Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

198 results about "Woodworking machinery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

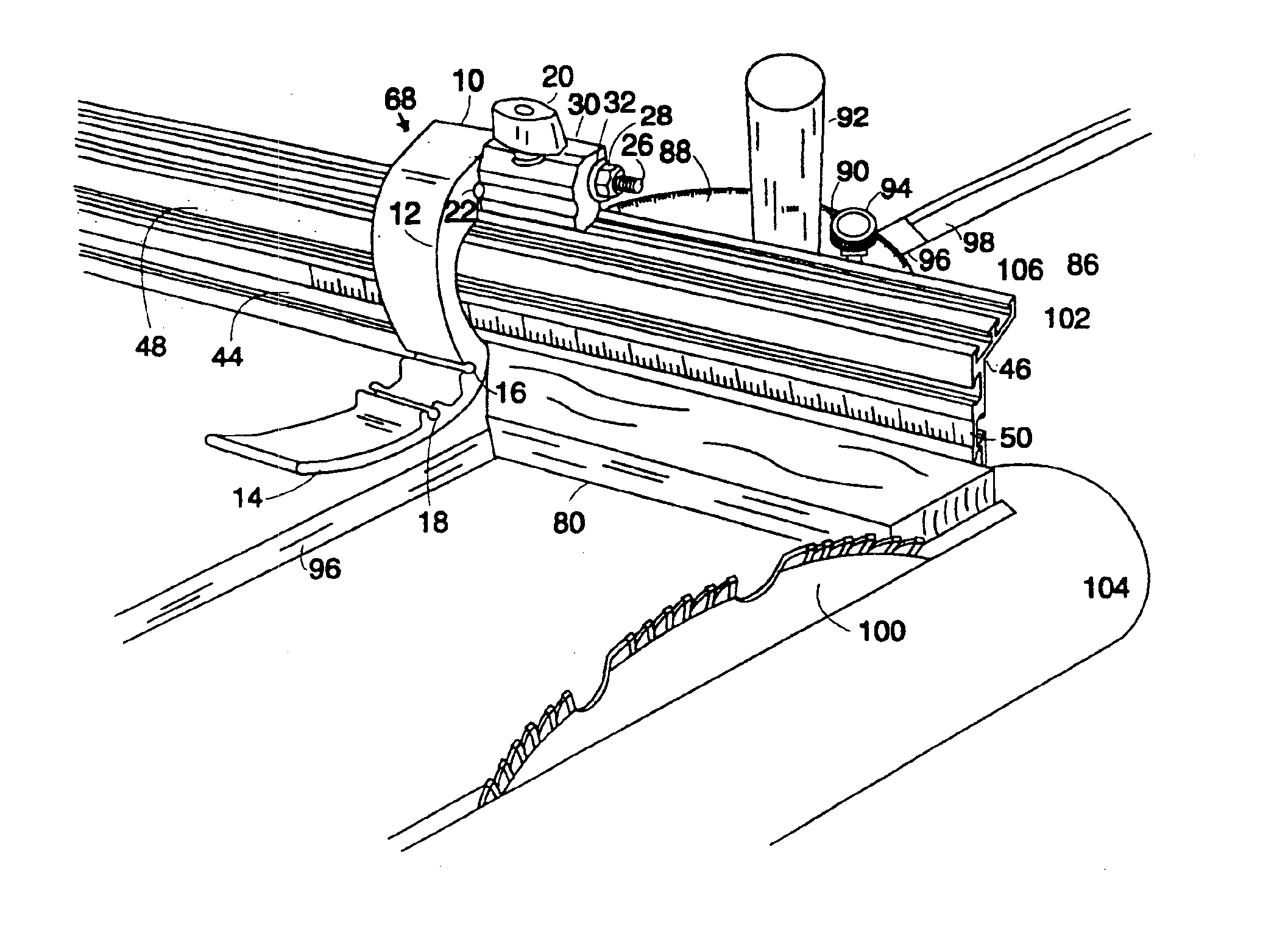

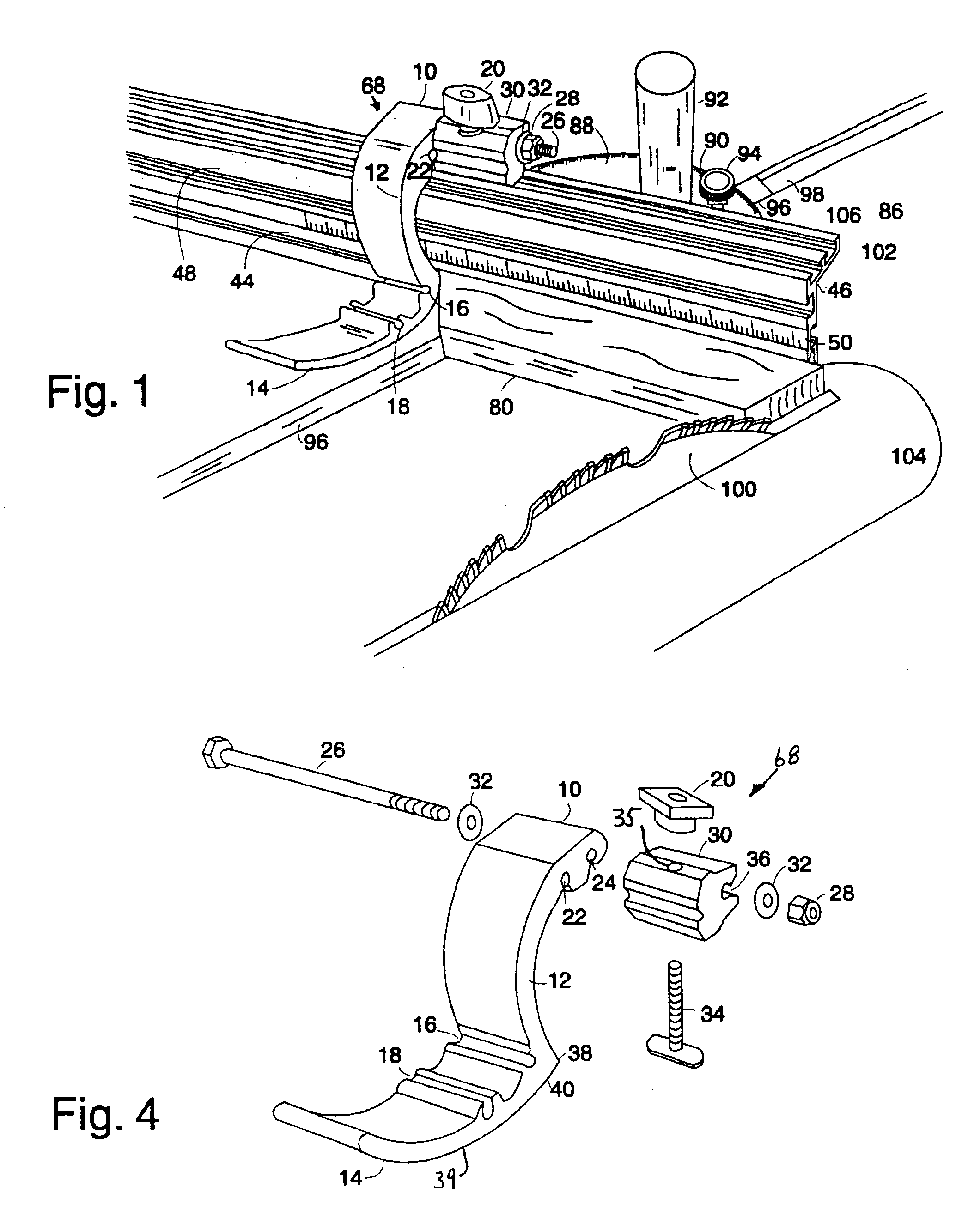

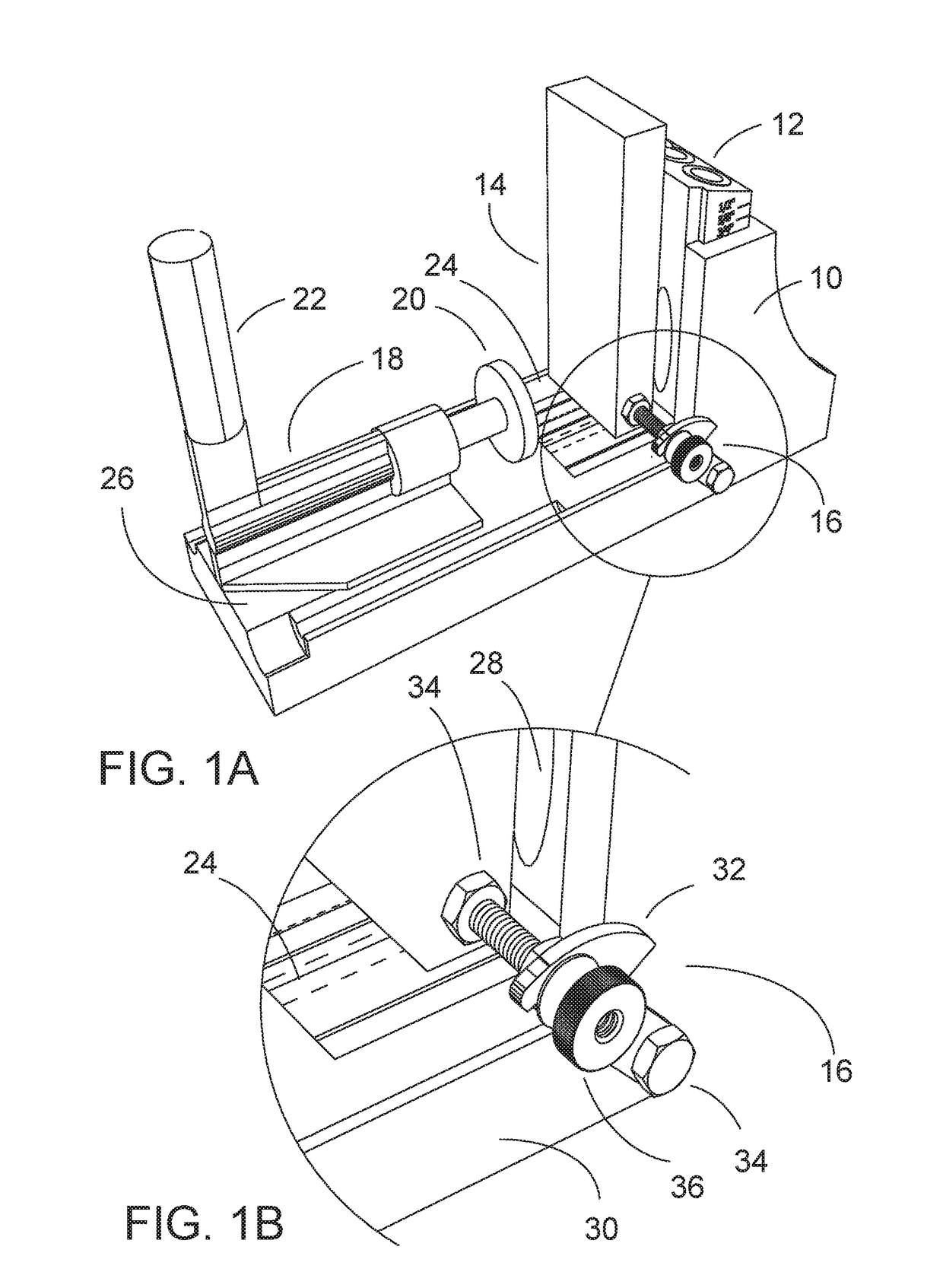

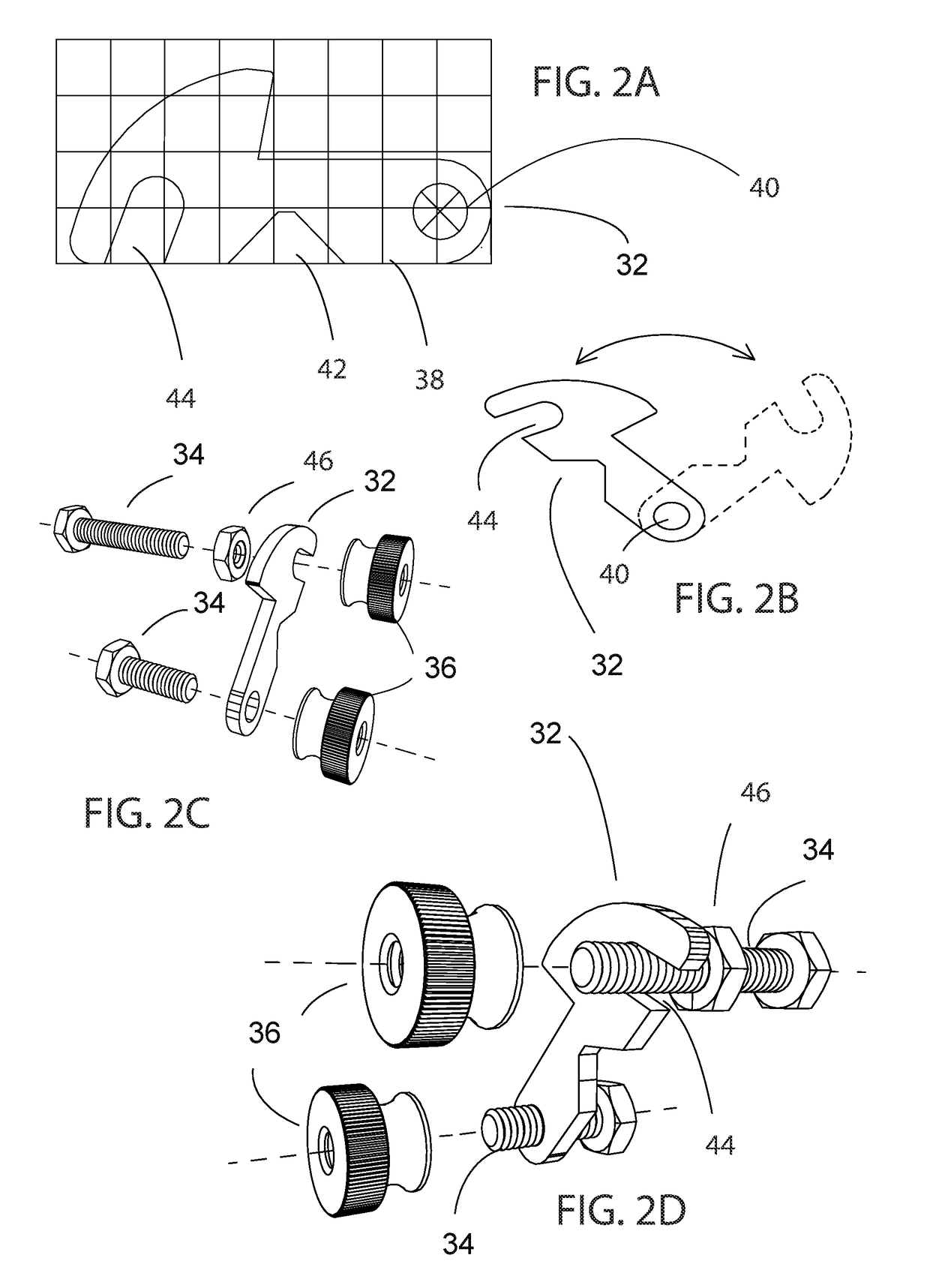

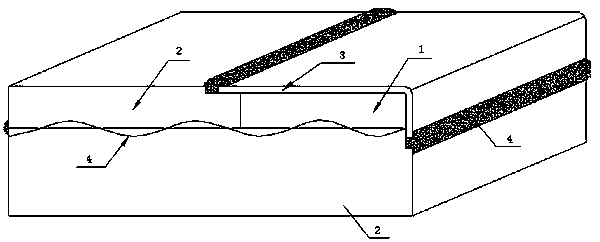

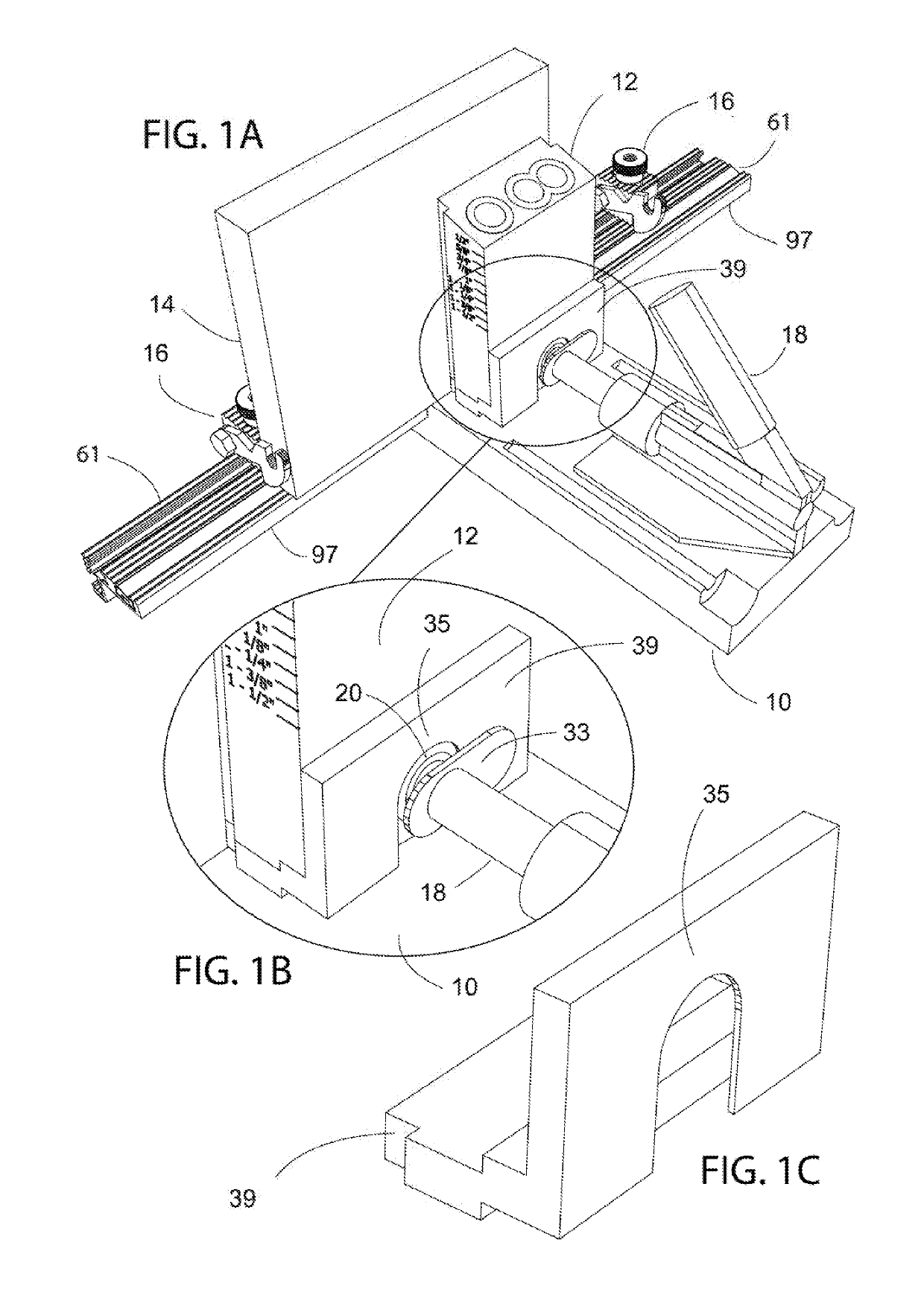

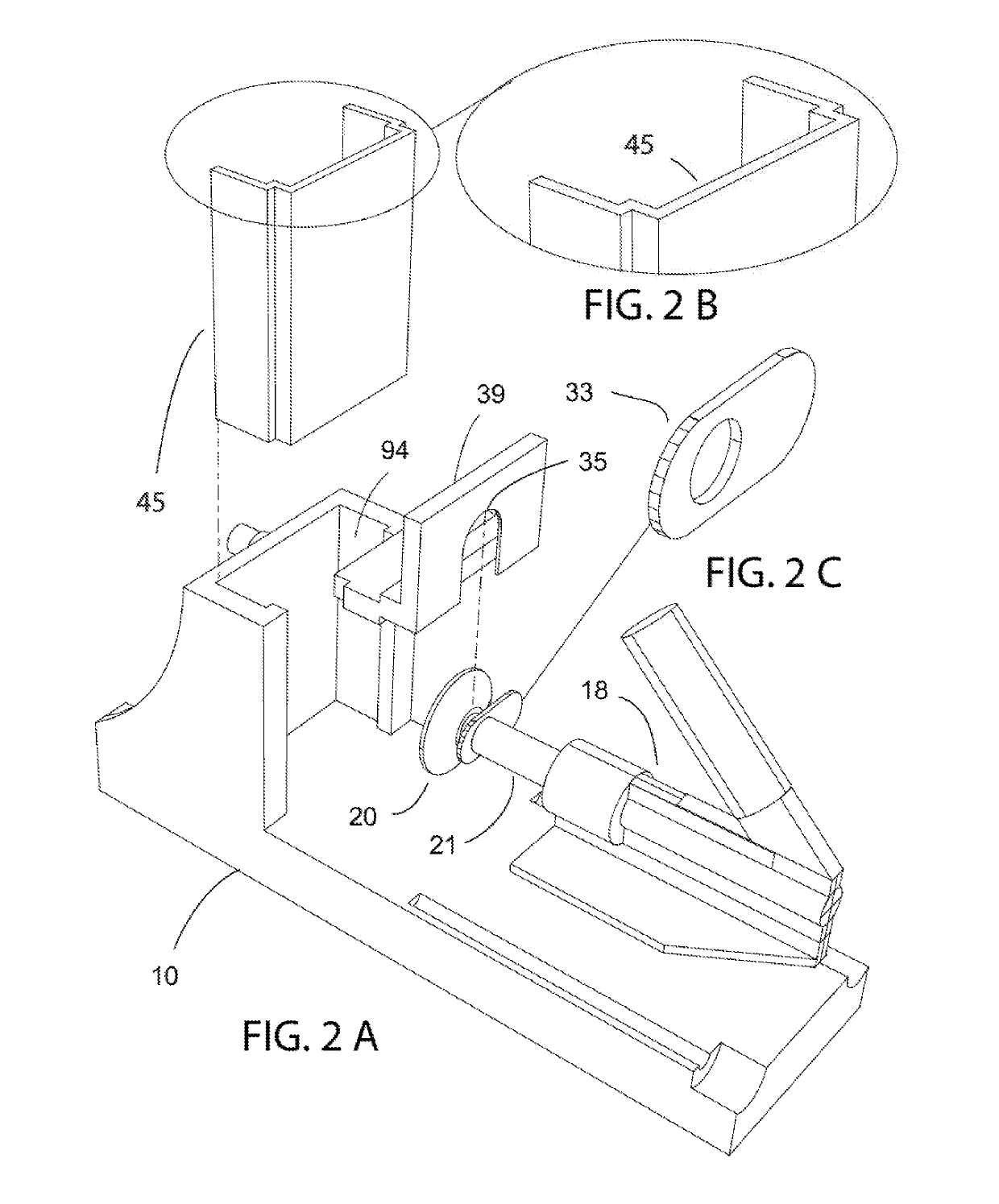

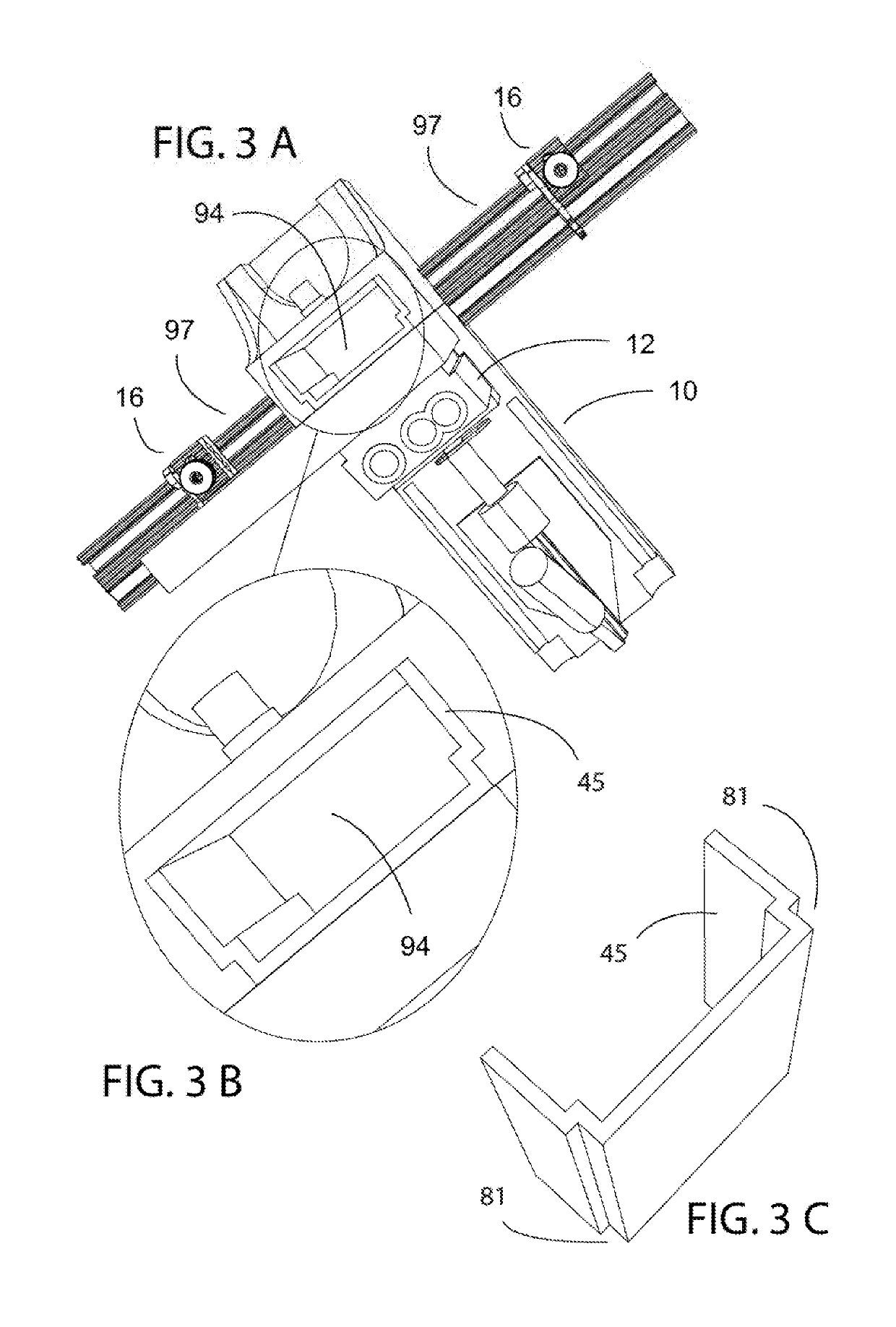

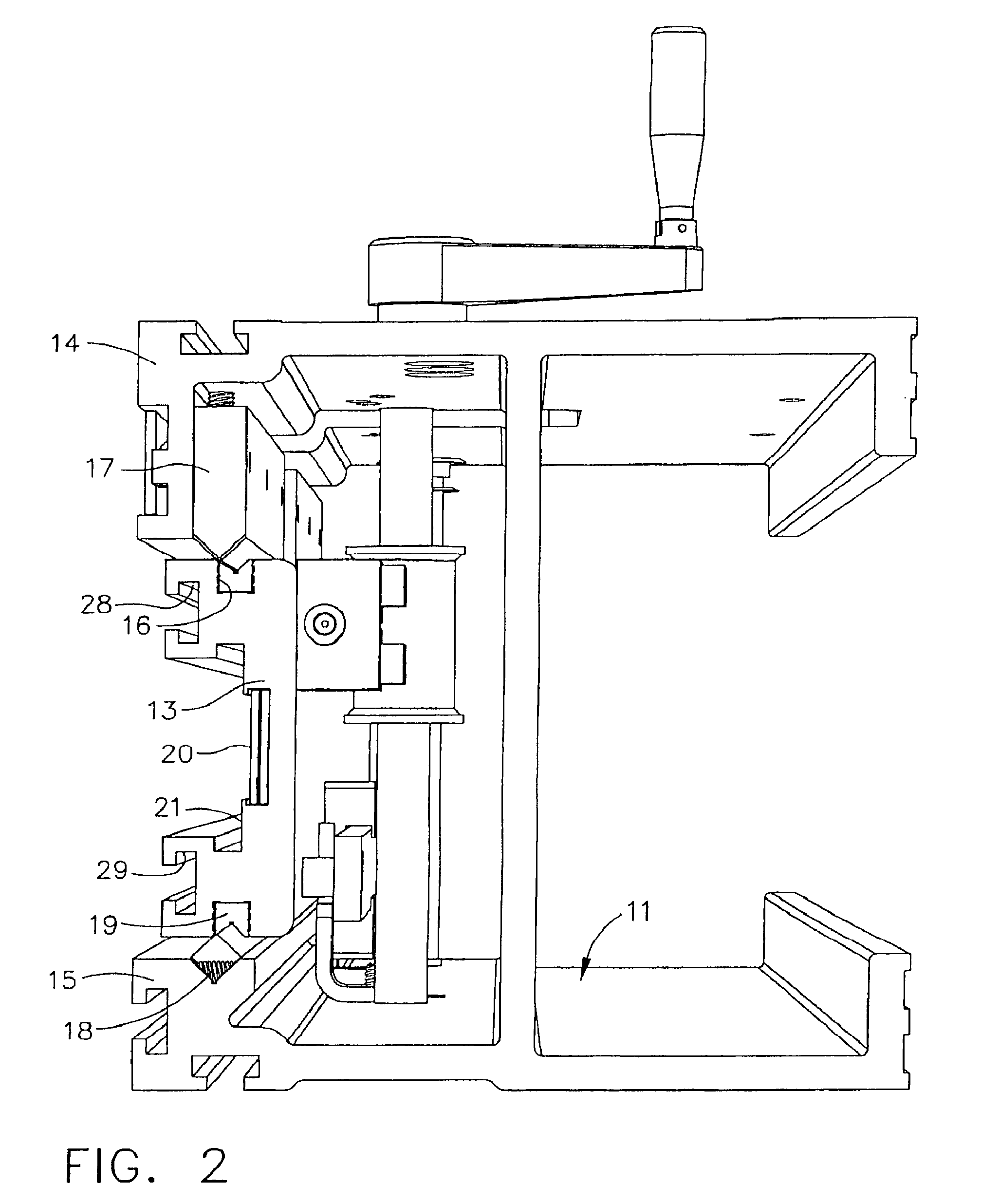

Woodworking machinery jig and fixture system

A woodworking machinery jig and fixture system includes a track which is or may be attached to a fence, a convex-concave curved flip stop and a base which mounts the stop to the track. The stop has a projecting portion which penetrates the plane of the fence so the stop isn't lifted by the point of a mitered board. The stop also has a lower convex surface which faces the work support surface and curves up at both ends. The top leg of the stop is concave toward the fence to allow clearance for a zero-clearance board and make the stop adaptable to different track and fence configurations. The base has opposite sides of different widths bordered by steps on one side and a ramp on the other side so the base can be used in a large range of T-track slot widths. The arm mounting hole of the base is offset from the base mounting so as to provide an offset to accommodate a ¾″ zero clearance board by turning the base a half turn relative to the slot. A two slot track is provided in which one of the slots can mount a sliding measurement tape or a base, and the other slot can also mount a base. In another track, a sidewall flange is provided which can be filed to accurately fit into a miter gauge slot of a cutting tool table.

