Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Ultrasonic ndt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for ultrasonically detecting weld quality of main loop pipeline of nuclear power plant by phased array

ActiveCN103336055AHigh-precision detectionEasy to adjustAnalysing solids using sonic/ultrasonic/infrasonic wavesOperational systemNuclear power

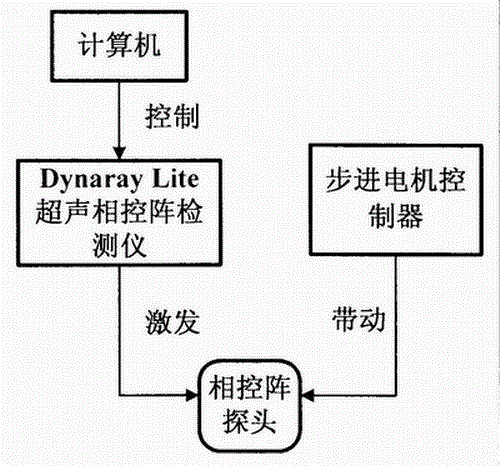

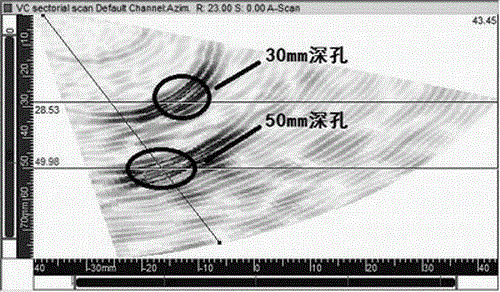

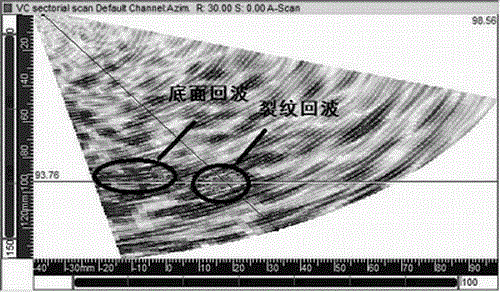

The invention discloses a method for ultrasonically detecting the weld quality of a main loop pipeline of a nuclear power plant by a phased array and belongs to the technical field of ultrasonic non-destructive detection and evaluation. According to the method, a phased array ultrasonic test system composed of a Dynaray Lite ultrasonic phased array tester, an integrated UltraVision3.2R9 phased array operation system, a scanning device and a calibration block is adopted. Aiming at the main pipeline having a thickness of 66-99 mm, a proper area array probe is selected, and a focusing principle parameter, an ultrasonic parameter and a mechanical parameter are matched, so as to perform layered detection on a weld of the main pipeline and the peripheral region. Layered permeation in the existing means for detecting the main pipeline is only capable of detecting the surface open defects of the weld; radiographic detection is incapable of quantifying defect depths and insensitive to area defects such as cracks and incomplete fusion; and the conventional ultrasonic detection technology has the defects of being low in detection efficiency, high in cost, low in imaging capacity and the like. The method disclosed by the invention overcomes the defects is good in quantifying accuracy and high in efficiency in field detection, and has great economic benefits and social benefits.

Owner:DALIAN UNIV OF TECH +2

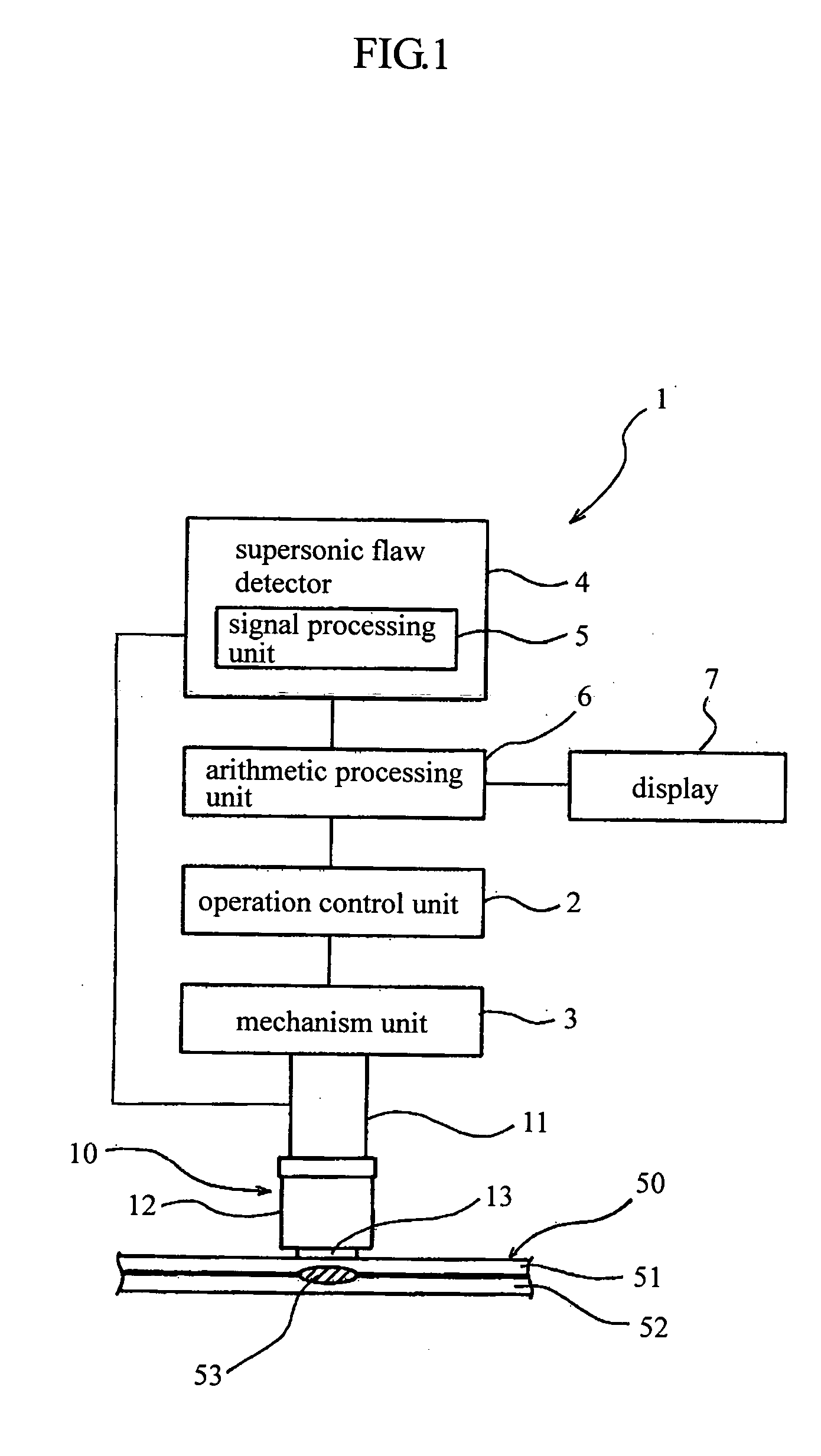

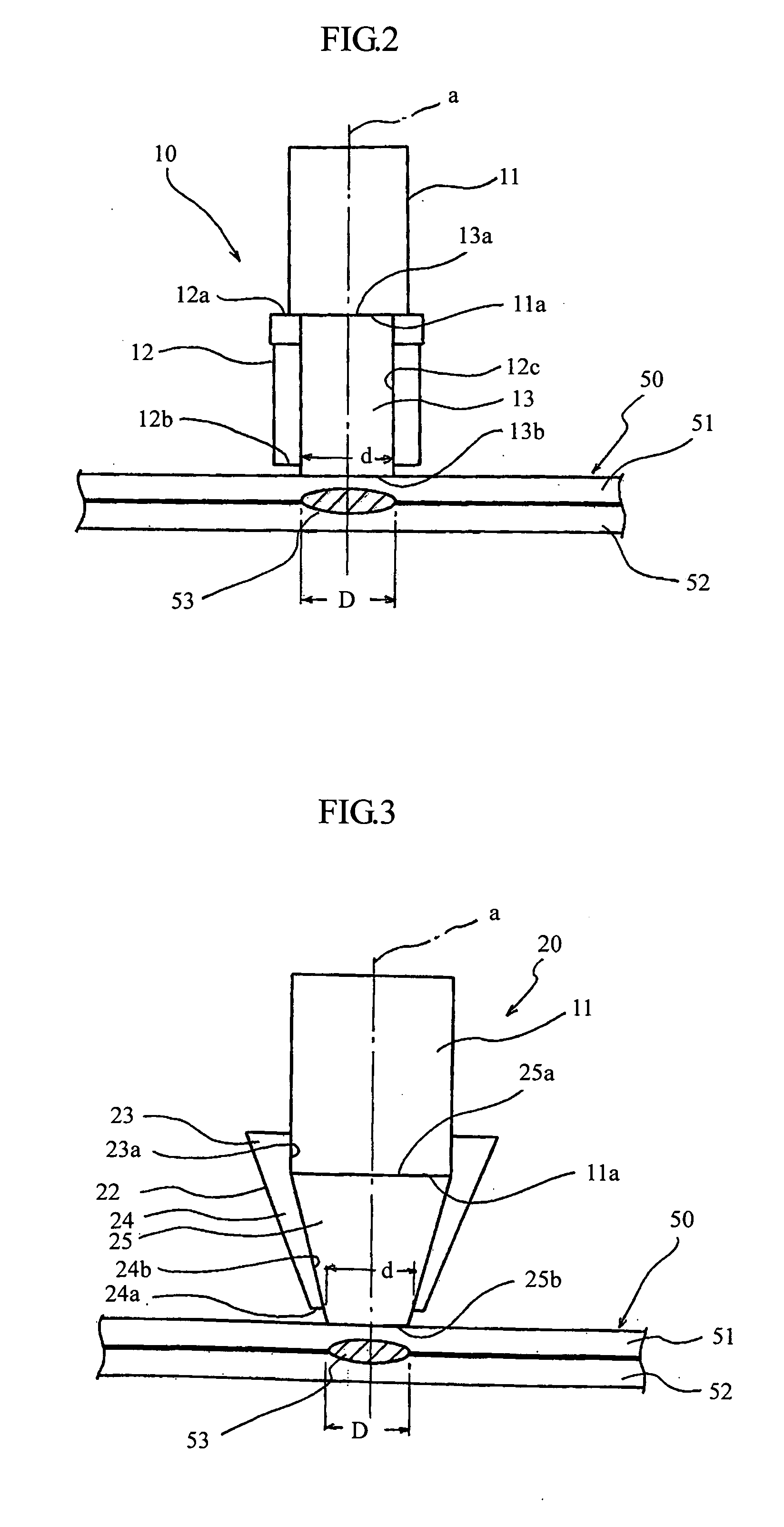

Supersonic sensor head for supersonic non-destructive test apparatus

InactiveUS20050183506A1Easy to transformSimple structureMeasurement of fluid loss/gain rateAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveSonification

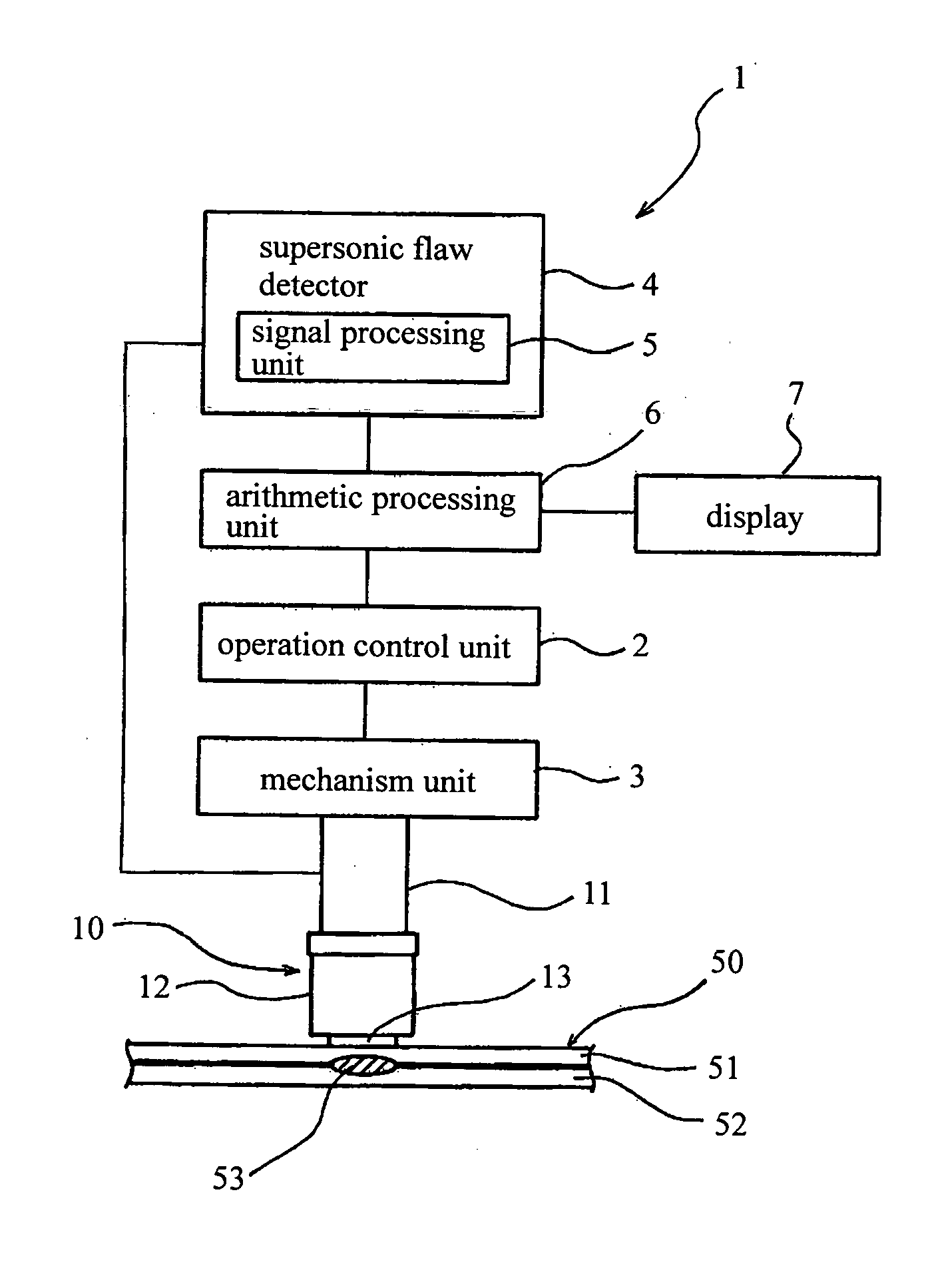

A supersonic sensor head for a supersonic non-destructive test apparatus is disclosed. The supersonic sensor head includes a supersonic vibrator for transmitting and receiving supersonic waves, a holder having a base end and an opening end, and a soft gel material contact medium provided in the holder between the vibrator and a test object. The holder is coaxial with the vibrator so that the base end of the holder is in contact with a free end of the vibrator. By way of the contact medium, the supersonic vibrator indirectly contacts the test object. When a contact part of the contact medium is pressed against the test object, the vibrator comes into close contact with the contact medium, and the contact medium comes into close contact with the test object. The opening end of the holder restricts the deformation of the contact part of the contact medium.

Owner:SUBARU CORP

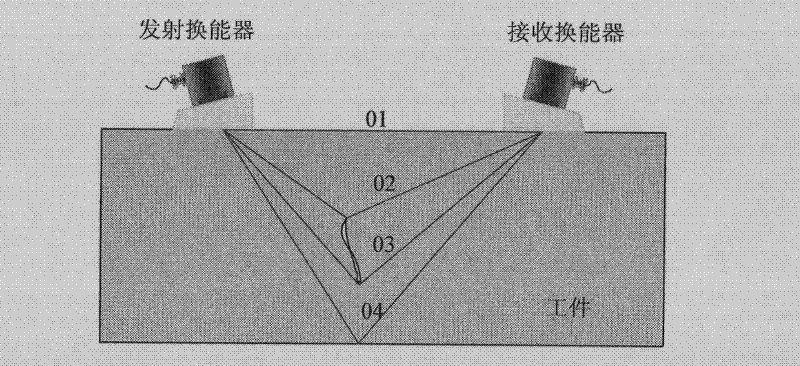

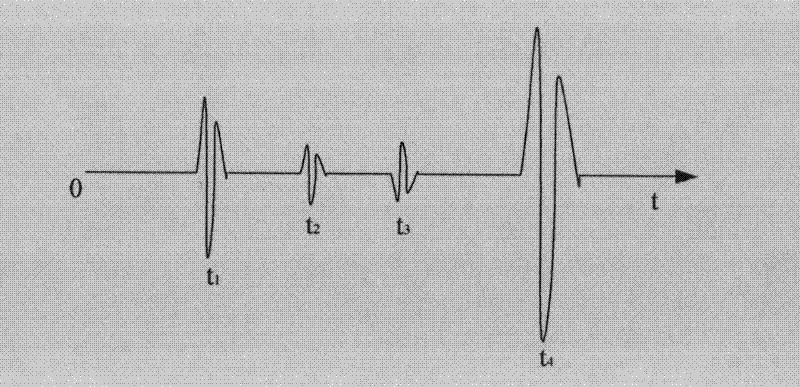

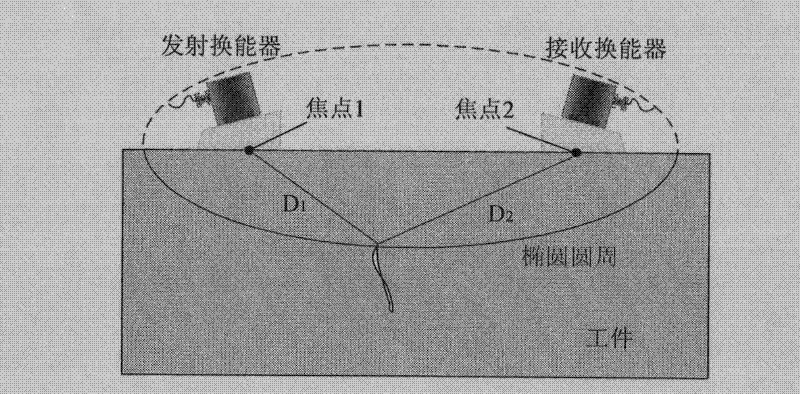

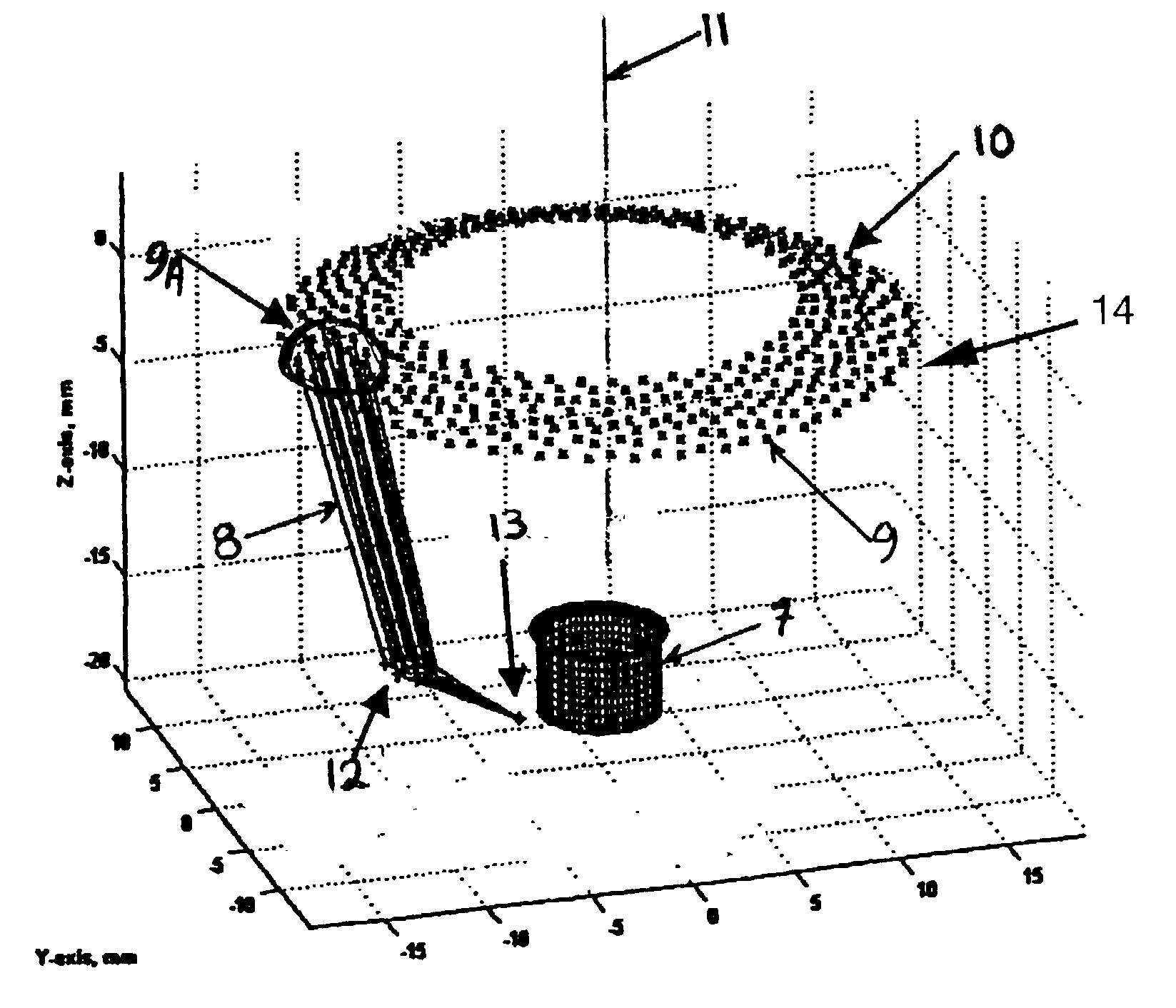

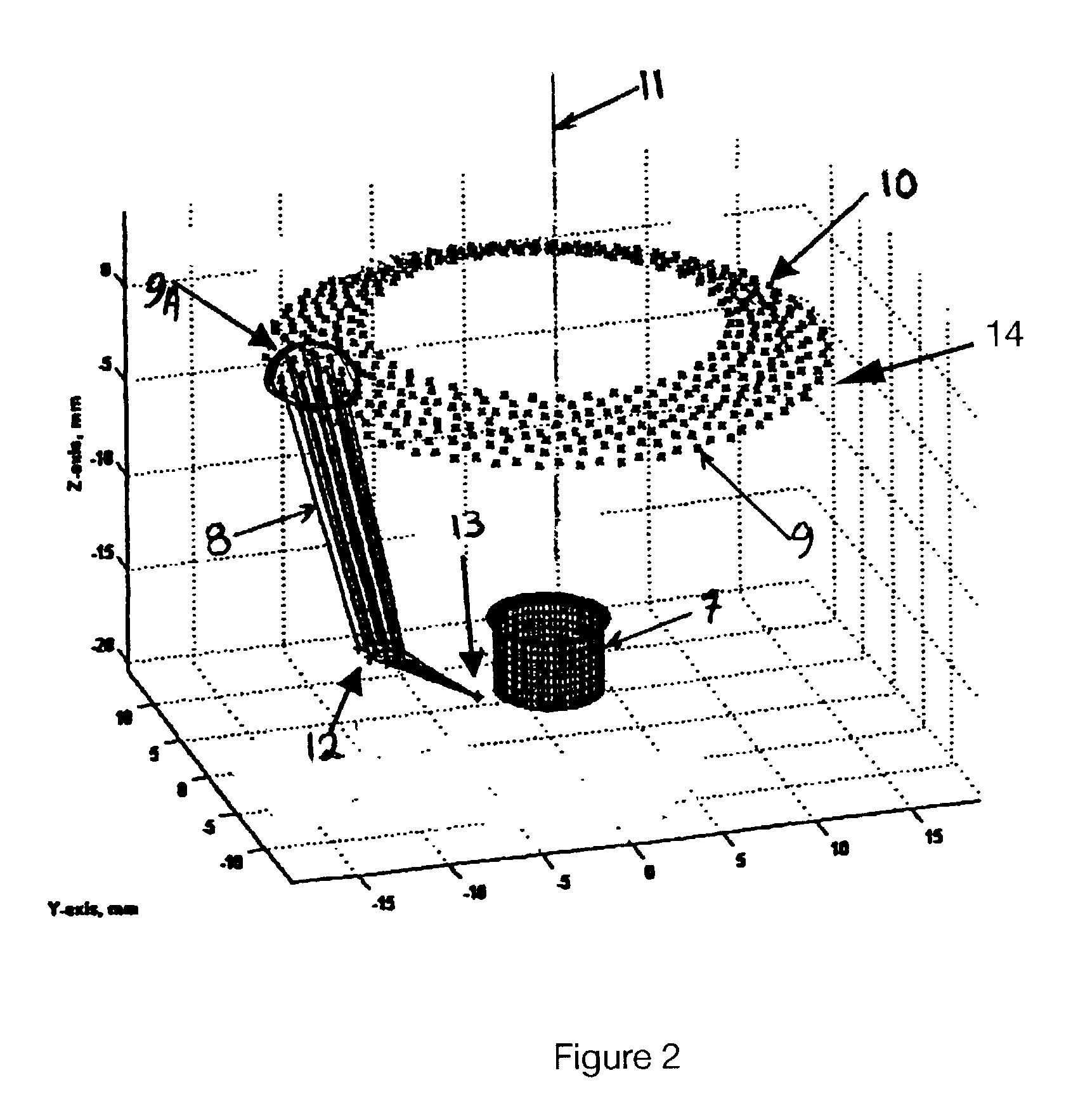

Positioning method of transverse wave TOFD (Time of Flight Diffraction) defect

InactiveCN102207488APrecise positioningAvoid interferenceAnalysing solids using sonic/ultrasonic/infrasonic wavesLongitudinal waveClassical mechanics

