Wooden mug processing device for wood-working machinery

A technology for processing devices and woodworking machinery, which is applied in the direction of grinding drive devices, metal processing equipment, and machine tools suitable for grinding the edge of workpieces, etc. It can solve the problem of slowing down the grinding speed of wooden cups and achieve the effect of automatic feeding and grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

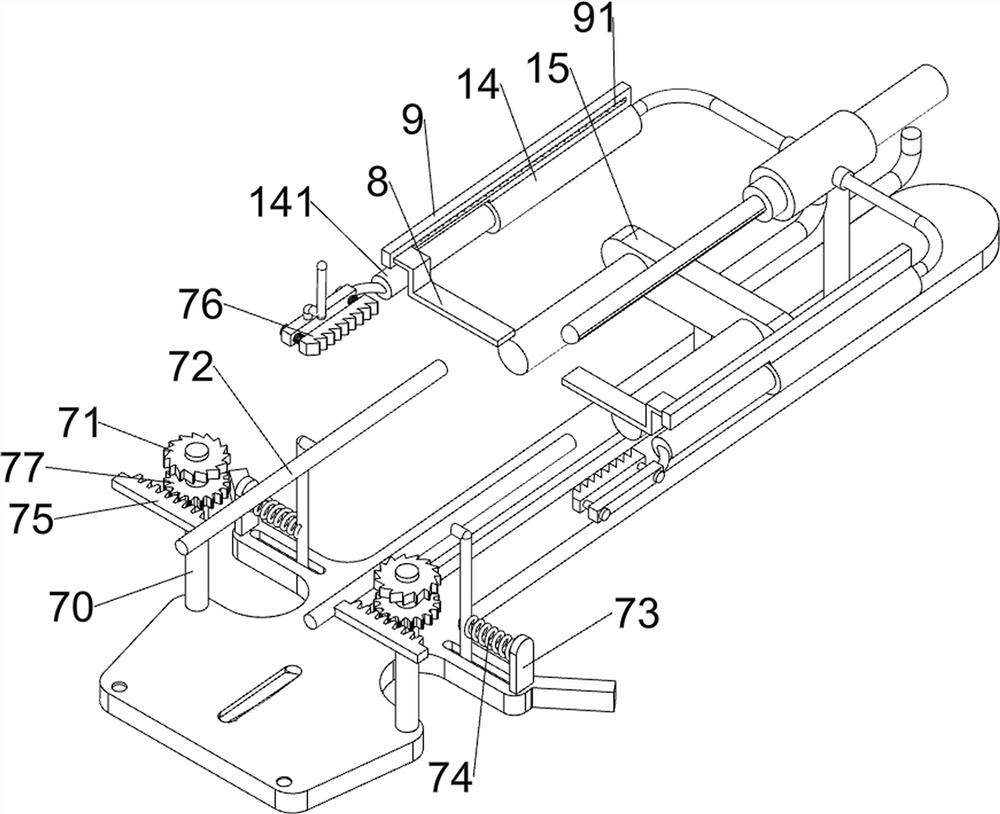

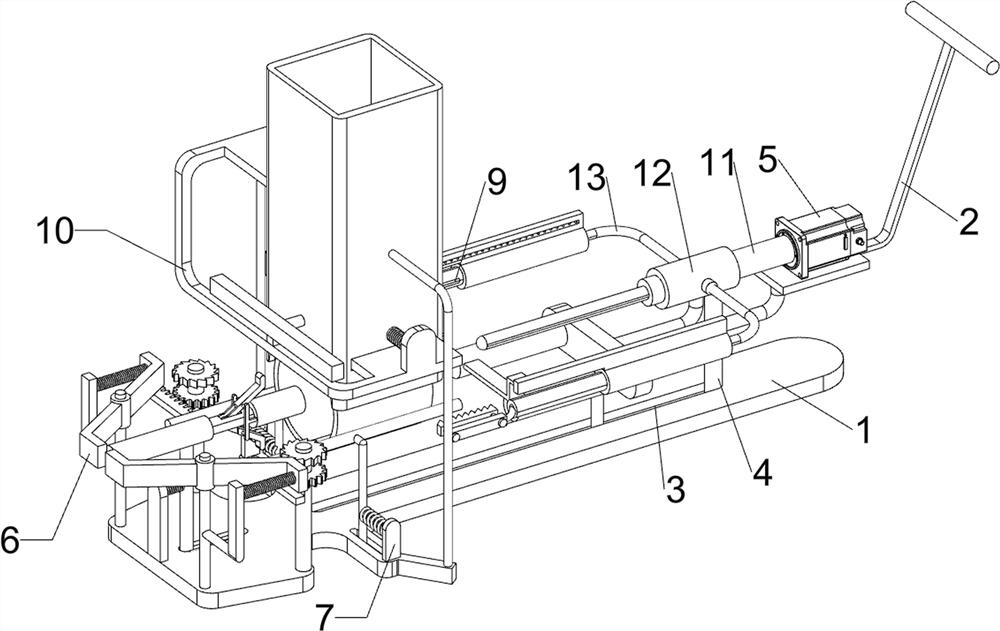

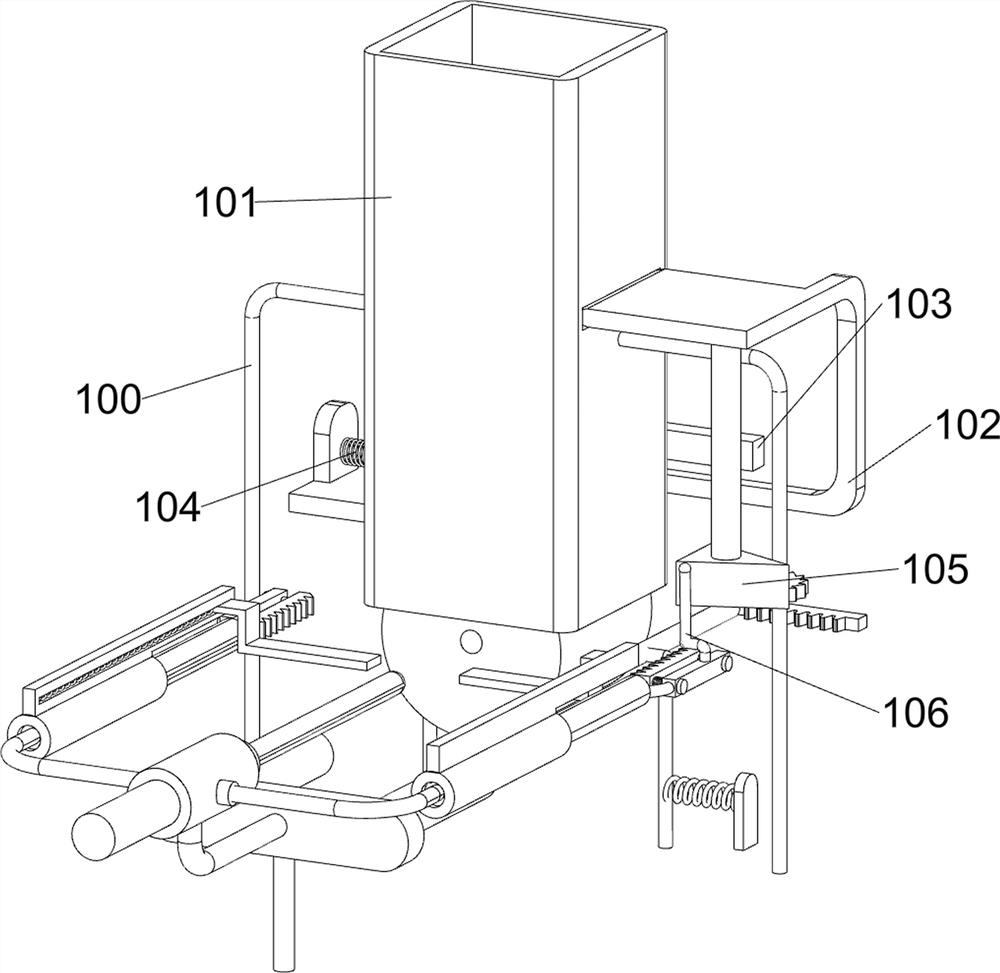

[0023] A wooden cup processing device for woodworking machinery, such as Figure 1-6 As shown, it includes a base 1, a push handle 2, a first support rod 4, a servo motor 5, a clamping mechanism 6, a fixing mechanism 7, a push plate 8, a first slide rail 9, a fifth spring 91, a blanking mechanism 10, The second rotating shaft 11, the second bearing seat 12, the second connecting rod 13, the hollow cylinder 14, the slide shaft 141, the grinding machine 15, the spline shaft 16, the seventh spring 17 and the eighth spring 18, the base 1 top middle has a The chute 3 is provided with a sliding first support rod 4 inside the chute 3, the first support rod 4 is provided with a pusher 2, the upper left side of the pusher 2 is provided with a servo motor 5, and the upper left side of the base 1 is provided with a clamping mechanism 6. The upper part of the base 1 is provided with a fixing mechanism 7, the upper part of the first support rod 4 is provided with a second bearing seat 12, ...

Embodiment 2

[0026] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, the clamping mechanism 6 includes a baffle 60, a first slide bar 61, a first spring 62, a first bearing seat 63, a first rotating shaft 64, a fixed block 65, a fixed shaft 66, a sleeve 67, a second spring 68, support column 69, the third spring 610 and crank 611, base 1 upper left side is provided with baffle plate 60, base 1 upper left side sliding type is provided with first slide bar 61, between first slide bar 61 and baffle plate 60 A first spring 62 is connected between them, a first bearing seat 63 is provided on the top of the first sliding rod 61, a first rotating shaft 64 is rotatably provided on the first bearing seat 63, and a sleeve 67 is slidingly provided on the first rotating shaft 64, A second spring 68 is connected between the sleeve 67 and the first rotating shaft 64. The sleeve 67 is provided with fixed blocks 65 on the front and rear sides. 66, a rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com