Owner:KREG ENTERPRISES

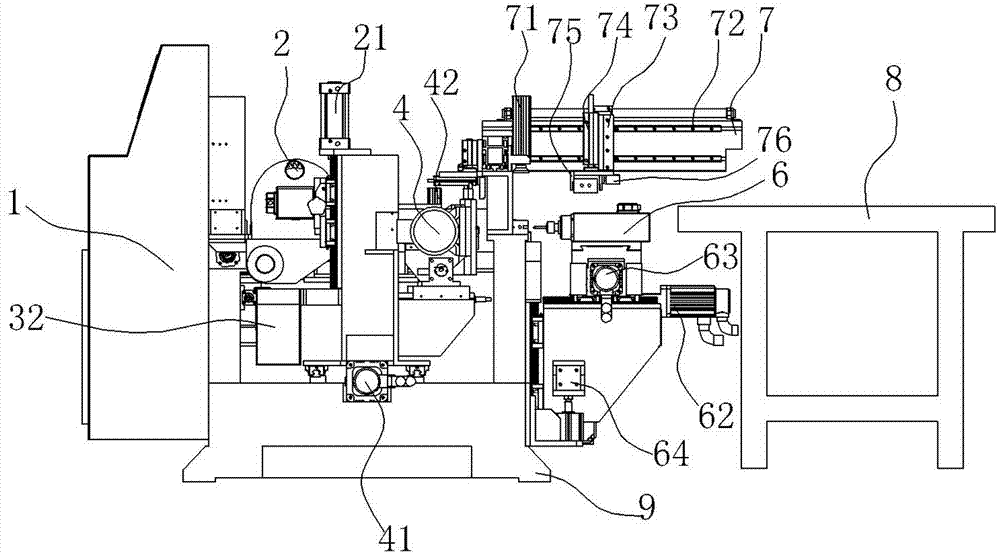

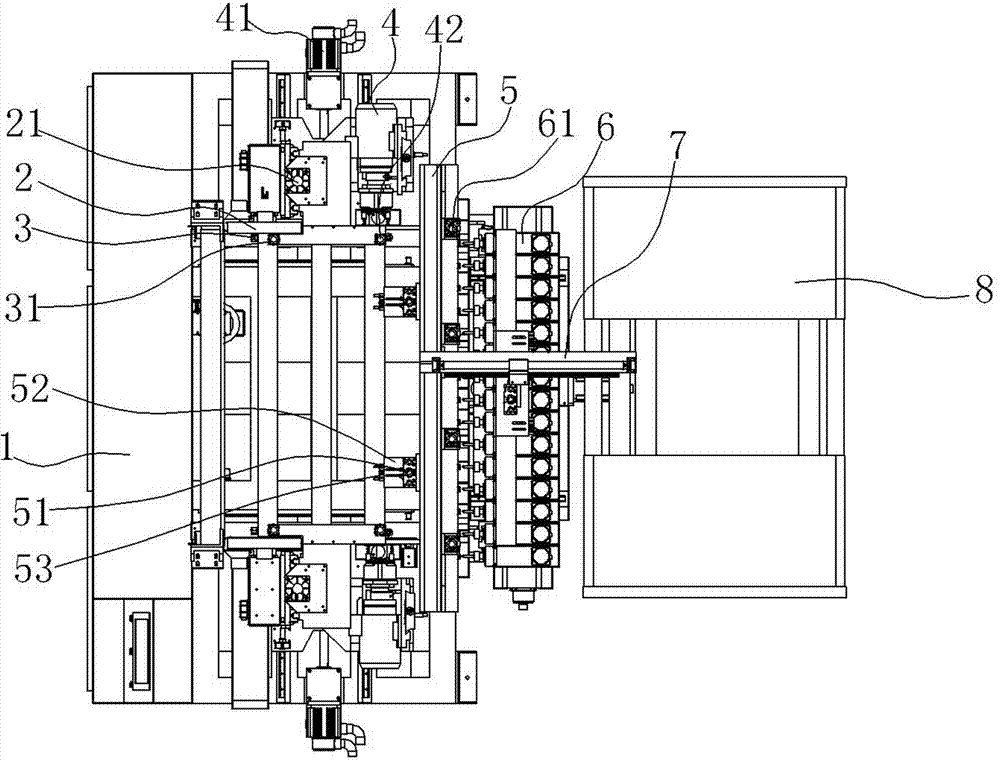

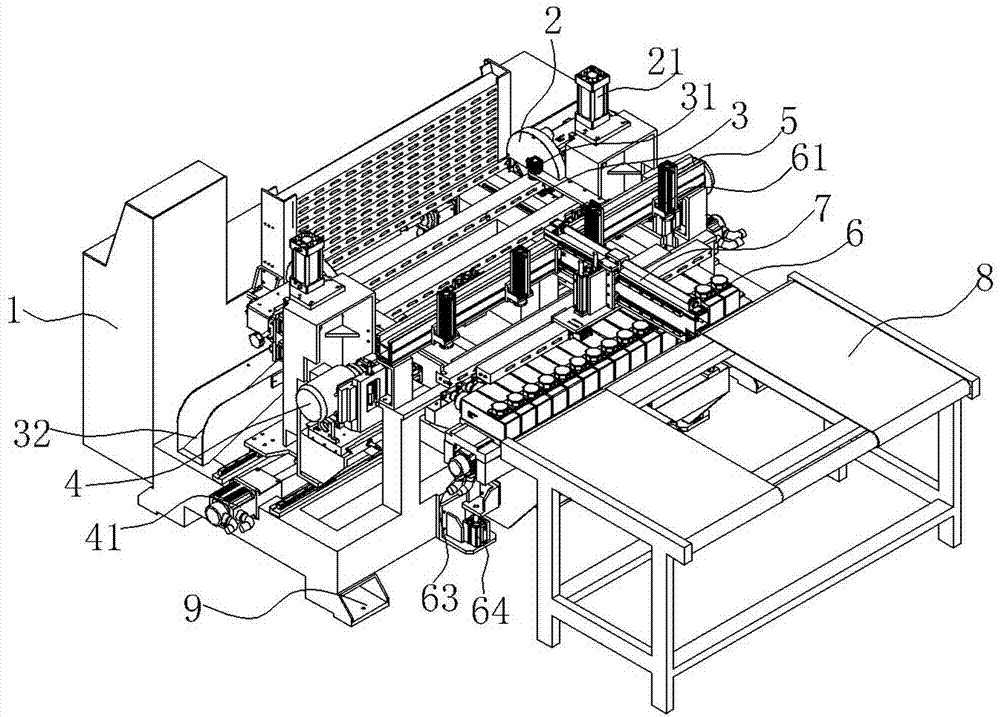

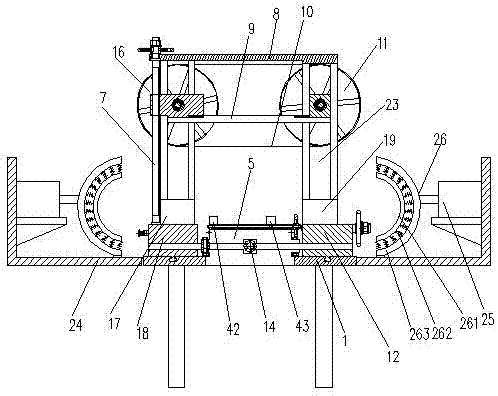

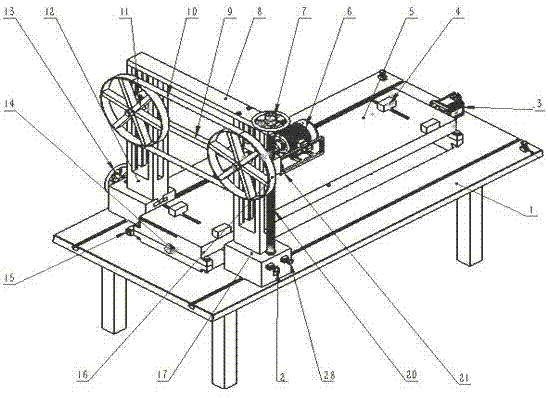

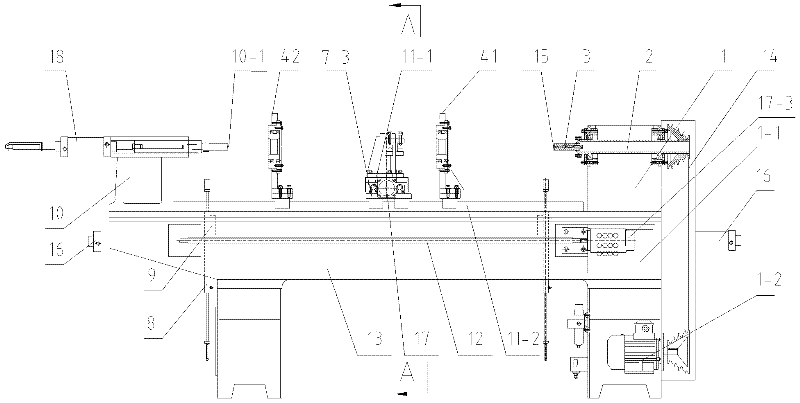

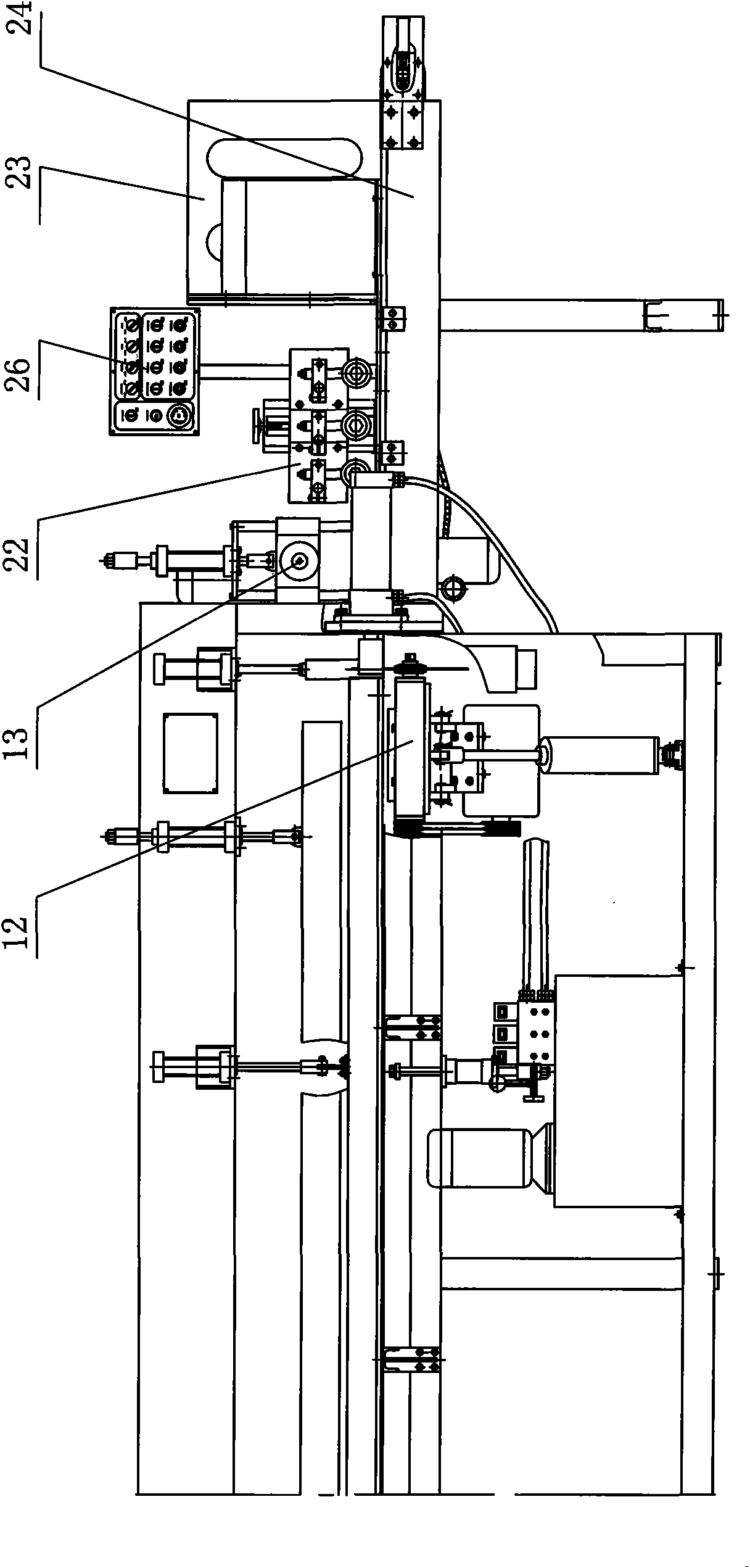

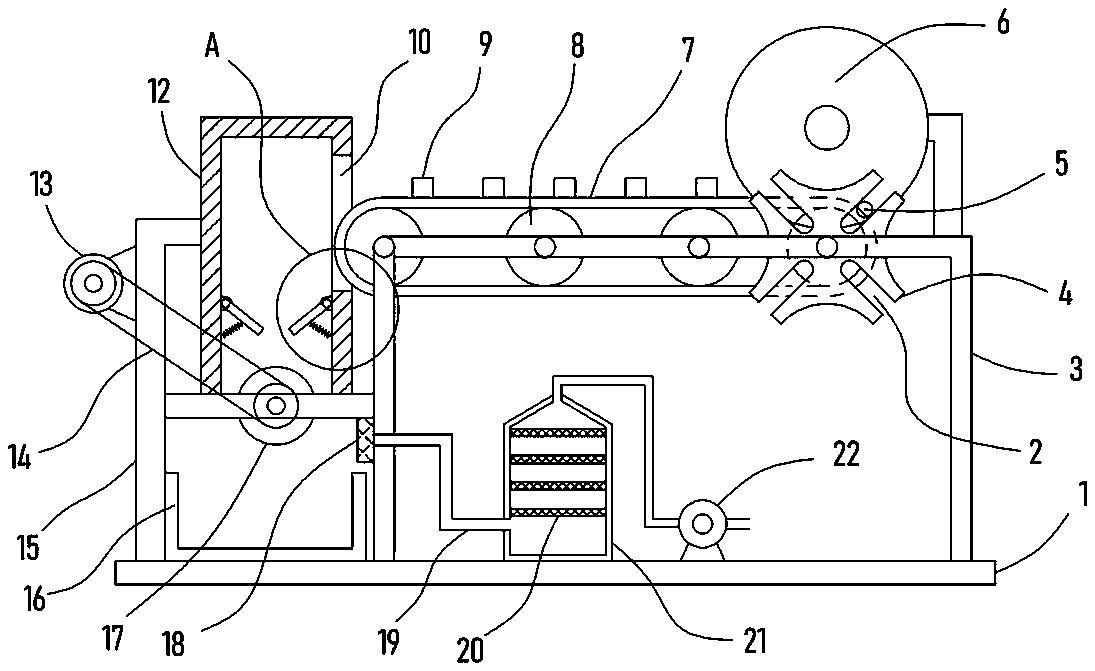

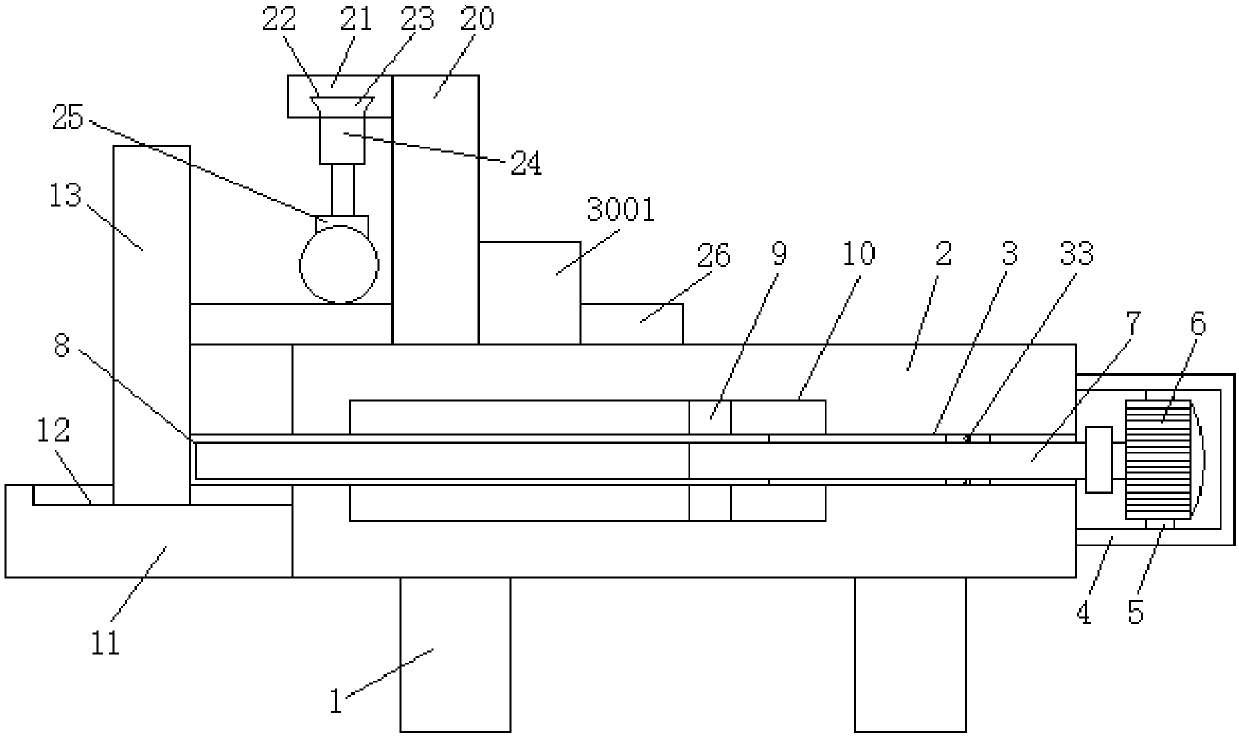

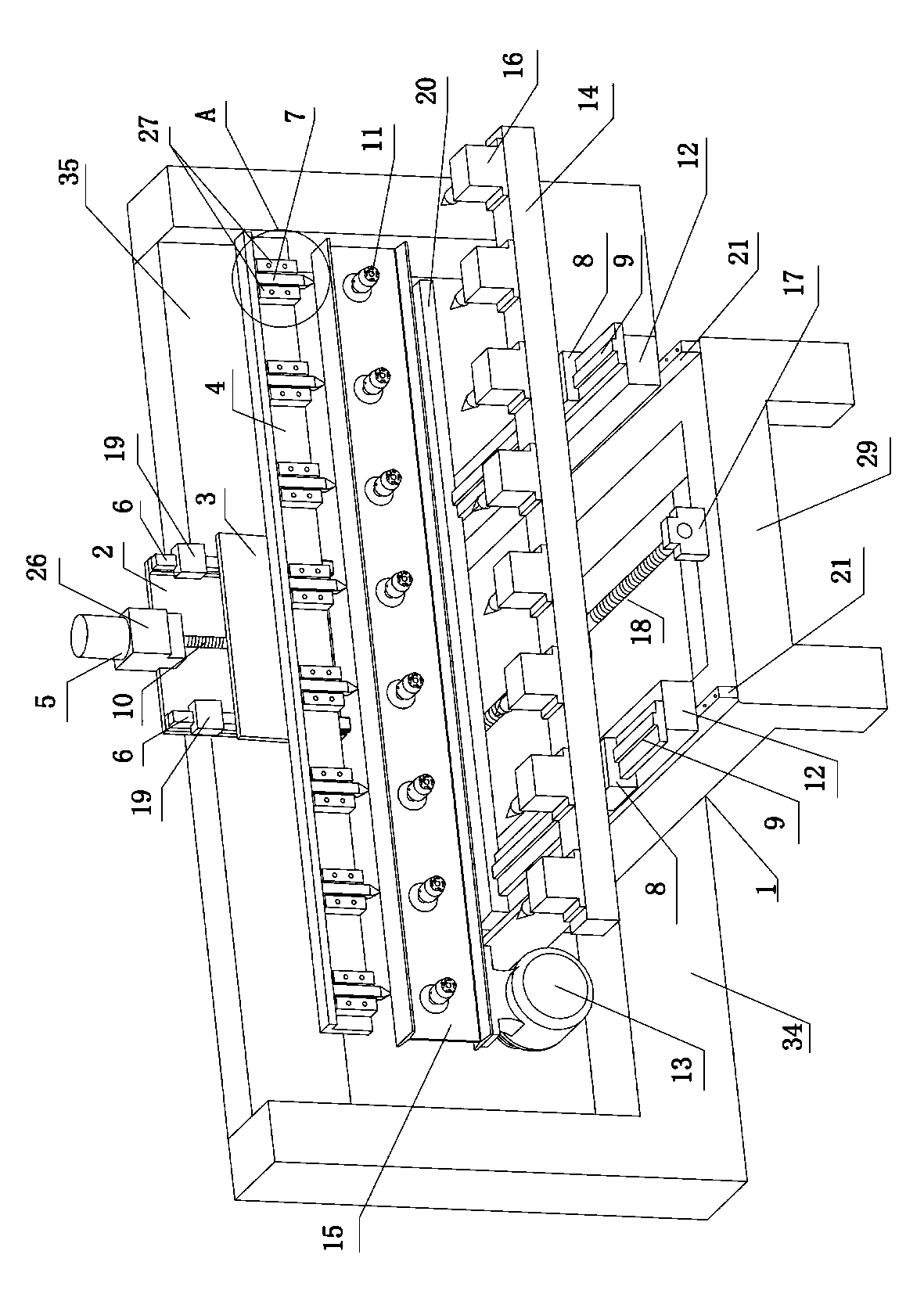

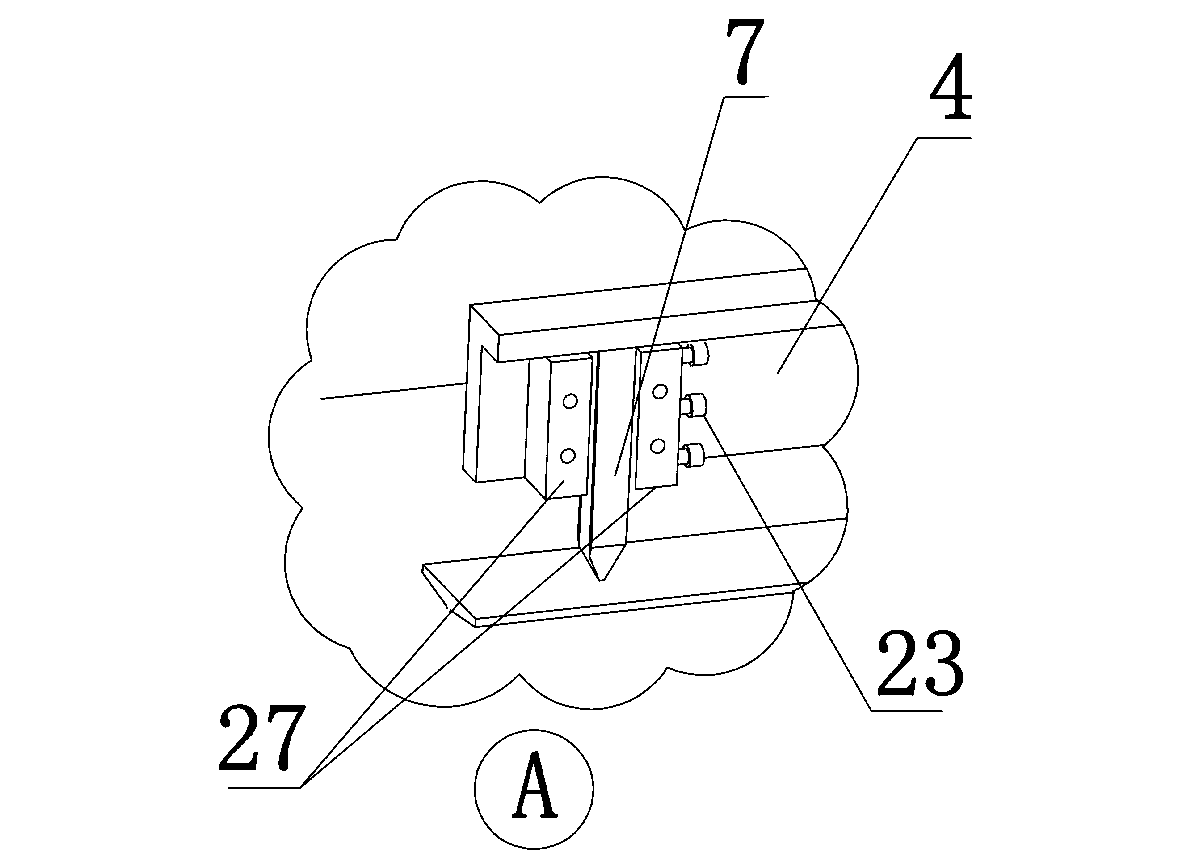

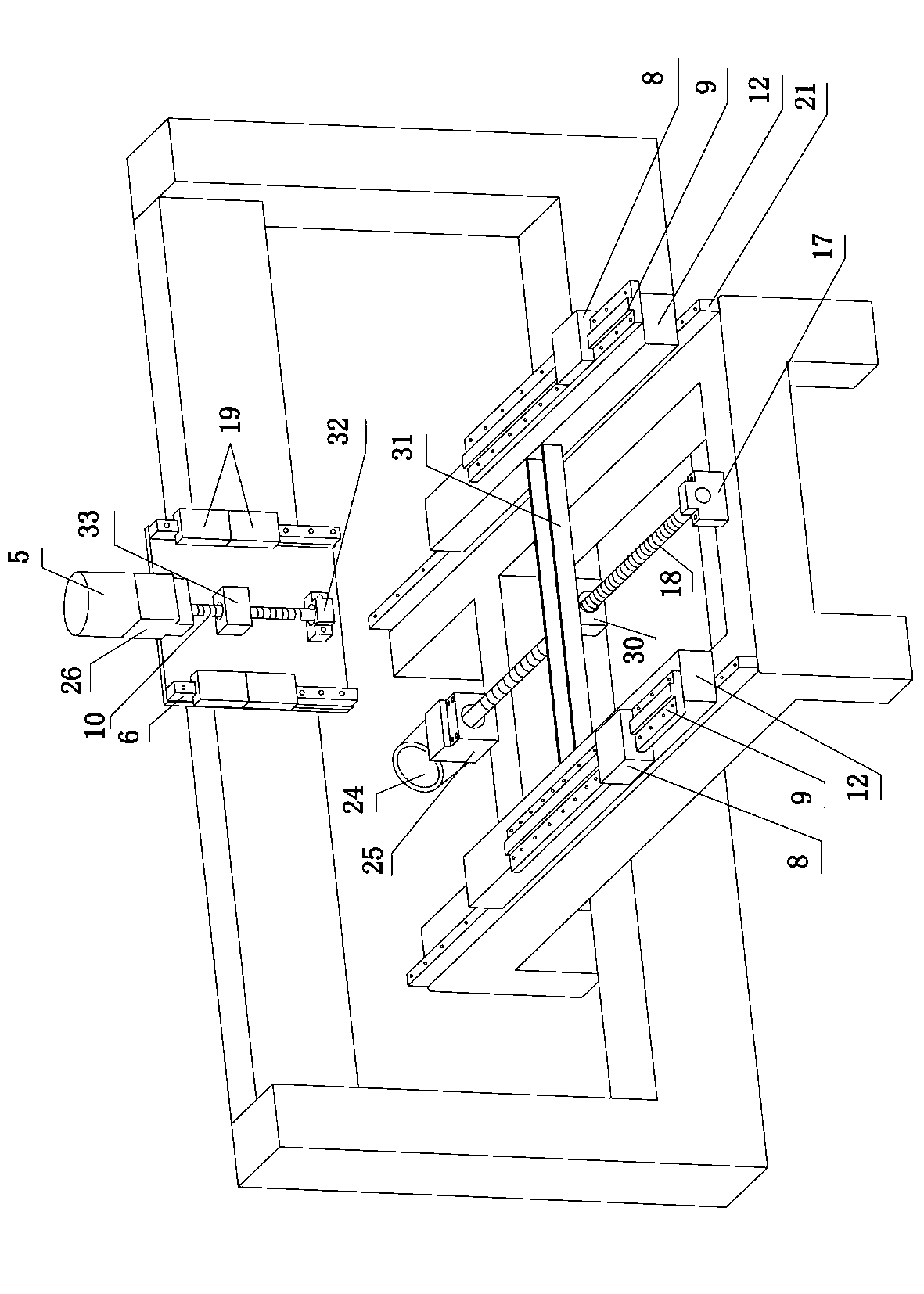

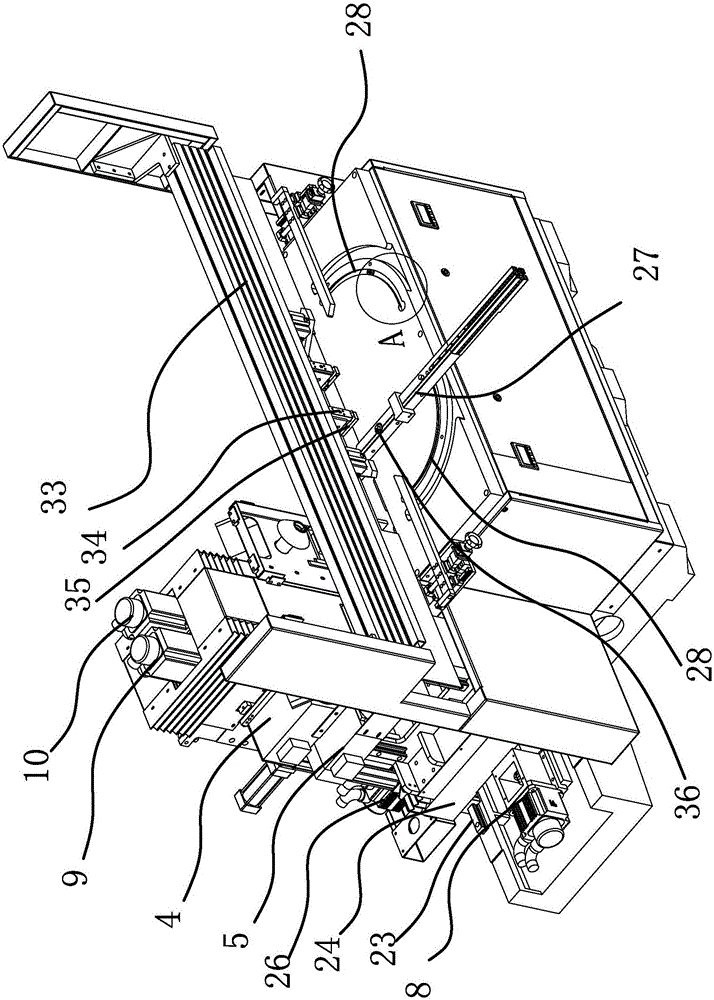

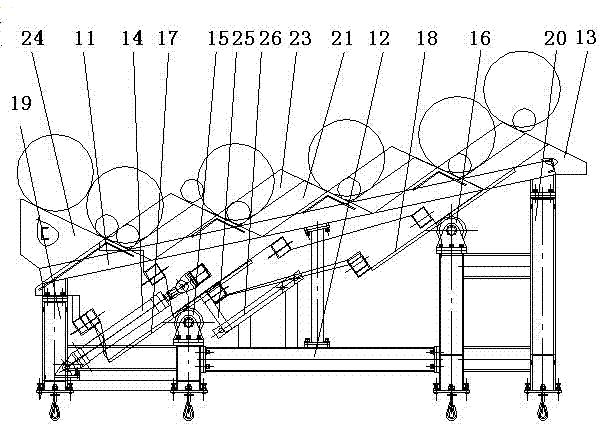

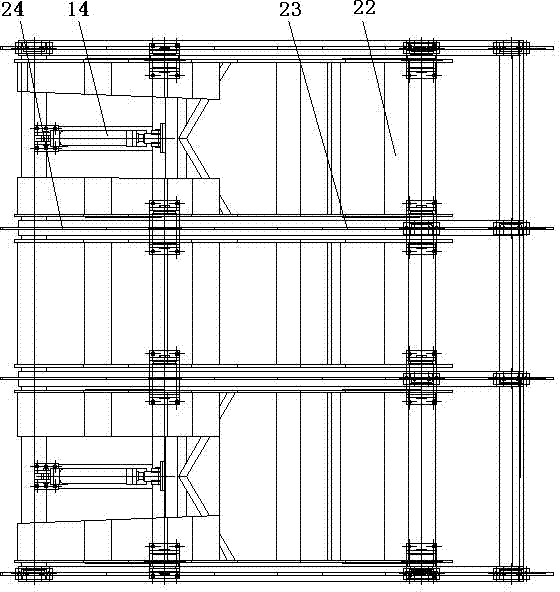

Automatic woodworking machine

InactiveCN103481335AImprove machining accuracyHigh degree of automationMulti-purpose machinesWoodworking machineServomotor

The invention provides an automatic woodworking machine, belongs to the technical field of woodworking machines, and solves the problems that a conventional woodworking machine is not high in processing efficiency and relatively low in product precision. The automatic woodworking machine comprises a machine frame, wherein a workpiece conveying mechanism is arranged on the machine frame; a feed hopper is arranged at the front end of the conveying mechanism; a cutting mechanism, a drilling mechanism and a groove milling mechanism are also arranged on the machine frame; the cutting mechanism comprises power heads respectively arranged at two ends of the machine frame, saw blades arranged on the output shafts of the power heads and lifting air cylinders for driving the saw blades to move up and down. According to the invention, a PLC system is adopted to control a servomotor, the cylinders, the power heads and other electric appliance mechanisms to act together, so that flush cutting, end-part drilling, side-surface groove milling and the like of sheet metal can be realized through one-time positioning, and the machining precision is high; end products can be grabbed and placed on a conveying line through an automatic reclaiming mechanism after the processing is finished, so that the degree of automation and the processing efficiency are high.