In the ultrasonic nondestructive testing field, the traditional time of flight diffraction (TOFD) is used for finding defects of a welding line by only using a longitudinal wave scattering signal; because the type of used signals is single, the three-dimensional positioning of the internal defect of the welding line cannot be realized by the single linear scanning. Aiming the problem, the invention provides a transverse wave TOFD detecting method; one pair of transverse wave probes are used for performing the single linear scanning along the welding line; at the same time, the longitudinal wave and the transverse wave scattering signals of the internal defect of the welding line are used for analyzing to point out that the defect is located on an elliptic trajectory determined by the transverse wave scattering signal and is also located on a circular trajectory determined by the longitudinal wave scattering signal, thus the three-dimensional positioning of the internal defect of the material can be realized by obtaining the intersecting point of the two curves.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

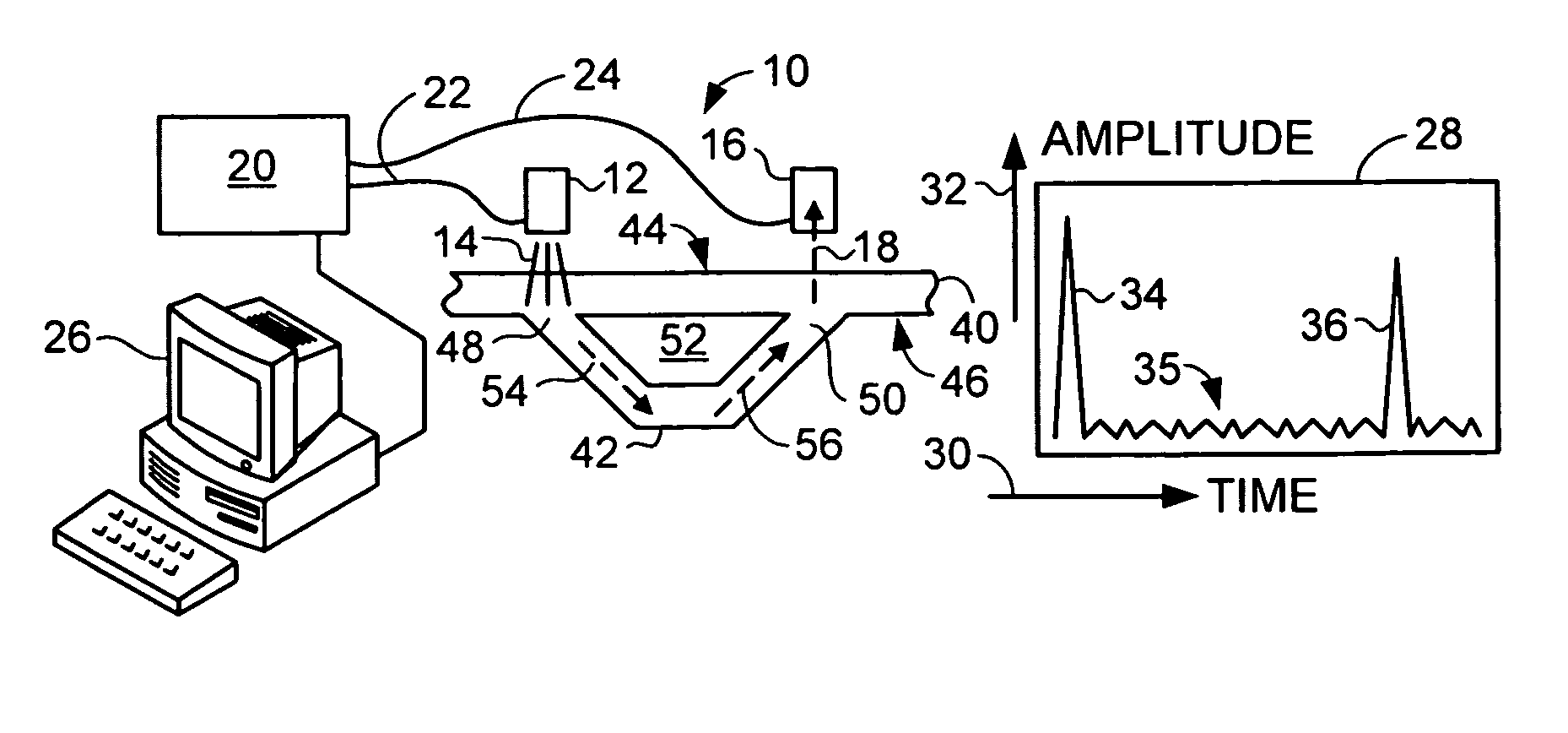

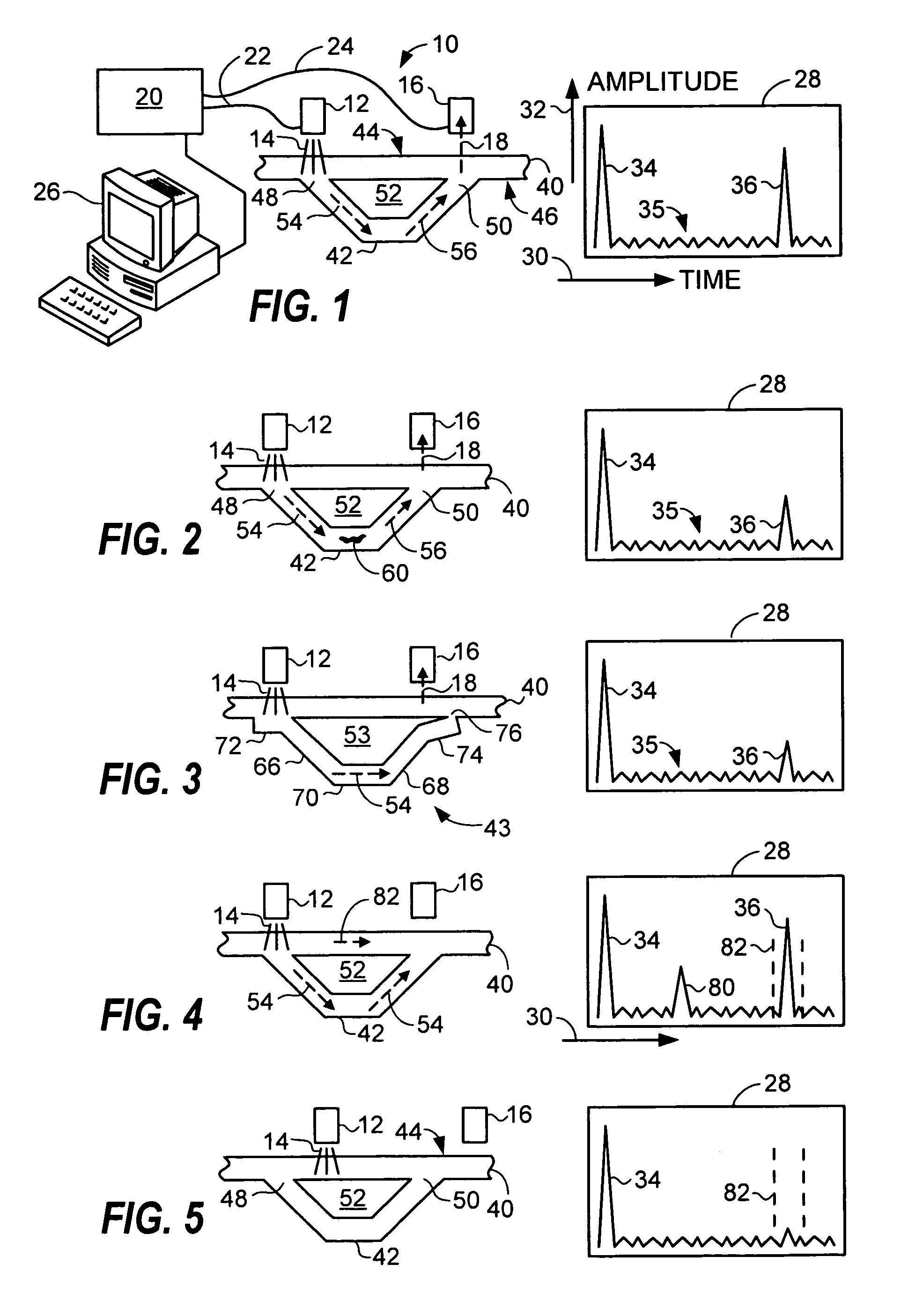

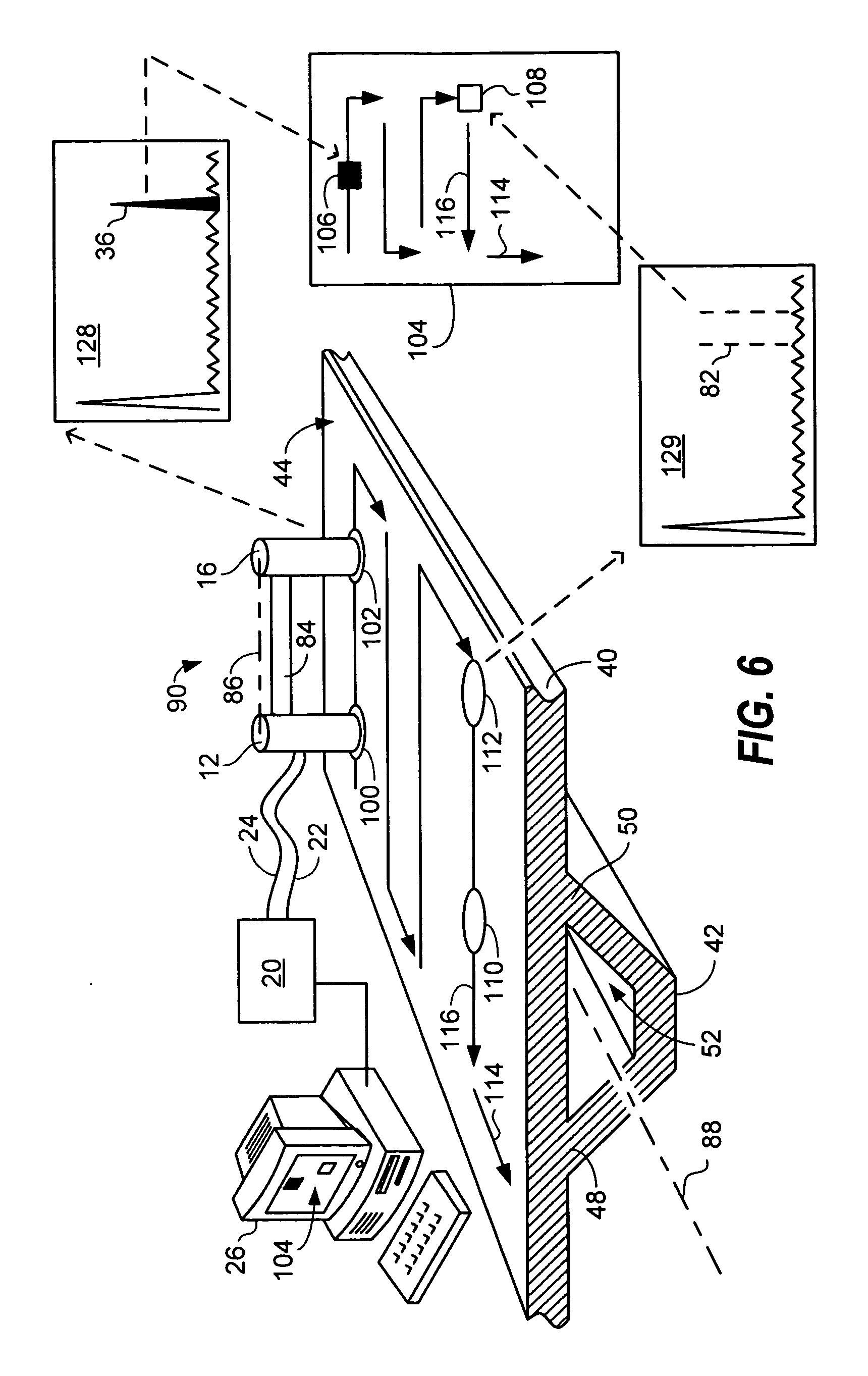

Single-side ultrasonic inspection systems and methods

ActiveUS20070095140A1Analysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionNon destructiveTime gating

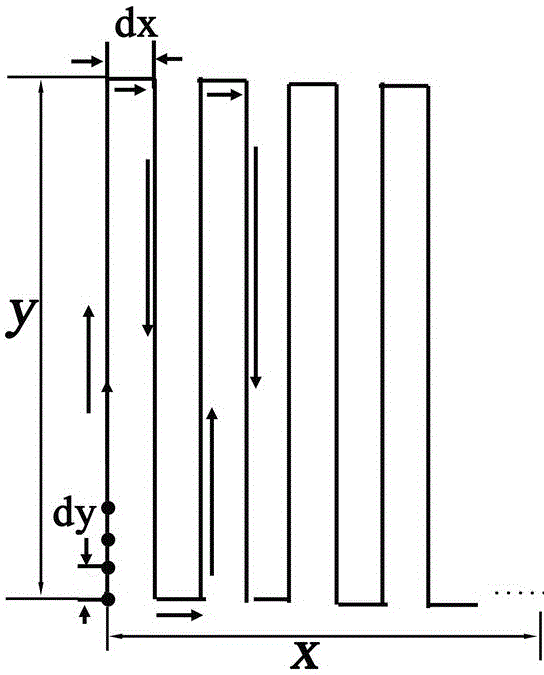

Ultrasonic systems and methods for inspecting a channel member through a skin or panel are provided. The channel member may be a stiffener for an aircraft component such as a trapezoidal stringer attached to a skin of an aircraft fuselage. Transducers of the system are disposed on a side of the skin opposite the channel member. Ultrasonic waves generated on a first side of a skin propagate through the skin, across a channel member attached to a second side of the skin, and through the skin again to be received on the first side of the skin. Times of flight are measured for the collection of time-gated data. A two dimensional C-scan is generated for identifying flaws and irregularities in a structure by way of single-side ultrasonic non-destructive inspection (NDI).

Owner:THE BOEING CO

Phased array ultrasonic NDT system for fastener inspections

InactiveUS7328619B2Analysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansTolerance limitBeam search

An ultrasonic probe suited for testing the integrity of sheet metal surfaces around fastener openings is provided with means to center the probe over such openings. Both a mechanical centering rod and an electronic display assist the user in centering such probe. Once positioned within tolerance limits, phased array ultrasonic beams search for defects within the metal surfaces, allowing for residual offsets in the centering of the probe. Also described are test fixtures for calibrating the probe.

Owner:R D TECH +1

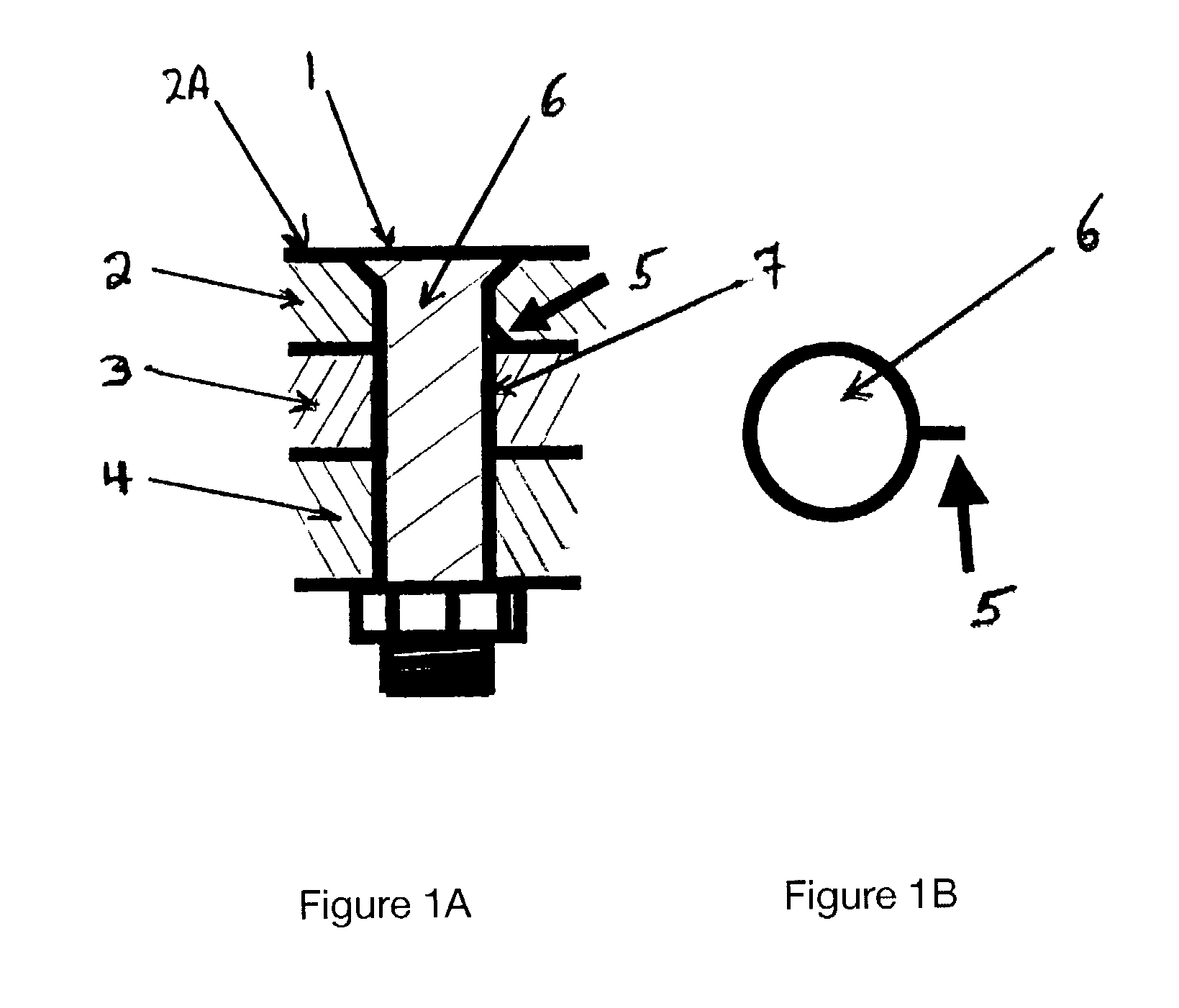

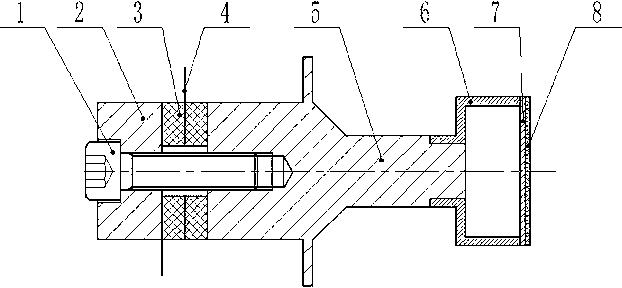

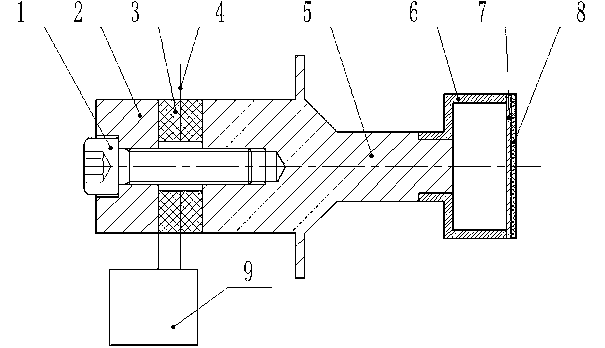

Large-power air coupling ultrasonic vibration transducer

InactiveCN103341439ASimple structureEasy to controlMechanical vibrations separationTransformerAir coupled

The invention discloses a large-power air coupling ultrasonic vibration transducer which comprises a bolt, a back shroud, a piezoelectric ceramic piece, an electrode piece, an amplitude transformer, a conversion sleeve, a vibrating plate and a coupling layer, wherein the coupling layer is stuck to the vibrating plate. The back shroud, the piezoelectric ceramic piece, the electrode piece and the amplitude transformer are sleeved on the bolt in sequence, the back shroud and the amplitude transformer clamp the piezoelectric ceramic piece and the electrode piece tightly through the bolt, the conversion sleeve is arranged at the front end of the amplitude transformer, and the vibrating plate and the coupling layer which is stuck to the vibrating plate are arranged at the front end of the conversion sleeve. The large-power air coupling ultrasonic vibration transducer uses a sandwich type piezoelectric transducer structure and has the advantages of being large in power capacity, high in sound field output strength and the like. The large-power air coupling ultrasonic vibration transducer can be applied to the fields of ultrasonic defoaming, ultrasonic suspension, ultrasonic medical treatment, ultrasonic dedusting, ultrasonic drying, ultrasonic gas medium sound field focusing, multi-phase sound field focusing, ultrasonic coagulation, ultrasonic nondestructive testing and the like.

Owner:SUZHOU UNIV OF SCI & TECH

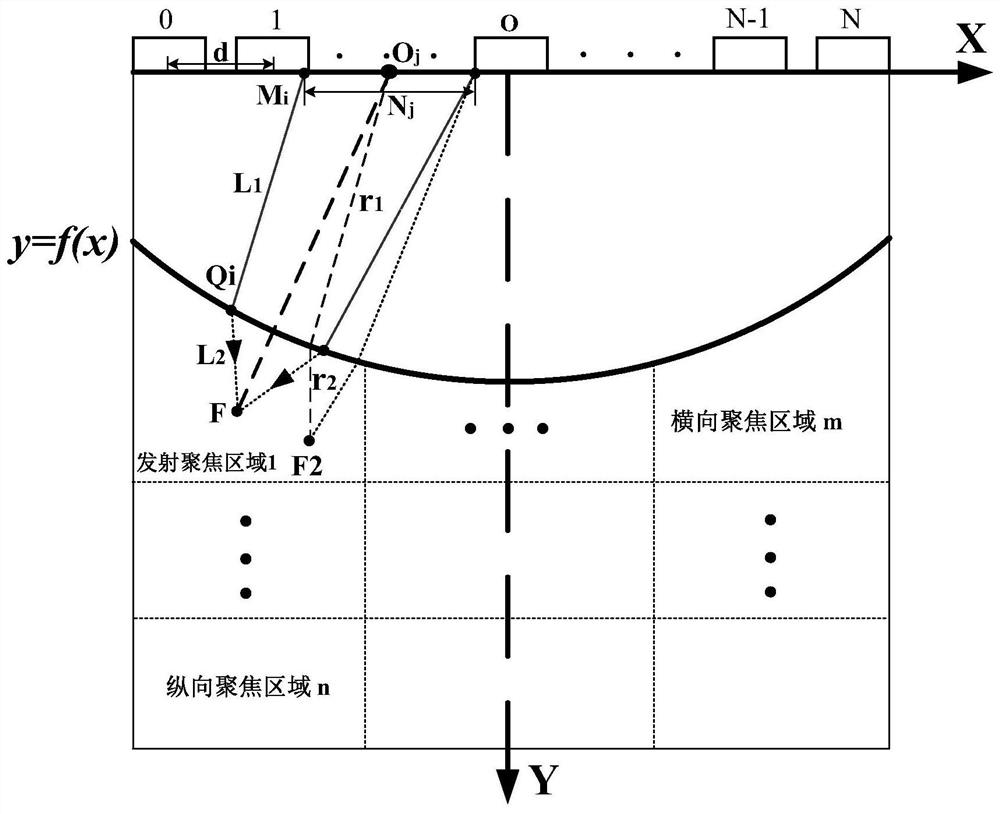

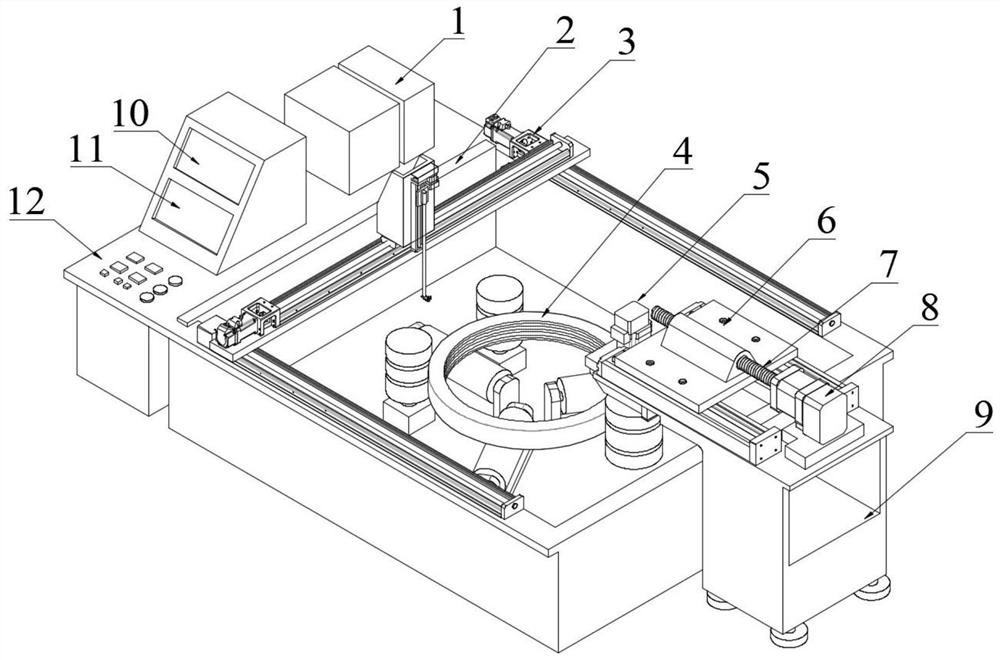

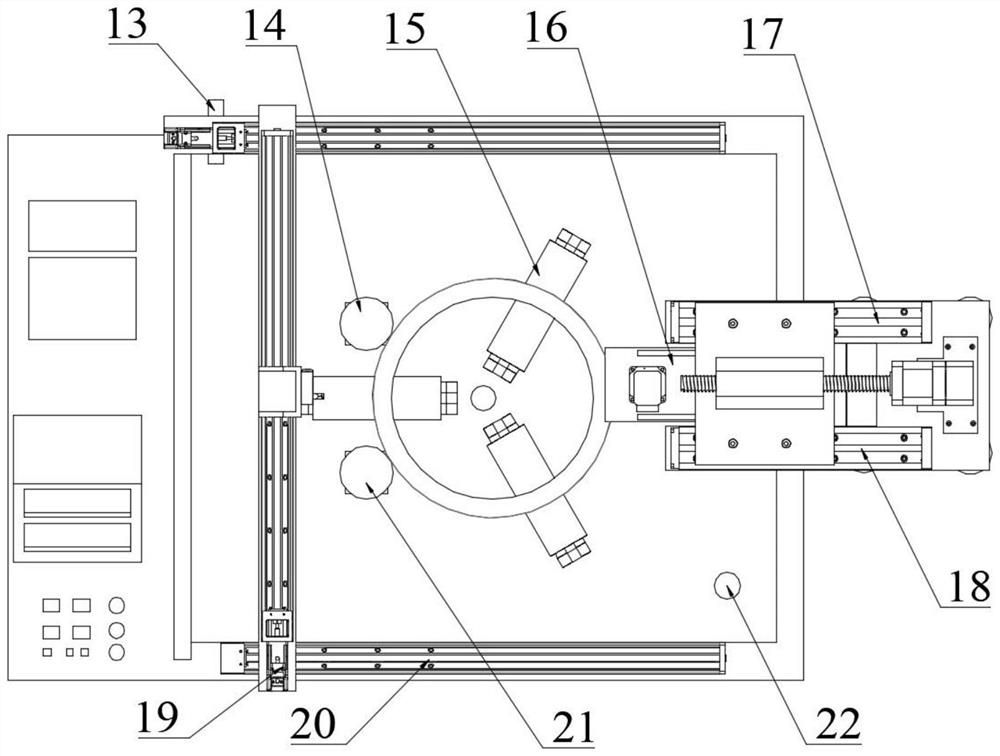

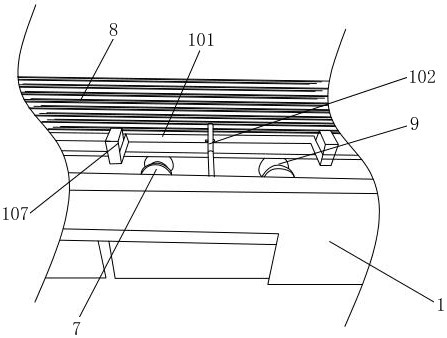

Ultrasonic water immersion automatic detection device and method for complex ring forgings

ActiveCN111796028AEnables high-resolution detectionEnhanced couplingAnalysing solids using sonic/ultrasonic/infrasonic wavesWater immersionDynamic aperture

The invention discloses an ultrasonic water immersion automatic detection device and method for complex ring forgings. The method comprises the steps of: placing a to-be-detected complex ring forgingin a water tank, carrying out the single detection of a complex curved surface through an ultrasonic phased array, and carrying out the regional detection of a flat end surface through a multi-frequency array water immersion probe according to the detection depth; during detection of complex curved surfaces, determining the optimal emission dynamic aperture array center and the array element number of each detection region according to a dynamic aperture emission focusing method; determining array emission delay time of each region according to a curved surface multi-medium emission focusing delay time calculation method, and calculating delay superposition time of all sampling points of each region according to a dynamic received beam synthesizer delay algorithm; during detection of the flat end face, selecting array water immersion probes of various different frequency models, and achieving full-coverage detection of the end face of the ring forging. A complete water immersion methodis adopted, the problem of poor coupling is solved, and full-coverage ultrasonic nondestructive testing can be achieved.

