Multi-station automatic finger joint machine

A finger-joining machine and multi-station technology, applied in the direction of manufacturing tools, wood processing equipment, circular saws, etc., can solve the problems of unstable quality of finished wood, low production efficiency, cumbersome operation, etc., and achieve high degree of automation and high production efficiency High, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

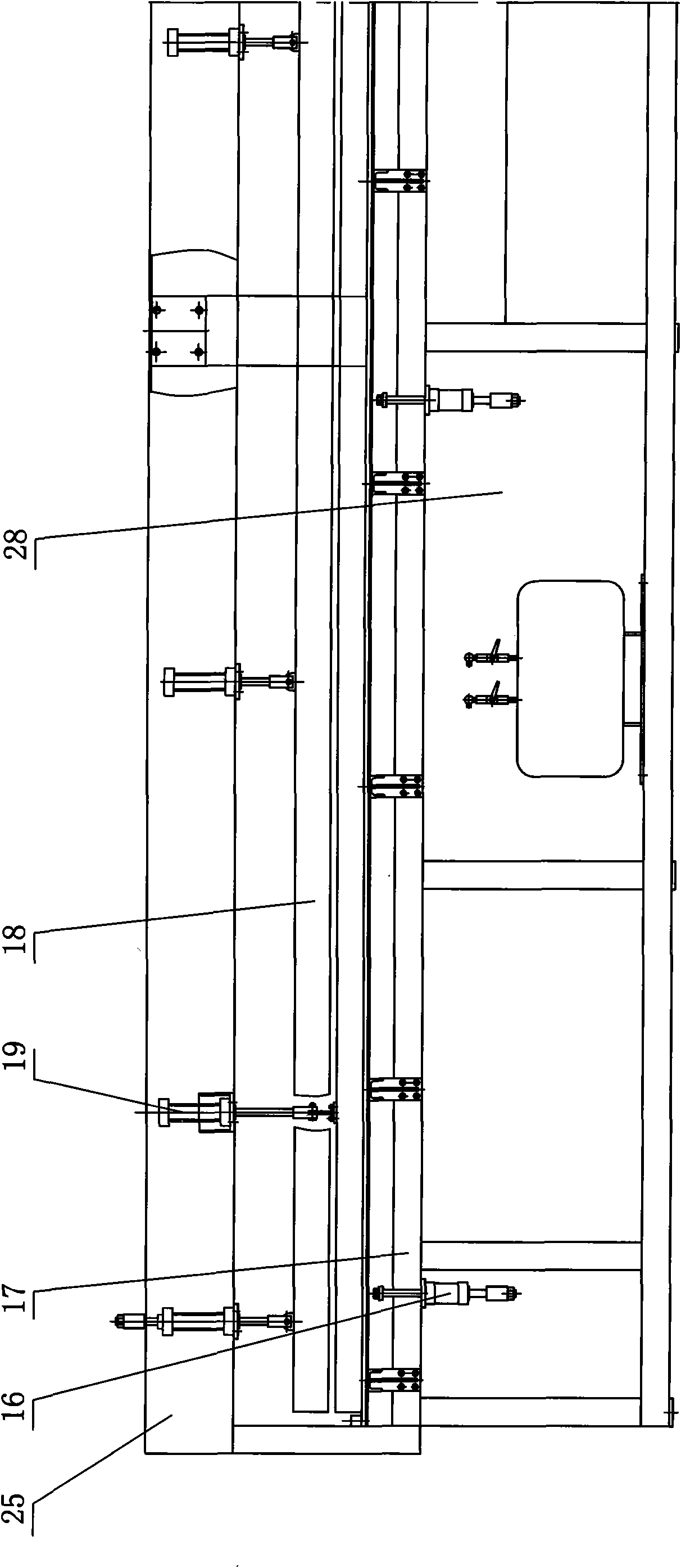

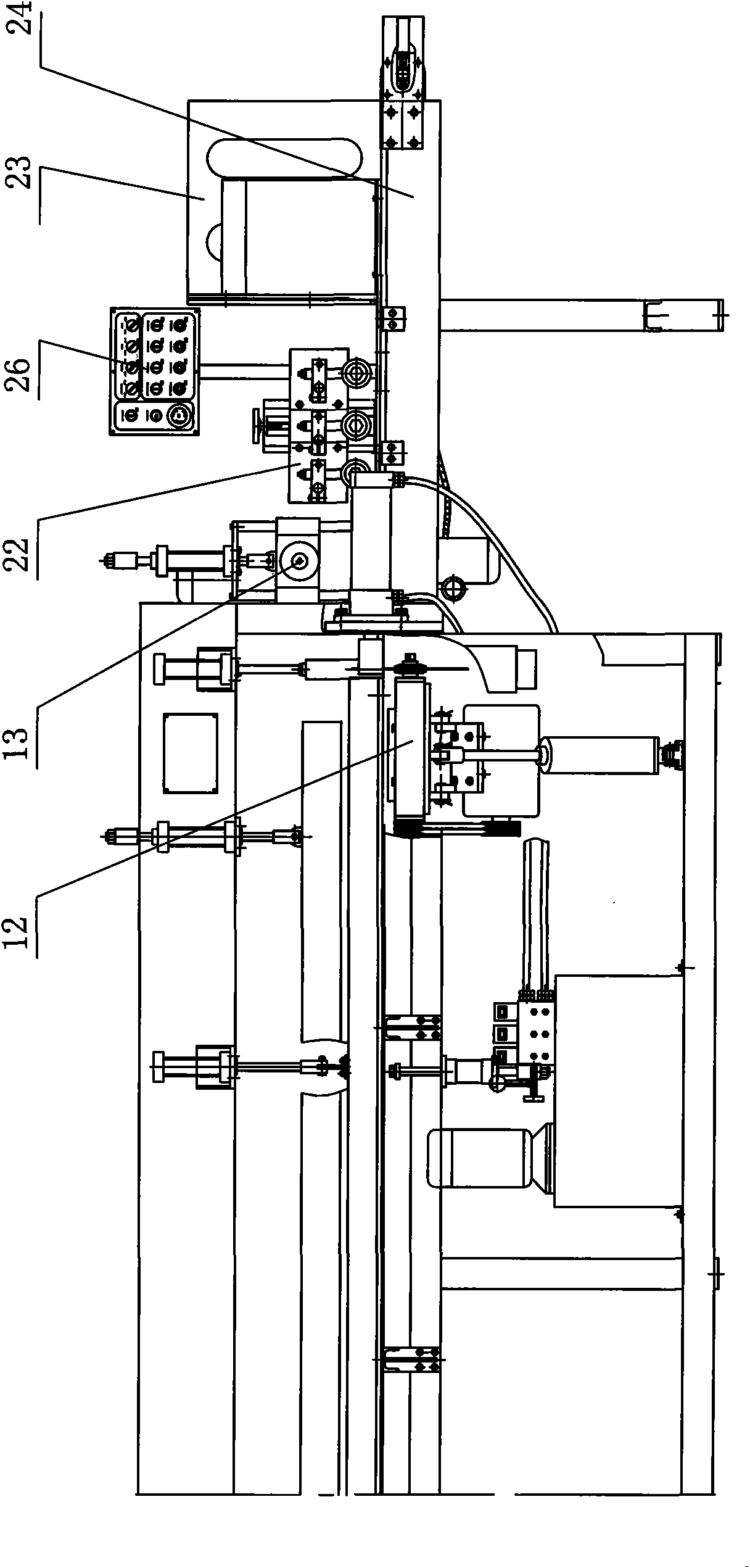