Owner:TAIZHOU EVOK MASCH CO LTD

Woodworking machinery stop and track system

Owner:KREG ENTERPRISES

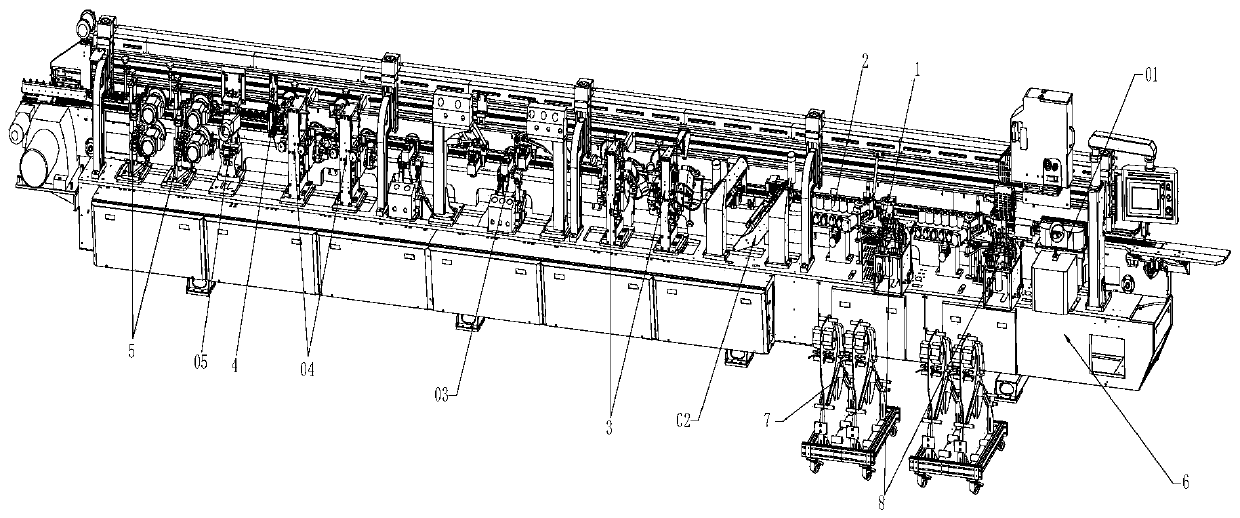

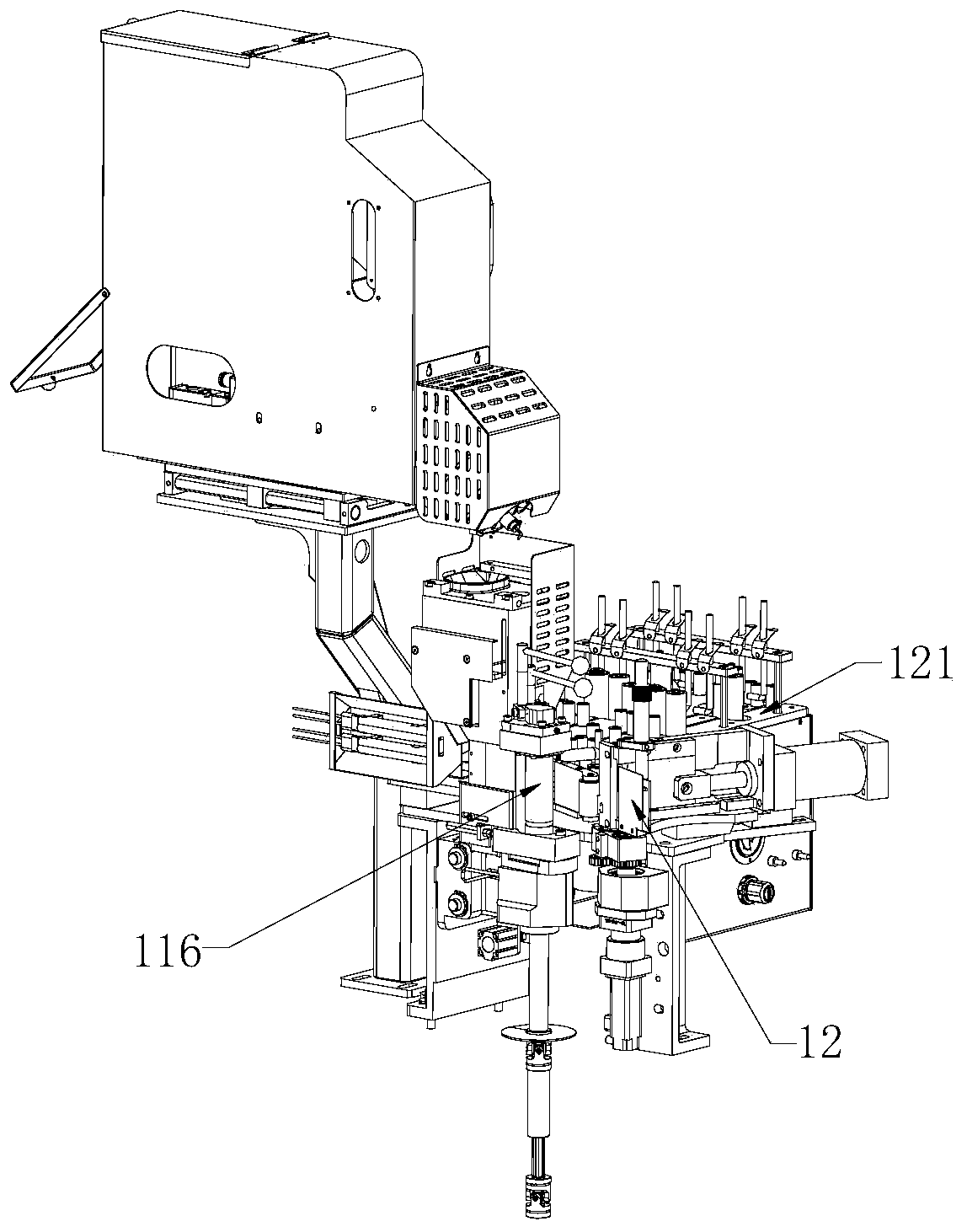

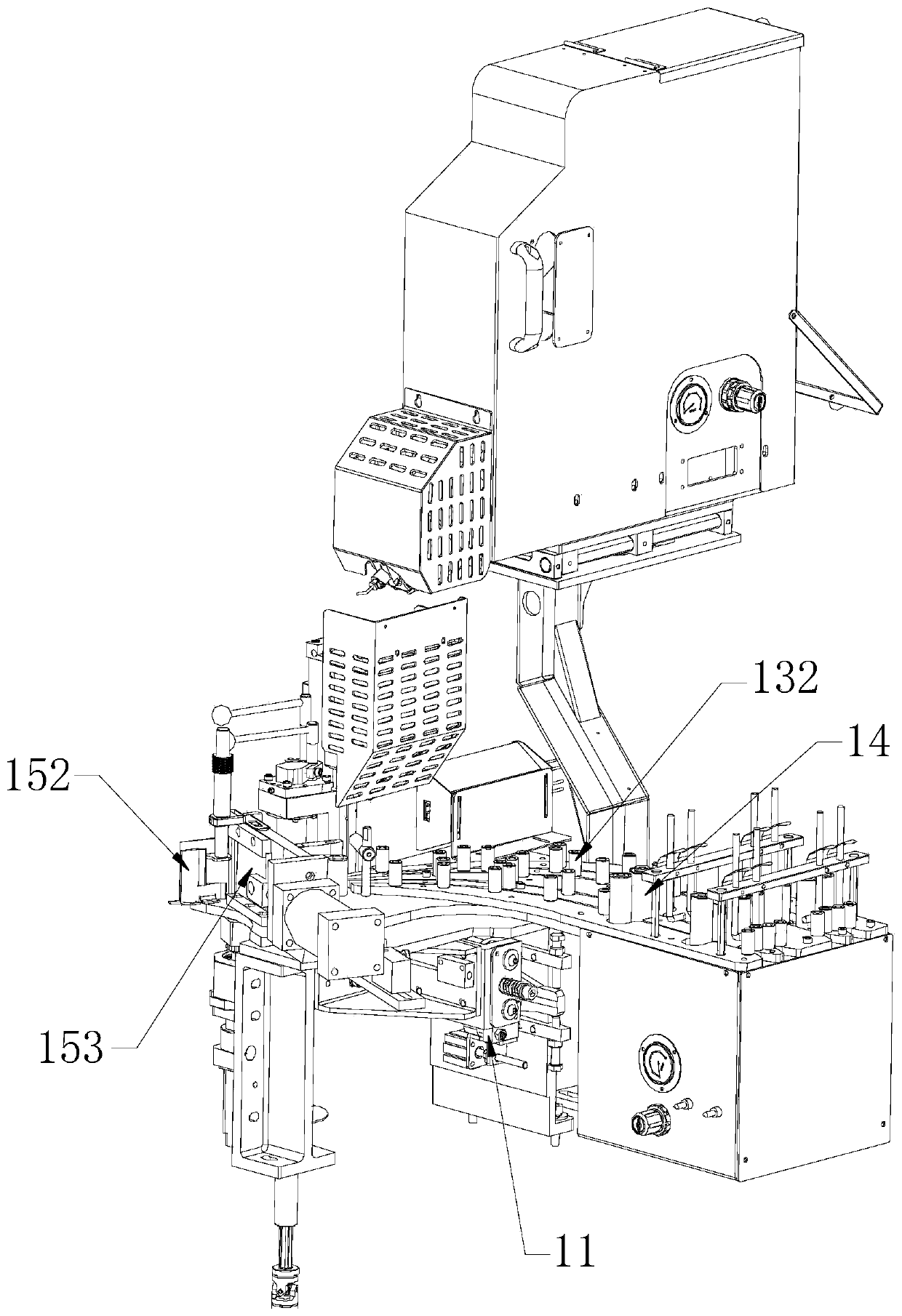

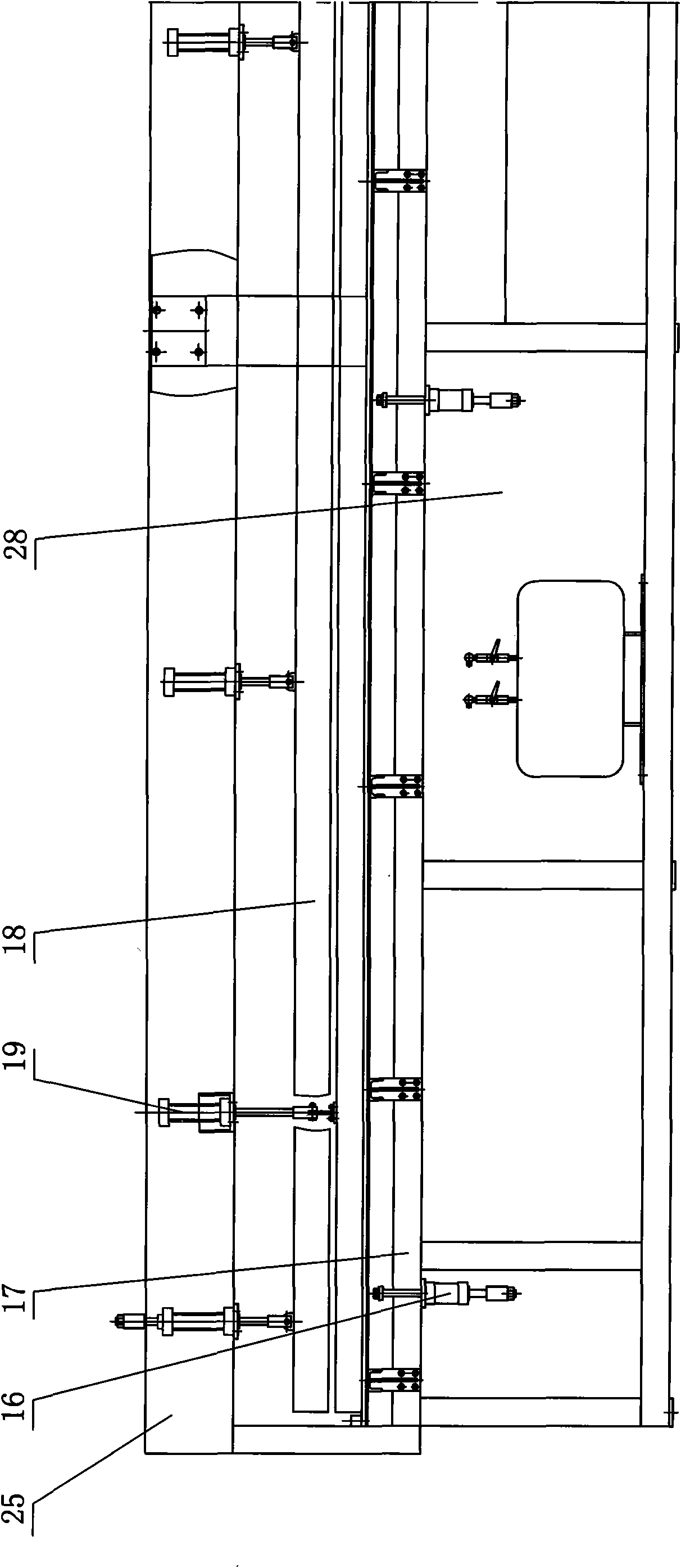

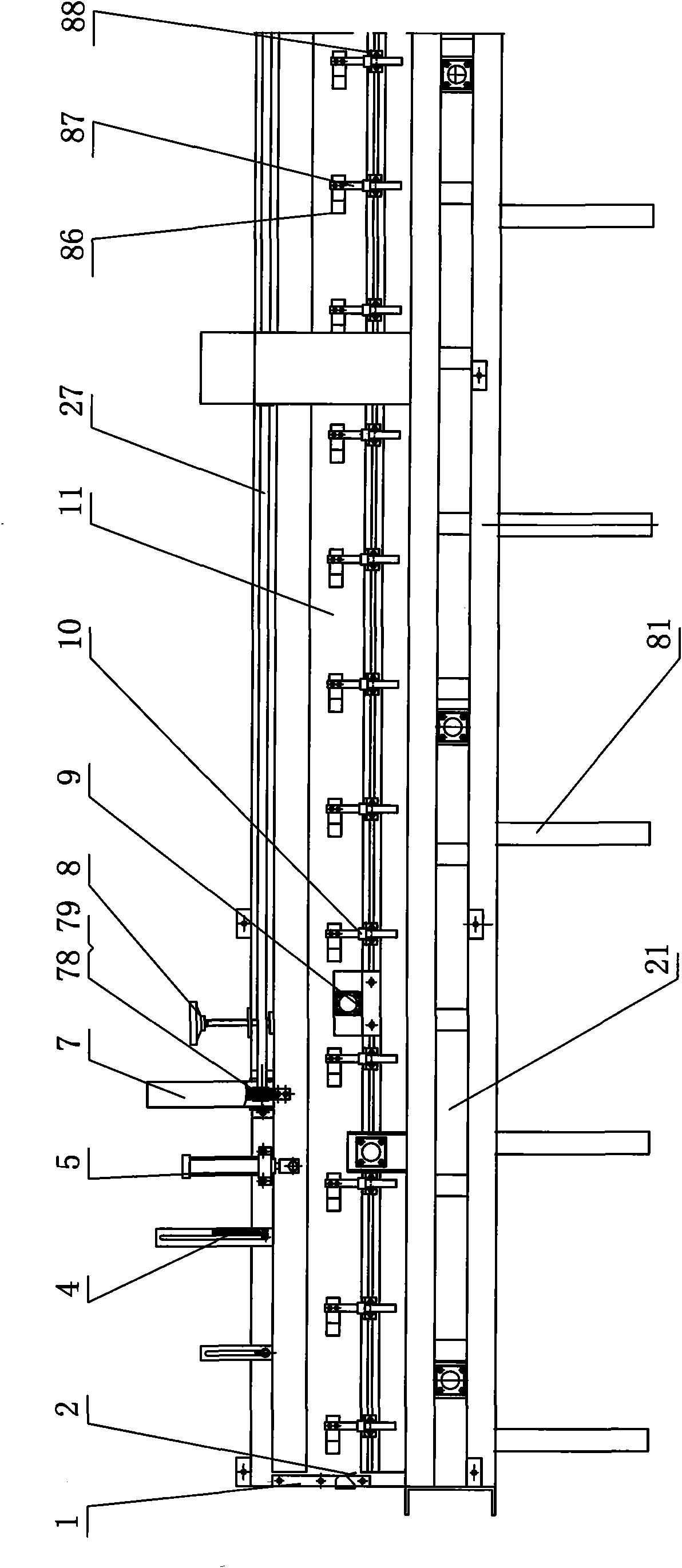

Double-station automatic switching edge-sealing machine

ActiveCN110466036AEasy maintenanceEasy to replaceWood working apparatusDomestic articlesEngineeringWood plank

The invention relates to the technical field of woodworking machinery, in particular to a double-station automatic switching edge-sealing machine. The double-station automatic switching edge-sealing machine comprises a panel conveying frame for transferring external plates. A pre-milling and trimming mechanism, two groups of edge-sealing band gluing fitting mechanisms, an edge-sealing band jump-butt rough trimming mechanism, two groups of edge-sealing band edge finishing trimming mechanisms, a profile tracking and edge-trimming mechanism, two groups of automatic edge-scraping mechanisms, an edge-sealing band wired mechanism, an edge-sealing band cleaning mechanism and two groups of edge-sealing band polishing mechanisms are arranged in turn in the moving direction of the plates carried bythe panel conveying frame. According to the double-station automatic switching edge-sealing machine, a double-station automatic switching mode is adopted to realize the conveying of the panel conveying frame without stopping conveying of the plates, so that the edge sealing of edge-sealing bands with different specifications is realized, the production efficiency is greatly improved, and the laborcost is reduced.