Owner:WUHAN UNIV OF TECH

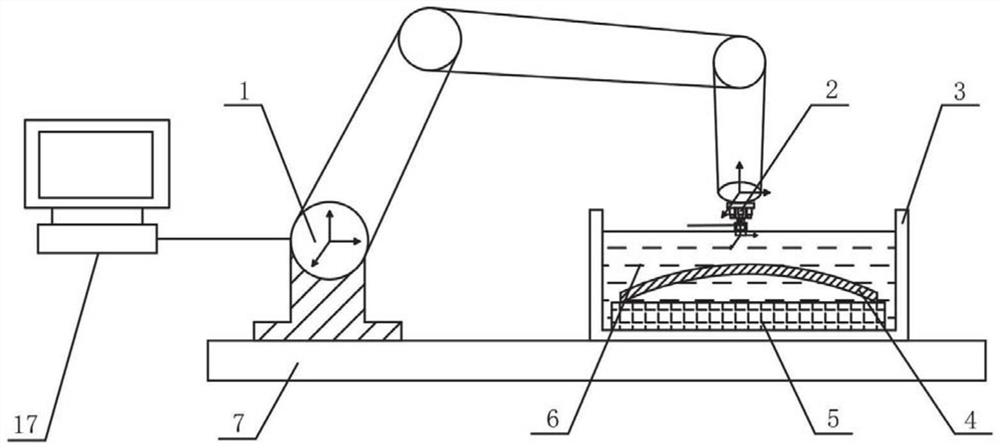

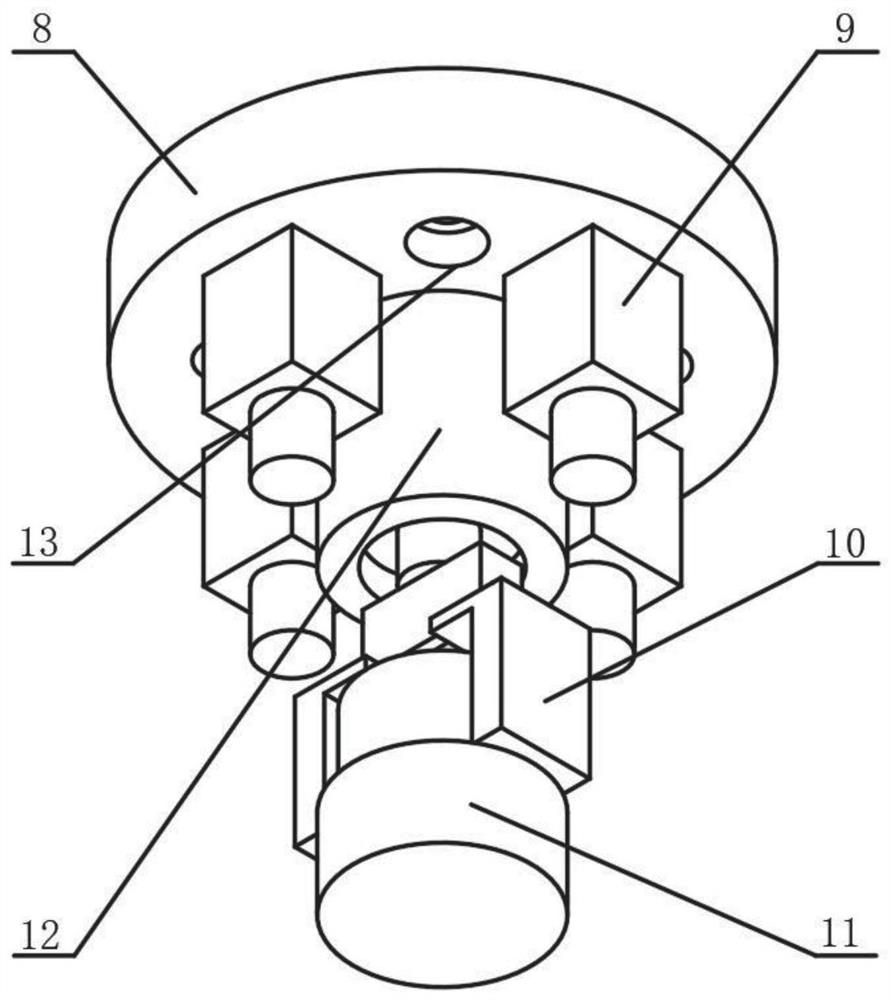

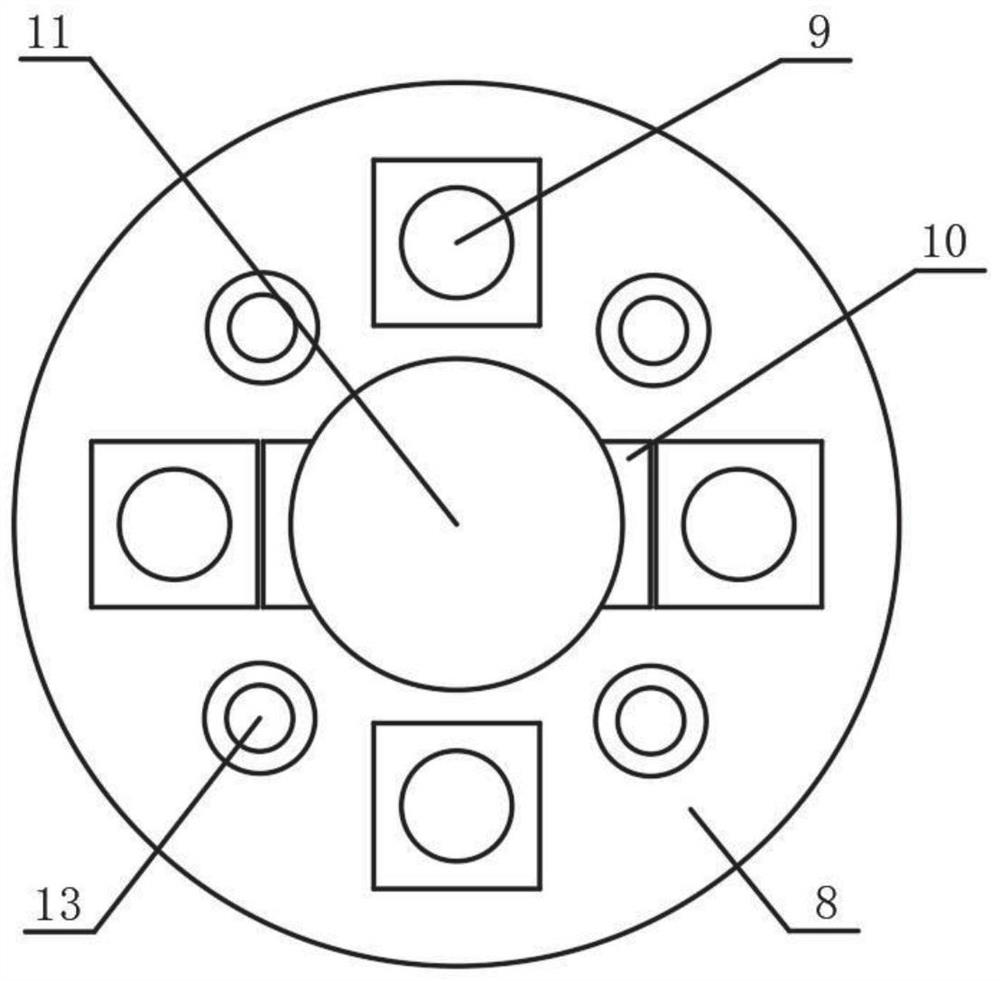

Auto-collimation device for ultrasonic non-destructive testing probe based on manipulator and working method

PendingCN112077850ACompact structureEasy to operateProgramme-controlled manipulatorMaterial analysis using sonic/ultrasonic/infrasonic wavesLaser rangingEngineering

The invention relates to an auto-collimation device for an ultrasonic non-destructive testing probe based on a manipulator and a working method, and is suitable for industrial and mining enterprises.The auto-collimation device for the ultrasonic non-destructive testing probe is provided at the front end of a six-degree-of-freedom joint manipulator, and comprises a bolt base; the bolt base is provided with a plurality of bolt holes connected to the front end of the six-degree-of-freedom joint manipulator; an elastic connecting mechanism is provided at the center of the bolt base; an ultrasonicprobe is connected to the elastic connecting mechanism by means of a probe clamping mechanism; and a plurality of laser distance measuring sensors are arranged around the elastic connecting mechanism. When the ultrasonic probe is in contact with a curved surface during use, a spring in the elastic connecting mechanism is adjusted in a self-adaptive manner to enable the ultrasonic probe to be tightly attached to the surface of a workpiece to be tested; then ultrasonic scanning is started; and the auto-collimation device is compact in structure, convenient to operate and good in use effect, andhas wide practicability in the technical field.

Owner:CHINA UNIV OF MINING & TECH

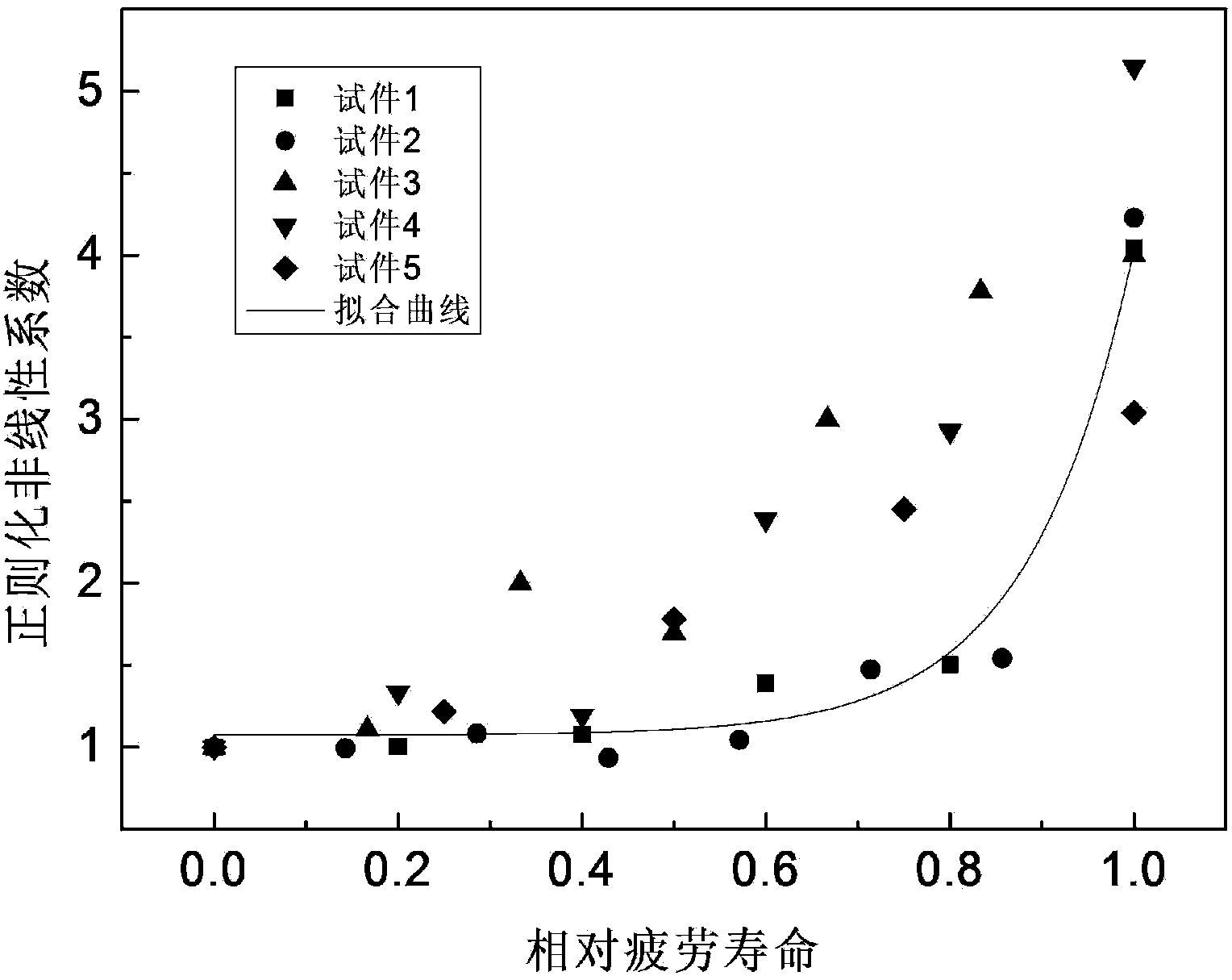

Nonlinear ultrasound evaluating method for impact fatigue damage of metal bonding interface

InactiveCN103776902AGuaranteed safe operationAnalysing solids using sonic/ultrasonic/infrasonic wavesFatigue damageUltrasound attenuation

The invention discloses a nonlinear ultrasound evaluating method for impact fatigue damage of a metal bonding interface, belonging to the field of ultrasonic nondestructive detection. According to the nonlinear ultrasound evaluating method, the defect of insensitivity in material mechanical performance degradation by parameters such as sound velocity, attenuation and impedance of ultrasonic waves is overcome, and the impact damage degree is objectively evaluated through a nonlinear coefficient. A testing method comprises the steps: firstly, testing an initial nonlinear coefficient of a material bonding interface, secondly, performing an impact test on a bonding structure, determining a nonlinear coefficient once every impacting for a certain times until the bonding structure is damaged; and regularizing the nonlinear coefficient, and establishing a curve relationship of the regularized nonlinear coefficient and the relative fatigue life. As a result, the regularized nonlinear coefficient is increased with the increase of the relative fatigue life. According to the nonlinear ultrasound evaluating method, a fatigue life relation of the metal bonding structure under an impact is established, an effective nondestructive detection method is provided for a large industrial bonding facility bearing the impact in future, and a great significance is obtained for ensuring the safety operation of industrial equipment and predicting the service life of the equipment.

Owner:BEIJING JIAOTONG UNIV

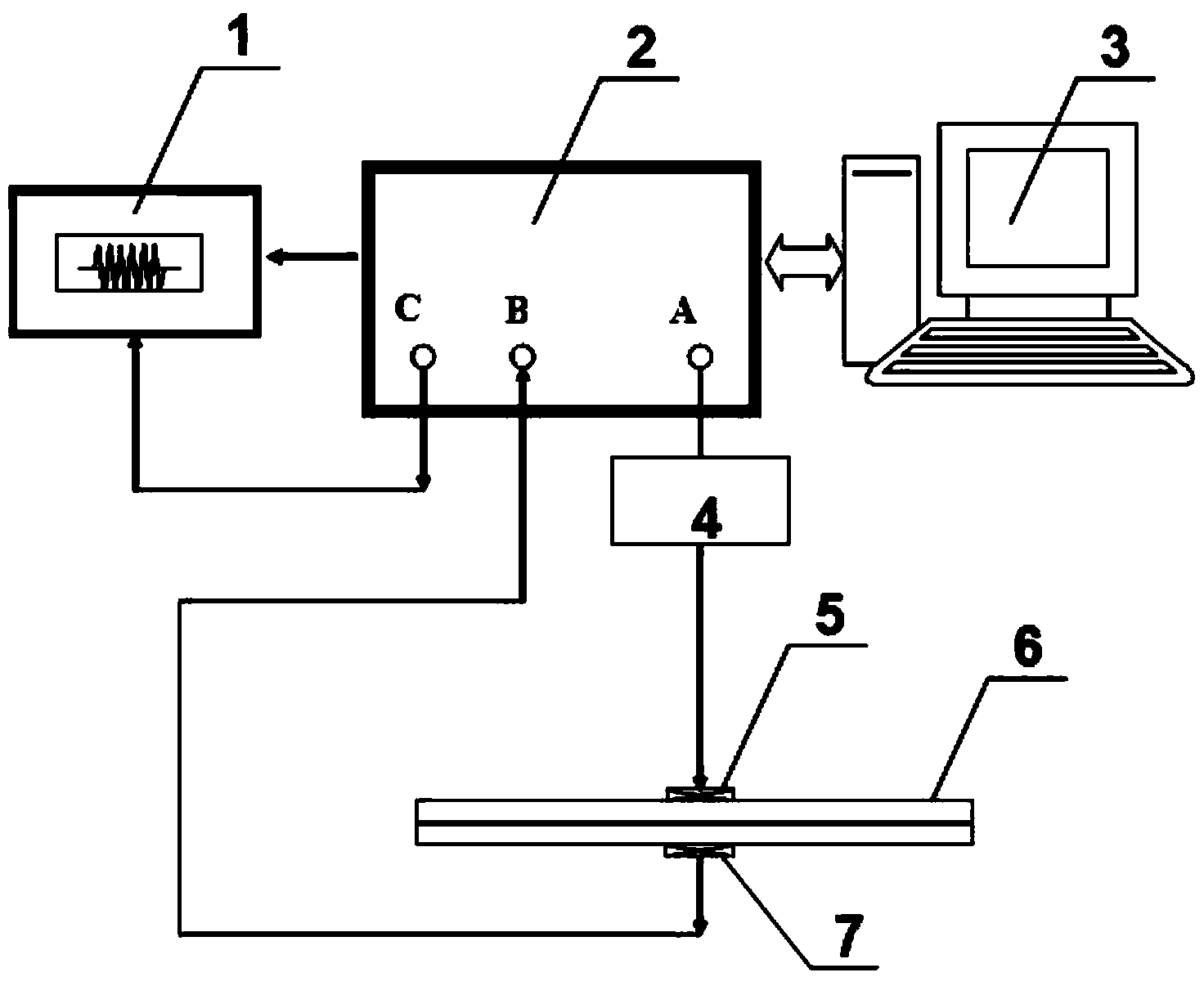

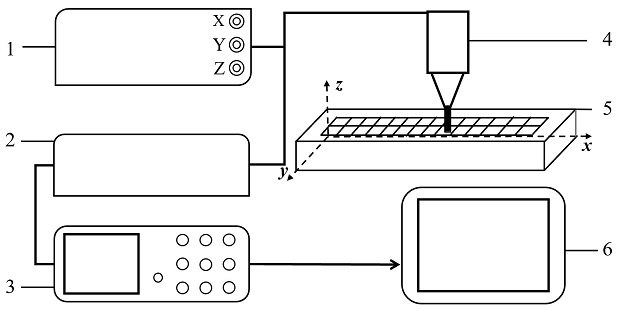

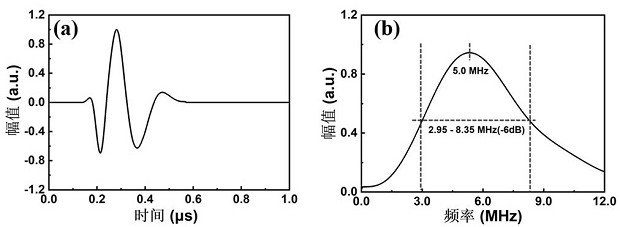

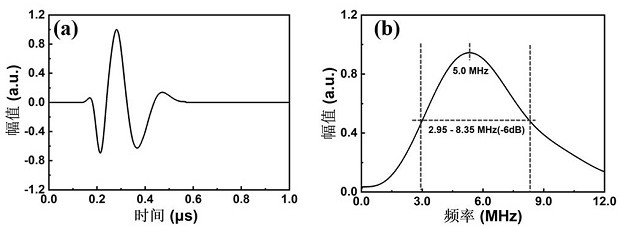

Ultrasonic nondestructive testing system

PendingCN111830134AHigh precisionImprove work efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalLight spotData acquisition

The invention discloses an ultrasonic nondestructive testing system. The ultrasonic nondestructive testing system comprises a laser ultrasonic transmitting system, an ultrasonic receiving system, a control and analysis imaging system and a three-axis platform system; the laser ultrasonic transmitting system comprises a high-frequency fiber laser, a light spot shaping device, a scanning galvanometer and a focusing mirror; the ultrasonic receiving system comprises a multi-array-element piezoelectric sensor, a charge amplifier and a multi-channel high-speed data acquisition card; the control andanalysis imaging system comprises a computer, a waveform processor and an imaging display and controller; the three-axis platform system comprises a three-dimensional mobile platform, a to-be-detectedworkpiece and an ultrasonic probe. According to the system of the invention, omnibearing 360-degree detection of surface and internal defects can be realized, the working efficiency is higher, the signal receiving sensitivity is higher, the price is low, the signal envelope extraction precision is higher, and the system is more suitable for industrial use.

