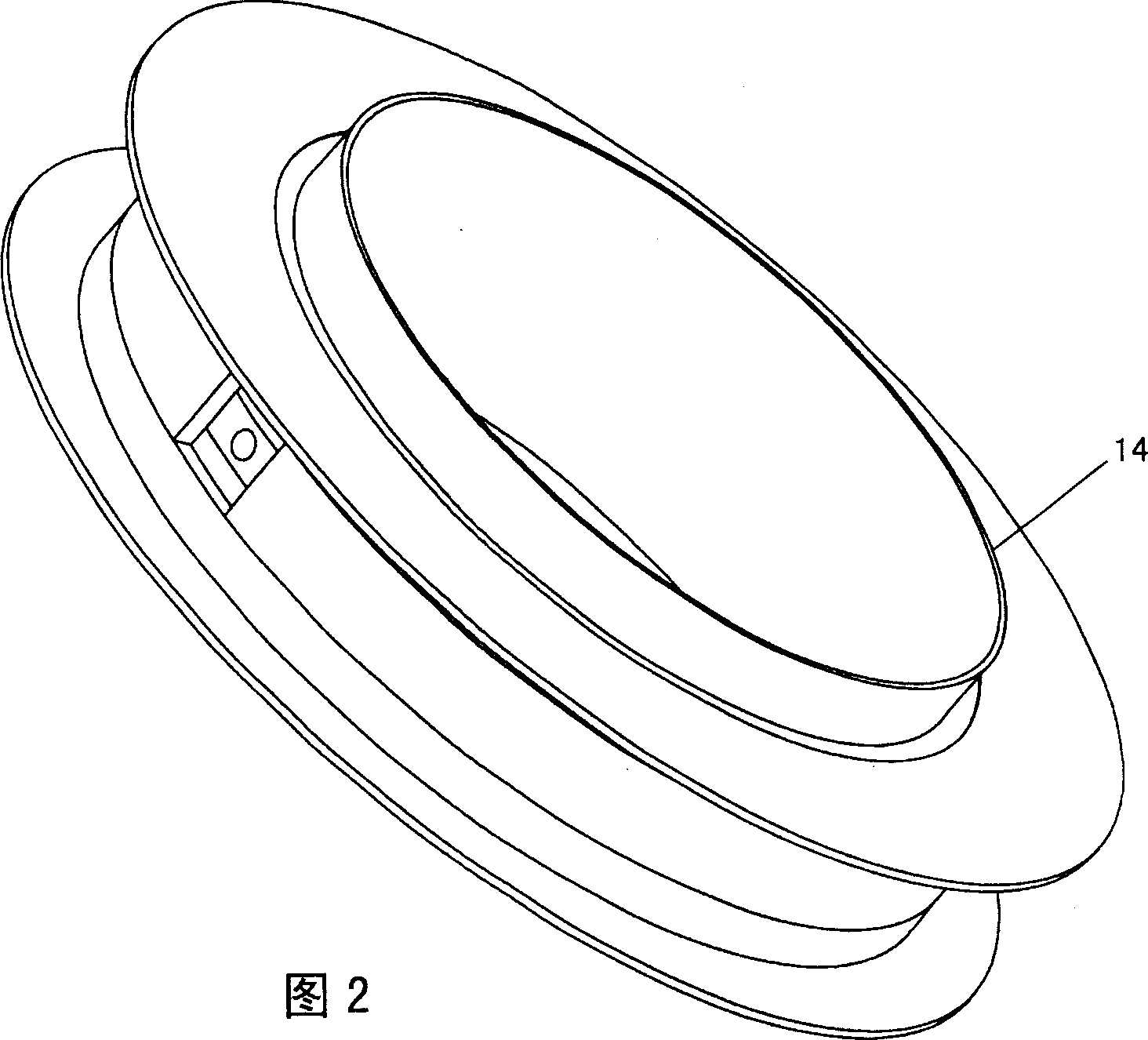

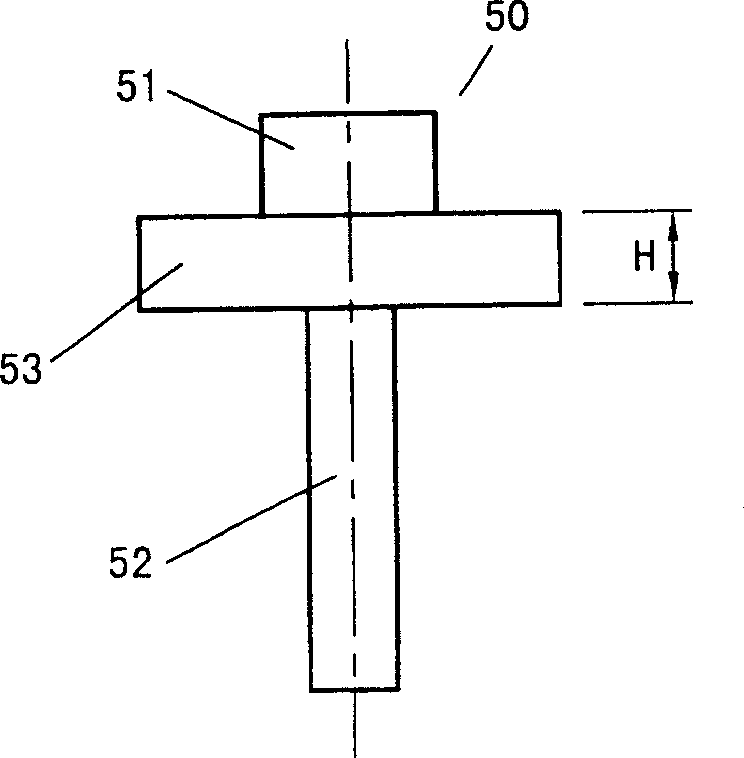

[0016] see figure 1 , the structure of the double-anode electric vacuum tube provided by the present invention includes in order: the first anode 10, the first anode seat 11, the ceramic insulating section assembly 20, the transition section assembly 30 and the second anode 40, the transition section assembly 30 and the first anode An anode 10 is made of oxygen-free copper like the second anode 40 , and the inner diameter of the transition section assembly 30 is the same as the inner diameter of the second anode 40 . In order to ensure accurate positioning and connection stability between the transition section assembly 30, the ceramic insulating section assembly 20 and the second anode assembly 40, a step 31 is provided outside one port of the transition section assembly 30, and a step 31 is provided on the inside of the other port. A step 32 is provided, wherein the outer step 31 is connected with the inner diameter of a port of the ceramic insulating component 20 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com