Owner:NANXING MACHINERY CO LTD

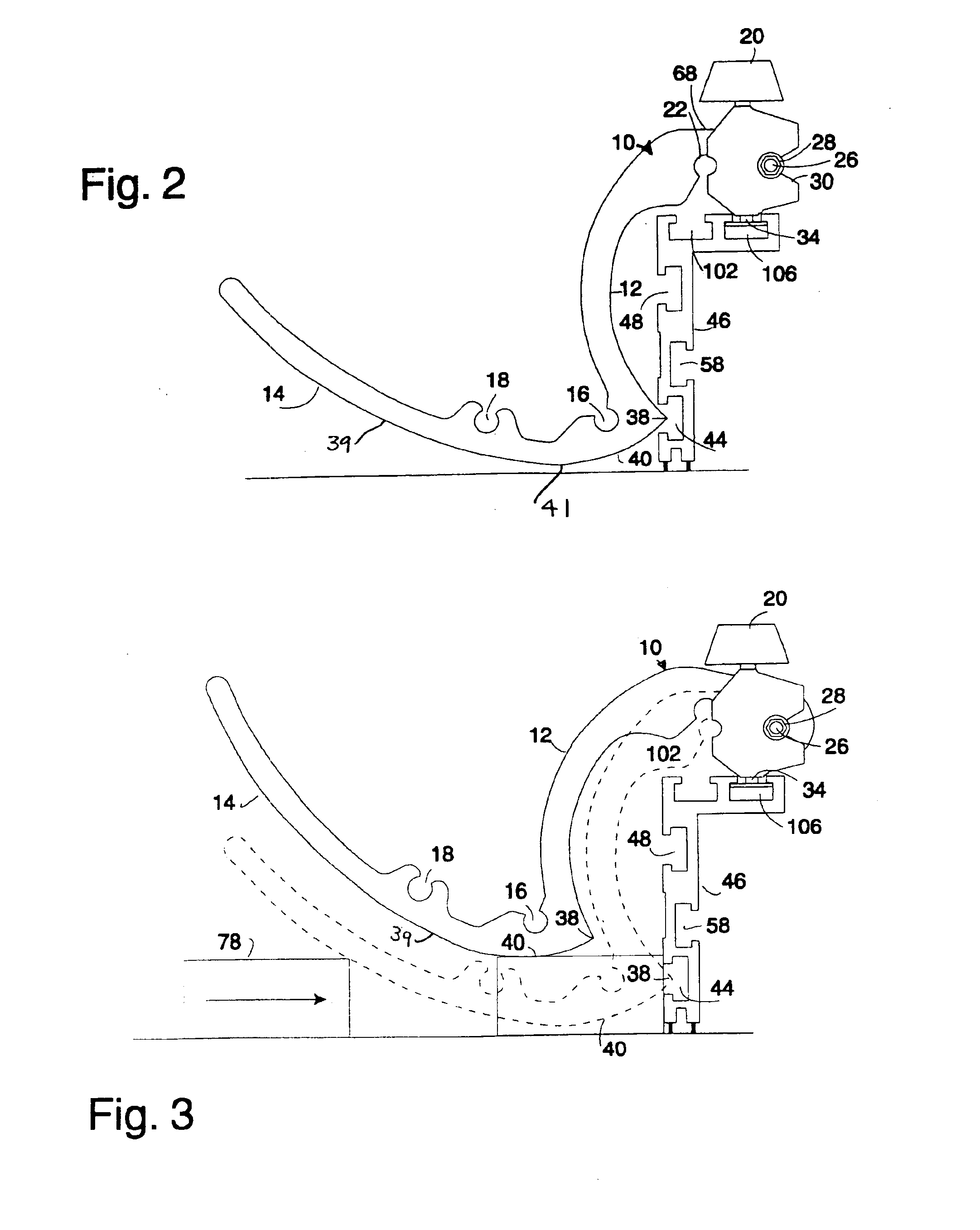

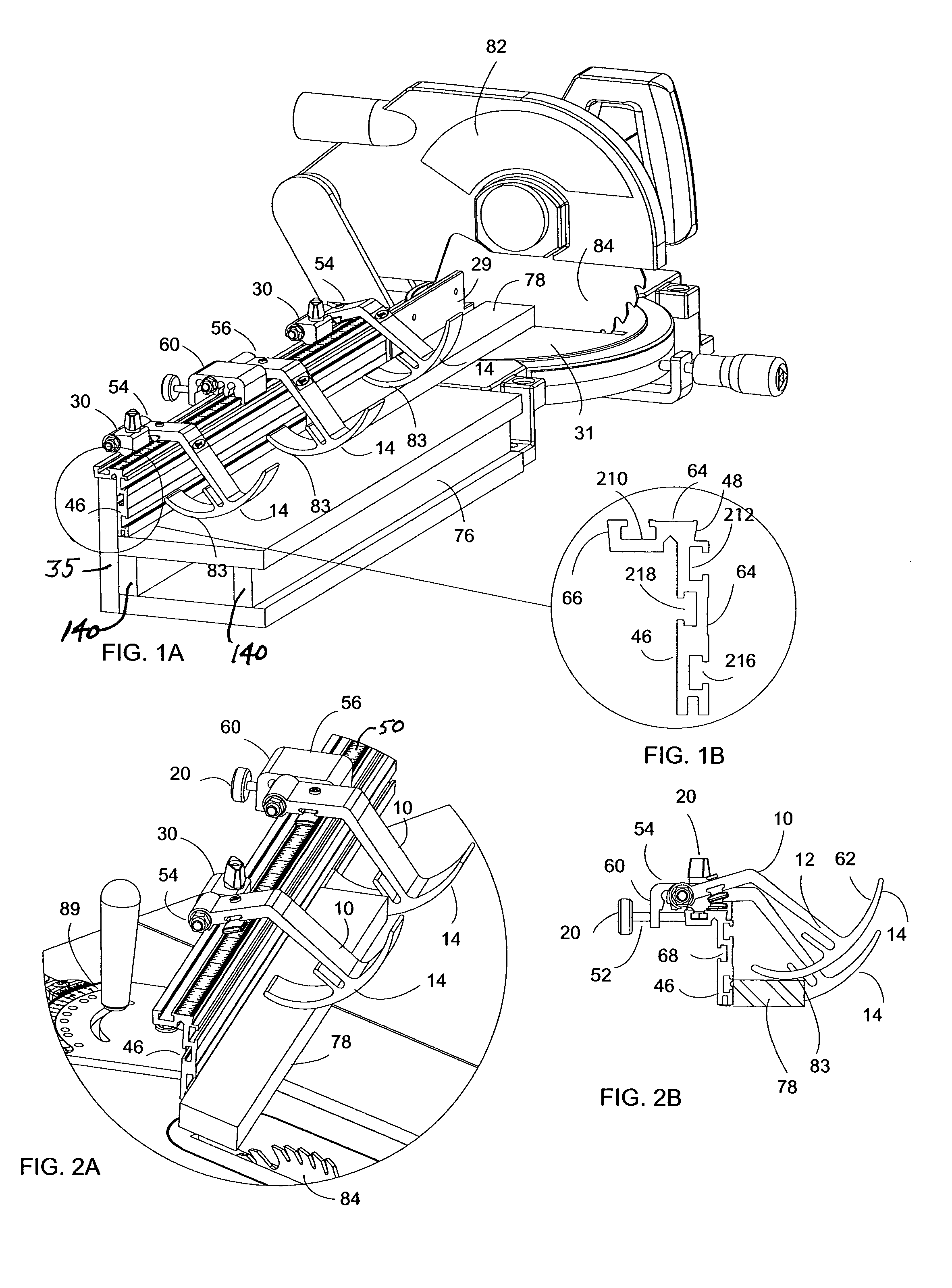

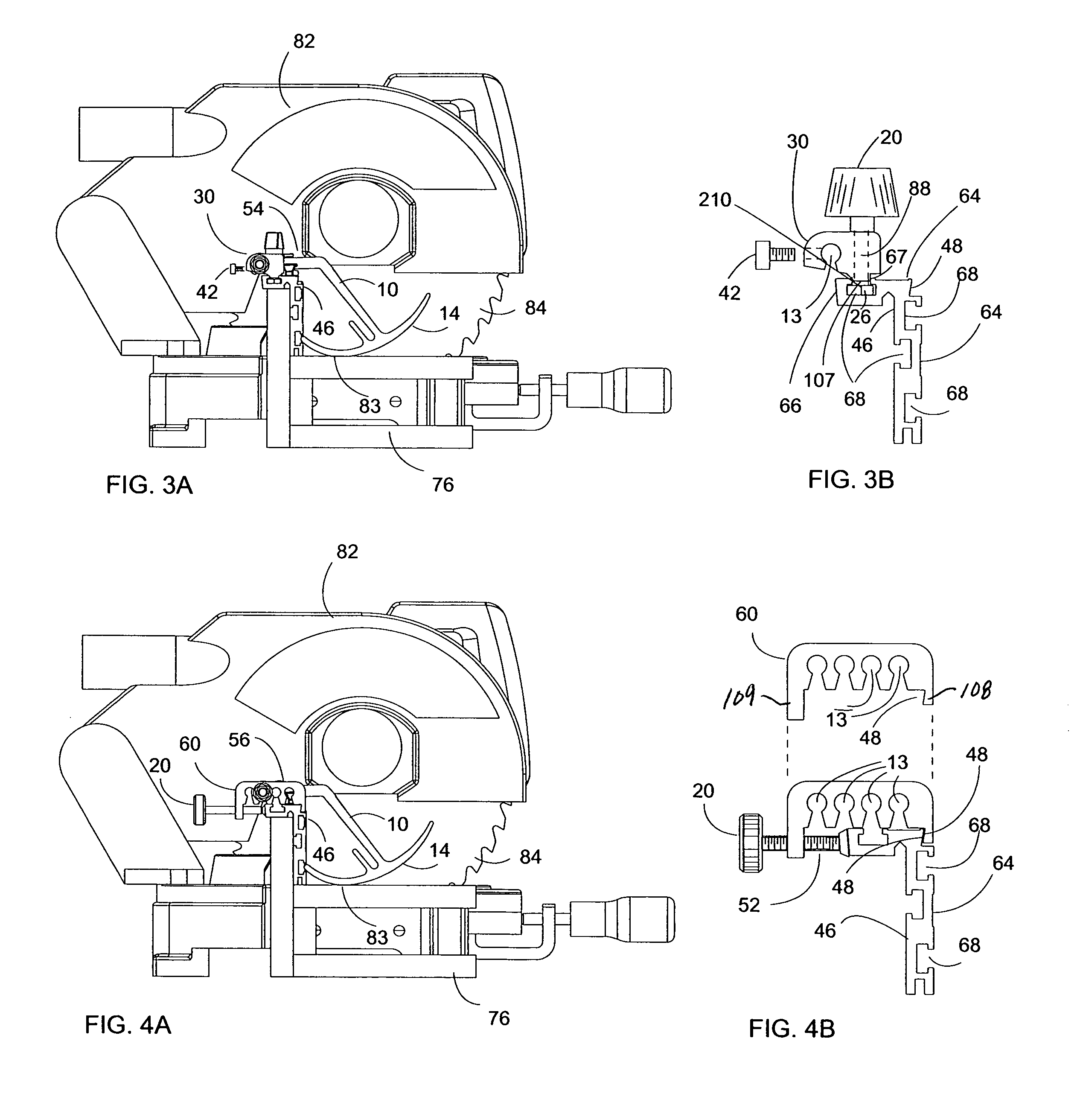

Woodworking Machinery Jig and Fixture System

ActiveUS20180185930A1Drilling/boring measurement devicesMetal working apparatusEngineeringWoodworking machinery

Jigs and fixtures for aligning, guiding, and / or holding a workpiece on woodworking machinery during a woodworking operation are described, as well as methods of making, modifying, and using jigs and fixtures.

Owner:DUGINSKE MARK A

Improved log sawing machine

PendingCN107336286AOptimize the installation structureHigh precisionGripping devicesClamping devicesReciprocating motionSmall footprint

The invention discloses an improved log sawing machine, which comprises an operating desk, a saw bench and a saw blade device. The saw bench is arranged on the operating desk. The saw blade device is connected with the operating desk in a sliding mode. The saw blade device is arranged on the saw bench. The saw bench is provided with at least one clamping device of magnetic type. The operating desk is provided with at least two adjustable clamping devices. The log sawing machine has the advantages of being compact in structure, small in occupied area, achievable in adopting an ordinary feed screw nut pair for driving the reciprocating motion of the saw blade device, achievable in adopting a travel switch for simple control, high in cutting efficiency, low in labor intensity and convenient to operate. Furthermore, the improved log sawing machine is a practical woodworking machinery product of mechanical and electrical integration, and has a certain promotion value; the clamping device has a good improved effect, thereby being suitable for clamping logs of different sizes.

Owner:TAIZHOU POLYTECHNIC COLLEGE

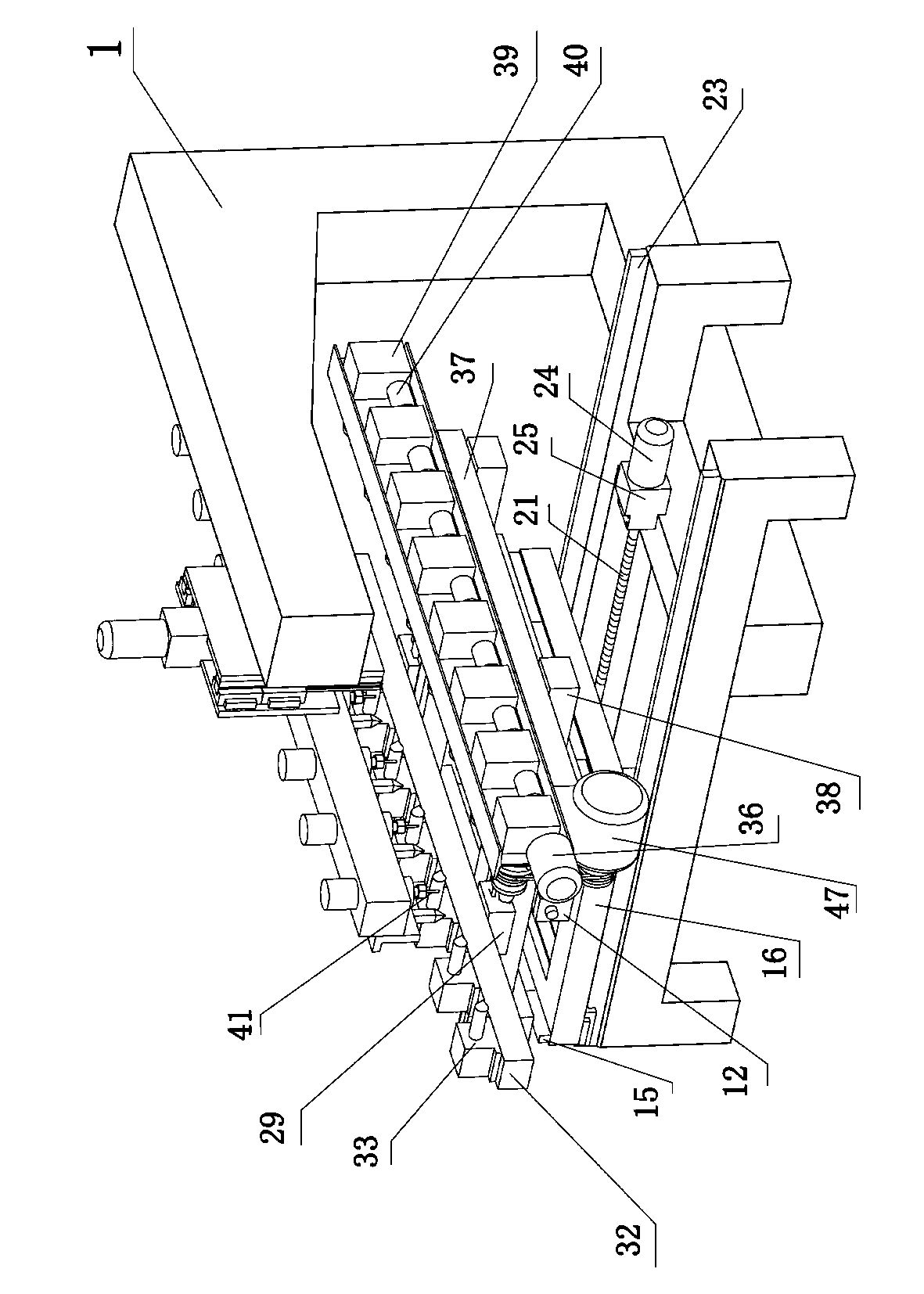

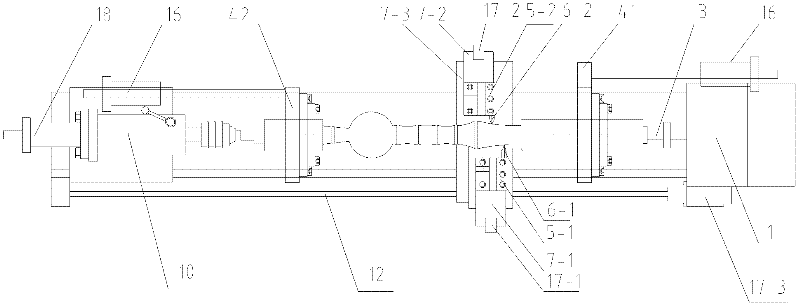

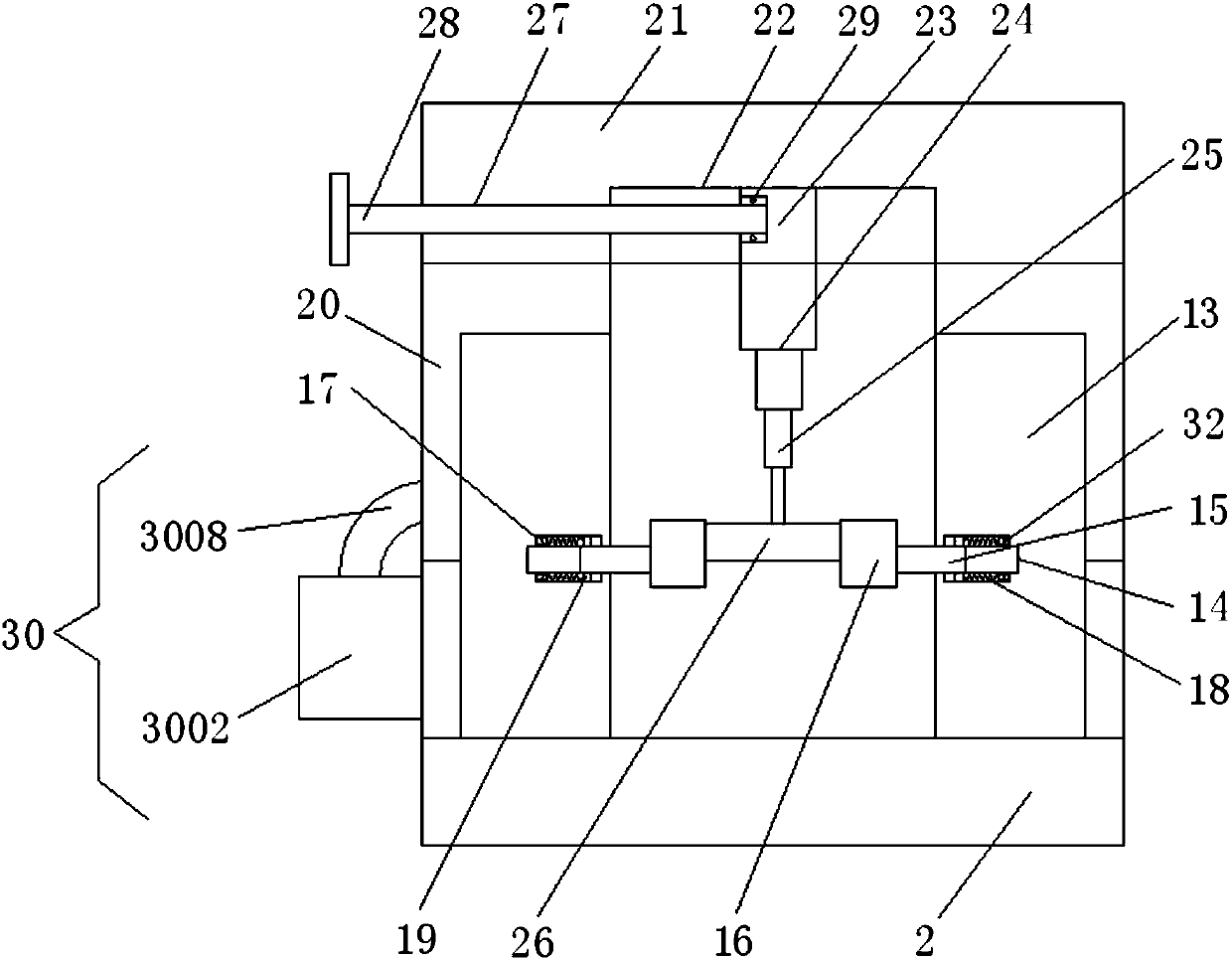

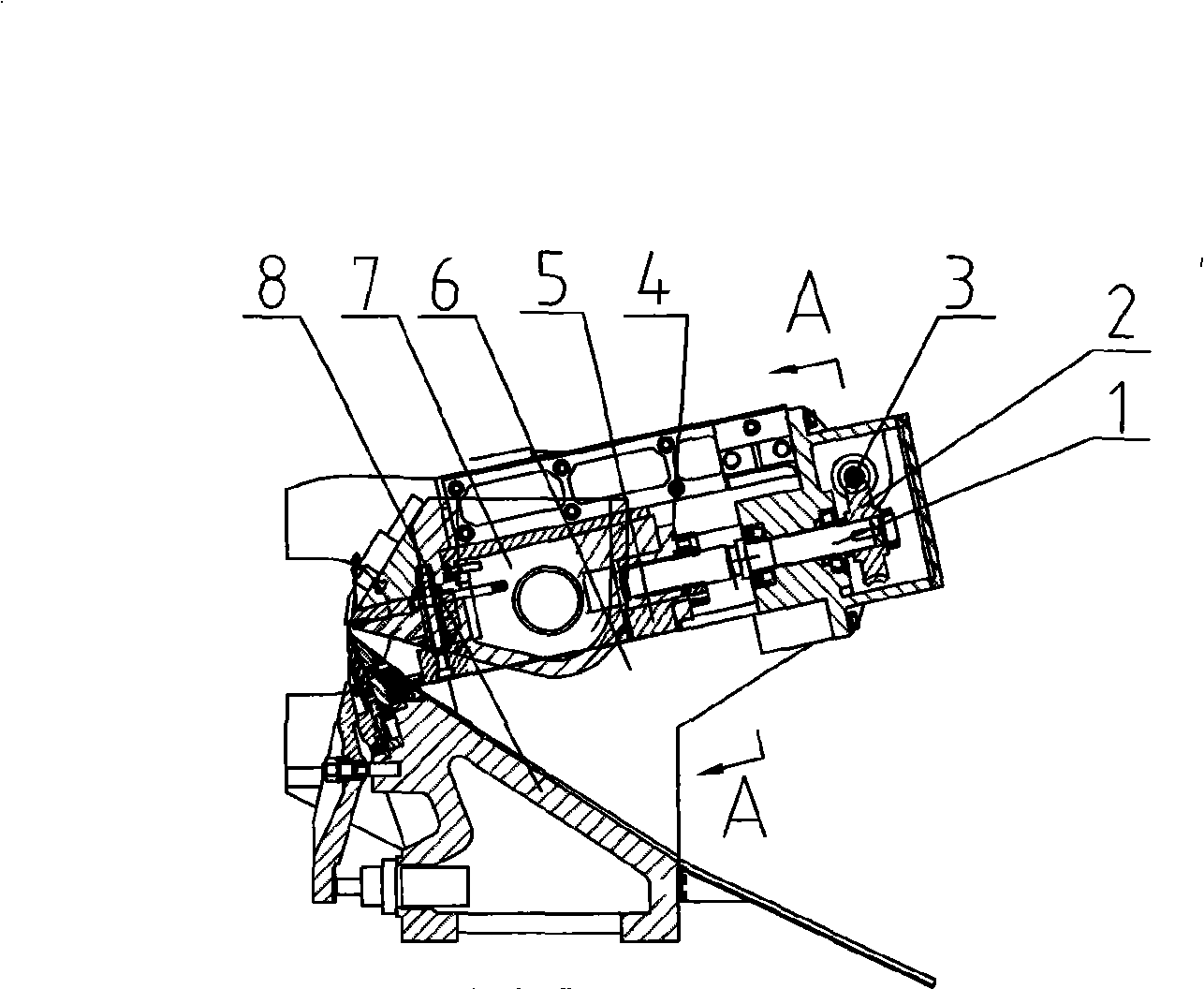

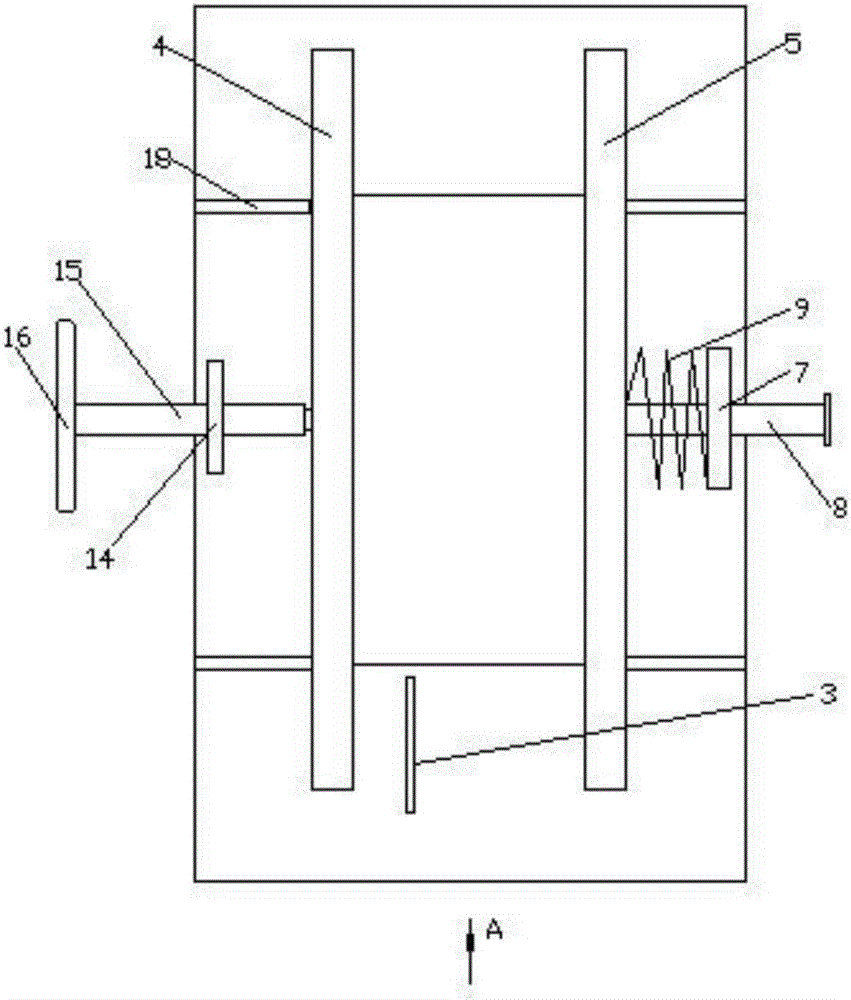

Numerical control wood working lathe and carving integrated machine

ActiveCN102699961AImprove machining accuracyReduce labor costsWood-turning machinesModel makingNumerical controlElectric machinery

The invention relates to a numerical control wood working lathe and carving integrated machine, and belongs to the technical field of wood-working machinery. The numerical control wood working lathe and carving integrated machine comprise a machine frame, a cross beam, a vertical driving mechanism, a cutter device, a horizontal driving mechanism, a vertical driving mechanism and a workpiece clamping driving mechanism. The cross beam is arranged on the upper part of the machine frame, and the vertical driving mechanism is arranged on the cross beam. The vertical driving mechanism comprises a first driving motor, a first motor fixing seat, a first block, a vertical guide rail, a first screw rod, a first connecting block, a vertical guide rail mounting board and a vertical planker. The cutter device comprises a cutter frame, a lathe tool frame, a carving cutter, a lathe tool, a lathe tool fixing plate, an adjusting screw and a motor. The vertical driving mechanism comprises a vertical worktable, a vertical guide rail, a fourth sliding block, a third driving motor, a third motor fixing seat, a third screw rod, a third connecting block and a third bearing supporting block. The horizontal driving mechanism comprises a horizontal worktable, a horizontal guide rail, a third sliding block, a second driving motor, a second motor fixing seat, a second screw rod, a second connecting block and a second bearing supporting block.

Owner:NANTONG OUKE CNC EQUIP CO LTD

a woodworking machine

InactiveCN102259355AEasy to processGuaranteed balance and stabilityWood-turning machinesElectric machineryEngineering

The invention relates to a woodworking machine tool, which belongs to the field of woodworking machinery and equipment, and comprises an interconnected headstock, a spindle, a chuck, a tool holder, a tool holder, a turning tool, a sliding plate, a feeding cylinder, a feeding rack, a tailstock, and a bed Body, guide rail, lead screw, stepping motor, wherein, the number of said tool holders is more than two, which are respectively arranged on the sliding plate; on the sliding plate; the number of the turning tool is the same as the number of the tool holder, the turning tool is arranged in a direction perpendicular to the axis of the lathe, and the tip of the turning tool is along the axis of the lathe The parallel directions are misaligned with each other. Compared with the prior art, the present invention has a novel structure and simple operation, effectively overcomes the defects of single knife and single knife holder for wood production and processing, greatly improves the processing efficiency, increases the smoothness of the finished product, and correspondingly reduces the economic cost. The invention is suitable for popularization and application in wood processing related fields.