Owner:SHANGHAI UNIV OF ENG SCI

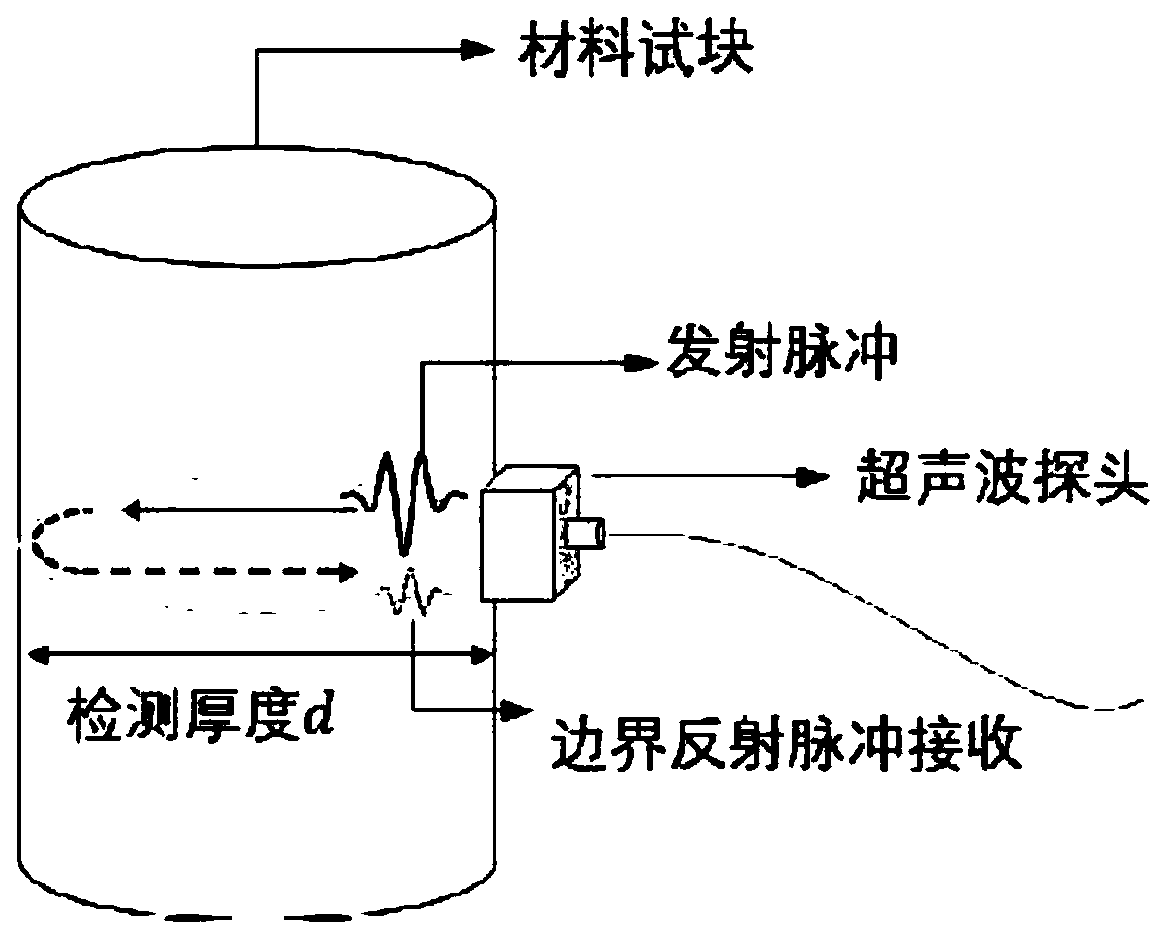

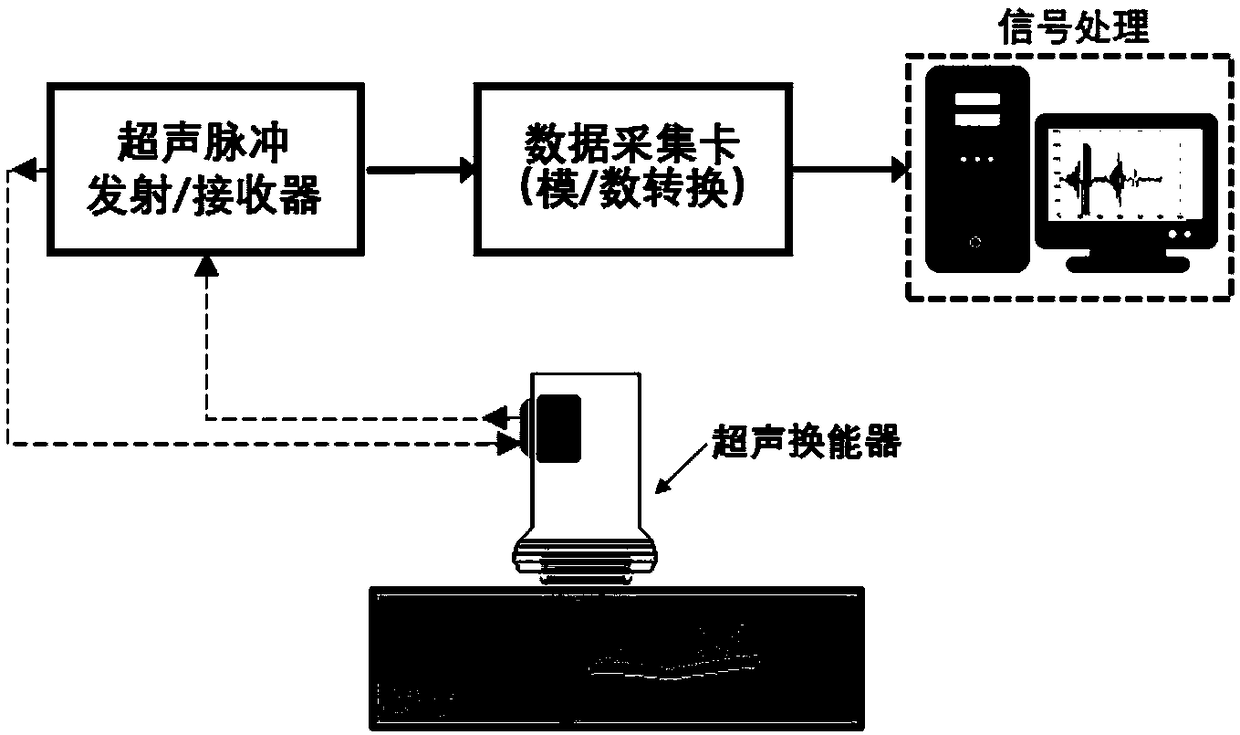

Ultrasonic nondestructive detection characteristic imaging system based on LabVIEW

InactiveCN105067705ASimple structureImaging is powerfulAnalysing solids using sonic/ultrasonic/infrasonic wavesSpecial data processing applicationsSoftware systemData acquisition

The present invention relates to an ultrasonic nondestructive detection characteristic imaging system based on LabVIEW. The system comprises a hardware part and a software part, wherein the hardware part comprises an industrial personal computer, a high-speed data acquisition card, an ultrasonic pulse transmitting and receiving device and the like, and the software part comprises a synchronous control module, a movement control module, a waveform data acquisition module, a characteristic value calculation module and the like. With the system, the scanning signal A of the ultrasonic C type scanning process can be recorded, and the ultrasonic detection characteristic value can be automatically solved according to the scanning signal A; and the B type ultrasonic imaging and the C type ultrasonic imaging are performed according to the characteristic value, such that the defect shape, the defect size, the defect position, the material structure uniformity and other important non-destructive detection information can be intuitively displayed, and the chromatographic detection on the material defect and the non-uniformity can be achieved. According to the present invention, the system uses the modular construction way, has characteristics of simple structure, powerful imaging function, strong functional scalability and simple operation, and provides the powerful hardware and software system for the ultrasonic nondestructive detection of the material.

Owner:NANCHANG HANGKONG UNIVERSITY

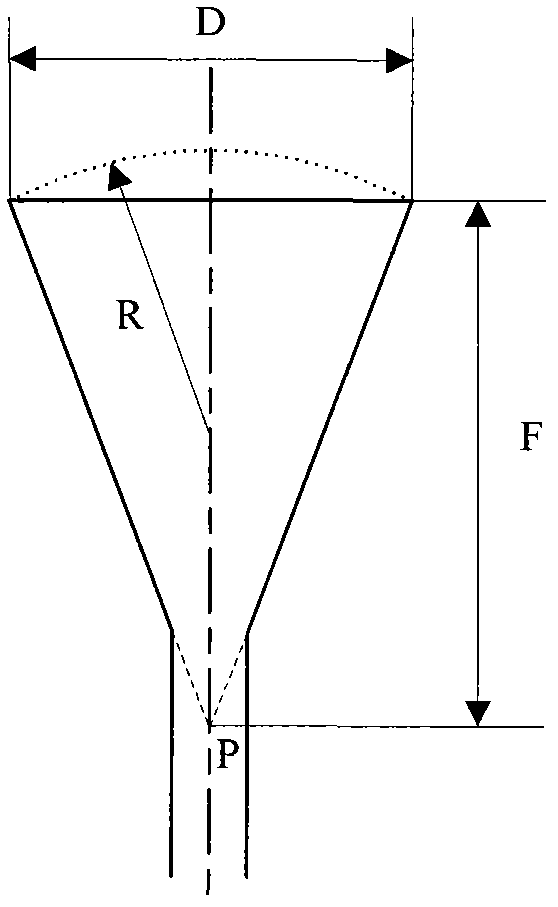

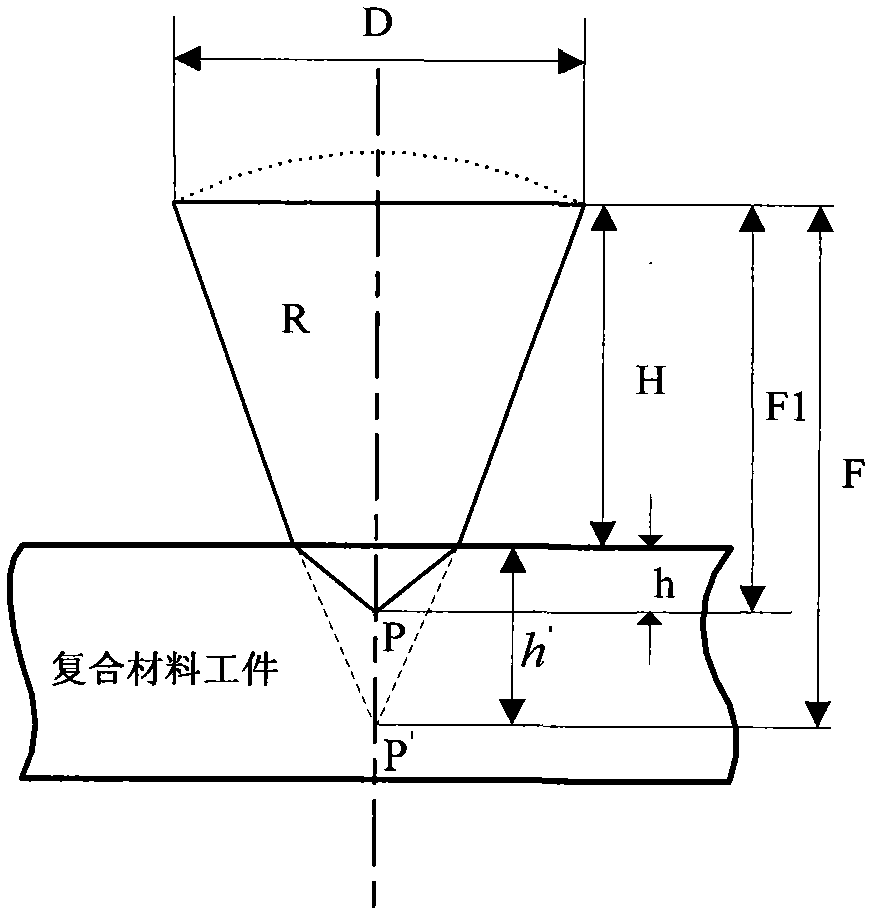

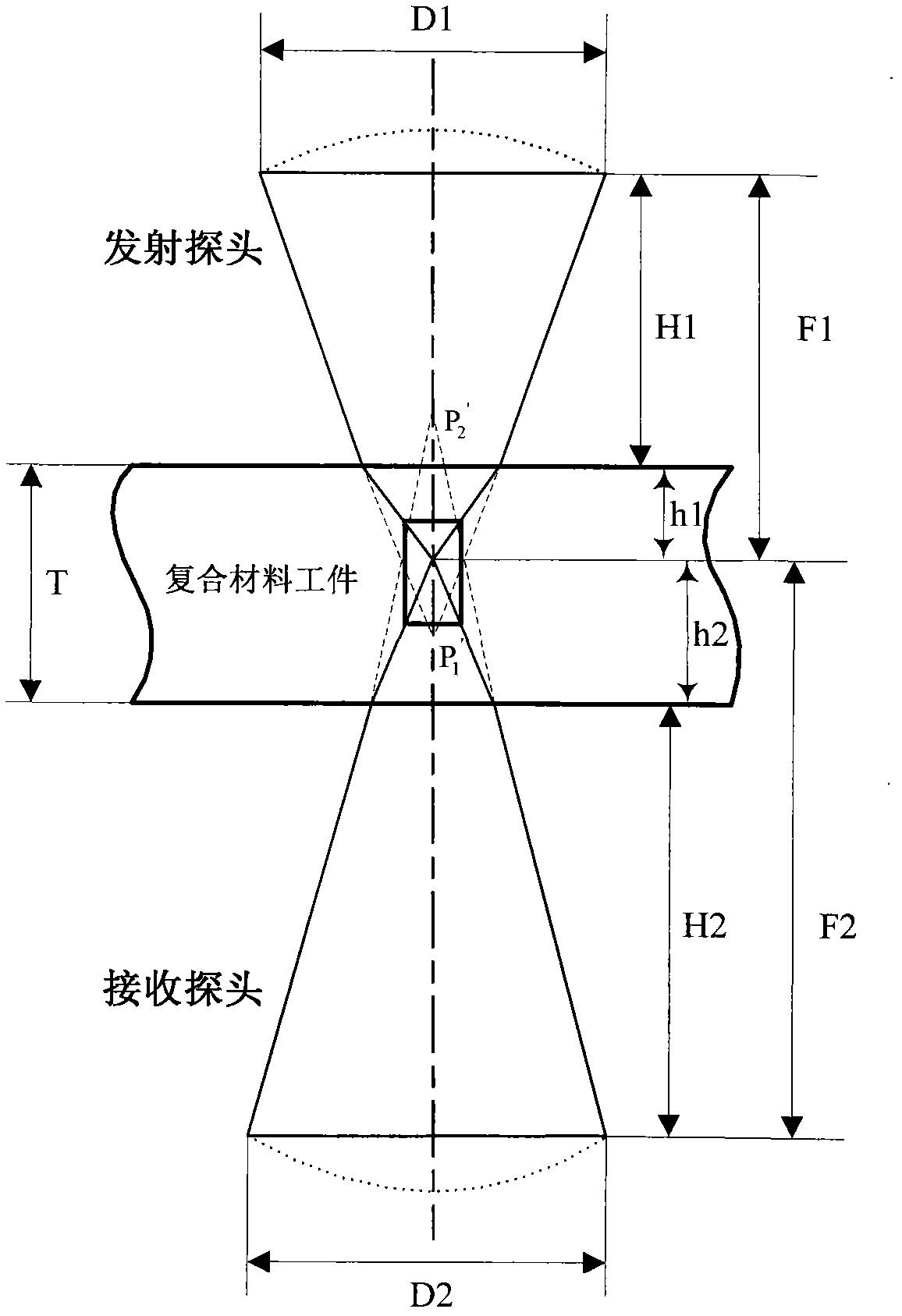

Optimization method for probe location during immersion ultrasonic detection of filament winding composite material

InactiveCN102507747AMaterial analysis using sonic/ultrasonic/infrasonic wavesTransducerFilament winding

The invention relates to an optimization method for probe location during immersion ultrasonic detection of filament winding composite material. As focusing rules and characteristics of focused transducers in water or the composite material and with different frequencies, wafer diameters and focal lengths are studied, formulas are given respectively for calculating the focal length F, the distance H from the probe to a piece and others when the reflection method and the transmission method are adopted for detection. Therefore the method for the optimization location of the focusing probe is given so as to improve the defect detection accuracy and the sensitivity during the detection and realize reliable detection for work pieces.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

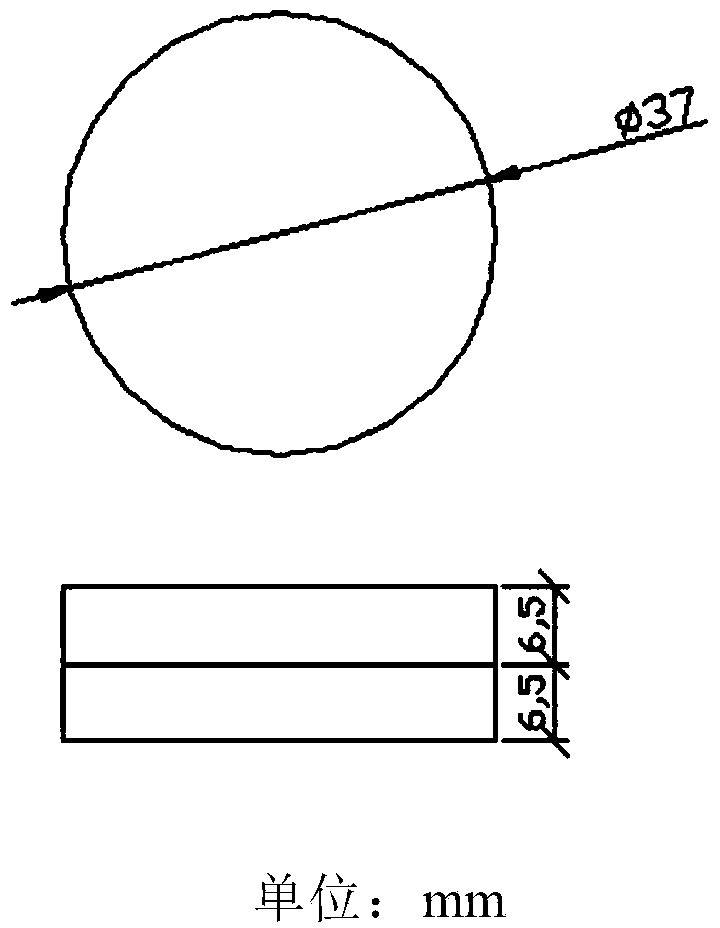

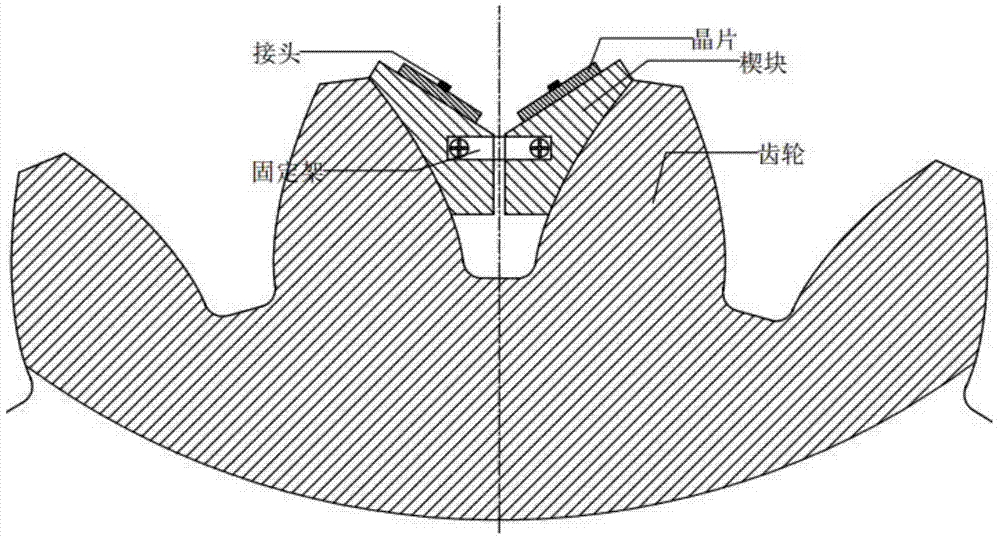

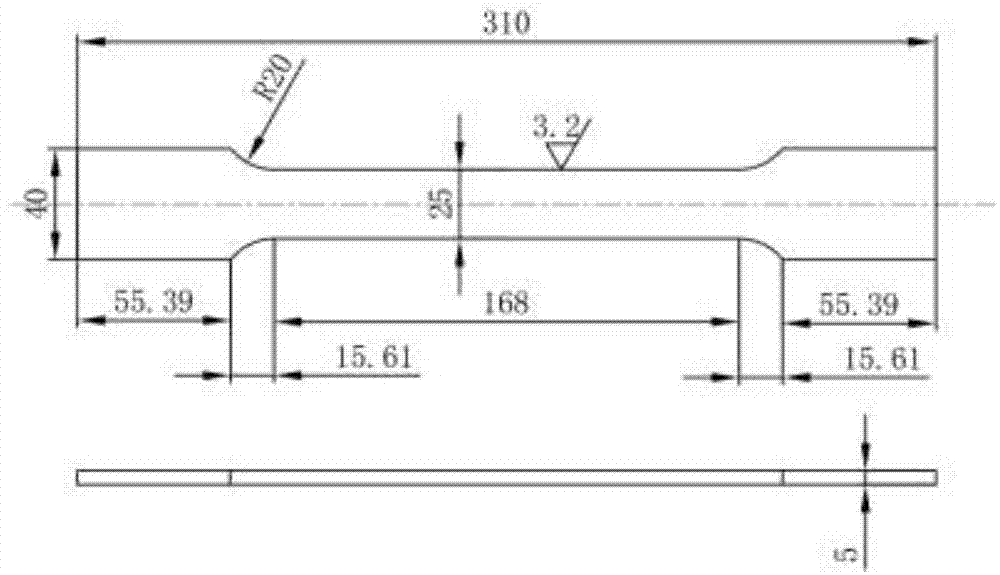

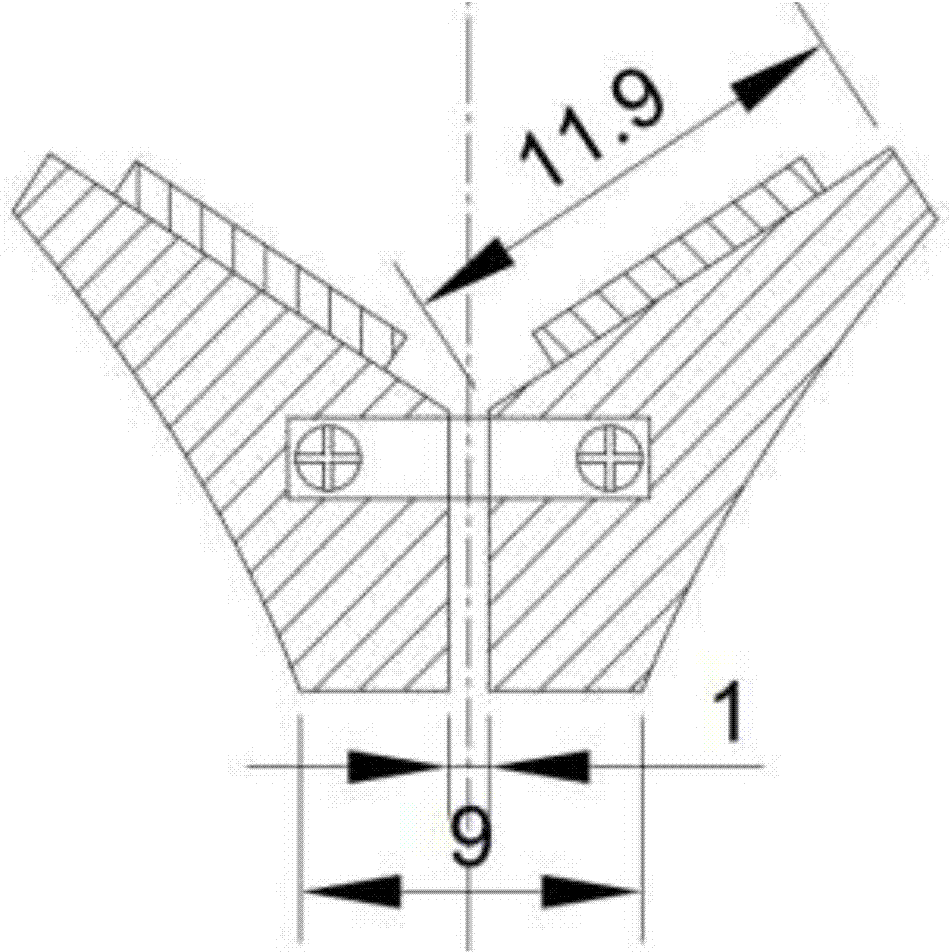

Wafer type ultrasonic non-destructive testing probe for low-modulus gear root residual stress

InactiveCN104267103AEliminate distractionsAnalysing solids using sonic/ultrasonic/infrasonic wavesLow modulusNondestructive testing

The invention provides a wafer type ultrasonic non-destructive testing probe for a low-modulus gear root residual stress. The method can be applied to non-destructive testing for gear root circumferential residual stress, combines an ultrasonic non-destructive testing system with a piezoelectric wafer and a wedge block, stimulates critical refraction longitudinal waves which are most sensitive to the residual stress nearby the root, and accurately calculates the residual stress at the area according to a sound time difference of the critical refraction longitudinal waves between the stress situation and non-stress situation nearby the root. The method can accurately, quickly and non-destructively test the low-modulus gear root residual stress.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

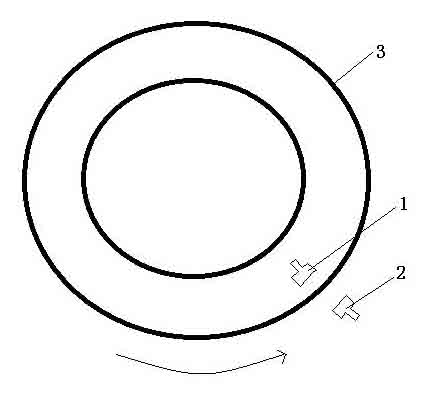

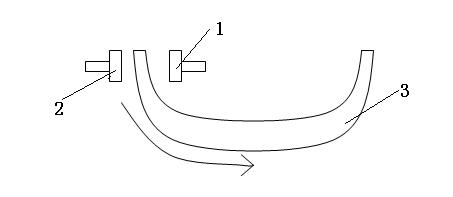

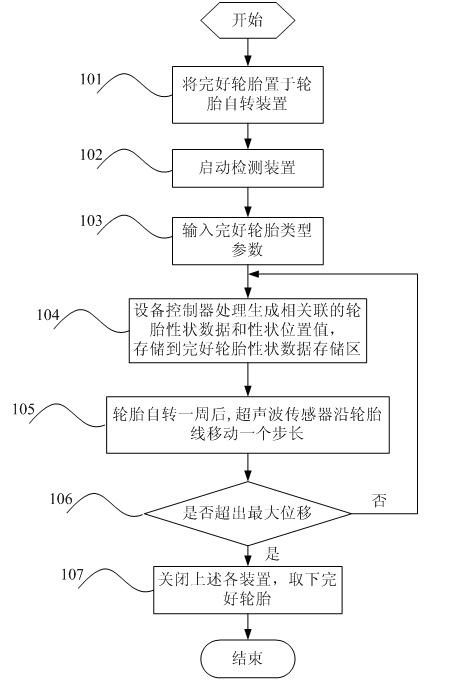

Tire ultrasonic NDT (Non-Destructive Testing) device and method

InactiveCN102043013AEasy to operatePromote repairAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveCoupling

The invention provides a tire air coupling ultrasonic NDT (Non-Destructive Testing) device and method. The method can be used for carrying out NDT on a tire in an air coupling way by utilizing low-frequency ultrasonic waves and comprises the following steps of: analyzing and judging in real time to obtain the damaged condition of the tire in the process of ultrasonic scanning on the tire; then marking the damaged part of the tire; and finally sending an analysis result to a control end and visually displaying the analysis result to the operator of the device in the form of a 3D (Three-Dimensional) view and a three-side map. In the testing method, the damaged condition of the tire is shown by using a simple and visual tire health position map without a fluid couplant, and finally the damaged condition of the tire is visually displayed in forms of damage marking, the 3D view and the three-side map so that the tire testing process becomes simple, visual and efficient, the tire testing cost is lowered, and the practicability for tire ultrasonic NDT is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for measuring elastic modulus and Poisson's ratio of all parts in material by ultrasonic waves

ActiveCN110261485AContribute to a comprehensive assessmentAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalEngineeringMechanical engineering

The invention discloses a method for measuring elastic modulus and Poisson's ratio of all parts in a material by ultrasonic waves. The method comprises the following steps of: S1, performing scanning and checking for a material to be detected by utilizing ultrasonic nondestructive testing, performing measuring to obtain one-way propagation time of ultrasonic waves in the material, and giving out the relation between the one-way propagation time of the ultrasonic waves in the material and the longitudinal wave velocity VL and the transverse wave velocity VT; S2, expressing the transverse wave velocity VT by using shear modulus, and expressing the longitudinal wave velocity VL by using shear modulus and Poisson's ratio; S3, determining the shear modulus of each position in the material; S4, determining the Poisson's ratio of each position in the material; and S5, calculating the tensile modulus of each position in the material. The method is based on ultrasonic nondestructive testing, can measure and characterize the elastic modulus and the Poisson's ratio of any point position in the inner space of the material, and can evaluate the non-uniformity of the performance of each position in the material.

