Tunnel concrete duct piece defect detection method and device

A defect detection and concrete technology, which is applied to measuring devices, processing response signals of detection, and analyzing solids using sonic/ultrasonic/infrasonic waves, to achieve the effect of improving accuracy and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

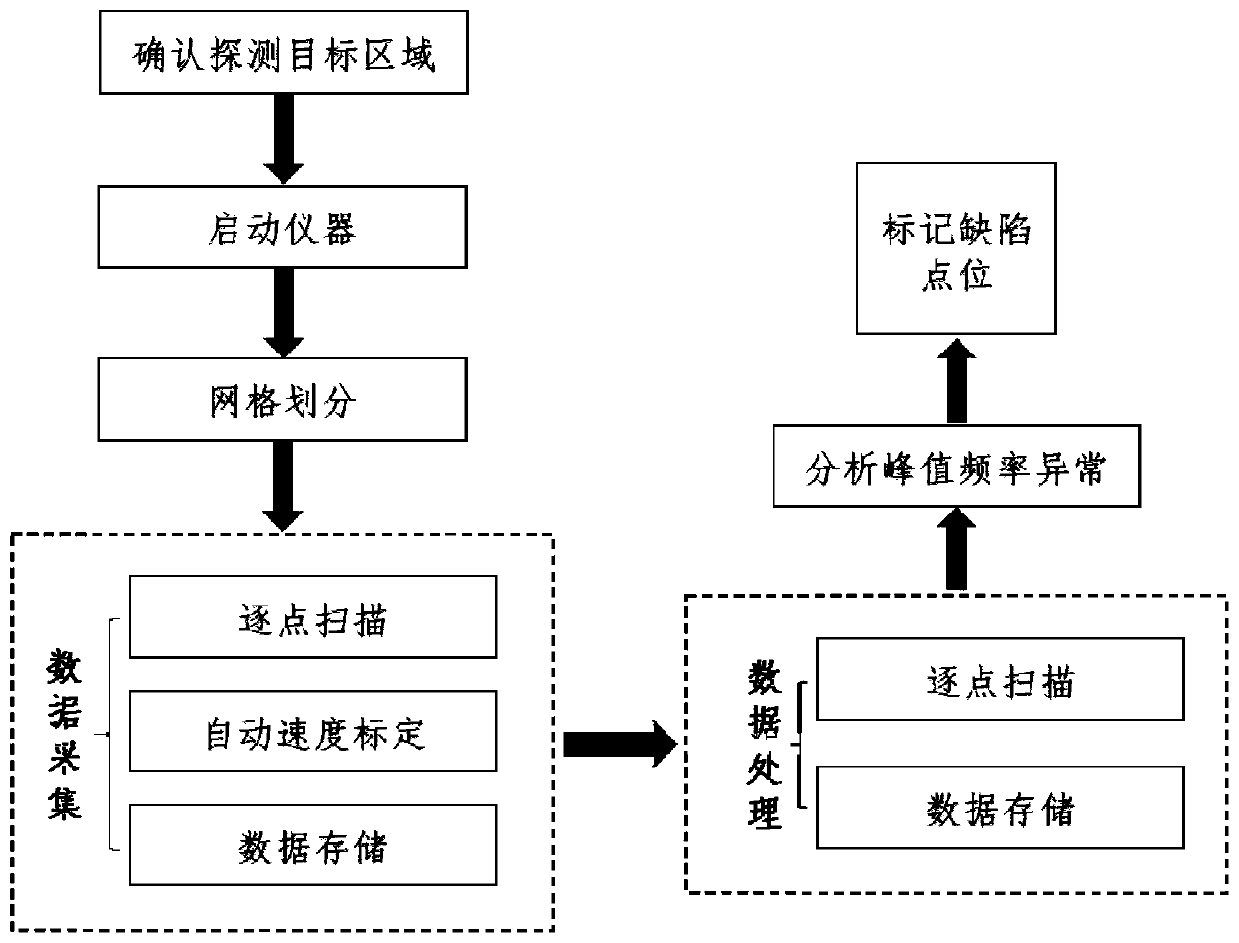

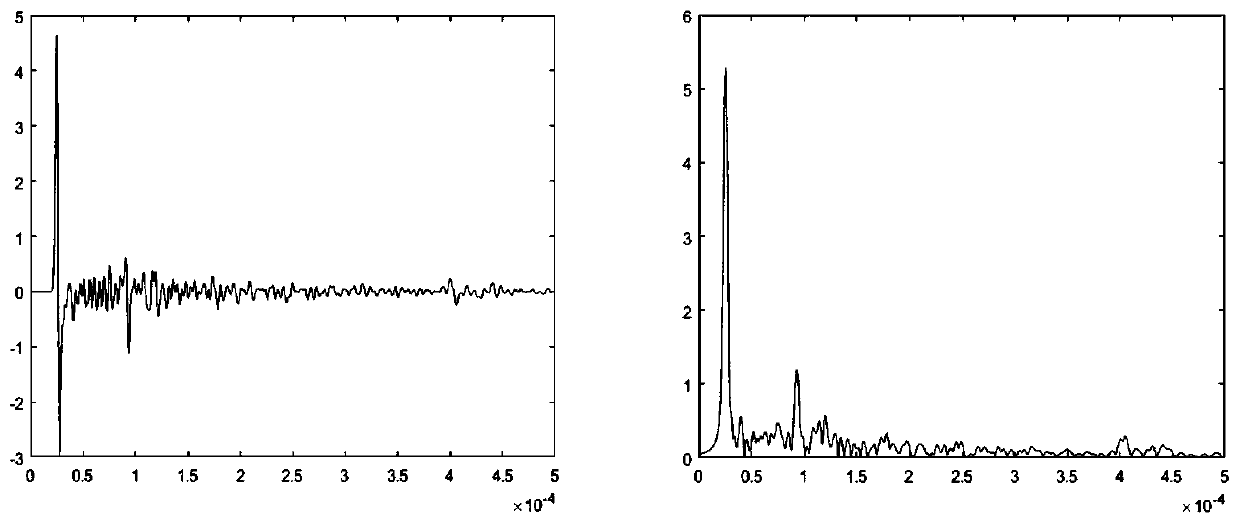

[0037] The method of the present invention mainly includes three stages of signal acquisition, signal optimization processing and defect location, and the specific steps are as follows: figure 1 shown, including:

[0038] (1) Before starting data collection, first determine the detection area, and perform grid division on the surface to be measured according to the detection horizontal resolution requirements, usually the cell size is 5cm*5cm;

[0039] (2) Determine all scanning points. Then move from left to right along the first horizontal grid line, scan each point in turn, and repeat the process until all points in the area are scanned;

[0040] (3) Collecting signals;

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com