Owner:陆卫斌

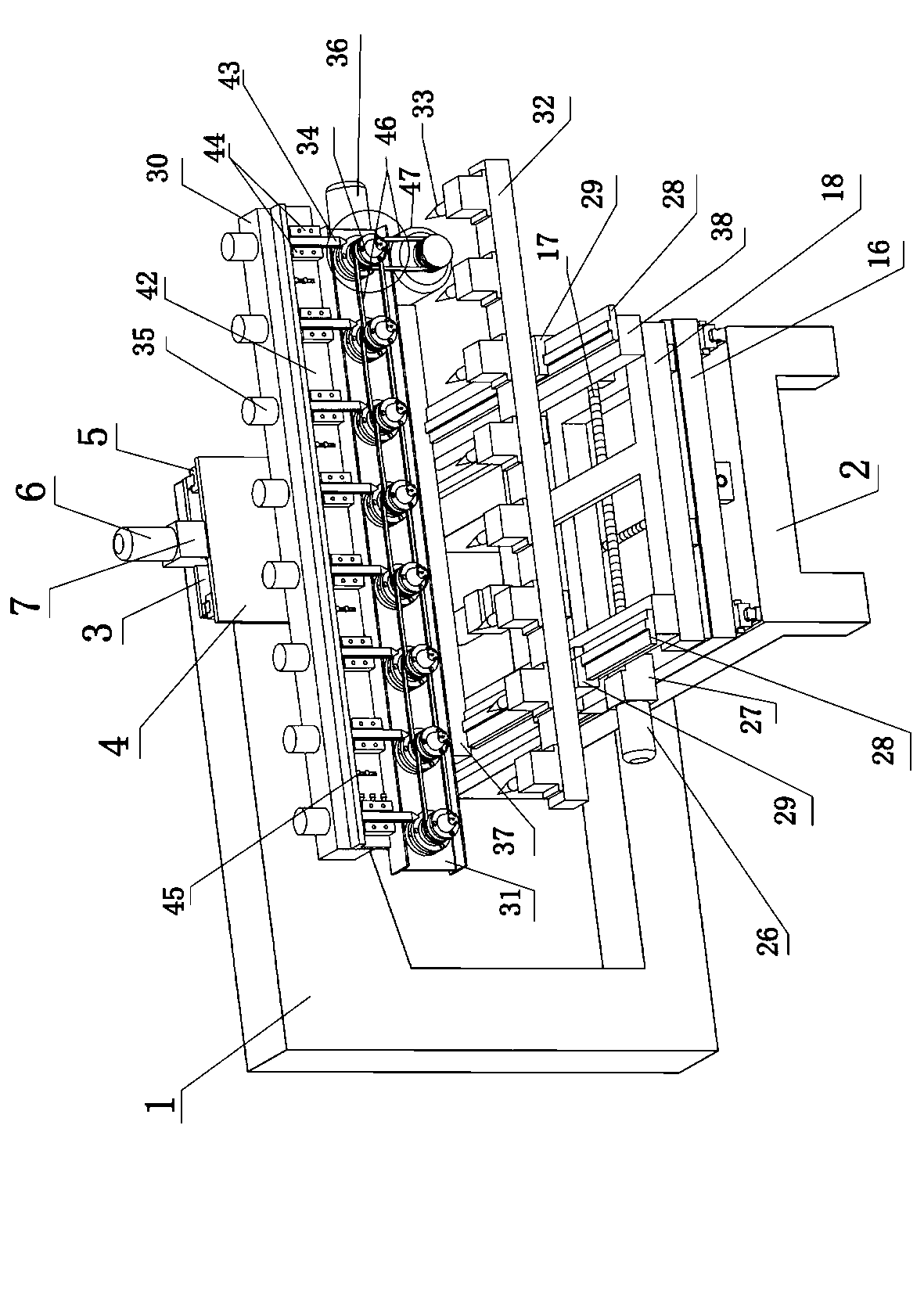

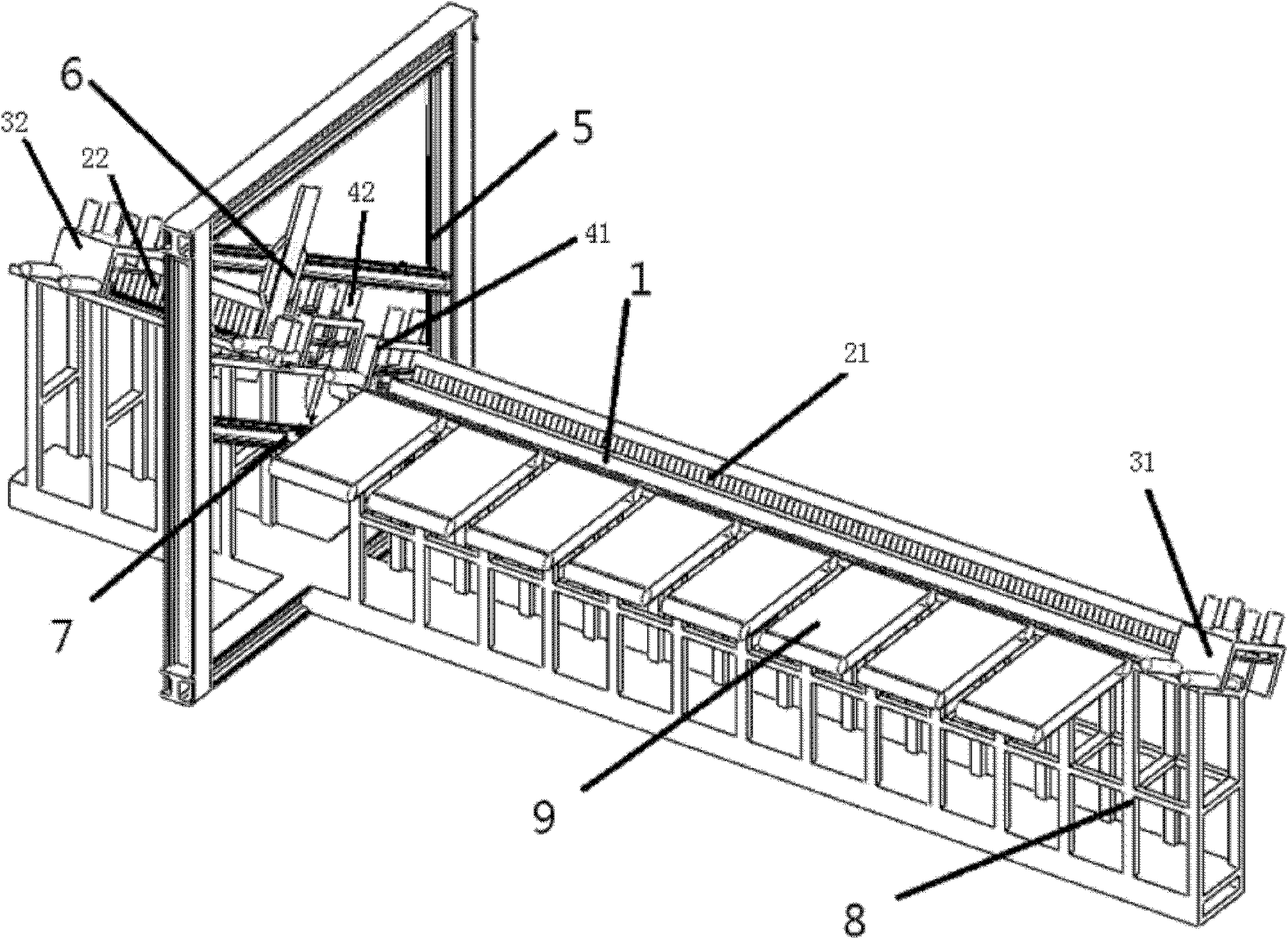

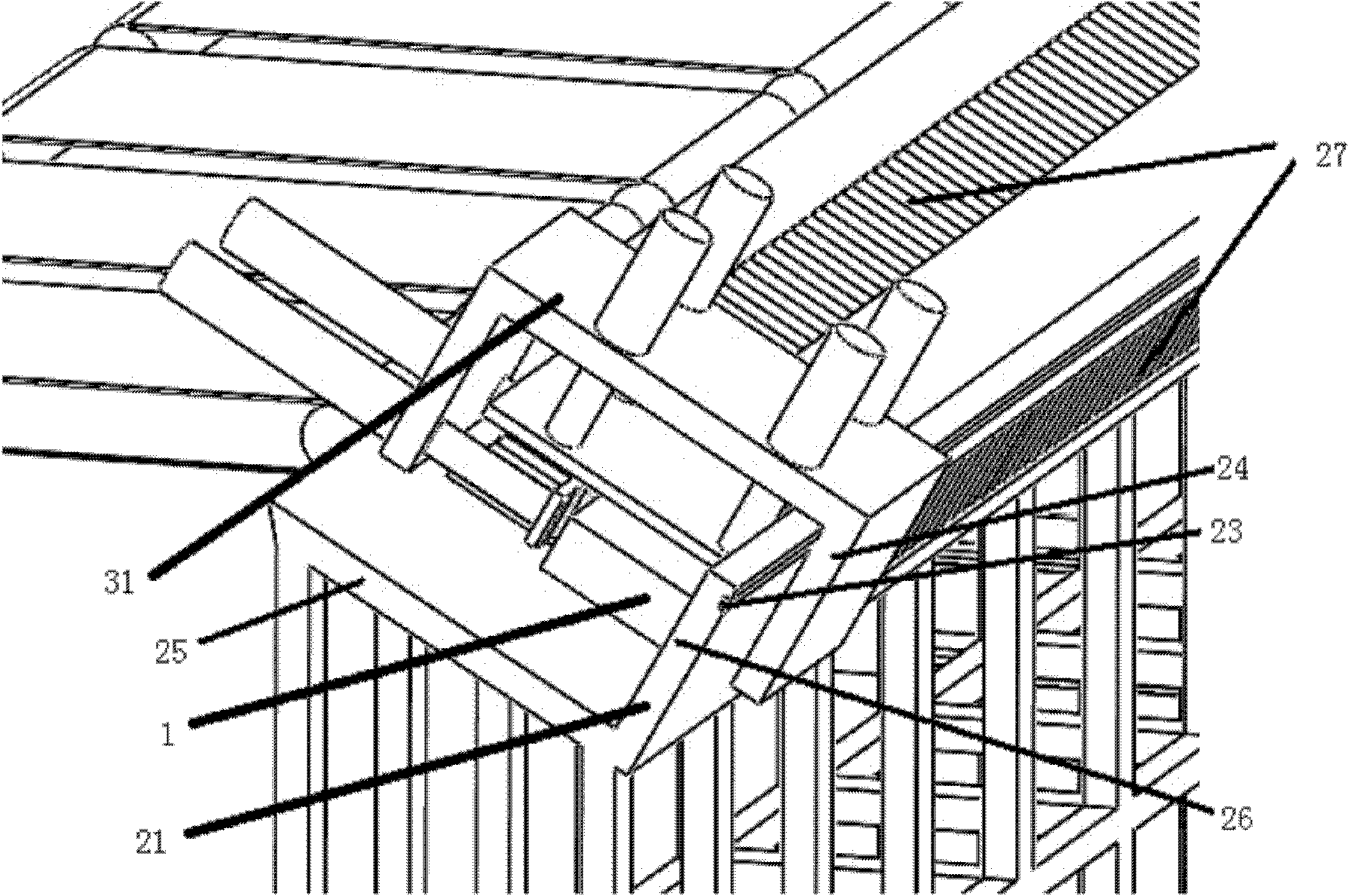

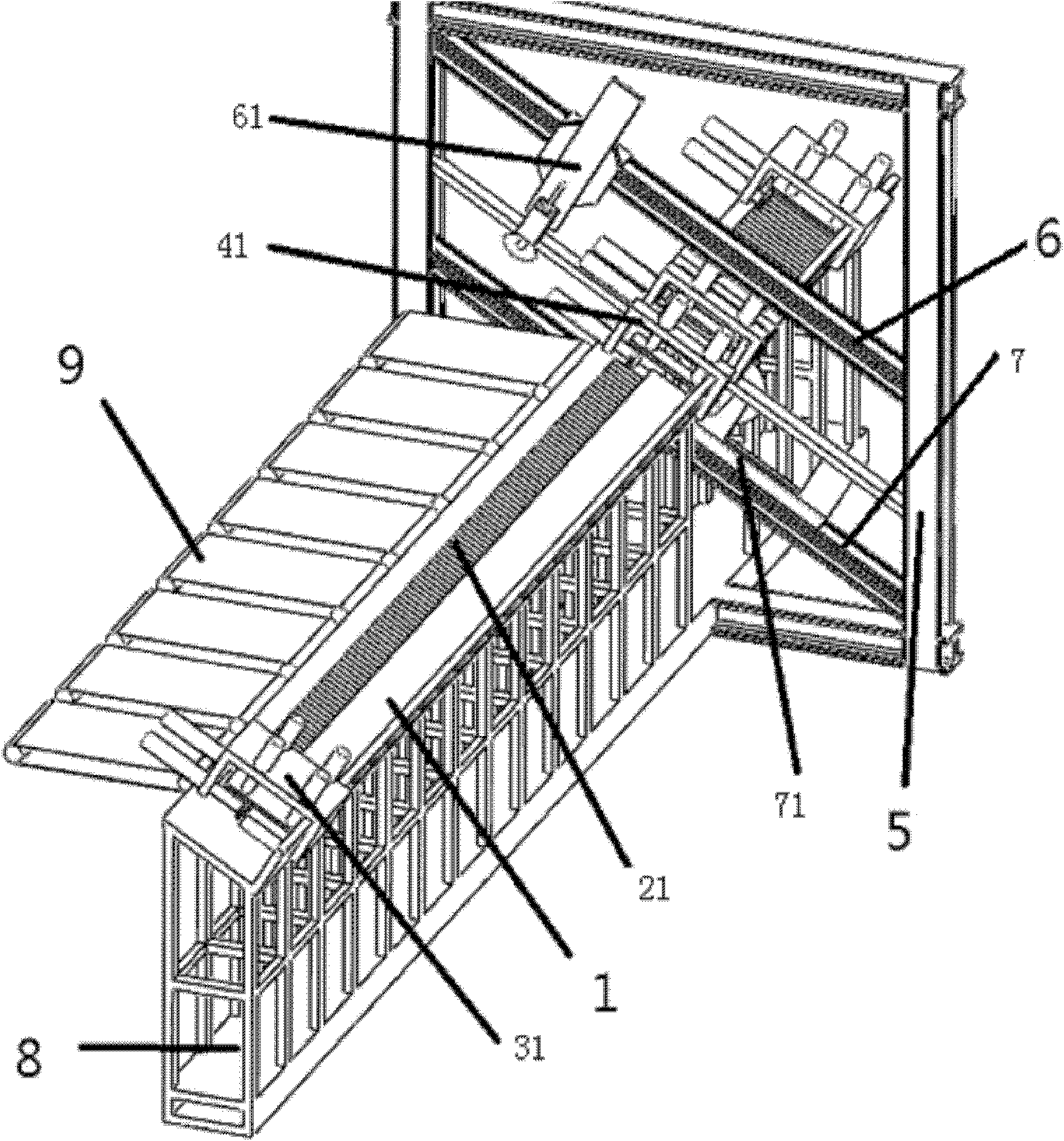

Multi-station automatic finger joint machine

InactiveCN101850572AIncrease productivityHigh degree of automationWood compressionCircular sawsControl systemCompression device

The invention relates to the woodworking machinery field, and specifically discloses a multi-station automatic finger joint machine which comprises a machine body, an extrusion workbench, an extrusion oil cylinder, a baffle, a support beam, an air cylinder, a front backup plate, a side pressure plate, an upper pressure plate and an electrical apparatus control system. The multi-station automatic finger joint machine is characterized in that the workbench is step-like in shape, one side of the extrusion workbench is provided with a pre-joint workbench, the feed end of the pre-joint workbench is provided with a sawing device, the other end is provided with the baffle which is provided with a travel switch, a pre-joint backup plate is arranged at the joint of the pre-joint workbench and the extrusion workbench, the pre-joint workbench is provided with a locating device, one side of a push plate is provided with the air cylinder and a guiding device, the feed end of the pre-joint workbench is provided with a feeding device and a feeding frame, the back end of the feeding device of the feeding frame is provided with a compression device, both sides of a conveyer belt on the feeding frame are provided with wood guide plates which are provided with storing boxes, and the outer end of the extrusion workbench is provided with a discharging bracket. The finger joint machine has the advantages of high automation degree, high production efficiency, stable processing quality and the like.

Owner:山东工友集团股份有限公司

High alloy cutting tool steel for wood-working machine rotary cutter blades and hot processing process of high alloy cutting tool steel

ActiveCN103757546AImprove toughnessImprove wear resistanceMetal rolling arrangementsManganeseHot working

The invention provides high alloy cutting tool steel for wood-working machine rotary cutter blades and a hot processing process of the high alloy cutting tool steel. The cutting tool steel comprises the following components by weight percent: 0.58-0.69 percent of carbon, 0.75-0.95 percent of silicon, 0.35-0.55 percent of manganese, 7.20-8.20 percent of chromium, 0.2-0.40 percent of vanadium, 0.95-1.45 percent of tungsten, 1.55-1.90 percent of molybdenum, not greater than 0.030 percent of sulfur, not greater than 0.030 percent of phosphorus and the rest of iron. The alloy cutting tool steel has the advantages of high strength and toughness, high abrasion resistance, high hardness and good red hardness and can meet the requirements of slicing and rotatably cutting veneers. The cutting tool steel and other plate materials are combined in a high strength to perform hot processing; the performances of the cutting tool steel are played to the maximum through the processes of hot molecules infiltration, hot rolling pressing and secondary quenching; the hardness, the abrasive resistance and the strength and toughness of the cutting tool steel are further improved.

Owner:上海晔川机械刀片有限公司

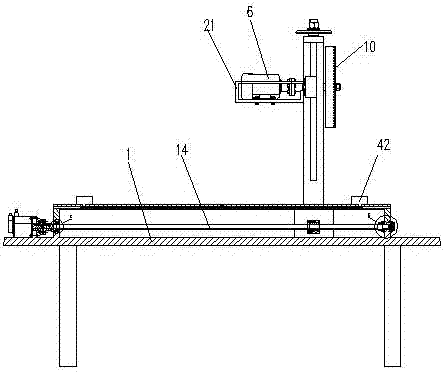

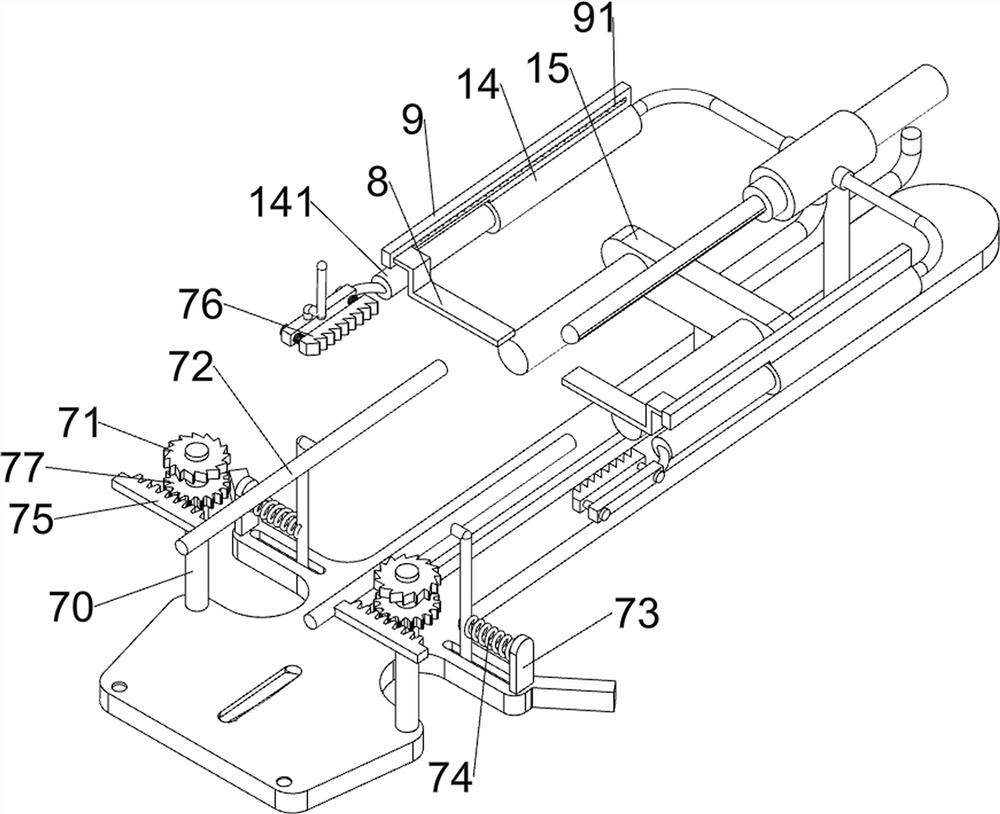

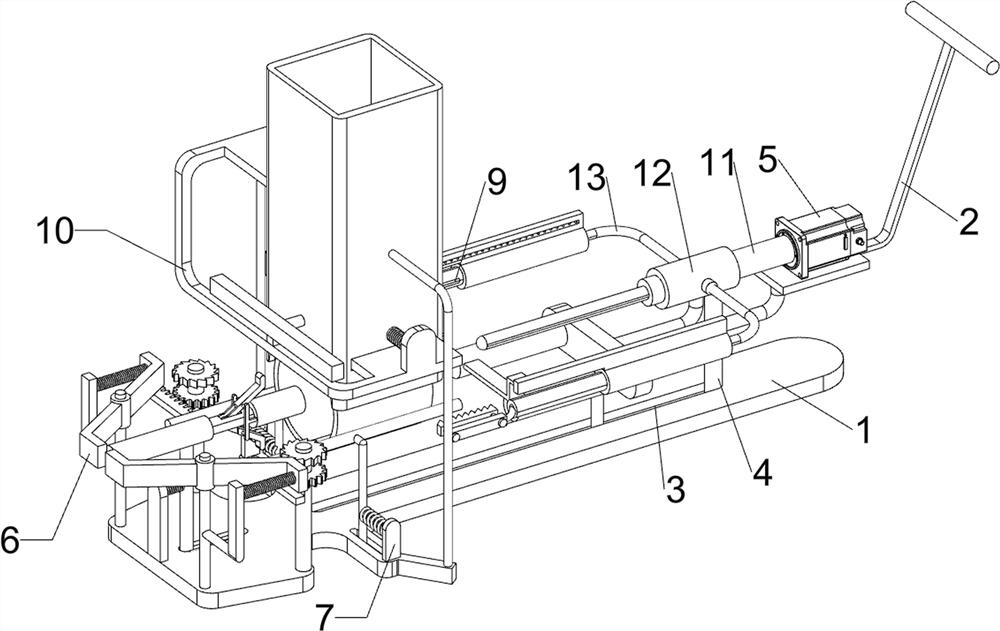

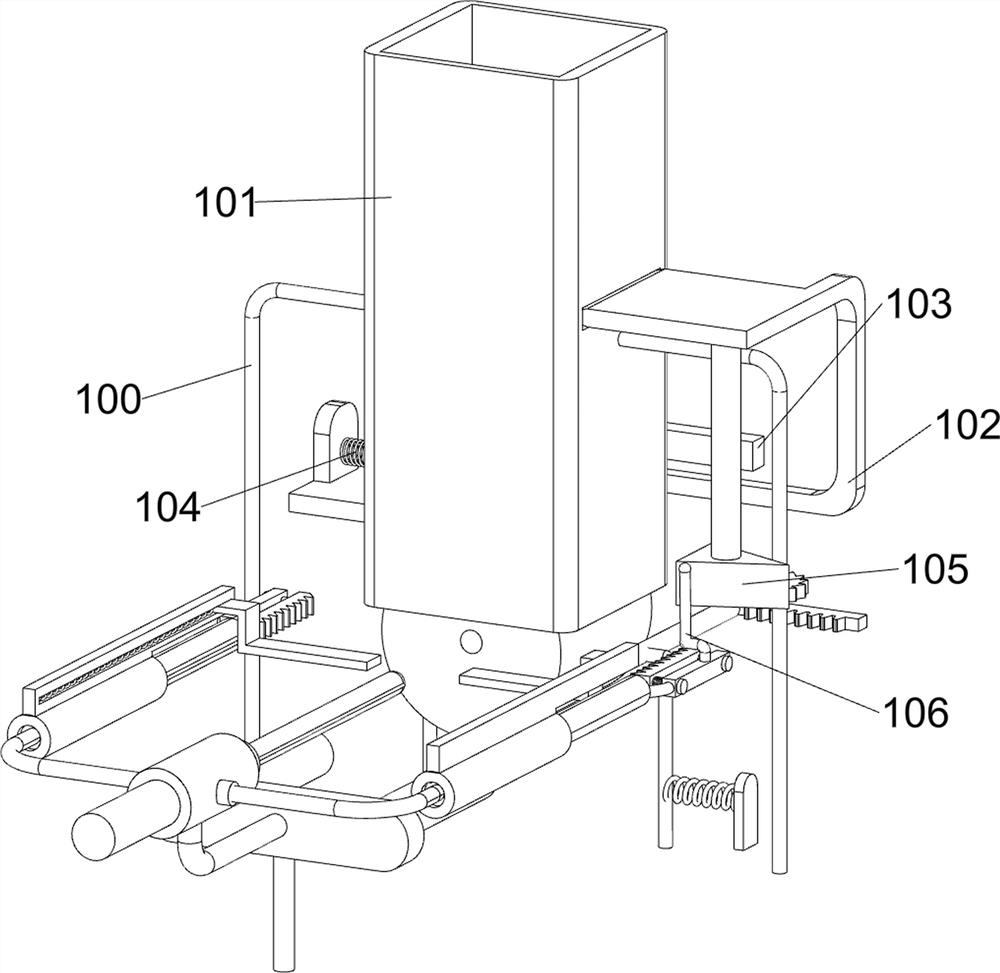

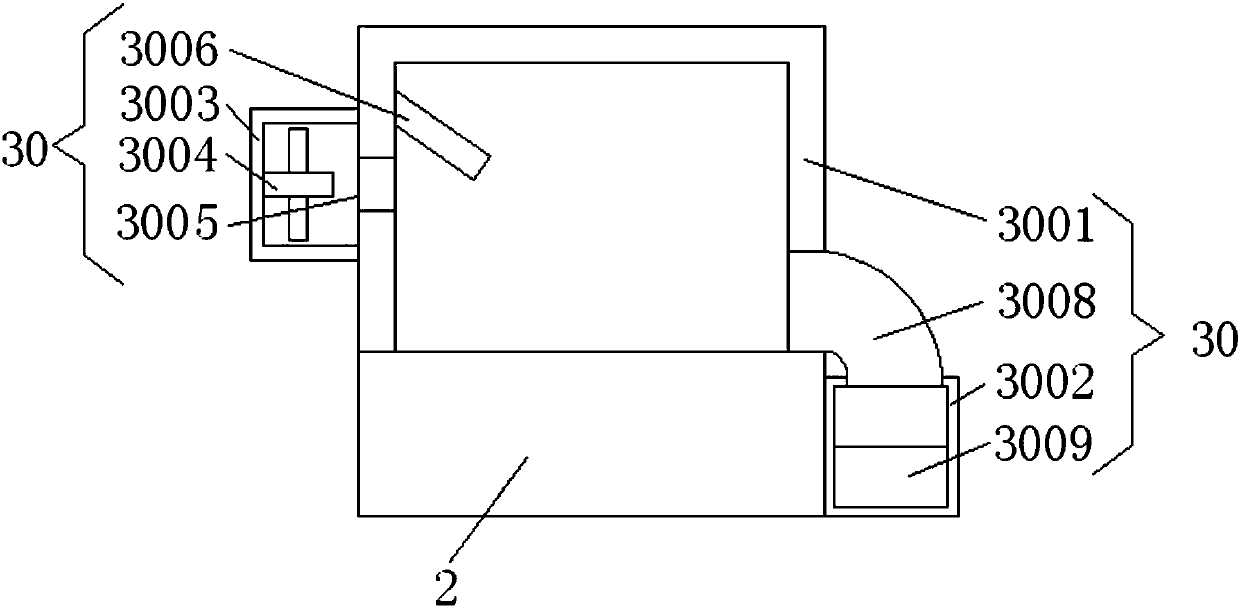

Wooden mug processing device for wood-working machinery

InactiveCN112108958AQuick sandingEdge grinding machinesGrinding drivesWoodworking machineryIndustrial engineering

The invention relates to a processing device, in particular to a wooden mug processing device for wood-working machinery. The technical problem is to provide the wooden mug processing device for the wood-working machinery capable of automatically feeding and quickly polishing wooden mugs. The wooden mug processing device for the wood-working machinery comprises a base used for installing the wholedevice; a sliding groove arranged at the middle of the upper portion of the base; a first supporting rod arranged in the sliding groove in a sliding mode; and a pushing handle arranged on the first supporting rod. According to the wooden mug processing device for the wood-working machinery provided by the invention, the effects that automatic feeding can be achieved, and the wooden mugs can be quickly polished are achieved; and the wooded mugs are placed in a work bin, a wedge-shaped block is pushed through movement of a push rod, the wedge-shaped block drives a first connecting rod to move front and back, and therefore the wooden mugs can be automatically discharged in the front-back moving process of the first connecting rod.

Owner:刘志辉

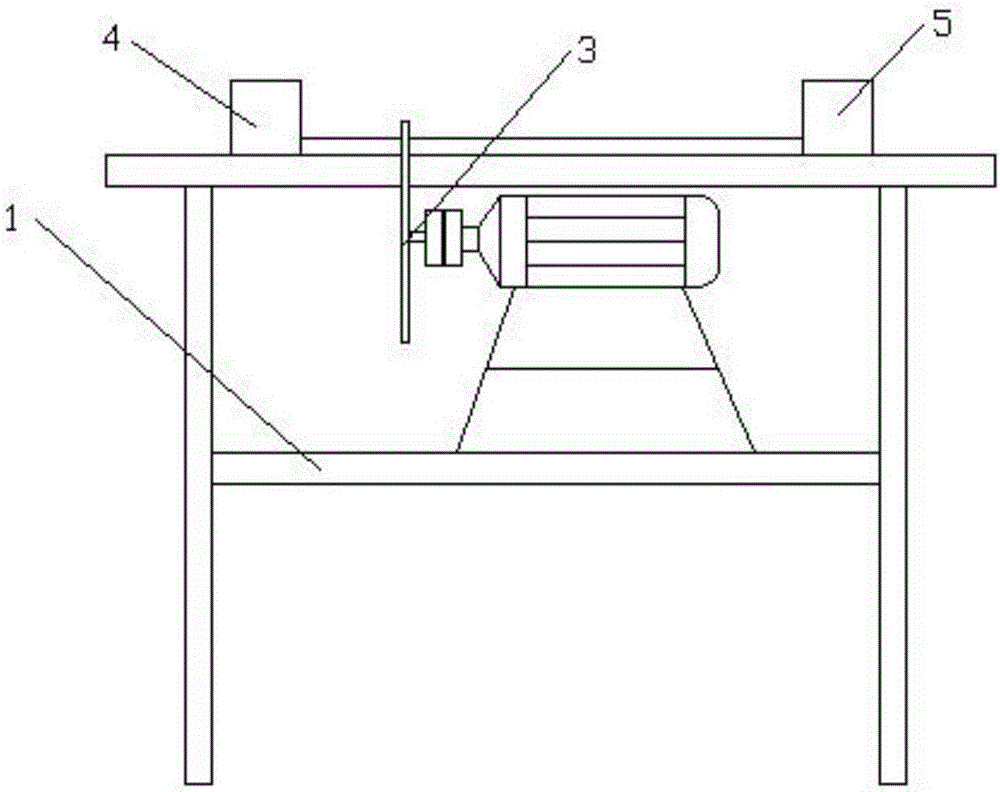

Wood working machine and processing platform thereof

ActiveCN102490216ARealize processingRealize self-calibration functionMulti-purpose machinesRear quarterPulp and paper industry

The invention belongs to the technical field of wood processing equipment, and relates to a wood working machine platform. The platform comprises a support frame, and a feeding region, a discharging region and a processing region which are formed on the support frame, wherein the processing region is positioned between the feeding region and the discharging region; the feeding region comprises a 90-DEG V-shaped feeding slipway fixed on the support frame; a material loading conveyor belt is arranged on one side of the feeding slipway; the discharging region comprises a 90-DEG V-shaped discharging slipway fixed on the support frame; both the feeding slipway and the discharging slipway comprise a bottom plate and a side plate which have an inclined angle of 90 DEG; and the two bottom plates and the two side plates are positioned on the same surface respectively. The invention also provides a wood working machine using the platform. The platform and the machine can be self-calibrated, have a small occupied area and are suitable for processing square wood.

Owner:浪潮数字(山东)科技有限公司

Equidistant automatic cutting device for wood

InactiveCN109397398AReduce impactReduce labor intensityProfiling/shaping machinesBark-zones/chip/dust/waste removalFixed frameEngineering

The invention discloses an equidistant automatic cutting device for wood, and relates to the technical field of woodworking machinery. The equidistant automatic cutting device for the wood comprises abottom plate, wherein a supporting frame and a fixing frame are fixedly installed on the bottom plate; a guide frame is vertically fixed to the fixing frame; cylindrical pin shafts are eccentricallyfixed to the front surface of a driving center plate; the strip-shaped wood strips are uniformly placed on a conveyor belt; a feeding inlet is formed in the right side wall of the guide frame; and a collecting tank fixed to the bottom plate isarranged below the guide frame. According to the equidistant automatic cutting device for the wood, the rotation of the driving center plate drives the cylindrical pin shafts to rotate, so that a driven sheave intermittently drives the driven sheave to rotate, and further the conveyor belt is used for conveying the wood strips-shaped wood to the inside of into the guide frame in a step-by-step mode; and a limiting baffle connected with a shock absorption spring is used for perform shock absorption on the wood strips-shaped wood, so that the impact force on a cutting blade is effectively reduced, the smoothness of cutting by the cutting blade is improved, the cutting blade has equidistant cutting effect on the wood strips-shaped wood, the cuttingaction has small labor intensity and high automation degree, and the cutting operation efficiency is effectively improved.