Owner:北京领示科技有限公司

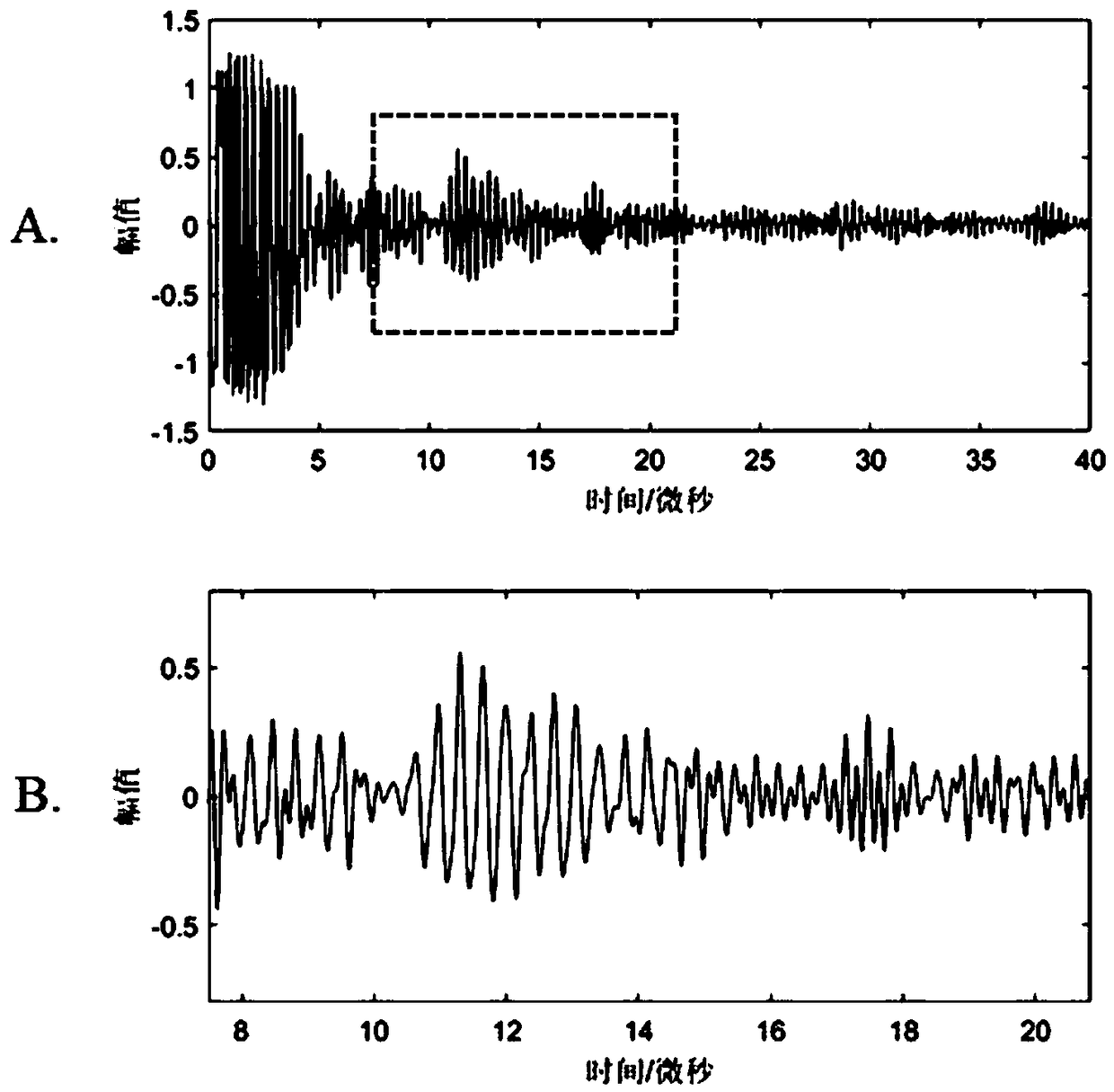

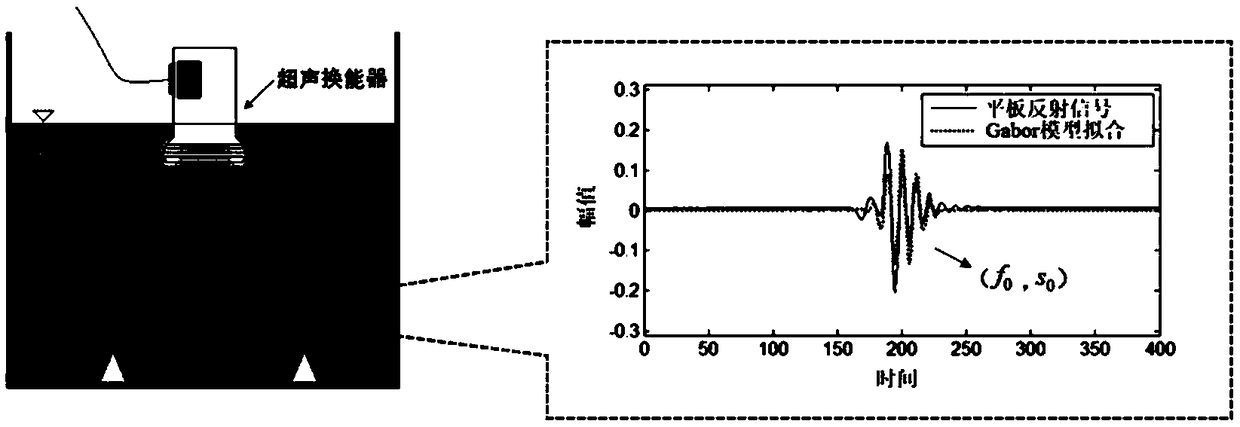

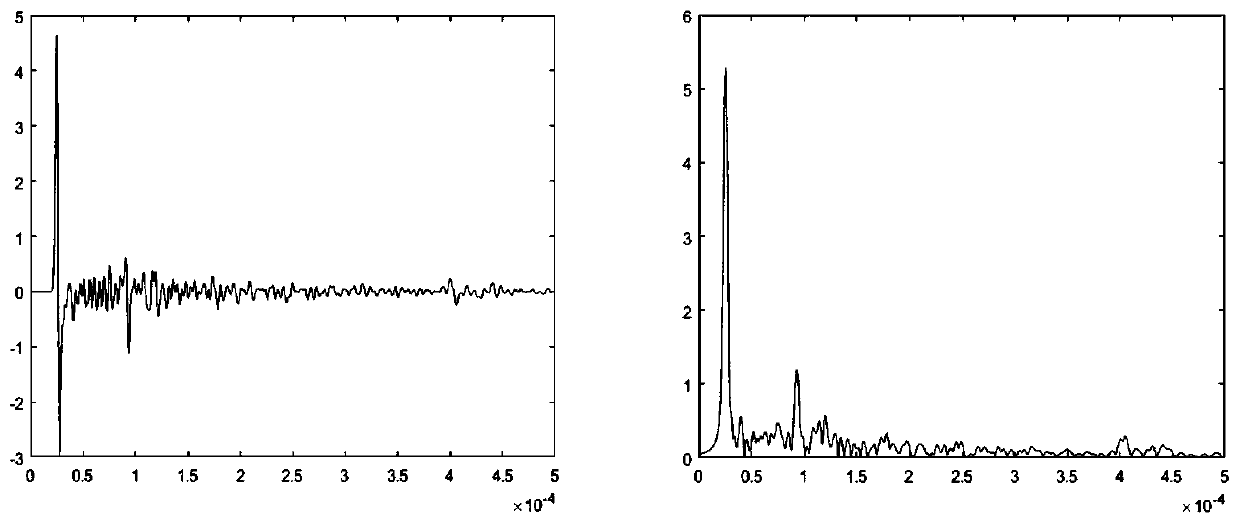

An ultrasonic signal sparse decomposition method and a signal noise reduction and defect detection method thereof

InactiveCN109165617AImprove robustnessAchieve lossless denoisingAnalysing solids using sonic/ultrasonic/infrasonic wavesCharacter and pattern recognitionSonificationSparse constraint

An ultrasonic signal sparse decomposition method and a signal noise reduction and defect detection method are disclosed, relating to the field of ultrasonic nondestructive testing. The method includes: step 1, adopting a Gabor model to approximate fit the ultrasonic signal, selecting a Gabor dictionary parameter set, combining to form dictionary matrix, and utilizing sparse Bayesian learning algorithm to solve the optimal approximate solution of coefficient vector under sparse constraint condition. The number of defects is the number of non-zero terms in the coefficient vector. The atomic vector parameters are used to eliminate the corresponding noise terms in the coefficient vector and the energy threshold is set to further denoise. The invention can realize noise reduction of ultrasonicnondestructive testing signal containing complex noise, recovery of defect reflected signal and defect detection and location with low signal-to-noise ratio.

Owner:HARBIN INST OF TECH

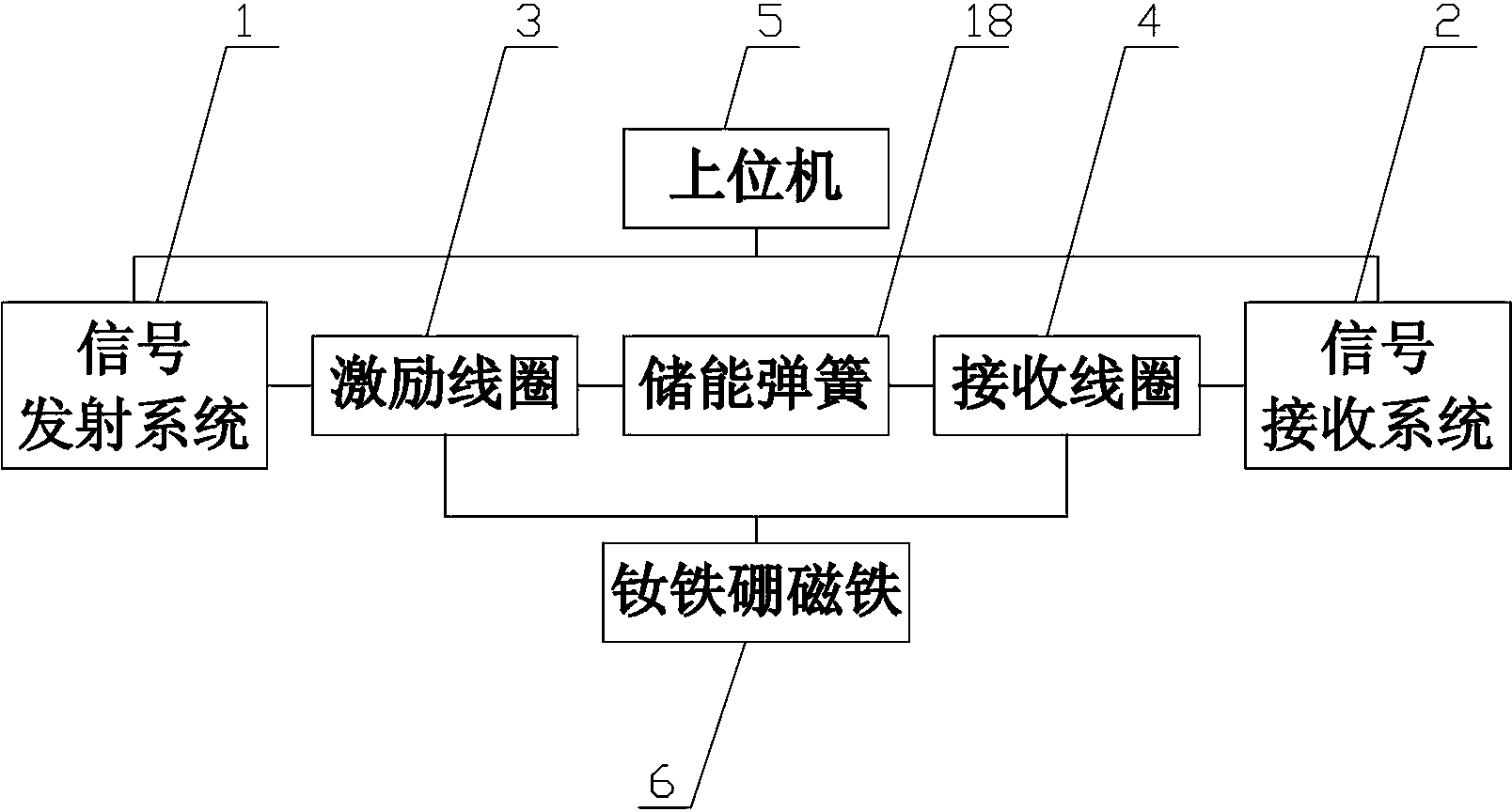

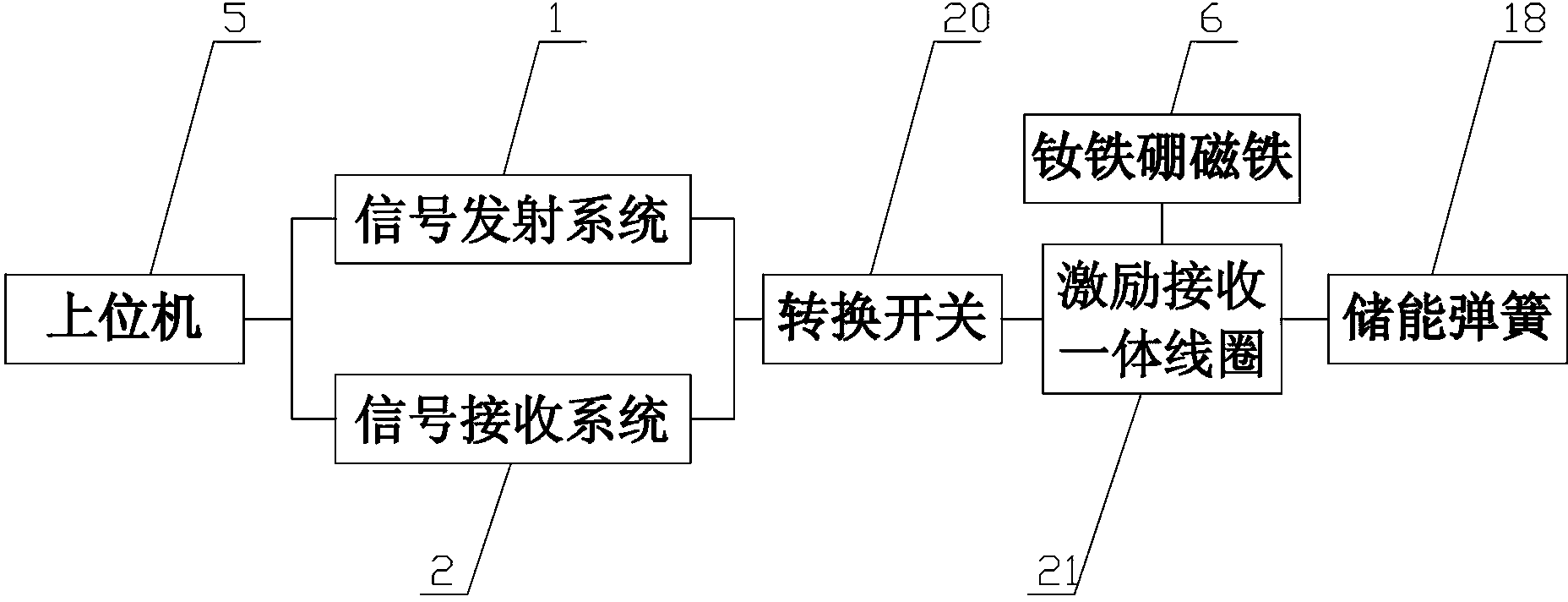

Energy-storage spring damage status detector for circuit breaker of spring operating mechanism and detection method

ActiveCN104316600ASimple structureIngenious designAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveWorkload

The invention discloses an energy-storage spring damage status detector for a circuit breaker of a spring operating mechanism and a detection method, and belongs to the field of electromagnetic ultrasonic non-destructive testing. The energy-storage spring damage status detector comprises a signal transmitting system, a signal receiving system, an upper computer, an Nd-Fe-B magnet, and an excitation-receiving integrated coil or excitation-receiving separated coils, wherein the signal transmitting system generates sine wave excitation signals to the excitation coil or the excitation-receiving integrated coil; the sine wave excitation signals are converted to ultrasonic signals through the coil under action of the magnetic field; the ultrasonic signals are transmitted along the energy-storage spring and reflected at the damaged position of the energy-storage spring wire; the reflected ultrasonic waves are converted to electric signals through the receiving coil or the excitation-receiving integrated coil in the magnetic field environment, and then received by the signal receiving device; the electric signals are transmitted to the upper computer; at last, the upper computer analyzes and judges the fault and the faulted position of the energy-storage spring. When the energy-storage spring damage status detector disclosed by the invention is used for detection, the circuit breaker is not required to quit operation, so as to lower the workload and facilitate the operation to be simple and convenient.

Owner:STATE GRID CORP OF CHINA +2

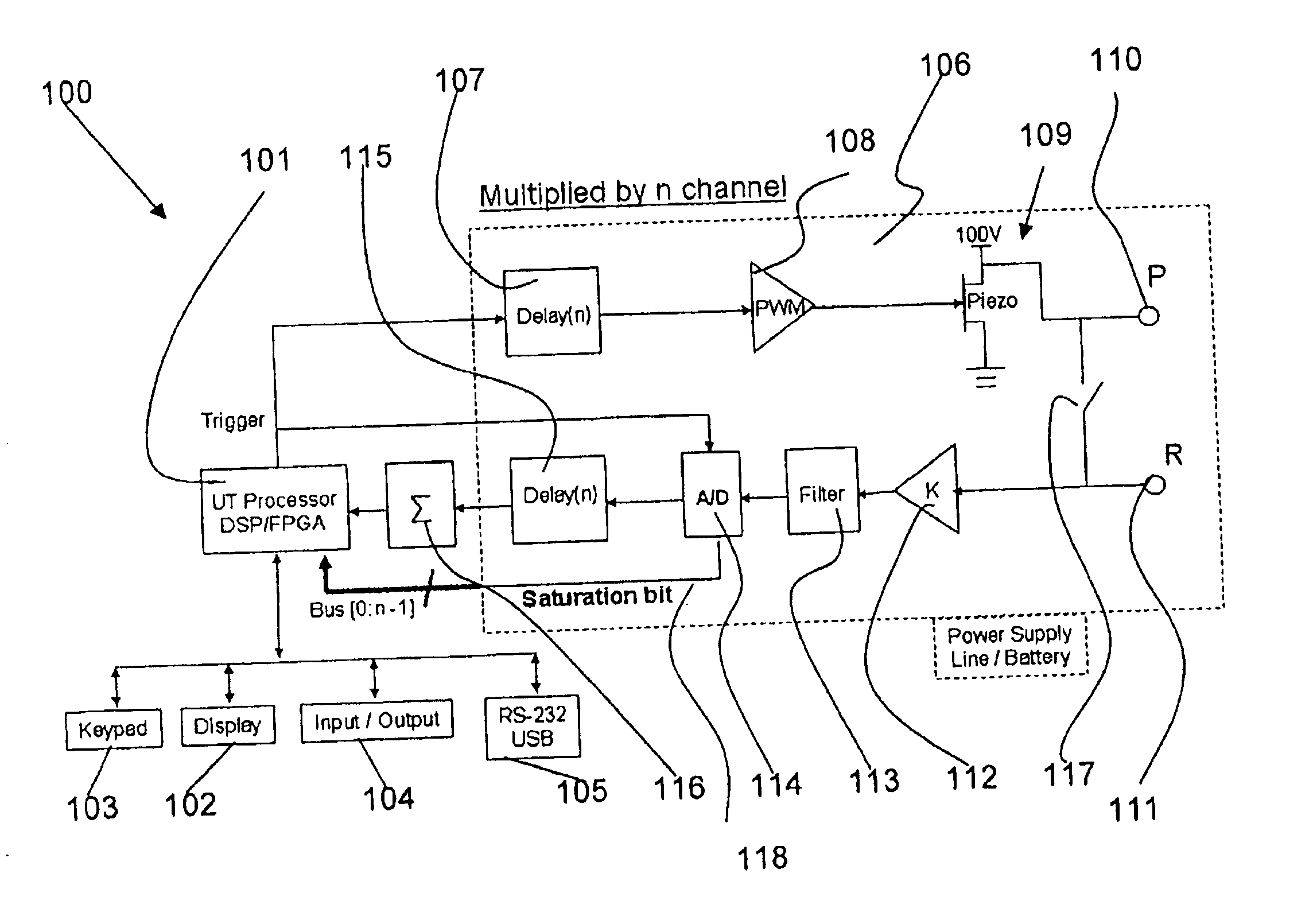

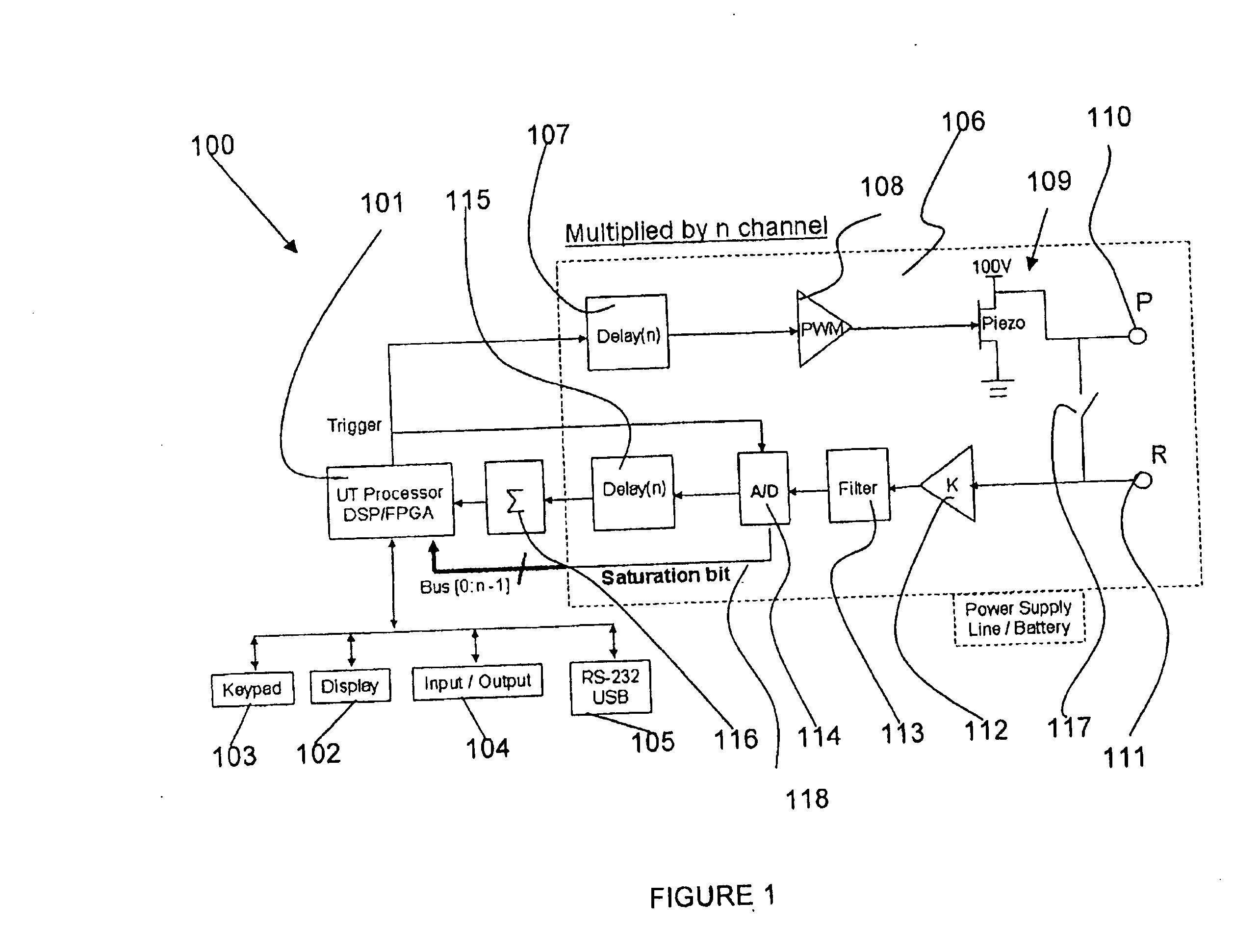

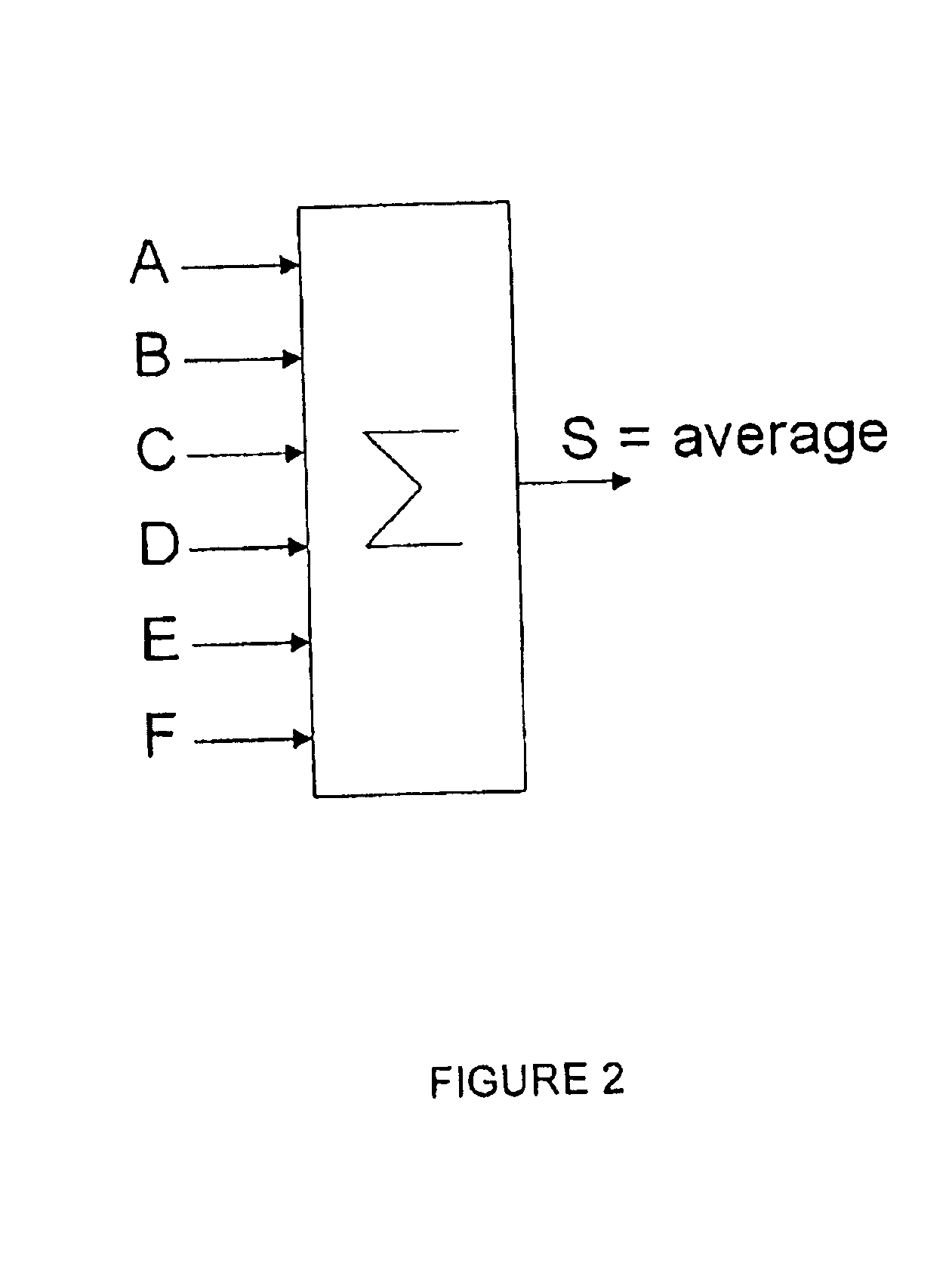

Detection of channel saturation in phase-array ultrasonic non-destructive testing

ActiveUS20070034010A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement deviceEngineering

The present invention relates to a method of detecting non-linear operation of a measuring device comprising an array of transducers and at least one receiver channel portion. The method comprises receiving measured signals through transducers of the array, processing the measured signals from the transducers through the receiver channel portion, combining the processed measured signals to produce a combined measurement signal, and detecting non-linearity of the combined measurement signal and non-linear operation of the measuring device by detecting saturation of the receiver channel portion. In one embodiment, the receiver channel portion comprises an analog-to-digital converter, a threshold is assigned to a digital output of the analog-to-digital converter, and saturation of the receiver channel portion is detected when the digital output of the analog-to-digital converter oversteps the assigned threshold. In one application of the invention, the measuring device is a non-destructive testing device.