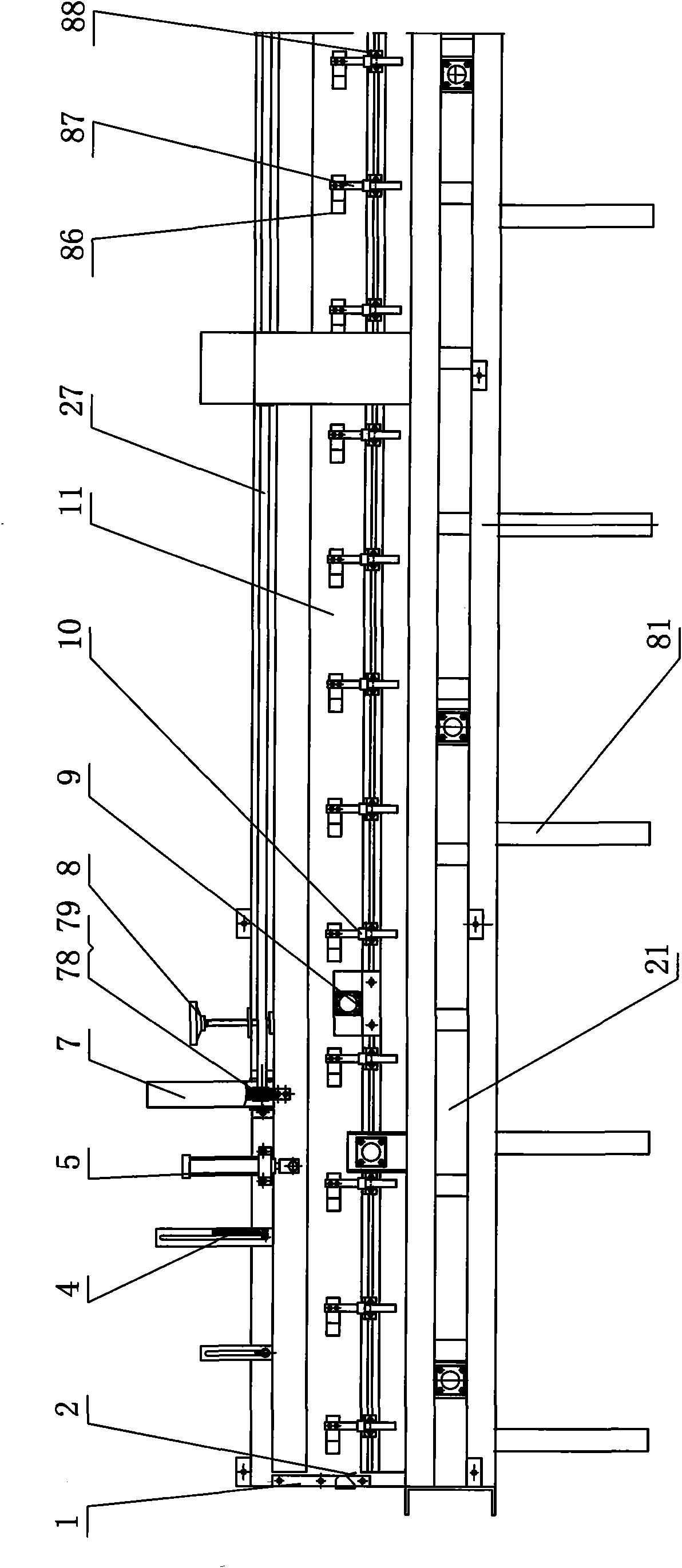

[0039] Below in conjunction with accompanying drawing, the present invention is further described:

[0040] A multi-station automatic finger joint machine, comprising a machine body 28, an extrusion workbench 21, an extrusion cylinder 14, a baffle plate 1, a support beam 25, a cylinder 16, a front support plate 17, a side pressure plate 20, an upper pressure plate 18 and electrical appliances Control system, body 28, extruding workbench 21, extruding oil cylinder 14, baffle plate 1, support beam 25, cylinder 16, front board 17, side pressing plate 20, upper pressing plate 18 and the connection relation of electrical control system and existing The technology is the same, the structure and connection relationship of the oil cylinder 14 are the same as the prior art, and the structure and connection relationship of the cylinder 16 are the same as the prior art, which will not be described in detail here. ,, One side of the extruding workbench 21 is the pre-connection workbench 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com