Owner:孙震

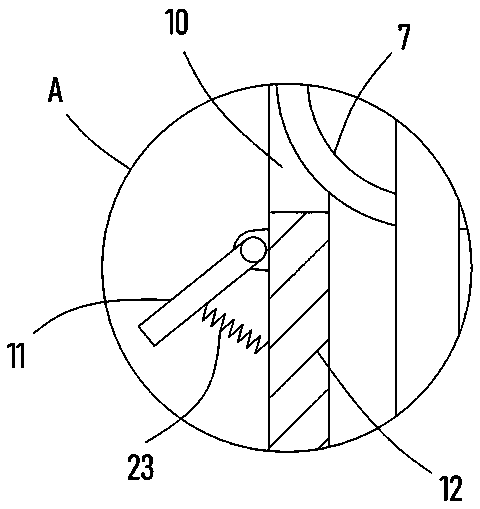

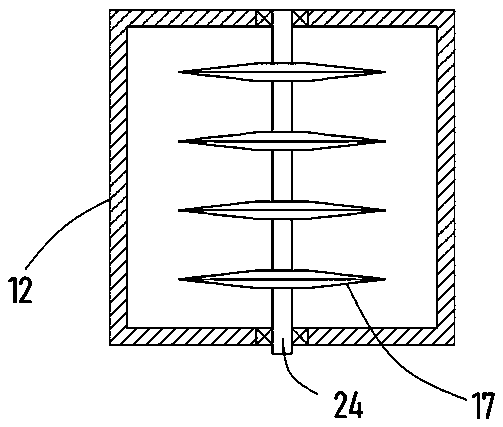

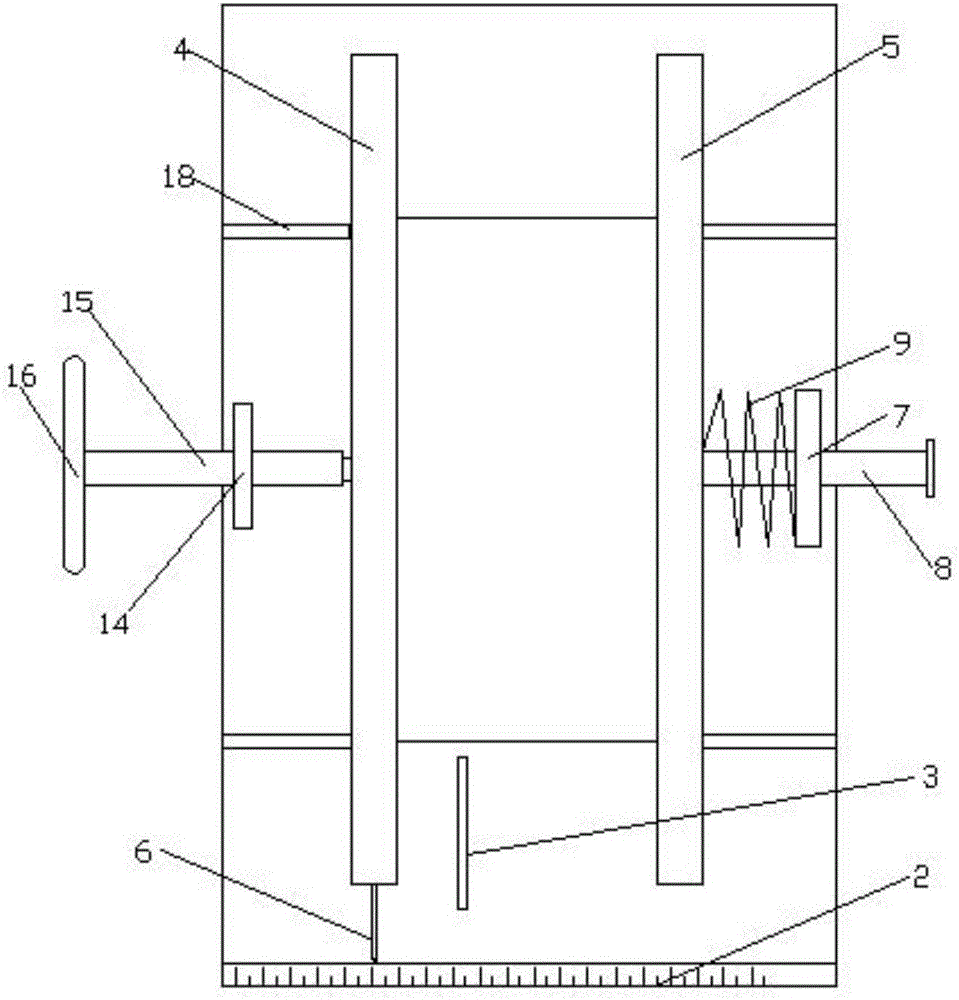

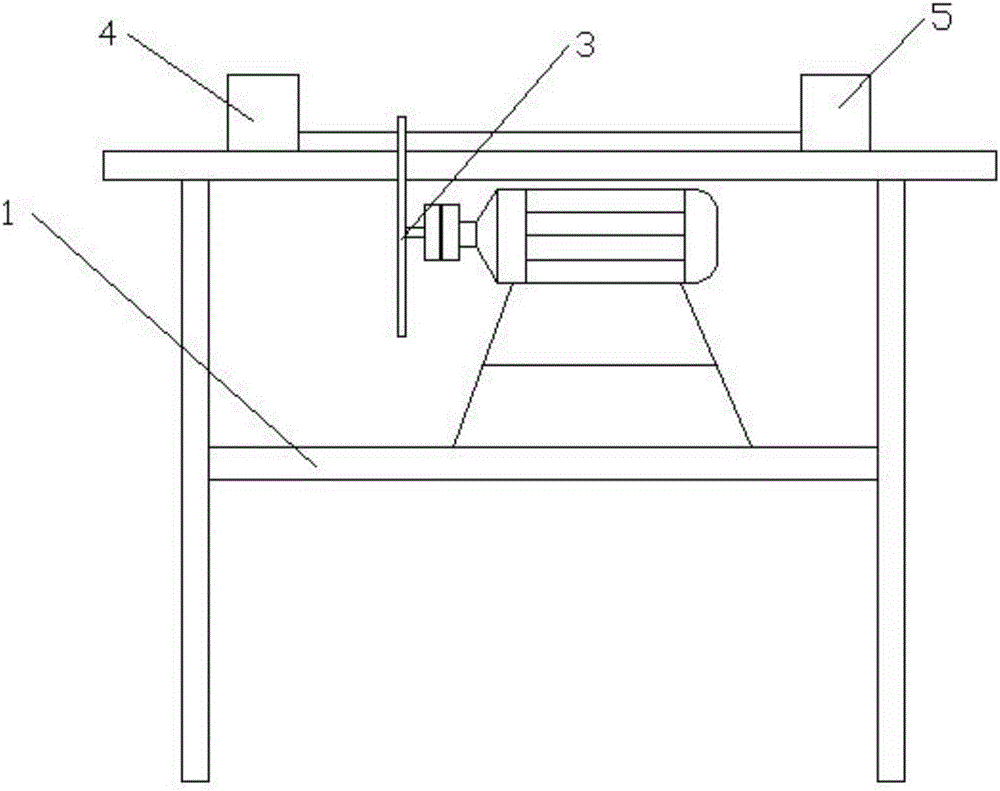

Measurement-adjustable woodworking push table saw

InactiveCN106064406AGuaranteed cutting accuracyGuaranteed accuracyCircular sawsSawing componentsInstabilityEngineering

The invention discloses a measurement-adjustable woodworking push table saw, and belongs to the technical field of woodworking machinery. The measurement-adjustable woodworking push table saw comprises a push table frame, and a dividing ruler and a saw blade positioned on the push table frame; a left push plate and a right push plate are slidingly arranged on two sides of the saw blade; a finger corresponding to the dividing ruler is arranged at the end part of the left push plate; a support block is fixed in the slide direction of the left push plate, and is in threaded connection with a push rod; one end of the push rod is rotationally arranged with the left push plate, and a handle is arranged at the other end; a stopper is arranged in the slide direction of the right push plate; a slide rod is slidingly arranged on the stopper; and the slide rod is fixedly connected with the side surface of the right push plate, and is coated with a spring. The measurement-adjustable woodworking push table saw solves the problems of a traditional push table saw incapable of accurately positioning boards to be machined and weaker cutting quality of the boards caused by instability in the machining process.

Owner:武侯区华聚家私经营部

Worktable having adjusting function and used for woodworking cutting

InactiveCN107901135AWith adjustment functionImprove work efficiencyCircular sawsBark-zones/chip/dust/waste removalCouplingArchitectural engineering

The invention discloses a woodworking cutting workbench with an adjustment function, which comprises a support leg, the surface of the support leg is fixedly connected with the workbench, the interior of the workbench is provided with a through hole, and the surface of the workbench is fixedly connected with a first A chassis, the inner wall of the first chassis is fixedly connected with a first support rod, the surface of the first support rod is fixedly connected with a motor, and the output shaft of the motor is fixedly connected with a threaded rod through a coupling. The woodworking cutting workbench with adjustment function, when it needs to be used for cutting, put the wood between the push plate and the workbench, start the motor, the motor drives the threaded rod to rotate, the threaded rod drives the threaded pipe to rotate, and the threaded pipe drives the second The support rod slides and advances inside the chute, which achieves the effect of replacing manual propulsion and improving work efficiency, thus effectively solving the problem that the general woodworking machinery is inconvenient to adjust, consumes a lot of manpower, and affects work efficiency to a certain extent. .

Owner:绍兴新越机械制造有限公司

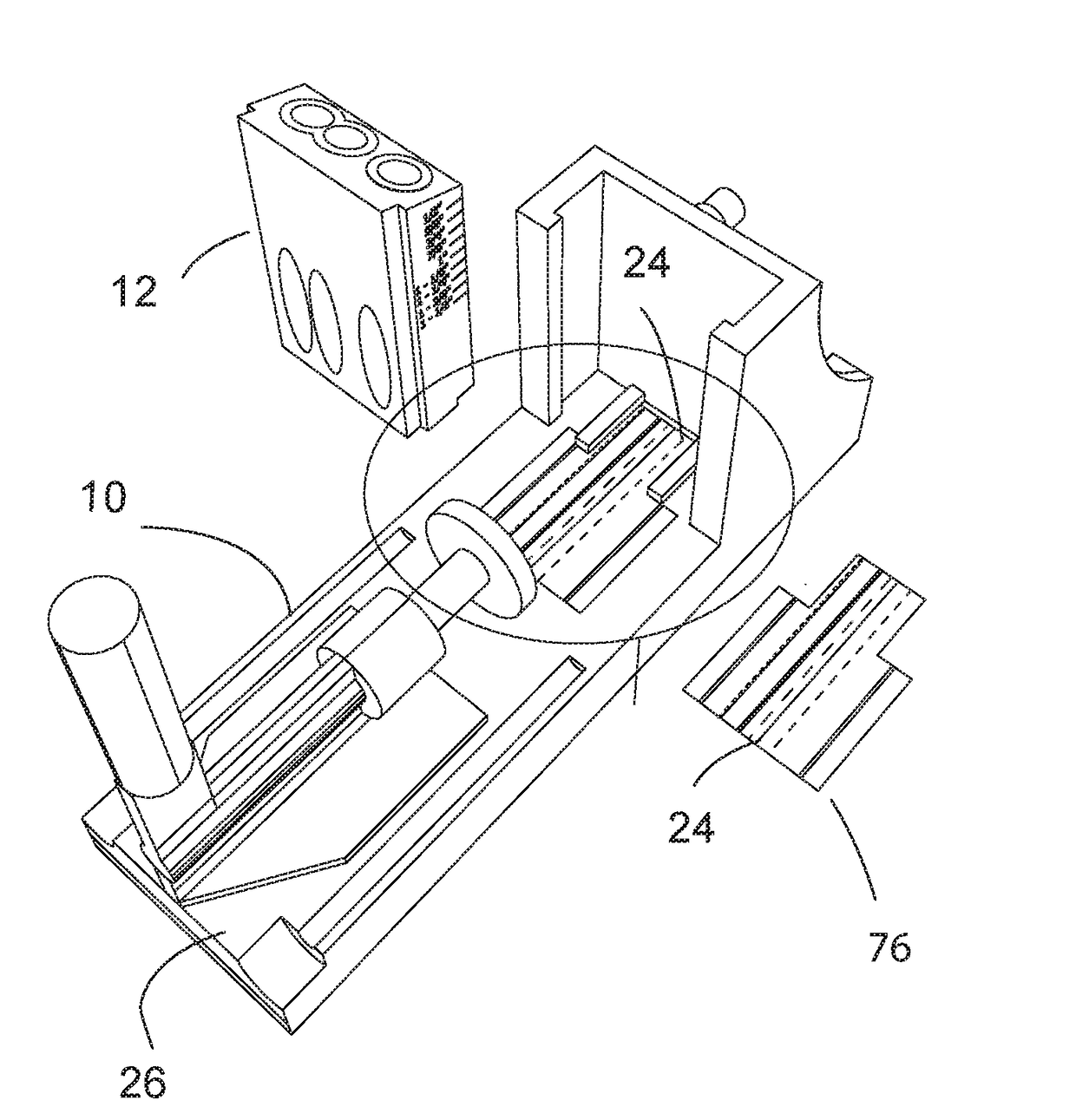

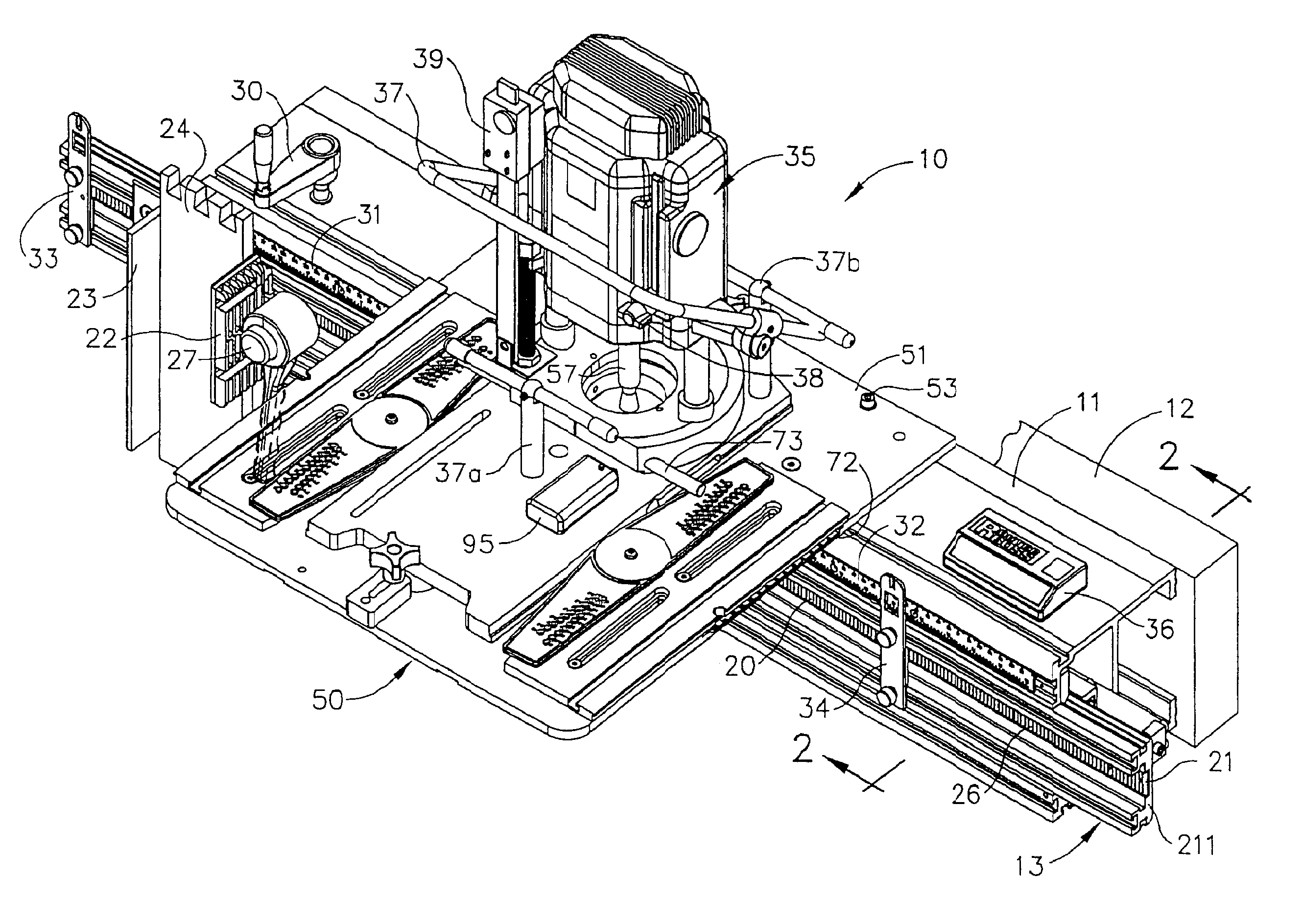

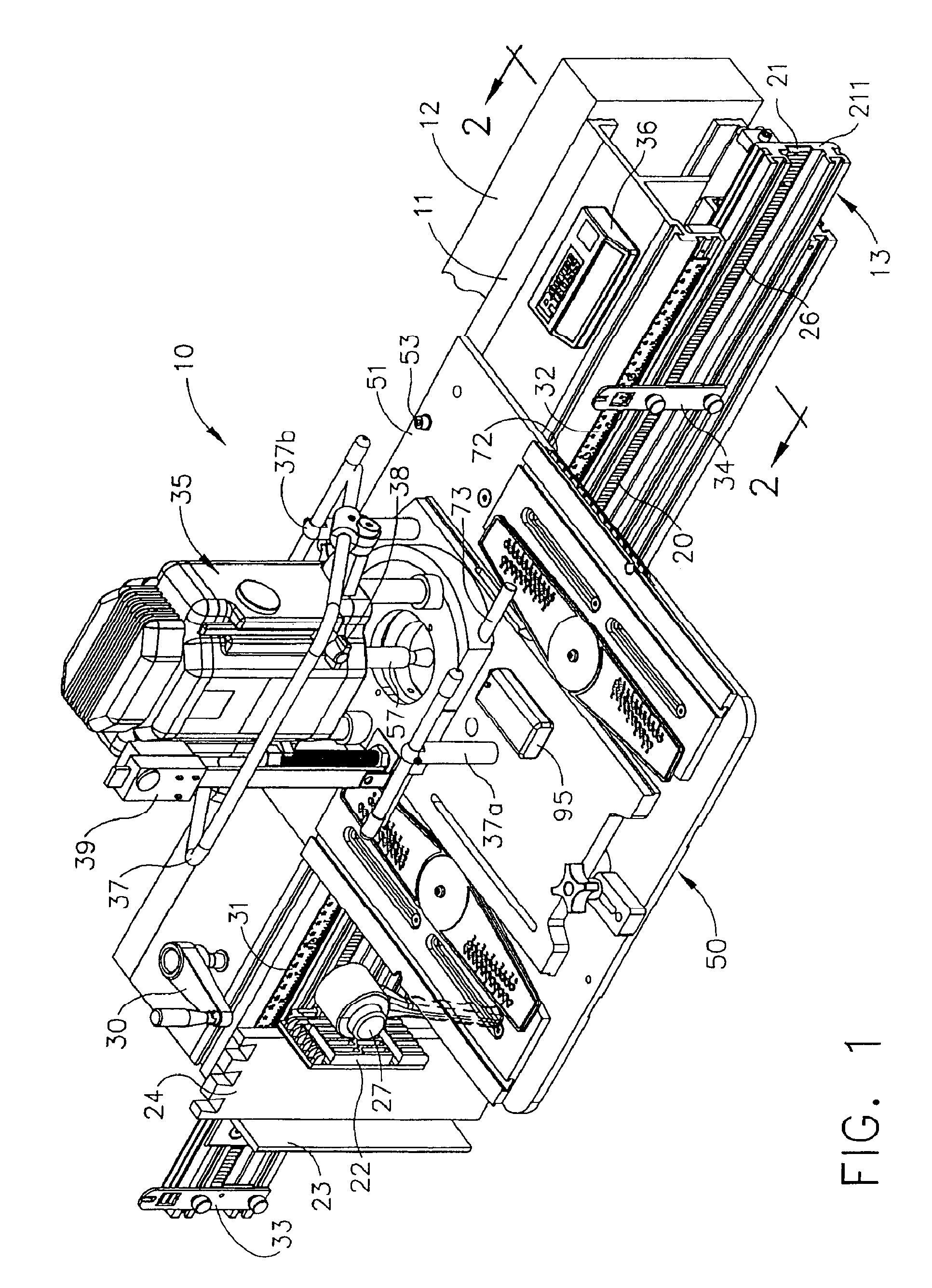

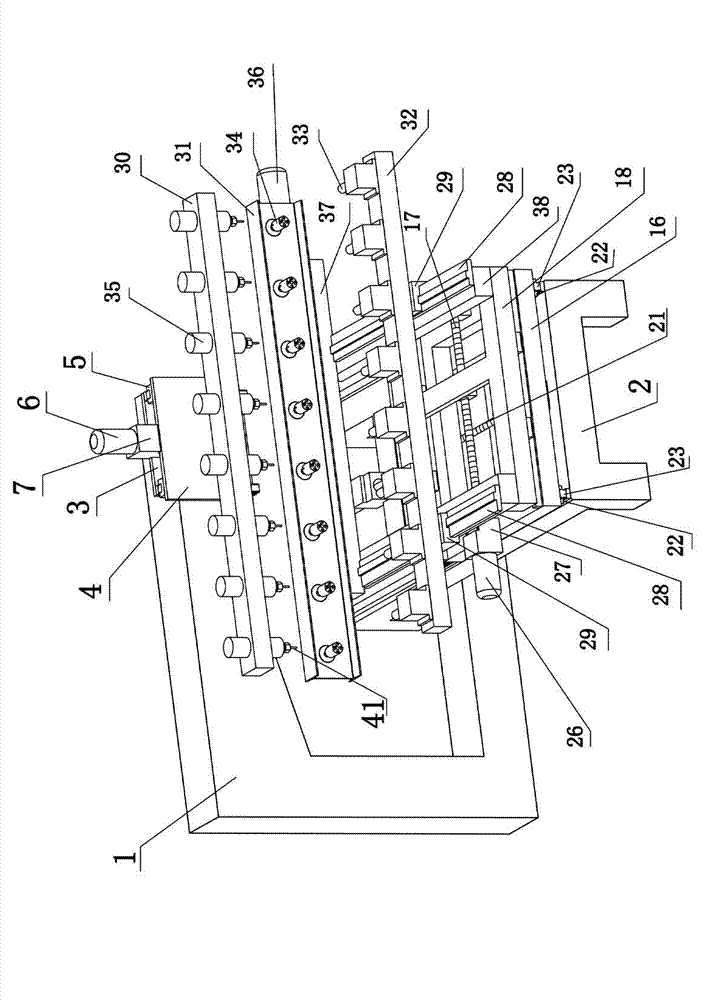

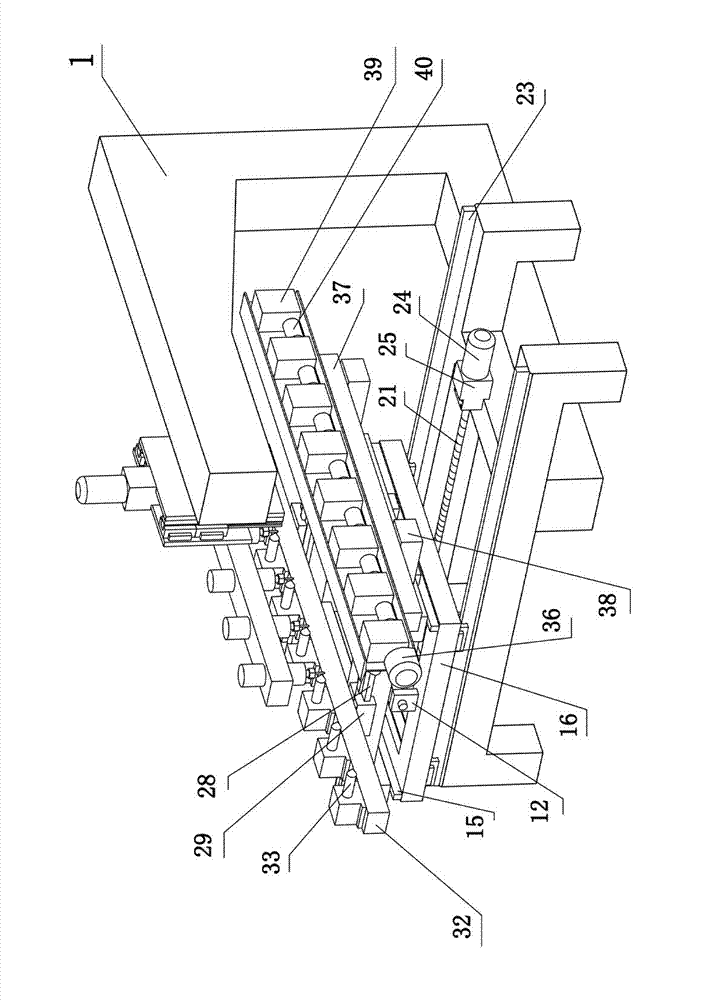

Modular Jig and Fixture Systems and Methods

ActiveUS20190270143A1Simple processGuide fencesMetal working apparatusModular fixtureWoodworking machinery

Jigs and fixtures for aligning, guiding, and / or holding a workpiece on woodworking machinery during a woodworking operation are described, as well as methods of making, modifying, and using jigs and fixtures.

Owner:DUGINSKE MARK A

Wood working machine

InactiveUS7997308B2Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workTool bitEngineering

Owner:STEPP LEWIS E

Wood planing machine with backstop

InactiveCN104260155AHigh degree of automationAdjust planing depth at willFlat surfacing machinesThickness planerWoodworking machinery

The invention discloses a planing machine, particularly relates to a double-faced wood planing machine with a backstop, and belongs to the technical field of wood-working machines. The double-faced wood planing machine comprises a rack, a conveying mechanism, a lower planing mechanism, an upper planing mechanism, a worktable and a driving mechanism, wherein the rack is arranged on the worktable and supports the conveying mechanism; the conveying mechanism is used for conveying a wood on the worktable; the upper planing mechanism and the lower planing mechanism are driven by the driving mechanism to plane the upper end and lower end of the wood; a plurality of non-returning sheets are arranged between the lower planing mechanism and the rack to form the backstop and a height difference is formed between the adjacent two non-returning sheets; and the worktable comprises a fixed platform and a movable platform. According to the double-faced wood planing machine with the backstop, the automation degree of machining the wood is improved and the planing depth of the wood can be adjusted randomly; the backstop can effectively prevent the potential safety hazard caused by the factor that the wood backs up; and meanwhile, the double-faced wood planing machine has double-faced planing capability and damages on a cutting surface of the planed wood, caused by secondary machining, are avoided, so that the production efficiency is improved and the energy consumption is reduced.

Owner:ANJI DEMAI BAMBOO & WOOD MACHINERY

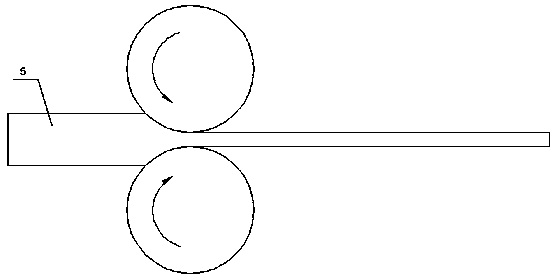

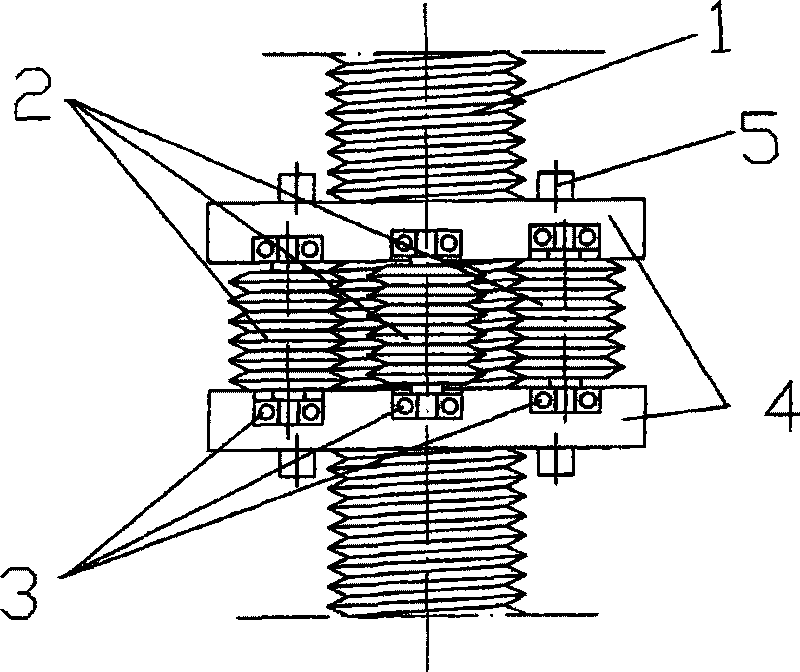

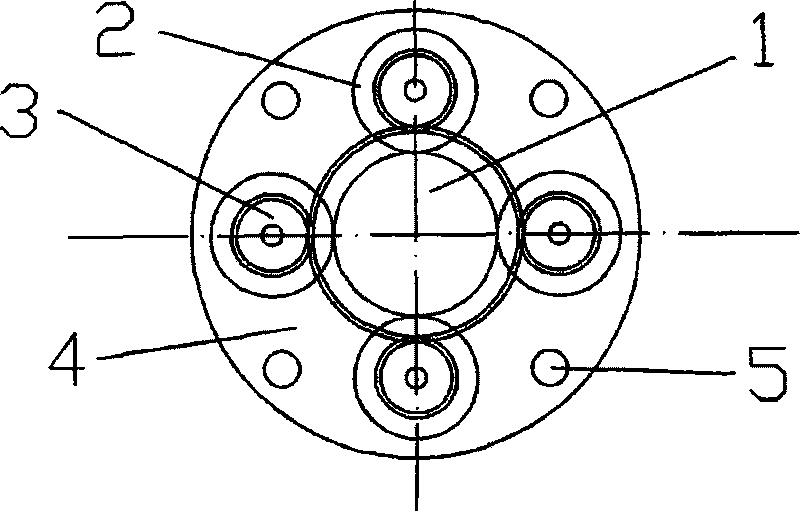

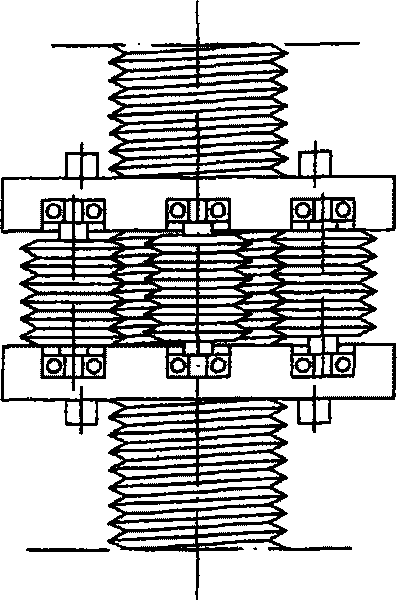

Screw rod with rollers

The invention relates to a screw rod with rollers, which comprises a screw rod, rollers, a bearing, a bearing pedestal and pin bolts, wherein the rollers are uniformly distributed on the circumference of the screw rod, both ends of the rollers are positioned in the bearing pedestal by the bearing, the bearing pedestal is fixed by the pin bolts, and the uniformly distributed rollers are distributed in parallel with an equal height difference in an axial direction and engaged with the threads of the long screw rod. During running, the rotation of the screw rod drives the engaged rollers to rotate and translate, and the rollers are supported by rolling bearings at both ends to rotate and drive the translation of the bearing pedestal. The screw rod can be widely used on straight-line motion mechanisms driven by a screw or transmitted by a ball screw, such as a machine tool, woodworking machinery, medical treatment and automation equipment.