Owner:OLYMPUS NDT

Ultrasonic non-destructive characterization method for structure uniformity of non-uniform medium

ActiveCN112083068AEasy to implementImprove robustnessAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationEngineeringSupport vector regression machine

The invention discloses an ultrasonic non-destructive characterization method for the structure uniformity of a non-uniform medium, and belongs to the technical field of ultrasonic non-destructive detection and evaluation of materials. Directed at the problems of complex ultrasonic scattering mechanism and difficulty in effective decoupling of tissue uniformity information caused by multiphase, nonhomogeneity, irregular scatterer morphology and large size change range in the ultrasonic non-destructive characterization process of the structure uniformity of the non-uniform medium, the ultrasonic non-destructive characterization method for the structure uniformity of the non-uniform medium adopts the ultrasonic pulse echo technology, and combines wavelet transform multi-scale analysis and asupport vector regression machine learning algorithm for non-destructive characterization on the non-uniform medium structure uniformity. The characterization method has the advantages of easy implementation, high robustness, high characterization precision and the like, overcomes the limitation that a traditional fitting method and a regularization method are difficult to deal with complex nonlinearity and ill-posedness problems of a physical mechanism, and has good application and popularization prospects.

Owner:DALIAN UNIV OF TECH

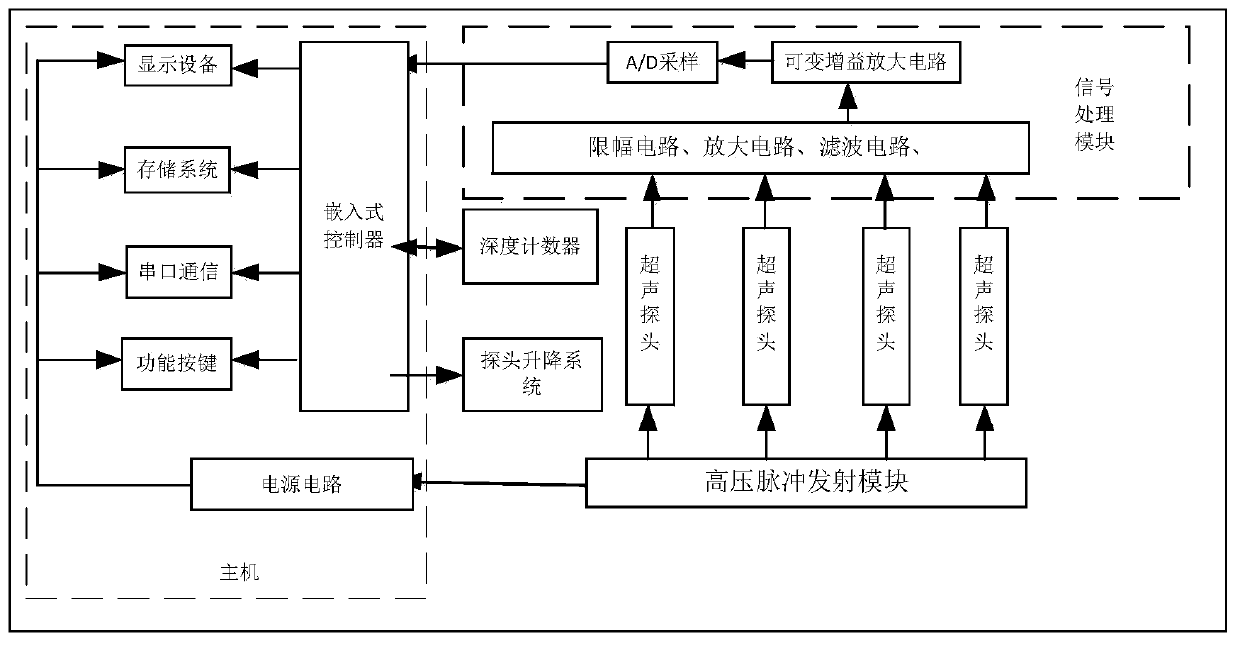

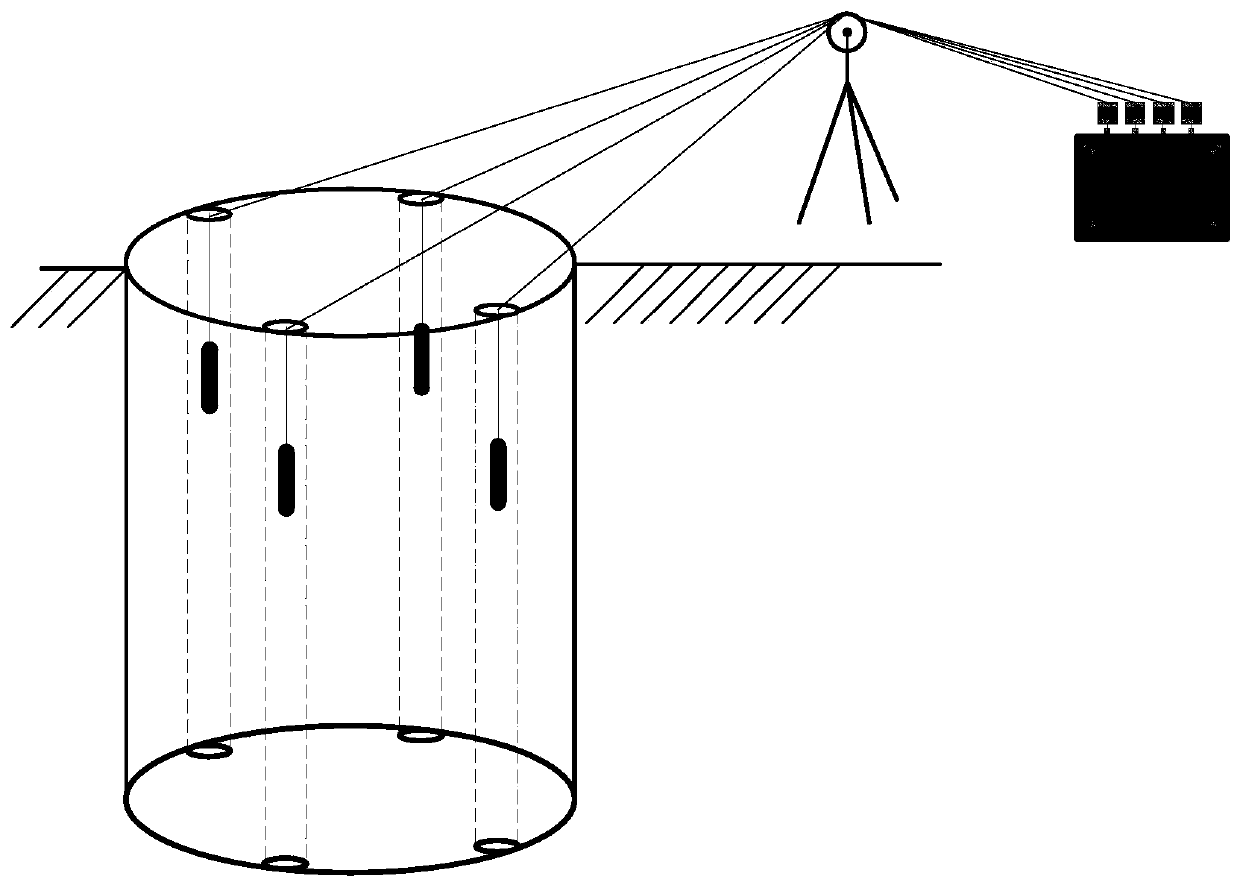

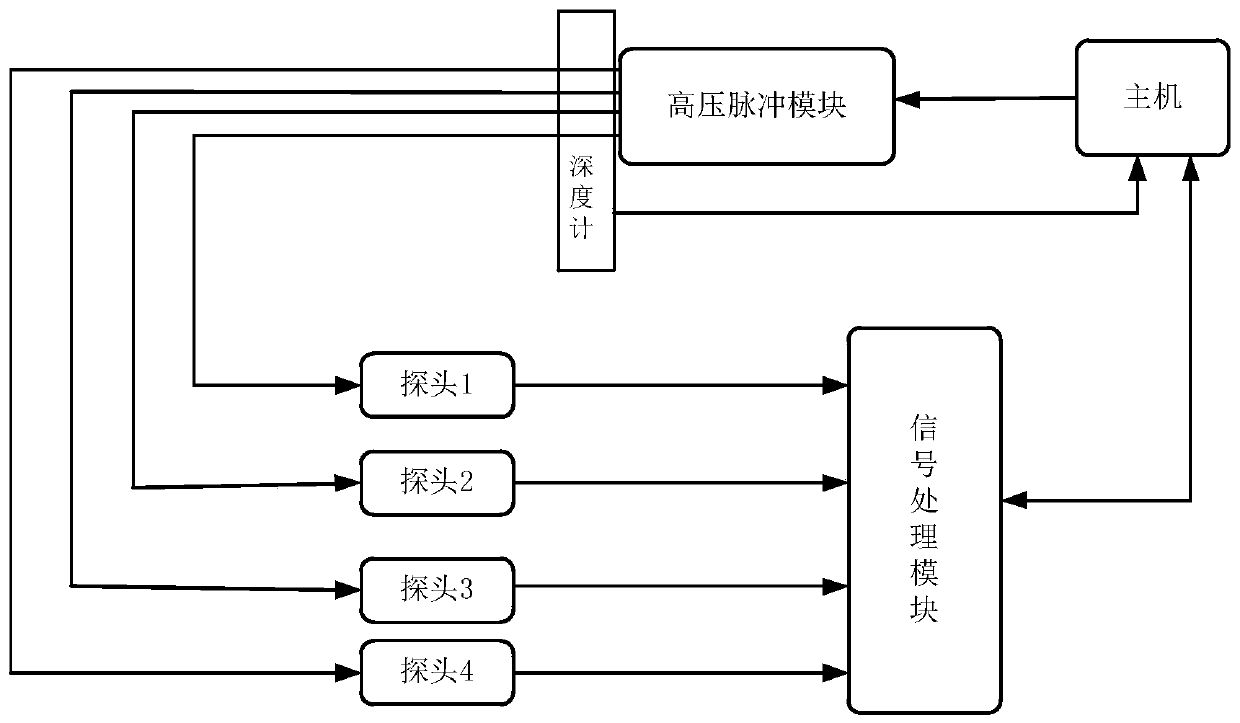

System and method for multiple pipeline ultrasonic non-destructive detection and automatic detection for three-dimensional modelling locating dead pixels

ActiveCN110656665AShorten detection timeSave materialAnalysing solids using sonic/ultrasonic/infrasonic wavesFoundation testingTransducerEngineering

The invention discloses a system and method for multiple pipeline ultrasonic non-destructive detection and automatic detection for three-dimensional modelling locating dead pixels. The system for multiple pipeline ultrasonic non-destructive detection and automatic detection for the three-dimensional modelling locating dead pixels comprises a high-pressure pulse emission module, a signal processingmodule, a probe lifting system, ultrasonic wave probes, depth counters and a host computer. Each ultrasonic wave probe comprises an ultrasonic wave emission transducer and a receiving transducer correspondingly. Cables are connected to the rear of the ultrasonic wave probes and fixed to cable grooves. Photoelectric counters are installed on the cable grooves, and the cables pass through the photoelectric counters. Each depth counter is constituted by combination of a cable coated with black and white paint at an interval of 0.5cm and a corresponding photoelectric counter, and each depth counter is connected with the host computer. In the probe lifting system, the ultrasonic wave probes are controlled to rise and fall through a stepping motor by the host computer according to information of the depth counters. According to the system for multiple pipeline ultrasonic non-destructive detection and automatic detection for the three-dimensional modelling locating dead pixels, real-time comparison is conducted through relative standard data and detection data acquired from calculation and pre-measuring of pile foundation, and the detection time is saved.

Owner:JIANGSU UNIV +1

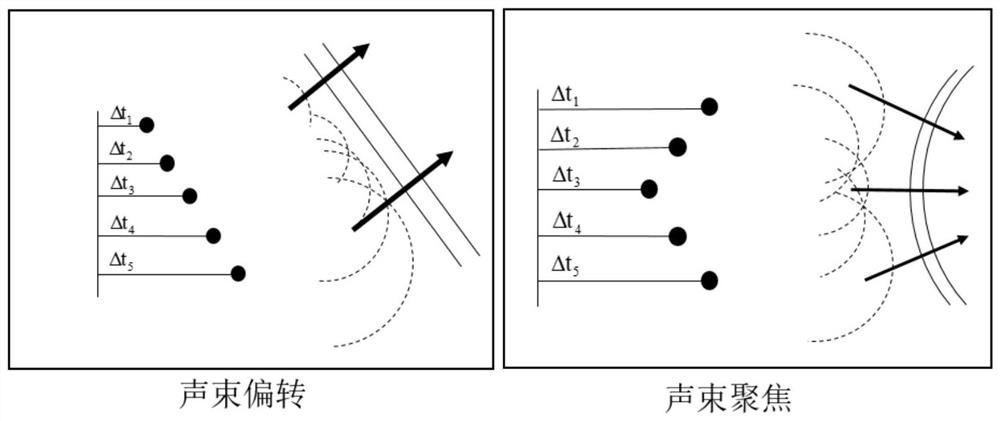

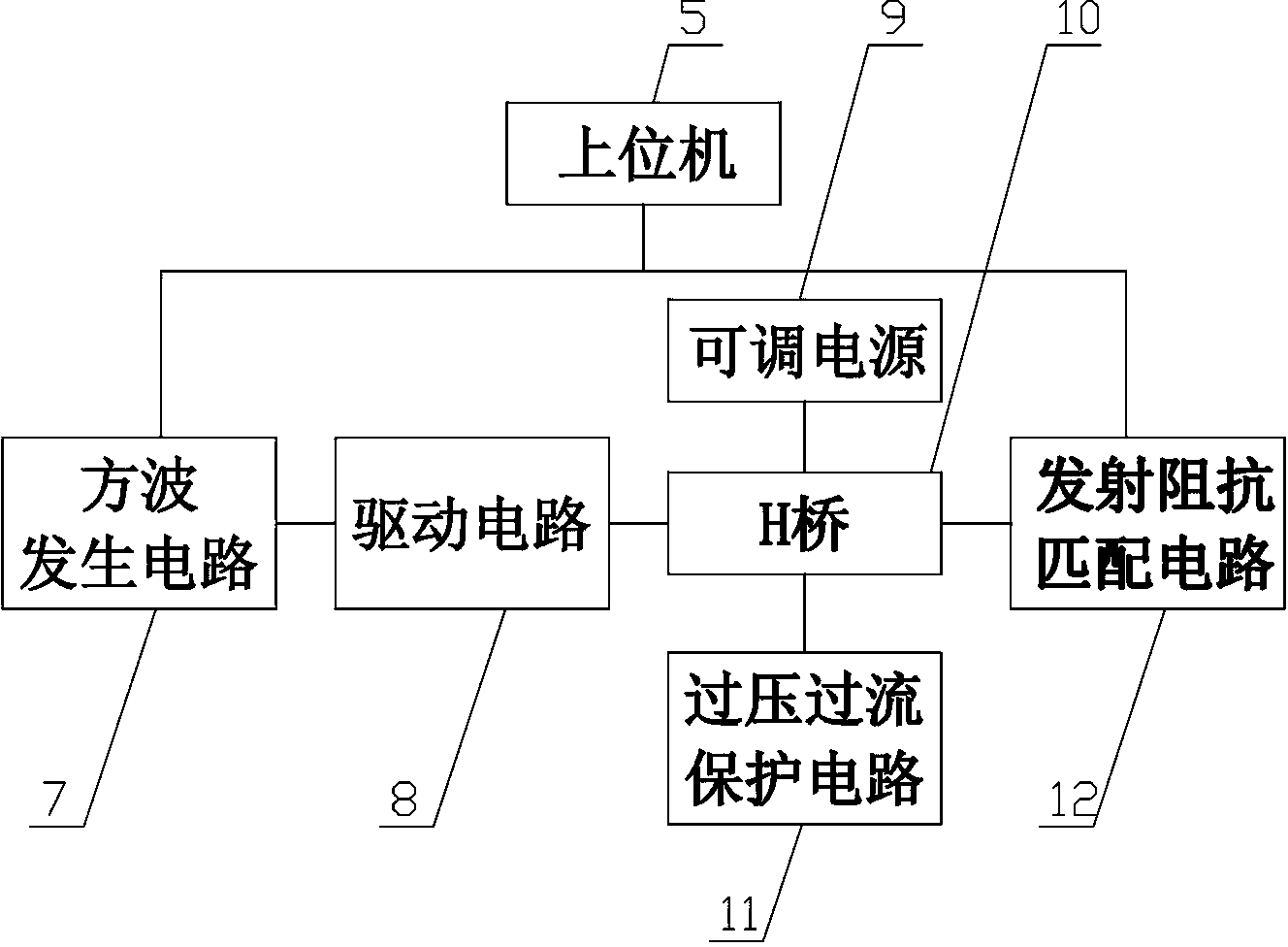

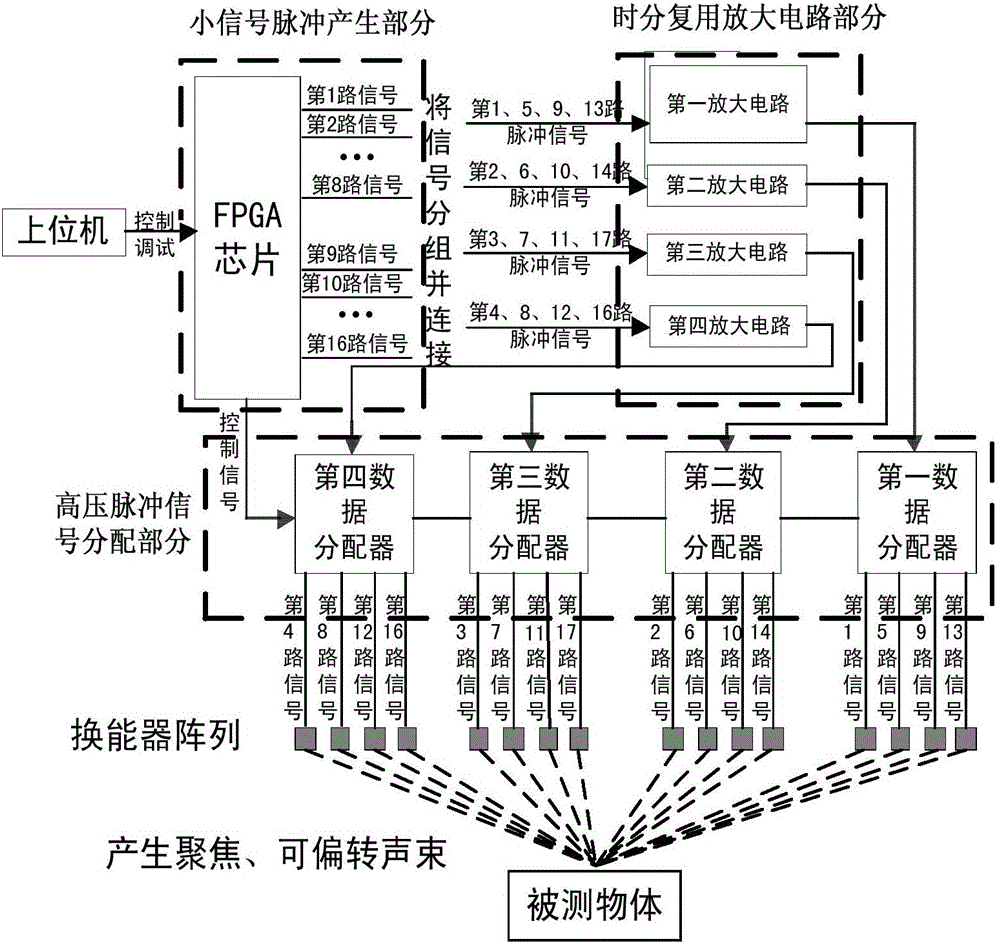

Time division multiplexing high power phased array ultrasonic signal generating device

InactiveCN105842347ASmall scaleReduce volumeUltrasonic/sonic/infrasonic wave generationGate arrayControl signal

The invention provides a time division multiplexing high power phased array ultrasonic signal generating device, which is mainly used for ultrasonic test of concrete structure. The device comprises a host computer control end, an on-site programmable logic gate array, a time division multiplexing high voltage pulse amplifying circuit, an ultrasonic transducer array and a data distributor. The on-site programmable logic gate array is connected to an input end of the time division multiplexing high voltage pulse amplifying circuit; the input end of the data distributor is respectively connected with a signal control output end of the on-site programmable logic gate array and the output end of the time division multiplexing high voltage pulse amplifying circuit; and the output end of the data distributor is connected with the ultrasonic transducer array. The device greatly reduces the circuit scale, reduces the volume of equipment, saves the cost of equipment, can produce a focusable sound beam used for industrial nondestructive testing of concrete structures, also can also adjust the pulse width of output signal for transducers with different center frequency; and the device reaches delay accuracy of Eta s level, and meets the requirements of the ultrasonic nondestructive test of concrete structure.

