Optimization method for probe location during immersion ultrasonic detection of filament winding composite material

A technology of composite materials and optimization methods, applied in measurement devices, analysis materials, material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as porosity, porosity, and poor resin curing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

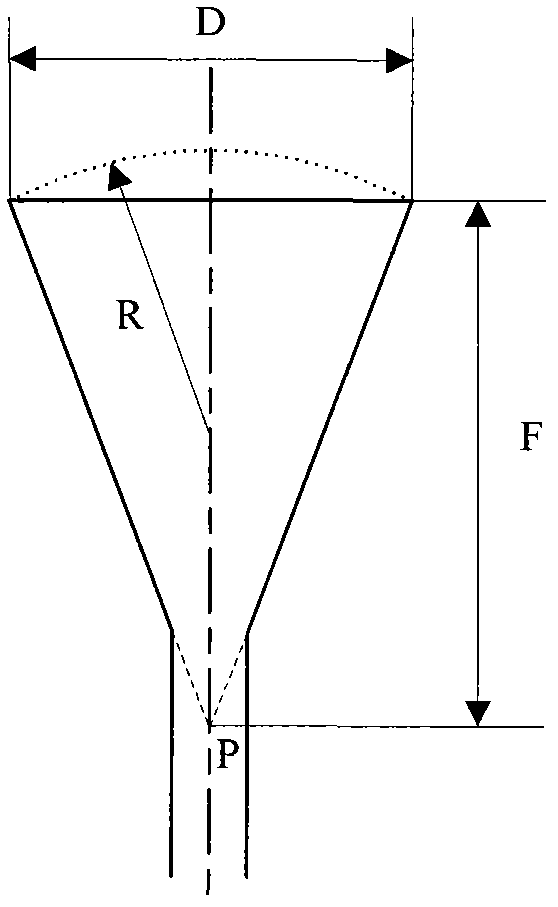

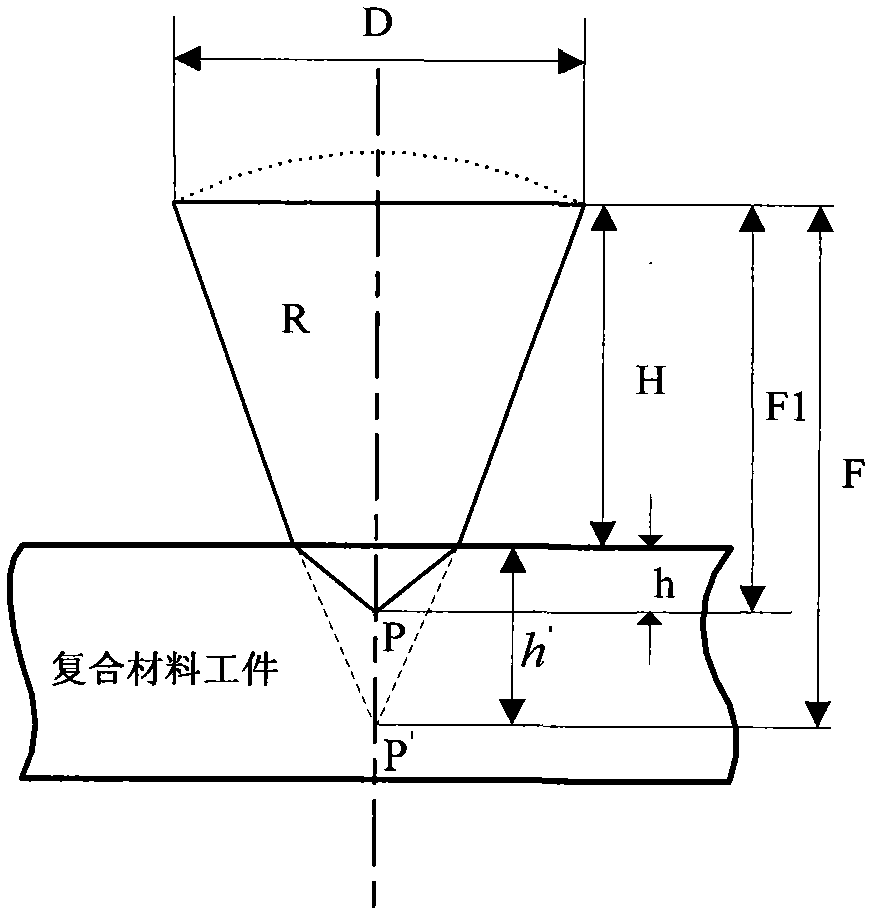

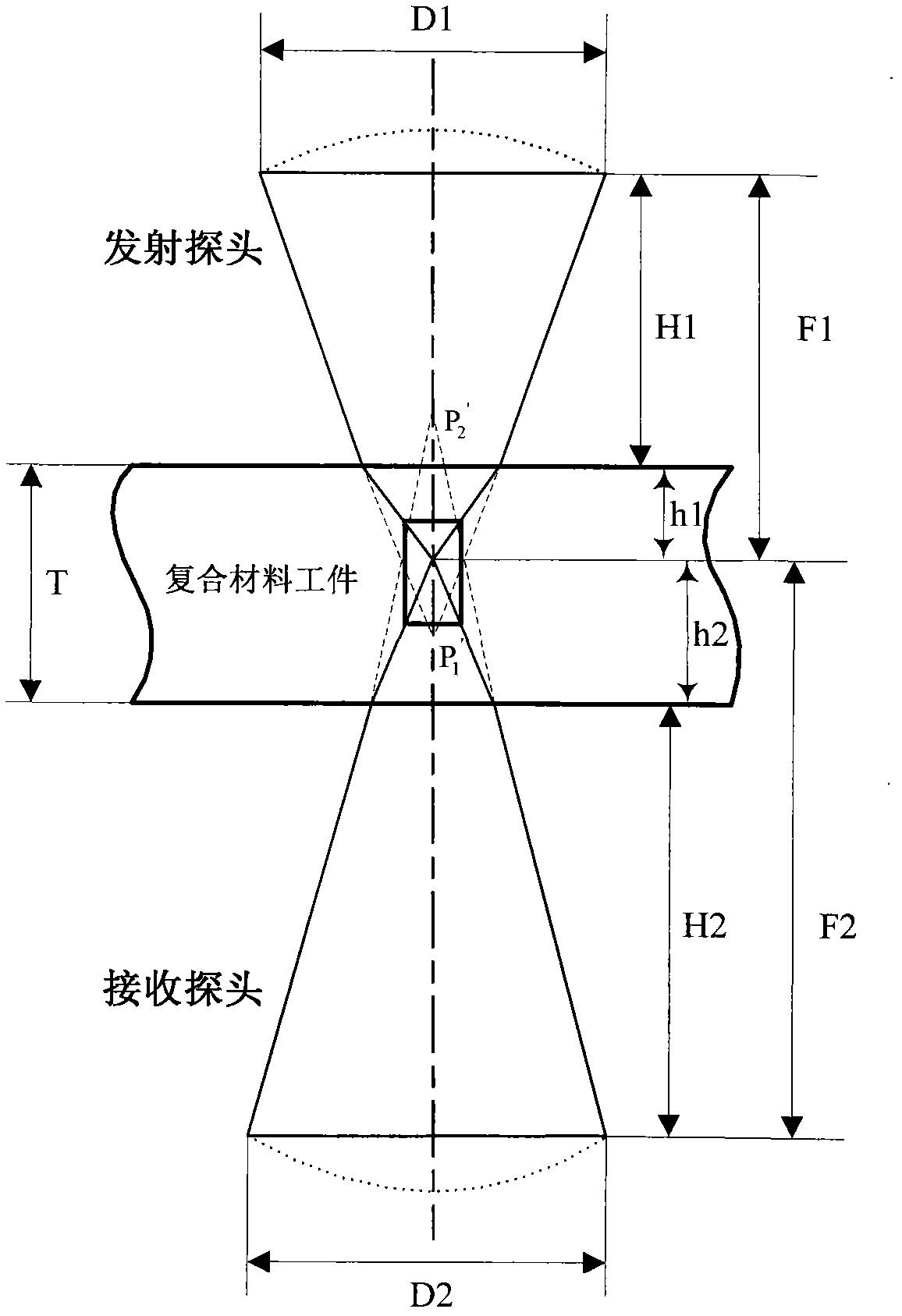

[0031] The specific implementation steps of the present invention are described in detail below:

[0032] 1) Determine the corresponding parameters of the composite material workpiece to be detected, including thickness T, sound velocity C 复合材料 .

[0033] 2) The reflection method can be used for the detection of near-surface defects. After determining the focusing probe used, calculate its focal area diameter and focal area length according to formulas (2) and (3). The principle of selecting a probe is that its focal area diameter and length should be As small as possible, the detection accuracy and sensitivity will be higher. Determine the value of h (according to the condition of the sound wave penetrating the composite material, to ensure that a clear bottom echo signal can be received), and substitute it into (7) to calculate H, which is the distance from the focusing probe to the workpiece during detection.

[0034] 3) The transmission method detection first ensures tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com