Screw rod with rollers

A technology of roller screw and roller, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of high wear and heat, high noise and high cost, achieve low friction, reduce manufacturing cost and The effect of running noise and low cost

Inactive Publication Date: 2010-06-23

徐众

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, compared with the traditional nut screw, the friction and heat are relatively large, the cost of the ball screw is high, the screw needs to be finely ground, and the noise is relatively high, and the planetary roller screw needs to process the tooth surface and the inner ring gear, and the cost is high. complex structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

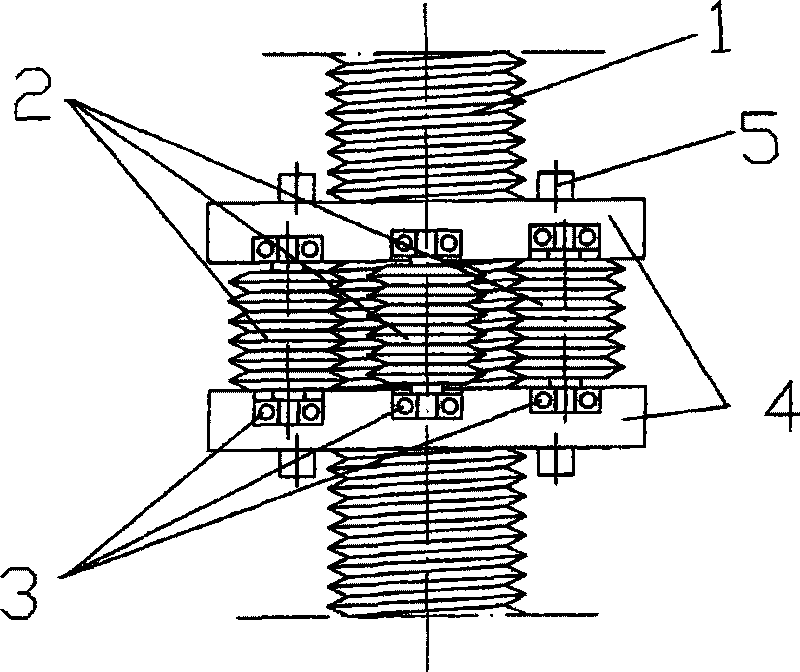

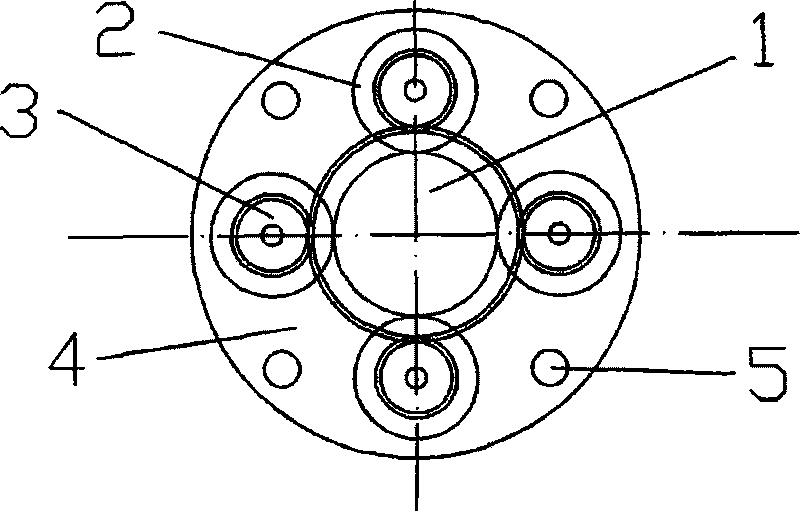

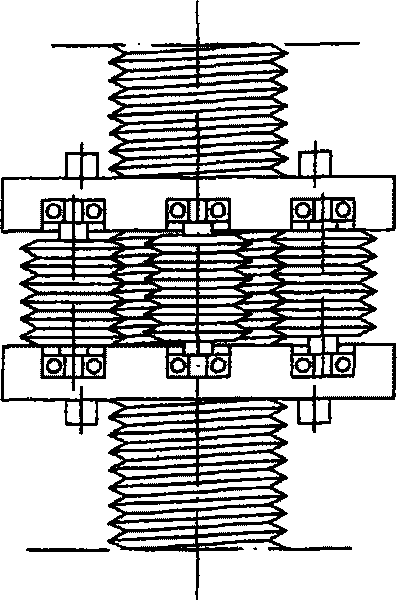

[0009] When the roller screw is in operation, the rotation of the screw (1) drives the meshed roller (2) to rotate and translate, and the roller (2) is supported by the bearings (3) at both ends to rotate and drives the bearing seat (4) to translate.

[0010] This kind of screw can be widely used in linear motion mechanisms driven by screw or ball screw, such as machine tools, woodworking machinery, medical and automation equipment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a screw rod with rollers, which comprises a screw rod, rollers, a bearing, a bearing pedestal and pin bolts, wherein the rollers are uniformly distributed on the circumference of the screw rod, both ends of the rollers are positioned in the bearing pedestal by the bearing, the bearing pedestal is fixed by the pin bolts, and the uniformly distributed rollers are distributed in parallel with an equal height difference in an axial direction and engaged with the threads of the long screw rod. During running, the rotation of the screw rod drives the engaged rollers to rotate and translate, and the rollers are supported by rolling bearings at both ends to rotate and drive the translation of the bearing pedestal. The screw rod can be widely used on straight-line motion mechanisms driven by a screw or transmitted by a ball screw, such as a machine tool, woodworking machinery, medical treatment and automation equipment.

Description

Technical field: [0001] A new type of roller screw can be widely used in linear drive systems of machine tools and various automation equipment. Background technique: [0002] At present, compared with the traditional nut screw, the friction and heat are relatively large, the cost of the ball screw is high, the screw needs to be finely ground, and the noise is relatively high, and the planetary roller screw needs to process the tooth surface and the inner ring gear, and the cost is high. complex structure. Invention content: [0003] In order to overcome the large friction and heat generated by the sliding friction between the nut and the screw, the design adopts the form of a roller, which meshes with the screw and rolls. The rotational motion is pure rolling, and the friction and wear of the screw are greatly reduced. It is suitable for long-term and reciprocating Movement body. [0004] attached figure 1 As shown, there are rollers (2) evenly distributed in the circu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16H25/22

CPCF16H25/2252

Inventor 徐众

Owner 徐众

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com