Owner:HOHAI UNIV CHANGZHOU

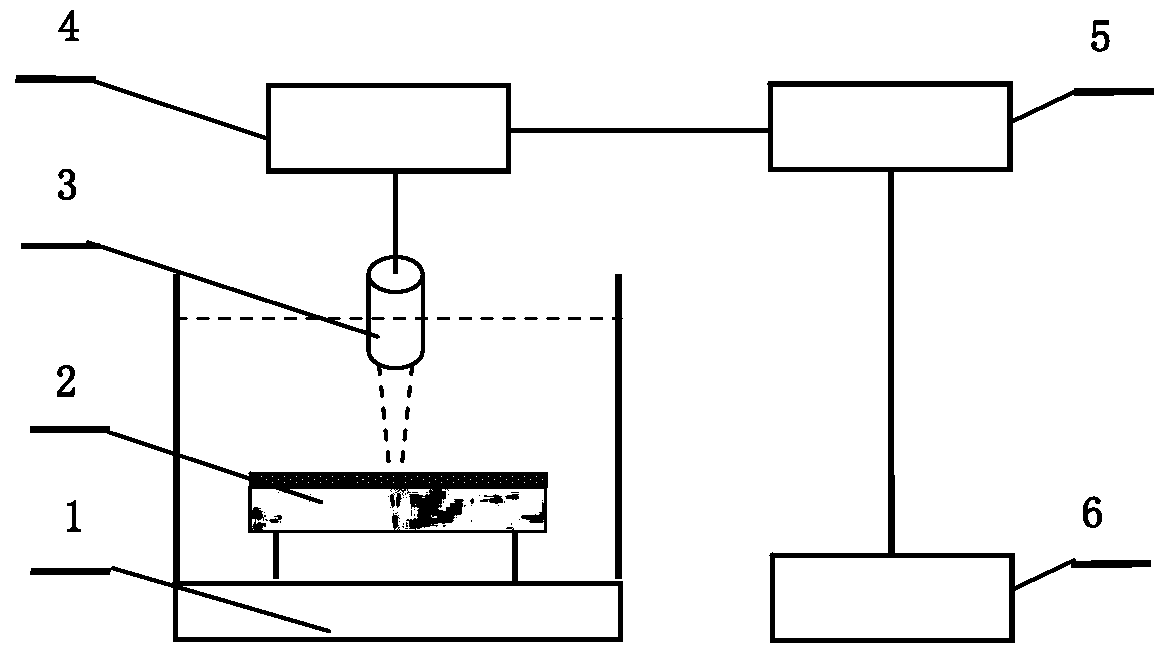

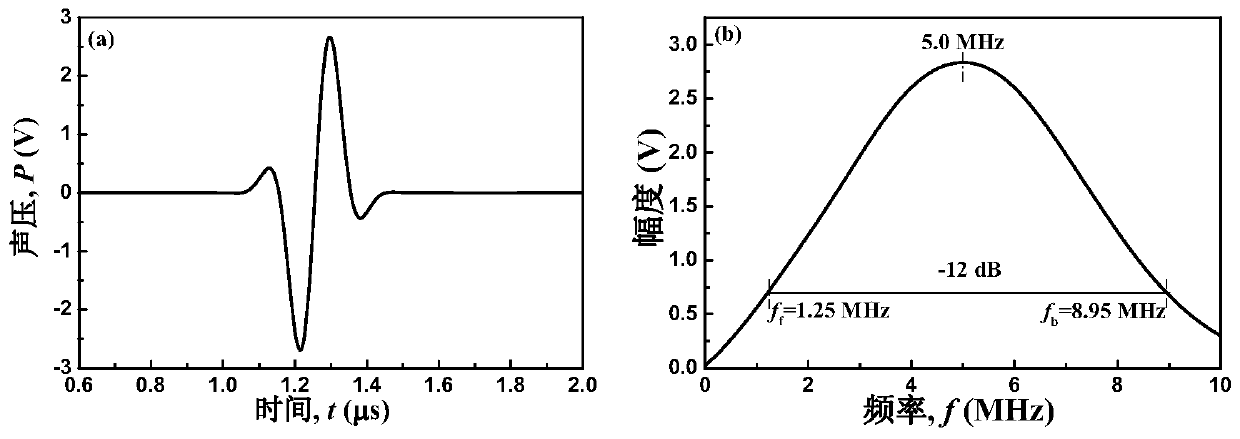

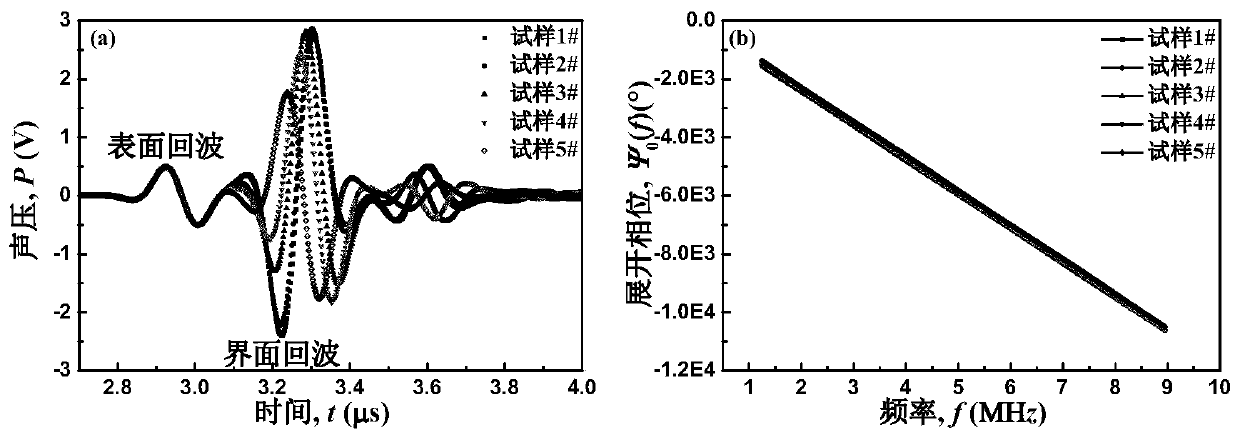

Method for nondestructively measuring bonding strength of coating interface by ultrasonic body wave phase spectrum

ActiveCN110726772AAvoid interferencePromote engineering applicationAnalysing solids using sonic/ultrasonic/infrasonic wavesWater immersionInterfacial stiffness

A method for nondestructively measuring the bonding strength of a coating interface by ultrasonic body wave phase spectrum belongs to the technical field of ultrasonic nondestructive testing. The method adopts a set of ultrasonic detection system which comprises a water tank, a coating sample, an ultrasonic water immersion probe, an ultrasonic flaw detector, an XYZ three-dimensional stepping device and a computer; wherein ultrasonic body waves of the ultrasonic detection system are vertically incident to the coating sample to perform detection, aliasing signals P<r>(t) of water / coating and coating / substrate interfaces are collected, fast Fourier transform is performed on the P<r>(t) to obtain an unwrapped phase psi<0>(f), the psi<0>(f) is subjected to linear fitting to obtain a phase spectrum psi(f), resonance frequencies f<n> and f<n+2> corresponding to adjacent odd or even zero phases of the psi(f) are identified, phase change phi<k> caused by interface rigidity change is solved, and quantitative measurement of interface bonding strength is realized according to a theoretical relationship between the phi<k> and a rigidity coefficient K<n>. The method of the invention solvesthe problems that the operation of ultrasonic surface wave and ultrasonic microscope technical equipment is complex, the engineering application is difficult, a traditional ultrasonic bulk wave technology is easily influenced by the thickness of a coating, and the quantitative precision is low.

Owner:DALIAN UNIV OF TECH

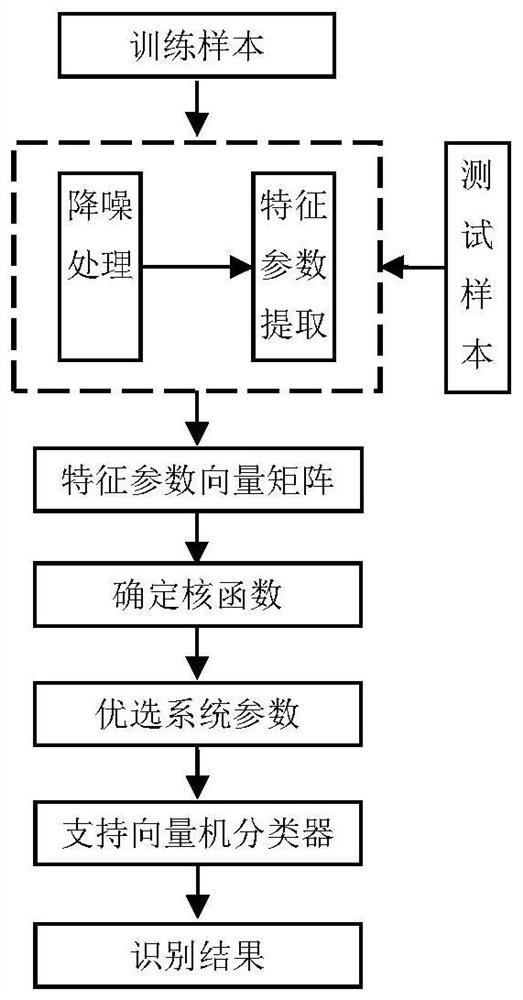

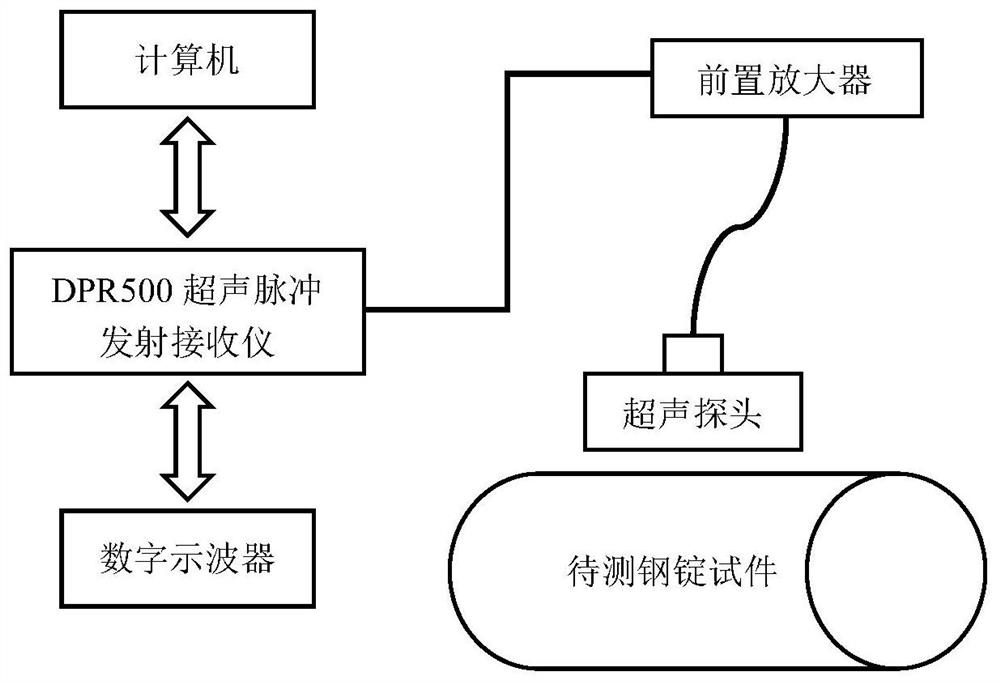

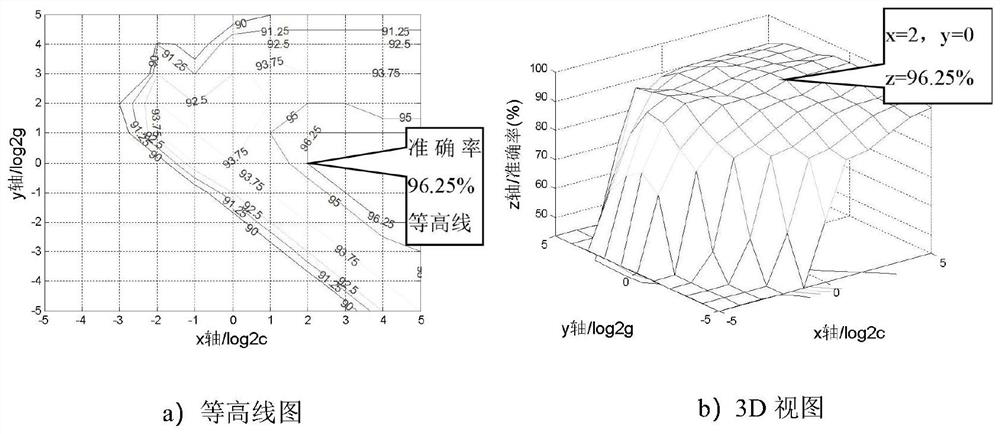

Method for identifying defect ultrasonic signals in steel ingot based on support vector machine

The invention discloses a method for identifying defect ultrasonic signals in a steel ingot based on a support vector machine, which belongs to the field of ultrasonic nondestructive testing, and is used for performing data processing on a characteristic parameter vector matrix of the defect ultrasonic signals in the steel ingot through a Gaussian radial basis kernel function based on a support vector machine algorithm. Linear inseparable data points in an original low-dimensional space are mapped to a high-dimensional space to enable the data points to be linearly separable, then an optimal classification hyperplane is constructed, the distance between different types of data on the two sides of the plane and closest to the plane is maximized, and therefore correct classification of different signals is achieved. In order to improve the signal identification rate in the identification process, the characteristic parameters of the signals and the system parameters of the support vector machine are optimized.

Owner:BEIJING UNIV OF TECH +1

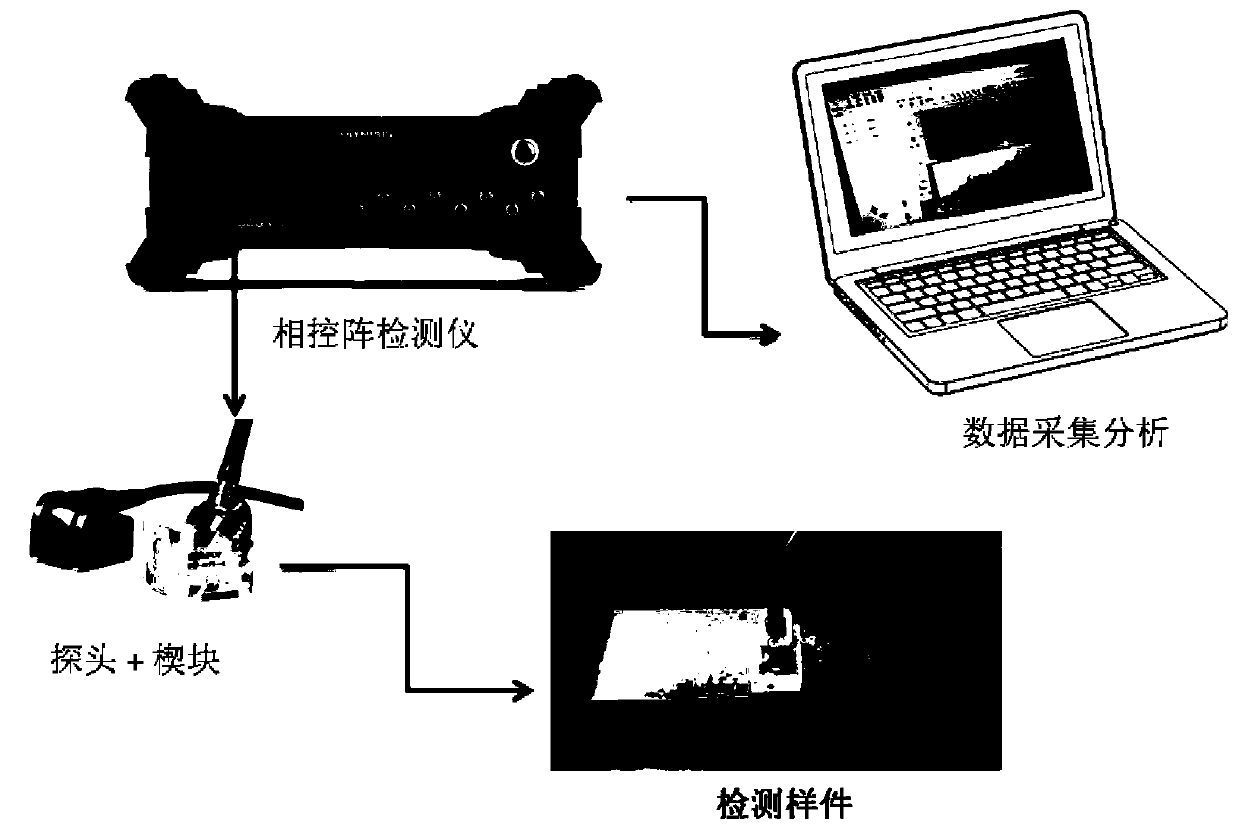

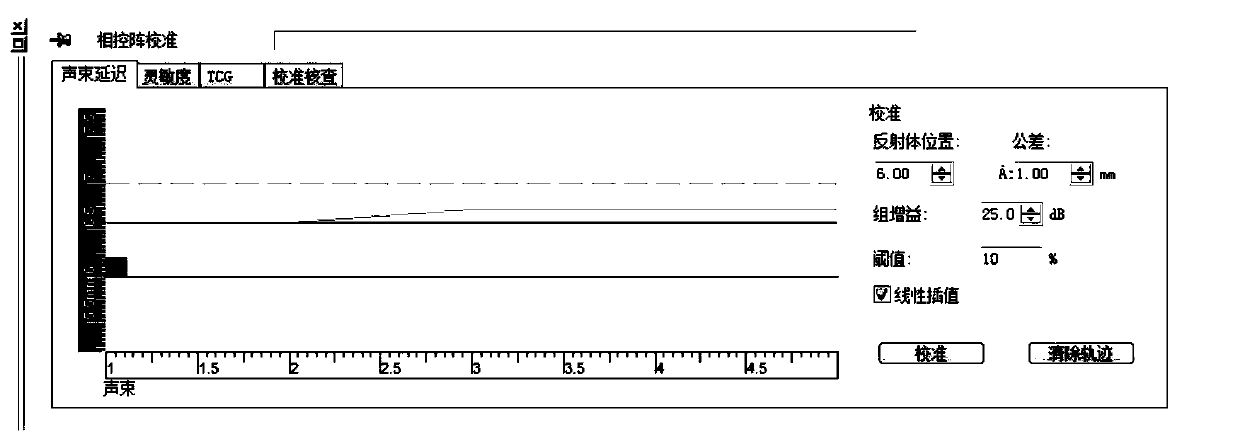

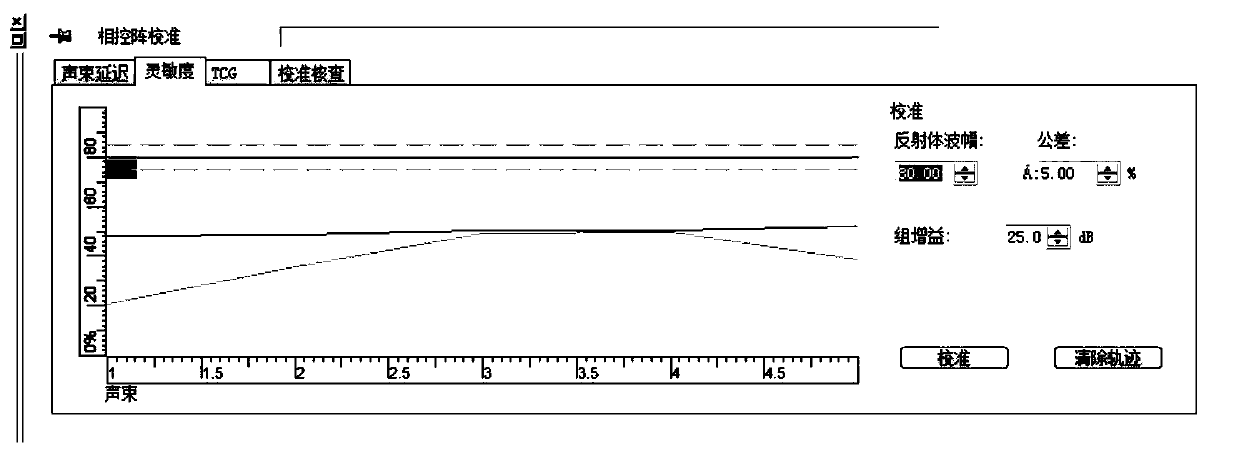

Method for detecting defects of additive manufacturing part based on ultrasonic phased array

InactiveCN111380955AHigh positioning accuracyHelp quantifyAnalysing solids using sonic/ultrasonic/infrasonic wavesWaferingSoftware engineering

The invention discloses a method for detecting defects of an additive manufacturing part based on an ultrasonic phased array, and belongs to the technical field of ultrasonic nondestructive detection.The method is carried out by adopting an ultrasonic phased array detection system, and comprises the steps of selecting an appropriate ultrasonic phased array detection instrument, an appropriate probe, an appropriate wedge block, an appropriate reference block and an appropriate coupling agent; establishing a detection group on data acquisition and analysis software, setting a focusing rule, calibrating sound velocity delay, calibrating sensitivity and establishing a TCG curve; adopting a manual scanning mode to carry out 100% detection on the part; and finally, collecting, storing and analyzing the detection information. According to the ultrasonic phased array detection, a plurality of detection wafers are integrated into one probe, so the detection efficiency can be greatly improved,and intuitive data imaging can be carried out.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Eddy-current ultrasonic nondestructive testing device for automobile fuel seamless steel tubes

PendingCN112114029AHigh precisionImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesSortingControl systemMechanical engineering

The invention discloses an automobile fuel seamless steel tube eddy current ultrasonic nondestructive testing device. The device comprises a feeding rack, a front roller path, an eddy current flaw detection device, an ultrasonic flaw detection device, a rear roller path, a discharging sorting device and a control system which are sequentially installed on a rack, wherein the ultrasonic flaw detection device comprises an ultrasonic rotating probe and an external circulating water tank, the ultrasonic rotating probe is a point focusing probe to improve the detection noise ratio, and the ultrasonic rotating probe is driven by an ultrasonic rotating probe host to rotate. The device is advantaged in that vortex detection and ultrasonic detection are carried out in sequence, detection precisionand detection efficiency are improved, the product quality is ensured, meanwhile, through the improved feeding and sorting structure, efficient feeding and orderly feeding are achieved, the improved sorting structure prevents steel pipes from being damaged after detection, and detection efficiency is improved; and meanwhile, efficient classified collection and marking operations are performed, sodetection accuracy of the whole detection device is improved.

Owner:台州华迪材料科技有限公司

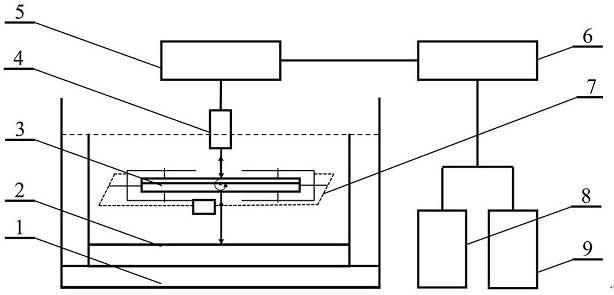

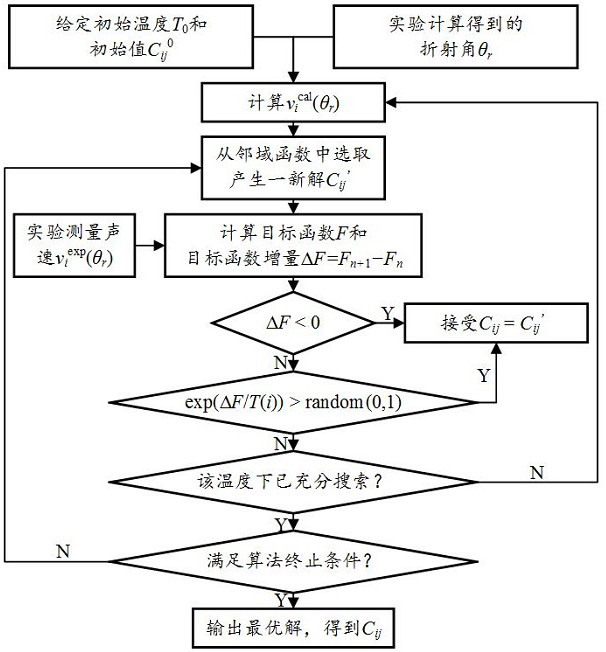

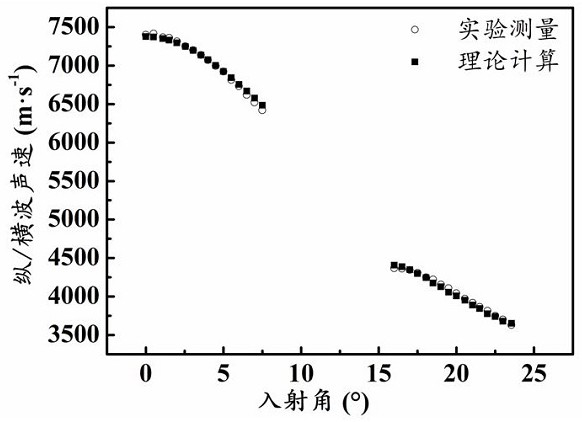

Ultrasonic measurement and inversion method for elastic constant of coating layer with uniform substrate

ActiveCN112362745AAccurately describe elastic anisotropySolve problems that are difficult to measure non-destructivelyAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalLongitudinal waveTransverse wave

The invention discloses an ultrasonic measurement and inversion method for an elastic constant of a coating layer with a uniform substrate, which belongs to the technical field of ultrasonic nondestructive testing. According to the ultrasonic measurement and inversion method for the elastic constant of the coating layer with the uniform substrate, the geometric dimensions, the density and the sound velocity of a sample containing the coating layer and the substrate are measured, and a reflection signal containing longitudinal and transverse wave refraction information of the coating layer is acquired by utilizing an ultrasonic water immersion measurement device; and effective angle ranges of longitudinal waves and transverse waves of the coating layer are determined by combining the soundvelocity, sound velocities of the longitudinal waves and the transverse waves of the coating layer at different angles are calculated by utilizing a sound time algorithm of a water / coating layer / substrate multi-interface structure, and inverting is carried out by virtue of a simulated annealing algorithm on the basis of a Christoffel equation to obtain an elastic constant of the coating layer. According to the method, the problem that the elastic constant of the coating layer with the substrate is difficult to measure in a nondestructive manner is solved, and an effective method is provided for evaluating the elastic performance of the coating layer and acquiring the elastic constant in coating layer material modeling simulation.