Owner:徐众

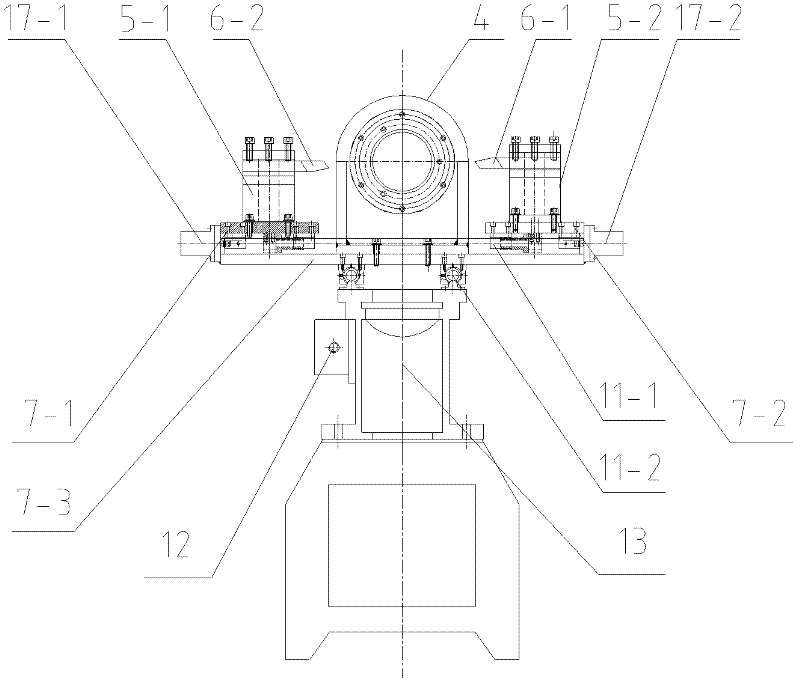

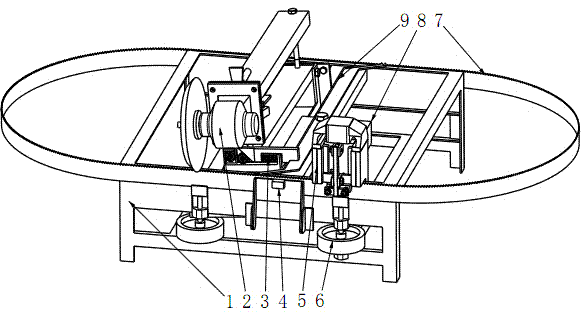

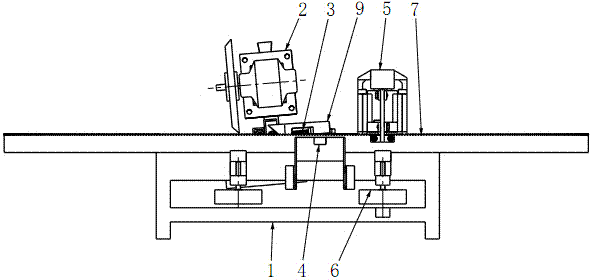

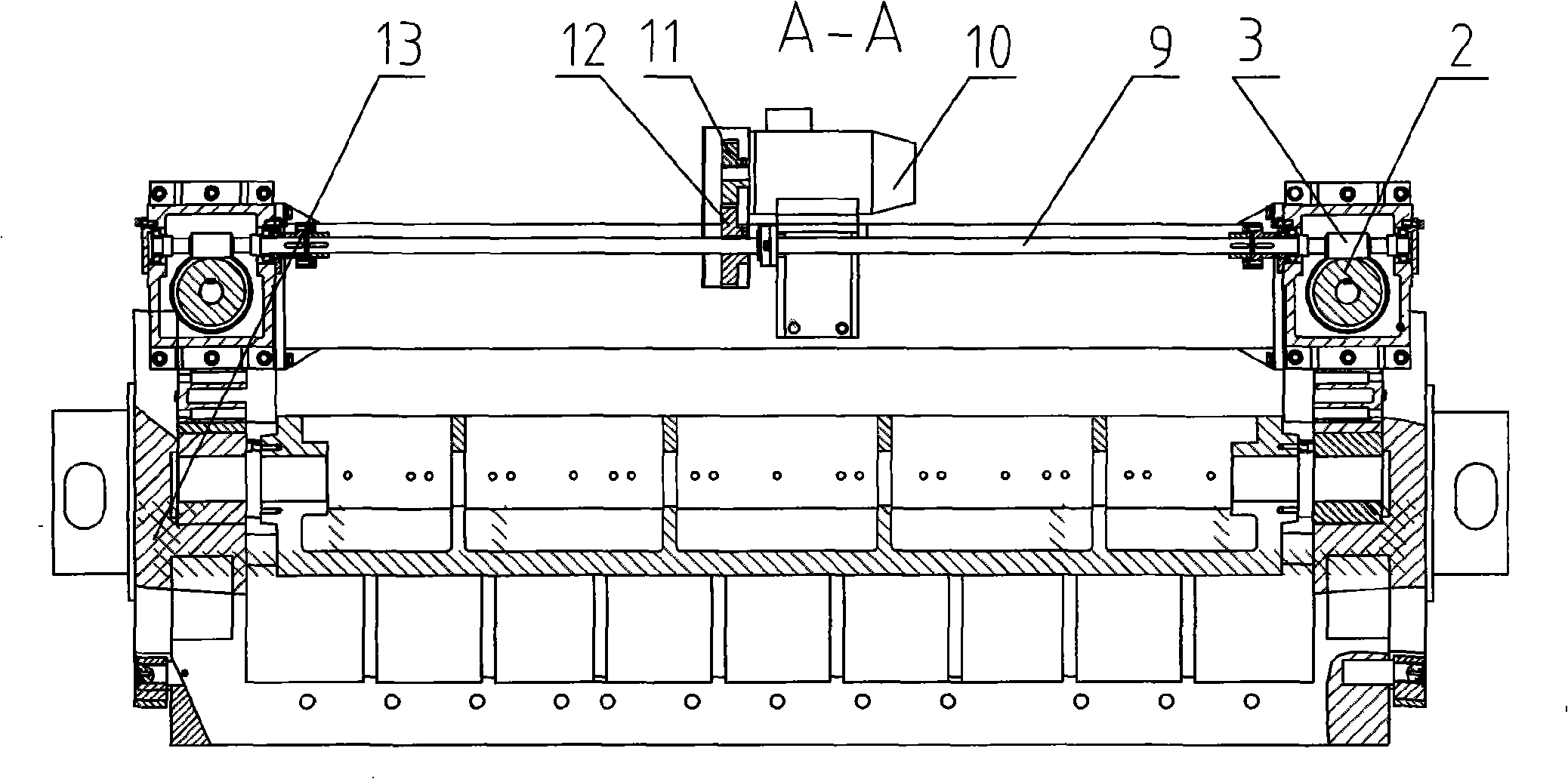

Multi-station numerically-controlled wood lathe

ActiveCN102699962AImprove processing efficiencySave labor costWood-turning machinesWoodworking machineWoodworking machinery

The invention relates to a multi-station numerically-controlled wood lathe and belongs to the technical field of a woodworking machine. The multi-station numerically-controlled wood lathe comprises a rack, and a cross beam fixed above the rack and horizontally transversely arranged, wherein the rack is comprises an H-shaped base and a U-shaped base; a toolframe for mounting a plurality of tools is arranged on the side of the cross beam; a plate block fixed on the cross beam is arranged between the cross beam and the toolframe; a vertical dragging block connected with a vertically arranged vertical guide rail is arranged on the plate body; simultaneously, a vertical dragging plate connected with the vertical dragging block is arranged between the cross beam and the toolframe; the toolframe is fixed on the vertical dragging plate; a drive mechanism 1 for driving the vertical dragging block to move along the vertical guide rail is arranged on the plate block; two horizontally longitudinally arranged longitudinal guide rails are arranged on the H-shaped base; a sliding block 2 capable of sliding along the longitudinal direction of the guide rail is arranged on the longitudinal guide rail; workpiece clamping devices of which the quantity is the same as that of the tools are arranged on the sliding block 2; and a drive mechanism 2 capable of driving the sliding block 2 to move along the longitudinal guide rail is arranged on the H-shaped base.

Owner:NANTONG OUKE CNC EQUIP CO LTD

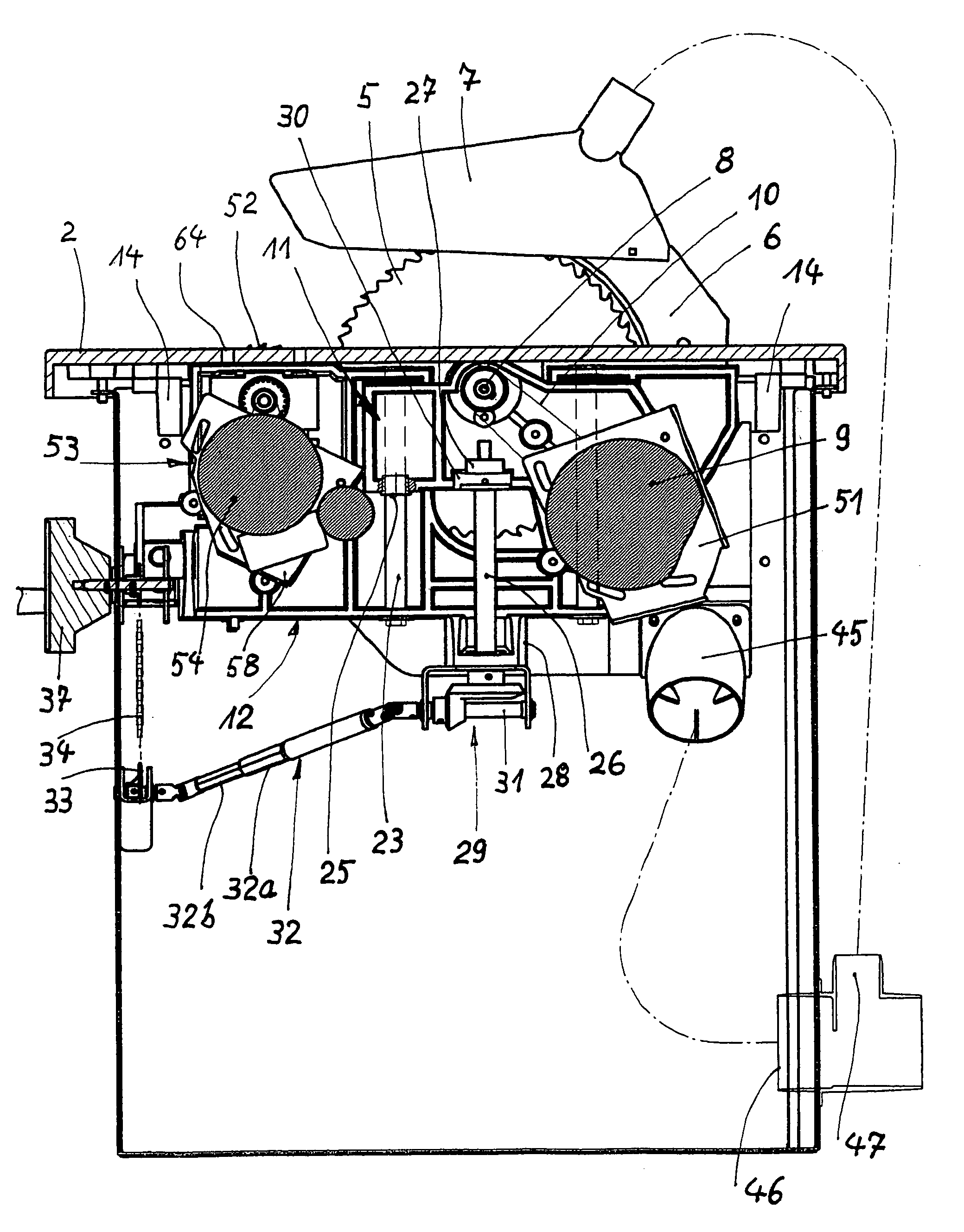

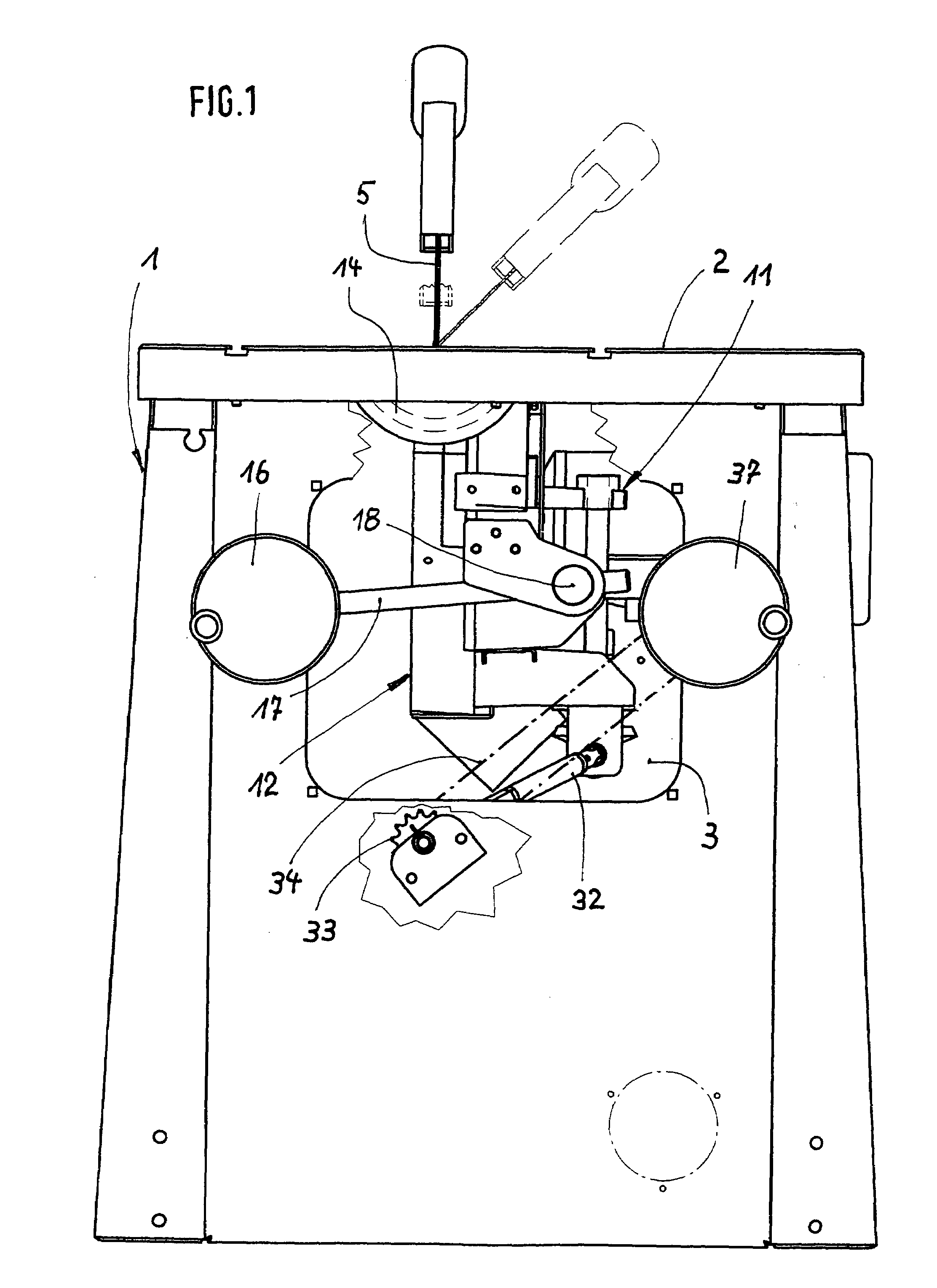

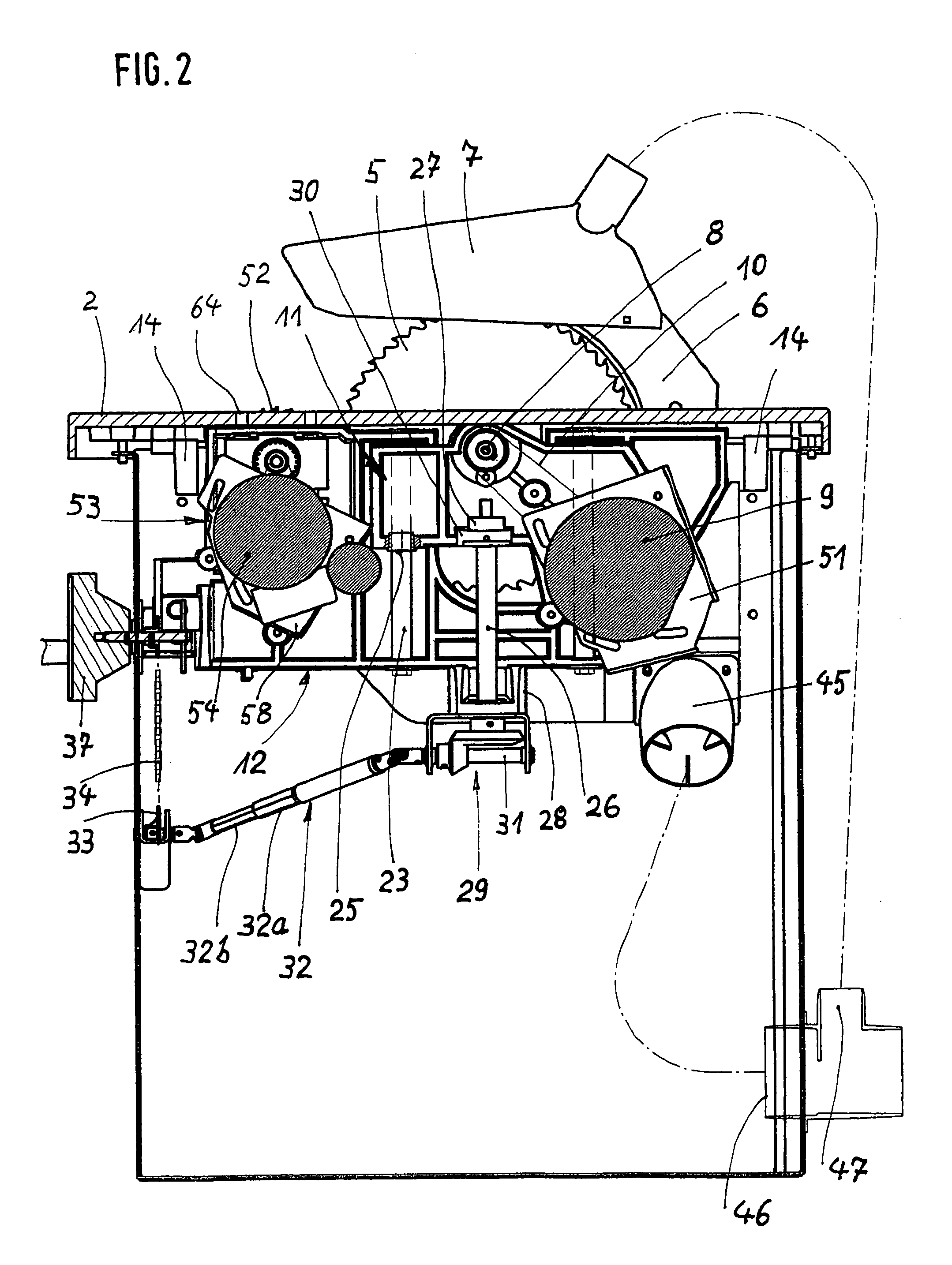

Woodworking machine

InactiveUS7587967B2High degreeImprove securityMetal sawing devicesGuide fencesCircular sawEngineering

A circular saw having a machine frame having a table board and a swivel frame arranged underneath the table board, which is swiveled about a swivel axis coplanar with the top side of the table board. The swivel frame accommodates a height adjustable tool bracket carrying at least one cutting tool engaging an associated slot in the table board. The swivel frame in the region of its ends is swivel-suspended on bearing brackets which are mountable on the bottom side of the table board, and are swiveled by an articulated adjusting rod. The tool bracket is height adjusted by an adjusting element which is arranged in driving linkage with an extendable articulated shaft. The adjusting rod and the articulated shaft are operated by cranks mounted on the operating side of the machine frame.

Owner:SCHWEPPACH FAB VON HOLZBEARBEITUNGSMASCHINEN GMBH

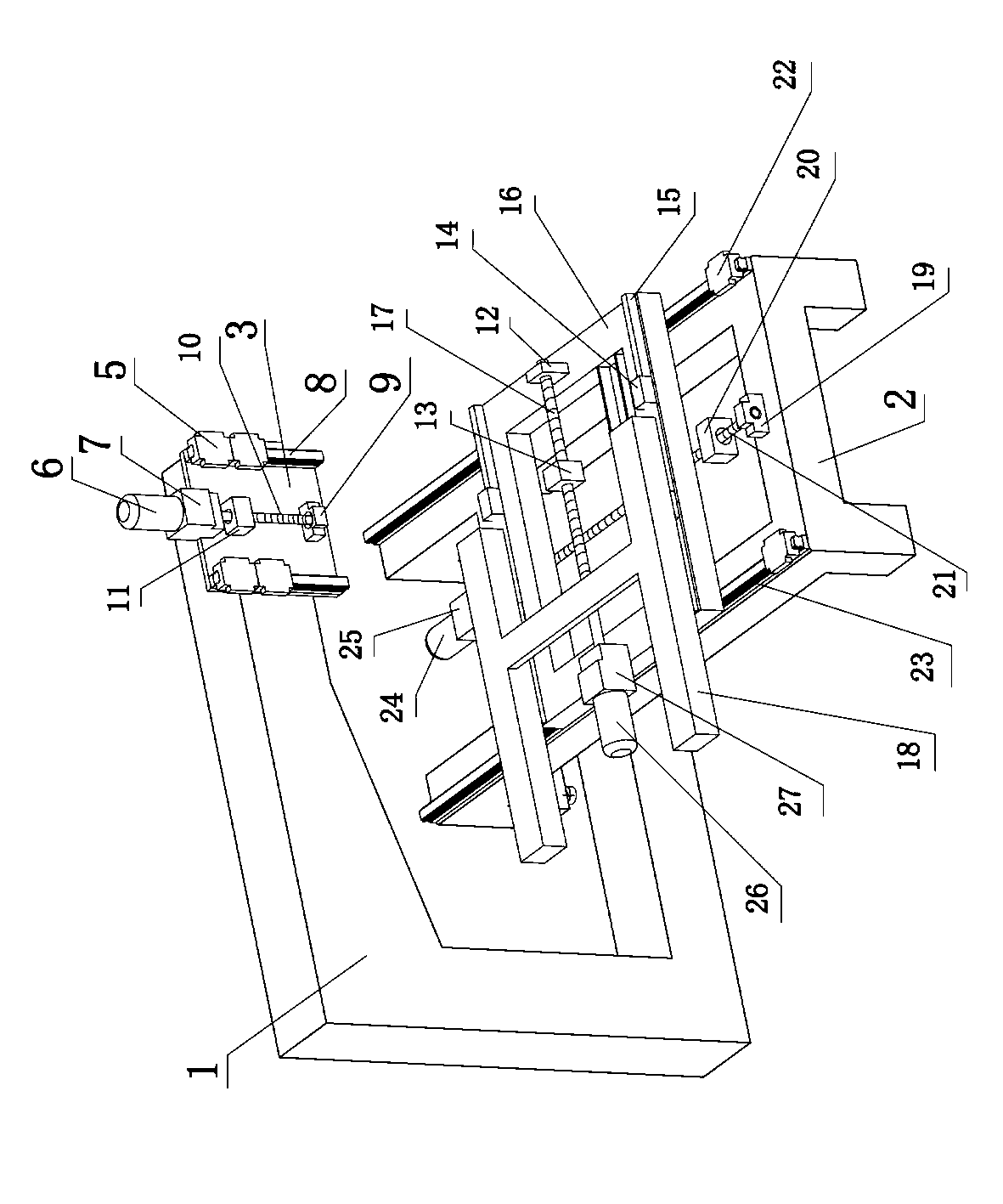

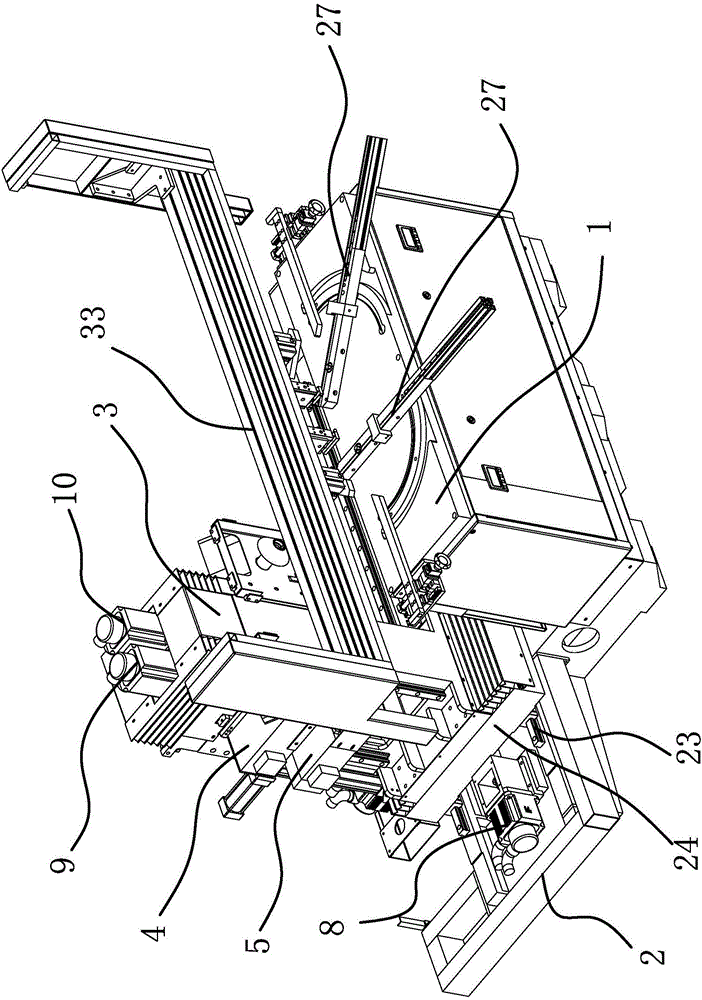

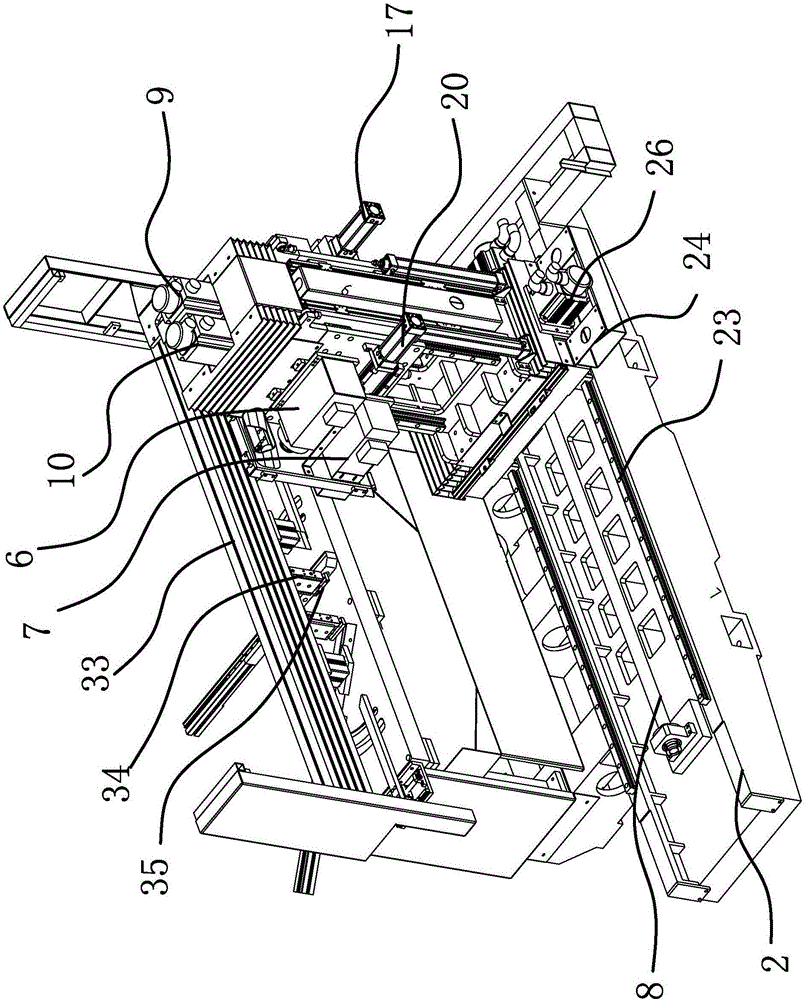

Numerical control three-dimensional engraving machine

InactiveCN102729708AImprove machining accuracyGuaranteed uptimeModel makingNumerical controlElectric machinery

The invention relates to a numerical control three-dimensional engraving machine and belongs to the technical field of wood-working machines. The numerical control three-dimensional engraving machine comprises a frame, a beam, a vertical driving mechanism, a cutter device, a transverse driving mechanism, a longitudinal driving mechanism and a workpiece clamping driving mechanism, wherein the vertical driving mechanism is arranged on the crossbeam and comprises a first driving motor, a first motor fixing seat, a first slide block, vertical guide rails, a first lead screw, a first connecting block, a vertical guide rail mounting plate and a vertical carriage; the cutter device comprises a cutter holder, a cutter and a motor; the longitudinal driving mechanism comprises a longitudinal worktable, longitudinal guide rails, a fourth slide block, a third driving motor, a third lead screw and the like; the transverse driving mechanism comprises a transverse worktable, transverse guide rails, a third slide block, a second driving motor, a second motor fixing seat, a second lead screw, a second connecting plate and a second bearing supporting block; and the workpiece clamping driving mechanism comprises workpiece clamping guide rails, a second cushion block, a second slide block, a tip mounting plate, tips, a first cushion block, a workpiece chuck mounting plate, workpiece chucks, a fourth motor, a reducer and the like.

