Pneumatic automatic filing forceps machine with saw

A pneumatic and band saw technology, applied in metal sawing equipment, tool trimming of sawing machine devices, metal processing equipment, etc., can solve the problems of manual pliers easily scratching workers, uneven tooth shape, low efficiency, etc. Achieve the effects of simple structure, light strength and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the content of the invention, features and functions of the present invention, in conjunction with the accompanying drawings, give an example to describe in detail as follows:

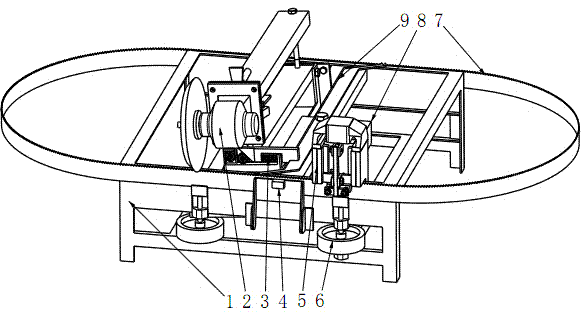

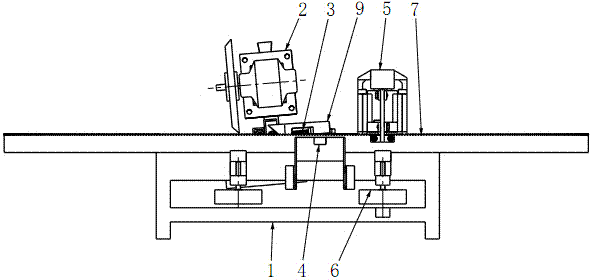

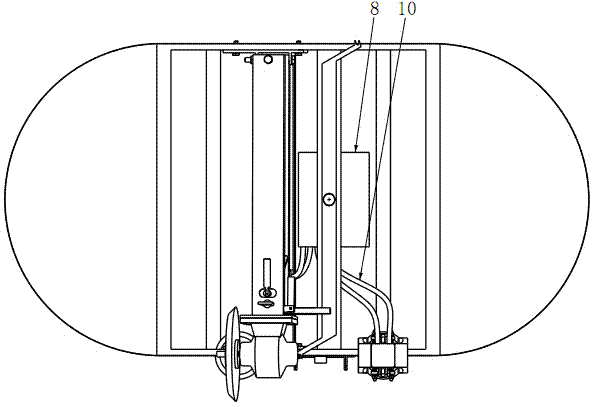

[0037] figure 1 , 2 , 3 shows the overall view of the working state of the present invention, the overall structure of the present invention consists of a machine housing 1, a tooth filing device 2, a tooth pulling mechanism 9, a tooth pliers device 5, a band saw position regulator 6 and an electrical control system 8 Composition, the upper part of the housing is provided with a file tooth device 2, a tooth pulling mechanism 9 and a tooth clamp device 5 in sequence; four band saw position regulators 6 are respectively provided on the front and rear ends of the housing, and the band saw position regulator 6 functions in And support the band saw blade 7, and adjust the position of the band saw blade 7 according to the width of the band saw blade 7 and the size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com