Owner:DALIAN UNIV OF TECH

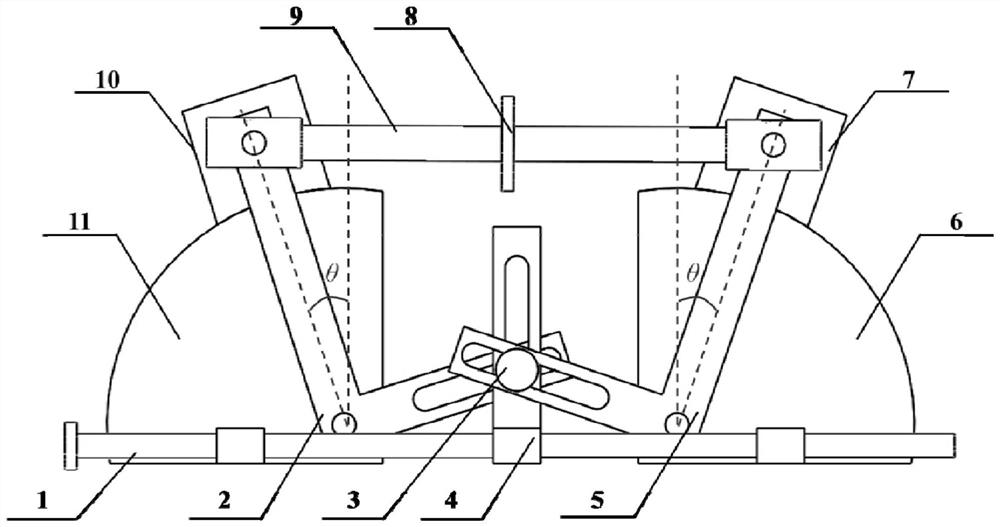

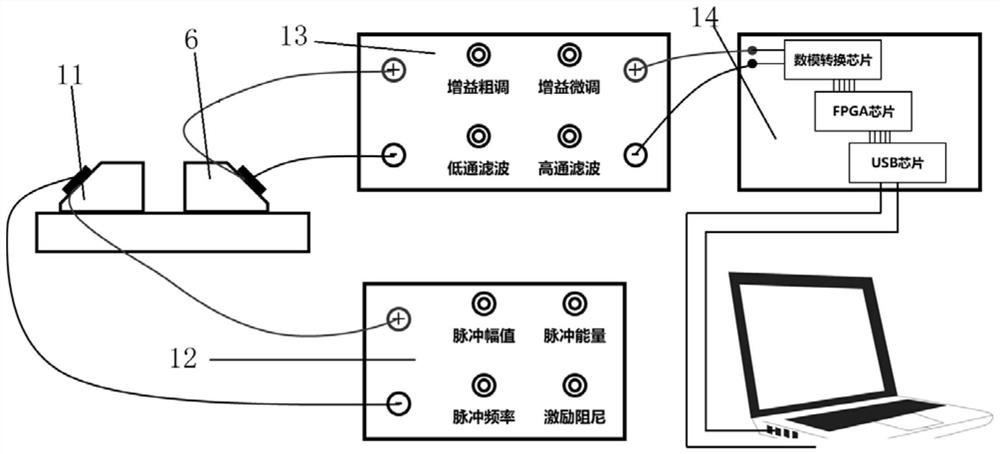

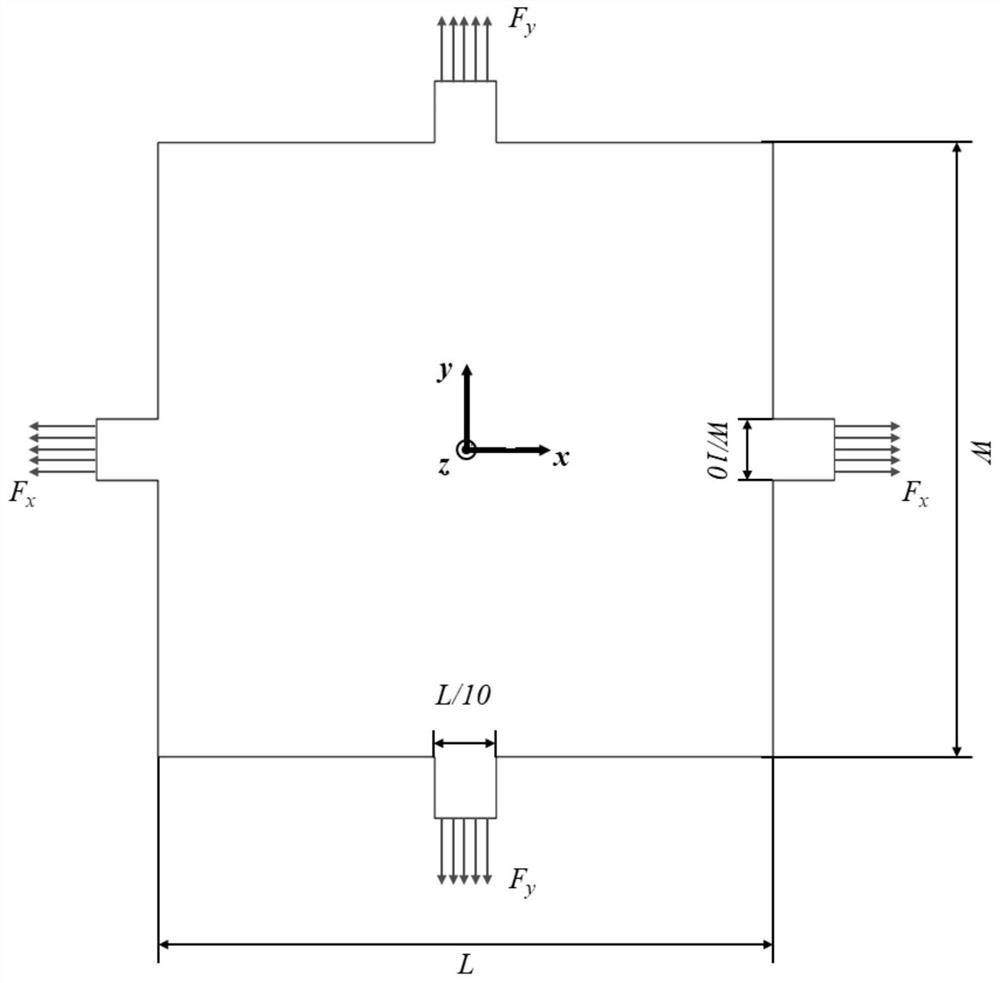

Distance and angle synchronously-adjustable linkage device, receiving and transmitting module and plane stress field detection device and method

ActiveCN114034420AExcellent spatial resolutionSolve complexityAnalysing solids using sonic/ultrasonic/infrasonic wavesForce measurementTransducerData acquisition

The invention discloses a distance and angle synchronously-adjustable linkage device, a receiving and transmitting module and a plane stress field detection device and method, and relates to the field of ultrasonic non-destructive testing. In the existing technical means for measuring plane stress in the field of ultrasonic detection, the same detection is only suitable for a single material, and the consistency of deflection angles of transmitting and receiving transducers cannot be realized. The linkage device comprises a distance adjusting lead screw, an angle adjusting lead screw, a left connecting rod, a right connecting rod, a shaft column and a column lock. Based on the linkage device, a receiving end wedge block, a receiving probe, a transmitting end wedge block and a transmitting probe are added to form a receiving and transmitting module, a pulse transmitting device, an amplifying device and a data acquisition device are added to form a stress detection device based on the receiving and transmitting module, a stress detection method suitable for the stress detection device is provided, and the distance and the deflection angle of the transmitting-receiving probe of the detection device are adjusted according to a detected part. The invention is suitable for stress measurement application in the machining and manufacturing process of mechanical parts.

Owner:HARBIN INST OF TECH

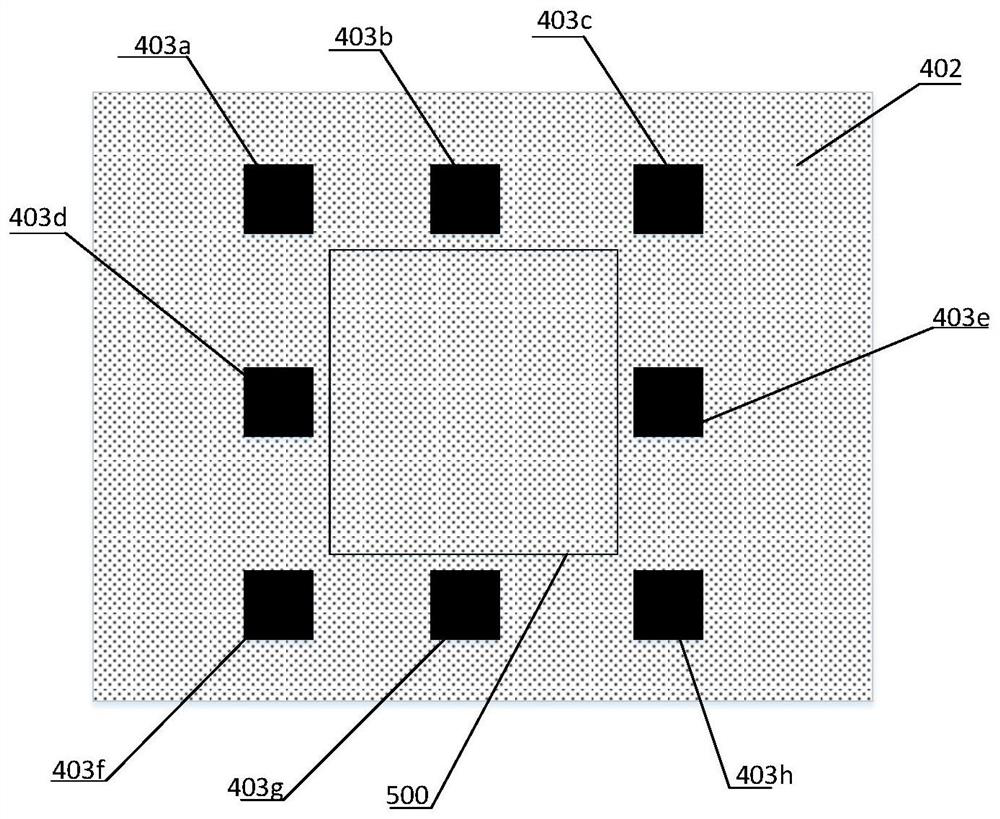

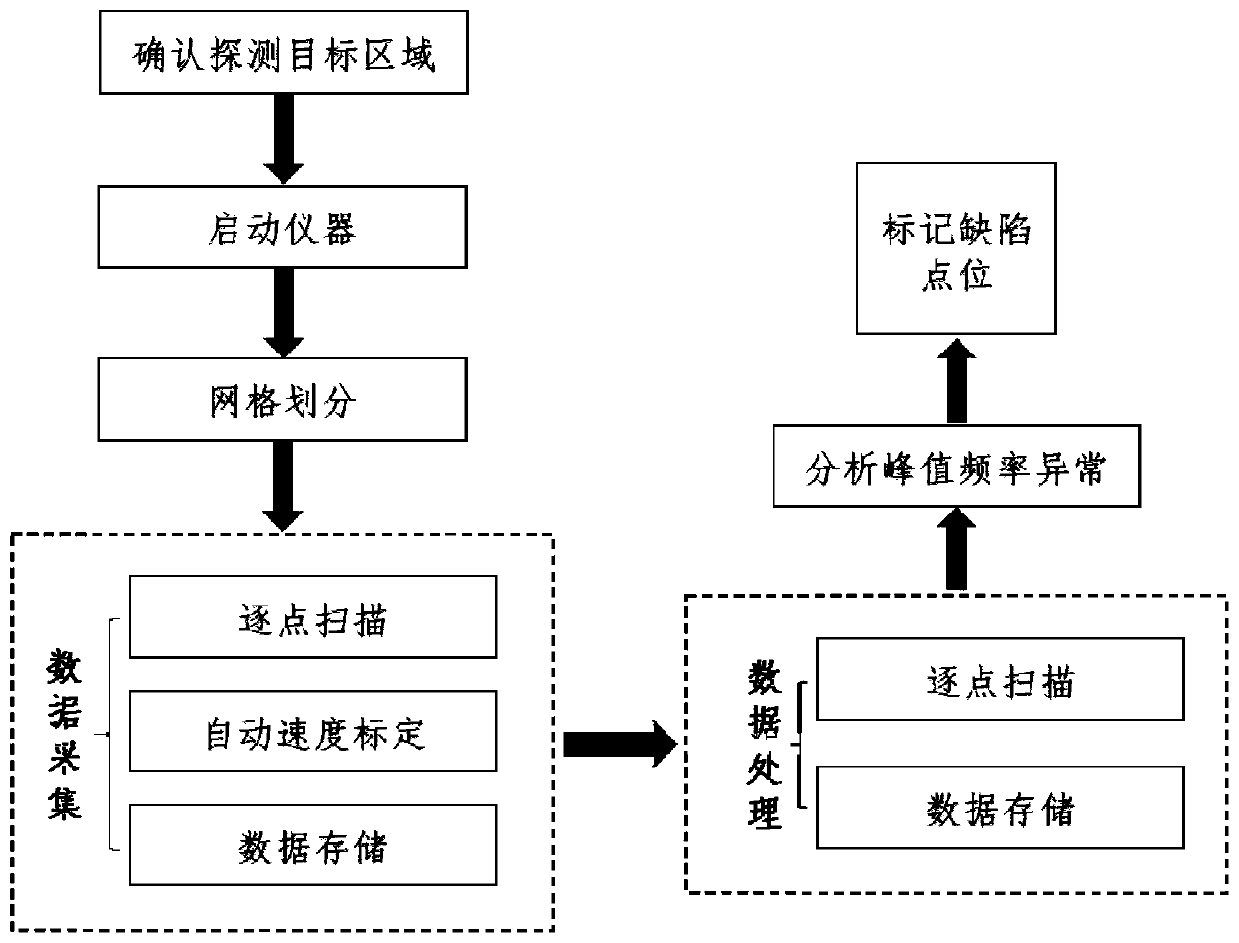

Tunnel concrete duct piece defect detection method and device

InactiveCN110988143AImprove accuracyImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationData acquisitionNoise

The invention, which relates to the field of tunnel concrete duct piece defect detection, discloses a tunnel concrete duct piece defect detection method and device. The method comprises the followingsteps: (1), determining a detection region, and carrying out the mesh generation of the detection region; (2), determining all scanning points; (3), collecting data signals; and (4), performing data processing on the data signals, and analyzing whether each scanning point has a defect or not. The method for collecting the data signals specifically comprises the steps that a data collection deviceis arranged on the surface of the detection region; each column of probes of the data collection device sequentially transmit pulse signals; other columns of probes receive echo signals, wherein the number of the probes of the data collection device is greater than or equal to two, and the number of the probes in each column is greater than or equal to two. Therefore, the accuracy of sound velocity calibration during concrete ultrasonic nondestructive testing is improved, the signal-to-noise ratio is improved, and the difficulty of time domain echo signal analysis is greatly reduced.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP 2ND ENG CO LTD

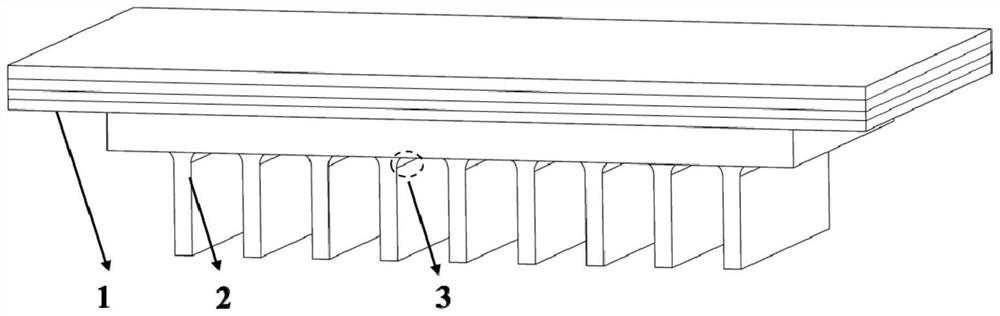

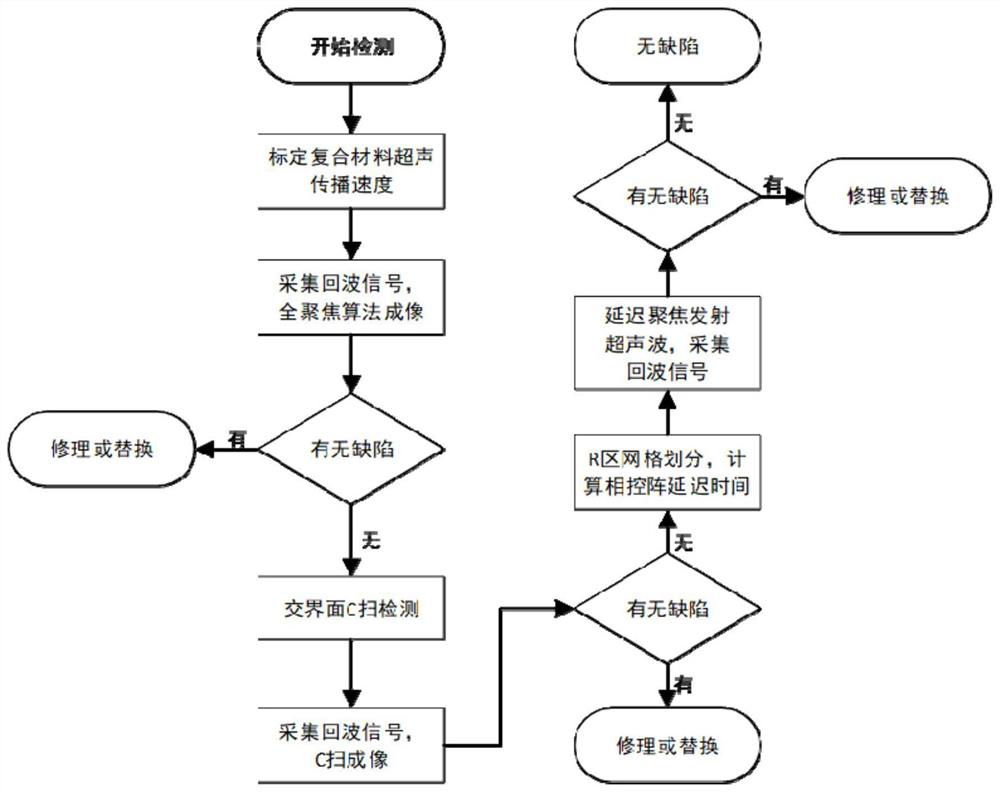

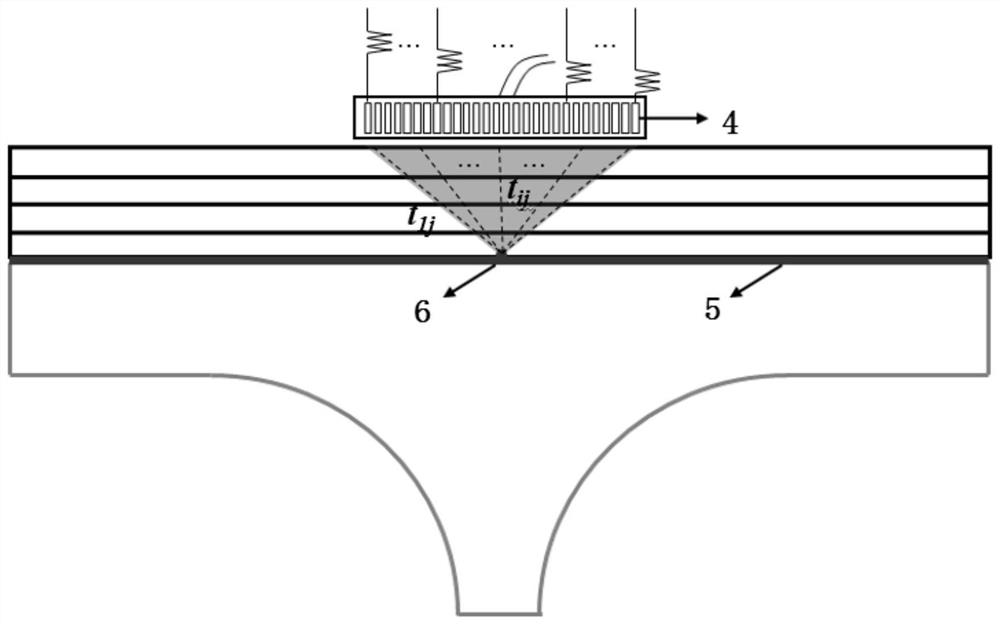

Ultrasonic nondestructive testing device and method for T-shaped composite structure and R-region detection method and device

ActiveCN113899816AImprove defect detection efficiencyImprove stabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalEcho intensityEngineering

The invention discloses an ultrasonic non-destructive testing device and method for a T-shaped composite structure and an R-region testing method and device, and relates to the field of non-destructive testing. An existing T-shaped composite structure is low in defect detection precision, and no method capable of accurately detecting defects of an R region exists. In order to solve the problems, the technical scheme adopted by the invention comprises the following steps: calibrating the propagation speed of ultrasonic waves in all directions in a tested composite material, and collecting reflection echoes generated when the ultrasonic waves are propagated in the material for imaging; obtaining the reflection echo intensity at the interface of the two materials, and carrying out imaging; detecting from the back surface of the R region; and performing judging according to a detection result and an imaging result. In-service ultrasonic nondestructive testing is carried out on the T-shaped composite structure by adopting a layer-by-layer scanning mode, the defect detection precision of the T-shaped composite structure is effectively improved, and meanwhile, the difficulty of R-region detection is simplified by utilizing a method of emitting focused ultrasonic waves from the back surface of the R region. The method and device can be applied to the detection work of the T-shaped composite structure in the aerospace field.

Owner:国营芜湖机械厂 +1

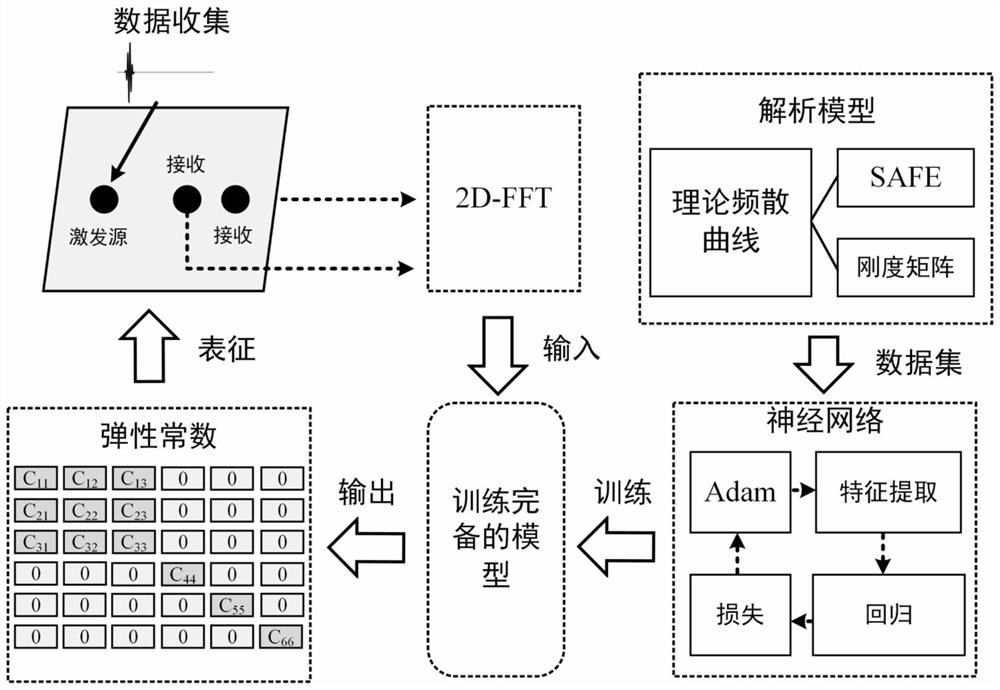

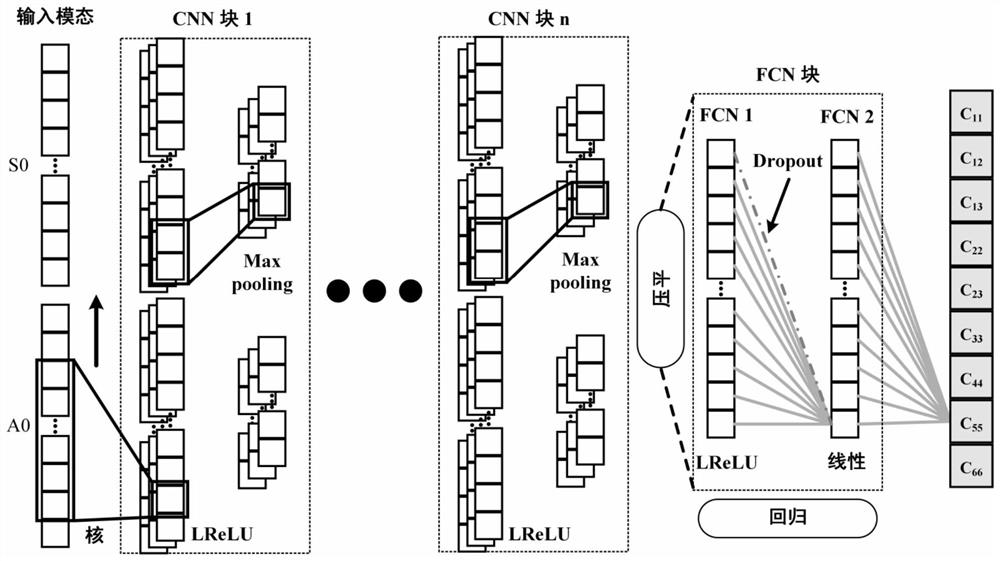

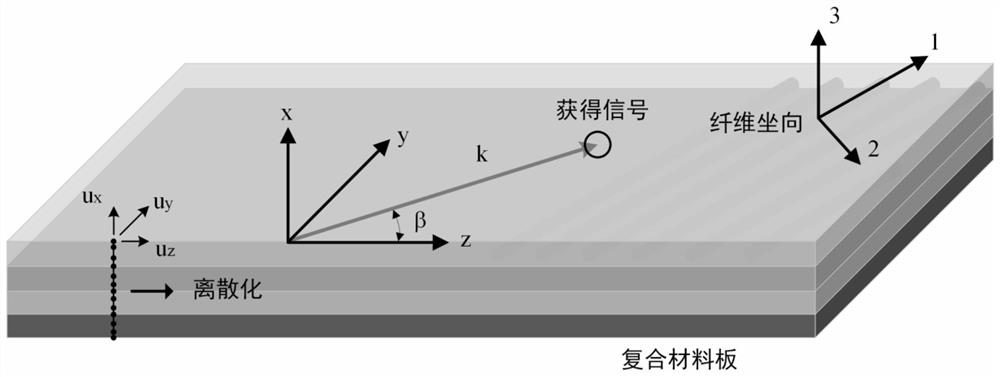

Method for monitoring elasticity modulus of composite material based on deep learning

PendingCN114048673AReal-time monitoring elastic modulus technologyHigh precisionDesign optimisation/simulationNeural architecturesData setMechanical engineering

The invention discloses a method for monitoring elasticity modulus of composite materials based on deep learning. According to the method, a deep neural network is utilized to establish a complex relationship between a frequency dispersion curve of a guided wave propagating in composite materials and elasticity modulus of the composite materials, so that accurate testing on elastic constants of the composite materials is realized; and meanwhile, a spectral element method improved semi-analytical finite element method is used for generating a related data set for training a neural network, the method can be applied to industrial facilities, aerospace equipment and the like, and rapid ultrasonic nondestructive testing of elastic properties of the composite materials is achieved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com