Owner:NANTONG OUKE CNC EQUIP CO LTD

Planing machine

InactiveCN104209989AEasy to planHigh degree of automationWood feeding arangementsGear driveGear wheel

The invention discloses a planing machine, in particular a two-sided planing machine capable of planing upper and lower surfaces of a timber, and belongs to the technical field of wood-working machines. The planing machine comprises a conveying mechanism, a frame, a lower planing mechanism and a working table, wherein the frame is arranged on the working table, and supports the conveying mechanism; the conveying mechanism comprises a conveying roller, a conveying chain, a conveying motor and a conveying gear; the conveying motor rotates to drive the conveying chain and the conveying gear and to finally drive the conveying roller to rotate; a timber passing space is formed between the conveying roller and the working table; the lower planing mechanism is arranged on the working table; the working table comprises a fixed table and a movable table; the movable table vertically moves, and fits the conveying roller to clamp the timber; and an upper planing mechanism is additionally arranged on the frame. The planing machine can synchronously plane the upper and lower end surfaces of the timber to prevent secondary processing, so that the production efficiency is improved, and the energy consumption is reduced.

Owner:ANJI DEMAI BAMBOO & WOOD MACHINERY

Pneumatic automatic filing forceps machine with saw

InactiveCN104722844ALighten the intensityAvoid scratchesSawing tools dressing arrangementsElectricityControl system

Owner:叶天云

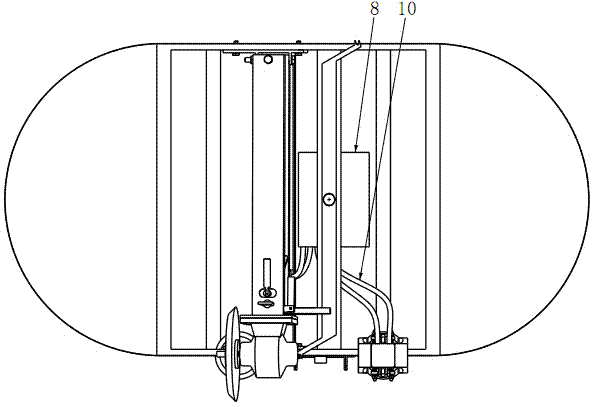

Device for adjusting knife door of numerical control hydraulic double-clamp veneer lathe

ActiveCN101347944AEasy to operateHigh adjustment accuracyVeneer manufactureNumerical controlEngineering

The invention discloses a device for adjusting the cutter of a numerical control hydraulic double-spindle veneer lathe, which relates to woodworking machinery. A cutter frame body is arranged on a machine body, a guide rail is arranged above the cutter frame body, a sliding seat is arranged on the guide rail, and a pressure bar frame is arranged on the sliding seat; a servo motor is arranged on the machine body and is connected with a leading screw; nuts are arranged on the leading screw, and the nuts are connected with the sliding seat. As the guide rail is arranged above the cutter frame body, the sliding seat is arranged on the guide rail, the pressure bar frame is arranged on the sliding seat, the servo motor is arranged on the machine body, the servo motor is connected with the leading screw, the nuts are arranged on the leading screw, and the nuts are connected with the sliding seat, the cutter can be adjusted in the operating state of the veneer lathe. When the thickness of a rotary veneer is changed, the servo motor is driven to adjust the cutter without shutting the machine down. The device has the advantages of simple operation, high adjusting precision and high working efficiency, and is suitable for adjusting the cutter of the numerical control hydraulic double-spindle veneer lathe.

Owner:SHANDONG BAISHENGYUAN GRP

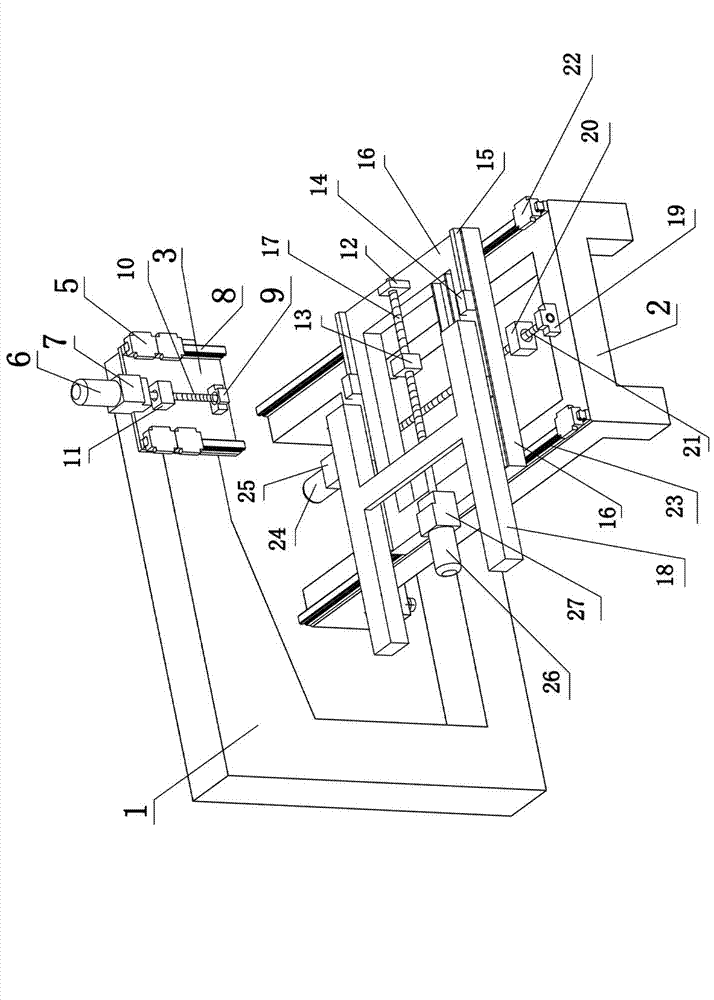

Multi-head joggling machine for woodworking

ActiveCN106239642AIncreased versatilityImprove installationTongue/grooves making apparatusMulti-purpose machinesEngineeringWoodworking machinery

The invention provides a multi-head joggling machine for woodworking, belongs to the technical field of woodworking machinery, and solves the problem of poor machining quality in the prior art. The multi-head joggling machine for woodworking comprises a working table located at the front part and a base located at the back part; a vertical support seat is arranged on the base and is glidingly connected onto the base in the horizontal direction; a power source I for driving the support seat to move relatively to the base is arranged between the support seat and the base; a power head I and a power head II are arranged on the support seat, are glidingly connected onto the support seat in the vertical direction and can move relatively in the horizontal direction; a power source II for driving the power head I and the power head II to move relative to the support seat is arranged on the support seat; the output end of the power head I and the output end of the power head II face the working table; and the axis of an output shaft of the power head I is parallel with the axis of an output shaft of the power head II. With the multi-head joggling machine for woodworking, the working efficiency for joggling machining can be improved.

Owner:TAIZHOU EVOK MASCH CO LTD

Woodworking sliding table saw capable of being adjusted conveniently and rapidly

InactiveCN106182193AGuaranteed cutting accuracyGuaranteed accuracySawing componentsCircular sawsInstabilityEngineering

The invention discloses a conveniently adjustable woodworking sliding table saw, which belongs to the technical field of woodworking machinery, and comprises a sliding table frame and a saw blade located on the sliding table frame, and a left push plate is provided on both sides of the sliding table saw blade and the right push plate, the sliding direction of the left push plate is fixed with a support block, the support block is threadedly connected with a push rod, one end of the push rod is rotated with the left push plate, and the other end is provided with a handle; the right push plate There is a stopper in the sliding direction of the stopper, a slide bar is set on the stopper, the slide bar is fixedly connected to the side of the right push plate, and a spring is set on the slide bar, which solves the problem that the existing table saw cannot accurately process the wood board to be processed. Instability during positioning and processing leads to poor cutting quality of wood boards.

Owner:武侯区华聚家私经营部

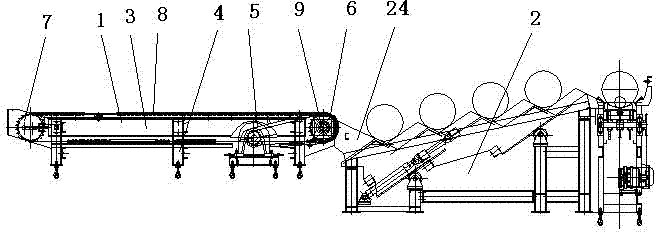

Step-type stepping wood feeding machine

ActiveCN103612289ANovel structureNo need for manual handlingSawing componentsHydraulic cylinderAgricultural engineering

The invention relates to the technical field of wood-working machines, in particular to a step-type stepping wood feeding machine. The step-type stepping wood feeding machine is characterized in that the step-type stepping wood feeding machine is provided with a transverse-moving device and a step-type wood feeding device, and the step-type wood feeding device comprises a positioning frame, a base, a step-type wood feeding frame, a conveying hydraulic cylinder, a rear supporting roller, a front supporting roller, rear guide rails and front guide rails; the rear end of the lower portion of the positioning frame is fixedly connected with the base through a short supporting leg and the front end of the lower portion of the positioning frame is fixedly connected with the base through a high supporting leg to make the positioning frame inclined; the step-type wood feeding frame is arranged in the middle of the positioning frame, and unit triangle positioning plates are sequentially arranged on the two sides of the positioning frame from back to front and are connected end to end; the rear guide rails are arranged at the rear ends of the two sides of the lower end of the step-type wood feeding frame respectively, the front guide rails are arranged at the front ends of the two sides of the lower end of the step-type wood feeding frame respectively, the conveying hydraulic cylinder is arranged in the middle of the step-type wood feeding frame, one end of the conveying hydraulic cylinder is hinged to the base, and the other end of the conveying hydraulic cylinder is hinged to the step-type wood feeding frame. The step-type stepping wood feeding machine has the advantages of being novel in structure, capable of automatically feeding wood, low in labor intensity, high in working efficiency, low in production cost and the like.

Owner:SHANDONG BAISHENGYUAN GRP

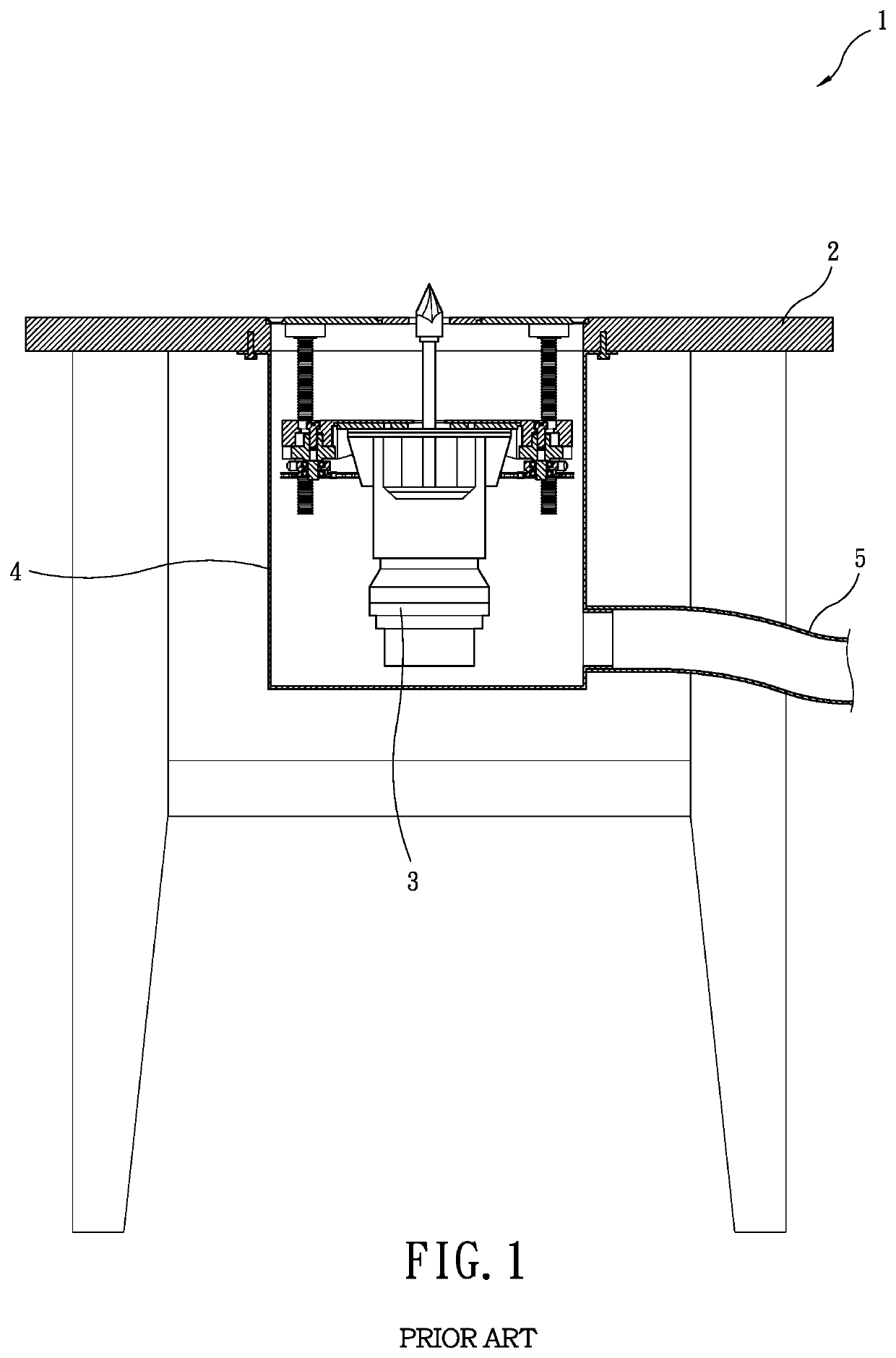

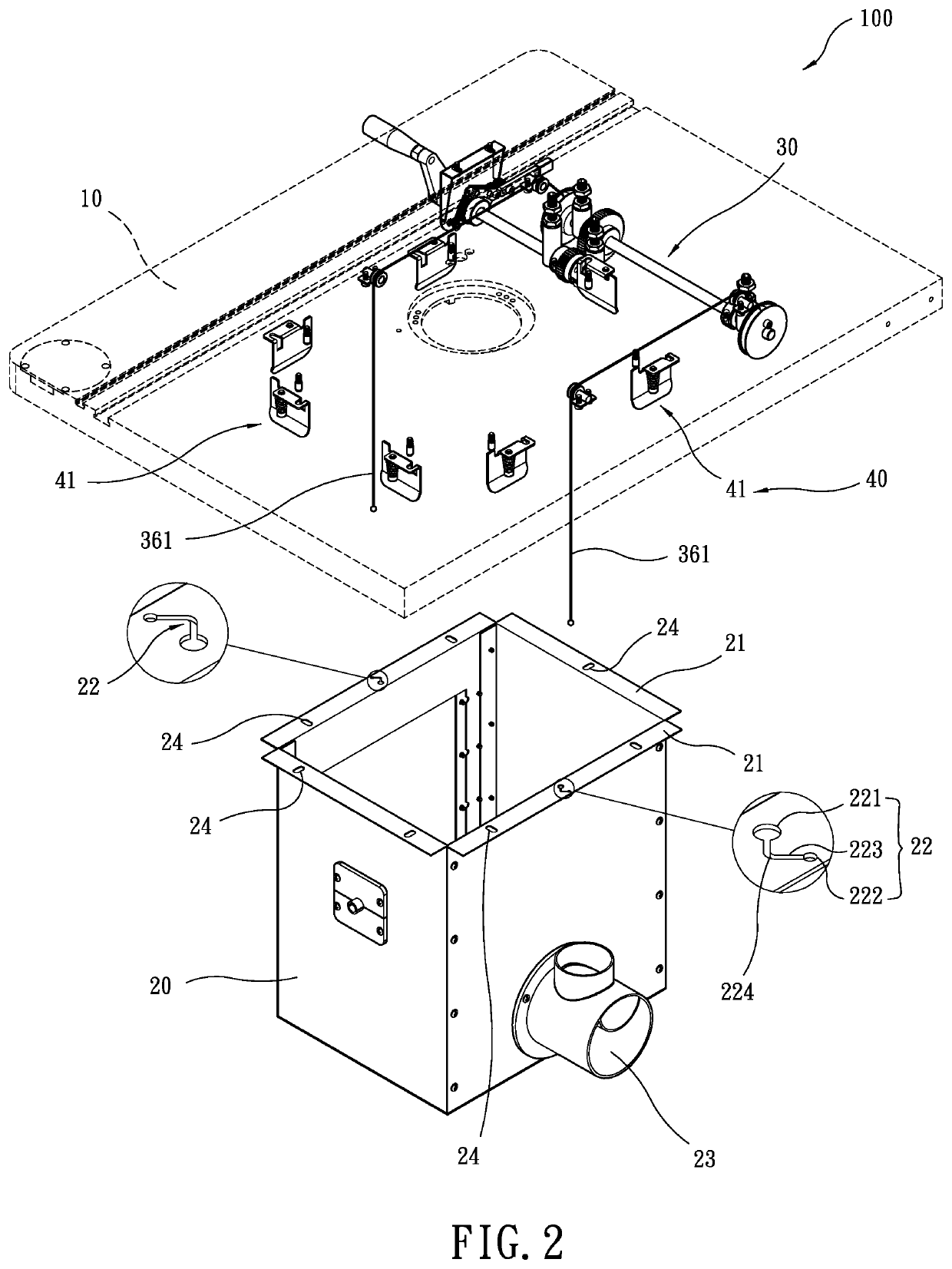

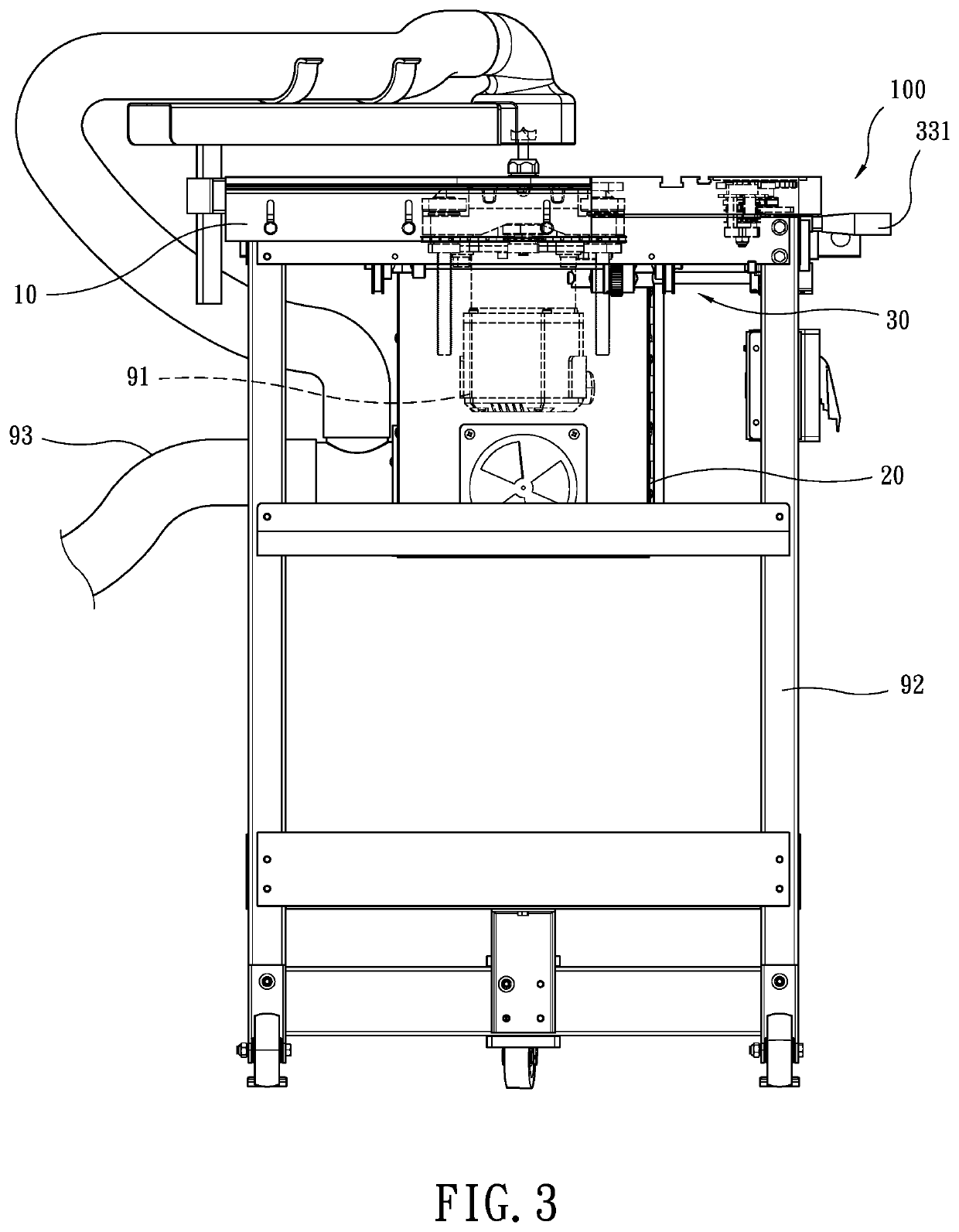

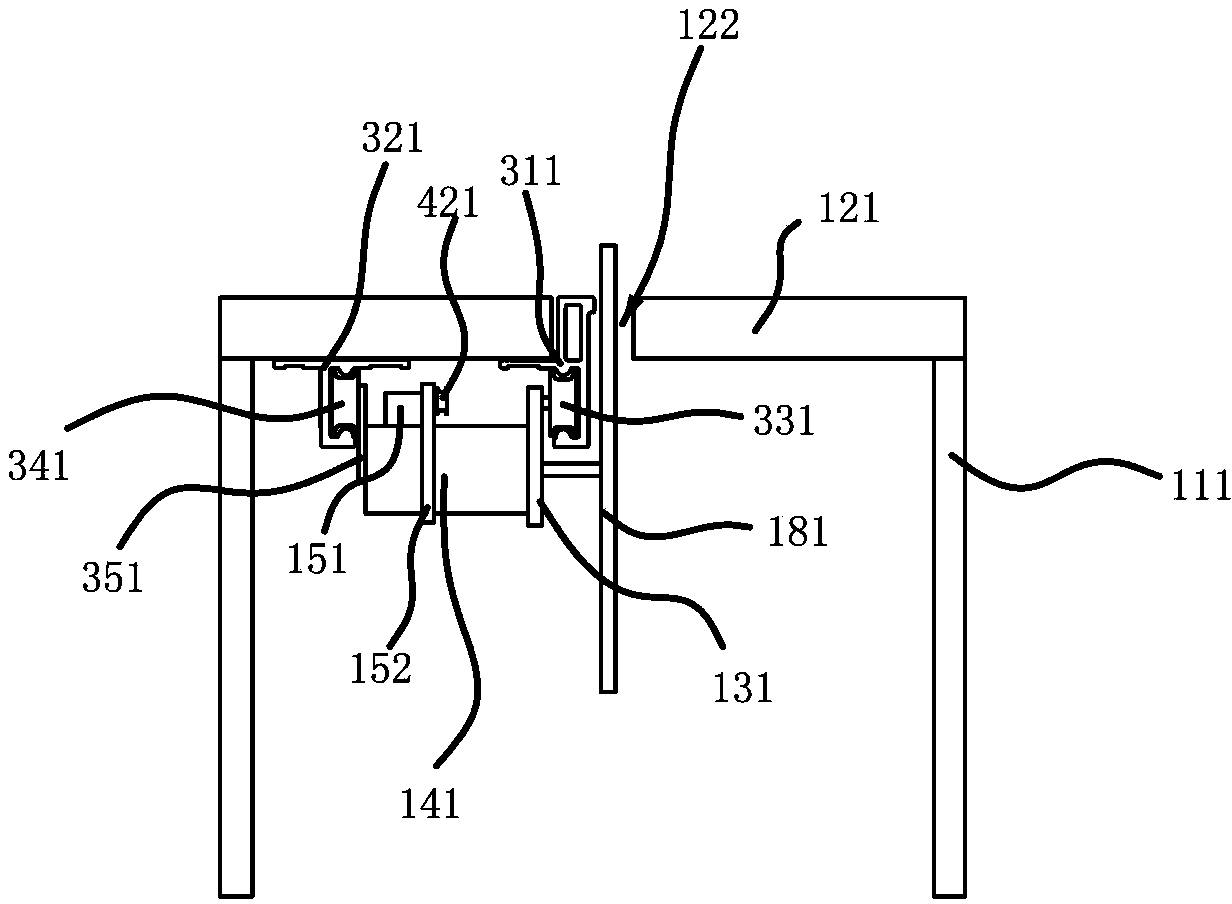

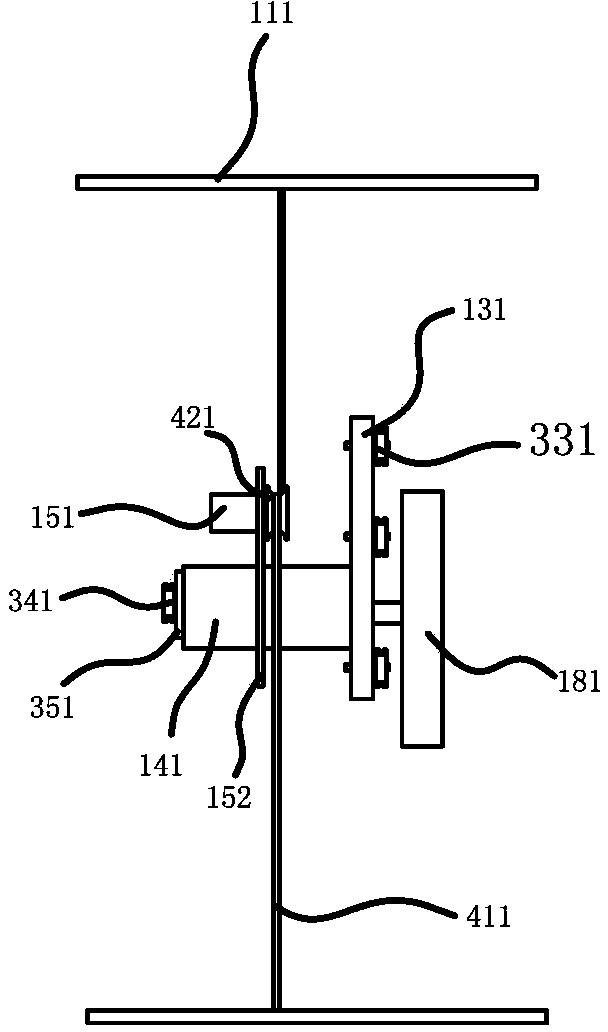

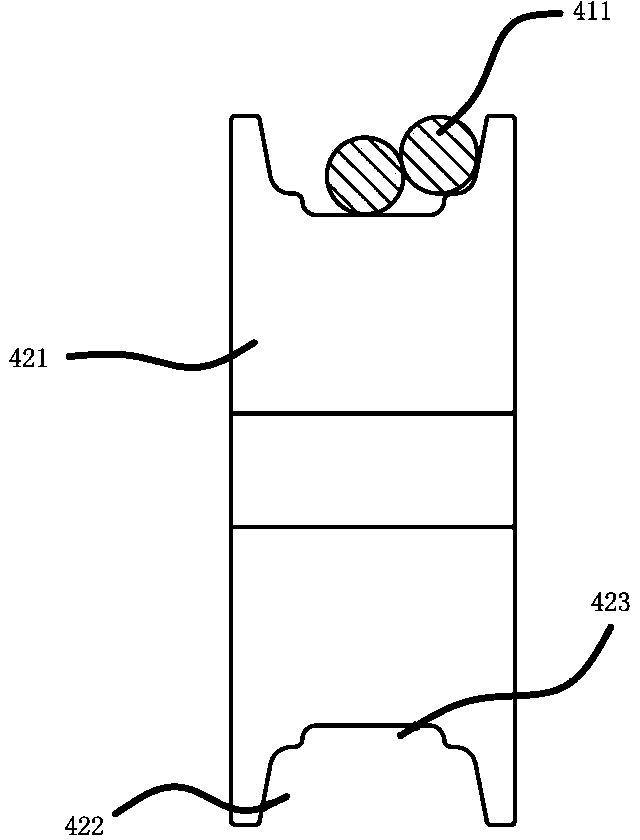

Lift device for dust collection box of wood working machine

ActiveUS10787346B1Prevent fallingMulti-purpose machinesProfiling/shaping machinesGear wheelDrive shaft

A lift device for a dust collection box of a wood working machine includes a driving shaft unit, a passive shaft unit, a rotary unit, a break unit, a pulley unit and a cable unit. The driving shaft unit and the passive shaft unit are connected to the underside of the working table. The driving shaft unit includes a first gear and a second gear. The passive shaft unit includes a third gear which is engaged with the second gear. The rotary unit is connected to the driving shaft unit to rotate the driving shaft. The break unit is pviotable between a break position and a loose position. When the break unit is at the break position, the break unit prevents the driving shaft from self-rotating. The lift device lifted or lowers the dust collection box by cooperation of the pulley unit and the cable unit the lift device.

Owner:YU HSI HUI

Sawing machine

ActiveCN103358358AGuaranteed to be smoothReduce the use of laborCircular sawsEngineeringWoodworking machinery

The invention provides a sawing machine, and belongs to the technical field of wood-working machines. The sawing machine solves the technical problems that an existing sawing machine can only drive an electric saw to move through a motor, and the electric saw cannot be manually pushed to move. The sawing machine comprises a rack, a workbench fixedly arranged on the rack and an electric saw capable of sliding along the workbench, the electric saw is provided with a handle used for manually pushing the electric saw to move, the sawing machine further comprises a guide rope and a fixed rod, the guide rope is arranged in the sliding direction of the electric saw, one end of the guide rope is fixedly arranged at one end of the rack, the other end of the guide rope is fixedly arranged on the fixed rod, the fixed rod is arranged at the other end of the rack, an adjusting mechanism capable of adjusting the distance between the fixed rod and one end of the rack to tighten or loosen the guide rope is arranged between the fixed rod and the rack, and a walking motor which can drive the electric saw to move along the guide rope when the guide rope is tightened is arranged on the guide rope. The electric saw can be automatically driven to move through the walking motor or is manually pushed to move through the handle, and the sawing machine has the advantage of having multiple operating modes.

Owner:颜夏根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com